Page 1

INSTRUCTION MANUAL

RWIS Stations

3/05

Copyright (c) 2005

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The RWIS STATIONS are warranted by CAMPBELL SCIENTIFIC, INC. to

be free from defects in materials and workmanship under normal use and

service for twelve (12) months from date of shipment unless specified

otherwise. Batteries have no warranty. CAMPBELL SCIENTIFIC, INC.'s

obligation under this warranty is limited to repairing or replacing (at

CAMPBELL SCIENTIFIC, INC.'s option) defective products. The customer

shall assume all costs of removing, reinstalling, and shipping defective products

to CAMPBELL SCIENTIFIC, INC. CAMPBELL SCIENTIFIC, INC. will

return such products by surface carrier prepaid. This warranty shall not apply

to any CAMPBELL SCIENTIFIC, INC. products which have been subjected to

modification, misuse, neglect, accidents of nature, or shipping damage. This

warranty is in lieu of all other warranties, expressed or implied, including

warranties of merchantability or fitness for a particular purpose. CAMPBELL

SCIENTIFIC, INC. is not liable for special, indirect, incidental, or

consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle repairs

for customers within their territories. Please visit www.campbellsci.com to

determine which Campbell Scientific company serves your country. To obtain

a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container.

CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

CAMPBELL SCIENTIFIC, INC. does not accept collect calls.

Page 3

CS500 Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. General........................................................................1

2. Specifications .............................................................1

2.1 Temperature Sensor ..................................................................................1

2.2 Relative Humidity Sensor .........................................................................2

3. Installation...................................................................2

4. Wiring ..........................................................................6

5. Example Programs .....................................................6

5.1 Example for CR1000 ................................................................................7

5.2 Example for CR10X .................................................................................7

6. Long Lead Lengths.....................................................8

7. Absolute Humidity......................................................9

8. Maintenance..............................................................11

9. References ................................................................11

Figures

1. CS500 and 41301 Radiation Shield on a CM6/CM10 Tripod Mast ...........3

2. CS500 and 41303 Radiation Shield ............................................................4

3. CS500 and 41003 Radiation Shield on a CM6/CM10 Tripod Mast ...........4

4. Radiation Shield, CS500, and 41381 Adapter ............................................5

5. CS500 Wiring .............................................................................................5

Tables

1. Datalogger Connections..............................................................................6

2. Calibration for Temperature .......................................................................6

3. Calibration for Relative Humidity...............................................................6

4. Wiring for CR1000 and CR10X Examples.................................................7

5. CR10(X) Wiring for Example 1..................................................................9

i

Page 4

This is a blank page.

Page 5

RWIS Stations

Campbell Scientific RWIS stations are intended to automatically collect

weather and road information. Standard met sensors are used with surfacespecific sensors to measure additional site conditions. As with all Campbell

Scientific stations, these are configurable by the customer to their

requirements.

RWIS stations conform to national standards defined by the National

Transportation Communications for ITS Protocol (NTCIP). They have

developed standards for implementation of several aspects of RWIS. The

NTCIP guide is available at http://www.ntcip.com/library/guide.asp. The

specification that we conform to is ESS-1204. ESS (Environmental Sensor

Station) is a term that refers to the weather station.

Each station that we supply has the following components listed below.

Power enclosure for the batteries:

Equipment enclosure:

AC recharge

DC recharge/tripod for solar panels

CR10X-2M or CR1000

SDM-SIO4

NL110

Modem

In addition to the standard met sensors, there are options that add function to

the station to allow it to make road-related measurements. Some are listed

below. As with any station, if a customer needs another measurement that they

feel is appropriate, it will be added if possible.

SR50 (acoustic snow sensor)

Lufft IRS21 (road sensor – 2 ea generally)

Present weather (such as Vaisala PWD22)

Camera

107 probes for sub surface temperatures

The purpose for the instruments in the equipment enclosure doesn't need a lot

of explanation with the exception of the SDM-SIO4 and the modem.

The SDM-SIO4 is used primarily for interfacing to the IRS21. The handshake

required to communicate with the sensor doesn’t allow for operation with the

CR10X alone since four control ports are required. In addition, many of the

sensors used with this application have serial interfaces making the SDM-SIO4

a good addition to the application.

The modem used needs an RS-232 interface and also needs to be faster than the

9600 baud offered in Campbell modems. This is due to the requirement for

image retrieval from a camera. If using FTP (desired) to extract an image from

the logger, FTP shuts down before the image can be retrieved.

1

Page 6

RWIS Stations

Theory of operation

The NL110 provides communication for all system devices, converts logger

measurements to NTCIP compliant data, routes images from an installed

camera to the logger, provides SNMP communication, and stores text

generated in the CR10X to text values required by NTCIP.

Customers call in through the modem and establish a PPP connection. This

connection makes a private network and has its own IP address.

The NL110 also provides the necessary function for providing NTCIP

compliant data to ANY NTCIP compliant software that can interrogate NTCIP

compliant systems. This makes the RWIS system compatible with other

systems supplied by other manufacturers.

The logger makes all measurements. As they are made, output is generated

that the NL110 accepts. The NL100 then converts the data to NTCIP

compliant values by changing the variable names to variable names that

comply with the specification.

The camera installed outputs an image automatically on a fixed interval. As

the image is sent, it is routed from the camera to the 10 base t input on the

NL110. The NL110 then routes the image to the logger for later use. One

image is stored in the logger, and when a new image is sent, it replaces the

image last sent.

All sensors have their own measurement instructions, but there are some

unique setups for the equipment installed in the ESS. The following pages

describe those setups.

2

Page 7

RWIS Stations

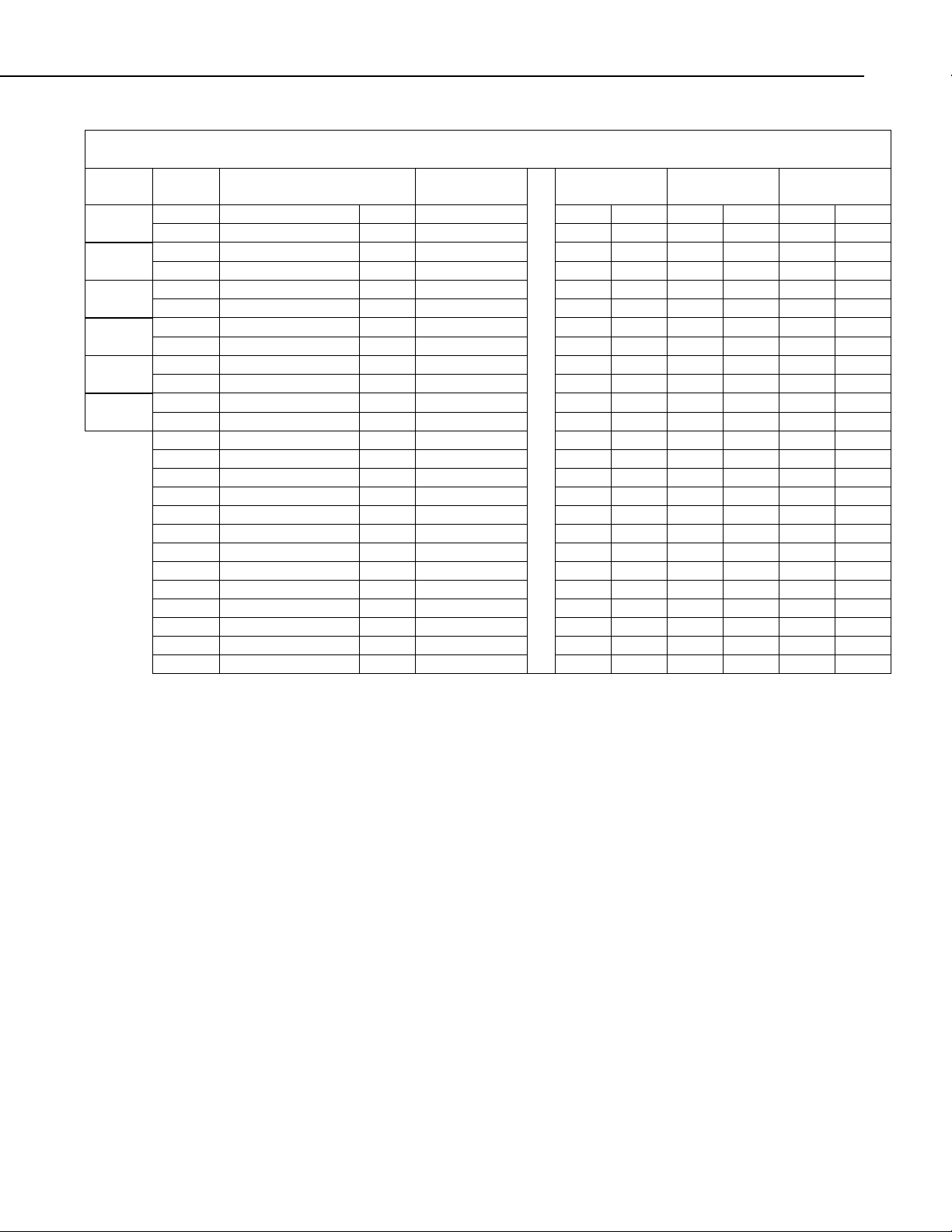

Loggermap

diff

channelsechannel sensor/color function 12v/color AG/color G/color

1 1H humidity

2L Air temp

2 3H open option(oo)

4L wind direction

35H solrad

6L solrad

4 7H sub surface

8L sub surface

5 9H sub surface

10L sub surface

6 11H rain y/n(oo)*

12L rainy/n(oo)*

p1 wind speed

p2 tipping bucket

e1

e2 sub surface

e3 wind direction

c1 sdm-sio4

c2 sdm-sio4

c3 sdm-sio4

c4

c5

c6

c7

c8 snow depth

Logger Setup

The CR10X-2M *D and *A menus set the logger for image collection and pb

operation.

*D15 location 1 is the pakbus address and is set to 1

fill in the remainder of the table with values of 4

*D16 location is the amount of memory to set aside for the image in the logger

and is set to 6

*D18 location is the beacon and is set to 60

*D19 location 01 is set to 17 with nothing after

*A location 6 is set to 3000 for the text values that ess1204 requires

3

Page 8

RWIS Stations

NL110 Setup

NL100/105:

TLink config: [RS232]

RS485 config: [disabled]

CS I/O config: [PakBus]

CS I/O SdcAddr/bps: [SDC7]

CS I/O beacon interval (sec): [60]

RS232 config: [PPP]

RS232 bps: [38k]

EtherNet 10BASE-T: [enabled]

10BASE-T port IP address: [192.168.7.53]

10BASE-T port network mask: [255.255.255.0]

Is there a default gatway: [no]

PakBus node Id: [678]

Clock neighbor node Id: [1]

PakTcp server config: [enabled]

PakTcp server port number: [4001]

PakTcp client config: [disabled]

Configuration monitor telnet port: [23]

Telnet session password: [nl100]

Serial server watchdog (minutes): [2]

Power Saving Mode: [disabled]

MODBUS/TCP gateway config: [disabled]

SNMP Version 2: [enabled]

Logger ID for PakBus: [1]

PMPP PC Address: [50]

Network Address for PPP: [192.168.18.150]

Network Mask for PPP: [255.255.248.0]

PPP Password (Max. 8 characters): [ntcip]

Enable Ethernet Port: [enabled]

Set Modem Answer Rings (1: default): [1]

Modem Initialization: [AT]

NL100/105 (ver, last, curr, show, edit, defaults, reset, help, bye):

4

Page 9

Dial up Setup

RWIS Stations

5

Page 10

RWIS Stations

6

Page 11

RWIS Stations

Collecting the image as data

When FTP cannot be used for image removal from the logger, cora_cmd can

be. In this case the image is treated just like data in that it is downloaded

during a task for routine data removal or by itself in a task. The following

batch files are used. The files in the images below have different names, but

do the same thing. If you’re going to get data and a picture during the same

call, the following set up can be used in the Loggernet tasks.

User may or may not be needed for the function.

All files need to be placed in the programs\campbellsci\loggernet directory

1. connect with rasconnect

2. connect to the station and collect the data

3. execute pictask.bat which in turn calls getpic.txt to retrieve the image

4. disconnect with rasdisconnect

Rasconnect.bat

RASDIAL rwis1 user

Rasdisconnect.bat

RASDIAL rwis1 /DISCONNECT

Getpic.txt

connect localhost;

get-file rwispba dr1 CRD:netca m.jpg.tmp --save-as=c:\ campbellsci \loggernet 3\netcam.j pg;

exit;

pictask.bat

c:\"program files\campbellsci\loggernet3\cora_cmd.exe" <getpic.txt>what.log

7

Page 12

RWIS Stations

8

Page 13

RWIS Stations

9

Page 14

RWIS Stations

FTP image retrieval

To FTP an image from a logger

C:\Documents and Settings\donbrown.CSI-INTRANET>ftp 192.168.18.150

Connected to 192.168.18.150.

220 FTP server ready.

User (192.168.18.150:(none)): ntcip

331 Password required.

Password:ntcip

231 User name accepted.

ftp> get netcam.jpg.tmp netcam.jpg

200 OK.

150 ready to send file.

226 closing.

ftp: 10796 bytes received in 9.92Seconds 1.09Kbytes/sec.

ftp>

10

Page 15

The image is sent to the default directory.

RWIS Stations

CAUTION

Ayantra Modem Setup

Ayantra IML560

Switch Position

1off

2on

3off

4on

5off

6off

7off

8on

9on

10 off

11 off

12 off

The modem is set to 38.4kb to match the speed of the serial port on the NL110.

Be aware that the power connector of t he Ayantra modem

is the same as for our loggers, ex cept th at the con nections

are reversed. Be certain to wire the power of the modem

according to the label on the modem.

11

Page 16

RWIS Stations

Blackbox Modem Setup

Blackbox MD3200A setup for use with Rwis stations

Follow the manual instructions for configuring the modem

Set the following

AT&F1 Sets the default values

ATS0=1 Answers after 1 ring

ATS46=136 Disables compression

AT&D0=0 Ignores DTR

AT&W Writes the changes

Netcam Setup

12

Page 17

RWIS Stations

Troubleshooting

There may be times that a partial image is seen. In this case an image was

being transferred to the logger, and something interrupted it. Calling in during

the image transfer can cause this to happen. Ideally a polled camera would

solve this problem since we could ask for an image with a control port just

before a scheduled call. The problem can be minimized by scheduling image

downloads at times other than scheduled calls. For an hourly schedule, if the

camera is set to 13 minute downloads, interruptions of the image transfer are

very seldom.

13

Page 18

RWIS Stations

If there is a time that the station is called but the authentication fails, the

NL110 is hung and needs to be reset. This can done locally by using the

NL110 configuration menu, or by programming a control port to power rest the

modem on a regular interval. The control port is wired to the SW12V ctrl, and

the NL110 is powered by the SW12V of the CR10X-2M.

If there is a time that the phone lines are good but the connection rings busy,

the modem could be hung and needs to be reset. This, too, can be managed by

a power reset with the modem also being controlled by the SW12V.

Connection speeds for telephones are also a concern in that speeds less that

about 16kb are not practical for image retrieval. Since the modem connects to

the serial port of the NL110 and the maximum speed of the serial port is

33.6kb, a modem with at least that speed is needed. Experience has shown that

with speeds less than about 16kb, FTP times out and there is no image sent.

Possible configurations

There are two verified ways to connect to the RWIS station.

The first is phone modem to NL110. Using the setups described in earlier

sections reliable communication is accomplished.

The second is phone modem to RF400 to NL110. In this case, a null modem is

needed for connection to the base RF400 and the modem. On the logger side a

straight cable is used to connect the RS-232 port of the RF400 to the RS-232

port on the NL110.

Setups for the RF400s are all default with the following exceptions.

Active interface – rs232

Baud rate 38.4 kb

RF_ON 24ma

14

Programming

There are some requirements of ESS-1204 that require special consideration

for the CR10X-2M. They are text and large numbers. Large numbers are

Page 19

RWIS Stations

converted to text with the P190 instruction, and text is created also with the

P190. This is the set settings instruction, and when using this technique the 68

instruction is used to spell out the text. In both cases the form is

variablename=value. There is a limit though to the amount of text that can be

created. Twenty-nine characters maximum are allowed on either side of the

equal sign for CR10X-2M datalogger.

ESS-1204 defines all the measurements to be made. All measurements aren't

required, but values have to be provided for all measurements. If a sensor isn’t

part of a station, the specification requires that a no sensor value be present.

The way that this is done is by writing an initialization subroutine to provide

values for all sensors and creating values that correspond to the type of

measurement. The subroutine is executed one time at startup or when the

program is recompiled. In this way default values are already established. As

sensors are added in the measurement section of the of the program, the

measured values replace the default values in the output.

15

Page 20

RWIS Stations

This is a blank page.

16

Page 21

This is a blank page.

Page 22

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com

info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za

sales@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au

info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br

suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca

dataloggers@campbellsci.ca

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk

sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr

campbell.scientific@wanadoo.fr

Campbell Scientific Spain, S. L.

Psg. Font 14, local 8

08013 Barcelona

SPAIN

www.campbellsci.es

info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...