Page 1

Operating Instructions and Parts Manual DG460500CK S

Orbital Jig Saw

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain

the product described. Protect yourself and others by observing all safety information. Failure to comply with

instructions could result in personal injury and/or property damage! Retain instructions for future reference.

IN714000AV 3/06

For parts, product & service information

visit www.chpower.com

BUILT TO LAST

© 2006 Campbell Hausfeld/Scott Fetzer

See Warranty on page 6 for important information about commercial use of this product.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

Description

Jig Saws are designed to perform cutting

tasks that are not possible with other

saws. They are most useful for circular

cuts, curve and scroll cutting. The orbital

settings allow for faster cuts in different

material. Some settings may not be

appropriate for certain tasks. Please

familiarize yourself with all the

components of this tool before use.

Unpacking

When unpacking this product,

carefully inspect for any damage that

may have occurred during transit.

General Safety

Information

This manual contains information that

is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe

the following symbols.

Danger indicates

an imminently

hazardous situation which, if not

avoided, will result in death or serious

injury.

Warning indicates

a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

Caution indicates a

potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

NOTICE

!

CAUTION

!

WARNING

!

DANGER

CALIFORNIA PROPOSITION 65

You can

create dust when you cut,

sand, drill or grind materials

such as wood, paint, metal,

concrete, cement, or other masonry. This

dust often contains chemicals known to

cause cancer, birth defects, or other

reproductive harm. Wear protective

gear.

This

product or its power cord

contains chemicals known

to the State of California to

cause cancer and birth defects or other

reproductive harm. Wash hands after

handling.

The following safety precautions must

be followed at all times along with any

other existing safety rules.

1. Read all manuals included with this

product carefully. Be thoroughly

familiar with the controls and the

proper use of the equipment.

2. Only persons well acquainted with

!

WARNING

!

DANGER

these rules of safe operation should

be allowed to use the saw.

Safety

glasses and ear protection

must be worn during

operation.

3. Do not wear loose fitting clothing,

scarves, or neck ties in work area.

Loose clothing may become caught

in moving parts and result in serious

personal injury.

!

WARNING

MANUAL

Specifications

Rated Voltage . . . . . . . 115/120V ~ 60Hz

Rated Frequency . . . . . 60Hz

Power Rating . . . . . . . . 5.5A

No Load Speed . . . . . . 500-3000 spm

Cutting Capacities:

Wood . . . . . . . . . . . 2 9/16" (65mm)

Steel . . . . . . . . . . . .

15

/64" (6mm)

Cutting Angles: . . . . . . 45 degrees Left,

90 degrees, and

45 degrees Right

20 Sp

Manual de Instrucciones y Lista de Piezas

Garantía Limitada

1 DURACION: A partir de la fecha de compra por el comprador original tal como se especifica a continuación:

Dos años

2. QUIEN OTORGA ESTA GARANTIA (EL GARANTE: Campbell Hausfeld / The Scott Fetzer Company 100

Production Drive, Harrison, Ohio 45030 Teléfono: (800) 543-6400

3. QUIEN RECIBE ESTA GARANTIA (EL COMPRADOR): El comprador original (que no sea un revendedor) del

producto Campbell Hausfeld.

4. PRODUCTOS CUBIERTOS POR ESTA GARANTIA: Cualquier herramienta a motor de Campbell Hausfeld

proporcionada o fabricada por el garante.

5. COBERTURA DE LA GARANTIA: Los defectos substanciales de material y fabricación que ocurran dentro del

período de validez de la garantía.

6. LO QUE NO ESTA CUBIERTO POR ESTA GARANTIA:

A. Las garantías implícitas, incluyendo aquellas de comercialidad E IDONEIDAD PARA FINES

PARTICULARES, ESTAN LIMITADOS A LO ESPECIFICADO EN EL PARRAFO DE DURACION. Si este producto

es empleado para uso comercial, industrial o para alquiler, no se aplicará ninguna garantía. En algunos

estados no se permiten limitaciones a la duración de las garantías implícitas, por lo tanto, en tales casos

esta limitación no es aplicable.

B. CUALQUIER PERDIDA DAÑO INCIDENTAL, INDIRECTO O CONSECUENTE QUE PUEDA RESULTAR DE UN

DEFECTO, FALLA O MALFUNCIONAMIENTO DEL PRODUCTO CAMPBELL HAUSFELD. En algunos estados

no se permite la exclusión o limitación de daños incidentales o consecuentes, por lo tanto, en tales

casos esta limitación o exclusión no es aplicable

C. Cualquier falla que resulte de un accidente, abuso, negligencia o incumplimiento de las instrucciones

de funcionamiento y uso indicadas en el (los) manual(es) que se adjunta(n) al producto. Dichos

accidentes, abusos por parte del comprador, o falta de operar el producto siguiendo las instrucciones

del manual de instrucciones suministrado también debe incluir la desconexión o modificación de los

instrumentos de seguridad. Si dichos instrumentos de seguridad son desconectados, la garantía

quedaría cancelada.

D. Los ajustes normales explicados en el(los) manual(es) suministrado(s) con el producto.

7. RESPONSABILIDADES DEL GARANTE BAJO ESTA GARANTIA: Reparar o reemplazar, como lo decida el

Garante, los productos o componentes que estén defectuosos, se hayan dañado o hayan dejado de

funcionar adecuadamente, durante el período de validez de la garantía

8. RESPONSABILIDADES DEL COMPRADOR BAJO ESTA GARANTIA:

A. Suministrar prueba fechada de compra y la historia de mantenimiento del producto.

B. Entregar o enviar el producto o componente Campbell Hausfeld al Centro de Servicio autorizado

Campbell Hausfeld más cercano. Los gastos de flete, de haberlos, deben ser pagados por el comprador.

C. Seguir las instrucciones sobre operación y mantenimiento del producto, tal como se indica(n) en el (los)

manual(es) del propietario

Esta garantía limitada es válida sólo en los EE.UU., Canadá y México y otorga derechos legales específicos.

Usted también puede tener otros derechos que varían de un Estado a otro. o de un país a otro.

Page 2

19 Sp

DG460500CK

Para Ordenar Repuestos o Asistencia Técnica, Llame al Teléfono 1-800-424-8936

Sirvase darnos la siguiente información:

• Número del modelo

• Código impreso

• Descripción y número del repuesto según la lista de repuestos

Número del

Descripción Repuesto

Dirija toda la correspondencia a:

Campbell Hausfeld

Attn: Customer Service

100 Production Drive

Harrison, OH 45030 U.S.A.

Lista de Repuestos

Hoja de la sierra DG025800AV

Tubo de polvo DG025900AV

Guía del borde DG026000AV

Llave Allen de 3mm DG026100AV

4. Do not wear jewelry when

operating any tool. Jewelry may

become caught in moving parts and

result in serious personal injury.

5. Always use attachments designed

for use with this tool. Do not use

damaged or worn attachments.

6. Never trigger the tool when not

applied to a work object.

Attachments must be securely

attached. Loose attachments can

cause serious injury.

7. Never point a tool at oneself or any

other person. Serious injury could

occur.

8. Use steady, even pressure when

using tool. Do not force. Too much

pressure can cause blade to break

or overheat.

9. Keep all nuts, bolts and screws tight

and ensure equipment is in safe

working condition.

10. Do not put hands near or under

moving parts.

WORK AREA

Do not

operate a power tool in an

explosive atmosphere,

such as in the presence of

flammable liquids, gases,

or dust. Power tools create

sparks which may ignite the fumes or

dust.

Keep work area

clean and well lighted. Cluttered

benches and dark areas invite

accidents.

Keep bystanders,

children, and visitors away while

operating a power tool. Distractions

can cause you to lose control.

ELECTRICAL SAFETY

Double insulated tools are equipped with

a polarized plug (one plug blade is wider

that the other). This plug will fit in a

polarized outlet only one way. If the plug

does not fit fully into the outlet, turn the

plug over and insert into plug again.

Do not expose

power tools to rain or wet conditions.

Water entering a power tool will

increase the risk of electric shock.

!

WARNING

!

CAUTION

!

CAUTION

!

WARNING

Avoid

body contact with

grounded surfaces such as

pipes, radiators, ranges,

and refrigerators. There is an increased

risk of electric shock if your body is

grounded.

Do not abuse cord.

• Never carry tool by its cord.

• Never pull the cord to disconnect

from receptacle.

1. Make sure cord is located so that it

will not be stepped on, tripped over,

or otherwise subjected to damage or

stress.

2. Do not use an extension cord unless

absolutely necessary. Use of improper

extension cord could result in a risk of

fire and electric shock. If an extension

cord must be used, make sure:

• That the pins on plug of extension

cord are the same number, size and

shape as those of plug.

• That the extension cord is properly

wired and in good electrical

condition.

• If an extension cord is to be used

outdoors it must be marked with

the suffix “W-A” or “W” following

the cord type designation to

indicate it is acceptable for outdoor

use. For example – SJTW-A

3. Do not expose to rain, snow or frost.

Water entering a power tool will

increase the risk of electric shock.

PERSONAL SAFETY

Do not misuse this

product. Excessive exposure to

vibration, work in awkward positions,

and repetitive work motions can cause

injury to hands and arms. Stop using any

tool if discomfort, numbness, tingling, or

pain occur, and consult a physician.

1. Stay alert, watch what you are doing,

and use common sense when

operating a power tool. Do not use

tool while tired or under the

influence of drugs, alcohol, or

medication. A moment of inattention

while operating power tools may

result in serious personal injury.

Avoid accidental

starting. Be sure switch is in the locked

or OFF position before making any

adjustments, changing accessories, or

storing the tool. Carrying tools with

your finger on the switch while the

switch is in the ON position invites

accidents.

!

CAUTION

!

WARNING

!

WARNING

!

WARNING

2. Remove adjusting keys or wrenches

before turning ON the tool. A key or

wrench attached to a rotating part of

the tool may result in personal injury.

3. Do not overreach. Keep

proper footing and

balance at all times.

Proper footing and

balance enable better

control of the tool in

unexpected situations.

4. Always work in a wellventilated area. Wear an

OSHA-approved dust

mask and safety glasses.

5. Hold tool by insulated gripping

surface when performing an

operation where the tool may

contact hidden wiring. Contacting a

“live” wire will make exposed metal

parts of the tool “live” and shock the

operator.

6. Keep hands away from rotating parts.

7. Use clamps or another practical way

to secure the workpiece to a stable

platform. Never hold work in your

hand, lap, or against other parts of

your body when cutting.

8. Always use blades with correct size

and shape (diamond vs. round) arbor

holes. Blades that do not match the

mounting hardware of the saw will

run eccentrically, causing great risk or

injury to the user and damage to the

tool.

9. NEVER hold piece being cut in your

hands or across your leg. It is

important to support the work

properly to minimize body exposure,

blade binding, or loss of control.

10. Wear ear protection

when using the tool for

extended periods.

Prolonged exposure to

high intensity noise can

cause hearing loss.

11. Make sure that all nails have been

pulled from workpiece before

starting cutting operation.

12. This saw is not designed to cut hollow

pipe. Perform cuts on approved

materials only.

13. Do not touch metal parts of saw

while cutting in blind areas. Blind

spots like walls and floors may

contain live electric wires.

14. Do not touch metal parts of saw or

blade immediately after use. Parts

will be hot and can cause serious

burn.

2

www.chpower.com

Operating Instructions and Parts Manual

General Safety

Information (Cont’d.)

limpiar la herramienta, evitando todos

los contactos eléctricos.

Ciertos agentes de limpieza y solventes

son nocivos para los plásticos y otras

piezas aisladas. Algunos de éstos

incluyen gasolina, aguarrás, solvente

para laca, solvente de pintura,

solventes de limpieza con cloro,

amoníaco y detergentes de uso

doméstico que contengan amoníaco.

Nunca use solventes inflamables ni

combustibles cerca de las herramientas.

SERVICIO TÉCNICO

Para obtener información con relación

al funcionamiento o reparación de

este producto, sírvase llamar al

1-800-424-8936.

El servicio de la herramienta debe

ser realizado sólo por personal de

reparaciones calificado. El servicio

o mantenimiento realizado por personas

no calificadas puede provocar riesgo

de lesiones.

!

PRECAUCION

Al realizarle un servicio a la herramienta,

utilice únicamente piezas de repuesto

idénticas. Siga las instrucciones de la

sección Mantenimiento de este manual.

El uso de piezas no autorizadas o el no

seguir las instrucciones de

Mantenimiento puede crear un riesgo

de choque eléctrico o lesión.

Mantenimiento (Cont.)

Page 3

CORTES DIAGONALES/EN ÁNGULO

• Asegúrese de que la sierra esté

desenchufada de la fuente de

corriente antes de hacer ajustes

a los ángulos de corte.

• La placa base se puede inclinar 45°

en ambas direcciones para realizar

cortes en ángulo. Estos son valores

para 45° y para 90° contra la pieza

de trabajo. Para otros ángulos use

un graduador para medir

(Figura 2).

Hole Cutting

CORTES DE BOLSILLO

Los cortes de bolsillo se hacen en el

medio de la pieza de trabajo cuando

no pueden cortarse desde un borde.

Se pueden comenzar con un orificio

pretaladrado o la sierra vertical puede

crear un punto de inicio (corte por

penetración).

Los cortes por penetración no se

recomiendan para materiales más

duros como el acero y no se deben

usar las hojas de calar para cortes

por penetración.

CORTES POR PENETRACIÓN

1. Si el corte en bolsillo es de líneas

rectas, no se necesita un orificio

pretaladrado.

2. Toque el pie de la sierra sobre la

pieza de trabajo dejando la hoja

bien por encima del material

(Figura 3).

3. Asegúrese de que el valor orbital

esté en 0 y encienda la sierra.

4. Una vez que la sierra alcanza la

velocidad máxima, bájela

lentamente en la pieza de trabajo.

5. Mantenga ambas manos sobre la

sierra mientras esté cortando

(Figura 4).

6. Para 90° u otras esquinas en

ángulo, corte hasta la esquina

luego retroceda antes de

redondear la esquina. Una vez que

haya cortado el bolsillo, acérquese

a la esquina desde la dirección

contraria y corte el ángulo.

CORTES EN CÍRCULO

Una guía de corte en círculo puede

ayudarlo para cortar círculos. El

corte se debe preparar con un

orificio pretaladrado o un leve corte

por penetración próximo a la línea

de corte. Si usa una guía, asegúrese

de que cumpla con las instrucciones

de la sierra vertical y del fabricante.

Calados

Se pueden realizar trabajos

complicados con una sierra vertical

usando una hoja de calado. Asegúrese

de que la hoja se utilice de acuerdo a

las instrucciones del fabricante. Para

un mejor control, use la sierra en el

valor I con la hoja de calado. Esto

ofrece un corte y un manejo más

sencillo.

Corte de metales

• Antes de comenzar un corte de

metal, coloque el valor orbital

correspondiente 0 ó 1.

• Cuando corte piezas de trabajo de

metal, sujete el material con

abrazaderas y corte cerca del punto

de sujeción para reducir la

posibilidad de que se tuerza y la

vibración.

• Si la hoja comienza a vibrar o a

hacer un ruido excesivo, reemplace

la hoja con una hoja para cortes en

metal que tenga dientes más finos.

• Para metales blandos, la hoja se

puede obstruir por lo tanto use una

hoja con dientes más gruesos.

• Los conductos, hierro en ángulo

o tuberías se deben sujetar en una

prensa de tornillo y cortar lo más

cerca posible de la prensa.

• Los metales de hoja delgada deben

colocarse entre dos tablas de madera

o se deben colocar sobre tablones de

madera más gruesos, como madera

terciada y el diseño o diagramado se

debe poner encima. Esto permite

cortar el metal sin problemas y evita

el desgarro del material de metal.

• La hoja se puede lubricar para

facilitar el corte. Use una barra

de cera para corte, si hubiese

disponible, y use aceite para corte

cuando corte acero.

• La porción expuesta de la barra de

la sierra se debe mantener limpia.

Elimine frecuentemente los restos

de metal usando un paño con aceite.

Después de usar, deseche

adecuadamente el paño con aceite

para evitar riesgos de incendio.

EXTRACCIÓN DEL POLVO

Se pueden realizar operaciones de corte

limpias conectando esta herramienta a

una aspiradora. Introduzca la

manguera de la aspiradora en el

orificio de la parte trasera de la

herramienta. Baje la tapa para polvo

antes de poner la herramienta en

funcionamiento.

La extracción del polvo no se puede

realizar cuando se hacen cortes en

diagonal.

Mantenimiento

El servicio de la herramienta debe ser

realizado sólo por personal de

reparaciones calificado. El servicio

o mantenimiento realizado por

personas no calificadas puede provocar

riesgo de lesiones.

Limpieza

Limpie el polvo y los desechos de

los orificios y contactos eléctricos,

soplando con aire comprimido.

Los orificios de ventilación del motor

y los interruptores deben mantenerse

limpios y libres de materiales extraños.

No intente limpiarla introduciendo

objetos con punta a través de las

aberturas. Mantenga los mangos de

las herramientas limpios, secos y libres

de aceite o grasa. Use únicamente un

jabón suave y un paño húmedo para

AVISO

18 Sp

Manual de Instrucciones y Lista de Piezas

0

I

II

I

I

I

Figura 4

Figura 3

Funcionamiento (Cont.)

TOOL USE AND CARE

Do not use tool if

switch does not turn it ON or OFF. Any

tool that cannot be controlled with the

switch is dangerous and must be repaired.

1. This tool must NOT be modified or

used for any application other than

that for which it was designed.

Do not force the

tool. Use the correct

tool for your application. The correct tool

will do the job better and safer at the

rate for which it is designed.

2. Maintain tools with care. Keep

cutting tools sharp and clean.

Properly maintained tools with

sharp cutting edges are less likely

to bind and are easier to control.

3. Check for misalignment or binding

of moving parts, breakage of parts,

and any other condition that may

affect the tool’s operation. If

damaged, have the tool serviced

before using. Many accidents are

caused by poorly maintained tools.

4. Use only accessories that are

recommended by the manufacturer

for your model. Accessories suitable

for one tool may create a risk of

injury when used on another tool.

5. Some woods contain preservatives

which can be toxic. Take extra care

to prevent inhalation and skin

contact when working with these

materials. Request and follow all

safety information available from

your material supplier.

6. Store tools out of reach of children

and other untrained persons. Tools

are dangerous in the hands of

untrained users.

CAUSES AND USER PREVENTION

OF KICKBACK:

Kickback is a sudden reaction to a

pinched, bound or misaligned saw

blade, causing an uncontrolled saw to

lift up and out of the workpiece

toward the operator.

When the blade is pinched or bound

tightly by the kerf, or cutting slot,

closing down, the blade stalls and the

motor reaction drives the unit rapidly

back toward the operator.

If the blade becomes twisted or

misaligned in the cut, the teeth at the

back edge of the blade can dig into

the top surface of the wood causing

the blade to climb out of the kerf and

jump back toward operator.

!

CAUTION

!

WARNING

Kickback is the result of tool misuse

and/ or incorrect operating procedures

or conditions and can be avoided by

taking proper precautions as given

below:

1. Maintain a firm grip with both

hands on the saw and position your

body and arm to allow you to resist

kickback forces. Kickback forces can

be controlled by the operator, if

proper precautions are taken.

2. When blade is binding, or when

interrupting a cut for any reason,

release the trigger and hold the saw

motionless in the material until the

blade comes to a complete stop.

Never attempt to remove the saw

from the work or pull the saw

backward while the blade is in

motion or kickback may occur.

Investigate and take corrective

actions to eliminate the cause of

blade binding.

3. When restarting a saw in the

workpiece, center the saw blade in

the kerf, or cut, and check that saw

teeth are not engaged into the

material. If saw blade is binding, it

may walk up or kickback from the

workpiece as the saw is restarted.

4. Support large panels to minimize

the risk of blade pinching and

kickback. Large panels tend to sag

under their own weight. Supports

must be placed under the panel on

both sides, near the line of cut and

near the edge of the panel.

5. Do not use dull or damaged blades.

Unsharpened or improperly set

blades produce narrow kerf causing

excessive friction, blade binding and

kickback.

6. Blade depth and bevel adjusting

locking levers must be tight and

secure before making cut. If blade

adjustment shifts while cutting, it

may cause binding and kickback.

7. Use extra caution when making a

“Pocket Cut” into existing walls or

other blind areas. The protruding

blade may cut objects that can

cause kickback.

8. Be cautious of pitchy, knotty, wet or

warped stock. These are most likely

to create pinching conditions and

possible kickback.

Assembly

ATTACHING THE BLADE

Always unplug tool and place the

switch in the locked or OFF position

before making any assembly,

adjustments or changing accessories.

Such preventive safety measures

reduce the risk of starting the tool

accidentally.

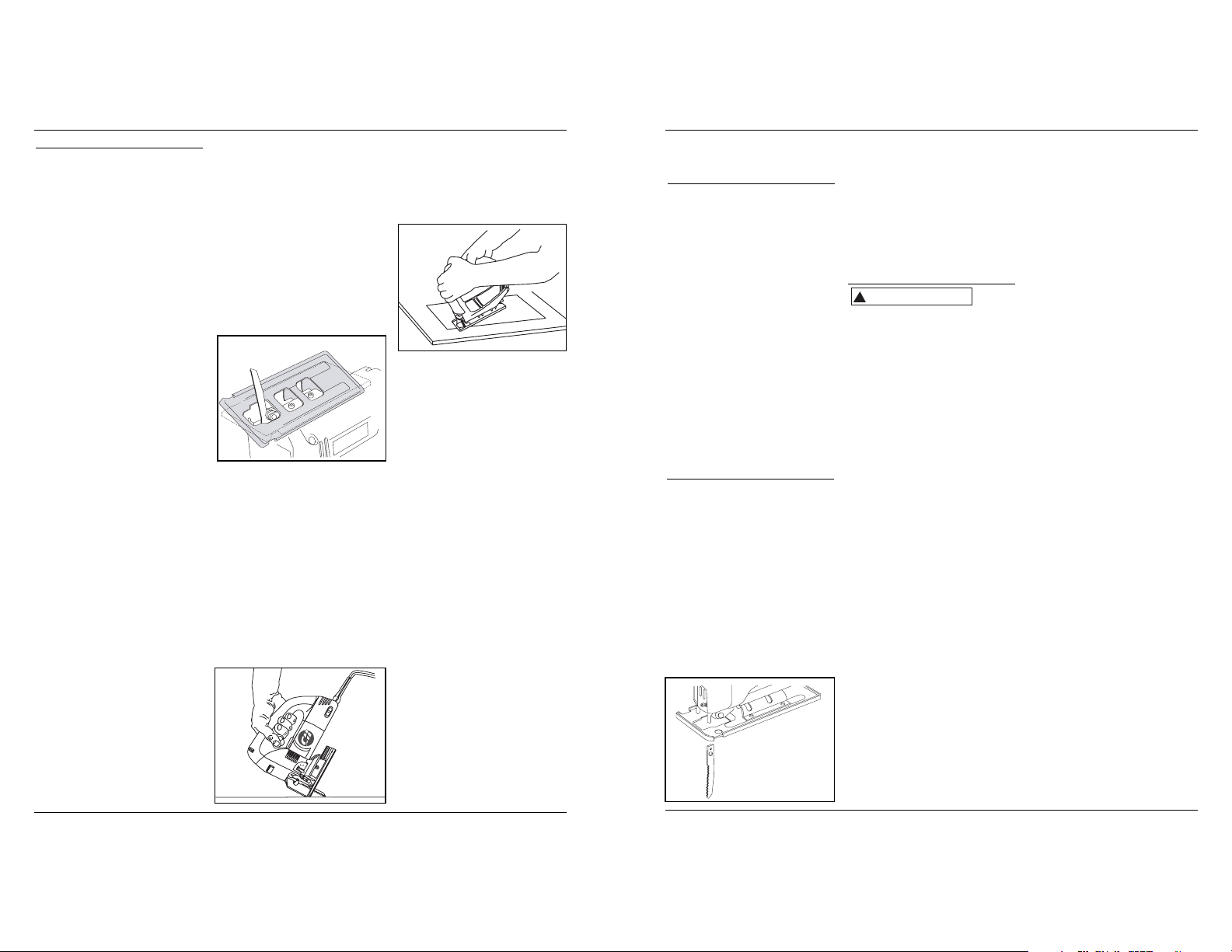

1. Using the hex key provided, loosen

the two blade lock bolts enough for

a blade to be removed or inserted.

2. Insert blade in slot with teeth facing

forward (Figure 1). The blade’s top

should be inserted far enough to

touch blade clip.

3. While blade is in fitted slot and

touching blade clip top, tighten the

blade lock bolts securely.

4. Test saw in a safe direction, away

from others, before beginning use

with new blade. A poorly secured

blade risks the possibility of it

coming unattached during operation

that could result in serious injury.

Operation

Use safety

equipment. Always wear eye

protection. Dust mask, non-skid safety

shoes, hard-hat, or hearing protection

must be used for appropriate condition.

GENERAL OPERATION

• Always clamp the work piece securely

on a saw horse or bench.

• Before cutting, make sure the space

below the material to be cut is

deeper than the saw blade.

• If using a fence or guide, make sure it

is securely fastened and complies with

manufacturer’s instructions.

• Certain blades are useful for different

types of cuts and materials. Make

sure the blade in use is approved by

the manufacturer for the operation

being performed.

!

WARNING

3

www.chpower.com

DG460500CK

General Safety

Information (Cont’d.)

Figure 1

Figura 2

Page 4

5. No utilice hojas desafiladas ni

dañadas. Las hojas desafiladas o en

mal estado producen que la entalla

se angoste causando fricción

excesiva, atascamiento de la hoja

y contragolpe.

6. La profundidad de la hoja y las

palancas que bloquean el ajuste del

corte en diagonal deben estar

ajustadas y seguras antes de hacer

el corte. Si el ajuste de la hoja se

mueve durante el corte, puede

provocar atascamiento y

contragolpe.

7. Tenga extremo cuidado al hacer

un “Corte en bolsillo” en paredes

existentes u otras áreas ciegas.

La hoja que sobresale puede cortar

objetos que pueden causar

contragolpe.

8. Tenga cuidado con los materiales

inclinados, enredados, húmedos

o deformados. Es muy probable que

estos materiales creen condiciones

de mordida y posiblemente

contragolpe.

Ensamblaje

CÓMO COLOCAR LA HOJA

Siempre desconecte la herramienta

y deje el interruptor en la posición de

bloqueo o de apagado antes de hacer

cualquier armado, ajuste o de cambiar

accesorios. Dichas medidas de

seguridad preventivas reducen el riesgo

de que la herramienta se active por

accidente.

1. Usando la llave hexagonal que se

proporciona, afloje los dos pernos

de bloqueo de la hoja para poder

retirar o introducir una hoja.

2. Introduzca la hoja en la ranura con

los dientes hacia adelante (Figura 1).

La parte superior de la hoja se debe

introducir lo suficiente hasta que

toque el sujetador de la hoja.

3. Mientras la hoja está en la ranura de

calce y tocando el sujetador superior

de la hoja, apriete con seguridad los

pernos de bloqueo de la hoja.

4. Pruebe la hoja en una dirección

segura, lejos de las demás personas,

antes de comenzar a usar la nueva

hoja. Una hoja mal asegurada

arriesga la posibilidad de

desprenderse durante el

funcionamiento lo que podría

resultar en lesiones graves.

Funcionamiento

Use equipo de seguridad. Siempre use

protección para los ojos. Se debe usar

máscara para polvo, calzado de

seguridad antideslizante, o protección

de audición para la condición adecuada.

FUNCIONAMIENTO GENERAL

• Siempre sujete la pieza de trabajo

en forma segura en un caballete de

aserrar o banco.

• Antes de cortar, asegúrese de que el

espacio debajo del material a cortar

sea más profundo que la hoja de la

sierra.

• Si usa un delimitador o guía,

asegúrese de que esté fijada con

seguridad y que cumpla con las

instrucciones del fabricante.

• Ciertas hojas son útiles para

diferentes tipos de cortes y

materiales. Asegúrese de que la hoja

en uso esté aprobada por el

fabricante para la operación que se

está llevando a cabo.

• Mida todos los cortes a realizar para

asegurarse de que están claramente

marcados.

• Encienda la sierra y deje que alcance

el valor de velocidad establecido

antes de tocar el material.

• Cuando haya completado el corte,

deje que la sierra se detenga por

completo antes de retirarla del

material de trabajo.

CONTROL DE VELOCIDAD

VARIABLE

El control de velocidad es un

interruptor de disco de velocidad

de 6 posiciones ubicado en el frente

superior del mango. Al girar el

interruptor de 1 a 6, la velocidad

de la hoja se puede fijar entre 500

y 3,000 RPM. Se debe fijar la velocidad

de recorrido para el material específico

a cortar. Las velocidades menores se

usan para comenzar los cortes.

Las velocidades medias son ideales para

!

ADVERTENCIA

cortar materiales duros como metales

y plásticos. Las velocidades altas se

deben usar para materiales más

blandos como la madera. Los metales

blandos como el aluminio pueden

requerir altas velocidades de corte.

Ajuste las velocidades acorde a esto.

BLOQUEO DEL INTERRUPTOR

DE ENCENDIDO/APAGADO

Al presionar el interruptor de

encendido/apagado y usar el botón

de “bloqueo”, se puede usar la sierra

vertical de forma continua. El botón

de bloqueo se puede desbloquear de

inmediato simplemente presionando

una vez más el botón de

encendido/apagado.

ACCIÓN ORBITAL

El selector de modo de corte se puede

ajustar para seleccionar el modo de

corte recto o el modo de corte orbital.

Esta sierra tiene 4 valores de posición.

El valor marcado con 0 es para cortes

rectos y los valores marcados I, II y III

son para cortes orbitales.

Corte de paneles y tablas

Los paneles grandes y las tablas largas

se curvan o doblan si no están sujetados

correctamente. Si intenta cortar sin

nivelar ni sujetar la pieza de trabajo

correctamente, la hoja tenderá a

atascarse, provocando un contragolpe.

Sujete los paneles grandes. Asegúrese

de definir la profundidad del corte para

que solamente pueda cortar a través de

la pieza de trabajo, no a través de los

soportes.

TIPOS DE CORTE

Cortes rectos

Se puede lograr un corte recto

fácilmente sin usar un delimitador

de corte o una guía. Sujete con

abrazaderas un borde recto o una

pieza de madera pareja sobre la pieza

de trabajo y guíe el borde de la sierra

contra éste. Complete el corte sólo en

una dirección.

CORTES EN DIRECCIÓN DE LA VETA

Serrar es cortar a lo largo siguiendo

la veta. Seleccione la hoja adecuada

para su trabajo. Use una guía de

corte para cortes a lo largo de

4" de ancho o menos.

CORTES CRUZADOS

Cortar cruzado es cortar

transversalmente a la veta. Seleccione

la hoja adecuada para su trabajo.

Avance con la sierra lentamente para

evitar astillar la madera.

17 Sp

DG460500CK

Informaciones

Generales de

Seguridad (Continuación)

• Measure all cuts to be made and

make sure they are marked clearly.

• Start saw and allow it to reach speed

setting before touching it to the

material.

• When cut is completed, allow saw to

come to a complete stop before

removing from work material.

VARIABLE SPEED CONTROL

The speed control is a 6-position speed

dial switch located on the top front of

the handle. By rotating the switch

from 1 to 6, the blade speed can be set

from 500 to 3,000 RPM. Stroke rate

should be set for specific material

being cut. The lower speeds are used

to start cuts. The medium speeds are

ideal for cutting hard materials such as

metals and plastics. The higher speeds

should be used for softer materials

such as wood. Soft metals like

aluminum may require high speeds for

cutting. Adjust speeds accordingly.

LOCK ON/OFF SWITCH

Pressing the ON/OFF switch and using

the “lock” button, the jig saw can be

used continually. The lock button can

be unlocked immediately by simply

pressing the on/ off button again.

ORBITAL ACTION

The cutting mode selector can be

adjusted to select the straight cutting

mode or orbital cutting mode. This saw

has 4 position settings. The setting

marked 0 is for straight cutting and

the settings marked I, II, and III are for

orbital cutting.

CUTTING PANELS AND BOARDS

Large panels and long boards sag or

bend if they are not correctly

supported. If you attempt to cut

without leveling and properly

supporting the workpiece, the blade

will tend to bind, causing kickback.

Support large panels. Be sure to set the

depth of the cut so that you only cut

through the workpiece, not through

the supports.

TYPES OF CUTTING

Straight Cuts

Without the use of a rip-fence or

guide, a straight cut can very easily be

made. Clamp a straight edge or even a

piece of wood to the workpiece and

guide the edge of the saw against it.

Complete the cut in one direction only.

RIP-CUTTING

Ripping is cutting length wise with

the grain. Select the proper blade

for your job. Use a rip fence for rips

4" wide or less.

CROSS-CUTTING

Cross-cutting is cutting across the

grain. Select the proper blade for

your job. Advance the saw slowly to

avoid splintering the wood.

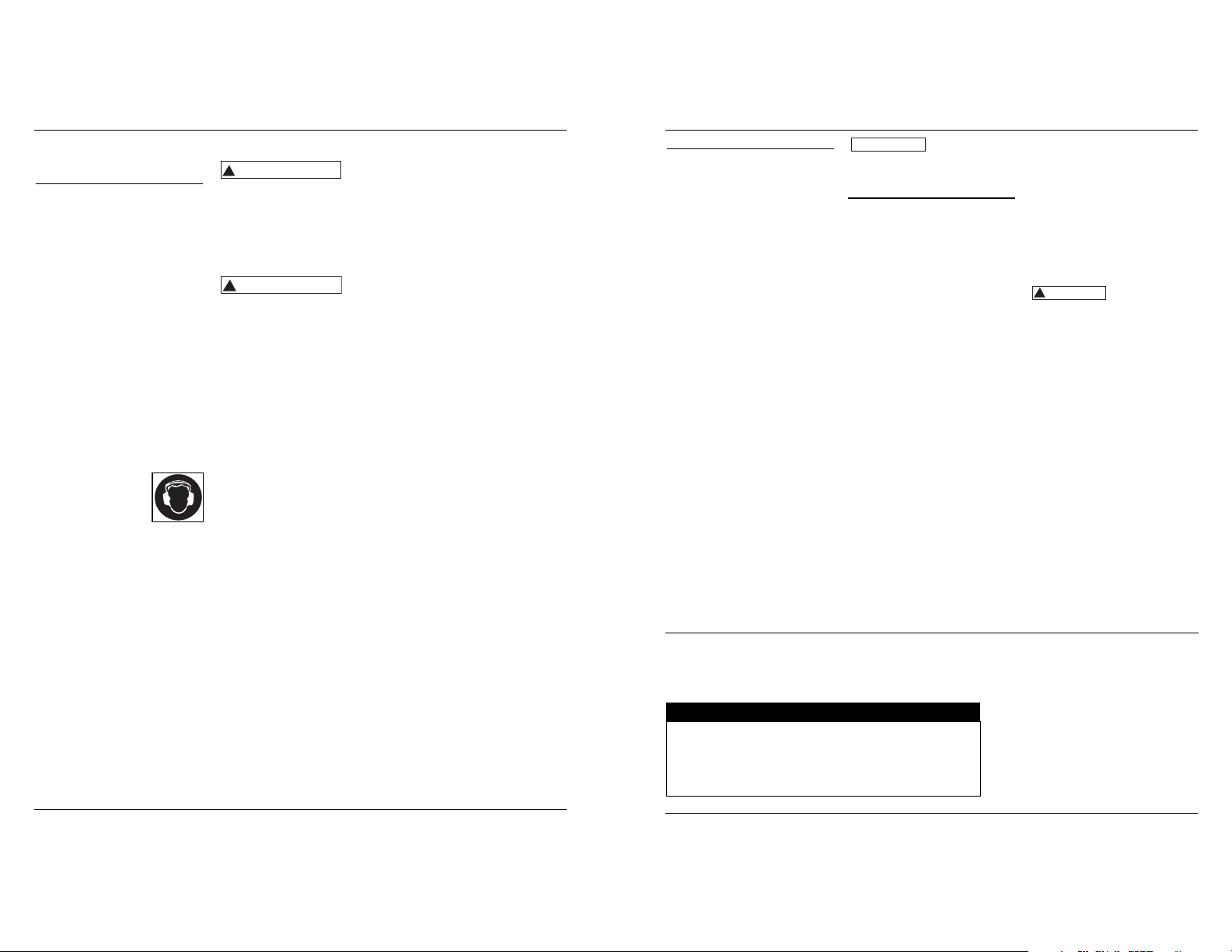

BEVEL/ ANGLE CUTTING

• Make sure the saw is unplugged

from the power source before

making adjustments to the cutting

angles

• The base plate can be tilted 45° in

both directions to perform angle

cuts. There are settings for 45° and

for 90° against the workpiece. For

other angles use a protractor to

measure (Figure 2).

Hole Cutting

POCKET CUTS

Pocket cuts are made in the middle of

the workpiece when it cannot be cut

from an edge. They can start at a predrilled hole or the jig saw can create

the starting point (plunge cut).

Plunge cutting is not recommended

for harder materials like steel and

scroll blades should not be used for

plunging.

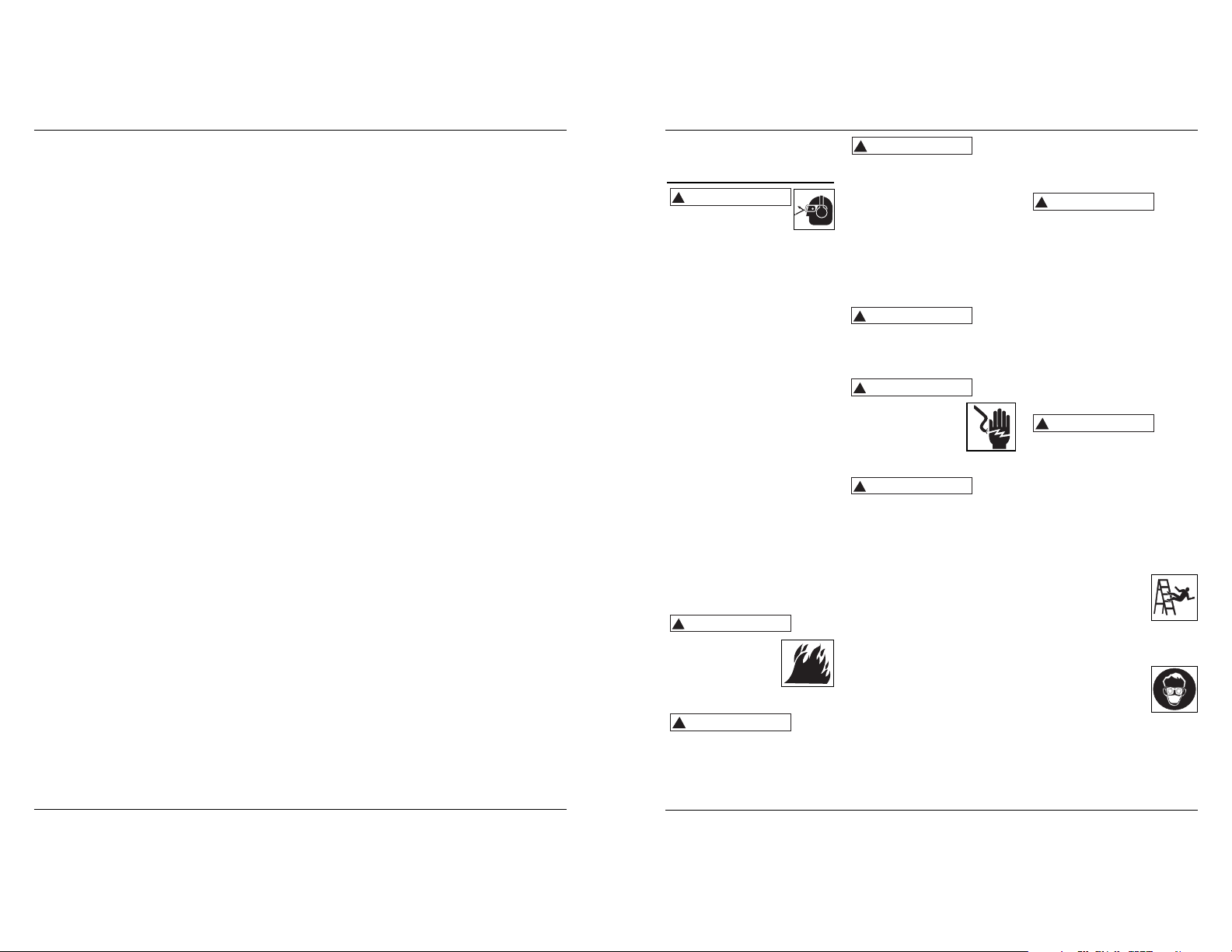

PLUNGE CUTS

1. If the pocket cut is straight-lined,

a pre-drilled hole is not necessary.

2. Touch the toe of the saw to the

workpiece leaving the blade well

above the material (Figure 3).

3. Make sure the orbital setting is on

0 then turn ON the saw.

4. Once the saw reaches maximum

speed, lower it slowly into the

workpiece.

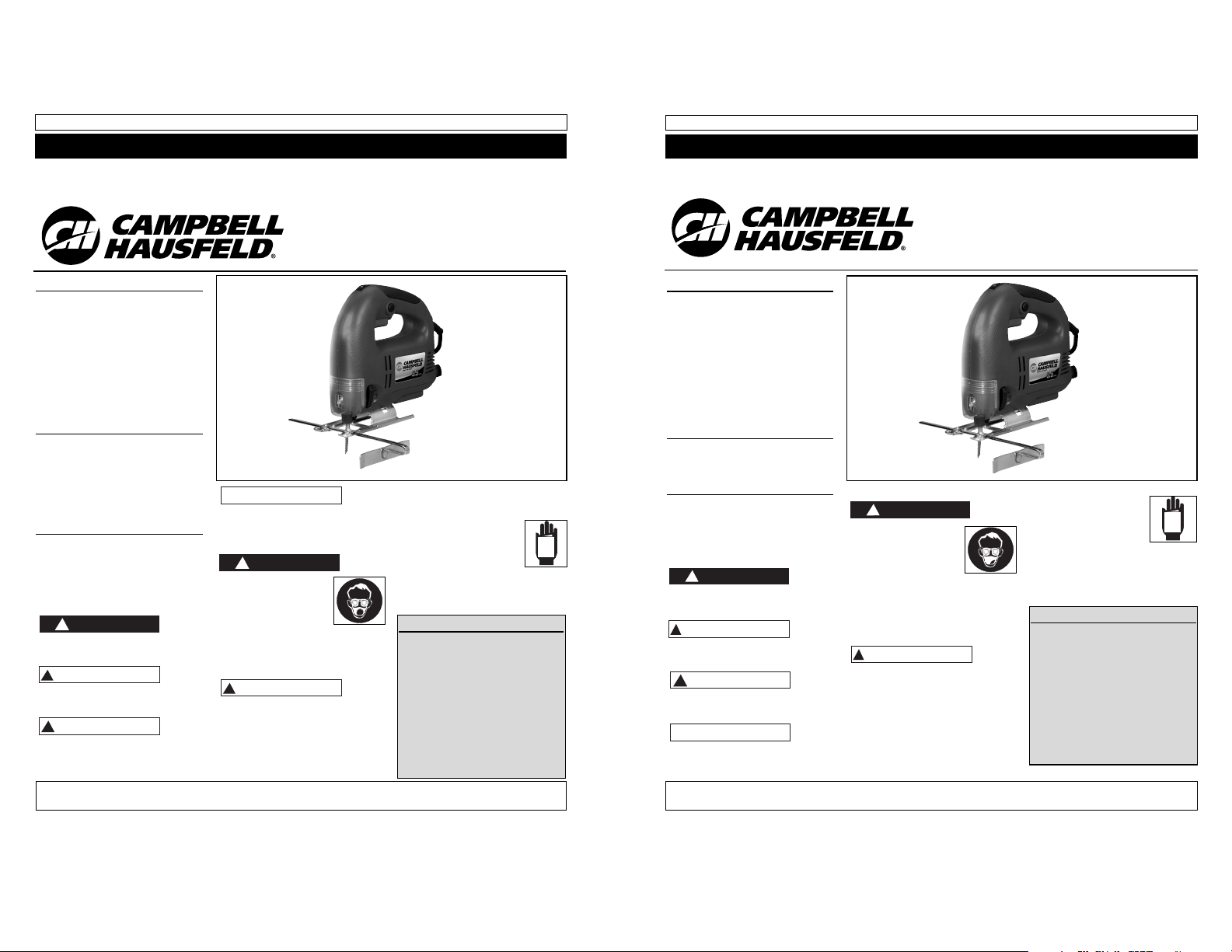

5. Keep both hands on the saw while

cutting (Figure 4).

6. For 90° or other sharp corners, cut

up to the corner then back out

before rounding the corner off.

Once opening the pocket,

approach the corner from the

opposite direction to square it off.

CIRCLE CUTS

A circle cutting guide can help assist

in the sawing of circles. The cut

should be prepared by a pre-drilled

hole or a slight plunge cut near the

cutting line. If using a guide, make

sure it complies with the jig saw and

the manufacturer’s instructions.

Scroll Cutting

Intricate work can be performed by a

jig saw using a scrolling blade. Make

sure that the blade being used

according to the manufacture’s

instructions. For best control, use the

saw on setting I with the scroll blade.

This provides easier cutting and

maneuvering.

Metal Cutting

• Before beginning a metal cut, place

orbital setting accordingly to 0 or I.

• When cutting metal workpieces,

clamp the material down and saw

close to the clamping point to

reduce bending and vibration.

• If the blade begins to vibrate or

chatter excessively, replace blade

with a metal cutting blade with finer

teeth.

• For soft metals the blade can

become clogged so use a blade with

coarser teeth.

• Conduit, angle iron, or pipe should

be clamped in a vice and cut as close

to the clamp as possible

4

www.chpower.com

Operating Instructions and Parts Manual

Operation (cont.)

0

I

II

I

I

I

Figure 3

Figure 2

Figure 4

Figura 1

Page 5

electricidad y el usuario recibirá un

choque eléctrico.

6. Mantenga las manos alejadas de

las piezas giratorias.

7. Use sujetadores u otra manera

práctica de asegurar la pieza de

trabajo a una plataforma estable.

Nunca sostenga el trabajo en sus

manos, su regazo o contra otras

partes de su cuerpo cuando corte.

8. Siempre utilice hojas con orificios

del mandril del tamaño y forma

correctos (diamante contra

redondas). Las hojas que no

coincidan con la ferretería de

montaje de la sierra funcionarán

excéntricamente, causando un gran

riesgo o lesión al usuario y daño

a la herramienta.

9. NUNCA sostenga una pieza que está

cortando en sus manos ni sobre sus

piernas. Es importante apoyar el

trabajo correctamente para

minimizar la exposición corporal,

el atascamiento de la hoja o la

pérdida de control.

10. Use protección para los

oídos cuando use la

herramienta por

períodos prolongados.

La exposición

prolongada a ruido de

alta intensidad puede causar

pérdida de audición.

11. Asegúrese de que se hayan quitado

todos los clavos de la superficie de

trabajo antes de poner en

funcionamiento la herramienta.

12. Esta sierra no está diseñada para

cortar tuberías huecas. Realice cortes

únicamente en materiales

aprobados.

13. No toque las piezas de metal de la

sierra mientas corta en áreas donde

no puede ver. Los lugares que no

permiten ver del otro lado como las

paredes y los pisos pueden contener

cables con electricidad.

14. No toque las piezas metálicas de la

sierra ni la hoja inmediatamente

después de usarla. Las piezas estarán

calientes y pueden causar

quemaduras graves.

CUIDADO Y USO DE LA

HERRAMIENTA

No use la herramienta si el interruptor

no la enciende ni apaga. Cualquier

herramienta que no pueda ser

controlada con el interruptor es

peligrosa y debe repararse.

1. Esta herramienta NO debe

modificarse ni usarse para cualquier

aplicación que no sea la aplicación

para la cual fue diseñada.

No fuerce la herramienta. Use la

herramienta correcta para su

aplicación. La herramienta correcta

hará el trabajo mejor y en forma más

segura a la velocidad para la cual fue

diseñada.

2. Cuide sus herramientas.

Mantenga sus herramientas para

cortar afiladas y limpias. Es menos

probable que las herramientas con

un mantenimiento adecuado y con

bordes de corte afilados se

atasquen y además son más fáciles

de controlar.

3. Verifique que no haya partes

mal alineadas, atascadas o rotas,

o cualquier otra condición que

pueda afectar el funcionamiento de

la herramienta. Si la herramienta

presentara un daño, hágala reparar

antes de usarla. Las herramientas

con mantenimiento inadecuado

causan muchos accidentes.

4. Use solamente accesorios

recomendados por el fabricante

de su modelo. Los accesorios

apropiados para una herramienta

pueden causar un riesgo de lesión

cuando se usan con otra

herramienta.

5. Algunas maderas contienen

conservadores que pueden ser

tóxicos. Tenga especial cuidado

para evitar la inhalación y el

contacto con la piel con estos

materiales. Solicite y cumpla con

toda la información de seguridad

disponible por parte de su

proveedor de materiales.

6. Guarde las herramientas fuera del

alcance de los niños y de otras

personas no capacitadas para

usarlas. Las herramientas son

peligrosas cuando están en manos

de usuarios inexpertos.

!

PRECAUCION

!

ADVERTENCIA

CAUSAS Y PREVENCIÓN DEL

CONTRAGOLPE POR PARTE DEL

USUARIO:

El contragolpe es una reacción

repentina de una hoja de sierra

mordida, atascada o mal alineada,

provocando que una sierra fuera de

control se levante y salga de la pieza

de trabajo hacia el operador.

Cuando la hoja esté mordida o atascada

firmemente por la entalla o ranura de

corte, cerrándose, la hoja se parará y la

reacción del motor impulsará la unidad

rápidamente hacia el operador.

Si la hoja se tuerce o se desaliña en el

corte, los dientes del borde posterior

de la hoja pueden perforar la superficie

superior de la madera provocando que

la hoja se zafe de la entalla y salte

hacia el operador.

El contragolpe es el resultado de

un mal uso de la herramienta y/o

de procedimientos o condiciones de

operación incorrectos y puede evitarse

tomando las precauciones necesarias

que se proporcionan a continuación:

1. Sostenga la sierra con firmeza con

las dos manos y posicione su cuerpo

y brazo para permitirle resistir las

fuerzas de contragolpe. El operador

puede controlar las fuerzas de

contragolpe si toma las

precauciones necesarias.

2. Cuando la hoja se atasque, o cuando

se interrumpa el corte por algún

motivo, libere el gatillo y sostenga la

sierra sin moverla sobre el material

hasta que la hoja se detenga por

completo. Nunca intente retirar la

sierra del trabajo ni tirar la sierra

hacia atrás mientras la hoja esté en

movimiento o puede haber un

contragolpe. Investigue y tome

acciones correctivas para eliminar la

causa del atascamiento de la hoja.

3. Cuando reinicie una sierra en la

pieza de trabajo, centre la hoja de

la sierra en la entalla, o corte,

y verifique que los dientes de la

sierra no queden enganchados en el

material. Si la hoja de la sierra está

atascada, puede salir o provocar un

contragolpe desde la pieza de

trabajo mientras se reinicia la sierra.

4. Sostenga los paneles grandes para

minimizar el riesgo de morder la

hoja y de contragolpe. Los paneles

grandes tienden a curvarse por su

propio peso. Se deben colocar

apoyos a ambos lados debajo del

panel, junto a la línea de corte

y cerca del borde del panel.

16 Sp

Manual de Instrucciones y Lista de Piezas

Informaciones

Generales de

Seguridad (Continuación)

• Thin sheet metals should be

“sandwiched” between or laid on

top of tougher wood boards, like

plywood, and the design or layout

set on top. This allows the metal to

be cut smoothly and prevents

tearing on the metal material.

• The blade may be lubricated for

easier cutting. Use a stick of cutting

wax, when available, and use cutting

oil when cutting steel.

• The exposed portion of the saw bar

must be kept clean. Wipe metal

chips away frequently by using an

oily cloth. After use, dispose of oily

cloth appropriately, to prevent fire

hazards.

DUST EXTRACTION

Clean cutting operations can be

performed by connecting this tool to a

vacuum cleaner. Insert the hose of the

vacuum cleaner into the hole at the

rear of the tool. Lower the dust cover

before operation.

Dust extraction

cannot be performed when making

bevel cuts.

Maintenance

Tool service must be performed only

by qualified repair personnel. Service

or maintenance performed by

unqualified personnel could result in

a risk of injury.

Cleaning

Clean out dust and debris from vents

and electrical contacts by blowing with

compressed air. Motor vents and

switch levers must be kept clean and

free of foreign matter. Do not attempt

to clean by inserting pointed objects

through openings. Keep tool handles

clean, dry and free of oil or grease.

Use only mild soap and a damp cloth

to clean the tool, keeping away from

all electrical contacts.

NOTICE

Certain cleaning agents and solvents

are harmful to plastics and other

insulated parts. Some of these include

gasoline, turpentine, lacquer thinner,

paint thinner, chlorinated cleaning

solvents, ammonia and household

detergents containing ammonia.

Never use flammable or combustible

solvents around tools.

TECHNICAL SERVICE

For information regarding the

operation or repair of this product,

please call 1-800-424-8936.

Tool service must

be performed only by qualified repair

personnel. Service or maintenance

performed by unqualified personnel

could result in a risk of injury.

When servicing a tool, use only

identical replacement parts. Follow

instructions in the Maintenance section

of this manual. Use of unauthorized

parts or failure to follow Maintenance

instructions may create a risk of

electrical shock or injury.

!

CAUTION

5

www.chpower.com

DG460500CK

For Replacement Parts or Technical Assistance, call 1-800-424-8936

or visit our website: www.chpower.com

Please provide following information:

• Model number

• Serial number (if any)

• Part description and number as shown in parts list

Address any correspondence to:

Campbell Hausfeld

Attn: Customer Service

100 Production Drive

Harrison, OH 45030 U.S.A.

Description Part Number

Saw Blade DG025800AV

Dust Tube DG025900AV

Edge Guide DG026000AV

3mm Allen Wrench DG026100AV

Replacement Parts List

Operation (cont.)

Page 6

Se deberán usar gafas de

seguridad durante la

operación.

3. No use vestimenta suelta, bufandas

o corbatas en el área de trabajo.

Las prendas sueltas pueden quedar

atrapadas en las partes móviles y

provocar graves lesiones personales.

4. No use alhajas al manejar

herramientas. Las alhajas pueden

quedar atrapadas en las partes

móviles y provocar graves lesiones

personales.

5. Utilice siempre los accesorios

diseñados para usar con esta

herramienta. No utilice accesorios

dañados ni desgastados.

6. Nunca accione la herramienta si

no está aplicada a un objeto de

trabajo. Los accesorios deben

colocarse en forma segura.

Los accesorios sueltos pueden causar

lesiones graves.

7. Nunca apunte una herramienta

hacia usted ni hacia otra persona.

Pueden ocurrir lesiones graves.

8. Utilice presión firme y pareja al usar

la herramienta. No la fuerce.

Demasiada presión puede provocar

que la hoja se quiebre o se recaliente.

9. Mantenga todas las tuercas, pernos

y tornillos ajustados y asegúrese de

que el equipo esté en condiciones

de trabajo seguras.

10. No acerque las manos a las piezas

móviles ni las coloque debajo de ellas.

ÁREA DE TRABAJO

No haga funcionar una

herramienta a motor en

un entorno explosivo,

como por ejemplo cuando

haya líquidos, gases o

polvo inflamable. Las

herramientas a motor hacen chispas que

pueden encender los gases o el polvo.

Mantenga el área de trabajo limpia

y bien iluminada. Los bancos

desordenados y las áreas oscuras

propician accidentes.

!

PRECAUCION

!

ADVERTENCIA

!

ADVERTENCIA

Mantenga alejados a los observadores,

niños y visitantes mientras hace

funcionar una herramienta a motor.

Las distracciones pueden hacerle perder

el control.

SEGURIDAD ELÉCTRICA

Las herramientas doblemente aisladas

están equipadas con un enchufe

polarizado (un borne del enchufe es más

ancho que el otro). Este enchufe calzará

en un solo sentido en un tomacorriente

polarizado. Si el enchufe no calza

completamente en el tomacorriente, dé

vuelta el enchufe y vuelva a introducirlo.

No exponga las herramientas a motor

a la lluvia ni a superficies mojadas.

Si entra agua dentro de una herramienta

a motor, aumentará el riesgo de choque

eléctrico.

Evite el contacto corporal

con las superficies

conectadas a tierra, tales

como tuberías, radiadores,

cocinas eléctricas o

refrigeradores. Existe un

mayor riesgo de choque eléctrico si su

cuerpo está conectado a tierra.

Trate el cable con cuidado.

• Nunca tome la herramienta

por el cablepara transportarla.

• Nunca tire del cable para

desenchufarla del receptáculo.

1. Asegúrese de que el cable esté

ubicado de tal manera que nadie

lo pise ni se tropiece con él, y que

no esté sujeto de alguna otra manera

a algún daño o tensión.

2. No use un cable de extensión a

menos que sea absolutamente

necesario. El uso de un cable de

extensión inadecuado puede resultar

en un riesgo de incendio y choque

eléctrico. Si se debe usar un cable de

extensión, asegúrese de que:

• Que las clavijas del enchufe del

cable de extensión tengan el mismo

número, tamaño y forma que las

del enchufe.

• Que el cable de extensión esté

correctamente cableado y en

buenas condiciones eléctricas.

• Si el cable de extensión va a usarse

en exteriores debe estar marcado

con el sufijo “W-A” o “W” después

de la designación del tipo de cable

para indicar que es apto para usarse

en exteriores. Por ejemplo: SJTW-A

!

ADVERTENCIA

!

ADVERTENCIA

!

ADVERTENCIA

!

PRECAUCION

3. No la exponga a la lluvia, nieve o

heladas. Si entra agua dentro de una

herramienta a motor, aumentará el

riesgo de choque eléctrico.

SEGURIDAD PERSONAL

No use este producto en forma

inadecuada. La exposición excesiva

a la vibración, trabajar en posiciones

incómodas y los movimientos de

trabajo repetitivos pueden causar

lesiones a las manos y brazos. Deje de

usar cualquier herramienta si aparece

incomodidad cosquilleo o dolor

y consulte a un médico.

1. Manténgase alerta, preste atención

a lo que hace y use su sentido

común cuando maneje cualquier

herramienta a motor. No use la

herramienta si está cansado o bajo

la influencia de drogas, alcohol o

medicamentos. Un momento de

distracción mientras maneja

cualquier herramienta a motor

puede dar como resultado graves

lesiones personales.

Evite que se encienda accidentalmente.

Asegúrese de que el interruptor esté en

la posición de bloqueo o de apagado

antes de hacer algún ajuste, cambiar los

accesorios o guardar la herramienta.

El transportar herramientas con el dedo

en el interruptor encendido favorece

los accidentes.

2. Quite las llaves de ajuste o antes

de encender la herramienta.

Una conectada a una pieza giratoria

de la herramienta puede provocar

lesiones personales.

3. No intente alcanzar

lugares alejados.

Mantenga un buen

soporte y equilibrio

en todo momento.

Un soporte y equilibrio

adecuados permiten un mejor

control de la herramienta en

situaciones inesperadas.

4. Trabaje siempre en un

área bien ventilada.

Use gafas de seguridad

y una máscara para

polvo aprobada

por OSHA.

5. Sostenga la herramienta por la

superficie de sujeción aislada

cuando realice una operación en la

que la herramienta pueda entrar en

contacto con un cableado oculto.

Al entrar en contacto con un cable

de corriente las piezas metálicas de

la herramienta conducirán la

!

PRECAUCION

!

ADVERTENCIA

15 Sp

DG460500CK

Informaciones

Generales de

Seguridad (Continuación)

6

www.chpower.com

Operating Instructions and Parts Manual

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: two years.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Production

Drive, Harrison, Ohio, 45030, Telephone: (800) 424-8936.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale)

of the Campbell Hausfeld product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Campbell Hausfeld power tool supplied or

manufactured by Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects in material and workmanship which occur

within the duration of the warranty period.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE

LIMITED FROM THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If this product is used

for commercial, industrial or rental purposes ,no warranty applies. Some States do not allow limitation

on how long an implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT

FROM ANY DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some States

do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in

accordance with instructions provided in the owner’s manual(s) supplied with product. Accident,

purchaser's abuse, neglect or failure to operate products in accordance with instructions shall also

include the removal or alteration of any safety devices. If such safety devices are removed or altered,

this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the product.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option,

products or components which are defective, have malfunctioned and/or failed to conform within duration

of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Call Campbell Hausfeld (800-424-8936) to obtain your warranty service options. Freight costs must be

borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in the owner’s

manual(s).

This Limited Warranty applies in the United States, Canada and Mexico only and gives you specific legal rights.

You may also have other rights which vary from state to state or country to country.

Page 7

®

Manual de Instrucciones y Lista de Piezas DG460500CKS

Sierra vertical orbital

Sírvase leer y guardar estas instrucciones. Lea con cuidado antes de tratar de armar, instalar, manejar o darle

servicio al producto descrito en este manual. Protéjase Ud. y a los demás observando todas las reglas de

seguridad. El no seguir las instrucciones podría resultar en heridas y/o daños a su propiedad. Guarde este

manual como referencia.

IN714000AV 3/06

BUILT TO LAST

© 2006 Campbell Hausfeld/Scott Fetzer

Ver la Garantía en página 20 para información importante sobre el uso comercial de este producto.

Descripción

Las sierras verticales están diseñadas

para efectuar tareas de corte que no

son posibles con otras sierras. Son las

más útiles para cortes circulares,

curvos y calados. Los valores orbitales

permiten cortes más rápidos en

diferentes materiales. Algunos valores

pueden no ser adecuados para ciertas

tareas. Sírvase familiarizarse con todos

los componentes de esta herramienta

antes de usarla.

Para desempacar

Cuando desempaque este producto,

inspecciónelo cuidadosamente para

detectar cualquier daño que pueda

haber ocurrido durante el envío.

Informaciones

Generales de

Seguridad

Este manual contiene información que

es muy importante que sepa y

comprenda. Esta información se la

suministramos como medida de

SEGURIDAD y para EVITAR PROBLEMAS

CON EL EQUIPO. Debe reconocer los

siguientes símbolos.

Ésto le indica que hay una situación

inmediata que LE OCASIONARIA la

muerte o heridas de gravedad.

Ésto le indica que hay una situación que

PODRIA ocasionarle la muerte o heridas

de gravedad.

Ésto le indica que hay una situación que

PODRIA ocasionarle heridas no muy

graves.

!

PRECAUCION

!

ADVERTENCIA

!

PELIGRO

Ésto le indica una información

importante, que de no seguirla, le podría

ocasionar daños al equipo.

PROPOSICIÓN DE CALIFORNIA 65

Cuando corta lija, taladra

o pule materiales como

por ejemplo madera,

pintura, metal, hormigón,

cemento, u otro tipo de

mampostería se puede

producir polvo. Con frecuencia este

polvo contiene productos químicos que

se conocen como causantes de cáncer,

defectos congénitos u otros daños

reproductivos. Use equipo de protección.

Este producto, o su cordón eléctrico,

contiene productos químicos conocidos

por el estado de California como

causantes de cáncer y defectos de

nacimiento u otros daños

reproductivos. Lave sus manos

minuciosamente después de usar.

!

ADVERTENCIA

!

PELIGRO

AVISO

Las siguientes precauciones de seguridad

se deben seguir en todo momento junto

con cualquier otra norma de seguridad.

1. Lea con cuidado los

manuales incluidos con

este producto. Familiarícese

con los controles y el uso

adecuado del equipo.

2. Sólo se les debe permitir usar la

sierra a aquellas personas bien

familiarizadas con estas reglas de

manejo seguro.

MANUAL

14 Sp

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

Especificaciones

Voltaje clasificado . . . . . 115/120V ~ 60Hz

Frecuencia clasificada . . . 60Hz

Clasificación de

corriente . . . . . . . . . . . . 5,5A

Velocidad sin carga . . . . 500-3000 cpm

Capacidades de corte:

Madera . . . . . . . . . . 2 9/16" (65mm)

Acero. . . . . . . . . . . . 15/64" (6mm)

Ángulos de corte: 45 grados a la

izquierda,

90 grados, y

45 grados a la

derecha

7Fr

Instructions d’Utilisation et Manual de Pièces DG460500CK S

Scie sauteuse orbitale

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de

procéder à l’entretien du produit décrit. Se protéger ainsi que les autres en observant toutes les instructions de

sécurité, sinon, il y a risque de blessure et/ou dégâts matériels! Conserver ces instructions comme référence.

IN714000AV 3/06

BUILT TO LAST

© 2006 Campbell Hausfeld/Scott Fetzer

Voir la Garantie à la page 13 pour de l’information importante sur l’utilisation commercial de ce produit.

MÉMENTO: Gardez votre preuve datée d’achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

Description

Les scies sauteuses sont conçues pour

exécuter des travaux de coupe qui ne

sont pas possibles avec d’autres scies

Elles sont les plus utiles pour les coupes

circulaires, en courbe et de découpage.

Les réglages orbitaux permettent des

coupes plus rapides dans différents

matériaux. Certains réglages pourraient

ne pas être appropriés pour certaines

tâches. Il faut se familiariser avec tous

les composants de cet outil avant

d’utiliser la scie.

Déballage

En déballant ce produit, inspecter

attentivement pour tout signe de

dommage en transit.

Directives De Sécurité

Ce manuel contient de l’information très

importante qui est fournie pour la

SÉCURITÉ et pour ÉVITER LES

PROBLÈMES D’ÉQUIPEMENT. Rechercher

les symboles suivants pour cette

information.

Danger indique une situation

hasardeuse imminente qui RÉSULTERA

en perte de vie ou blessures graves.

Avertissement indique une situation

hasardeuse potentielle qui PEUT résulter

en perte de vie ou blessures graves.

Attention indique une situation

hasardeuse potentielle qui PEUT résulter

en blessures.

Avis indique l’information importante

pour éviter le dommage de

l’équipement.

AVIS

!

ATTENTION

!

AVERTISSEMENT

!

DANGER

PROPOSITION 65 CALIFORNIE

Vous pouvez créer de la

poussière en coupant,

ponçant, perçant ou

meulant les matériaux tels

que le bois, la peinture, le

métal, le béton, le ciment

ou autre maçonnerie. Cette poussière

contient souvent des produits

chimiques reconnus pour causer le

cancer, les déformations congénitales

ou autres problèmes de la

reproduction. Portez de l’équipement

de protection.

Ce produit ou son cordon contient des

produits chimiques qui de l’avis de l’État

de Californie peut causer le cancer et des

anomalies congénitales ou autres

problèmes de reproduction. Lavez-vous

les mains après la manipulation.

Les précautions de sécurité suivantes

doivent être respectées en tout temps

en plus de toute autre règle de

sécurité actuelle.

!

AVERTISSEMENT

!

DANGER

1. Lire attentivement tous

les manuels, y compris

celui de ce produit. Bien

se familiariser avec les

commandes et

l’utilisation correcte de

l’équipement.

2. Seules les personnes familières avec

ces règles d’utilisation sans danger

devraient utiliser la scie.

MANUAL

Spécifications

Tension nominale. . . . . . . 115/120 V ~ 60 Hz

Fréquence nominale . . . . 60 Hz

Puissance nominale . . . . . 5,5 A

Vitesse sans charge. . . . . . 500 à 3 000 cpm

Capacités de coupe

Bois . . . . . . . . . . . . . . . 65 mm (2 9/16 po)

Acier . . . . . . . . . . . . . . 6 mm (15/64 po)

Angles de coupe : . . . . . . 45 degrés gauche,

90 degrés, et

45 degrés droite

Page 8

13 Fr

DG460500CK

Porter des lunettes de

sécurité et une protection

des oreilles pendant son

fonctionnement.

3. Ne pas porter de vêtements amples,

de foulards ou de cravates dans

l’aire de travail. Les vêtements

amples pourraient se prendre dans

les pièces mobiles de l’appareil et

mener à de graves blessures.

4. Ne pas porter de bijoux en utilisant

tout outil. Les bijoux peuvent se

prendre dans les pièces mobiles et

mener à de graves blessures.

5. Toujours utiliser les accessoires

conçus pour cet outil. Ne pas utiliser

d’accessoires endommagés ou usés.

6. Ne jamais déclencher l’outil n’est

pas appliqué à un travail. Les

accessoires doivent être bien

attachés. Tout accessoire desserré

peut provoquer de graves blessures.

7. Ne jamais pointer un outil vers

soi-même ou vers toute autre

personne. Des blessures graves

pourraient en résulter.

8. Utiliser une pression constante et

uniforme en utilisant l’outil. Ne pas

forcer. Trop de pression pourrait mener

au bris ou à la surchauffe de la lame.

9. Garder tous les écrous, boulons et

vis serrés et faire en sorte que

l’équipement soit en bon état de

marche.

10. Ne pas mettre les mains près

ou sous les pièces mobiles.

AIRE DE TRAVAIL

Ne pas faire fonctionner

un outil électrique dans

une atmosphère explosive

comme en présence de

liquides, gaz ou poussières

inflammables. Les outils

électriques créent des

étincelles qui peuvent enflammer

la fumée ou la poussière.

Garder l’aire de travail propre et bien

éclairée. Les établis encombrés et les

coins sombres attirent les accidents.

Garder les spectateurs, les enfants et

les visiteurs loin en utilisant un outil

électrique. Les distractions peuvent

faire perdre le contrôle.

!

ATTENTION

!

ATTENTION

!

AVERTISSEMENT

!

AVERTISSEMENT

SÉCURITÉ ÉLECTRIQUE

Les outils à double isolant sont dotés

d’une fiche polarisée (une lame est plus

large que l’autre). Cette fiche entre

dans une prise polarisée seulement

d’une manière. Si la fiche n’entre pas

entièrement dans la prise, l’inverser

et l’insérer à nouveau.

Ne pas exposer les outils électriques

à la pluie ou à des conditions humides.

Toute eau pénétrant dans l’outil

électrique augmente le risque de choc

électrique.

Éviter tout contact avec

les surfaces mises à la terre

telles que les tuyaux, les

radiateurs, les cuisinières

et les réfrigérateurs. Il y

a un risque accru de choc

électrique si votre corps

est mis à laterre.

Ne pas mal utiliser le cordon.

• Ne jamais porter le chargeur par

son cordon.

• Ne jamais débrancher le cordon en

le tirant de la prise. Tirez la fiche

plutôt que le cordon en débranchant

l’outil.

1. S’assurer que le cordon soit placé de

telle manière que l’on ne puisse pas

marcher dessus, trébucher ou subir

des dommages ou un stress

quelconque.

2. Ne pas utiliser de rallonges à moins

que cela ne soit absolument

nécessaire. Une mauvaise utilisation

de rallonge pourrait mener à un

risque d’incendie ou de choc

électrique. S’il faut utiliser une

rallonge, s’assurer que :

• Les broches de la fiche de la

rallonge sont du même nombre,

de même taille et forme que

celles de la fiche.

• La rallonge est bien câblée et en

bon état.

• Si vous utilisez une rallonge à

l’extérieur, elle doit porter le

suffixe « W-A » ou « W » selon la

désignation du type de cordon

pour indiquer s’il peut servir à

l’extérieur. Par exemple - SJTW-A

3. Ne pas exposer à la pluie, à la neige

ou au gel. Toute eau pénétrant dans

l’outil électrique augmente le risque

de choc électrique.

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

SÉCURITÉ PERSONNELLE

Ne pas abuser de ce produit. Toute

exposition excessive à la vibration, tout

travail dans les positions encombrantes

et les motions de travail à répétition

peuvent provoquer des blessures aux

mains et aux bras. Cesser d’utiliser tout

outil si l’on ressent un malaise, un

engourdissement, un fourmillement ou

une douleur et consulter un médecin.

1. Il faut rester vigilant, savoir ce

qu’on fait et utiliser son sens

commun en faisant fonctionner

un outil électrique. Ne pas faire

fonctionner l’appareil fatigué ou

sous l’influence de drogues, d’alcool

ou de médicaments. Un moment

d’inattention en faisant fonctionner

les outils électriques peut mener

à des blessures graves.

Éviter tout démarrage accidentel.

S’assurer que l’interrupteur soit

verrouillé ou en position d’arrêt (off)

avant d’apporter toute modification,

de changer les accessoires ou de ranger

l’outil. Transporter les outils avec le

doigt sur l’interrupteur en position de

marche invite les accidents.

2. Retirer les clés à ouverture fixe ou

les clés d’ajustement avant de

mettre l’outil en marche. Une clé ou

une clé à ouverture fixe installée sur

une pièce mobile de l’outil pourrait

mener à une blessure.

3. Ne pas trop se pencher.

Garder bon pied et bon

équilibre en tout temps.

Ceci permet d’avoir un

meilleur contrôle de

l’outil dans les situations

imprévues.

4. Toujours travailler dans

un endroit bien ventilé.

Porter des lunettes

de sécurité et un

masque anti-poussières

homologué OSHA.

5. Tenir l’outil par une surface de prise

isolée en effectuant le travail lorsque

l’outil pourrait entrer en contact

avec un câblage caché. Un contact

avec un fil « sous tension » rendra les

pièces de métal exposées de l’outil

« sous tension » et produira un choc

pour l’opérateur.

6. Garder les mains loin des pièces

mobiles.

7. Utiliser des pinces ou tout autre

moyen pratique pour fixer le travail

à une plate-forme stable. Ne jamais

!

ATTENTION

!

AVERTISSEMENT

Instructions d’Utilisation et Manual de Pièces

8Fr

Directives De Sécurité

(Suite)

Garantie Limitée

1. DURÉE: À partir de la date d’achat par l’acheteur original comme suit - Deux Ans

2. GARANTIE ACCORDÉE PAR (GARANT): Campbell Hausfeld/Scott Fetzer Company, 100 Production Drive,

Harrison, Ohio, 45030, Téléphone: (800) 543-6400

3. BÉNÉFICIAIRE DE CETTE GARANTIE (ACHETEUR): L’acheteur original (sauf en cas de revente) du produit

Campbell Hausfeld.

4. PRODUITS COUVERTS PAR CETTE GARANTIE: Tout outil mécanique Campbell Hausfeld fourni ou fabriqué

par le garant.

5. COUVERTURE DE LA PRÉSENTE GARANTIE: Défauts de matière et de fabrication considérables qui se

révèlent pendant la période de validité de la garantie.

6. LA PRÉSENTE GARANTIE NE COUVRE PAS:

A. Les garanties implicites, y compris celles de commercialisabilité et D’ADAPTION À UNE FONCTION

PARTICULIÈRE SONT LIMITÉES À PARTIR DE LA DATE D’ACHAT INITIALE TELLE QU’INDIQUÉE DANS LA

SECTION DURÉE. Si ce produit est utilisé à des fins commerciaux, industriels ou de locations, aucune

garantie ne s’applique.. Quelques Provinces (États) n’autorisent pas de limitations de durée pour les

garanties implicites. Les limitations précédentes peuvent donc ne pas s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT OU INDIRECT POUVANT RÉSULTER DE TOUT DÉFAUT,

PANNE OU MAUVAIS FONCTIONNEMENT DU PRODUIT CAMPBELL HAUSFELD. Quelques Provinces (États)

n’autorisent pas l’exclusion ni la limitation des dommages fortuits ou indirects. La limitation ou

exclusion précédente peut donc ne pas s’appliquer.

C. Toute panne résultant d’un accident, d’une utilisation abusive, de la négligence ou d’une utilisation ne

respectant pas les instructions données dans le(s) manuel(s) accompagnant le produit. Un accident,

l’utilisation abusive par l’acheteur, la négligence ou le manque de faire fonctionner les produits selon les

instructions comprend aussi l’enlevage ou la modification de n’importe quel appareil de sûreté. Si ces

appareils de sûreté sont enlevés ou modifiés, la garantie sera annulée.

D. Réglages normaux qui sont expliqués dans le(s) manuel(s) d’utilisation accompagnant le produit.

7. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE: Réparation ou remplacement, au choix

du Garant, des produits ou pièces qui se sont révélés défectueux pendant la durée de validité de la garantie.

8. RESPONSABILITÉS DE L’ACHETEUR AUX TERMES DE CETTE GARANTIE:

A. Fournir une preuve d’achat datée et un état d’entretien.

B. Livraison ou expédition du produit ou de la pièce Campbell Hausfeld au Centre De Service Autorisé

Campbell Hausfeld. Taux de frais, si applicables, sont la responsabilité de l’acheteur.

C. Utilisation et entretien du produit avec un soin raisonable, ainsi que le décri(vent)t le(s) manuel(s)

d’utilisation.

Cette Garantie Limitée s’applique aux É.-U., au Canada et au Mexique seulement et vous donne des droits

juridiques précis. L’acheteur peut également jouir d’autres droits qui varient d’une Province, d’un État ou d’un

Pays à l’autre.

Page 9

Instructions d’Utilisation et Manual de Pièces

12 Fr

tenir le travail dans les mains,

sur les genoux ou contre toutes

parties du corps en coupant.

8. Toujours utiliser les lames avec la

bonne taille et la bonne forme

(losange par rapport à rond) des

alésages centraux. Les lames qui ne

sont pas associées à la quincaillerie

de montage de la scie fonctionneront

de manière excentrique et

provoqueront ainsi un risque

important de blessure à l’utilisateur

et de dommages à l’outil.

9. NE JAMAIS tenir la pièce à couper

dans les mains ou sur votre jambe.

Il est important de supporter

correctement le travail pour réduire

l’exposition du corps, le grippage de

la lame ou la perte de contrôle.

10. Porter une protection

pour les oreilles en

utilisant l’outil pour

de longues périodes.

Une exposition

prolongée à des bruits

de fortes intensités peut

provoquer des pertes auditives.

11. S’assurer que tous les clous sont tirés

de la pièce de travail avant de

commencer à couper.

12. Cette scie n’est pas désignée pour

couper les tuyaux creux. Exécuter les

coupes seulement sur des matériaux

approuvés.

13. Ne pas toucher de pièces

métalliques de la scie en coupant

dans les coins en retrait. Ces coins

comme les murs et les planchers

peuvent contenir des fils électriques

sous tension.

14. Ne pas toucher de pièces

métalliques de la scie ou de la

lame immédiatement après l’usage.

Les pièces seront chaudes et peuvent

causer de graves brûlures.

UTILISATION ET ENTRETIEN

DE L’OUTIL

Ne pas utiliser l’outil si l’interrupteur

ne se met pas en marche ou ne s’éteint

pas. Tout outil qui ne peut pas être

contrôlé par l’interrupteur est

dangereux et doit être réparé.

1. Cet outil NE peut PAS être modifié

ou utilisé pour toute application

autre que celle pour laquelle il

a été conçu.

!

AVERTISSEMENT

Ne pas forcer l’outil. Utiliser le bon

outil pour votre application. Le bon

outil effectuera le meilleur travail

sécuritaire au rythme pour lequel il a

été conçu.

2. Il faut entretenir les outils avec soin.

Il faut garder les outils tranchants et

propres. Des outils bien entretenus