Page 1

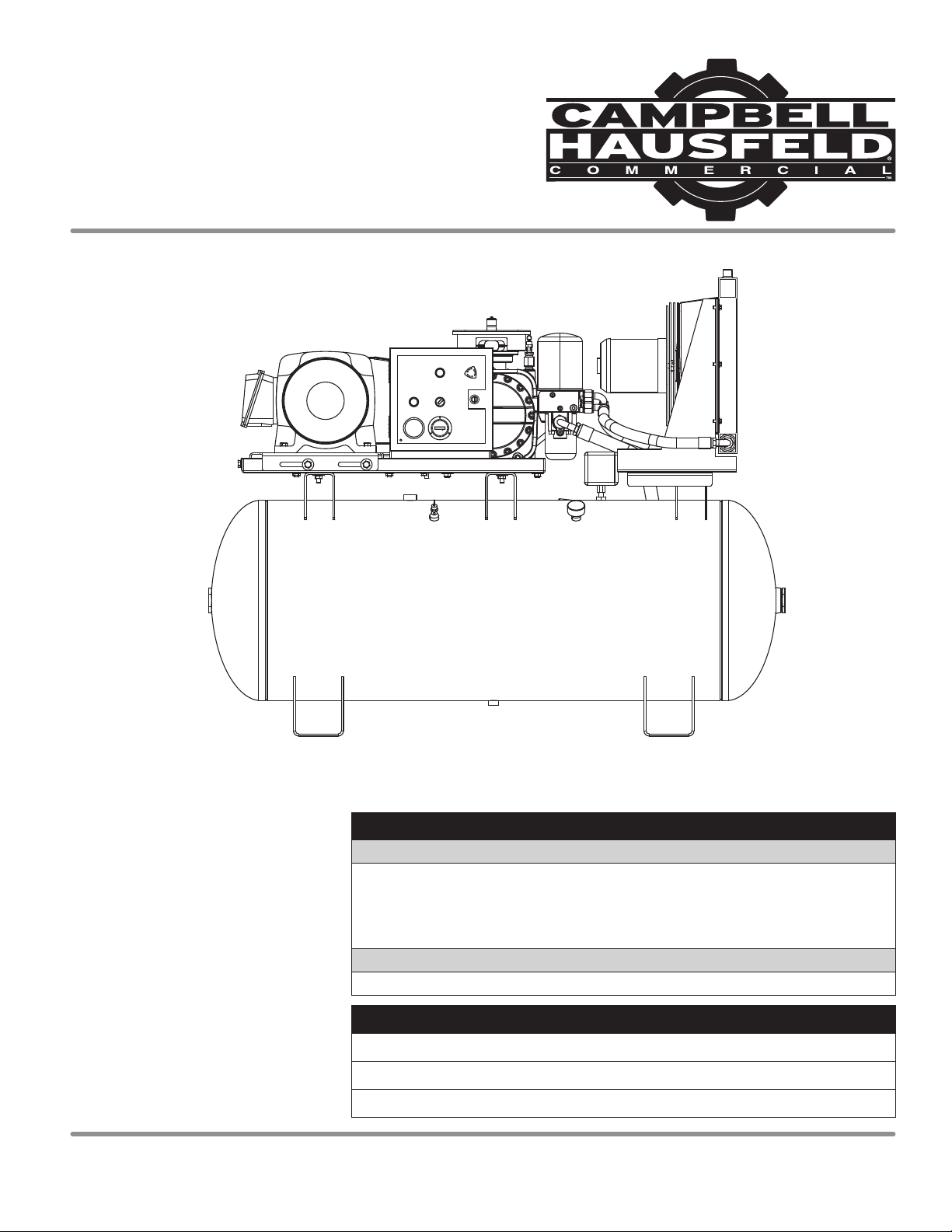

Operating Instructions

Rotary Screw

Air Compressors

Series CS Rotary Screw Compressors

Table of Contents

Safety Guidelines. . . . . . . . . . . . . . . . . . . . . 2

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . 2

Important Safety Information . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 2

Getting To Know Your Compressor . . . . 4

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . 9

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . 14

Troubleshooting Guide . . . . . . . . . . . . . . 18

Limited Warranty. . . . . . . . . . . . . . . . . . . . 20

Quick Reference

OIL

Single viscosity ISO100 rotary screw compressor oil

(Part number GS903800AV - 1 Gallon Container).

Available from Campbell Hausfeld, please call 1-855-504-5678 for customer

assistance.

OIL CAPACITY

2.1 gallons

RETAIN THIS INFORMATION FOR FUTURE REFERENCE

Serial Number:

Model Number:

Date of Purchase:

IN564600AV 10/12© 2012 Campbell Hausfeld/Scott Fetzer For parts, product & service information

visit www.campbellhausfeld.com

1-855-504-5678

Page 2

Operating Instructions

Please read and save these instructions. Read carefully before attempting to assemble, install,

Safety Guidelines

This manual contains information

that is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Important Safety Information

This manual contains important safety, operational and maintenance information. If

you have any questions, please call 1-855-504-5678 for customer assistance.

recognize this information, observe

the following symbols.

Danger indicates

an imminently

hazardous situation which, if not avoided,

WILL result in death or serious injury.

Warning indicates

a potentially

hazardous situation which, if not avoided,

COULD result in death or serious injury.

Caution indicates

a potentially

hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

Notice indicates

important

information, that if not followed, may cause

damage to equipment.

IMPORTANT: Information that

requires special attention.

CALIFORNIA PROPOSITION 65

This product or its power cord may contain chemicals known to the State

harm. Wash hands after handling.

You can create dust when you cut, sand, drill or grind

other masonry. This dust often contains chemicals known to cause cancer, birth

defects, or other reproductive harm. Wear protective gear.

This compressor/pump is not equipped and should not be used “as is” to supply

breathing quality air. For any application of air for human consumption, the air

compressor/pump will need to be fitted with suitable in-line safety and alarm

equipment. This additional equipment is necessary to properly filter and purify

the air to meet minimal specifications for Grade D breathing as described in

Compressed Gas Association Commodity Specification G 7.1, OSHA 29 CFR 1910.

134, and/or Canadian Standards Associations (CSA).

Safety Symbols

The following Safety Symbols appear

throughout this manual to alert you

to important safety hazards and

precautions.

DISCLAIMER OF WARRANTIES

In the event the compressor is used for the purpose of breathing air application

and proper in-line safety and alarm equipment is not simultaneously used,

existing warranties shall be voided, and Campbell Hausfeld disclaims any

liability whatsoever for any loss, personal injury or damage.

of California to cause cancer and birth defects or other reproductive

materials such as wood, paint, metal, concrete, cement, or

Breathable Air Warning

Wear Eye

and Mask

Protection

Risk of

Moving Parts

Risk of

Fumes

www.campbellhausfeld.com

2

MANUAL

Read Manual

First

Risk of

Hot Parts

Risk of

Pressure

Risk of

Fire

Risk of

Explosion

Risk of

Electrocution

Specifications

Air Delivery @ 150 psi

Model HP Voltage Phase

CS2152 15 208 3 46 CFM 120

CS2153 15 230 3 46 CFM 120

CS2154 15 460 3 46 CFM 120

CS2202 20 208 3 68 CFM 120

CS2203 20 230 3 68 CFM 120

CS2204 20 460 3 68 CFM 120

CS2252 25 208 3 87 CFM 120

CS2253 25 208 3 87 CFM 120

CS2254 25 460 3 87 CFM 120

Operating Pressure Tank Size (Gallons)

Page 3

Important Safety Information (Continued)

Series CS Rotary Screw Compressors

GENERAL SAFETY

◆ Read all manuals included with this product

carefully. Be thoroughly familiar with the controls

MANUAL

and the proper use of the equipment.

◆ Follow all local electrical and safety codes as well as

the United States National Electrical Codes (NEC) and

Occupational Safety and Health Act (OSHA).

◆ Only persons well acquainted with these rules of safe

operation should be allowed to use the compressor.

◆ Keep visitors away and NEVER allow children in the work

area.

◆ Wear safety glasses and use hearing protection when

operating the unit.

◆ Do not stand on or use the unit as a handhold.

◆ The protection devices fitted to this compressor are provided

to offer safety of operation. The operator is solely responsible

for personal safety at all times.

These devices should not be adjusted except by an authorised

service agent.

◆ Before each use, inspect compressed air system and electrical

components for signs of damage, deterioration, weakness or

leakage. Repair or replace defective items before using.

◆ Check all fasteners at frequent intervals for proper tightness.

Motors, electrical equipment

and controls can cause electrical

arcs that will ignite a fl ammable gas or vapor. Never

operate or repair in or near a fl ammable gas or vapor.

Never store fl ammable liquids or gases in the vicinity of the

compressor.

Never operate compressor without

a beltguard. This unit can start

automatically without warning. Personal injury or

property damage could occur from contact with moving

parts.

◆ Do not wear loose clothing or jewelry that will get caught in

the moving parts of the unit.

Compressor parts may be hot even if

the unit is stopped.

◆ Keep fingers away from a running compressor;

fast moving and hot parts will cause injury and/or

burns.

◆ If the equipment should start to vibrate abnormally, STOP

the engine/motor and check immediately for the cause.

Vibration is generally an indication of trouble.

◆ To reduce fire hazard, keep engine/motor exterior free of oil,

solvent, or excessive grease.

An ASME code safety relief valve with a setting

no higher than the Maximum Allowable

Working Pressure (MAWP) of the tank MUST be installed in the air

lines or in the tank for this compressor. The ASME safety valve must

have suffi cient fl ow and pressure ratings to protect the pressurized

components from bursting. The fl ow rating can be found in the parts

manual. The safety valve in the intercooler does not provide system

protection.

Maximum operating pressure is 150 psi. Do not

operate with pressure switch or pilot valves set

higher than the factory setting.

◆ Never attempt to adjust ASME safety valve. Keep safety valve

free from paint and other accumulations.

Never attempt to repair or modify

a tank! Welding, drilling or any

other modifi cation will weaken the tank resulting in

damage from rupture or explosion. Always replace worn,

cracked or damaged tanks.

Drain liquid from tank daily.

◆ Tanks rust from moisture build-up, which weakens the tank.

Make sure to drain tank regularly and inspect periodically for

unsafe conditions such as rust formation and corrosion.

◆ Fast moving air will stir up dust and debris which may be

harmful. Release air slowly when draining moisture or

depressurizing the compressor system.

SPRAYING PRECAUTIONS

Do not spray fl ammable materials

in vicinity of open fl ame or near

ignition sources including the compressor unit.

◆ Do not smoke when spraying paint, insecticides,

or other flammable substances.

◆ Use a face mask/respirator when spraying and

spray in a well ventilated area to prevent health

and fire hazards.

◆ Do not direct paint or other sprayed material

at the compressor. Locate compressor as far away from

the spraying area as possible to minimize overspray

accumulation on the compressor.

◆ When spraying or cleaning with solvents or toxic

chemicals, follow the instructions provided by the chemical

manufacturer.

SAVE THESE INSTRUCTIONS

DO NOT DISCARD

The DANGER, WARNING, CAUTION, and NOTICE

notifications and instructions in this manual cannot cover

all possible conditions and situations that may occur.

It must be understood by the operator that caution is a

factor which cannot be built into this product, but must be

supplied by the operator.

www.campbellhausfeld.com

3

Page 4

Operating Instructions

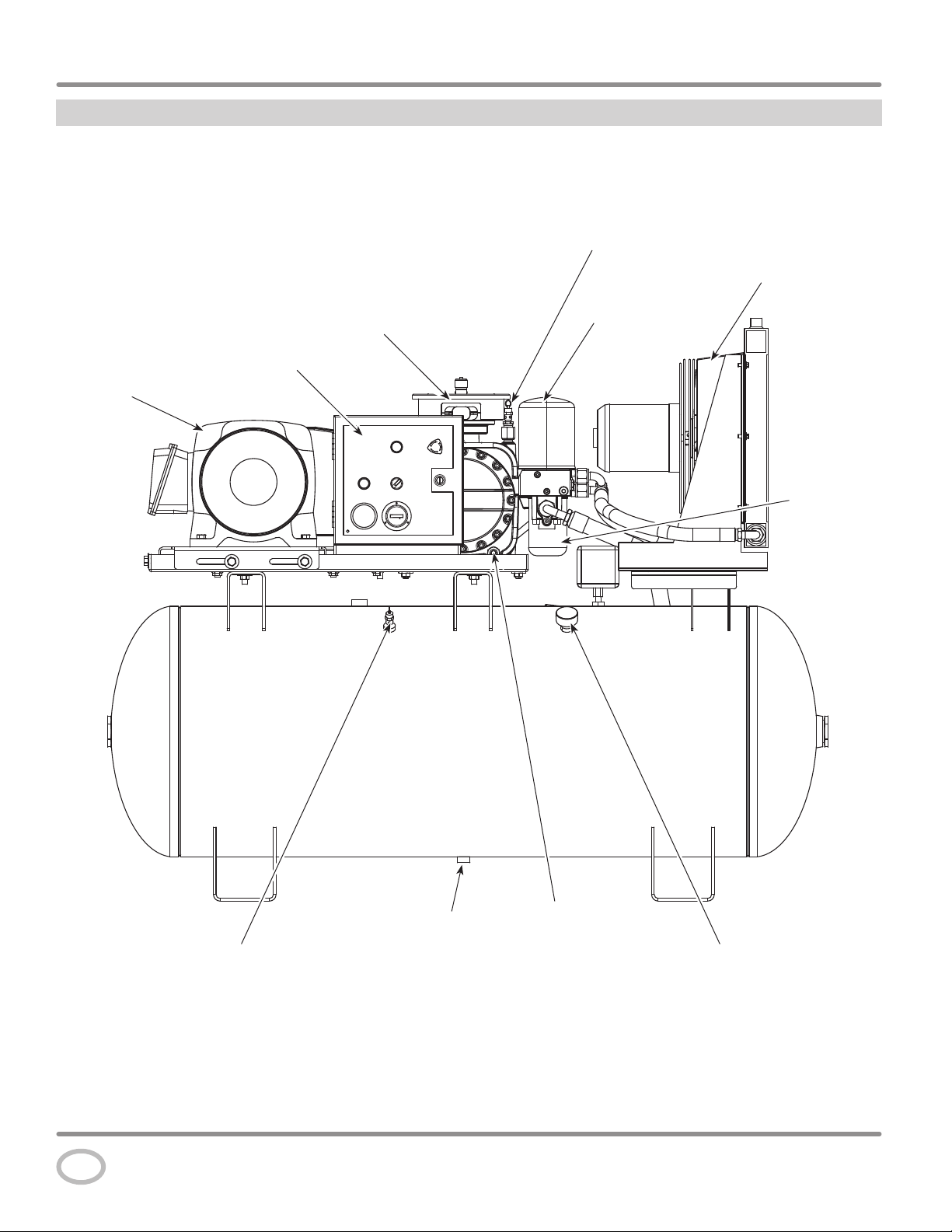

Getting To Know Your Compressor

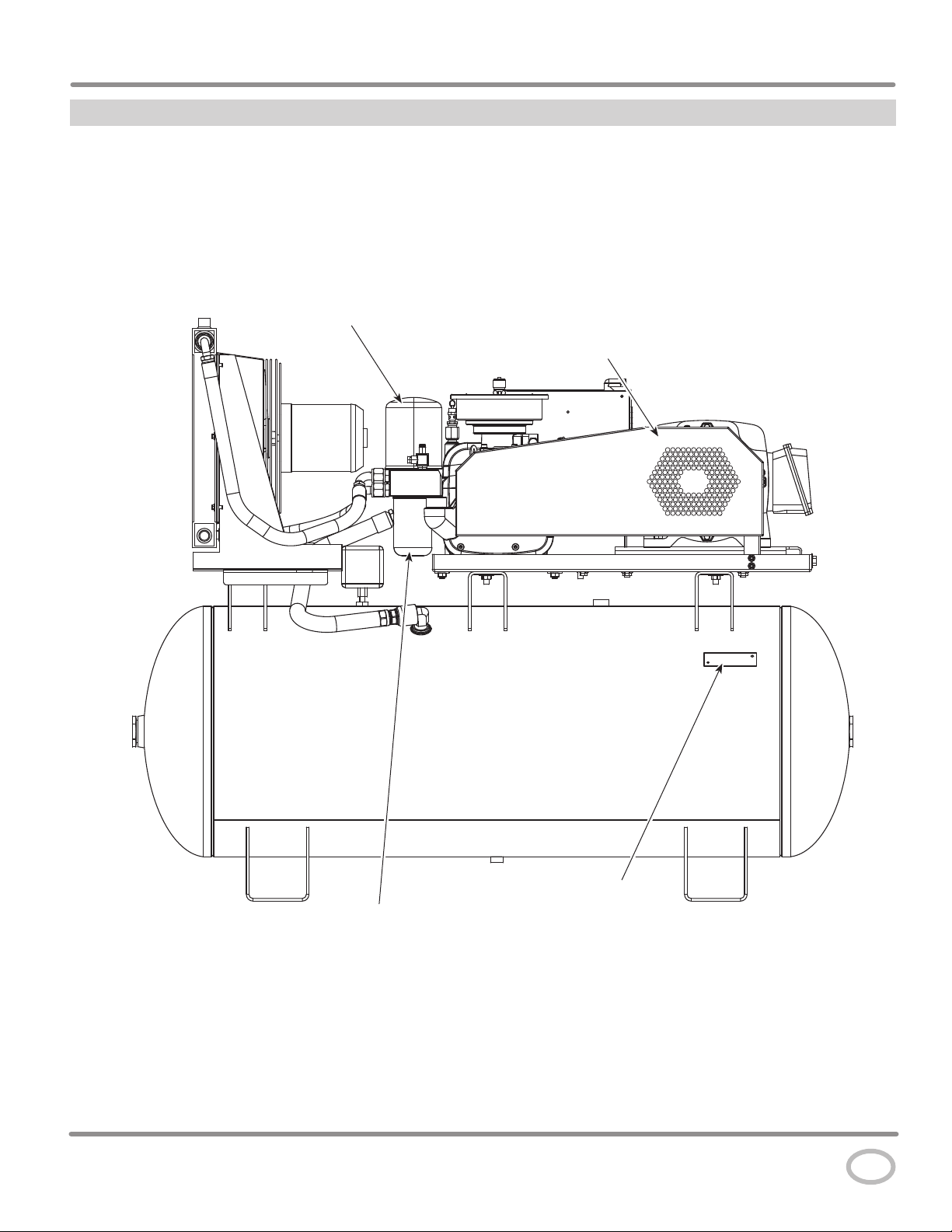

Control Box

Motor

Air End Safety

Valve

Oil Cooler

Assembly

Air / Oil

Separator

Air End

Oil

Filter

Tank Safety Valve

Figure 1 - Components of the compressor

www.campbellhausfeld.com

4

Tank Drain

Oil

Drain

Tank Pressure

Gauge

Page 5

Getting To Know Your Compressor

Air / Oil

Separator

Series CS Rotary Screw Compressors

Beltguard

Figure 2 - Components of the compressor

Oil Filter

ASME Label

www.campbellhausfeld.com

5

Page 6

Operating Instructions

Getting To Know Your Compressor

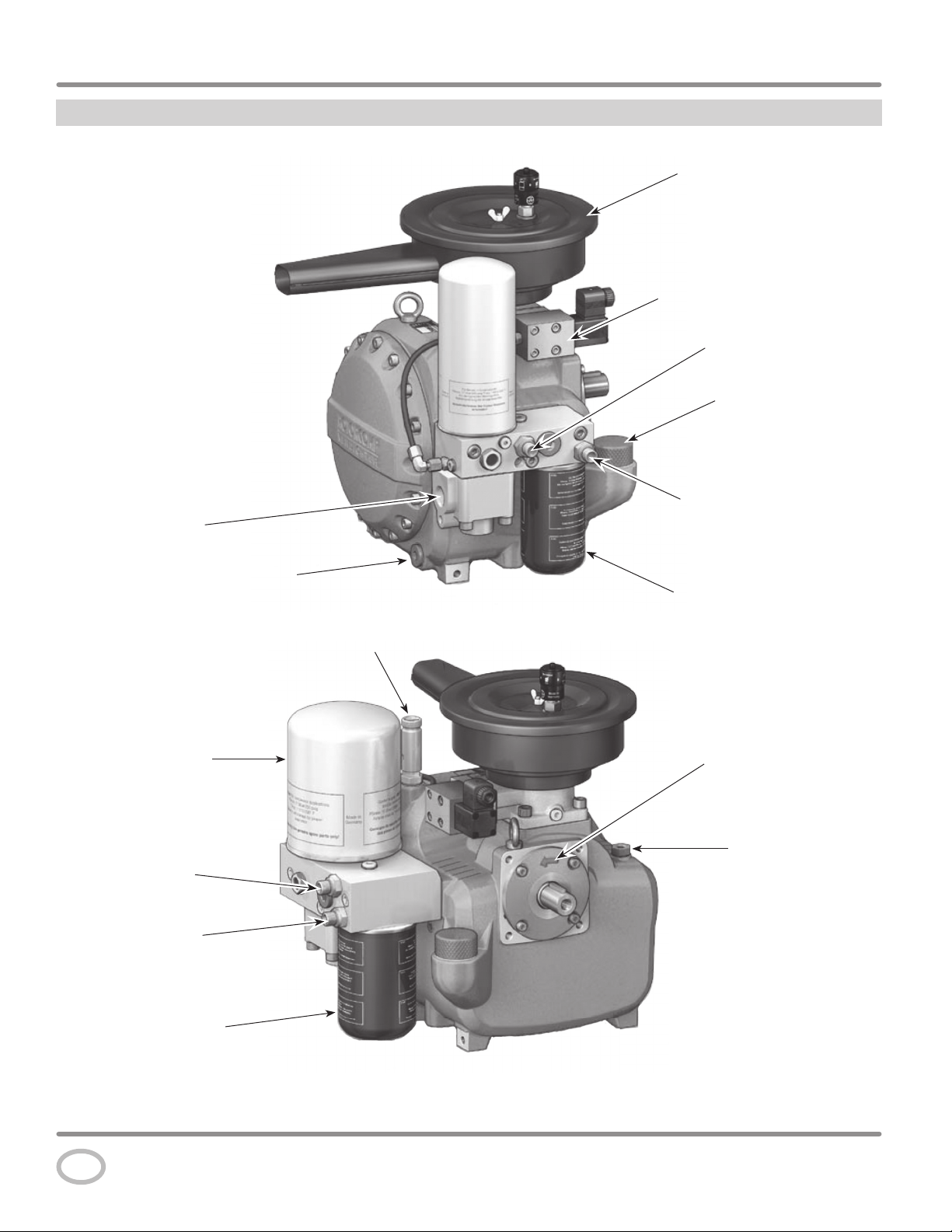

Air Intake / Filter Assembly

Electric Control Unit

Oil Circulation

Connection / Outlet

Oil Fill Opening and Cap

Compressed

Air Outlet

Air / Oil Separating

Element

Oil Circulation

Connection / Outlet

Oil Circulation

Connection / Inlet

Oil Circulation

Connection / Inlet

Oil Drain Screw

Oil Filter

Safety Valve

Rotation Direction

Preset

Temperature Sensor

Connection

Oil Filter

Figure 3 - Components of the air end

www.campbellhausfeld.com

6

Page 7

Series CS Rotary Screw Compressors

Unpacking

Do not lift or move unit without appropriately rated equipment. Be sure the unit is securely attached to lifting device used.

Do not lift unit by holding onto tubes or coolers. Do not use unit to lift other attached equipment.

After unpacking the unit, inspect carefully for any damage that may have occurred during transit. Check for loose, missing or

damaged parts. Check to be sure all supplied accessories are enclosed with the unit. In case of questions, damaged or missing parts,

please call 1-855-504-5678 for customer assistance.

Do not operate unit if damaged during shipping, handling or use. Damage may result in bursting and cause injury

or property damage.

Installation

Disconnect, tag and lock out power

source then release all pressure from the

system before attempting to install, service, relocate or perform

any maintenance.

Do not lift or move unit without appropriately

attached to lifting device used. Do not lift unit by holding onto tubes or

coolers. Do not use unit to lift other attached equipment.

Never use the wood shipping skids for mounting

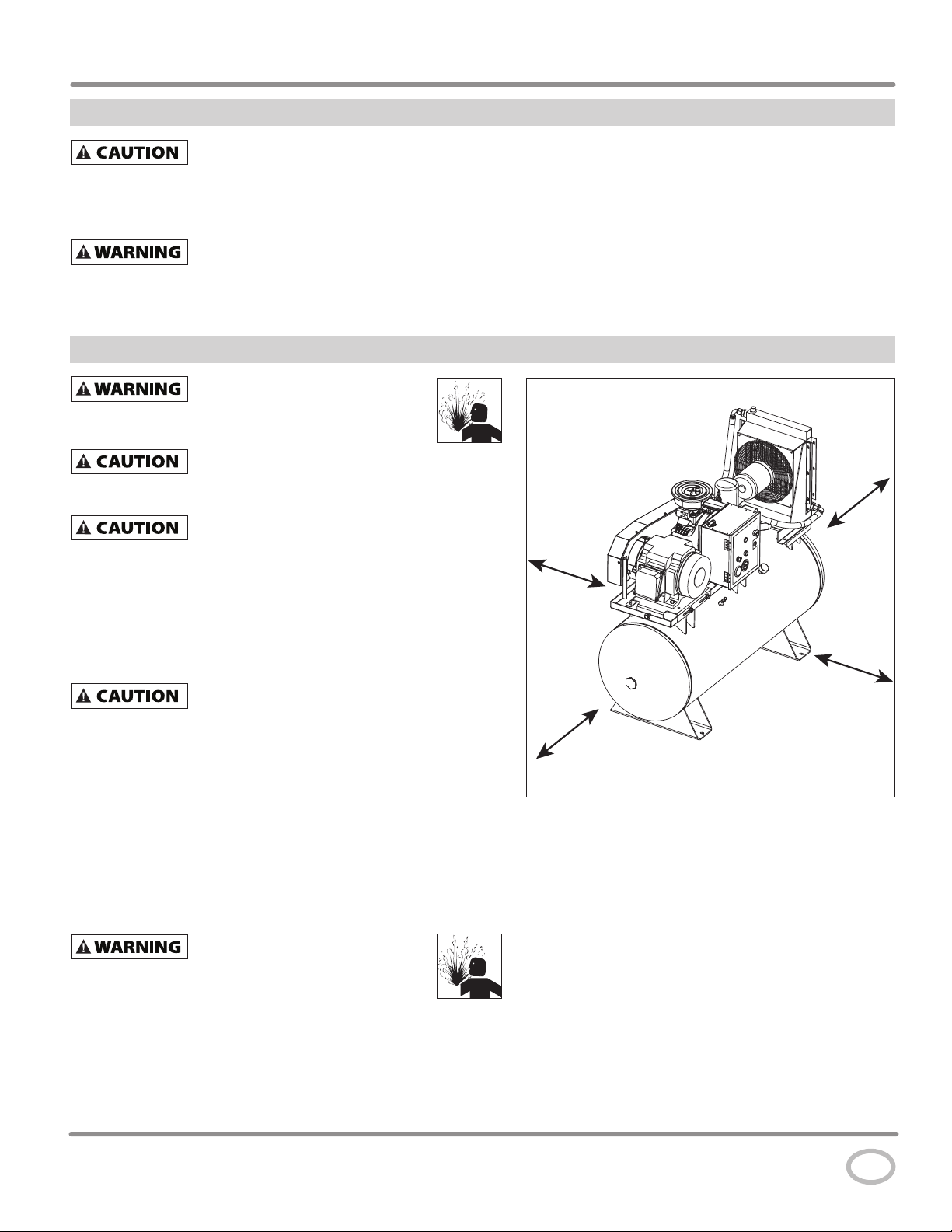

PICKING THE LOCATION

Install and operate unit at least 36 inches from any obstructions in a

clean, ventilated area. The surrounding air temperature should not

exceed 100° F or fall below 40° F. This will ensure an unobstructed

flow of air to cool compressor and allow adequate space for

maintenance.

Do not locate the compressor air inlet near

source of contamination.

NOTE: If compressor operates in a hot, moist environment, supply

compressor pump with clean, dry outside air. Supply air should be

piped in from external sources.

TANK MOUNTING

The tank should be bolted into a flat, even, concrete floor or on a

separate concrete foundation.

If using isolator pads, do not draw bolts tight. Allow the pads

to absorb vibrations. When isolators are used, a flexible hose or

coupling should be installed between the tank and service piping.

Failure to properly install the tank can

possible bursting.

rated equipment. Be sure the unit is securely

the compressor.

steam, paint spray, sandblast areas or any other

lead to cracks at the welded joints and

36 inches

36 inches

36 inches

36 inches

Figure 4 - Location

www.campbellhausfeld.com

7

Page 8

Operating Instructions

Installation (Continued)

PIPING

Never use plastic (PVC) pipe for compressed air.

Serious injury or death could result.

Any tube, pipe or hose connected to the unit must be able to

withstand the temperature generated and retain the pressure. All

pressurized components of the air system must have a pressure

rating of 200 psi or higher. Incorrect selection and installation

of any tube, pipe or hose could result in bursting and injury.

Connect piping system to tank using the same size fitting as the

discharge port.

INSTALLING A SHUT-OFF VALVE

A shut-off valve should be installed on the discharge port of the

tank to control the air flow out of the tank. The valve should be

located between the tank and the piping system.

Never install a shut-off valve between the

compressor pump and the tank. Personal injury

and/or equipment damage may occur. Never use reducers in discharge

piping.

When creating a permanently installed system to distribute

compressed air, find the total length of the system and select

pipe size from the chart. Bury underground lines below the

frost line and avoid pockets where condensation can gather and

freeze.

Apply air pressure to the piping installation and make sure

all joints are free from leaks BEFORE underground lines are

covered. Before putting the compressor into service, find and

repair all leaks in the piping, fittings and connections.

WIRING (see page 9 for wiring diagrams)

All wiring and electrical connections must be

performed by a qualifi ed electrician familiar

with induction motor controls. Installations must be in accordance

with local and national codes.

Overheating, short circuiting and fi re damage

will result from inadequate wiring.

Wiring must be installed in accordance with National Electrical

Code and local codes and standards that have been set up

covering electrical apparatus and wiring. These should be

consulted and local ordinances observed. Be certain that

adequate wire sizes are used, and that:

1. Service is of adequate ampere rating.

2. The supply line has the same electrical characteristics

(voltage, cycles and phase) as the motor. Refer to motor

name plate for electrical ratings and specifications.

3. The line wire is the proper size and that no other equipment

is operated from the same line. The chart gives minimum

recommended wire sizes for compressor installations.

MINIMUM PIPE SIZE FOR COMPRESSED AIR LINE

Length Of Piping System

CFM

25 feet 50 feet 100 feet 250 feet

10 1/2 inch 1/2 inch 3/4 inch 3/4 inch

20 3/4 inch 3/4 inch 3/4 inch 1 inch

40 3/4 inch 1 inch 1 inch 1 inch

60 3/4 inch 1 inch 1 inch 1 inch

100 1 inch 1 inch 1 inch 1-1/4 inch

Figure 5 - Shut-off Valve

MINIMUM WIRE SIZE

(USE A MINIMUM OF 75°C COPPER WIRE)

Make sure voltage is correct with the motor wiring.

NOTE: If using 208 volts single phase, make sure the motor

name plate states it is rated for 208 volts single phase. 230 volt

single phase motors do not work on 208 volts unless they have

the 208 volt rating.

Three Phase

HP 208/230V 460/575V

5 12 AWG 14 AWG

7.5 10 AWG 12 AWG

10 8 AWG 12 AWG

15 6 AWG 10 AWG

20 3 AWG 8 AWG

25 3 AWG 8 AWG

Recommended wire sizes may be larger than the minimum set up by

local ordinances. If so, the larger size wire should be used to prevent

excessive line voltage drop. The additional wire cost is very small

compared with the cost of repairing or replacing a motor electrically

“starved” by the use of supply wires which are too small.

www.campbellhausfeld.com

8

Page 9

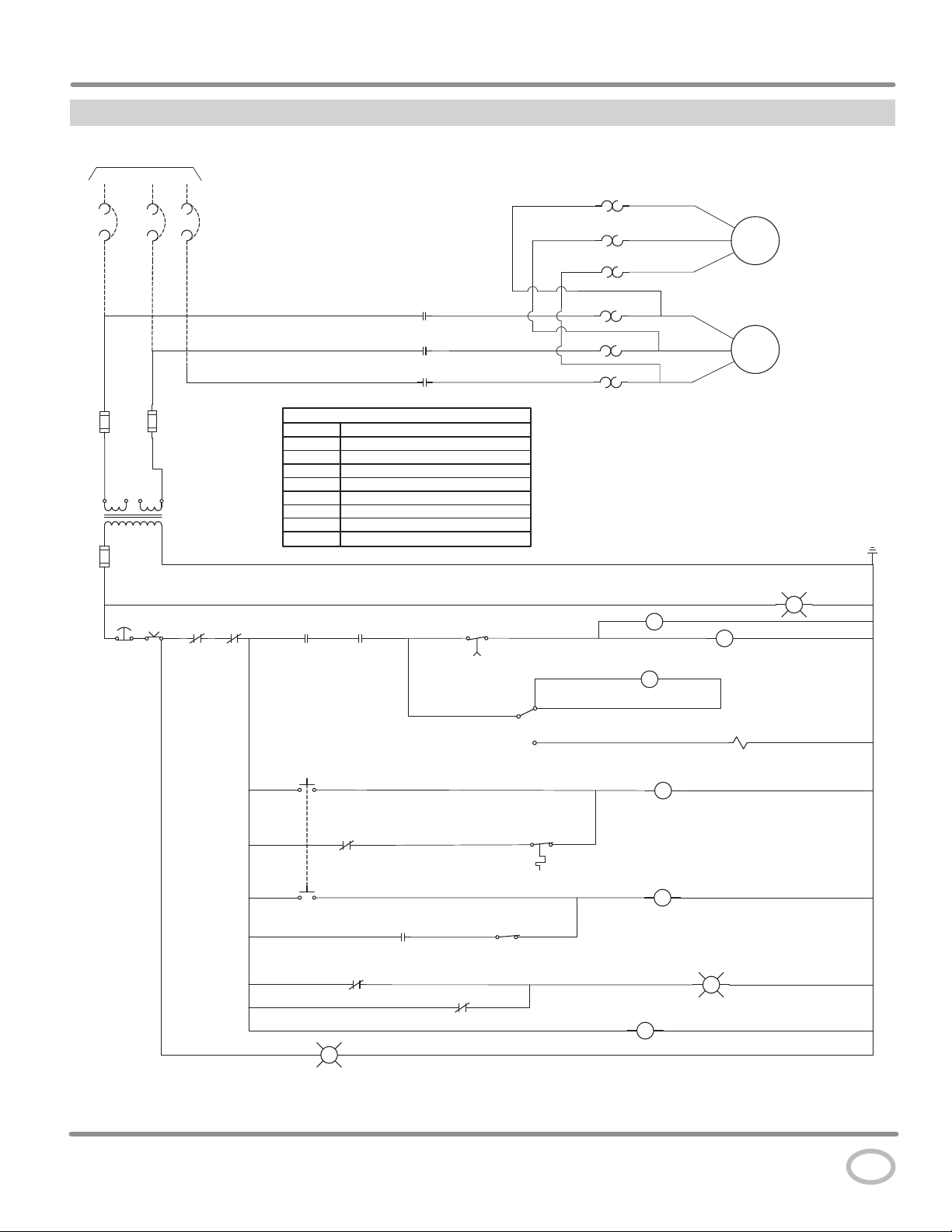

Wiring Diagram

TO SUPPLY

L1

L2 L3

Series CS Rotary Screw Compressors

OL

OL

OL

T4

T5

T6

M1

FAN

MOTOR

ESTOP

OFF

M

L1

M

L2

M

L3

OL

OL

OL

T1

T2

M2

T3

COMP

MOTOR

LEGEND

CT CONTROL TRANSFORMER

COL COIL OVERLOAD

FOL FAN OVERLOAD

HATR HIGH AIR TEMPERATURE RELAY

HPR HIGH PRESSURE RELAY

TR TIMER RELAY

TPS SWITCH, TANK PRESSURE

CT

ON

COL

FOL

M CONTACTOR-MAIN

HPS SWITCH, HIGH PRESSURE

HATR 1

HPR 1

POWER ON

HOUR

TR

TPs

5

METER

TR

M

7

INLET

VALVE

w

RESET

G

HATR 2

9

HATR 3

HATR

13

14

HATS

24

5

HPR 2

HPR 3

HPS

26

HPR

R

TR

www.campbellhausfeld.com

9

Page 10

Operating Instructions

Installation (Continued)

GROUNDING

Improperly grounded electrical

components are shock hazards.

Make sure all the components are properly grounded to

prevent death or serious injury.

This product must be grounded. Grounding reduces

the risk of electrical shock by providing an escape wire for the

electric current if short circuit occurs. This product must be

installed and operated with a cable that has a grounding wire.

BREAKERS AND FUSES

The entire electrical system should be checked by a certified

electrician. Time delay breakers and fuses are required for this

compressor. A tripped breaker or blown fuses may indicate a

direct short to ground, high current draw, improper wiring,

incorrect fuse or breaker size and/or type. This needs to be

evaluated by a certified electrician.

MOTOR HOOKUP AND STARTER INSTALLATION

Branch circuit protection must be provided as specified in

the United States National Electrical Code, Chapter 2, “Wiring

Design and Protection.” Article 210, using the applicable article

“For Motors and Motor Controllers,” (Article 430,

Table 430-1 52).

DIRECTION OF ROTATION

NOTE: Improper rotation will result in failure or compressor.

The direction of rotation must be counterclockwise (as shown

by the arrow on the air end in Figure 6) while facing the flywheel

side of the pump.

The direction of rotation of 3 phase motors can be reversed by

interchanging any two motor-line leads.

Rotation

Figure 6 - Direction of rotation

CHECKING ROTATION DIRECTION

ROTATION DIRECTION: rotating to the left (counterclockwise)

looking at the shaft.

The rotation direction of the screw compressor

system must be checked during initial start-up

and each time changes are made to the electrical supply line of the

electric motor drive. For this purpose, switch on the drive motor briefl y

and then switch off again immediately. ROTATION FOR MORE THAN

2 SECONDS IN THE WRONG ROTATION DIRECTION WILL DESTROY

THE SCREW COMPRESSOR. If necessary, reverse the connections of the

connecting cable.

www.campbellhausfeld.com

10

Page 11

Installation (Continued)

LUBRICATION

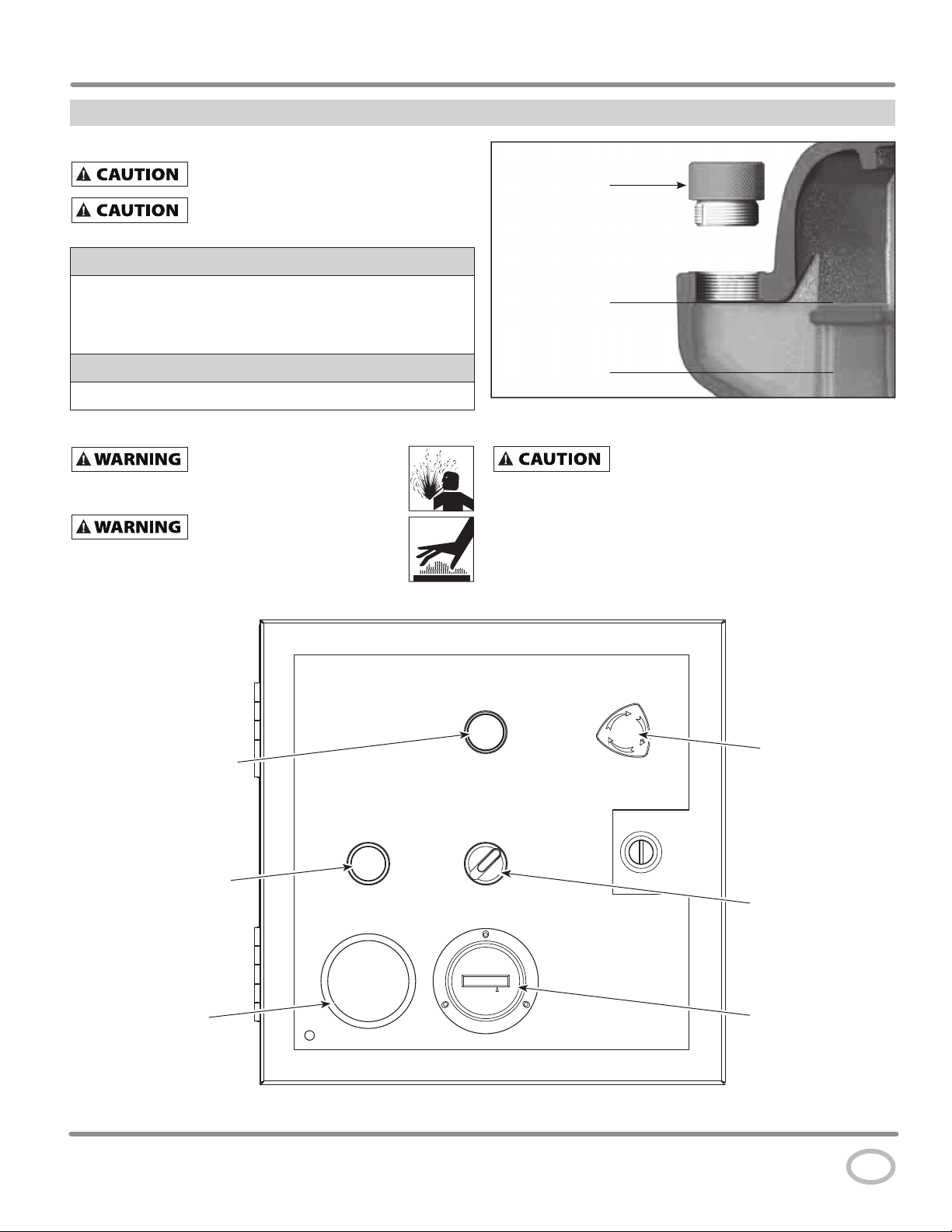

THIS UNIT CONTAINS OIL. Before operating

compressor, check oil level (see Figure 7).

Using any other type of oil may shorten pump

life and result in damage.

Recommended Oil

Single viscosity ISO100 rotary screw compressor oil (Part

number GS903800AV - 1 Gallon Container). Available from

Campbell Hausfeld, please call 1-855-504-5678 for customer

assistance.

Oil Capacity

2.1 gallons

OIL LEVEL

Disconnect, tag and lock out

power source then release all

pressure from the system before attempting to install,

service, relocate or perform any maintenance.

RISK OF BURNS! The unit parts, oil,

and screw plug can be hotter than

175° F (80° C)! Wear personal safety equipment!

Series CS Rotary Screw Compressors

Oil Plug

Maximum

(cold oil level)

Minimum

(cold oil level)

Figure 7 - Oil Level

With hot oil, the oil level can be approximately

3/4 inch higher than with cold oil shortly after

discharging.

An important factor for the operating safety of the compressor

system is the oil level in the oil reservoir. The oil level check must

be performed before initial operation of the compressor and

then repeated every 100 operating hours.

Power Indicator

(WHITE)

High Temperature /

High Pressure

Indicator Light

and Reset (RED)

Temperature

Gauge

Figure 8 - Control Panel

E-Stop

ON / OFF Switch

[Lighted when in

ON position (GREEN)]

Hour Meter

www.campbellhausfeld.com

11

Page 12

Operating InstructionsOperating Instructions

Prime Port

Pulley

Installation (Continued)

OIL LEVEL CHECK (See Figure 7)

• Check oil level by removing oil plug.

• With hot oil, the level will be higher than with cold oil.

As a result, oil may escape when the oil plug is opened at the

maximum oil level. If this does happen, close the oil plug

immediately and carefully clean up the oil that has escaped.

NOTE: The oil plug is provided with a safety hole on the side

from which oil or air escapes if there is any residual pressure

in the air end. Wait for one minute after the unit is at standstill

before opening the oil plug.

1. Switch off the system, prevent it from being switched back

on without authorization.

2. Wait for one minute at standstill.

3. Unscrew the oil plug on the filler neck by hand with the air

end depressurized.

4. Check the oil level.

5. If necessary, top off oil of the same oil type and the same

brand up to the maximum level (see Figure 7 and Lubrication

section).

NOTE: The oil filler neck is positioned so that it is not possible to

overfill the system. Excess oil runs out of the filler neck.

6. Screw on the oil plug firmly by hand.

7. Switch on the system.

8. Wipe off and clean up any spilled oil.

START-UP INFORMATION

READ AND UNDERSTAND ALL STEPS BELOW

BEFORE TURNING ON POWER .

1. Check oil level (See Figure 7).

2. If it has been longer than 12 weeks since the compressor has

been operated the air end must be primed with 8 ounces of

oil.

units must be checked for leaks and proper function. Loose

connections must be refastened and damaged lines must be

replaced.

Screw compressor systems that are switched off, shut down,

or stored for longer than 12 weeks cannot be placed into

operation again until after the following steps have been

carried out:

a. Manually rotate the compact module screw compressor

in the rotation direction several times.

b. With the compressor system stopped, add approximately

8 ounces of oil (same oil type as in the air end) into the

rotor chamber (see Figure 9).

c. Once again, manually rotate the compressor module

compressor stage in the rotation direction several times.

Before resuming operation, the

electrical equipment and all safety-relevant

Prime Port

Pulley

Figure 9 - Air End Priming Location

d. Check the oil level in the air end and top off if necessary

(see Maintenance section).

e. Monitor operation of the compressor system for at least

15 minutes, but at least until the steadystate temperature

is reached (continuous operating temperature).

3. Direction of rotation must be checked. Operation of the

air end for more than 2 seconds in the wrong direction will

destroy the screw compressor.

4. Check direction of rotation by quickly bumping the power to

ON and having someone else watch the motor pulley to see

which way it turns. Belt guard should remain installed. Also

check the direction of rotation of the oil cooler fan. The fan

must suck air in from the wire guard side and push air out

through the radiator when turning the correct direction. This

can be checked by holding a small strip of paper in front of

the radiator. With the correct direction of rotation the paper

will blow out away from the radiator.

5. Reset E-Stop switch if needed (see Figure 8).

6. Turn on the incoming power at the disconnect switch/circuit

breaker. The White incoming power indicator lamp will

illuminate. The motor will not turn on with this step.

7. Turn the on/off switch to the On position. The green lamp

will illuminate indication the compressor is ready to run.

The RED High temperature/High Pressure Failure Lamp will

illuminate. The motor will not turn on with this step.

8. Keep your hand on the on/off switch ready to turn off

immediately after start up to check the rotation direction.

Also check the direction of the cooler fan.

9. The motor can now be started by pressing the High temp/

high pressure reset. The red lamp is also a momentary

contact switch. The motor will start with this step.

10. Immediately turn off the on/off switch. The motor will stop

with this step.

11. If the direction of rotation is incorrect, disconnect, lock out

and tag out all incoming power. Change the position of two

of the incoming power lines and repeat steps 5-10.

12. When the direction of rotation has been confirmed the

compressor is ready to run for an initial start up operation

check.

www.campbellhausfeld.com

12

Page 13

Operation

INITIAL OPERATION CHECK

IMPORTANT: Check motor rotation before operating the

compressor.

After confirming the correct direction of rotation for the main

motor and cooler fan, the compressor is ready to run for an

operation check.

With a valve installed at the outlet of the tank, close the valve

and isolate the tank from any pipeline system so only the

compressor tank will fill up with compressed air.

1. Turning the compressor on. Confirm position of E-stop.

White incoming power lamp (Power Indicator) should be on.

2. Turn the ON / OFF switch to the ON position. The green light

of the switch should be on. The compressor will start. If the

red high temperature / high pressure light is on, press it to

reset and the compressor will start.

3. Allow the compressor to run for approximately 5 minutes.

The pressure in the tank will rise as the compressor runs.

The following will take place:

a. When first turned on the air end will build up internal

pressure prior to sending air into the tank. This may take

15-20 seconds. You may notice a slight change in the

sound when the minimum pressure valve opens inside

the air end allowing air to flow into the tank.

b. Air pressure in the tank will rise until the pre-set

maximum pressure is reached. Upon reaching the

maximum pressure the compressor will switch to the

Unloaded Mode. The noise level will change to be quieter.

Air is no longer being pumped into the tank. The air

intake valve is now closed inside the air filter housing.

High pressure air from inside of the compressor housing

is vented slowly (Lasts about 1 minute) out through the

air filter housing to allowing the compressor to run at

idle. You may hear the high pressure air being vented for

about 1 minute. You may see a small amount of oil smoke

coming from the inlet. This is normal as a small amount

of oil may be released with the high pressure air.

Do not remove air fi lter housing or

perform any maintenance with pressure

in the air end or air pressure tank.

c. While the compressor is running look and listen for any

leaks with which may have developed during shipping

and handling.

RISK OF BURNS! Surfaces

and parts will become hot.

4. Allow compressor to run for approximately 5 minutes. Turn

off using the ON / OFF switch. Allow compressor to sit for at

least 1 minute while the high pressure air is released through

the compressor inlet. You will hear the air escaping.

Disconnect, tag and lock out

power source then release all

pressure from the system before attempting to install,

service, relocate or perform any maintenance.

5. Release all air pressure from the tank prior to performing any

maintenance or restarting the compressor for the next run

sequence in item #8.

6. Allow the compressor to cool, and then check the oil level.

Add oil if needed.

7. Seal any air or oil leaks if needed.

8. Restart air compressor. Check position of E-Stop. Turn

on main power. Turn ON / OFF switch to ON. Reset high

temperature / high pressure switch and the compressor will

start.

9. With valve at the tank outlet closed the air pressure will build

in the tank to the cut-out pressure. Air pressure in the tank

will rise until the pre-set maximum pressure is reached.

Upon reaching the maximum pressure the compressor will

switch to the Unloaded Mode. The noise level will change to

be quieter. Air is no longer being pumped into the tank. The

air intake valve is closed inside the air filter housing. High

pressure air from inside of the compressor housing is vented

slowly out through the air filter housing to allowing the

compressor to run at idle. You may hear the high pressure air

being vented for about 1 minute.

10. Inside the electrical box, the idle delay timer begins tracking

time. After approximately 15 minutes of operation at idle the

compressor will turn off.

11. Release pressure from the tank down to the cut-in pressure

and the compressor will automatically restart. Pressure

will build in the tank until the cut-out pressure and go into

unloaded mode again. Wait approximately 1 minute and

then release some air from the air tank.

When the pressure in the tank drops to the cut-in pressure the

air inlet valve will open allowing the air to be compressed and

re-fill the tank. The idle delay timer will reset for the next cycle.

This sequence of operation will continue until the ON/OFF

switch is turned to the off position.

Your compressor is now ready for use.

NOTE: All lubricated compressor pumps discharge some

condensed water and oil with the compressed air. Install

appropriate water/oil removal equipment and controls as

necessary for the intended application.

www.campbellhausfeld.com

13

Page 14

Operating Instructions

Operation (Continued)

Failure to install appropriate water / oil

removal equipment may result in damage to

machinery or workpiece.

AMBIENT OPERATING TEMPERATURE

The compressor is designed to operate in an ambient

temperature between 40° F and 100° F. At ambient temperatures

below 40° F, the unit must be heated up to at least 70° F before

start-up.

GUARDING

The belt guard provided must be

Never operate compressor without

automatically without warning. Personal injury or

property damage could occur from contact with moving parts.

All moving parts must be guarded. All electrical covers must be

installed before turning on the power.

DRAINING TANK

Condensate must be drained from the tank daily.

Maintenance

See Maintenance Schedule on Page 17.

Disconnect, tag and lock out power source then release all

pressure from the system before attempting to install, service,

relocate or perform any maintenance.

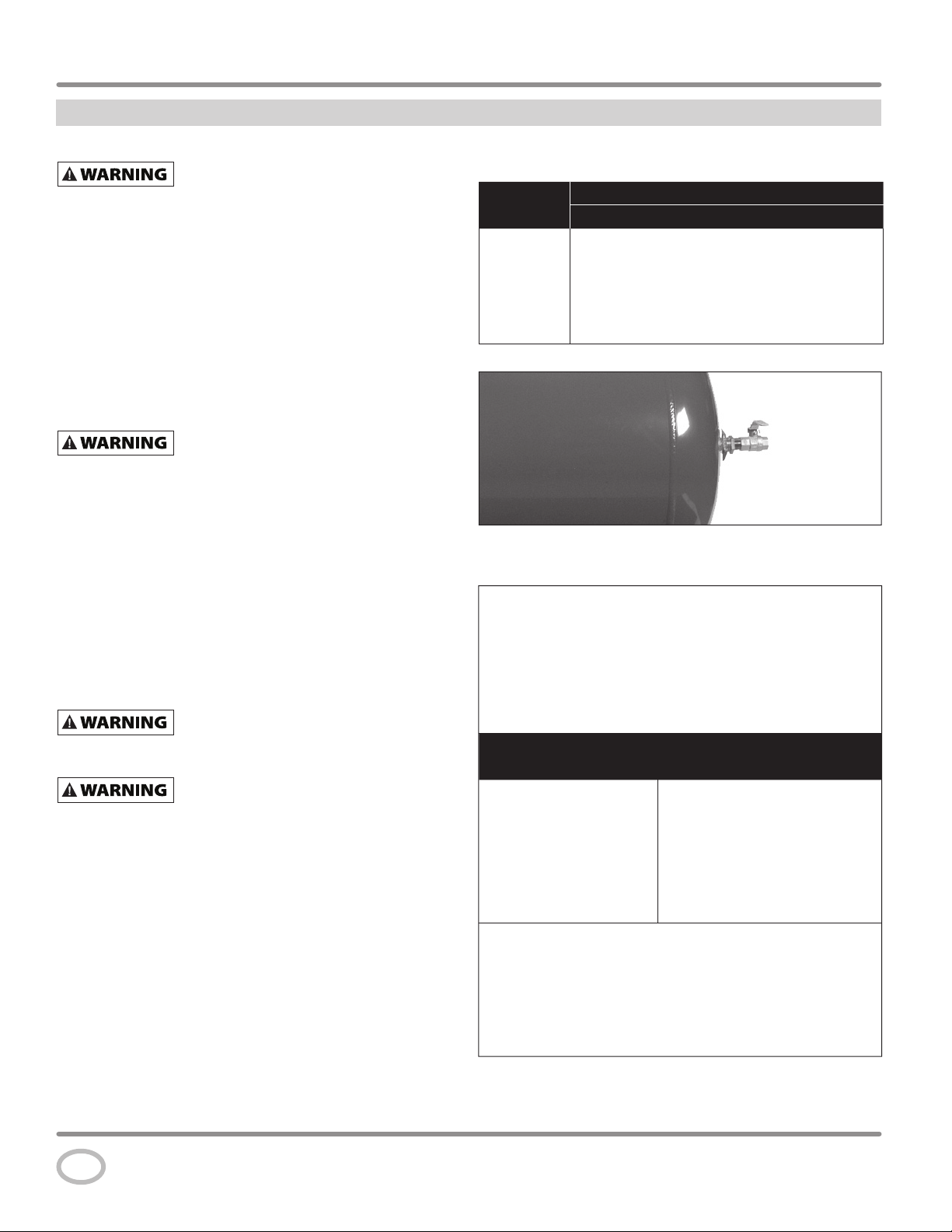

In order to maintain efficient operation of the compressor system, check the

air filter and oil level before each use. The ASME safety valve should also be

checked daily (see Figure 10). Pull ring on safety valve and allow the ring to snap back

to normal position. This valve automatically releases air if the tank pressure exceeds

the preset maximum. If air leaks after the ring has been released, or the valve is stuck

and cannot be actuated by the ring, the ASME safety valve must be replaced.

installed on the unit.

a beltguard. This unit can start

Figure 10 - ASME Safety Valve

Do not tamper with the ASME safety valve.

TANK

Never attempt to repair or modify a tank! Welding, drilling or

any other modifi cation will weaken the tank resulting in

damage from rupture or explosion. Always replace worn, cracked or damaged

tanks.

Drain liquid from tank daily.

The tank should be carefully inspected at a minimum of once a year. Look for cracks

forming near the welds. If a crack is detected, remove pressure from tank immediately

and replace.

www.campbellhausfeld.com

14

Page 15

Maintenance (Continued)

Series CS Rotary Screw Compressors

OIL CHANGE

RISK OF INJURY! The unit consists of rotating

and pressurized components. Do not attempt

to change oil until the unit has completely stopped and been fully

depressurized.

Disconnect, tag and lock out

power source then release all

pressure from the system before attempting to install,

service, relocate or perform any maintenance.

RISK OF BURNS! The unit parts, oil,

and screw plug can be hotter than

175° F (80° C)! Wear personal safety equipment!

1. Switch off the system, prevent it from being

switched back on without authorization, and

bring it into a horizontal position.

2. Depressurize the tank and system completely..

3. Unscrew the oil plug of the filler neck by hand.

4. Carefully unscrew the oil drain cap and catch the used oil in

a suitable container.

Dispose of the used oil, oil-contaminated

container, and cloths in accordance with local

regulations.

5. Clean the oil drain screw to remove any remaining oil.

Tighten drain cap to original closed position.

3. Remove the oil filter cartridge with a suitable tool, e.g. oil

filter strap wrench.

Dispose of the old oil fi lter cartridge in

accordance with the applicable regulations.

4. Oil the seal on the new oil filter cartridge with oil of the same

oil type as in the air end.

5. The new oil filter cartridge must be held vertically and filled

with oil of the same oil type as in the compressor module

before being screwed on.

6. Screw the new oil filter cartridge onto the multiblock and

tighten by hand. No tool is required.

7. Switch on the system.

8. The oil filter must then be checked for leaks with the system

running.

9. Check the oil level as explained earlier and top up the

missing oil quantity again to the maximum level.

Oil Drain Pipe and Cap

Figure 11 - Oil Drain

OIL FILTER

RISK OF INJURY! The unit consists of rotating

and pressurized components. Do not attempt

to change oil until the unit has completely stopped and been fully

depressurized.

RISK OF BURNS! The unit parts, oil,

and screw plug can be hotter than

175° F (80° C)! Wear personal safety equipment!

NOTE: Replace the oil filter with every oil change.

1. Switch off the screw compressor system and prevent it from

being switched back on without authorization.

2. Depressurize the system completely.

Oil Filter

Multiblock

Filter Seal

Figure 12 - Oil Filter

AIR-OIL SEPARATING ELEMENT

RISK OF INJURY! The unit consists of rotating

and pressurized components. Do not attempt

to change oil until the unit has completely stopped and been fully

depressurized.

RISK OF BURNS! The unit parts, oil,

and screw plug can be hotter than

175° F (80° C)! Wear personal safety equipment!

Heavily soiled intake air or low-

quality oil cause heavier soiling of

the cartridge, which can result in the premature need for replacement.

1. Switch off the screw compressor system and prevent it from

being switched back on without authorization.

2. Unscrew the air-oil separating element with a suitable tool,

e.g. oil filter strap wrench.

Dispose of the used oil, oil-contaminated

container, and cloths in accordance with local

regulations.

www.campbellhausfeld.com

15

Page 16

Operating Instructions

Maintenance (Continued)

3. Oil the seal on the new air-oil separating element with

oil of the same oil type as in the compact module screw

compressor.

4. Tighten the new air-oil separating element by hand. No tool

is required.

5. Switch on the compressor system.

6. The air-oil separating element must be checked for leaks

with the system running.

Air-Oil

Separating

Elements

Figure 13 - Air-Oil Separating Element

FILLING WITH OIL

Make sure to use recommended oil. Add oil

of the same oil type from the same manufacturer.

Switching over to another oil type can require fl ushing of the screw

compressor.

NOTE: Replace the oil filter with every oil change.

1. Switch off the system, prevent it from being switched back

on without authorization.

2. Through the filler neck on the separating tank, add oil up

to the maximum level and reinsert the screw plug, turning

firmly onto the filler neck by hand.

3. Switch on the screw compressor and allow it to run for

approximately three minutes.

4. Switch off the system, prevent it from being switched back

on without authorization.

6. Top off the oil to the maximum level.

7. Switch on the screw compressor and return to normal use.

AIR INTAKE FILTER

Do not remove air fi lter housing or perform any

maintenance with pressure in the air end or air

pressure tank.

Never run the compressor pump without an intake air filter or

with a clogged intake air filter. The air filter element should be

checked monthly (see Figure 14). Operating compressor with

a dirty filter can cause high oil consumption and increase oil

contamination in the discharge air. If the air filter is dirty it must

be replaced.

In case of heavily soiled intake air, replace and check more

frequently.

Dirt and dust particles must not be permitted to

get into the air inlet of the compressor module.

Air intake must be clean and maintained.

It is not permissible to clean the fi lter element;

the fi lter element must always be replaced!

Dispose of the old air fi lter element according to local regulations.

1. Switch off the screw compressor system and prevent it from

being switched back on without authorization.

2. Screw off the wing nut and remove the filter cover.

3. Remove the old filter element.

4. Carefully remove dust from the filter housing.

5. Insert the new filter element in the filter housing.

6. Install the filter cover, ensuring proper positioning during

assembly.

7. Tighten the wing nut.

8. Switch on the system.

Wing Nut

Filter Cover

Filter Element

www.campbellhausfeld.com

16

Figure 14 - Air Intake Filter

OIL COOLER

Weekly, check the oil cooler to be sure all fittings are secure and

tight. Clean all dirt, dust and other accumulations.

Page 17

Series CS Rotary Screw Compressors

Maintenance (Continued)

COMPONENTS

Turn off all power and clean the air end, motor, fan blades, air lines, oil cooler and tank on a monthly basis.

BELTS

Lock out and tag the power then release all pressure from the tank to prevent unexpected movement of the unit.

Check belt tension every 3 months. Adjust belt tension to allow 3/8 inch deflection with normal thumb pressure. Also, align belts

using a straight edge against the face of the pulleys and touching the rim on both sides of the face. The belts should be parallel to this

straight edge.

Slots in the bed-plate allow for sliding the motor back and forth to adjust belt tension.

MAINTENANCE SCHEDULE

The following table provides an overview of the screw compressor maintenance based on operating hours.

Maintenance schedule (operating hours) Maintenance Work

Before starting 1. Check the oil level in the air end.

2. Prime air end if it has not been used for longer than 12 weeks.

Daily 1. Check the safety valves.

2. Drain tank to remove water.

3. Check belt tension.

At 50 operating hours 1. Check the oil level in the air end.

2. Tighten all screw pipe fittings and electrical screw terminal fittings; check all other

connections for firm seating.

Every 100 operating hours 1. Check oil level in the air end, top off if oil is low.

2. Listen for abnormal running noise during operation.

Immediately switch off the unit, locate the problem and have it fi xed.

An abnormal noise could indicate a potentially hazardous situation.

3. Check all lines, hoses, and screw fittings for leaks and externally visible damage.

RISK OF INJURY! Have leaks and damage repaired immediately!

It is not permissible to repair hydraulic hoses.

Every 2,000 operating hours or 1 year,

whichever comes first

Every 6 years with normal demand Replace hose lines.

1. Change the air-oil separating element.

2. Perform an oil change.

3. Replace oil filter.

4. Replace filter element in intake air filter.

5. Check system for leaks.

6. Clean the system.

7. Check belts (replace as needed).

8. Inspect hoses.

It is not permissible to repair hose lines. Hose lines MUST be replaced.

www.campbellhausfeld.com

17

Page 18

Operating Instructions

Troubleshooting Guide

SYMPTOM CAUSE SOLUTION

Unit fails to start - Motor

makes no noise

Unit starts but does not

get to full speed

Unit does not make any

or very little air

Unit runs very noisy Damage to the compressor Check to make sure the compressor has not been damaged in the

Oil smoke out of inlet on

shutdown

Insufficient power to

compressor

Source electric to the compressor is either the incorrect voltage,

insufficient wire size to carry the load, the fuse box or breaker box is not

sufficient to carry the load requirements to the compressor.

Unit wired incorrectly Any wiring other than what is stated in the manual could cause a

malfunction (see Wiring Section).

Wrong voltage supplied to

Make sure voltage is correct with the motor wiring (see Wiring Section).

unit

Loose electrical connections The entire electrical system should be checked by a certified electrician.

The incoming wires and the compressor electrical connections should

be checked. Loose connections will cause malfunctions.

Wrong size wiring Check that wire size is rated for the current of the compressor. State and

local codes vary widely and need to be checked before installation.

Blown fuse and / or tripped

breaker

The breaker and fuses required for this unit must be time delay.

A tripped breaker or blown fuse may result from a direct short to

ground, high current draw, improper wiring, incorrect fuse or breaker

size and/or type. This needs to be evaluated by a service center or

certified electrician.

Starter overload tripped Check and reset if necessary. If the overload trips after the initial reset,

refer to the section of the manual that covers this issue.

Insufficient power to

compressor

Source electric to the compressor is either the incorrect voltage,

insufficient wire size to carry the load, the fuse box or breaker box is not

sufficient to carry the load requirements to the compressor.

Loose electrical connections The entire electrical system should be checked by a certified electrician.

The incoming wires and the compressor electrical connections should

be checked. Loose connections will cause malfunctions.

Drain valve open Make sure the drain valve at the bottom of the tank is closed.

Air leak Check the entire system for leaks, including the compressor unit and

any piping attached to the compressor

Restricted or blocked intake Make sure that the air intake of the compressor is not blocked in any

way.

shipping or installation. Make sure the belt guard was not damaged.

Belt guard should not be making contact with flywheel or pulley.

Loose fasteners Check all bolts and nuts to assure they did not loosen during shipping.

Loose pulleys or belts Check to assure pulley and flywheel are correctly tightened.

Normal operation A small amount of oil may be released with the high pressure air that

vents through the air filter.

Do not remove air fi lter housing or perform any

maintenance with pressure in the air end or air

pressure tank.

www.campbellhausfeld.com

18

Page 19

Series CS Rotary Screw Compressors

Service Record

DATE MAINTENANCE PERFORMED REPLACEMENT COMPONENTS REQUIRED

www.campbellhausfeld.com

19

Page 20

Operating Instructions

REGISTER YOUR PRODUCT ONLINE NOW!

http://reg.ch-commercial.com

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: Two years for the compressor air end. One year for

the balance of the compressor package.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive,

Harrison, Ohio, 45030, Telephone: (800) 543-6400.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Campbell

Hausfeld air compressor.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: This Campbell Hausfeld rotary screw air compressor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects in material and/or workmanship with the exceptions noted

below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM

THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. Some States do not allow limitations on how long an

implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY

DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some States do not allow the exclusion

or limitations of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to install and operate the compressor in

accordance with the instructions provided in the owner’s manual(s) supplied with the compressor

D. Pre-delivery service, i.e. assembly, oil or lubricants, and adjustment

E. Items or services that are normally required to maintain the product, e.g. lubricants, filters, etc.

F. General wear items, e.g. belts, shaft seals, etc.

G. Any component damaged in shipment or damage by contact with tools or surroundings.

H. Equipment that has been repaired or modified without authorization from Campbell Hausfeld.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, compressor or

component which is defective, has malfunctioned and/or failed to conform within duration of the warranty period. Warranted

repairs will be made at the Purchaser’s location.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

C. Repairs requiring overtime, weekend rates, or anything beyond the standard manufacturer warranty repair labor

reimbursement rate.

D. Time required for any security checks, safety training, or similar for service personnel to gain access to facility.

E. Location of unit must have adequate clearance for service personnel to perform repairs and easily accessible.

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will

be scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of

replacement parts.

This Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific legal rights. You may also have other

rights which vary from State to State or country to country.

OPTIONAL EXTENDED WARRANTY: An extended warranty against defects in workmanship and materials under normal use and

service is available as follows:

10. DURATION: From the date of purchase by the original purchaser as follows: Three years.

11. WHAT IS COVERED BY THIS EXTENDED WARRANTY: Defects in material or workmanship of the following items:

A. Airend

B. Oil cooler assembly

C. Air receiver (tank)

D. Parts and labor for the first year and parts only after the first year.

12. RESPONSIBILITIES OF PURCHASER UNDER THIS EXTENDED WARRANTY:

A. A properly completed Campbell Hausfeld warranty registration form. The registration form is available at

http://reg.ch-commercial.com and must be submitted within thirty days of start-up to be eligible for the extended warranty.

B. Maintenance/Service Parts and Fluids – The CS Series compressor must be maintained and serviced in accordance with the

operating manual. Genuine Campbell Hausfeld fluids and parts must be used or the Extended Warranty will be void. Proof of

purchase of genuine service parts and fluids must be maintained for the duration of the extended warranty period.

C. An oil sample must be submitted with any airend warranty claim.

www.campbellhausfeld.com

20

Page 21

Manual de Instrucciones

Compresores de Aire

de Tornillo Rotativo

Compresores de Tornillo Rotativo Serie CS

Índice

Medidas de Seguridad . . . . . . . . . . . . . . . S2

Símbolos de Seguridad. . . . . . . . . . . . . . . S2

Importantes Instrucciones

de Seguridad. . . . . . . . . . . . . . . . . . . . . . . . S2

Especificaciones . . . . . . . . . . . . . . . . . . . . S2

Conozca su Compresor . . . . . . . . . . . . . . S4

Desempaque. . . . . . . . . . . . . . . . . . . . . . . . S7

Instalación. . . . . . . . . . . . . . . . . . . . . . . . . . S7

Diagrama Eléctrico . . . . . . . . . . . . . . . . . . S9

Funcionamiento . . . . . . . . . . . . . . . . . . .S13

Mantenimiento . . . . . . . . . . . . . . . . . . . . S14

Guía de Resolución

de Problemas . . . . . . . . . . . . . . . . . . . . . . S18

Garantía Limitada . . . . . . . . . . . . . . . . . . S20

Referencia Rápida

ACEITE

Aceite para compresor rotativo de tornillo monogrado ISO 100 (Número de parte

GS903AV - Contenedor de 1 galón). Disponible en Campbell Hausfeld, por favor

contacte a su distribuidor local Campbell Hausfeld.

CAPACIDAD DE ACEITE

7,95 litros

GUARDE ESTA INFORMACIÓN PARA REFERENCIA FUTURA

Número de Serie:

N° del Modelo:

Fecha de Compra:

IN564600AV 10/12© 2012 Campbell Hausfeld/Scott Fetzer

Page 22

Manual de Instrucciones

Sírvase leer y guardar estas instrucciones.Lea con cuidado antes de tratar de armar, instalar,

Medidas de Seguridad

Este manual contiene información que

manejar o darle servicio al producto descrito en este manual. Protéjase Ud. y a los demás

observando todas las reglas de seguridad. El no seguir las instrucciones podría resultar en

heridas y/o daños a su propiedad. Guarde este manual como referencia.

es muy importante que se conozca

y comprenda. Esta información se

proporciona con fines de SEGURIDAD

y para EVITAR PROBLEMAS CON EL

EQUIPO. Para ayudar a reconocer esta

información, observe los siguientes

símbolos.

Peligro indica

una situación

inminentemente peligrosa, que si no se

evita, dará como resultado la muerte o

lesiones graves.

Advertencia

indica una

situación potencialmente peligrosa, que si

no se evita, PODRÍA ocasionar la muerte o

lesiones graves.

Precaución

indica una

situación potencialmente peligrosa, que

si no se evita, PUEDE dar como resultado

lesiones leves o moderadas.

Aviso indica una

información

importante, que de no seguirla, le podría

ocasionar daños al equipo.

IMPORTANTE: información que

requiere atención especial.

Importantes Instrucciones de Seguridad

Este manual contiene información sobre seguridad, funcionamiento y mantenimiento.

Si tiene preguntas, llame al 1-855-504-5678 para obtener asistencia al cliente.

PROPOSICIÓN 65 DE CALIFORNIA

Este producto, o su cordón eléctrico, puede contener productos

cáncer y defectos de nacimiento u otros daños reproductivos. Lave sus manos después de usar.

Cuando corta lija, taladra o pule materiales como por

tipo de mampostería se puede producir polvo. Con frecuencia este polvo contiene

productos químicos que se conocen como causantes de cáncer, defectos congénitos

u otros daños reproductivos. Use equipo de protección.

Este compresor/cabezal no viene listo de fábrica para suministrarle aire

respirable. Antes de utilizarlos con este fin, deberá instalarle un sistema

de seguridad y alarma incorporado a la línea. Este sistema adicional es

necesario para filtrar y purificar el aire adecuadamente, para cumplir con

las especificaciones mínimas sobre aire respirable de Grado D descritas en

la Especificación de Productos G 7.1 de la Asociación de Aire Compri-mido.

Igualmente, deberá cumplir los requisitos establecidos por el Artículo 29 CFR

1910. 134 de la Organización norteamericana OSHA y/o la Canadian Standards

Associations (CSA).

Símbolos de Seguridad

Los siguientes símbolos de seguridad

aparecen a lo largo de este manual para

advertirle de importantes peligros y

precauciones de seguridad.

RENUNCIA A LAS GARANTIAS

Si el compresor se utiliza para producir aire respirable SIN haberle instalado

el sistema de seguridad y alarma, todas la garantías se anularán y la compañia

Campbell Hausfeld no asumirá NINGUNA responsabilidad por pérdidas, heridas

personales o daños.

químicos conocidos por el estado de California como causantes de

ejemplo madera, pintura, metal, hormigón, cemento, u otro

Advertencia Sobre el Aire Respirable

Use protección

para los ojos y

máscara

Riesgo

de piezas

móviles

Riesgo de

vapores

S2

MANUAL

Lea primero

el manual

Riesgo

de piezas

calientes

Riesgo de

presión

Riesgo de

incendio

Riesgo de

explosión

Riesgo de

choque

eléctrico

Especificaciones

Caballos de

Modelo

Potencia Voltaje Fases

CS2152 15 208 3 1302,6 l/min 454,2

CS2153 15 230 3 1302,6 l/min 454,2

CS2154 15 460 3 1302,6 l/min 454,2

CS2202 20 208 3 1925,6 l/min 454,2

CS2203 20 230 3 1925,6 l/min 454,2

CS2204 20 460 3 1925,6 l/min 454,2

CS2252 25 208 3 2463,6 l/min 454,2

CS2253 25 230 3 2463,6 l/min 454,2

CS2254 25 460 3 2463,6 l/min 454,2

Suministro de Aire @ 10,34 bar

Presión de operación

Tamaño del

tanque (litros)

Page 23

Importantes Instrucciones de Seguridad ( Continuación)

Compresores de Tornillo Rotativo Serie CS

INFORMACIONES GENERALES DE SEGURIDAD

◆ Lea con cuidado todos los manuales incluídos con

este producto. Familiarícese con los controles y el

uso adecuado del equipo.

MANUAL

◆ Siga todos los códigos de seguridad laboral y

electricidad establecidos en su país, por ejemplo, los de la

NEC y OSHA en EUA.

◆ Este compresor sólo debe ser usado por personas que estén

bien familiarizadas con las reglas de seguridad de manejo.

◆ Mantenga a los visitantes alejados y NUNCA permita la

presencia de niños en el área de trabajo.

◆ Siempre use anteojos de seguridad y protéjase los oídos para

operar el cabezal o el compresor.

◆ No se pare sobre la unidad ni la use como asidero.

◆ Los dispositivos de protección acondicionados a este

compresor se suministran para ofrecer una operación segura.

El operador es completamente responsable de su seguridad

personal en todo momento. Este tipo de dispositivos solo

deben ser ajustados por un agente de servicio autorizado.

◆ Antes de cada uso, inspeccione el sistema de aire

comprimido y los componentes eléctricos para ver si están

dañados, deteriorados, desgastados o tienen fugas. Repare o

reemplace las piezas dañadas antes de usar el equipo.

◆ Chequée todas las conexiones frecuentemente para

cerciorarse de que estén bien apretadas.

Los motores, equipos eléctricos

arcos eléctricos que se encenderían con gases o vapores

infl amables. Nunca utilice o repare el compresor cerca de

gases o vapores infl amables. Nunca almacene líquidos o

gases infl amables cerca del compresor.

Nunca utilice el compresor sin

compresores se pueden encender automáticamente

sin previo aviso. Las piezas en movimiento podrían

ocasionarle heridas o daños a su propiedad.

y controles, pueden ocasionar

la tapa de las bandas. Los

◆ No se ponga ropa muy holgada o joyas, ya que éstas se le

podrían enredar en las piezas en movimiento.

Las piezas del compresor podrían

unidad esté apagada.

estar calientes, inclusive cuando la

◆ Mantenga los dedos alejados del compresor

cuando éste esté funcionando; las piezas en

movimiento o calientes, le ocasionarían heridas y/o

quemaduras.

◆ Si el equipo comienza a vibrar excesivamente, APAGUE el

motor y chequéelo inmediatamente para determinar la

razón. Generalmente, la vibración excesiva se debe a una

falla.

◆ Para reducir el peligro de incendio, mantenga la parte

exterior de la maquina/motor libre de aceite, solvente o

exceso de grasa.

Es obligación instalar en la tubería de aire o en

desfogue según las normas de seguridad ASME con ajuste no superior

el tanque de este compresor una válvula de

a la Presión Máxima Admisible de Trabajo (MAWP) del tanque. Esta

válvula debe estar diseñada para los valores máximos de fl ujo y

presión para proteger los componentes contra el peligro de explosión.

Los límites máximos del fl ujo se indican en el manual de repuestos. La

válvula de seguridad del sistema de enfriamiento interno no protege el

sistema.

La presión máxima de operación es de 150

psi. No opere el compresor con el interruptor

de presión o las válvulas piloto ajustadas más allá de los valores de

fábrica.

◆ Nunca trate de ajustar la válvula de seguridad ASME. Evite

que se le acumule pintura u otro residuos.

¡Nunca trate de reparar o modifi car

el tanque! Si lo suelda, taladra o

modifi ca de cualquier otra manera, el tanque se debilitará

y podría romperse o explotar. Siempre reemplace los

tanques desgastados, rotos o dañados.

Drene el líquido del tanque diariamente.

◆ Los tanques se oxidan debido a la acumulación de humedad

y ésto debilita el tanque. Cerciórese de drenar el tanque con

regularidad e inspeccionarlo periódicamente, para ver si está

en malas condiciones, por ejemplo, si está oxidado.

◆ La circulación rápida de aire podría levantar polvo y

desperdicios dañinos. Siempre libere el aire lentamente para

drenar el tanque o li-berar la presión del sistema.

PRECAUCIONES PARA ROCIAR

Nunca rocíe materiales infl amables

cerca de llamas al descubierto o

fuentes de ignición, incluyendo el compresor.

◆ No fume mientras esté rociando pintura,

insecticidas u otras substancias inflamables.

◆ Use una máscara/respirador cuando vaya a rociar

y siempre rocíe en un área bien ventilada, para

evitar peligros de salud e incendios.

◆ Nunca rocíe pintura ni otros materiales,

directamente hacia el compresor. Coloque el

compresor lo más lejos posible del área de trabajo, para

minimizar la acumulación de residuos en el compresor.

◆ Al rociar o limpiar con solventes o químicos tóxicos, siga las

instrucciones del fabricante de dichos químicos.

GUARDE ESTAS INSTRUCCIONES –

NO LAS DESECHE

Los símbolos de PELIGRO, ADVERTENCIA, PRECAUCIÓN,

y AVISO y las instrucciones en este manual no pueden

posiblemente cubrir todas las condiciones y situaciones

posibles que puedan presentarse. El operador debe

entender que la precaución es un factor que no puede ser

incluido en el producto, sino que debe ser proporcionada

por el operador.

S3

Page 24

Manual de Instrucciones

Conozca su Compresor

Caja de control

Motor

Válvula de seguridad en

la unidad de compresión

Conjunto enfriador

del aire

Separador de

aire/aceite

Unidad de compresión

Filtro de

aceite

Válvula de seguridad

del tanque

Figura 1 - Componentes del compresor

S4

Drenaje del tanque

Purga del

aceite

Manómetro

del tanque

Page 25

Conozca su Compresor

Compresores de Tornillo Rotativo Serie CS

Separador de

aire/aceitea

Tapa de la correa

Figura 2 - Componentes del compresor

Etiqueta ASME

Filtro de aceite

S5

Page 26

Manual de Instrucciones

Conozca su Compresor

Conjunto de entrada de

aire y filtro

Unidad de control eléctrico

Conexión/salida de

circulación de aceite

Tapón y apertura para el

llenado de aceite

Salida de aire

comprimido

Tapón roscado para

drenaje del aceite

Elemento separador del

aire/aceite

Conexión y salida

de la circulación de

aceite

Conexión y entrada

de la circulación de

aceite

Conexión/entrada de la

circulación de aceite

Filtro de aceite

Válvula de seguridad

Sentido de rotación

preestablecido

Conexión del sensor

de temperatura

Filtro de aceite

Figura 3 - Componentes de la unidad de compresión

S6

Page 27

Compresores de Tornillo Rotativo Serie CS

Desempaque

Nunca alce o mueva la unidad sin usar un equipo adecuado. Cerciórese de que la unidad esté bien segura. No la tome

por los tubos o piezas del sistema de enfriamiento para levantarla. No use la unidad para alzar otros equipos.

Después de desempacar la unidad, inspecciónela cuidadosamente para detectar cualquier daño que pueda haber ocurrido

durante el envío. Verifique que no haya piezas sueltas, faltantes ni dañadas. Asegúrese de que todos los accesorios proporcionados

vengan con la unidad. En caso de que tenga preguntas, o de que haya piezas dañadas o faltantes, llame a 1-855-504-5678 para

obtener asistencia al cliente.

No debe utilizar la unidad si se ha dañado durante el envío, manejo o uso. Los daños podrían ocasionar una explosión y

ocasionarle heridas o daños a su propiedad.

Instalación

Desconecte el cordón eléctrico, amárrelo

y aléjelo del tomacorrientes, después

libere toda la presión del tanque antes de tratar de instalar el

compresor, darle servicio, moverlo de sitio o darle cualquier tipo

de mantenimiento.

Nunca alce o mueva la unidad sin usar un equipo

adecuado. Cerciórese de que la unidad esté bien

segura. No la tome por los tubos o piezas del sistema de enfriamiento para

levantarla. No use la unidad para alzar otros equipos.

Nunca utilice la plataforma de embalaje para

montar el compresor.

ELECCIÓN DEL LUGAR

Realice la instalación y opere la unidad cuando menos a 92 cm

de cualquier obstrucción, en un área limpia y ventilada. La

temperatura del aire ambiente no deberá exceder los 38° C (100° F)

o caer por debajo de 4° C (40° F). Esto asegurará un flujo de aire sin

obstrucciones para el enfriamiento del compresor y permitirá el

espacio adecuado para el mantenimiento.

Nunca coloque la entrada de aire del compresor

cerca de un área donde haya vapor, donde se rocíe

pintura o arena, o haya otras fuentes de contaminación.

NOTA: Cuando utilice el compresor en un ambiente cálido y húmedo

le debe suministrar aire limpio y seco del exterior al cabezal. Utilice

una tubería para suministrarle el aire del exterior.

MONTAJE DEL TANQUE

El tanque debe de ser atornillado a una superficie plana y lisa de

concreto o sobre una cimentación independiente.

Si se emplean apoyos de amortiguación, no apriete las tuercas

demasiado fuerte. Permita que los bloques de amortiguación

absorban las vibraciones. Cuando se utilizan aislantes de

vibraciones, se requiere el empleo de una manguera o acoplamiento

flexible entre el tanque y la tubería de servicio.

Una instalación inadecuada del tanque

puede derivar en la fi sura de los puntos

de soldadura en las uniones y un posible estallido.

92 cm

92 cm

92 cm

92 cm

Figura 4 - Ubicación

S7

Page 28

Manual de Instrucciones

Instalación (Continuación)

TUBERIAS

Nunca use tuberías de plástico (PVC) con aire

comprimido. Ésto podría ocasionarle heridas

graves.

Cualquier tipo de tuberías o manguera que conecte al

compresor deben estar diseñados para el tipo de temperaturas

y presiones generadas. Todos los componentes presurizados

del sistema de aire deben tener una clasificación de presión de

13,79 bar (200 psi) o superior. Si selecciona e instala una tubería

o manguera incorrecta, éstas podrían explotar y ocasionarle

heridas. Para conectar las tuberías al tanque, utilice conexiones

del mismo tamaño que el orificio de salida.

PARA INSTALARLE UNA VALVULA DE CIERRE

Debe instalarle una válvula de cierre en la salida del tanque para

controlar el flujo de aire que sale del tanque. La válvula se debe

colocar entre el tanque y las tuberías.

Nunca instale una válvula de cierre entre el

cabezal y el tanque. Ésto le podría ocasionar

heridas y/o daños a su propiedad. Nunca use reductores en las tuberías

de salida.

Cuando vaya a instalar un sistema permanente de distribución

de aire comprimido, debe calcular la longitud total del sistema

y seleccionar las tuberías adecuadas según la tabla que le

ofrecemos en este manual. Las tuberías se deben instalar bajo

el nivel de congelamiento, para evitar que creen vacío donde se

pueda concentrar la condensación y se congelen.

Aplíquele presión de aire a las tuberías y cerciórese de que

ninguna conexión tenga fugas ANTES de cubrirlas. Antes de

utilizar el compresor, cerciórese de que no haya fugas en las

tuberías y conexiones y repárelas de haberlas.

ALAMBRADO (ver los diagramas eléctricos en la página S9)

Todo el cableado e instalaciones eléctricas

deberán ser realizados por un electricista

califi cado familiarizado con los controles de motores de inducción.

Las instalaciones se deben hacer según los códigos locales y

nacionales.

Si el sistema de alambrado no se instala

adecuadamente podría ocasionar

sobrecalentamiento, cortocircuitos e incendios.

El alambrado se debe hacer según todos los códigos nacionales

de electricidad y los reglamentos sobre artefactos eléctricos y de

alambrado. Consúltele a un técnico especializado en la materia

y cumpla con todas la ordenanzas. Cerciórese de usar los cables

adecuados y de que:

1. El amperaje sea adecuado.

2. La línea de suministro eléctrico sea similar a la del motor

(voltaje, ciclaje y fases).

3. Los alambres sean del calibre adecuado y de que no hayan

otros artefactos eléctricos conectados a la misma línea.

Aquí le ofrecemos una tabla con los tamaños adecuados

para instalar el compresor.

TAMAÑO MÍNIMO DE LAS TUBERÍAS DE

LAS LÍNEAS DE AIRE COMPRIMIDO

Longitud de las Tuberías

l/min

7,62 m 15,24 m 30,48 m 76,2 m

283,2 12,7 mm 12,7 mm 19,1 mm 19,1 mm

566,3 19,1 mm 19,1 mm 19,1 mm 2,54 cm

1132,7 19,1 mm 2,54 cm 2,54 cm 2,54 cm

1699,0 19,1 mm 2,54 cm 2,54 cm 2,54 cm

2831,7 2,54 cm 2,54 cm 2,54 cm 3,18 cm

Figura 5 - Valvula de cierre

TAMAÑO MÍNIMO DEL CABLE (UTILICE CABLE DE

COBRE DE AL MENOS 75 °C)

Asegúrese de que el voltaje concuerde con el cableado

del motor.

NOTA: Si usa corriente monofásica de 208 voltios, asegúrese

de que la placa de nombre del motor diga que está clasificado

para corriente monofásica de 208 voltios. Los motores para

corriente monofásica de 230 voltios no funcionan con 208

voltios a menos que tengan la clasificación de 208 voltios.

Triphasé

CP 208/230V 460/575V

5 12 AWG 14 AWG

7.5 10 AWG 12 AWG

10 8 AWG 12 AWG

15 6 AWG 10 AWG

20 3 AWG 8 AWG

25 3 AWG 8 AWG

Los tamaños de cable recomendados pueden ser más grandes que el

mínimo establecido por ordenanzas locales. Si fuera así, debe usarse

el cable de mayor tamaño para evitar un descenso excesivo de voltaje

en la línea. El costo adicional de los cables es muy bajo comparado

con el costo de la reparación o cambio de un motor subalimentado

por el uso de cables de suministro demasiado pequeños.

S8

Page 29

Diagrama Eléctrico

A LA FUENTE

L1

L2 L3

Compresores de Tornillo Rotativo Serie CS

OL

OL

OL

T4

T5

T6

M1

MOTOR

VENTILADOR

ENCENDIDO

PAR O

EMERGENTE

APAGADO

M

L1

M

L2

M

L3

OL

OL

OL

T1

T2

M2

T3

MOTOR

COMPRESOR

LEYENDA

CT CONTROL DEL TRANSFORMADOR

COL SOBRECARGA DE BOBINA

FOL SOBRECARGA DE VENTILADOR

HATR RELEVADOR ALTA TEMPERATURA DEL AIRE

HPR RELEVADOR DE ALTA PRESIÓN

TR RELEVADOR DEL TEMPORIZADOR

TPS INTERRUPTOR DE PRESIÓN DEL TANQUE

CT

COL

FOL

M CONTACTO PRINCIPAL

HPS INTERRUPTOR DE ALTA PRESIÓN

HATR 1

HPR 1

TR

ENCENDIDO

MEDIDOR

DE TIEMPO

TR

7

5

TPs

M

ENTRADA

DE AIRE

w

RESTABLECER

G

HATR 2

9

HATR 3

HATR

13

14

HATS

24

5

HPR 2

HPR 3

HPS

26

HPR

R

TR

S9

Page 30

Manual de Instrucciones

Instalación (Continuación)

PONER A TIERRA

Los choques eléctricos son causados

por la inadecuada puesta a tierra

de los componentes. Verifi que que todos los componentes

se encuentran aterrizados de manera adecuada para

prevenir lesiones serias o incluso la muerte.

Este producto debe ser puesto a tierra. Aterrizarlo reduce el

riesgo de electrocución mediante el suministro de una línea

de escape, en caso de un cortocircuito. Este producto debe ser

instalado y operado con cableado adecuadamente aterrizado.

DISYUNTORES Y FUSIBLES

Todo el sistema eléctrico deberá ser revisado por un electricista

certificado. Se requiere del uso de fusibles o disyuntores

(interruptores diferenciales) para este compresor. Un disyuntor

previamente disparado o un fusible fundido pueden indicar

un corto a tierra, alto consumo de corriente, cableado

inadecuado, un fusible equivocado o un disyuntor de tamaño

o tipo inadecuado. Esto debe ser evaluado por un electricista

certificado.

CONEXIÓN DEL MOTOR E INSTALACIÓN DEL

ARRANCADOR

La protección de la ramificación del circuito debe realizarse

como se especifica en el capítulo 2 del Código Eléctrico Nacional

de los Estados Unidos (NEC por sus siglas en Inglés), en “Diseño

y Protección del Cableado (Wiring Design and Protection)”.

Artículo 210, usando el artículo aplicable para “Motores y

Controladores de Motores,” (Artículo 430, Tabla 430-1 52).

VERIFICANDO EL SENTIDO DE ROTACIÓN

SENTIDO DE ROTACIÓN: hacia la izquierda (en sentido

contrario a las manecillas del reloj) con la vista hacia el eje.

El sentido de rotación del sistema de

compresor de tornillo debe de ser

inspeccionado durante su primer funcionamiento y siempre que se

realicen cambios al suministro de la línea eléctrica para el motor de

accionamiento. Para este propósito, accione brevemente el interruptor

del motor y apáguelo inmediatamente. LA ROTACIÓN POR MÁS

DE 2 SEGUNDOS EN EL SENTIDO EQUIVOCADO DE ROTACIÓN

DESTRUIRÁ EL TORNILLO COMPRESOR. DE SER NECESARIO,

INVIERTA LOS CONECTORES DEL CABLE DE SUMINISTRO

ELÉCTRICO.

LUBRICACIÓN

ESTA UNIDAD UTILIZA ACEITE. Antes de poner

en funcionamiento el compresor, revise el nivel

del aceite (ver Figura 7).

Utilizar cualquier otro tipo de aceite puede

disminuir la vida de la bomba y causar daños.

Aceite recomendado

Aceite monogrado ISO 100 para compresor de tornillo

(número de parte GS903800AV - contenedor de 1 galón).

Disponible en Campbell Hausfeld. Llame al departamento de

asistencia al consumidor al 1-855-504-5678.

Capacidad de aceite

7,95 litros

DIRECCIÓN DE ROTACIÓN

NOTA: El sentido de rotación equivocado causará la avería del

compresor.

La dirección de rotación debe ser en sentido opuesto a las

manecillas del reloj (tal como lo muestra la flecha en la unidad

de compresión Figura 6) vista frontal desde el lado del volante

del motor de la bomba

La dirección de rotación del motor trifásico puede invertirse al

intercambiar cualquiera de las dos líneas conductoras del motor.

Rotación

Figura 6 - Sentido de rotación

Tapón del aceite

Máximo (nivel de

aceite en frío)

Mínimo (nivel de

aceite en frío)

Figura 7 - Nivel de Aceite

S10

Page 31

Instalación (Continuación)

Compresores de Tornillo Rotativo Serie CS

NIVEL DE ACEITE

Desconecte el cordón eléctrico,

amárrelo y aléjelo del

tomacorrientes, después libere toda la presión del tanque

antes de tratar de instalar el compresor, darle servicio,

moverlo de sitio o darle cualquier tipo de mantenimiento.

La inadecuada puesta a tierra

PROVOCA RIESGO DE LESIONES