Page 1

CAMPBELL SCIENTIFIC

TDR SOIL MOISTURE MEASUREMENT

SYSTEM MANUAL

REVISION: 2/92

COPYRIGHT (c) 1991, 1992 CAMPBELL SCIENTIFIC, INC.

Page 2

WARRANTY AND ASSISTANCE

The following warranty applies to the

CONTROL MODULE

, and the

SDM1502 COMMUNICATION INTERFACE, PS1502B POWER

SDMX50 50 OHM COAX MULTIPLEXER

.

These products are warranted by CAMPBELL SCIENTIFIC, INC. to be free from defects in materials and

workmanship under normal use and service for twelve (12) months from date of shipment unless specified

otherwise. Batteries have no warranty. CAMPBELL SCIENTIFIC, INC.'s obligation under this warranty is

limited to repairing or replacing (at CAMPBELL SCIENTIFIC, INC.'s option) defective products. The

customer shall assume all costs of removing, reinstalling, and shipping defective products to CAMPBELL

SCIENTIFIC, INC. CAMPBELL SCIENTIFIC, INC. will return such products by surface carrier prepaid.

This warranty shall not apply to any CAMPBELL SCIENTIFIC, INC. products which have been subjected

to modification, misuse, neglect, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied, including warranties of merchantability or fitness for a particular

purpose. CAMPBELL SCIENTIFIC, INC. is not liable for special, indirect, incidental, or consequential

damages.

Products may not be returned without prior authorization. To obtain a Returned Materials Authorization

(RMA), contact CAMPBELL SCIENTIFIC, INC., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please write this number clearly on

the outside of the shipping container. CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

CAMPBELL SCIENTIFIC, INC. does not accept collect calls.

Non-warranty products returned for repair should be accompanied by a purchase order to cover the repair.

815 W. 1800 N.

Logan, UT 84321-1784

USA

Phone (435) 753-2342

FAX (435) 750-9540

www.campbellsci.com

Campbell Scientific Canada Corp.

11564 -149th Street

Edmonton, Alberta T5M 1W7

CANADA

Phone (403) 454-2505

FAX (403) 454-2655

Campbell Scientific Ltd.

Campbell Park

80 Hathern Road

Shepshed, Leics. LE12 9RP

ENGLAND

Phone (44)-50960-1141

FAX (44)-50960-1091

Page 3

TDR SOIL MOISTURE MEASUREMENTS

Warranty and Assistance

TABLE OF CONTENTS

PAGE

1. INTRODUCTION

1.1 Soil Moisture Measurement by Time Domain Reflectometry....................................................1

1.2 Probes and Cables.................................................................................................................... 1

1.3 Multiplexing................................................................................................................................ 1

2. SYSTEM COMPONENTS

3. INSTALLATION

3.1 Assigning Addresses................................................................................................................. 3

3.2 Installing 1502B in ENC TDR....................................................................................................4

3.3 Datalogger Wiring...................................................................................................................... 4

3.3.1 SDM Wiring......................................................................................................................... 4

3.3.2 PS1502B............................................................................................................................. 5

3.4 Soil Probes................................................................................................................................5

3.5 Grounding.................................................................................................................................. 6

3.6 Battery Connections ..................................................................................................................6

4. PROGRAMMING INSTRUCTION 100

5. CALIBRATION FOR WATER CONTENT

6. PROGRAMMING EXAMPLES

6.1 Example 1, Measure and Record Every Hour........................................................................... 8

6.2 Example 2, Hourly Average Using Topp's Calibration............................................................... 9

6.3 Example 3, TDR Measurements in Table 2 with Analog Measurements in Table 1............... 10

........................................................................................................................ 1

....................................................................................................... 2

.......................................................................................................................... 2

................................................................................ 6

.......................................................................... 7

.............................................................................................. 8

TABLES

3-1 SDM Addresses......................................................................................................................... 4

4-1 Waveform Resolution Determined by Probe Length................................................................. 7

FIGURES

2-1 TDR System Components......................................................................................................... 2

3-1 Address Switch on SDM1502....................................................................................................3

3-2 Location of Address Jumpers on SDMX50............................................................................... 3

3-3 Mounting 1502B in ENC TDR....................................................................................................4

3-4 SDM Wiring............................................................................................................................... 5

3-5 PB30 Assembly......................................................................................................................... 5

3-6 Terminal Strip Adapters for Connections to Battery.................................................................. 6

5-1 Comparison of Calibrations from Topp and Ledieu................................................................... 8

Page 4

TDR SOIL MOISTURE MEASUREMENTS

Since the application and advantages of using Time Domain Reflectometry to measure soil water

content were described by Topp, Davis, and Annan in 1980, the method has proven itself through the

work of numerous researchers. Campbell Scientific has developed a system in which the Tektronix

1502B cable tester is coupled with a CR10 or 21X datalogger and multiplexers to provide automated

multiple probe TDR soil moisture measurements.

1. INTRODUCTION

1.1 SOIL MOISTURE MEASUREMENT BY TIME DOMAIN REFLECTOMETRY

A waveform traveling down a coax or

waveguide is influenced by the type of material

surrounding the conductors. If the dielectric

constant of the material is high, the signal

propagates slower. Because the dielectric

constant of water is much higher than most

other materials, a signal within a wet or moist

medium propagates slower than in the same

medium when dry. Ionic conductivity affects the

amplitude of the signal but not the propagation

time. Thus, moisture content can be

determined by measuring the propagation time

over a fixed length probe embedded in the

medium being measured.

This process of sending pulses and observing

the reflected waveform is called Time Domain

Reflectometry (TDR). TDR is also used to

determine the location of failures in

telecommunications cables and, on cables

grouted in boreholes, to monitor rock mass

deformation.

The reflectometer used in our system is the

Tektronix 1502B TDR Cable Tester equipped

with Campbell Scientific's SDM1502

Communications Interface and PS1502B Power

Control Module. The Tektronix 1502C will also

work but cannot use the PS1502B for

controlling power.

1.2 PROBES AND CABLES

The simplest soil probe consists of two parallel

rods inserted into the soil. These are attached

directly to twin lead cable. The two rod probe

and the twin lead cable that attaches to it carry

a "balanced" signal (the signal travels on both

leads).

The 1502B has a 50 ohm coax connector; coax

carries an unbalanced signal. To convert from

an unbalanced to a balanced signal, and to

match impedances, a balancing transformer

(balun) is needed. The PB30B (-RG8 or RG58) is a two rod probe with 30 cm stainless

steel rods; a balun molded into the cable joins

the twin lead cable from the probe to the 1502B

(or multiplexer).

Another type of probe that has come into use

recently is the unbalanced probe. The probe

has three or more rods. A central rod is

connected to the signal lead of the coax. The

other rods are arranged radially around the

center and are connected to the shield of the

coax. The volume of soil sampled with this

configuration is smaller than with a balanced

design and is concentrated around the center

electrode. The probes connect directly to the

50 ohm coax cables used throughout the

system. In dry soils, the unbalanced probe may

produce a wave form that cannot be interpreted

by the algorithm used to determine propogation

velocity for the probe.

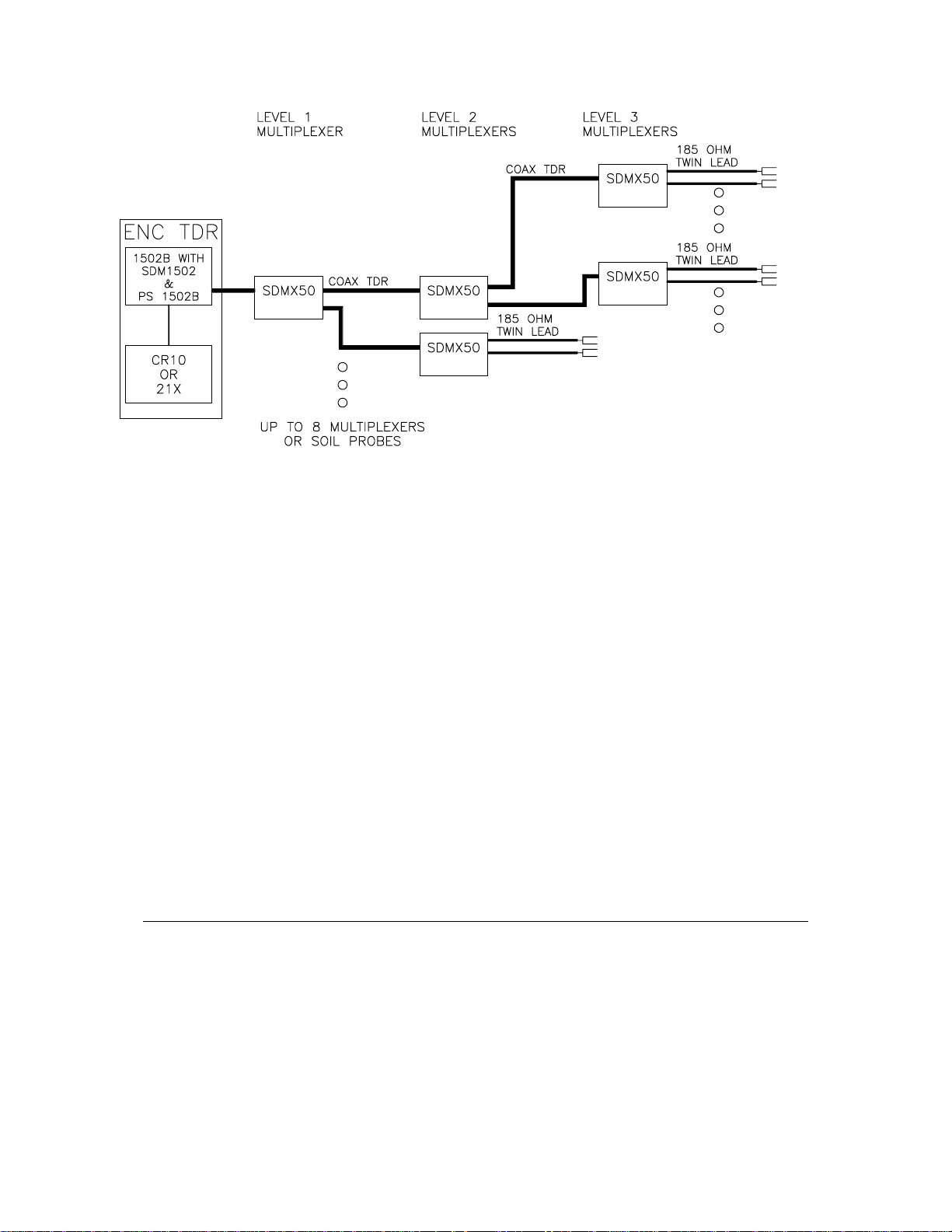

1.3 MULTIPLEXING

The SDMX50 is an eight to one 50 ohm coax

multiplexer with BNC connectors. The coax

cable coming from the 1502B connects to the

common.

The eight multiplexed connections are used to

connect additional multiplexers or probes. The

PB30B connects directly to the SDMX50. Up to

three levels of multiplexers may be used. Up to

512 soil probes may be measured on a fully

expanded system.

1

Page 5

TDR SOIL MOISTURE MEASUREMENTS

FIGURE 2-1. TDR System Components

2. SYSTEM COMPONENTS

1502B - Tektronix 1502B TDR Cable Tester.

SDM1502 - Communication Interface; this module plugs into the 1502B or 1502C and provides

a Synchronous Device for Measurement (SDM) interface to a CR10 or 21X datalogger.

PS1502B Power Control Module plugs into the battery receptacle of the 1502B; provides for

connection to an external 12 VDC source and allows the datalogger to control power to

the 1502B.

SDMX50 - 50 Ohm Coax Multiplexer - 8 to 1, BNC connectors, enclosure included. This

multiplexer is used to connect additional multiplexers or probes. Balanced probes

attached to this multiplexer require a balun for each probe.

PB30B (-RG8 or -RG58) - 30 cm soil probes; two rods, balanced design, with balun molded in

cable. A BNC connector on the coax cable attaches directly to SDMX50. The -RG8

version uses a low loss coax cable. The -RG58 version uses RG58 coax cable.

COAX TDR - 50 ohm coax cable with BNC connectors for connecting multiplexer.

6549 - 5 conductor cable used for SDM connection between datalogger and multiplexers.

21X or CR10 - The datalogger communicates with the 1502B and multiplexers with the SDM

interface using control ports 1-3 (and single ended channel 1 on the 21X). An additional

control port is used to switch power to the 1502B.

ENC TDR - Enclosure to hold 1502B and datalogger. The ENC TDR includes a transient

suppressor and cabling for connecting the power supply and datalogger. The 1502B

mount allows it to swing out to view screen.

Datalogger Software - Special PROMS for the CR10 or 21X datalogger include Instruction 100

for controlling the 1502B and multiplexers.

6590 - Transient suppressor attaches to cable from 1502B and is required if ENC TDR is

purchased.

3. INSTALLATION

The 1502B and datalogger are housed in the

ENC TDR. In most instances power is supplied

from an external 12 volt deep cycle battery

charged by a MSX18R solar panel. Each

SDMX50 multiplexer has its own enclosure.

not

Coax cable connects the 1502B and the

SDMX50 and SDMX50 to other SDMX50s. In

addition to the coax cable that carries the TDR

signal, the multiplexers must be connected to

the datalogger by a 5 conductor cable which

provides power to the multiplexers and allows

the datalogger to control the multiplexer

switching.

2

Page 6

3.1 ASSIGNING ADDRESSES

The SDM1502 and SDMX50 are Synchronous

Devices for Measurement (SDM); the

datalogger communicates with these devices

via control ports 1, 2, and 3 (and analog

channel 1H on the 21X). Addresses set in the

devices allow the datalogger to communicate

with the correct device.

There are sixteen possible addresses; a

maximum of four are used in a TDR system.

The address assigned the SDM1502

determines the addresses that need to be

assigned to the multiplexers: The multiplexer

with its input connected to the cable from the

1502B is level 1, level 2 multiplexers are those

connected to the level 1 multiplexer, level 3

multiplexers are those connected to a level 2

multiplexer. No more than 3 levels of

multiplexers are allowed. The level 1 address is

1 greater than that of the SDM1502. All level 2

multiplexers have the address set to that of the

SDM1502 plus 2 and all level 3 multiplexers

have the address set to that of the SDM1502

plus 3. The addresses are in base 4 (Table 3-

1); for example, if the SDM1502 address is 22,

the addresses for level one, level two, and level

three multiplexers are 23, 30 and 31,

respectively.

The address for the SDM1502 is set with

switches; the switches can be reached through

an access hole in the case (Figure 3-1). Table

3-1 lists the address settings.

TDR SOIL MOISTURE MEASUREMENTS

FIGURE 3-1. Address Switch on SDM1502

The address for the SDMX50 is set with

jumpers. There are two jumpers on each

multiplexer. The jumpers are labeled MSD for

Most Significant Digit and LSD for Least

Significant Digit. Each jumper has four pairs of

pins. Depending which pair of pins is

connected with the jumper, the digit can have

the value of 0, 1, 2, or 3 (Figure 3-2). Table 3-1

lists the address settings.

FIGURE 3-2. Location of Address Jumpers on SDMX50

3

Page 7

TDR SOIL MOISTURE MEASUREMENTS

FIGURE 3-3. Mounting 1502B in ENC TDR

TABLE 3-1. SDM Addresses

ADDRESS SDM1502 SDMX50

Base 4 Switches Jumper Settings

1234 MSD LSD

00 0000 0 0

01 1000 0 1

02 0100 0 2

03 1100 0 3

10 0010 1 0

11 1010 1 1

12 0110 1 2

13 1110 1 3

20 0001 2 0

21 1001 2 1

22 0101 2 2

23 1101 2 3

30 0011 3 0

31 1011 3 1

32 0111 3 2

33 1111 3 3

3.2 INSTALLING 1502B IN ENC TDR

The 1502B is mounted in the ENC TDR

enclosure by removing the handle (the required

Allen wrench is included with the ENC TDR)

and installing as shown in Figure 3-3.

3.3 DATALOGGER WIRING

3.3.1 SDM Wiring

Figure 3-4 shows the wiring of the SDM

communication cables from the SDM1502 and

SDMX50 to the datalogger. With the 21X, the

C1 connection from the SDM1502 must be

wired into analog input 1H with a 10 kilohm

resistor to C1. (This resistor is the short black

cable that is fastened to the SDM1502 handle

with a wire tie for shipping.) The resistor is not

used with the CR10.

The SDM1502 terminals are labeled above

the connector. The description for the

multiplexer terminals is on a label inside the

enclosure lid.

4

Page 8

TDR SOIL MOISTURE MEASUREMENTS

3.3.2 PS1502B

The PS1502B has three connections to the

datalogger: +12, Ground, and a control input

which allows the datalogger to switch the power

to the 1502B. In the example program

(Section 5), the control input is connected to

control port 4.

3.4. SOIL PROBES

The PB30 consists of two 30 centimeter

stainless rods and a twinlead cable. The

probes are shipped without the cable attached.

The rods are attached with the supplied screw

and star washer (Figure 3-5).

The two rods of the probe are pressed into the

soil with the rods parallel. The cable leads allow

the common 5 centimeter rod spacing.

The cable on the probe has a BNC connector

that connects directly to the SDMX50.

FIGURE 3-4. SDM Wiring

FIGURE 3-5. PB30 Assembly

5

Page 9

TDR SOIL MOISTURE MEASUREMENTS

3.5 GROUNDING

The TDR system should be installed with a

single ground point. A good earth ground

should be established close to the

datalogger/1502B.

A copper clad grounding rod comes with the

CM10 tripod or may be obtained along with

necessary clamps and wire from an electrical

supply house.

The ENC TDR has ground connections for the

datalogger, 1502B and 6590 Transient

Suppressor which are connected to a grounding

lug in the lower left corner of the enclosure. A

short run of heavy gage (10 AWG or lower) wire

should be connected from the lug to the earth

ground.

The ground lug on the multiplexer enclosures

should only be used if the multiplexer is close

enough to conveniently use the same ground

point as the datalogger.

3.6 BATTERY CONNECTIONS

Two terminal strip adapters for the battery posts

are provided with the ENC TDR (Figure 3-6).

These terminal strips will mount to the wing nut

battery posts on most deep cycle lead acid

batteries.

Options in instruction allow:

finding a soil moisture probe automatically

or specifying the "distance" to the probe

calculating water content or storing raw

waveform data

the starting point and time resolution of the

raw waveform.

Instruction 100 may also be used to step

through the multiplexers while manually

controlling the 1502B to examine the

waveforms, and to check the signature of the

PROM in the SDM1502

INSTRUCTION 100 PARAMETERS

PAR. DATA

NO. TYPE DESCRIPTION

01: 2 SDM1502 address

02: 2 Output option

0 Water content

1 Raw data

98 Manual step through

99 SDM1502 signature

03: FP Probe length, meters

04: FP Cable length, meters;

enter 0 for auto search

05: 4 Multiplexer channel/Reps

ABCD

A Chan. of 1st Mux, 0 if none

B Chan. of 2nd Mux, 0 if none

C Chan. of 3rd Mux, 0 if none

D No. of Probes to scan

06: 4 Input location

07: FP Multiplier

08: FP Offset

FIGURE 3-6. Terminal Strip Adapters for

Connections to Battery

4. PROGRAMMING INSTRUCTION 100

Instruction 100 is used to make TDR

measurements. A separate Instruction 100 is

entered for each multiplexer that has probes to

be measured or to measure separate groups of

probes on a single multiplexer.

6

Input Locations altered:

Water content - 1 per probe scanned

Raw data - 256 per probe scanned

Intermediate Locations required:

531 the first time Instruction 100 is used

16 intermediate locations for each

Instruction 100 thereafter.

Parameter 1, address: the address set into

the SDM1502 (Section 3.1).

Parameter 2 output option:

"Water Content", Code 0: the instruction

determines the end points of the probe using

the algorithm described by Baker and Allmaras,

Page 10

TDR SOIL MOISTURE MEASUREMENTS

1990, and calculates 1/Vp; the multiplier and

offset (parameters 7 and 8) may be used to

obtain the result directly in volumetric water

content (Section 5).

"Raw data", Code 1: 256 values are output for

each probe measured; the 251 values from the

waveform followed by the distance to the cursor

in meters, the distance between waveform

points, the gain, the offset, and the sample

number.

"Manual Step Through", Code 98: When the

program is compiled and run, the 1502B will be

left under manual control and the datalogger will

switch to the first channel and pause. To switch

to the next channel, set flag 8 (*6 Mode or with

TERM); the datalogger will switch to the next

channel and set flag 8 low. Repeatedly setting

flag 8 allows the user to step through all

programmed channels.

"Signature", Code 99: The signature of the

PROM in the SDM1502 is calculated and stored

in the location specified in parameter 6.

Parameter 3, Probe Length: The length of the

soil probe in meters. This length is used to

calculate the water content result (apparent

length divided by actual length, or 1/Vp), and to

determine the time/length resolution of the

waveform captured for the water content

calculation or raw output.

The probe length parameter is used to set the

resolution of the raw waveform for applications

where there is no actual "probe length". Table

4-1 lists the distance per division used at

different probe lengths.

TABLE 4-1. Waveform Resolution

Determined by Probe Length

Probe Length Distance/Division

0 to 0.02 0.025

0.03 to 0.06 0.05

0.07 to 0.13 0.1

0.14 to 0.2 0.25

0.3 to 0.4 0.5

0.5 to 0.9 1.0

1.0 to 2.0 2.5

2.1 to 4.3 5.0

4.4 to 9.2 10.0

9.3 to 9.9 25.0

> 10.0 50.0

Parameter 4 Cable length: The "length" in

meters to the probe or 1502B cursor. Enter "0"

and the datalogger will automatically search for

the soil probe.

This "length" is not the actual length as

measured with a meter stick; it is the distance

the 1502B measures using a propagating

velocity of 0.99 the speed of light (Vp = 0.99).

When capturing the waveform for raw output or

calculating water content, the cursor (start of

probe) is placed 1 division into the 1502B

display (10 divisions total).

If an automatic search for the soil probe fails,

and it is desired to enter the length to the cable,

it can be determined by manually stepping

through the multiplexer and finding the probe

with the 1502B display.

Parameter 5, Multiplexer channel/Reps:

Determines the multiplexer, first measurement

channel, and number of probes to measure.

The entry required is: channel number on level

1 multiplexer, channel on level 2 multiplexer,

channel on level 3 multiplexer, and number of

probes to measure. For example, 1008 would

indicate that there is 1 multiplexer; start on

channel 1 and step through 8 probes. The entry

2318 tells the datalogger to set the level one

multiplexer to channel 2, the level two

multiplexers to channel 3, and measure 8

probes that are connected to channels 1-8 on

the level 3 multiplexer.

Parameter 6, Input location: The Input

location in which to start storing data. When

outputting water content, one location is used

for each probe measured. When outputting raw

data, 256 locations are required for each

repetition.

5. CALIBRATION FOR WATER CONTENT

When the water content output option is

selected, the datalogger calculates the ratio of

the apparent length of the probe (the 1502B

results are in terms of length) to the actual

length as entered in parameter 3. The

datalogger corrects the length to what it would

be if the propagation velocity was the speed of

light. Thus, the ratio of lengths is the same as

the ratio of the speed of light divided by the

velocity of the signal down the probe.

7

Page 11

TDR SOIL MOISTURE MEASUREMENTS

The propagating velocity, Vp is defined as the

ratio of the actual velocity divided by the speed

of light. The result from the datalogger (with a

multiplier of 1 and an offset of 0) is 1/V

.

p

A multiplier of 0.1138 and an offset of -0.1758

gives volumetric water fraction using the

calibration of Ledieu et. al. 1986 (normalized to

accommodate probes of varying length):

= 0.1138/Vp - 0.1758

W

v

Topp et. al. 1980, used a third order equation to

equate volumetric water content, W

apparent dielectric constant Ka. Ka=(1/V

v

, to

)2;

p

with this substitution, the equation is

= -0.053+0.0292(1/Vp)2-0.00055(1/Vp)

W

v

+0.0000043(1/Vp)

6

4

Example 2 uses Topp's calibration.

0.7

0.6

0.5

0.4

0.3

0.2

0.1

VOLUMETRIC WATER CONTENT

0

1 3 5 7

1/Vp

LEDIEU TOPP

seconds each on subsequent

measurements). The program must be

written so that analog measurements,

output intervals other time based decisions

take this into account.

Switching power to the 1502B is valuable not

only for the conservation of batteries; it also

allows the 1502B to be reset if it should "bomb".

If the 1502B or 1502C does not respond

correctly to the datalogger's commands, -99999

will be loaded into the input locations that would

normally contain the results of the

measurements.

6.1 EXAMPLE 1, MEASURE AND RECORD EVERY HOUR

The following program is executed once an

hour. A single multiplexer with eight probes is

measured. The 1502B is switched on, the

measurements made with output in water

content using Ledieu's calibration, the 1502B is

switched off, and the time and 8 water content

measurements are output to Final Storage.

* 1 Table 1 Programs

01: 3600 Sec. Execution Interval

01: P86 Do

01: 44 Set high Port 4

02: P22 Excitation with Delay

01: 1 EX Chan

02: 0 Delay w/EX (units=.01sec)

03: 500 Delay after EX (units=.01sec)

04: 0 mV Excitation

FIGURE 5-1. Comparison of Calibrations

from Topp and Ledieu

6. PROGRAMMING EXAMPLES

There are several things to keep in mind when

writing a datalogger program to make TDR

measurements:

1. Set the control port high that controls the

PS 1502B 5 seconds prior to executing

Instruction 100. Switch it off after all

measurements are made.

2. TDR measurements require considerably

more time than other measurements

(approximately 1 minute each on the first

pass when finding the probe and 15 to 20

8

03: P100 SDM-1502

01: 11 Address

02: 0 Moisture

03: .3 Probe length (meters)

04: 0 Cable length (meters)

05: 1008 MMMP--Mux channels & Probes

06: 1 Loc [:WATER #1 ]

07: 0.1138 Mult

08: -0.1758 Offset

04: P86 Do

01: 54 Set low Port 4

05: P86 Do

01: 10 Set high Flag 0 (output)

06: P77 Real Time

01: 110 Day,Hour-Minute

Page 12

TDR SOIL MOISTURE MEASUREMENTS

07: P70 Sample

01: 8 Reps

02: 1 Loc WATER #1

08: P End Table 1

* A Mode 10 Memory Allocation

01: 28 Input Locations

02: 540 Intermediate Locations

6.2 EXAMPLE 2, HOURLY AVERAGE USING TOPP'S CALIBRATION

In this example measurements are made every

15 minutes and the average is output each

hour.

Note that Instruction 92, that sets the output

flag, is placed ahead of Instruction 100.

Instruction 92 has to be executed within the

specified minute in order to execute the

command. If it were after Instruction 100, the

actual time of execution would be a minute or

more after the even 15 minute interval on which

the table is executed (i.e., Flag 0 would never

be set).

05: P100 SDM-1502

01: 11 Address

02: 0 Moisture

03: .3 Probe length (meters)

04: 0 Cable length (meters)

05: 1008 MMMP--Mux channels & Probes

06: 1 Loc [:Wv #1 ]

07: 1 Mult

08: 0 Offset

06: P86 Do

01: 54 Set low Port 4

07: P87 Beginning of Loop

01: 0 Delay

02: 8 Loop Count

08: P36 Z=X*Y

01: 1-- X Loc Wv #1

02: 1-- Y Loc Wv #1

03: 1-- Z Loc [:Wv #1 ]

09: P37 Z=X*F

01: 1-- X Loc Wv #1

02: .1 F

03: 1-- Z Loc [:Wv #1 ]

This program uses Topp's calibration. A

multiplier of 1 and an offset of 0 results in output

of 1/Vp from Instruction 100. This result is

squared and multiplied by 0.1 before being

operated on by the polynomial. The factor of

0.1 allows the coefficients for the polynomial to

be scaled so all significant digits can be entered

in the polynomial Instruction 55.

* 1 Table 1 Programs

01: 900 Sec. Execution Interval

Every 15 minutes

01: P92 If time is

01: 0 minutes into a

02: 60 minute interval

03: 10 Set high Flag 0 (output)

02: P77 Real Time

01: 110 Day,Hour-Minute

03: P86 Do

01: 44 Set high Port 4

04: P22 Excitation with Delay

01: 1 EX Chan

02: 0 Delay w/EX (units=.01sec)

03: 500 Delay after EX (units=.01sec)

04: 0 mV Excitation

10: P95 End

11: P55 Polynomial

01: 8 Reps

02: 1 X Loc Wv #1

03: 1 F(X) Loc [:Wv #1 ]

04: -0.053 C0

05: .292 C1

06: -0.055 C2

07: 0.0043 C3

08: 0 C4

09: 0 C5

12: P71 Average

01: 8 Reps

02: 1 Loc Wv #1

13: P End Table 1

* A Mode 10 Memory Allocation

01: 28 Input Locations

02: 550 Intermediate Locations

9

Page 13

TDR SOIL MOISTURE MEASUREMENTS

6.3 EXAMPLE 3, TDR MEASUREMENTS IN TABLE 2 WITH ANALOG MEASUREMENTS IN TABLE 1

This example is for 4 multiplexers. The level 1

multiplexer has a multiplexer connected to each

of channels 1, 2, and 3 and probes connected

to channels 4 through 8. The second level

multiplexers each have 8 probes. The

measurements are made every 30 minutes and

the averages are output every 4 hours.

Placing the TDR measurements in Table 2

allows analog measurements to be made in

Table 1. The analog measurements will

continue to be made during TDR

measurements because Table 1 can interrupt

Table 2.

The interruption cannot take place if the output

flag is set in Table 2. Note that Instruction 92 is

used to set flag 1 every 4 hours prior to making

the TDR measurements. After making the

measurements, flag 1 is checked to see if it is

time for output.

* 1 Table 1 Programs

01: 10 Sec. Execution Interval

Table 1 contains the program for making analog

measurements; for example, a meteorological

station or a number of soil temperatures. The

measurements in Table 1 will be made at their

scheduled interval even while the TDR

measurements are made in Table 2 because

Table 1 can interrupt Table 2.

01: P End Table 1

* 2 Table 2 Programs

01: 60 Sec. Execution Interval

01: P92 If time is

01: 0 minutes into a

02: 30 minute interval

03: 30 Then Do

02: P92 If time is

01: 0 minutes into a

02: 240 minute interval

03: 11 Set high Flag 1

03: P86 Do

01: 44 Set high Port 4

04: P100 SDM-1502

01: 22 Address

02: 0 Moisture

03: .3 Probe length (meters)

04: 0 Cable length (meters)

05: 4005 MMMP--Mux channels & Probes

06: 21 Loc [:MUX 1 #1 ]

07: 0.1138 Mult

08: -.1758 Offset

05: P100 SDM-1502

01: 22 Address

02: 0 Moisture

03: .3 Probe length (meters)

04: 0 Cable length (meters)

05: 1108 MMMP--Mux channels & Probes

06: 26 Loc [:MUX 2-1#1]

07: 0.1138 Mult

08: 0.1758 Offset

06: P100 SDM-1502

01: 22 Address

02: 0 Moisture

03: .3 Probe length (meters)

04: 0 Cable length (meters)

05: 2108 MMMP--Mux channels & Probes

06: 34 Loc [:MUX 2-2#1]

07: 0.1138 Mult

08: 0.1758 Offset

07: P100 SDM-1502

01: 22 Address

02: 0 Moisture

03: .3 Probe length (meters)

04: 0 Cable length (meters)

05: 3108 MMMP--Mux channels & Probes

06: 42 Loc [:MUX 2-3#1]

07: 0.1138 Mult

08: 0.1758 Offset

08: P86 Do

01: 54 Set low Port 4

09: P91 If Flag/Port

01: 11 Do if Flag 1 is high

02: 10 Set high Flag 0 (output)

10: P86 Do

01: 21 Set low Flag 1

11: P77 Real Time

01: 110 Day,Hour-Minute

12: P71 Average

01: 29 Reps

02: 21 Loc MUX 1 #1

10

Page 14

13: P95 End

14: P End Table 2

* A Mode 10 Memory Allocation

01: 50 Input Locations

02: 700 Intermediate Locations

LITERATURE CITED

Baker, J.M. and R.R. Allmaras. 1990.

System for Automating and Multiplexing

Soil Moisture Measurement by TimeDomain Reflectometry.

Society of America Journal

Ledieu, J., P. DeRidder, P. DeClerck and S.

Dautrebande. 1986. A Method of

Measuring Soil Moisture by TimeDomain Reflectometry.

Hydrology

88: 319-328.

Soil Science

54: 1-6.

Journal of

TDR SOIL MOISTURE MEASUREMENTS

Topp, G.C., J.L. Davis, and A.P. Annan.

1980. Electromagnetic Determination

of Soil Water Content: Measurements

in Coaxial Transmission Lines.

Resources Research

16.3: 574-582.

Water

11

Loading...

Loading...