Page 1

TB4, TB4MM,

CS700, CS700H

Tipping Bucket Rain Gages

Revision

Copyright ©

Campbell Scientific, Inc.

: 8/19

1995 – 2019

Page 2

Limited Warranty

“Products manufactured by CSI are warranted by CSI to be free from defects in

materials and workmanship under normal use and service for twelve months

from the date of shipment unless otherwise specified in the corresponding

product manual. (Product manuals are available for review online at

www.campbellsci.com.) Products not manufactured by CSI, but that are resold

by CSI, are warranted only to the limits extended by the original manufacturer.

Batteries, fine-wire thermocouples, desiccant, and other consumables have no

warranty. CSI’s obligation under this warranty is limited to repairing or

replacing (at CSI’s option) defective Products, which shall be the sole and

exclusive remedy under this warranty. The Customer assumes all costs of

removing, reinstalling, and shipping defective Products to CSI. CSI will return

such Products by surface carrier prepaid within the continental United States of

America. To all other locations, CSI will return such Products best way CIP

(port of entry) per Incoterms ® 2010. This warranty shall not apply to any

Products which have been subjected to modification, misuse, neglect, improper

service, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied. The warranty for installation services

performed by CSI such as programming to customer specifications, electrical

connections to Products manufactured by CSI, and Product specific training, is

part of CSI's product warranty. CSI EXPRESSLY DISCLAIMS AND

EXCLUDES ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. CSI hereby disclaims,

to the fullest extent allowed by applicable law, any and all warranties and

conditions with respect to the Products, whether express, implied or

statutory, other than those expressly provided herein.”

Page 3

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle repairs

for customers within their territories. Please visit www.campbellsci.com to

determine which Campbell Scientific company serves your country.

To obtain a Returned Materials Authorization (RMA) number, contact

CAMPBELL SCIENTIFIC, INC., phone (435) 227-9000. Please write the

issued RMA number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our website at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 4

Safety

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON OR AROUND

TRIPODS, TOWERS, AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES,

ANTENNAS, ETC. FAILURE TO PROPERLY AND COMPLETELY ASSEMBLE, INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS,

TOWERS, AND ATTACHMENTS, AND FAILURE TO HEED WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS

INJURY, PROPERTY DAMAGE, AND PRODUCT FAILURE. TAKE ALL REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS.

CHECK WITH YOUR ORGANIZATION'S SAFETY COORDINATOR (OR POLICY) FOR PROCEDURES AND REQUIRED PROTECTIVE

EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not exceed design limits.

Be familiar and comply with all instructions provided in product manuals. Manuals are available at www.campbellsci.com or by

telephoning (435) 227-9000 (USA). You are responsible for conformance with governing codes and regulations, including safety

regulations, and the integrity and location of structures or land to which towers, tripods, and any attachments are attached. Installation

sites should be evaluated and approved by a qualified engineer. If questions or concerns arise regarding installation, use, or

maintenance of tripods, towers, attachments, or electrical connections, consult with a licensed and qualified engineer or electrician.

General

• Prior to performing site or installation work, obtain required approvals and permits. Comply

with all governing structure-height regulations, such as those of the FAA in the USA.

• Use only qualified personnel for installation, use, and maintenance of tripods and towers, and

any attachments to tripods and towers. The use of licensed and qualified contractors is highly

recommended.

• Read all applicable instructions carefully and understand procedures thoroughly before

beginning work.

• Wear a hardhat and eye protection, and take other appropriate safety precautions while

working on or around tripods and towers.

• Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take

reasonable precautions to secure tripod and tower sites from trespassers.

• Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

• You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are

installing, constructing, using, or maintaining, or a tool, stake, or anchor, come in contact with

overhead or underground utility lines.

• Maintain a distance of at least one-and-one-half times structure height, 20 feet, or the distance

required by applicable law, whichever is greater, between overhead utility lines and the

structure (tripod, tower, attachments, or tools).

• Prior to performing site or installation work, inform all utility companies and have all

underground utilities marked.

• Comply with all electrical codes. Electrical equipment and related grounding devices should be

installed by a licensed and qualified electrician.

Elevated Work and Weather

• Exercise extreme caution when performing elevated work.

• Use appropriate equipment and safety practices.

• During installation and maintenance, keep tower and tripod sites clear of un-trained or non-

essential personnel. Take precautions to prevent elevated tools and objects from dropping.

• Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

• Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks,

frayed cables, loose cable clamps, cable tightness, etc. and take necessary corrective actions.

• Periodically (at least yearly) check electrical ground connections.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS,

THE CUSTOMER ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER INSTALLATION, USE, OR

MAINTENANCE OF TRIPODS, TOWERS, OR ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS,

ENCLOSURES, ANTENNAS, ETC.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction................................................................ 1

2. Precautions ................................................................ 1

3. Initial Inspection ........................................................ 2

3.1 Ships With ............................................................................................2

4. QuickStart .................................................................. 2

5. Overview .................................................................... 4

5.1 Wind Screen .........................................................................................6

6. Specifications ............................................................ 6

6.1 Heated Rain Gage ................................................................................7

7. Installation ................................................................. 7

7.1 Wiring ..................................................................................................7

7.1.1 TB4, TB4M, or CS700 Connections .............................................7

7.1.2 CS700H Heated Rain Gage Connections ......................................7

7.2 Data Logger Programming ...................................................................9

7.2.1 PulseCount Instruction ................................................................ 10

7.2.2 SDI12Recorder Instruction ......................................................... 10

7.3 Siting .................................................................................................. 10

7.4 Mounting ............................................................................................ 10

7.4.1 Mounting to the CM240 and Leveling ........................................ 12

7.5 CS700H Power Supply Installation .................................................... 13

8. Operation ................................................................. 13

8.1 Sensor Schematic ............................................................................... 13

8.2 Long Cable Lengths ........................................................................... 14

8.3 CS700H Heated Rain Gage Operation ............................................... 14

8.3.1 SDI-12 Measurements ................................................................. 14

9. Troubleshooting and Maintenance ......................... 15

9.1 Troubleshooting ................................................................................. 15

9.2 Maintenance ....................................................................................... 16

9.2.1 Dismantling for Cleaning ............................................................ 16

9.2.2 Reassembling the Rain Bucket .................................................... 18

9.3 Calibration Check............................................................................... 19

i

Page 6

Table of Contents

Appendices

A. Importing Short Cut Code Into CRBasic Editor ... A-1

B. Example Programs ................................................ B-1

B.1 TB4 or CS700 Example Programs ................................................... B-1

B.1.1 CR6 Program for the TB4 or CS700 ......................................... B-1

B.1.2 CR1000X Programs for the TB4 or CS700 .............................. B-2

B.2 CS700H Example Programs ............................................................. B-4

B.2.1 CR6 Program for the CS700H .................................................. B-4

B.2.2 CR1000X Programs for CS700H .............................................. B-5

C. CS700H Operation Details ..................................... C-1

C.1 High Power Operation ...................................................................... C-3

C.2 External Control ............................................................................... C-3

C.3 Status LED ....................................................................................... C-4

C.4 Snow Sensor ..................................................................................... C-4

C.5 Operating Modes .............................................................................. C-5

C.6 SDI-12 Sensor Support .................................................................... C-6

C.6.1 Introduction ............................................................................... C-6

C.6.2 SDI-12 Command Basics .......................................................... C-6

C.6.2.1 Acknowledge Active Command (a!) .............................. C-8

C.6.2.2 Send Identification Command (aI!) ................................ C-8

C.6.2.3 Start Verification Command (aV!) ................................. C-8

C.6.2.4 Address Query Command (?!) ........................................ C-8

C.6.2.5 Change Address Command (aAb!) ................................. C-8

C.6.2.6 Start Measurement Commands (aM!) ............................ C-9

C.6.2.7 Start Concurrent Measurement Commands (aC!) .......... C-9

C.6.28 Start Measurement Commands with Cyclic

Redundancy Check (aMC! and aCC!) ...................... C-11

C.6.2.9 Stopping a Measurement Command ............................. C-11

C.6.2.10 Send Data Command (aD0! … aD9!) .......................... C-11

C.6.2.11 Continuous Measurement Command (aR0! … aR9!) .. C-12

C.6.2.12 Extended Commands .................................................... C-12

C.6.3 SDI-12 Transparent Mode....................................................... C-12

C.6.3.1 Changing an SDI-12 Address ....................................... C-13

C.6.4 References ............................................................................... C-13

D. Phoenix Contact Power Supply Specifications ... D-1

Figures

1-1. TB4 or TB4MM (left), CS700 (center), and CS700H (right)

Tipping Bucket Rain Gages ..............................................................1

5-1. CS700 Bucket Mechanism (housing not shown) .................................5

5-2. Phoenix Contact Power Supply ............................................................5

7-1. CS700H with Cables ............................................................................8

7-2. Phoenix Contact Power Supply ............................................................9

7-3. Typical Rain Gage Installation ........................................................... 11

7-4. CM300 Short Leg Pedestal Option (left) and J-Bolt Pedestal

Option ............................................................................................. 12

7-5. Transparent View of the TB4 (CS700 looks similar) ......................... 12

7-6. CM240 Mounting Bracket ................................................................. 13

ii

Page 7

Table of Contents

Tables

8-1. TB4, TB4M, and CS700 Schematic ................................................... 13

8-2. CS700H Heater Operation ................................................................. 14

9-1. Main Components of the CS700 ........................................................ 16

9-2. TB4 Base ............................................................................................ 17

9-3. Dismantling the Filter/Siphon Assembly ........................................... 17

9-4. Filter/Siphon Assembly ...................................................................... 18

9-5. Reassembling the CS700 .................................................................... 19

C-1. Locations of the CS700H Heater Components ................................ C-1

C-2. Diagram Depicting Overall Operation ............................................. C-2

C-3. Diagram showing how the “Snow Run-On” timer controls the

heater. ........................................................................................... C-3

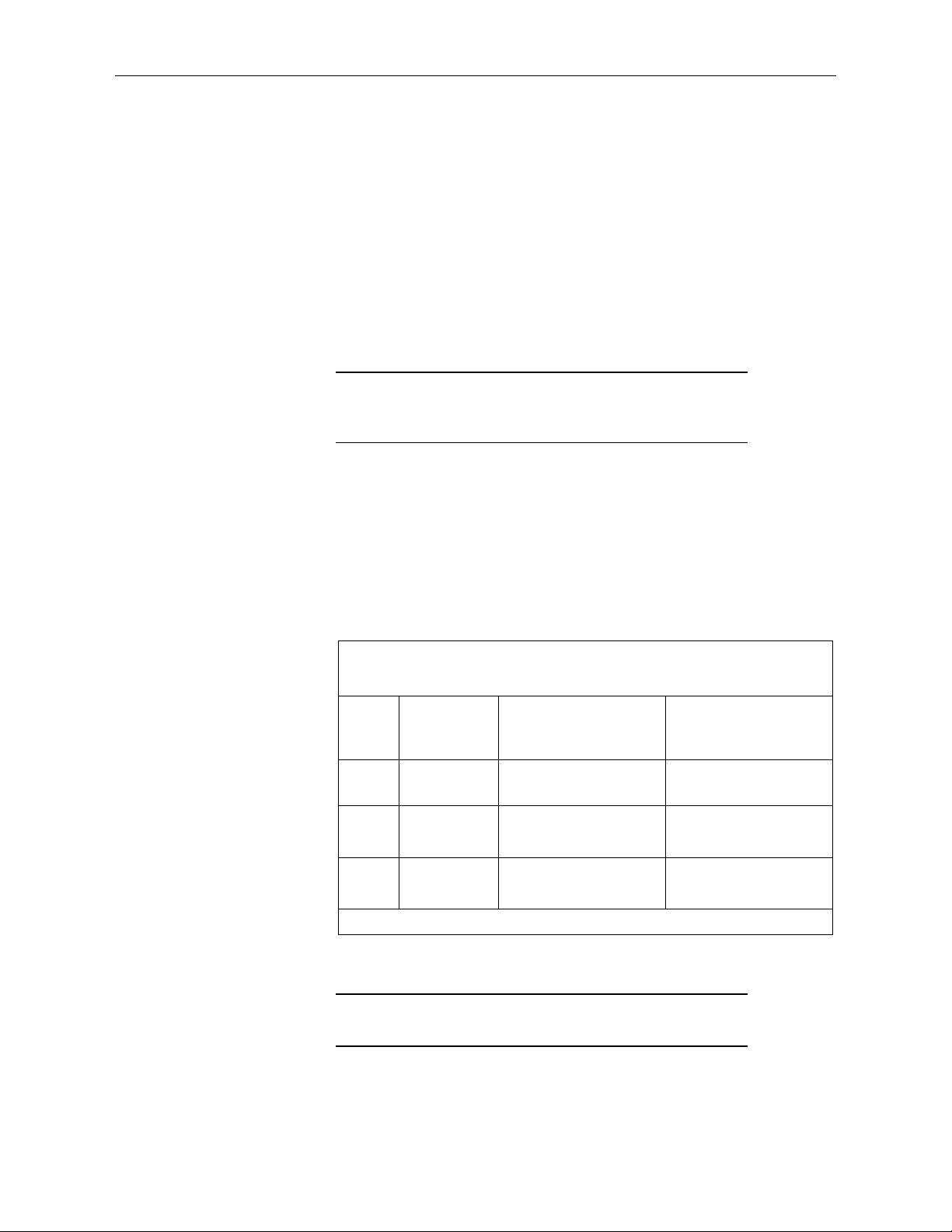

7-1. TB4, TB4MM, or CS700 Wire Color, Wire Function, and Data

Logger Connection ...........................................................................7

7-2. CS700H Sensor Cable Wire Color, Wire Function, and Data

Logger Connection ...........................................................................8

7-3. CS700H Power Cable Wire Color, Wire Function, and Power

Supply Connection ............................................................................8

C-1. CS700H Default Values ................................................................... C-1

C-2. Status LEDs ...................................................................................... C-4

C-3. Snow Sensor Power Options ............................................................ C-5

C-4. Operating Modes .............................................................................. C-5

C-5. Campbell Scientific Sensor SDI-12 Command and Response Set ... C-7

C-6. Example aM! Sequence .................................................................... C-9

C-7. Example aC! Sequence .................................................................. C-10

CRBasic Examples

B-1. CR6 Program Measuring the TB4 or CS700 .................................... B-1

B-2. CR1000X Program Using a Pulse Terminal to Measure the TB4

or CS700 ....................................................................................... B-2

B-3. CR1000X Program Using a Control Terminal to Measure the

TB4 or CS700 ............................................................................... B-3

B-4. CR6 Program Measuring the CS700H ............................................. B-4

B-5. CR1000X Program Measuring the CS700H .................................... B-5

B-6. CR1000X Program Measuring the CS700H and Monitoring

Heater............................................................................................ B-6

iii

Page 8

NOTE

TB4, TB4MM, CS700, and CS700H

Tipping Bucket Rain Gages

1. Introduction

The TB4, TB4MM, CS700, and CS700H are tipping bucket rain gages that

funnel rain into a mechanism that tips when filled. The TB4, CS700, and

CS700H measure in 0.01-inch increments and the TB4MM measures in

0.2-mm increments. The TB4 and TB4MM have a lightweight plastic base, and

the CS700 and CS700H have a heavy-duty, cast-aluminum base (FIGURE

1-1). The CS700H is a heated rain gage for measuring the water content of

snow.

2. Precautions

FIGURE 1-1. TB4 or TB4MM (left), CS700 (center), and CS700H

(right) Tipping Bucket Rain Gages

This manual provides information only for CRBasic data loggers.

For retired Edlog data logger support, see an older manual at

www.campbellsci.com/old-manuals.

• READ AND UNDERSTAND the Safety section at the front of this

manual.

• The rain gages are precision instruments. Please handle them with care.

• Before using the rain gage, remove the rubber band and cardboard that

secures the tipping bucket assembly during shipping.

®

• The black outer jacket of the cable is Santoprene

was chosen for its resistance to temperature extremes, moisture, and UV

rubber. This compound

1

Page 9

degradation. However, this jacket will support combustion in air. It is rated

as slow burning when tested according to U.L. 94 H.B. and will pass

FMVSS302. Local fire codes may preclude its use inside buildings.

• While assembling the CS700H, ensure that the coiled cable and the

neoprene jacket do not interfere with the tipping bucket mechanism when

placing the funnel on the base.

3. Initial Inspection

• Upon receipt of the tipping bucket rain gage, inspect the packaging and

contents for damage. File damage claims with the shipping company.

Immediately check package contents against the shipping documentation

(see Section 3.1, Ships With). Contact Campbell Scientific about any

discrepancies.

• The model number and cable length are printed on a label at the

connection end of the cable. Check this information against the shipping

documents to ensure the expected product and cable length are received.

3.1 Ships With

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

4. QuickStart

The rain gages ship with:

(1) Allen wrench from original manufacturer

CS700H-AC version also ships with:

(1) Power supply and mounting hardware (Quint Power made by Phoenix

Contact)

A video that describes data logger programming using Short Cut is available at:

www.campbellsci.com/videos/cr1000x-datalogger-getting-started-programpart-3. Short Cut is an easy way to program your data logger to measure the

rain gage and assign data logger wiring terminals. Short Cut is available as a

download on www.campbellsci.com. It is included in installations of

LoggerNet, PC200W, PC400, or RTDAQ.

The following procedure also describes programming with Short Cut.

1. Open Short Cut and click Create New Program.

2. Double-click the data logger model.

2

Page 10

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

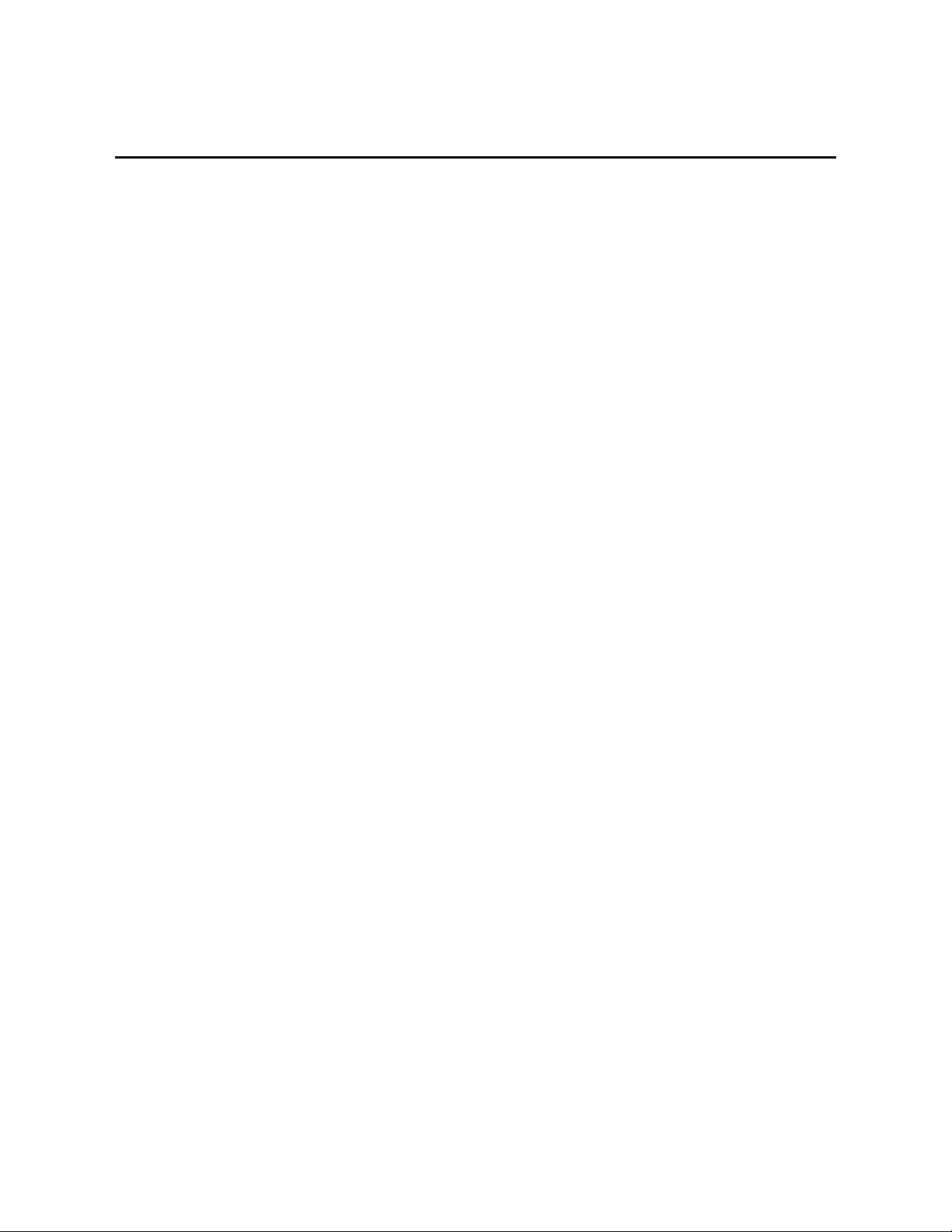

3. In the Available Sensors and Devices box, type TB4 or CS700. You can

also locate the sensor in the Sensors | Meteorological | Precipitation

folder. Double-click TB4/TB4MM or CS700 Rain Gauge. The units

defaults to millimeters, which can be changed by clicking the Rain box

and selecting one of the other options. The default rainfall per tip value of

0.01 inches should be used if the sensor is a TB4 or CS700 purchased at

Campbell Scientific (U.S. office). Select 0.2 mm if the sensor is a TB4MM

purchased at Campbell Scientific (U.S. office) or a TB4 or CS700

purchase at Campbell Scientific Canada.

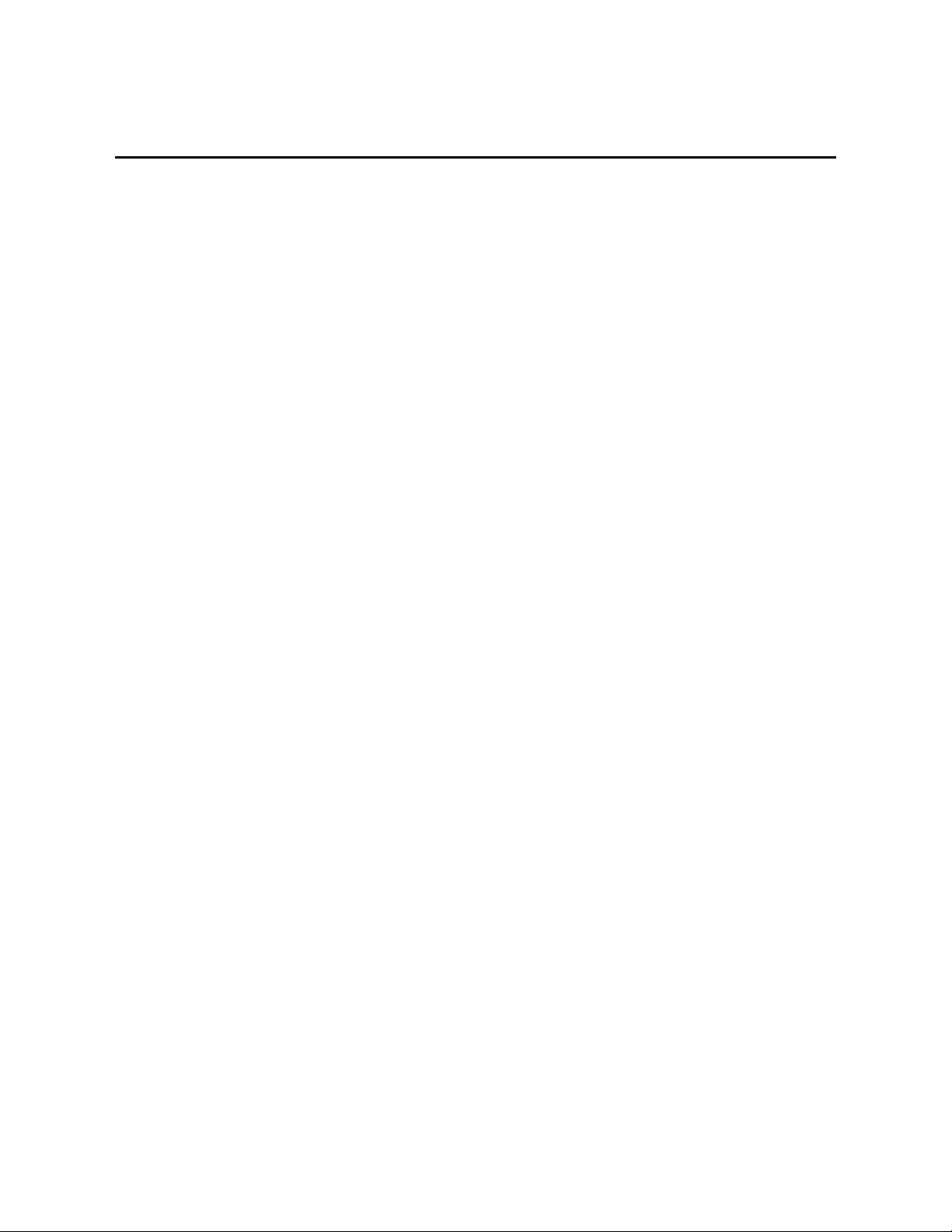

4. Click on the Wiring tab to see how the sensor is to be wired to the data

logger. Click OK after wiring the sensor.

5. Repeat steps three and four for other sensors. Click Next.

3

Page 11

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

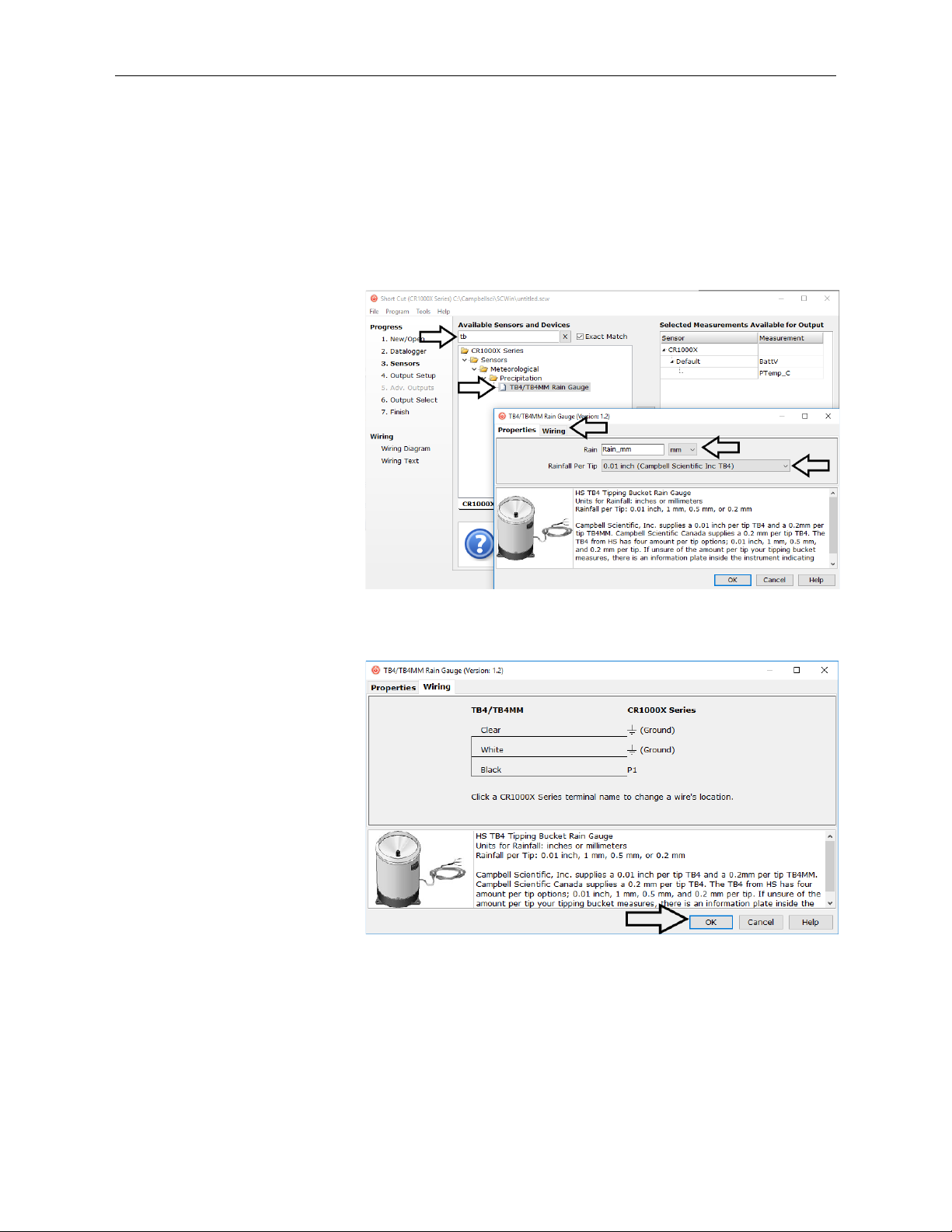

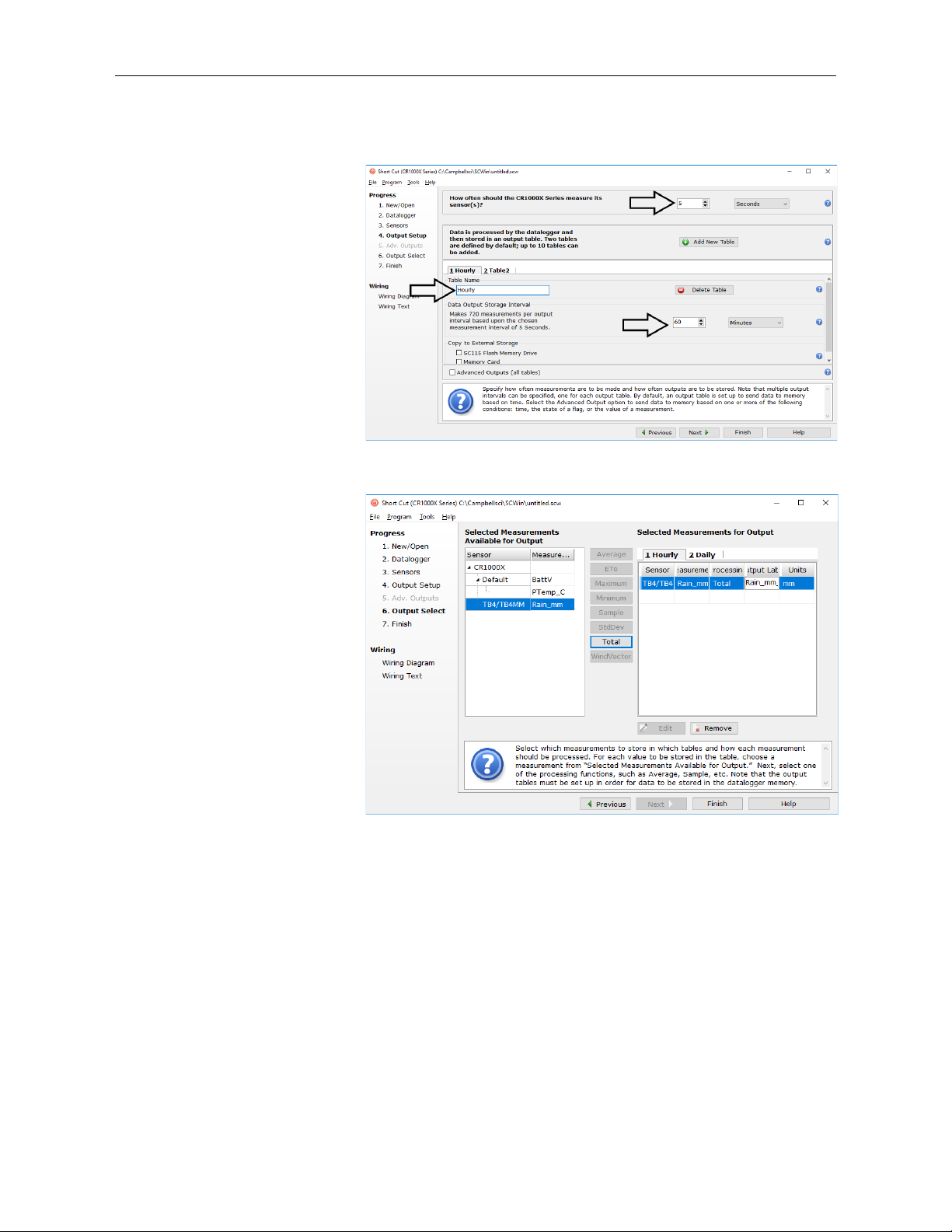

6. In Output Setup, type the scan rate, meaningful table names, and the

Data Output Storage Interval.

7. Select the output options.

5. Overview

8. Click Finish and save the program. Send the program to the data logger if

the data logger is connected to the computer.

9. If the sensor is connected to the data logger, check the output of the sensor

in LoggerNet, PC400, RTDAQ, or PC200W to make sure it is making

reasonable measurements.

The TB4, TB4MM, CS700, and CS700H tipping bucket rain gages are

manufactured by HS Hyquest Solutions Pty. Ltd. and modified for use with

Campbell Scientific data loggers. These rain gages funnel precipitation into a

bucket mechanism that tips when filled to a calibrated level (FIGURE 5-1).

The tipping mechanism activates a reed switch. The switch closure is recorded

4

Page 12

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

Bucket Mechanism

by the data logger. When the bucket tips, the water drains out the screened

fittings in the base of the gage.

The rain gages are ideal for locations where intense rainfall events may occur.

They include a siphoning mechanism that allows the rain to flow at a steady

rate regardless of rainfall intensity. The siphon reduces typical rain bucket

errors and produces accurate measurements for up to 50 cm per hour.

FIGURE 5-1. CS700 Bucket Mechanism (housing not shown)

The CS700H has two power configuration options (either AC or DC) for

powering the heater. With the AC option, a Phoenix Contact Power Supply is

shipped with the CS700H (FIGURE 5-2). Appendix D, Phoenix Contact Power

Supply Specifications

(p. D-1), provides more information about this power

supply.

FIGURE 5-2. Phoenix Contact Power Supply

5

Page 13

With the DC option, the CS700H is connected to a user-supplied battery. This

option is ideal for remote sites using wind or solar power to recharge the

battery. Battery capacity requirements vary according to the application and

site location.

5.1 Wind Screen

The 260-953 Alter-Type Wind Screen can be used with the rain gage to

minimize the effects of strong winds. Siting information and the installation

procedure for this wind screen is provided in our 260-953 manual.

6. Specifications

Features:

Orifice Diameter: 200 mm (7.87 in)

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

• More accurate measurement of high-intensity precipitation

• High precision

• Compatible with Campbell Scientific CRBasic data loggers:

CR200(X) series (except CS700H), CR300 series (except CS700H),

CR6 series, CR800 series, CR1000, CR1000X, CR3000, CR5000,

and CR9000(X) (except CS700H)

Measurement Range: 0 to 700 mm/hr (0 to 27.6 in/hr)

Accuracy: ±2% @ < 250 mm/hr (9.8 in/hr);

±3% @ 250 to 500 mm/hr (9.8 to 19.7 in/hr)

Resolution

TB4, CS700, CS700H: 0.254 mm (0.01 in)

TB4MM: 0.2 mm (0.008 in)

Temperature Range

TB4, TB4MM, CS700: 0 to 70 °C

CS700H: –40 to 70 °C

Humidity: 0 to 100%

Contact: Dual Reed Switch

Drain Tube: Both filters accept 12 mm inner diameter

tubing

Siphon: 0.4 mm (12 ml) capacity of rainfall; made

from brass with a non-hydroscopic outer

case. The syphon can be dismantled for

routine cleaning and servicing.

Weight with 25-ft signal cable

TB4/TB4MM: 2 kg (4.4 lb)

CS700/CS700H: 3.3 kg (7.4 lb)

Height

TB4/TB4MM: 33 cm (13 in)

CS700/CS700H: 34.2 cm (13.5 in)

6

Page 14

6.1 Heated Rain Gage

TABLE 7-1. TB4, TB4MM, or CS700 Wire Color, Wire Function,

⏚

⏚

⏚

NOTE

CAUTION

7. Installation

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

Snow Sensor and Heater

Operating Temperature Range: –20 to 5 °C

Output: SDI-12

Voltage Requirements

Main Power: 10 to 30 VDC or 12 to 28 VAC

SDI-12 Power: 9.6 to 16 VDC

Total Current Consumption

Snow sensor off, heater off: 6 mA @ 12 V, 0.072 W

Snow sensor on, heater off: 12 mA @ 12 V, 0.144 W

Snow sensor on, heater on: 5.8 A @ 12 V, 70 W

Specifications for the power supply used for the –AC option is

provided in Appendix D, Phoenix Contact Power Supply

Specifications

If programming the data logger with Short Cut, skip Section 7.1, Wiring (p. 7),

and Section 7.2, Data Logger Programming

you. See Section 4, QuickStart

(p. D-1).

(p. 9). Short Cut does this work for

(p. 2), for a Short Cut tutorial.

7.1 Wiring

7.1.1 TB4, TB4M, or CS700 Connections

and Data Logger Connection

Data Logger

Wire

Color

Black Rain Signal

White

Clear Shield

1

U and C terminals are automatically configured by the measurement instruction.

7.1.2 CS700H Heated Rain Gage Connections

The CS700H will only communicate over SDI-12 when both

its sensor cable and power cable are connected.

Wire

Function

Rain Signal

Reference

Connections Using a

Pulse Terminal

P, P_SW, or U1

(Pulse Terminal)

(Analog Ground)

(Analog Ground)

Data Logger

Connections Using a

Control Terminal

C

(Control Terminal)

5 V

(Analog Ground)

The CS700H has both a sensor cable and a power cable (FIGURE 7-1).

7

Page 15

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

TABLE 7-2. CS700H Sensor Cable Wire Color, Wire Function,

⏚

⏚

⏚

TABLE 7-3. CS700H Power Cable Wire Color,

Sensor Cable

Power Cable

FIGURE 7-1. CS700H with Cables

The sensor cable connects to the data logger (TABLE 7-2). The power cable

connects to the power supply (TABLE 7-3). FIGURE 7-2 shows the terminals

for connecting the power cable to the Phoenix Contact Power Supply.

and Data Logger Connection

Wire

Color

Wire

Function

Green SDI-12

Data Logger

Connections Using a

Pulse Terminal

Odd-numbered C or U

configured for SDI-12

1

Data Logger

Connections Using a

Control Terminal

Odd-numbered C or U1

configured for SDI-12

Red SDI-12 Power 12V 12V

Blue

Black Rain Signal

White

Clear Shield

1

U and C terminals are automatically configured by the measurement instruction.

2

When using a CR6 or CR1000X, a conflict occurs if the pulse measurement uses an

even C terminal that immediately follows the SDI-12 terminal. For example, if C1 is

used for the SDI-12 terminal, do not use C2 for the pulse terminal.

SDI-12 Power

Ground

Rain Signal

Reference

G G

P or U1

(Pulse Terminal)

(Analog Ground)

(Analog Ground)

C2

(Control Terminal)

5 V

(Analog Ground)

Wire Function, and Power Supply Connection

Wire Color Description Power Supply

Red +24 VDC +

Black Ground –

8

Page 16

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

NOTE

Power Out:

Power In:

110 VAC Adapter

Connects to CS700H

FIGURE 7-2. Phoenix Contact Power Supply

7.2 Data Logger Programming

Short Cut is the best source for up-to-date data logger programming code.

If your data acquisition requirements are simple, you can probably create and

maintain a data logger program exclusively with Short Cut. If your data

acquisition needs are more complex, the files that Short Cut creates are a great

source for programming code to start a new program or add to an existing

custom program.

Short Cut cannot edit programs after they are imported and edited

in CRBasic Editor.

A Short Cut tutorial is available in Section 4, QuickStart (p. 2). If you wish to

import Short Cut code into CRBasic Editor to create or add to a customized

program, follow the procedure in Appendix A, Importing Short Cut Code Into

CRBasic Editor

Programming basics for CRBasic data loggers are in the following sections.

Complete program examples for select CRBasic data loggers can be found in

Appendix B, Example Programs

(p. A-1).

(p. B-1). Programming basics and programming

Connects to

9

Page 17

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

CAUTION

examples for Edlog data loggers are provided at www.campbellsci.com/old-

manuals.

7.2.1 PulseCount Instruction

The tipping buckets use a reed switch for measuring precipitation. The

PulseCount() CRBasic instruction measures the reed switch.

PulseCount(Dest,Reps,PChan,PConfig,POption,Mult,Offset)

• Choose Switch Closure for the PConfig parameter. For the CR6 and

CR1000X, choose Switch Closure with pull up.

• The Multiplier parameter determines the units in which rainfall is

reported. For the TB4, CS700, and CS700H, a multiplier of 0.01

converts the output to inches and a multiplier of 0.254 converts the

output to millimeters. For the TB4MM, a multiplier of 0.2 converts

the output to millimeters and a multiplier of 0.008 converts it to

inches.

7.2.2 SDI12Recorder Instruction

When measuring a CS700H, the CRBasic program can include the

SDI12Recorder() instruction to retrieve real-time status information stored in

the CS700H microprocessor.

7.3 Siting

7.4 Mounting

SDI12Recorder ( Dest, SDIPort, SDIAddress, "SDICommand",

Multiplier, Offset, FillNAN, WaitonTimeout)

The Destination parameter must be an array of length 9. FillNAN and

WaitonTimeout are optional parameters (refer to CRBasic Help for more

information). Appendix C, CS700H Operation Details

information about the SDI-12 commands and other operational details for the

CS700H.

The CS700H will only communicate over SDI-12 when both

its sensor cable and power cable are connected (TABLE 7-2

and TABLE 7-3

Mount the rain gage in a relatively level location representative of the

surrounding area. Ensure that the orifice is horizontal, at least 1 m above the

ground, and higher than the average snow depth.

Place the rain gage away from objects that obstruct the wind. The distance

should be 2- to 4-times the height of the obstruction.

The tipping buckets have three equally-spaced feet for mounting them on a flat

surface. Each foot includes a hole that fits a 3/8-inch (M8) bolt. The three holes

form a 234 mm (9.21 in) diameter bolt circle.

).

(p. C-1), provides

10

Page 18

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

61 cm

(24 in)

20 cm

(8 in) dia.

CM240

CM310

61 cm

(24 in)

20 cm

(8 in) dia.

Campbell Scientific offers the CM240 mounting bracket for installing and

leveling the rain gages. The CM240 may be attached to a CM300-Series

mounting pole or to a user-supplied 1.5 in. IPS (1.9 in. OD) unthreaded pipe.

The pole or pipe can be placed directly into a concrete foundation (FIGURE

7-3), or attached to a concrete foundation using J-bolts or self-supporting with

legs (FIGURE 7-4). A concrete pad is recommended, but it should not be

installed over large paved or concrete surface.

142 cm (56 in)

mounting pole

FIGURE 7-3. Typical Rain Gage Installation

11

Page 19

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

Housing

Housing Screw

Base

Tipping Bucket

Bullseye Level

Funnel

Foot

61 cm

(24 in)

36 cm

(14 in)

4 cm (1.5 in)

9 cm (3.5 in)

FIGURE 7-4. CM300 Short Leg Pedestal Option (left) and J-Bolt

Pedestal Option

7.4.1 Mounting to the CM240 and Leveling

1. Remove the housing assembly from the base by loosening the three

housing screws and lifting the housing upward (FIGURE 7-5).

Assembly

FIGURE 7-5. Transparent View of the TB4 (CS700 looks similar)

12

Page 20

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

Black

White

Clear

100 Ω

White

Black

Clear

Leveling Screw

Leveling Screw

Leveling Screw

2. Remove the leveling screws from the CM240 (FIGURE 7-6).

FIGURE 7-6. CM240 Mounting Bracket

3. Place the tipping bucket on the CM240 and line up the holes in the tipping

bucket feet with the holes for the CM240 leveling screws (FIGURE 7-5

and FIGURE 7-6).

4. Use the leveling screws to loosely secure the rain gage to the CM240.

7.5 CS700H Power Supply Installation

8. Operation

8.1 Sensor Schematic

5. Place the CM240 and rain gage on the mounting pole.

6. Adjust the three leveling screws on the CM240 bracket to level the gage

(FIGURE 7-6). A bullseye level is mounted on the rain gage base to

facilitate leveling (FIGURE 7-5).

7. Remove the rubber band and cardboard securing the tipping bucket

assembly. Tip the bucket several times to ensure the tipping mechanism is

moving freely.

8. Replace the housing assembly and tighten the three housing screws to

secure the housing to the base.

A CS700H with option –AC includes a Phoenix Contact Power Supply that

must be housed in an environmental enclosure. A DIN rail mounting bracket is

shipped with the CS700H for securing this power supply to an enclosure

backplate. The DIN Rail mounts to the backplate using screws and grommets.

FIGURE 8-1. TB4, TB4M, and CS700 Schematic

13

Page 21

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

NOTE

8.2 Long Cable Lengths

Long cables have appreciable capacitance between the lines. A built up charge

could cause arcing when the switch closes, shortening switch life. A 100 ohm

resistor is connected in series at the switch to prevent arcing by limiting the

current (FIGURE 8-1). This resistor is installed on all rain gages currently sold

by Campbell Scientific.

8.3 CS700H Heated Rain Gage Operation

This section provides a brief discussion of the CS700H heater

operation. More in-depth information is provided in Appendix C,

CS700H Operation Details

The CS700H includes heating elements and an internal snow sensor, which is

activated when the air temperature drops below 4 °C. If the snow sensor detects

snow in the catch area (funnel), the heating elements automatically turn on and

keep the funnel temperature at 10 °C. The heater goes into a wait mode when

snow has not been detected for 18 minutes. It automatically deactivates when

the air temperature drops below –20 °C.

As the ambient temperature falls below the Active On Temperature (default

4 °C), the heater will turn on to heat the funnel area of the rain gage. Once the

funnel reaches the Funnel Set Point Temp (default 10 °C), the heater will begin

cycling on and off with a duty cycle dependent on the ambient temperature,

keeping the funnel temperature at or near 10 °C (FIGURE 8-2).

(p. C-1).

FIGURE 8-2. CS700H Heater Operation

8.3.1 SDI-12 Measurements

The M!, C!, and R! SDI-12 commands retrieve the following status

information from the CS700H:

1. Ambient temperature (°C or °F)

2. Block temperature (°C or °F)

3. Units (0=°C, 1=°F)

4. 0=no snow; 1=snow detected

14

Page 22

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

NOTE

5. 0=snow sensor disabled; 1=snow sensor enabled

6. 0=heater elements off; 1=heater elements on

7. 0=automatic control; 1=manual control

8. 0=cycle disabled; 1=cycle enabled

9. Low Power Heater cycle time left (mins)

When using an M! command, the data logger waits for the time specified by

the sensor, sends the D! command, pauses its operation, and waits until either it

receives the data from the sensor or the sensor timeout expires. If the data

logger receives no response, it will send the command a total of three times,

with three retries for each attempt, or until a response is received. Because of

the delays this command requires, it is only recommended in measurement

scans of 10 seconds or more or use SlowSequence.

A C! command follows the same pattern as an M! command with the

exception that it does not require the data logger to pause its operation until the

values are ready. Rather, the data logger picks up the data with the D!

command on the next pass through the program. Another measurement request

is then sent so that data is ready on the next scan. To use this command, the

scan interval should be 10 seconds or less.

An R! command switches the sensor to automatically make measurements and

send data every 11 seconds, ±2 seconds, based on the sensor internal clock. If

measurements are requested at 2 seconds or faster, the sensor will increase its

measurement rate to approximately every 5 seconds. This instruction usually

takes less than 300 milliseconds to execute. The automatic measurement mode

can only be cancelled by powering down the sensor to reset it.

The CS700H also uses extended commands (X) to control the heater and

change settings. Appendix C.6, SDI-12 Sensor Support

extended commands and provides detailed information about the SDI-12

interface. Additional SDI—12 information is also available at www.sdi-12.org,

or www.youtube.com/user/CampbellScientific.

9. Troubleshooting and Maintenance

All factory repairs and recalibrations require a returned material

authorization (RMA) and completion of the “Declaration of

Hazardous Material and Decontamination” form. Refer to the

Assistance page at the beginning of this manual for more

information.

9.1 Troubleshooting

Symptom: No Precipitation Measurement

1. Check that the sensor is wired to the pulse or control terminal

specified by the pulse count instruction.

2. Verify that the PConfig, and Multiplier and Offset parameters for the

PulseCount() instruction are correct for the data logger type.

3. Disconnect the sensor from the data logger and use an ohm meter to

do a continuity check of the switch. The resistance measured at the

terminal block on the inside of the bucket between the black and white

(p. C-5), describes the

15

Page 23

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

Tipping

Assembly

Funnel

Housing

Housing

Base

Bullseye

Insect

Screen

wires should vary from infinite (switch open) when the bucket is

tipped, to less than an ohm when the bucket is balanced.

Symptom: CS700H not communicating over SDI-12

1. Ensure that both the sensor and power cables are properly connected

(TABLE 7-2 and TABLE 7-3).

9.2 Maintenance

During each site visit, remove any debris, such as insects or sediment from the

collection funnel, debris screen, siphoning mechanism, or tipping bucket

assembly.

Verify the tipping bucket assembly moves freely, and that the data logger

records each bucket tip.

9.2.1 Dismantling for Cleaning

Regularly check the following items for cleanliness:

• Catch filter

• Siphon

• Interior of bucket

• Top surface of adjusting screws

• Housing locking screws; lightly lubricate after cleaning

• Insect screens

Level

To access them, dismantle the rain gage using the following procedure:

1. Remove the housing assembly from the base by loosening the three housing

screws and lifting the housing upward (FIGURE 9-1, FIGURE 9-2.

Bucket

Screw

FIGURE 9-1. Main Components of the CS700

16

Page 24

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

CAUTION

Do not

pulling.

Push Filter

Pull

Siphon

To dismantle the filter and siphon assembly,

Reed Switch Assembly

Tipping Bucket Assembly

Bullseye Level

Housing Screw

FIGURE 9-2. TB4 Base

twist

while

pushing

and

2. Separate the filter/siphon assembly from the funnel by pushing the filter

while pulling the siphon (FIGURE 9-3).

Do not twist the filter/siphon assembly while pushing and

pulling.

push filter and pull siphon at the same time.

Do not twist.

FIGURE 9-3. Dismantling the Filter/Siphon Assembly

17

Page 25

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

CAUTION

Filter Cover

Filter Screen

Stem Cap

Stem

Brass Nut

O Ring

Siphon Body

3. Disassemble the filter/siphon assembly by doing the following (FIGURE

9-4):

(a) Unscrew nut

(b) Lightly press stem down on surface until stem pops out of siphon body.

(c) Remove stem from siphon body.

(d) Unscrew cap

(e) Clean all items

FIGURE 9-4. Filter/Siphon Assembly

9.2.2 Reassembling the Rain Bucket

1. Screw cap on stem; finger tighten only (FIGURE 9-4).

2. Push stem into siphon body (FIGURE 9-4).

3. Replace nut and tighten (FIGURE 9-4).

Do not over tighten.

18

Page 26

TB4, TB4MM, CS700, and CS700H Tipping Bucket Rain Gages

CAUTION

To re-assemble,

4. Push filter/siphon assembly back into place (FIGURE 9-5).

Do not twist the filter/siphon assembly while putting it back

into place.

push the

filter/siphon

assembly back

in place.

Do not twist.

FIGURE 9-5. Reassembling the CS700

5. Place the housing assembly back onto the base and tighten the three screws

that secure the housing onto the base.

9.3 Calibration Check

The sensor is factory calibrated; recalibration is not required unless damage has

occurred or the adjustment screws have loosened.

Nevertheless, the following calibration check is recommended once every 12

months:

1. Remove the housing assembly from the base by removing the three

screws and lifting upward on the housing.

2. Check the bubble level to verify the rain gage is level.

3. Pour water through the inner funnel to wet the two bucket surfaces.

Using a graduated cylinder, slowly pour 314 cc (19.16 in

over a 15-minute period, into the collection funnel. This volume of

water is equal to 0.39 in of rainfall (10 mm).

4. After the water has passed through the rain gage, the tipping bucket

should have tipped 39 times.

3

) of water,

5. If the rain gage fails to record the correct number of tips, return the

unit to Campbell Scientific for recalibration (see Assistance in the

front of the manual).

19

Page 27

NOTE

Appendix A. Importing Short Cut Code Into CRBasic Editor

Short Cut creates a .DEF file that contains wiring information and a program

file that can be imported into the CRBasic Editor. By default, these files reside

in the C:\campbellsci\SCWin folder.

Import Short Cut program file and wiring information into CRBasic Editor:

1. Create the Short Cut program following the procedure in Section 4,

QuickStart

tab then the CRBasic Editor button. A program file with a generic name

will open in CRBasic. Provide a meaningful name and save the CRBasic

program. This program can now be edited for additional refinement.

Once the file is edited with CRBasic Editor, Short Cut can no

longer be used to edit the program it created.

(p. 2). After saving the Short Cut program, click the Advanced

2. To add the Short Cut wiring information into the new CRBasic program,

open the .DEF file located in the C:\campbellsci\SCWin folder, and copy

the wiring information, which is at the beginning of the .DEF file.

3. Go into the CRBasic program and paste the wiring information into it.

4. In the CRBasic program, highlight the wiring information, right-click, and

select Comment Block. This adds an apostrophe (') to the beginning of

each of the highlighted lines, which instructs the data logger compiler to

ignore those lines when compiling. The Comment Block feature is

demonstrated at about 5:10 in the CRBasic | Features video .

A-1

Page 28

CRBasic Example B-1. CR6 Program Measuring the TB4 or CS700

EndProg

Appendix B. Example Programs

B.1 TB4 or CS700 Example Programs

B.1.1 CR6 Program for the TB4 or CS700

In the following CR6 program, the TB4 or CS700 is connected to U1, and the

rain measurements are reported in inches. Battery voltage and panel

temperature are also measured.

'Program measures one TB4 or CS700

'Wiring Diagram

'==============

'Wire

'Color Function Terminal

'----- -------- -------'Black Rain signal U1

'White Rain signal ground Ground Symbol

'Clear Shield Ground Symbol

'Declare Variables and Units

Public BattV

Public PTemp_C

Public Rain_in

Units BattV = Volts

Units PTemp_C = Deg C

Units Rain_in = inch

'Define Data Tables

DataTable(OneMin,True,-1)

DataInterval(0,1,Min,10)

Totalize(1,Rain_in,FP2,False)

EndTable

DataTable(OneDay,True,-1)

DataInterval(0,1440,Min,10)

Minimum(1,BattV,FP2,False,False)

Totalize(1,Rain_in,FP2,False)

EndTable

'Main Program

BeginProg

Scan(5,Sec,1,0)

'Default Data Logger Battery Voltage measurement BattV

Battery(BattV)

'Default Data Logger Wiring Panel Temperature measurement 'PTemp_C'

PanelTemp(PTemp_C,60)

'Rain Gage measurement Rain_in

PulseCount(Rain_in,1,U1,1,0,0.01,0)

'Call Data Tables and Store Data

CallTable OneMin

CallTable OneDay

NextScan

B-1

Page 29

B.1.2 CR1000X Programs for the TB4 or CS700

CRBasic Example B-2. CR1000X Program Using a Pulse Terminal to Measure the TB4 or

'Program measures one TB4 or CS700

EndProg

CS700

'Wiring Diagram

'==============

'Wire

'Color Function Terminal

'----- -------- -------'Black Rain signal P1

'White Rain signal ground Ground Symbol

'Clear Shield Ground Symbol

'Declare Variables and Units

Public BattV

Public PTemp_C

Public Rain_in

Units BattV = Volts

Units PTemp_C = Deg C

Units Rain_in = inch

'Define Data Tables

DataTable(OneMin,True,-1)

DataInterval(0,1,Min,10)

Totalize(1,Rain_in,FP2,False)

EndTable

DataTable(OneDay,True,-1)

DataInterval(0,1440,Min,10)

Minimum(1,BattV,FP2,False,False)

Totalize(1,Rain_in,FP2,False)

EndTable

'Main Program

BeginProg

Scan(5,Sec,1,0)

'Default Data Logger Battery Voltage measurement BattV

Battery(BattV)

'Default CR1000X Data Logger Wiring Panel Temperature measurement 'PTemp_C'

PanelTemp(PTemp_C,60)

'CS700 Rain Gage measurement Rain_in

PulseCount(Rain_in,1,P1,1,0,0.01,0)

'Call Data Tables and Store Data

CallTable OneMin

CallTable OneDay

NextScan

Appendix B. Example Programs

This section includes two CR1000X programs. In the first program, the rain

gage is connected to P1, and the rain measurements are reported in inches.

Battery voltage and panel temperature are also measured. In the second

program, the rain gage is connected to C1, and the rain measurements are

reported in millimeters.

B-2

Page 30

Appendix B. Example Programs

CRBasic Example B-3. CR1000X Program Using a Control Terminal to Measure the TB4

'CR1000X

EndProg

or CS700

'Program measures one rain gage using control terminal

'Wiring Diagram

'==============

'Wire

'Color Function Terminal

'----- -------- -------'Black Rain signal C1

'White Rain signal ground 5V

'Clear Shield Ground Symbol

'Declare Public Variables and Units

Public Rain_mm

Units Rain_mm=mm

DataTable (Rain,True,-1)

DataInterval (0,60,Min,0)

Totalize (1,Rain_mm,FP2,0)

EndTable

'Main Program

BeginProg

Scan (1,Sec,1,0)

PulseCount (Rain_mm,1,C1,2,0,.254,0)

CallTable (Rain)

NextScan

B-3

Page 31

B.2 CS700H Example Programs

CRBasic Example B-4. CR6 Program Measuring the CS700H

EndProg

B.2.1 CR6 Program for the CS700H

In the following CR6 program, the CS700H is connected to U1, and the rain

measurements are reported in inches. This program does not retrieve real-time

status information using the SDI-12 protocol. An example program that

retrieves status information is provided in Appendix B.2.2, CR1000X

Programs for CS700H

'Program measures one CS700H

'Wiring Diagram

'==============

'CS700H

'Wire

'Color Function Terminal

'----- -------- -------'Black Rain signal U1

'White Rain signal ground Ground Symbol

'Clear Shield Ground Symbol

'Declare Variables and Units

Public BattV

Public PTemp_C

Public Rain_in

Units BattV = Volts

Units PTemp_C = Deg C

Units Rain_in = inch

'Define Data Tables

DataTable(OneMin,True,-1)

DataInterval(0,1,Min,10)

Totalize(1,Rain_in,FP2,False)

EndTable

DataTable(OneDay,True,-1)

DataInterval(0,1440,Min,10)

Minimum(1,BattV,FP2,False,False)

Totalize(1,Rain_in,FP2,False)

EndTable

'Main Program

BeginProg

Scan(5,Sec,1,0)

'Default Data Logger Battery Voltage measurement BattV

Battery(BattV)

'Default Data Logger Wiring Panel Temperature measurement 'PTemp_C'

PanelTemp(PTemp_C,60)

'CS700H Rain Gage measurement Rain_in

PulseCount(Rain_in,1,U1,1,0,0.01,0)

'Call Data Tables and Store Data

CallTable OneMin

CallTable OneDay

NextScan

(p. B-5).

Appendix B. Example Programs

B-4

Page 32

B.2.2 CR1000X Programs for CS700H

CRBasic Example B-5. CR1000X Program Measuring the CS700H

'Program measures one CS700H

EndProg

CAUTION

'Wiring Diagram

'==============

'CS700H

'Wire

'Color Function Terminal

'----- -------- -------'Black Rain signal P1

'White Rain signal ground Ground Symbol

'Clear Shield Ground Symbol

'Declare Variables and Units

Public BattV

Public PTemp_C

Public Rain_in

Units BattV = Volts

Units PTemp_C = Deg C

Units Rain_in = inch

'Define Data Tables

DataTable(OneMin,True,-1)

DataInterval(0,1,Min,10)

Totalize(1,Rain_in,FP2,False)

EndTable

DataTable(OneDay,True,-1)

DataInterval(0,1440,Min,10)

Minimum(1,BattV,FP2,False,False)

Totalize(1,Rain_in,FP2,False)

EndTable

'Main Program

BeginProg

Scan(5,Sec,1,0)

'Default Data Logger Battery Voltage measurement BattV

Battery(BattV)

'Default CR1000 Data Logger Wiring Panel Temperature measurement 'PTemp_C'

PanelTemp(PTemp_C,_60Hz)

'CS700H Rain Gage measurement Rain_in

PulseCount(Rain_in,1,P1,1,0,0.01,0)

'Call Data Tables and Store Data

CallTable OneMin

CallTable OneDay

NextScan

Appendix B. Example Programs

This section includes two CR1000X programs that measure the CS700H heated

tipping bucket rain gage. Both programs measure precipitation (mm), battery

voltage, and panel temperature. The second program also retrieves real time

status information by using SDI-12 protocol.

The CS700H will only communicate over SDI-12 when both

its sensor cable and power cable are connected (TABLE 7-2

and TABLE 7-3

).

B-5

Page 33

CRBasic Example B-6. CR1000X Program Measuring the CS700H and Monitoring Heater

'Program measures one CS700H and monitors heater via SDI-12

SDI12Recorder(Info(),C1,0,"M!",1,0)

'Wiring Diagram

'==============

'CS700H

'Wire

'Color Function Terminal

'----- -------- -------'Black Rain signal P1

'White Rain signal ground Ground Symbol

'Clear Shield Ground Symbol

'Green SDI-12 signal C1

'Red SDI-12 power 12V

'Blue SDI-12 ground G

'Declare Variables and Units

Public BattV

Public PTemp_C

Public Rain_in

Public Info(9)

Alias Info(1)=CS700H_AirTemp 'CS700H air temperature measurement

Alias Info(2)=CS700H_BlockTemp 'Heater block temperature

Alias Info(3)=CS700H_C0_F1 'Temperature units: 0 = deg C, 1 = deg F

Alias Info(4)=CS700H_NoSnow0_Snow1 'Snow detection

Alias Info(5)=CS700H_SnwSnsrActv 'Snow sensor on or off

Alias Info(6)=CS700H_Htr_On_off 'Heater on or off

Alias Info(7)=CS700H_Control_Auto_Man 'Automatic or Manual heater control

Alias Info(8)=CS700H_Cycle_Dis_Ena 'Heater cycle disabled or enabled

Alias Info(9)=CS700H_HTimeLeft 'Heater cycle time left in minutes

Units BattV = Volts

Units PTemp_C = Deg C

Units Rain_in = inch

'Define Data Tables

DataTable(OneMin,True,-1)

DataInterval(0,1,Min,10)

Totalize(1,Rain_in,FP2,False)

Sample(1,CS700H_AirTemp,FP2)

Sample(1,CS700H_BlockTemp,FP2)

Sample(1,CS700H_C0_F1,FP2)

Sample(1,CS700H_NoSnow0_Snow1,FP2)

Sample(1,CS700H_SnwSnsrActv,FP2)

Sample(1,CS700H_Htr_On_off,FP2)

Sample(1,CS700H_Control_Auto_Man,FP2)

Sample(1,CS700H_Cycle_Dis_Ena,FP2)

Sample(1,CS700H_HTimeLeft,FP2)

EndTable

DataTable(OneDay,True,-1)

DataInterval(0,1440,Min,10)

Minimum(1,BattV,FP2,False,False)

Totalize(1,Rain_in,FP2,False)

EndTable

'Main Program

BeginProg

Scan(10,Sec,1,0)

'Default Data Logger Battery Voltage measurement BattV

Battery(BattV)

'Default Data Logger Wiring Panel Temperature measurement 'PTemp_C'

PanelTemp(PTemp_C,_60Hz)

'CS700H Rain Gage measurement Rain_in

PulseCount(Rain_in,1,P1,1,0,0.01,0)

'SDI-12 Sensor measurements

Appendix B. Example Programs

B-6

Page 34

'Call Data Tables and Store Data

CallTable OneMin

EndProg

CallTable OneDay

NextScan

Appendix B. Example Programs

B-7

Page 35

TABLE C-1. CS700H Default Values

CAUTION

Appendix C. CS700H Operation Details

Factory settings have been set to adequately measure

precipitation during cold precipitation events. Changing

these settings is not recommended, and doing so may

change the data outcome or render the sensor inoperable.

TABLE C-1 shows the CS700H factory default settings for adequately

measuring precipitation during cold precipitation. Additionally, the default

setting for the SDI-12 address is zero.

External Control Off (=> Auto) (aX20! Command) = 0

Snow Sensor Enabled (aX22! Command) = 1

Active On Temperature 4 °C (aX23! Command)

Active Off Temperature 5 °C (aX24! Command)

Low Off Temperature –20 °C (aX25! Command)

Funnel Set Point Temp 10°C (aX26! Command)

Snow Run-On Time 18 mins (aX27! Command)

Units °C (aX28! Command) = 0

SDI-12 Address 0

(aAb! Command to change address;

?! Command to query address)

FIGURE C-1. Locations of the CS700H Heater Components

C-1

Page 36

Appendix C. CS700H Operation Details

NOTE

When the CS700H is not active, the status LED flashes every 1.5 s.

When the ambient temperature sensor detects the temperature falling below the

Active On temperature (4 °C) then the system becomes active and the snow

sensor is enabled (FIGURE C-2). The status LED flashes slightly faster at 2

flashes per second—indicating the system is active.

When the proximity sensor detects snow (for 5 s continuously), the heater

elements are turned on and the block temperature sensor is monitored. The

heaters are controlled so that the temperature inside the funnel reaches the Set

Point temperature (10 °C).

The actual block temperature will be higher than the set point as

substantial heat is dissipated.

The lower heating block keeps the tipping bucket and the drain tubes from

freezing up. While the heater elements are turned on, the status LED flashes

even faster at eight flashes per second.

FIGURE C-2. Diagram Depicting Overall Operation

C-2

Page 37

Appendix C. CS700H Operation Details

NOTE

When snow is last detected, a timer is left running to keep the heater cycling so

that any snow built up on the funnel will be melted. The Snow Run-on timer is

factory preset to 18 minutes but may be extended as required.

The heater will cycle on and off for the Run-on time or while ever snow is

detected (see FIGURE C-3).

FIGURE C-3. Diagram showing how the “Snow Run-On” timer controls

the heater.

C.1 High Power Operation

If the snow sensor is disabled (aX22! command set to 0), the heater will cycle

continually when the ambient temperature falls below the Active On

temperature (aX23! command) and is above the Low Off Temperature

(aX25! command). This assumes the system is active. Because this mode

consumes more power, high power operation is only recommended when the

CS700H uses AC power.

C.2 External Control

The CS700H is set to by default to Automatic control – where the CS700H

monitors the ambient temperature and the snow sensor and operates the heater

automatically. Data loggers in weather stations that monitor the ambient

temperature and the snowfall can control the tipping bucket heaters directly.

Set the aX20! command to 1 for External Control, and then use the aX29!

command to enable the heaters to cycle on/off (=1) or disable the cycling (=0).

The ambient temperature, block temperature, snow sensor and state of the

heaters can be measured using the aM!, aR!, or aC! command, as normal.

The Setpoint Temperature is the required temperature of the

funnel – and not the block temperature read from aM! and aR!

commands. The relationship between the funnel temperature,

block temperature and ambient temperature has been determined

through extensive testing.

There is an alternate external control mode, whereby the controlling system can

actually turn the heating elements on and off. This is done using the aX21!

command, with heater on (=1) and heater off (=0).

C-3

Page 38

C.3 Status LED

TABLE C-2. Status LEDs

CAUTION

NOTE

Appendix C. CS700H Operation Details

If the heating elements are left turned on, the funnel

temperature may reach a point where the snow evaporates

before it hits the funnel!

The Status LED, within the ambient temperature sensor probe, flashes to

indicate the mode that the CS700H is in (see TABLE C-2).

Mode Flash Rate Description

Long Flash LED on for 0.5 s Controller powering up.

C.4 Snow Sensor

The snow sensor is actually a capacitive proximity sensor that registers any

material object within a few mm range. The sensor power is turned on and off

to conserve power. TABLE C-3 lists the conditions that power is applied.

The state of the snow sensor (snow detected) is read using the measure (aM!)

and data (aD0!) commands (fourth

The snow sensor must detect snow continuously for 5 s before the

detected flag is set to 1. And conversely, snow must be absent for

5 s continuously before the detected flag is reset to 0. This process

prevents a premature heating cycle when in the automatic mode.

Slow Flash 1 flash every 1.5 s

Medium Flash 2 flashes per second

Fast Flash 8 flashes per second

value).

In standby mode waiting for a

heating cycle.

Within a heating cycle and the

heating elements are presently

turned off. Waiting for snow to be

present before turning on heaters.

Within a heating cycle and the

heating elements are presently

turned on.

C-4

Page 39

Appendix C. CS700H Operation Details

TABLE C-3. Snow Sensor Power Options

TABLE C-4. Operating Modes

Mode (aX20!

command)

Auto

Manual

C.5 Operating Modes

The CS700H can be put into automatic or manual operation modes. TABLE

C-4 describes how the modes are entered and the operation of the modes.

Snow Enabled

aX22! command

0

1

0

1

Description

Snow sensor isn’t powered. Cannot

detect real snow, instead it indicates

snow is always present.

Snow sensor only is powered only

when the ambient temperature is

below the Active On temperature.

Only detects snow when the

temperature is in this range.

Snow sensor isn’t powered. Cannot

detect real snow, instead it indicates

snow is always present.

Snow sensor always is powered, and

can detect snow at any time.

Auto/

Manual

X20

0 X X 1 0 / 1

0 X X 0 1

Cycle

Enable

X29

Heater

On/Off

X21

Snow

Enabled

X22

Snow

Description

Auto Mode:

When the Ambient temperature falls below the

Active On temperature X23, and Snow is

detected, then a Heating Cycle is started. (That

is, the heater elements are switched on and off

to keep inside the funnel at the SetPoint

temperature X26.) This is a low power mode,

as the heater cycle only begins when snow is

detected!

Auto Mode:

Same as the previous, but because the snow

sensor is disabled the snow detected flag is

always set. The Heating Cycle is started when

the Ambient temperature fall below the Active

On temperature X23. This mode uses more

power and should only be used when the

system is supplied by mains power.

C-5

Page 40

Appendix C. CS700H Operation Details

TABLE C-4. Operating Modes

NOTE

Auto/

Manual

X20

1 0 / 1 0 X X

1 0 0 / 1 X X

(X = Don’t Care)

Cycle

Enable

X29

Heater

On/Off

X21

Snow

Enabled

X22

Snow

Description

Manual Mode:

The Cycle Enable flag X29 is used to force a

Heating Cycle. This is set or cleared by another

system at the site – as it determines whether

heating is required. When the Cycle Enable

flag is “0” the heaters are off. When the Cycle

Enable flag is “1” then the Heating Cycle is

started. (That is, the heater elements are

switched on and off to keep inside the funnel at

the SetPoint temperature X26.) The snow

sensor state can be read using the measure/data

commands, but its state is ignored when

controlling the heaters.

Manual Mode:

The heater elements can be controlled directly

with the Heater On/Off flag X21. When the

flag is “0” the heaters are off, and when the

flag is “1” the heaters are on. Note that the

heaters must be cycled by the controlling

system in order to control the funnel

temperature. This mode must be used with

caution!

C.6 SDI-12 Sensor Support

The CS700H will only communicate over SDI-12 when both its

sensor cable and power cable are connected (TABLE 7-2 and

TABLE 7-3

C.6.1 Introduction

SDI-12, Serial Data Interface at 1200 baud, is a protocol developed to simplify

sensor and data logger compatibility. Only three wires are necessary — serial

data, ground, and 12 V. With unique addresses, multiple SDI-12 sensors can

connect to a single SDI-12 terminal on a Campbell Scientific data logger.

This appendix discusses the structure of SDI-12 commands and the process of

querying SDI-12 sensors. For more detailed information, refer to version 1.4 of

the SDI-12 protocol, available at www.sdi-12.org.

For additional information, refer to the SDI-12 Sensors | Transparent Mode

and SDI-12 Sensors | Watch or Sniffer Mode videos.

C.6.2 SDI-12 Command Basics

SDI-12 commands have three components:

).

C-6

Page 41

Appendix C. CS700H Operation Details

TABLE C-5. Campbell Scientific Sensor SDI-12 Command and

Sensor address (a) – a single character and the first character of the command.

Use the default address of zero (0) unless multiple sensors are connected to the

same port.

Command body – an upper case letter (the “command”), optionally followed by

one or more alphanumeric qualifiers.

Command termination (!) – an exclamation mark.

An active sensor responds to each command. Responses have several standard

forms and always terminate with <CR><LF> (carriage return and line feed).

Standard SDI-12 commands are listed in TABLE C-5.

Response Set

Name Command Response1

Acknowledge

Active

Send Identification aI!

a! a<CR><LF>

allccccccccmmmmmmvvvxxx...xx

<CR><LF>

Start Verification aV! atttn <CR><LF>

Address Query ?! a<CR><LF>

Change Address aAb! b<CR><LF>

Start Measurement

Start Measurement

and Request CRC

Start Concurrent

Measurement

Start Concurrent

Measurement and

Request CRC

aM!

aM1!...aM9!

aMC!

aMC1!...aMC9!

aC!

aC1!...aC9!

aCC!

aCC1!...aCC9!

atttn<CR><LF>

atttn <CR><LF>

atttnn<CR><LF>

atttnn<CR><LF>

a<values><CR><LF>

Send Data aD0!...aD9!

or

a<values><CRC><CR><LF>

Continuous

Measurement

aR0!...aR9! a<values><CR><LF>

Continuous

Measurement and

Request CRC

Extended

Commands

1

Information on each of these commands is given in following sections.

aRC0!...aRC9! a<values><CRC><CR><LF>

aXNNN! a<values><CR><LF>

C-7

Page 42

C.6.2.1 Acknowledge Active Command (a!)

The Acknowledge Active command (a!) is used to test a sensor on the SDI-12

bus. An active sensor responds with its address.

C.6.2.2 Send Identification Command (aI!)

Sensor identifiers are requested by issuing command aI!. The reply is defined

by the sensor manufacturer but usually includes the sensor address, SDI-12

version, manufacturer’s name, and sensor model information. Serial number or

other sensor specific information may also be included.

aI! allccccccccmmmmmmvvvxxx...xx<CR><LF>

a Sensor SDI-12 address

ll SDI-12 version number (indicates compatibility)

cccccccc 8-character vendor identification

mmmmmm 6 characters specifying the sensor model

vvv 3 characters specifying the sensor version (operating system)

Up to 13 optional characters used for a serial number or other

xxx…xx

specific sensor information that is not relevant for operation of the

data logger

Appendix C. CS700H Operation Details

<CR><LF> Terminates the response

Source: SDI-12: A Serial-Digital Interface Standard for Microprocessor-Based Sensors

(see Appendix C.6.4, References

C.6.2.3 Start Verification Command (aV!)

The response to a Start Verification command can include hardware

diagnostics, but like the aI! command, the response is not standardized.

Command: aV!

Response: atttn<CR><LF>

a = sensor address

ttt = time, in seconds, until verification information is available

n = the number of values to be returned when one or more subsequent D!

commands are issued

C.6.2.4 Address Query Command (?!)

Command ?! requests the address of the connected sensor. The sensor replies

to the query with the address, a. This command should only be used with one

sensor on the SDI-12 bus at a time.

(p. C-13)).

C.6.2.5 Change Address Command (aAb!)

Multiple SDI-12 sensors can connect to a single SDI-12 terminal on a data

logger. Each device on a single terminal must have a unique address.

C-8

Page 43

Appendix C. CS700H Operation Details

TABLE C-6. Example aM! Sequence

NOTE

A sensor address is changed with command aAb!, where a is the current

address and b is the new address. For example, to change an address from 0 to

2, the command is 0A2!. The sensor responds with the new address b, which in

this case is 2.

Only one sensor should be connected to a particular terminal at a

time when changing addresses.

C.6.2.6 Start Measurement Commands (aM!)

A measurement is initiated with the M! command. The response to each

command has the form atttn<CR><LF>, where

a = sensor address

ttt = time, in seconds, until measurement data is available. When the data is

ready, the sensor notifies the data logger, and the data logger begins issuing D

commands.

n = the number of values returned when one or more subsequent D commands

are issued. For the aM! command, n is an integer from 0 to 9.

When the aM! is issued, the data logger pauses its operation and waits until

either it receives the data from the sensor or the time, ttt, expires.

Depending on the scan interval of the data logger program and the response

time of the sensor, this may cause skipped scans to occur. In this case make

sure your scan interval is longer than the longest measurement time (ttt).

0M!

00352<CR><LF>

The data logger makes a request to sensor 0 to start

a measurement.

Sensor 0 immediately indicates that it will return

two values within the next 35 seconds.

Within 35 seconds, sensor 0 indicates that it has

0<CR><LF>

completed the measurement by sending a service

request to the data logger.

0D0!

0+.859+3.54<CR><LF>

The data logger immediately issues the first D

command to collect data from the sensor.

The sensor immediately responds with the sensor

address and the two values.

C.6.2.7 Start Concurrent Measurement Commands (aC!)

A concurrent measurement (aC!) command follows the same pattern as the

aM! command with the exception that it does not require the data logger to

pause its operation, and other SDI-12 sensors may take measurements at the

same time. The sensor will not issue a service request to notify the data logger

that the measurement is complete. The data logger will issue the aD0!

command during the next scan after the measurement time reported by the

sensor has expired. To use this command, the scan interval should be 10

C-9

Page 44

Appendix C. CS700H Operation Details

TABLE C-7. Example aC! Sequence

seconds or less. The response to each command has the form atttn<CR><LF>,

where

a = the sensor address

ttt = time, in seconds, until the measurement data is available

nn = the number of values to be returned when one or more subsequent D

commands are issued.

See the following example. A data logger has three sensors wired into terminal

C1. The sensors are addresses X, Y, and Z. The data logger will issue the

following commands and receive the following responses:

The data logger makes a request to

XC!

sensor X to start a concurrent

measurement.

Sensor X immediately indicates that

X03005<CR><LF>

it will have 5 (05) values ready for

collection within the next 30 (030)

seconds.

YC!

Y04006<CR><LF>

ZC!

Z02010<CR><LF>

ZD0!

Z+1+2+3+4+5+6+7+8+9+10<CR><LF>

XD0!

The data logger makes a request to

sensor Y to start a concurrent

measurement.

Sensor Y immediately indicates that

it will have 6 (06) values ready for

collection within the next 40 (040)

seconds.

The data logger makes a request to

sensor Z to start a concurrent

measurement.

Sensor Z immediately indicates that it

will have 10 values ready for

collection within the next 20 (020)

seconds.

After 20 seconds have passed, the

data logger starts the process of

collecting the data by issuing the first

D command to sensor Z.

Sensor Z immediately responds with

the sensor address and the 10 values.

10 seconds later, after a total of 30

seconds have passed, the data logger

starts the process of data from sensor

X by issuing the first D command.

X+1+2+3+4+5<CR><LF>

The sensor immediately responds

with the sensor address and the 5

values.

C-10

Page 45

Appendix C. CS700H Operation Details

Ten seconds later, after a total of 40

YD0!

Y+1+2+3+4+5+6<CR><LF>

seconds have passed, the data logger

starts the process of data from sensor

Y by issuing the first D command.

The sensor immediately responds

with the sensor address and the 6

values.

C.6.28 Start Measurement Commands with Cyclic Redundancy Check

(aMC! and aCC!)

Error checking is done by using measurement commands with cyclic

redundancy checks (aMC! or aCC!). This is most commonly implemented

when long cable lengths or electronic noise may impact measurement

transmission to the data logger. When these commands are used, the data

returned in response to D or R commands must have a cyclic redundancy

check (CRC) code appended to it. The CRC code is a 16-bit value encoded

within 3 characters appended before the <CR><LF>. This code is not returned

in the data table but checked by the data logger as it comes. The code returned

is based on the SDI-12 protocol. See the SDI-12 communication specification

for version 1.3 available at www.sdi-12.org to learn more about how the CRC

code is developed.

C.6.2.9 Stopping a Measurement Command

A measurement command (M!) is stopped if it detects a break signal. A break

signal is sent by the data logger before most commands.

A concurrent measurement command (C!) is aborted when another valid

command is sent to the sensor before the measurement time has elapsed.

C.6.2.10 Send Data Command (aD0! … aD9!)

The Send Data command requests data from the sensor. It is issued

automatically with every type of measurement command (aM!, aMC!, aC!,

aCC!). When the measurement command is aM! or aMC!, the data logger

issues the aD0! command once a service request has been received from the

sensor. When the data logger is issuing concurrent commands (aC! or aCC!),