Page 1

INSTRUCTION MANUAL

RF450 Spread Spectrum Radio

Copyright © 2001- 2015

Campbell Scientific, Inc.

Revision: 4/15

Page 2

Page 3

Limited Warranty

“Products manufactured by CSI are warranted by CSI to be free from defects in

materials and workmanship under normal use and service for twelve months

from the date of shipment unless otherwise specified in the corresponding

product manual. (Product manuals are available for review online at

www.campbellsci.com.) Products not manufactured by CSI, but that are resold

by CSI, are warranted only to the limits extended by the original manufacturer.

Batteries, fine-wire thermocouples, desiccant, and other consumables have no

warranty. CSI’s obligation under this warranty is limited to repairing or

replacing (at CSI’s option) defective Products, which shall be the sole and

exclusive remedy under this warranty. The Customer assumes all costs of

removing, reinstalling, and shipping defective Products to CSI. CSI will return

such Products by surface carrier prepaid within the continental United States of

America. To all other locations, CSI will return such Products best way CIP

(port of entry) per Incoterms ® 2010. This warranty shall not apply to any

Products which have been subjected to modification, misuse, neglect, improper

service, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied. The warranty for installation services

performed by CSI such as programming to customer specifications, electrical

connections to Products manufactured by CSI, and Product specific training, is

part of CSI's product warranty. CSI EXPRESSLY DISCLAIMS AND

EXCLUDES ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. CSI hereby disclaims,

to the fullest extent allowed by applicable law, any and all warranties and

conditions with respect to the Products, whether express, implied or

statutory, other than those expressly provided herein.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an application engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Precautions

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON OR AROUND

TRIPODS, TOWERS, AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES,

ANTENNAS, ETC. FAILURE TO PROPERLY AND COMPLETELY ASSEMBLE, INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS,

TOWERS, AND ATTACHMENTS, AND FAILURE TO HEED WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS

INJURY, PROPERTY DAMAGE, AND PRODUCT FAILURE. TAKE ALL REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS.

CHECK WITH YOUR ORGANIZATION'S SAFETY COORDINATOR (OR POLICY) FOR PROCEDURES AND REQUIRED PROTECTIVE

EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not exceed design

limits. Be familiar and comply with all instructions provided in product manuals. Manuals are available at www.campbellsci.com or

by telephoning (435) 227-9000 (USA). You are responsible for conformance with governing codes and regulations, including safety

regulations, and the integrity and location of structures or land to which towers, tripods, and any attachments are attached. Installation

sites should be evaluated and approved by a qualified engineer. If questions or concerns arise regarding installation, use, or

maintenance of tripods, towers, attachments, or electrical connections, consult with a licensed and qualified engineer or electrician.

General

• Prior to performing site or installation work, obtain required approvals and permits. Comply

with all governing structure-height regulations, such as those of the FAA in the USA.

• Use only qualified personnel for installation, use, and maintenance of tripods and towers, and

any attachments to tripods and towers. The use of licensed and qualified contractors is

highly recommended.

• Read all applicable instructions carefully and understand procedures thoroughly before

beginning work.

• Wear a hardhat and eye protection, and take other appropriate safety precautions while

working on or around tripods and towers.

• Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take

reasonable precautions to secure tripod and tower sites from trespassers.

• Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

• You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are

installing, constructing, using, or maintaining, or a tool, stake, or anchor, come in contact

with overhead or underground utility lines.

• Maintain a distance of at least one-and-one-half times structure height, 20 feet, or the

distance required by applicable law, whichever is greater, between overhead utility lines and

the structure (tripod, tower, attachments, or tools).

• Prior to performing site or installation work, inform all utility companies and have all

underground utilities marked.

• Comply with all electrical codes. Electrical equipment and related grounding devices should

be installed by a licensed and qualified electrician.

Elevated Work and Weather

• Exercise extreme caution when performing elevated work.

• Use appropriate equipment and safety practices.

• During installation and maintenance, keep tower and tripod sites clear of un-trained or non-

essential personnel. Take precautions to prevent elevated tools and objects from dropping.

• Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

• Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks,

frayed cables, loose cable clamps, cable tightness, etc. and take necessary corrective actions.

• Periodically (at least yearly) check electrical ground connections.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS,

THE CUSTOMER ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER INSTALLATION, USE, OR

MAINTENANCE OF TRIPODS, TOWERS, OR ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS,

ENCLOSURES, ANTENNAS, ETC.

Page 6

Page 7

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. General Description .................................................... 1

2. Cautionary Statements ............................................... 1

3. Specifications ............................................................. 1

4. Configuration .............................................................. 2

4.1 Theory of Radio Operation .................................................................. 2

4.2 PakBus Graph ...................................................................................... 3

4.3 Location of the Transceivers ................................................................ 4

4.4 Using the Device Configuration Utility ............................................... 4

4.5 Quick Start ........................................................................................... 7

4.6 Deployment Settings ............................................................................ 8

4.6.1 Active Interface ............................................................................. 8

4.6.2 SDC Address................................................................................. 8

4.6.3 Baud Rate ...................................................................................... 8

4.6.4 RF450 Operation Mode Setting .................................................... 9

4.6.4.1 Operation Mode Description .............................................. 9

4.6.5 Network ID ................................................................................. 10

4.6.6 Frequency Key Setting ................................................................ 10

4.6.7 Repeater Frequency Key Setting ................................................. 10

4.6.8 Transmit Power Setting ............................................................... 10

4.6.9 Low Power Mode Setting ........................................................... 11

4.6.10 Transmit Subnet ID Setting ........................................................ 12

4.6.11 Radio ID Setting ......................................................................... 12

4.7 Master Radio ...................................................................................... 13

4.8 Slave ................................................................................................... 14

4.9 Repeater ............................................................................................. 14

4.10 Power Considerations ........................................................................ 15

5. Antennas ................................................................... 15

6. LoggerNet Software Setup ....................................... 18

7. RF450s with RF401 or CR206(X) in the Same

8. Troubleshooting........................................................ 19

5.1 Antennas for the RF450 Series .......................................................... 15

5.2 Antenna Cables and Surge Protection ................................................ 17

5.2.1 Antenna Cables ........................................................................... 17

5.2.2 Electrostatic Issues ...................................................................... 17

5.2.3 Antenna Surge Protector Kit ....................................................... 17

Network ................................................................... 19

i

Page 8

Table of Contents

Appendix

Installation Scenarios ............................................. A-1

A.

A.1 Example 1: PC-to-RF Network ...................................................... A-1

A.2 Example 2: PC-to-RF Network with Repeater ............................... A-3

A.3 Example 3: PC-to-RF Network with Parallel Repeaters (using

the SubNet ID) ............................................................................. A-5

A.4 Example 4: Phone-to-RF Base ....................................................... A-7

A.5 Example 5: Call-back ..................................................................... A-8

Appendix B. Settings Editor ...................................... B-1

Figures

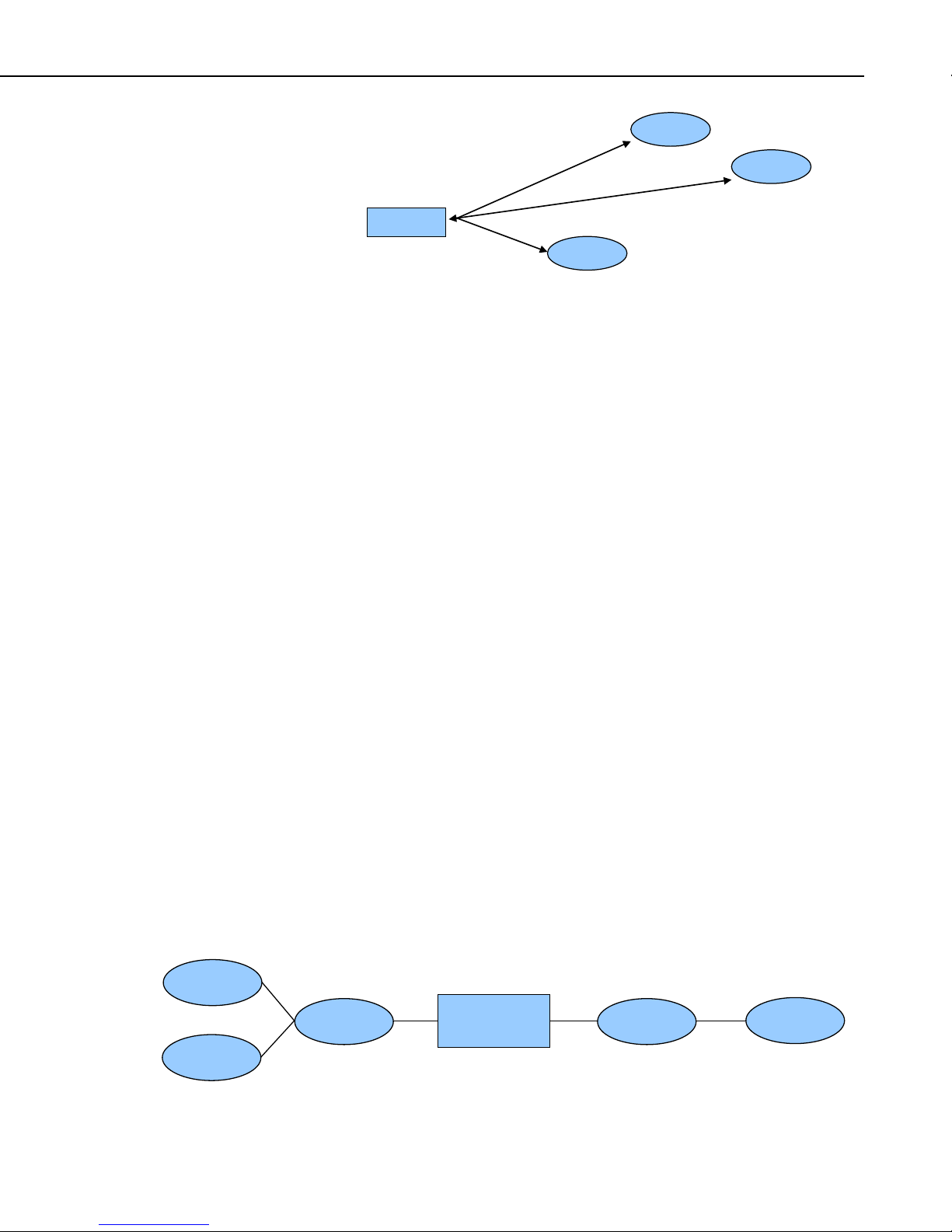

4-1. Simplest Form of a Multi-Point Network ............................................ 3

4-2. Point to Multi-Point Network with Two Routers ................................ 3

4-3. RF450 Point to Multi-Point Network with Two Routers as

Displayed in PakBus Graph ............................................................. 4

4-4. Start-up DevConfig Screen for Configuring the RF450 ...................... 5

4-5. DevConfig Screen Showing the RF450 Settings ................................. 6

4-6. DevConfig RF450 Summary Screen ................................................... 7

4-7. DevConfig Screen Showing Settings for Multi-Point Master ............ 13

4-8. DevConfig Screen Showing Settings for a Slave in a Multi-Point

Network ......................................................................................... 14

4-9. DevConfig Screen Showing Settings for Repeater in a Multi-Point

Network ......................................................................................... 14

6-1. LoggerNet Setup Screen for an RF450 Multi-Point Network ........... 18

8-1. RF450 Front Side View ..................................................................... 19

A-1. Schematic of PC-to-RF450 Network ............................................... A-1

A-2. DevConfig Screen Showing Master Radio Settings for

Example 1 .................................................................................... A-2

A-3. Schematic of PC-to-RF450 Network with Repeater ....................... A-3

A-4. DevConfig Screen Showing Master Radio Settings for

Example 2 .................................................................................... A-4

A-5. DevConfig Screen Showing Slave/Repeater Radio Settings for

Example 2 .................................................................................... A-4

A-6. DevConfig Screen Showing Slave Radio Settings for

Example 2 .................................................................................... A-5

A-7. Schematic of PC-to-RF Network with Parallel Repeaters (using

the SubNet ID) ............................................................................. A-6

A-8. Schematic of Phone-to-RF Base ...................................................... A-7

Tables

4-1. Transmit Power Settings ................................................................... 11

4-2. Low Power Mode Settings ................................................................ 12

4-3. Power Requirements at 12 VDC ....................................................... 15

8-1. Multi-Point Network LED Status ...................................................... 19

A-1. RF450 Settings for Example 1 ........................................................ A-2

A-2. RF450 Settings for Example 2 ........................................................ A-3

A-3. RF450 Settings for Example 3 ........................................................ A-6

A-4. RF450 Settings for Example 4 ........................................................ A-7

ii

Page 9

CAUTION

FCC Notifications

This device complies with part 15 of the FCC rules. Operation is subject to the

following two conditions: 1) This device may not cause harmful interference

and 2) this device must accept any interference received, including

interference that may cause undesired operation. This device must be operated

as supplied by Campbell Scientific, Inc. Any changes or modifications made

to the device without the express written approval of Campbell Scientific, Inc

may void the user's authority to operate the device.

The module number FGR09 has a maximum transmitted

output power of 955mW. It is recommended that the

transmit antenna be kept at least 23cm (approximately 10

inches) away from nearby persons to satisfy FCC RF

exposure requirements.

This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of

the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected

• Consult an experienced radio/TV technician for help

• Consult Campbell Scientific

Page 10

Page 11

RF450 Spread Spectrum Radio

1. General Description

The RF450 Spread Spectrum Radio is a 900 MHz license-free radio

specifically designed to work with Campbell Scientific dataloggers. RF450

radios consist of a FreeWave DGR09 radio module and an interface board.

This manual addresses the RF450’s interface with CR3000, CR1000, and

CR800-series dataloggers and a PC running LoggerNet. Though the radios

may be setup in a point-to-point mode, this manual will only address multipoint applications, as this is the only way to take advantage of the low-power

mode of the Slave radios at the datalogger site. This reduces the required

power at remote sites from about 75 mA to less than 10 mA in most

applications.

2. Cautionary Statements

IMPORTANT — Radios must be configured to use the proper hop table

version to comply with local laws and to avoid interference with other RF

installations such as cellular services. Available hop table versions are listed in

the Device Configuration Utility Settings Editor for the RF450. Hop table

versions include North America (default), Australia, New Zealand, Taiwan,

Brazil, International, and Notch (custom). See Appendix B, Settings Editor

(p. B-1), for more information.

3. Specifications

Frequency: 902 to 928 Mhz

Transmit:

Output Power 5 mW to 1 W, user selectable

Range 60 miles maximum assuming ideal conditions,

line-of-sight, and appropriate antenna. Note

that line-of-sight obstructions, RF interference,

and antenna type will affect transmission

distance. Realistic, reliable distances are

approximately 13 miles.

Modulation Spread spectrum GFSK, 120 or 170 kbps

Spreading Method Frequency hopping

Occupied Bandwidth 230 kHz, at 60 dB

Channel Spacing 230 kHz

Hopping Patterns 15 per band, 105 total, user selectable

Hopping Channels 50 to 112, user selectable

Hopping Bands 7, user selectable

Frequency Zones 16 Zones, 7 Channels per zone

Receive:

Sensitivity -108 dBm for 10-6 bit error rate

-110 dBm for 10-4 bit error rate

Selectivity -20 dB at Fc +/- 115 kHz

-60 dB at Fc +/- 145 kHz

System Gain 140 dB

1

Page 12

RF450 Spread Spectrum Radio

NOTE

Data Transmission:

Error Detection 32 bit CRC, retransmit on error

Data Encryption Substitution, dynamic key

Link Throughput 115.2 kbps, max

Data Interface:

Protocol RS-232, DCE, CS I/O, ME, and SDC;

user selectable

RS-232 Baud Rate: 1200 bps, 4800 bps, 9600 bps, 19.2 kbps,

38.4 kbps, 57.6 kbps, 115.2 kbps;

user selectable

Connectors DB9

Antenna SMA female connector

External antenna required

Power Requirements:

Voltage 7 to 28 Vdc

Current Transmit 500 mA

Receive 76 mA*

Idle 22 mA*

Sleep 7 mA*

Environmental:

Operating Temperature -40° to +75°C

Dimensions 1.44” x 3.17” x 5.70” (3.66 x 8.05 x 14.48 cm)

1.44” x 3.17” x 7.5” (3.66 x 8.05 x 19.05 cm) with

mounting plate

Weight 0.7 lbs (0.3 kg)

Humidity 0 to 95% non-condensing

FCC ID: KNY-6231812519

Canada: 2329B-DGR09RAS

4. Configuration

4.1 Theory of Radio Operation

In a point-to-multi-point network (multi-point network) the transceiver

designated as a Master, is able to simultaneously communicate with numerous

Slaves. In its simplest form, a multi-point network functions with the Master

broadcasting its messages to all Slaves and the Slaves responding to the Master

when given data by the datalogger connected to the data port (see FIGURE 4-1).

There may be only one RF450 Master in a network and it must be

connected to a PakBus router. A PakBus router may be software

such as LoggerNet or PC400 or a datalogger configured as a

router.

2

Page 13

RF450 Spread Spectrum Radio

Master

Slave

Slave

Slave

[4] Site4

[5] Site

5

[2] Site2

[4094]

LN Server

[1] Site1

[3

] Site

3

FIGURE 4-1. Simplest Form of a Multi-Point Network

In a multi-point network, outbound packets from the Master or repeater to

Slaves or other repeaters are sent a set number of times determined by the user.

The receiving transceiver, Slave or repeater, will accept the first packet

received with the correct signature (32 bit CRC). However, the packet is not

acknowledged. On the return trip to the Master, all packets sent are

acknowledged or retransmitted until they are acknowledged. Therefore, the

return link in a multi-point network is generally very robust.

Traditionally, a multi-point network is used in applications where data is

collected from one to many dataloggers and reported back to one central site.

The central site is typically a PC running LoggerNet, but could be a datalogger.

Refer to Appendix A, Installation Scenarios

scenarios.

(p. A-1), for different installation

Though the radios may be setup in a point-to-point mode, this manual will only

address multi-point applications, as this is the only way to take advantage of

the low-power mode of the Slave radios at the datalogger site. This reduces the

required power at remote sites from about 75mA to less than 10mA in most

applications.

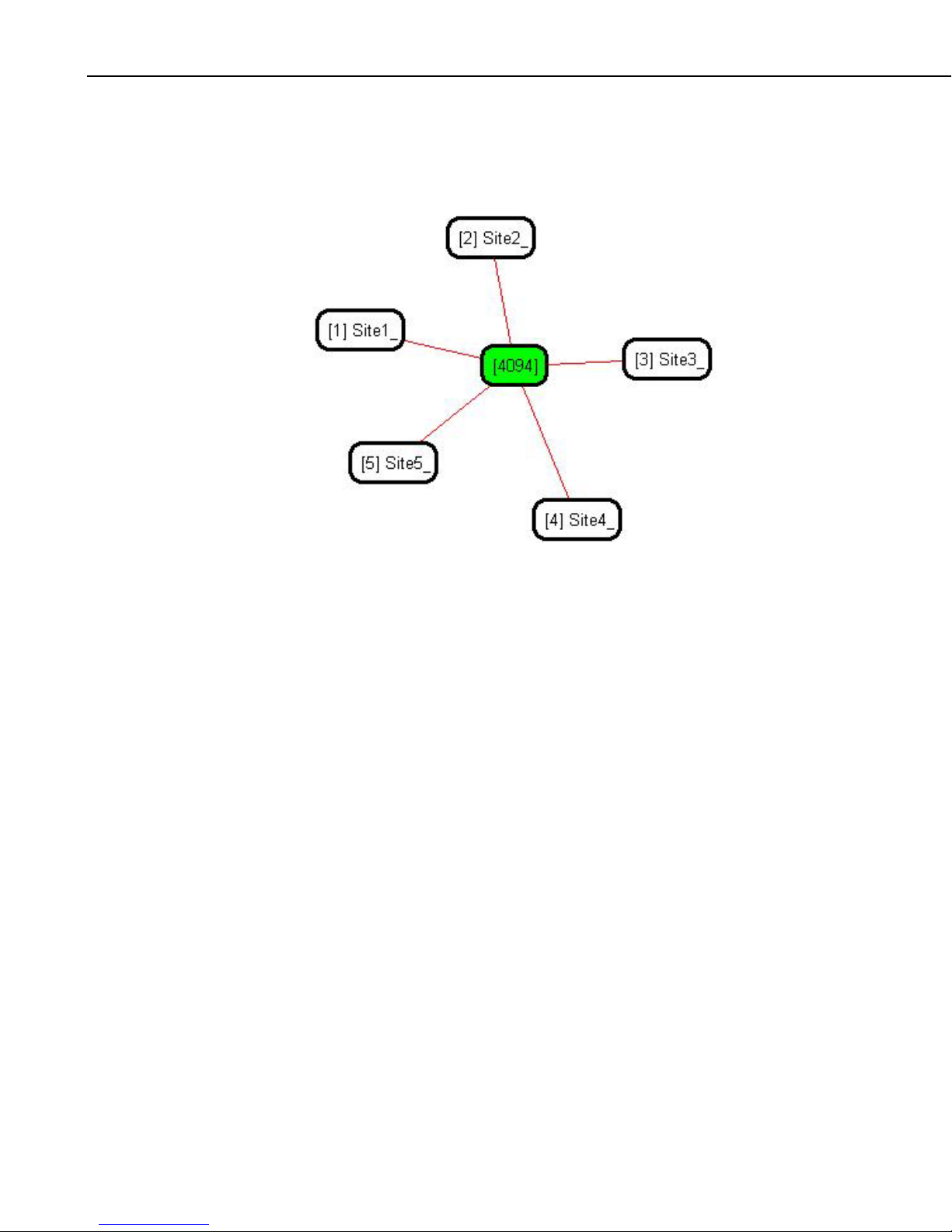

4.2 PakBus Graph

PakBus Graph is a LoggerNet utility that graphically depicts the devices and

connections in a PakBus datalogger network. In PakBus graph, the LoggerNet

server is typically represented by PakBus address 4094, and each of the

PakBus dataloggers that have been configured in Setup will be shown by the

PakBus address in brackets followed by its name assigned through LoggerNet

setup.

Because RF450 networking protocols are used to direct packets, not PakBus

protocols, the network's representation in PakBus Graph may be significantly

different than one would expect. FIGURE 4-2 depicts the physical network of

six dataloggers and one LoggerNet server. Dataloggers numbered 1 and 2

route packets to other dataloggers from the LoggerNet server.

FIGURE 4-2. Point to Multi-Point Network with Two Routers

3

Page 14

RF450 Spread Spectrum Radio

This same network will be depicted in PakBus Graph as shown in FIGURE

4-3. Dataloggers numbered 1 and 2 have RF450 radios configured as

Slave/Repeaters. The RF450 radios are doing the networking, not the PakBus

dataloggers.

FIGURE 4-3. RF450 Point to Multi-Point Network with

Two Routers as Displayed in PakBus Graph

4.3 Location of the Transceivers

Placement of the radio is likely to have a significant impact on its performance.

The key to the overall robustness of the radio link is the height of the antenna.

4.4 Using the Device Configuration Utility

Radios are configured using the CSI Device Configuration Utility (DevConfig)

software tool that comes with LoggerNet (see FIGURE 4-4). To avoid COM

port conflict, DevConfig is usually run when LoggerNet is shut down, and vice

versa. The following general procedure is used to configure the RF450 radios

via DevConfig:

1. Launch DevConfig by double clicking the icon on the Windows Desktop

or through the Windows Start Menu | Start | All Programs | LoggerNet |

Device Configuration Utility.

2. From the Device Type list, select the RF450. Information, instruction and

help are provided on each screen.

4

Page 15

RF450 Spread Spectrum Radio

FIGURE 4-4. Start-up DevConfig Screen for Configuring the RF450

3. Select the correct COM port for serial communications with the radio.

4. Power the RF450 radio by using the power plug or by using the SC12

cable to connect the radio’s CS I/O port to the datalogger’s CS I/O port.

5. Connect an RS-232 or USB-to-RS-232 cable between the RF450 and PC.

6. Click Connect then press the green “setup” button located on the side of

the RF450 between the RS-232 and power ports. The radio CD and CTS

LEDs should turn green. After several seconds, a screen similar to

FIGURE 4-5 will appear:

5

Page 16

RF450 Spread Spectrum Radio

FIGURE 4-5. DevConfig Screen Showing the RF450 Settings

Deployment, Settings Editor, Terminal, and Send OS tabs are available. The

Deployment tab contains all the standard parameters that need to be set for a

PakBus network. The Settings Editor or Terminal tabs may be used to access

all of the FreeWave Radio settings. They should be used by experienced

FreeWave Radio users only. New operating systems for the CSI board are

loaded through the Send OS tab.

DevConfig makes applying the same settings to multiple devices easy. Once

settings are configured for one device, click the Apply button; a summary

screen similar to FIGURE 4-6 will show. Click the Save button to save a

configuration file. This file can then be used to load the settings into another

RF450. Click the Read File button to load the settings in DevConfig then the

Apply button to load the settings into the RF450.

6

Page 17

RF450 Spread Spectrum Radio

FIGURE 4-6. DevConfig RF450 Summary Screen

4.5 Quick Start

1. Using DevConfig, set a unique PakBus Address for each datalogger in the

2. Decide on a unique Network Identification Number between 0 and 4095,

3. Select a Frequency Key Number between 0 and 14. It is recommended

4. Select one radio to be the Master; the others will be designated as Slaves.

5. Slave Radios: Using DevConfig, set the “Radio Operation Mode” to

network. Keep the other settings as their default.

excluding 255. All radios in the network will have the same Network ID.

that you change this from 5 which is the default. Generally all radios in

the network will have the same Frequency Key.

Multi-Point Slave. Set the Network ID to the number decided upon in step

2 above. Set the Frequency Key to the number decided upon in step 3

above. Set the Radio ID to the PakBus Address assigned in step 1 above.

Keep the remaining settings as their defaults. (See note below regarding

repeaters.)

7

Page 18

RF450 Spread Spectrum Radio

NOTE

NOTE

4.6 Deployment Settings

4.6.1 Active Interface

6. Master Radio: Using DevConfig, set the “Radio Operation Mode” to

Multi-Point Master. Set the Network ID to the number decided upon in

step 2 above. Set the Frequency Key to the number decided upon in step 3

above. Set the Radio ID to the PakBus Address assigned in step 1 above.

Keep the remaining settings as their defaults. (See note below regarding

repeaters.)

7. Select a datalogger, or PC running LoggerNet, to be a router. Using

DevConfig, set this node to beacon. Attach the Master Radio to this node.

If RF450 repeaters will be used, select Multi-Point Slave/Repeater

as the Radio Operation Mode. Check the “Repeaters Used” box

for all radios in the Network.

See Appendix A, Installation Scenarios (p. A-1), for example radio

settings in different network configurations.

Specify the interface that will be used for normal operations. The following

active interfaces are available:

• Auto-Sense: The RF450 will choose between the RS-232 port and the

• RS-232: The RS-232 port is used at the baud rate selected.

• CS I/O SDC: The CS I/O port is used, and configured as SDC at the SDC

• CS I/O Modem Enable: The CS I/O port is used, and configured as

• ME Master: The CS I/O port is used, and configured for direct connection

4.6.2 SDC Address

Specifies the SDC address that will be used on the RF450 CS I/O port when

CS I/O SDC or Auto-Sense is selected as the active interface.

CS I/O SDC, depending upon whether the +5 V line of the CS I/O port is

present.

Address selected.

Modem Enable at the baud rate selected.

to a CSI COM200, COM210, COM220, or other ME configured device

(MD485, RF416, etc.). The connection is a type of "null modem" that

crosses TX & RX, and ME & RING; this line swapping is done by using

an A100. The baud rates of both the COM2xx (or other device) and

RF450 must be the same.

4.6.3 Baud Rate

Specifies the baud rate that will be used on the RS-232 port or CS I/O ME port.

8

Page 19

4.6.4 RF450 Operation Mode Setting

The Operation Mode option designates the method FreeWave transceivers use

to communicate with each other. FreeWave transceivers operate in a Masterto-Slave configuration. Before the transceivers can operate together, they must

be set up to properly communicate.

In a point-to-point configuration, Master or Slave mode may be used on either

end of the communication link without performance degradation. When

setting up the transceiver, remember that a number of parameters are controlled

by the settings in the Master. Also, radio network diagnostics can only be

accessed at the Master radio. Therefore, we suggest you deploy the Master on

the communications end where it will be easier to access.

For a datalogger PakBus network, the multi-point radio modes should be used.

For other configurations, the Operation Mode will need to be set through the

Settings Editor tab.

4.6.4.1 Operation Mode Description

Point-to-MultiPoint Master

This mode designates the transceiver as a Master in multi-point mode. This

mode allows one Master transceiver to simultaneously be in communication

with numerous Slaves and repeaters. A point-to-multi-point Master

communicates only with other transceivers designated as point-to-multipoint

Slaves or point-to-multipoint repeaters.

RF450 Spread Spectrum Radio

Point-to-MultiPoint Slave

This mode designates the transceiver as a Slave in multi-point mode. This

mode allows the Slave to communicate with a multi-point Master. The Slave

may communicate with its Master through one or more repeaters.

Point-to-MultiPoint Repeater

This option allows the transceiver to operate as a repeater in a multi-point

network.

Point-to-MultiPoint Slave/Repeater

This option allows the transceiver to operate as a repeater and a Slave in a

multi-point network. The radio will repeat packets sent across the network as

well as use the active interface. Choosing this setting effectively sets the

operation mode to multi-point repeater and sets the Slave/repeater mode.

Repeaters Used Setting

In a multi-point network, it is critical to transmission timing to configure this

parameter correctly. This box should be checked (set to 1 in Settings Editor) if

there are any repeaters in the network. It should be left unchecked (set to 0 in

Settings Editor) if there are no repeaters present.

This parameter should be set to the same value in all transceivers in a multipoint network.

9

Page 20

RF450 Spread Spectrum Radio

NOTE

NOTE

NOTE

4.6.5 Network ID

4.6.6 Frequency Key Setting

This box should be checked (set to 1 in Settings Editor) when

running diagnostics from the Master.

All radios in a multi-point network need to have the same Network ID. The

value must be between 0 and 4095 (excluding 255). The ID of 255 is reserved

for point-to-point networks.

Slaves will link with the first Master or repeater that it hears with a matching

Network ID. Assigning a unique Network ID will reduce the chance a radio in

your network links with another, unrelated, network in the same RF area.

If necessary, the Network ID function can be used in conjunction with the

SubNet ID feature.

The Frequency Key determines the frequency hopping sequence of the

transceiver. There are 15 choices available (0-14) which represent 15 unique

pseudo-random hop patterns. This setting allows you to minimize RF

interference with other FreeWave transceivers operating in the same RF area.

The Frequency Key setting should be the same for all radios in the

entire network. The exception to this is if the Repeater Frequency

Key setting is used. If this is used, the Repeaters' Frequency Key

would be different from the Master radio, and downstream radios

intended to connect to the repeater would have the same

Frequency Key setting (as the repeater).

4.6.7 Repeater Frequency Key Setting

This is a setting that is only used by repeaters. The Repeater Frequency Key

must be checked when you want a repeater to use a Frequency Key other than

that of the Master.

This is useful when there are parallel repeaters in a network, and you want to

force communication through a particular repeater. When this setting is used,

the repeater will receive on the Frequency Key of the upstream Master (or

repeater), and transmit on its Frequency Key setting (which typically is set to a

different value than the Master’s).

The default setting of box not checked (Use Master Frequency) causes the

repeater to transmit on the Master’s Frequency Key.

When this setting is not used, the Frequency Key setting should

match that of the Master or of the repeater acting as the Master for

that transceiver.

4.6.8 Transmit Power Setting

This setting specifies the RF transmit power. Use a transmit power of 0 when

bench testing to reduce RF exposure.

10

Page 21

RF450 Spread Spectrum Radio

TABLE 4-1. Transmit Power Settings

RF Transmit

Power Setting

RF Power (dBm)

RF Power (mW)

10

30.5

1122

9

30.0

1000

8

29.5

891

7

28.8

759

6

27.4

550

5

26.4

437

4

24.4

275

3

21.5

141

2

18.2

66

1

12.3

17

0

7.5

6

The FCC specifies a maximum EIRP (Effective Isotropic Radiated Power) of

36 dBm.

EIRP = (Transmitter Power) + (Antenna Gain) - (Cable Losses) [all in dB or

dBm]

The RF450 maximum power is 30.5 dBm; therefore, a 6 dB (or lower) gain

antenna can be used with any Transmit Power setting. If higher gain antennas

are used, the cable loss will need to be determined, and the Transmit Power

adjusted so as not to exceed the FCC limit of 36 dBm.

Note that lower transmit power can be used (to conserve battery power) if the

required range allows it.

TABLE 4-1 shows the RF450 RF transmit power versus the setting.

4.6.9 Low Power Mode Setting

This setting allows a multi-point Slave to consume less power. This is

achieved primarily by dimming the transceiver's LEDs. When set to 2 through

31, the transceiver will sleep between slots. For example, at a setting of 2 the

transceiver sleeps 1 out of 2 slots; at a setting of 3 the transceiver sleeps 2 out

of 3 slots, and so on.

TABLE 4-2 shows the changes at different low power mode settings. The

actual current draw depends on many factors. The table below gives only a

qualitative indication of supply current savings. A low number reduces latency

and a high number reduces current consumption. An optimum setting

(balancing latency and power savings) is 2 or 3.

11

Page 22

RF450 Spread Spectrum Radio

TABLE 4-2. Low Power Mode Settings

Setting

Description

0

Low Power, disabled

1

LEDs dimmed, transceiver remains awake, transceiver is listening

to the Master's transmissions on every slot.

2

LEDs dimmed, transceiver sleeps every other slot

3

LEDs dimmed, transceiver sleeps 2 of 3 slots

4-31

LEDs dimmed, transceiver sleeps the number of slots

slots.

NOTE

NOTES

4.6.10 Transmit Subnet ID Setting

corresponding to the setting.

For example, with a setting of 31 the transceiver sleeps 30 of 31

Low power mode is used only in multi-point Slaves. Power

savings occur only when the Slave is linked. There are no power

savings when the Slave is transmitting data. Low power mode is

of little value when a Slave has a constant, high throughput.

In a multi-point network, a Slave or repeater will connect with the first repeater

or Master that it hears with the same Network ID. There are scenarios,

however, where communications need to be forced to follow a specific path.

For instance, the Subnet ID is particularly helpful to force two repeaters in the

same network to operate in series rather than in parallel; or, if desired, to force

Slaves to communicate to a specific repeater for load balancing purposes.

There are two components to the Subnet ID:

1. Receive Subnet ID. This setting identifies which transceiver a repeater or

Slave will listen to.

2. Transmit Subnet ID. This setting identifies the Network ID on which this

device transmits, and in turn which devices will listen to it. This setting is

only relevant to repeaters in multi-point networks.

The default setting for both receive and transmit is 15 which disables

SubNetwork functions. For the Master, this setting (15) causes the Master to

actually use 0. So, if the Subnet ID is to be used, the downstream radios that

need to connect to the Master will need their Receive Subnet ID set to 0.

Changing these settings on the Master is not recommended, under

normal circumstances. The Receive Subnet ID on the Master has

no effect on the network. If both Receive Subnet ID and Transmit

Subnet ID are set to 0, a mobile Slave can roam from subnet to

subnet and possibly from network to network.

4.6.11 Radio ID Setting

This setting allows a transceiver to be designated with an arbitrary, userselectable, 4-digit number which identifies the transceiver in diagnostics mode.

When used in conjunction with PakBus dataloggers, it is recommended that

12

Page 23

this value be assigned the PakBus address of the station. This is because the

NOTE

radio ID appears in the FreeWave diagnostics program, and allows the user to

associate a particular datalogger with its attached radio.

To further this association of the RF450 RF network with the PakBus network,

the dataloggers (CR1000, CR800, etc.) read the serial number of the attached

radio and include this in the datalogger settings when the CS I/O SDC interface

is used. This serial number is the main radio identifier used by the FreeWave

Diagnostics program.

4.7 Master Radio

A multi-point network may only contain a single Master radio. Slave radios

communicate from and to the Master radio.

The Master RF450 must be connected to a PakBus router. A

PakBus router may be software such as LoggerNet or PC400 or a

datalogger configured as a router.

Selecting “Multi-Point Master” in the Radio Operation Mode designates the

transceiver as a Master in multi-point mode. This mode allows one Master

transceiver to simultaneously be in communication with numerous Slaves and

repeaters. A point-to-multipoint Master communicates only with other

transceivers designated as point-to-multipoint Slaves or point-to-multipoint

repeaters.

RF450 Spread Spectrum Radio

One setting, Low Power Mode, is not applicable to Master radios, thus is

greyed out in DevConfig (see FIGURE 4-7).

FIGURE 4-7. DevConfig Screen Showing Settings for Multi-Point

Master

13

Page 24

RF450 Spread Spectrum Radio

4.8 Slave

Radios configured as Slaves in a multi-point network are allowed to

communicate with a multi-point Master (see FIGURE 4-8). The Slave may

communicate with its Master through one or more repeaters.

4.9 Repeater

FIGURE 4-8. DevConfig Screen Showing Settings for a Slave in a

Multi-Point Network

Setting the Radio Operation Mode to “Multi-Point Repeater” allows the

transceiver to operate as a repeater in a multi-pPoint network. The “Repeaters

Used” box should be checked if there are any repeaters in the network; it

should be set the same for all transceivers in a multi-point network (see

FIGURE 4-9).

FIGURE 4-9. DevConfig Screen Showing Settings for Repeater in a

14

Multi-Point Network

Page 25

4.10 Power Considerations

TABLE 4-3. Power Requirements at 12 VDC

Transmit current, for 1 W power at 100% duty cycle

500 mA

Receive current

75 mA

Idle current

21 mA

Sleep current

6 mA

NOTE

The RF450 radio requires 6 to 30 VDC power. This may be supplied through

either a wall charger (CSI part number 15966) connected to the DC power jack

on the side of the radio or through the datalogger via the CS I/O port.

Networks configured in multi-point mode take advantage of the low power

mode of the Slave radios at the datalogger site. This reduces the required

power at remote sites from about 75mA to less than 10 mA in most

applications. Power savings occur only when the Slave is not transmitting

data. Also, low power mode is of little value when a Slave has a constant, high

throughput. Master and repeater radios do not go into a low power mode.

RF450 power requirements in the various states of operation are listed in

TABLE 4-3.

For help with determining a power budget and solar panel sizes for remote

sites, see the Campbell Scientific Application Note titled “Power Supplies”

available from our web site:

http://www.campbellsci.com/documents/apnotes/pow-sup.pdf

RF450 Spread Spectrum Radio

.

5. Antennas

5.1 Antennas for the RF450 Series

Several antennas are offered to satisfy the needs for various Master and Slave

requirements. These antennas have been tested at an authorized FCC openfield test site and are certified to be in compliance with FCC emissions limits.

The use of an unauthorized antenna could cause transmitted field strengths in

excess of FCC rules, interfere with licensed services, and result in FCC

sanctions against user.

An FCC authorized antenna is a REQUIRED component. You

must pick one of the antennas listed below.

Omnidirectional antennas are normally used at the base station and nearby

stations. Yagi antennas are needed at distant stations or other special cases.

Call one of our Applications Engineers for help in choosing an antenna. Only

the following FCC approved antennas can be used.

15

Page 26

RF450 Spread Spectrum Radio

Indoor, Omnidirectional

19512 0 dBd, ½ wave whip. SMA connector attaches directly to

the radio; no antenna cable is needed.

20644 1 dBd, dipole, with window/wall mount. The antenna is

shipped with a 79 in. cable that has an SMA male

connector that attaches to the radio.

Outdoor, Omindirectional

14221 3 dBd with rugged FM2 antenna mounts and a Type N

female connector. It requires an antenna cable to connect

to the radio.

Outdoor, Yagi

14201 9 dBd, with mounts and a Type N female connector. It

requires an antenna cable to connect to the radio. Please

note that because the FCC limits EIRP to36 dBm, use of this

antenna may require a reduction of the RF450’s transmit

power.

Antenna Cables and Surge Protectors for Outdoor

Antennas

Recommended for cable lengths less than 10 ft.

COAXSMA-L LMR195 antenna cable with type SMA to type N Male

Connector

Recommended for cable lengths greater than 10 ft and/or use with

lightning protection

COAXNTN-L Low-loss (4.1 dB/100 ft) RG8 antenna cable with type N

male to type N male connectors (requires 19533 surge

protector). Specify length, in feet, after the L.

19533 Surge Suppressor that is recommended when the length of

the antenna cable is greater than 10 feet. The surge

suppressor helps protect the radio from electrical

discharge being conducted down the antenna cable. It

includes a COAXSMA-L1.5 cable and requires the

COAXNTN-L antenna cable.

Additional Accessories

15966 AC Wall charger for base station radio

14291 Optional DC power cable

18663 Null modem cable used to connect the radio to the RS-

232 port on the datalogger.

CM230 Adjustable Angle Mounting Kit for attaching an outdoor

antenna to a tripod or tower.

20625 FreeWave Diagnostics cable and Software CD

16

Page 27

FCC OET Bulletin No. 63 (October 1993)

CAUTION

Changing the antenna on a transmitter can significantly increase, or decrease,

the strength of the signal that is ultimately transmitted. Except for cable

locating equipment, the standards in Part 15 are not based solely on output

power but also take into account the antenna characteristics. Thus, a low

power transmitter that complies with the technical standards in Part 15 with a

particular antenna attached can exceed the Part 15 standards if a different

antenna is attached. Should this happen it could pose a serious interference

problem to authorized radio communications such as emergency, broadcast,

and air-traffic control communications.

In order to comply with the FCC RF exposure requirements,

the RF450 series may be used only with approved

antennas that have been tested with this radio and a

minimum separation distance of 20 cm must be maintained

from the antenna to any nearby persons.

5.2 Antenna Cables and Surge Protection

5.2.1 Antenna Cables

RF450 Spread Spectrum Radio

The 14201, 14221, 19512, and 20XXX antennas require an antenna cable;

either (1) the COAXSMA-L cable or (2) the COAXNTN-L cable with surge

protector. Indoor omnidirectional antennas are either supplied with an

appropriate cable or connect directly to the radio.

5.2.2 Electrostatic Issues

Many RF450 series installations are out of doors and therefore susceptible to

lightning damage, especially via the antenna system. Also, depending on

climate and location, electro-statically charged wind can damage sensitive

electronics if sufficient electric charge is allowed to accumulate on the antenna

and cable. To protect against this, Campbell Scientific offers the Item # 19533

Antenna Surge Protection Kit.

Antenna surge protection is recommended in the following applications:

• When the antenna cable length exceeds 10 feet

• When use of COAXSMA cable would result in too much signal loss

• When the radio will be used in an environment susceptible to lightning or

electro-static buildup

5.2.3 Antenna Surge Protector Kit

The Surge Protector Kit includes the following:

• Polyphaser protector

• COAXSMA-L cable with 1.5 ft length (its type N male connector fastens

to the polyphaser’s equipment connector; its SMA connector fastens to the

radio’s antenna connector)

• Screw (pn 505) and grommet (pn 6044) to secure the polyphaser protector

to the backplate of an enclosure

17

Page 28

RF450 Spread Spectrum Radio

• 1.5 ft, 10 AWG ground wire (insert one end of the wire between the #505

screw and the polyphaser, then secure the other end to a ground lug)

6. LoggerNet Software Setup

The Device Map is configured from the “Setup” button on the LoggerNet or

PC400 toolbar. Configure the Device Map as described below (see FIGURE

6-1).

1. Select Add Root | COM Port.

2. Add a PakBusPort, set the Maximum Baud Rate to 115200, set the beacon

interval to 60 seconds if the Master radio will be at the PC.

3. Add datalogger, set the PakBus address to match that of the datalogger.

4. Apply Settings.

FIGURE 6-1. LoggerNet Setup Screen for an RF450 Multi-Point

18

Network

Page 29

RF450 Spread Spectrum Radio

TABLE 8-1. Multi-Point Network LED Status1

7. RF450s with RF401 or CR206(X) in the Same

Network

Using RF450s in the same network as Campbell Scientific's RF401 radios or

CR206(X) dataloggers is not recommended. RF450s will not communicate

directly with RF401s and CR206(X)s. The RF450s will interfere with the

RF401s’ and CR206(X)s’ transmissions. If RF450s and RF401/CR206(X)s

must be in the same network, there are some things you can do to get better

performance out of the RF401 portion of your network:

1. Use Yagi antennas and separate them.

2. Disable Frequency Zones 4 through 11 on the RF450. This is done

through the Settings Editor Tab of DevConfig.

8. Troubleshooting

LED Status

The RF450 has three red/green LED status indicator lights. TABLE 8-1 shows

the status of each light when the RF450 is in various states of communication.

FIGURE 8-1. RF450 Front Side View

Master Slave Repeater

Condition

Powered,

not linked

Repeater

and Slave

linked to

Master, no

data

Carrier

Detect

(CD)

Solid

bright

red

Solid

bright

red

Transmit

(TX)

Solid dim

red

Solid dim

red

Clear to

Send

(CTS)

Off Solid

Off Solid

Carrier

Detect

(CD)

bright

red

green

Clear to

Transmit

(TX)

Off Blinking

Off Solid

Send

(CTS)

red

bright

red2

Carrier

Detect

(CD)

Solid

bright

red

Solid

green

Transmit

(TX)

Off Blinking

Solid dim

red

Clear to

Send

(CTS)

2

red

Solid

bright

red2

19

Page 30

RF450 Spread Spectrum Radio

Repeater

and Slave

linked to

Master,

Master

sending

data to

Slave

Repeater

and Slave

linked to

Master,

Slave

sending

data to

Master

Master

with

diagnostics

program

running

1

Solid green CD and CTS LEDs indicate that the RF450 is in a setup state. The only way to exit the setup state is through

the proper exit command issued by DevConfig when disconnecting or applying changes.

2

Clear to Send will be solid red with a solid link, as the link weakens the CTS on the Repeater and Slave will begin to flash.

Solid

bright

red

Solid

bright

red OR

Solid

green

RCV

data

Solid

bright

red

Solid dim

red

Solid dim

red

Solid dim

red

Off Solid

green

Intermittent

flashing

red

Intermittent

flashing

red

Solid

green

Solid

green

Off Solid

bright

red2

Intermittent

flashing

red

Intermittent

flashing

red

Solid

bright

2

red

Solid

bright

red2

Solid

green

Solid

green

Solid

green

Solid dim

red

Solid

bright red

Solid

bright red

Solid

bright

red2

Solid

bright

red2

Solid

bright

red2

If DevConfig is unable to establish a connection with the RF450:

1. Check that other Campbell Scientific software is closed.

2. Check power to the radio. The Carrier Detect (CD) light should be

flashing red.

3. Check serial cable connections.

4. Check serial port assignment for DevConfig.

5. Press green Setup button on the RF450 and wait several seconds. CD and

Clear to Send (CTS) lights should be solid green.

Radios not networked together, not communicating:

1. Check Network IDs of all RF450s; they should be the same.

2. Check Frequency Key Number of all RF450s; they should be the same

unless two branches of the network are operating in a parallel manner. See

Appendix A, Installation Scenarios

(p. A-1), Example 3 for settings used in a

parallel network.

3. Check the “Repeaters Used” box for all RF450s.

4. Check the PakBus address of dataloggers connected to RF450s and in

LoggerNet.

5. Check that antenna and antenna cables are SMA (SubMiniature version

A). They will have a yellow heat shrink label to distinguish them from

RPSMA (Reverse Polarity SubMiniature version A) devices. RPSMA

antennas and cables are not compatible with the RF450.

20

Page 31

RF450 Spread Spectrum Radio

LEDs flash when LoggerNet command transmitted but no response from

datalogger:

1. Check SC12 cable on the datalogger's CS I/O port.

2. Check SDC address in RF450.

3. Check SDC address in datalogger.

4. Check the baud rate of LoggerNet; it should match the baud rate of the

RF450 attached to it.

Using the diagnostics port.

A special FreeWave Diagnostics cable and software (CSI part number 20625)

can be useful in troubleshooting radio problems. Contact FreeWave Inc. for

more information on using the Diagnostics cable.

21

Page 32

RF450 Spread Spectrum Radio

22

Page 33

Master

RF450

Slave

Slave

Slave

PC Running

LoggerNet

/PC400

Appendix A. Installation Scenarios

A.1 Example 1: PC-to-RF Network

In this example, the Master radio is connected to a PC running LoggerNet (see

FIGURE A-1). Slave radios are connected to CR1000s in the field. LoggerNet

may be used to view real-time values from the dataloggers, collect data, set

datalogger clocks, and send programs.

Remember, each datalogger must have a unique PakBus Address.

FIGURE A-1. Schematic of PC-to-RF450 Network

Using DevConfig setup the Master and Slave RF450 radios according to

TABLE A-1 below. The Deployment tab of DevConfig should look similar to

FIGURE A-2.

A-1

Page 34

Appendix A. Installation Scenarios

TABLE A-1. RF450 Settings for Example 1

Master

Slave(s)

Network ID

1726 (yours may be different)

1726 (yours may be different)

(a) All Slave Radios in the network will have these same settings except for the Radio ID. The Radio ID

FIGURE A-2. DevConfig Screen Showing Master Radio Settings for

Example 1

Hardware

RF450 connected to PC running

LoggerNet

RF450 connected to CR1000's CS I/O

port

Keep all factory default settings except:

Radio Operation Mode Multi-Point Master Multi-Point Slave

Frequency Key 1 (yours may be different) 1 (yours may be different)

Radio ID

4094 (to match LoggerNet’s PakBus

Address)

2 (to match CR1000's PakBus

Address) (a)

should match the PakBus Address of the datalogger it is connected to.

The Device Map in LoggerNet’s Setup screen will look something like this:

A-2

Page 35

Appendix A. Installation Scenarios

Master

RF450

Slave

Slave

Slave/

Repeater

PC Running

LoggerNet

/PC400

TABLE A-2. RF450 Settings for Example 2

Master

Slave/Repeater

Slave(s)

Hardware

RF450 connected to PC

running LoggerNet

RF450 connected to

CR1000's CS I/O port

RF450 connected to

CR1000's CS I/O port

PakBus Address

4094

2 3 Keep all factory default settings except:

Radio Operation

Mode

Multi-Point Master

Multi-Point Slave/Repeater

Multi-Point Slave

Repeaters Used

Yes, check box

Yes, check box

Yes, check box

Network ID

1726 (yours may be

different)

1726 (yours may be

different)

1726 (yours may be

different)

Frequency Key

1 (yours may be different)

1 (yours may be different)

1 (yours may be different)

Radio ID

4094 (to match LoggerNet’s

2 (to match CR1000's

3 (to match CR1000's

A.2 Example 2: PC-to-RF Network with Repeater

In this example, the Master radio is connected to a PC running LoggerNet (see

FIGURE A-3). Slave radios are connected to CR1000s in the field. One Slave

radio, also connected to a CR1000, is used as a repeater to go around an

obstacle such as a hill. To take advantage of the low power mode, those

devices that are NOT repeaters should be configured as multi-point Slaves and

not as mult-point Slave/repeaters. In this configuration, it may be desirable to

use an external omni directional antenna at the repeater.

When a repeater is used, the RF throughput is cut in half. When more than one

repeater is used there is no further degradation in the RF throughput of the link.

Throughput is the rate at which data is sent or received. Reducing throughput

means less data can be transmitted in a specified amount of time.

Remember, each datalogger must have a unique PakBus Address.

FIGURE A-3. Schematic of PC-to-RF450 Network with Repeater

PakBus Address)

PakBus Address) (a)

PakBus Address) (a)

A-3

Page 36

Appendix A. Installation Scenarios

Master Radio Settings:

FIGURE A-4. DevConfig Screen Showing Master Radio Settings for

Example 2

Slave/Repeater Radio Settings:

FIGURE A-5. DevConfig Screen Showing Slave/Repeater Radio

Settings for Example 2

A-4

Page 37

Appendix A. Installation Scenarios

Slave Radio Settings:

FIGURE A-6. DevConfig Screen Showing Slave Radio Settings for

Example 2

The Device Map in LoggerNet’s Setup screen will look something like this:

A.3 Example 3: PC-to-RF Network with Parallel

Repeaters (using the SubNet ID)

In this example, the Master radio is connected to a PC running LoggerNet (see

FIGURE A-7 and TABLE A-3). One stand-alone repeater (Repeater 1) is used

to access several Slave radios connected to CR1000s in the field. The standalone repeater consists of an RF450, power supply, and antenna. Another

repeater (Slave/Repeater 2) connected to a CR1000 is used to access several

other Slave radios on CR1000s.

To take advantage of the low power mode, those devices that are NOT

repeaters should be configured as multi-point Slaves and not as multi-point

Slave/repeaters. In this configuration, it may be desirable to use an external

omni directional antenna at the repeaters.

When a repeater is used, the RF throughput is cut in half. When more than one

repeater is used there is no further degradation in the RF throughput of the link.

Throughput is the rate at which data is sent or received. Reducing throughput

means less data can be transmitted in a specified amount of time.

A-5

Page 38

Appendix A. Installation Scenarios

Master

RF450

Slave 12

Slave 11

PC Running

LoggerNet

/PC400

Repeater

1

Slave/

Repeater

Slave 22

Slave 21

TABLE A-3. RF450 Settings for Example 3

Master

Repeater

Slave/Repeater

Slave

11, 12 etc.

Slave

21, 22 etc.

Hardware(d)

PC running

LoggerNet, RF450

RF450

CR1000, RF450

CR1000,

RF450

CR1000,

RF450

Baud Rate

115.2K

115.2K

115.2K

115.2K

115.2K

Radio Operation

Multi-Point Master

Multi-Point

Multi-Point

Multi-Point

Multi-Point

Repeaters Used

Yes; check box

Yes; check

Yes; check box

Yes; check

Yes; check

Network ID (a)

1726

1726

1726

1726

1726

Frequency Key

(a)

1 1 1 1 1

Receive SubNet

ID

NA 0 0 1 2

Transmit SubNet

15 (default)

1 2 0

0

Radio ID

4094(b)

2

3 (c)

11, 12 etc.

21, 22, etc

Notes:

Remember, each datalogger must have a unique PakBus Address.

FIGURE A-7. Schematic of PC-to-RF Network with Parallel Repeaters

(using the SubNet ID)

Mode

Repeater

box

Slave/Repeater

Slave

box

Slave

box

ID

(c)

(c)

(a) your Network ID and Frequency Key may be different

(b) to match LoggerNet’s PakBus Address

(c) to match CR1000's PakBus Address

(d) not inclusive; other typical hardware items may include power supply, antenna, enclosure, etc.

NA = not applicable

A-6

Page 39

A.4 Example 4: Phone-to-RF Base

Phone

Modem

Slave 2

Slave 1

PC Running

LoggerNet

/PC400

Phone

to RF450

Base

TABLE A-4. RF450 Settings for Example 4

Hardware(d)

PC running

, Phone Modem

COM220,

CR1000, RF450

Network ID (a)

1726

1726

In this example, a COM220 phone modem and Master radio are connected

without a datalogger to a network of CR1000s in the field (see FIGURE A-8

and TABLE A-4). The computer running LoggerNet uses a phone modem to

call into the Master site and connect to the rest of the network. The rest of the

network can be configured as in other examples. In this configuration,

datalogger-to-datalogger communications and datalogger call-back is NOT

supported; see Example 5.

Appendix A. Installation Scenarios

FIGURE A-8. Schematic of Phone-to-RF Base

Phone to RF450 Base Slaves

LoggerNet

RF450, A100

Active Interface ME Master Auto-Sense

Baud Rate 115.2K 115.2K

Radio Operation Mode Multi-Point Master Multi-Point Slave

Frequency Key (a) 1 1

Radio ID 2 3 (c)

Notes:

(a) your Network ID and Frequency Key may be different

(b) to match LoggerNet’s PakBus Address

(c) to match CR1000's PakBus Address

(d) not inclusive; other typical hardware items may include power supply, antenna, enclosure, etc.

NA = not applicable

A-7

Page 40

Appendix A. Installation Scenarios

A.5 Example 5: Call-back

Call-back is the ability of a remote site to initiate a call to LoggerNet and have

LoggerNet call back to collect data. Call-back is supported in networks

consisting of RF450s as the single communications device as in Examples 1, 2,

and 3. Example configurations where call-back is supported:

LN-RF450 Master ~~~~~RF450 Slave -DL

LN-RF450 Master ~~~~~~RF450 Slave/Repeater-DL~~~~~~RF450 Slave-DL

LN-RF450 Master ~~~~~~~~RF450 Repeater ~~~~~~~~RF450 Slave -DL

LN-Phone Modem -----COM220-DL-RF450 Master ~~~~~~RF450 Slave -DL

NOTE: LN=LoggerNet; DL=Datalogger

In a mixed-communication devices network, e.g. phone to RF450, the base site

makes the transition between communication types. Call-back is NOT

supported when the base RF450's Active Interface is configured as Modem

Enable (ME) Master. The RF450's Active Interface is configured as ME

Master when the CS I/O port is used for direct connection to a ME device

(COM200, COM210, COM220, MD485, etc). The connection is done by

using an A100. Example configurations where call-back is NOT supported:

LN-Phone Modem -----COM220-CSI null modem-RF450 Master~~~~~RF450

Slave -DL(1)

LN--Ethernet--RavenXT-rs232nullmodem-RF450 Master~~RF450 Slave -DL

NOTE: LN=LoggerNet; DL=Datalogger

In this example the RF450s are set-up as described in Example 1. In the

following program the datalogger will send a variable named Callback to

LoggerNet (PakBus address 4094) when the CallBackFlag variable is “true”.

After LoggerNet receives the variable "Callback" it will begin collecting data

from the datalogger and store it into a file based on the data collection settings

in LoggerNet’s Setup window. Note that the PakBus Port setting in

LoggerNet’s Setup window must be set to Always Open.

'CR1000 Series Datalogger

'Declare Public Variables

Public counter, Result

Public CallBackFlag As Boolean

Dim scratch 'this variable is a place-holder it is not used

'Define Data Tables

DataTable (Test,true,-1)

DataInterval (0,15,Sec,10)

Sample (1,counter,FP2)

EndTable

A-8

Page 41

Appendix A. Installation Scenarios

'Main Program

BeginProg

'Configure the CR1000's CS I/O port to match the SDC address and baud rate

'set in the RF450

SerialOpen (ComSDC7,-115200,0,0,10000)

Scan (1,Sec,0,0)

counter = counter + 1

If CallBackFlag = true Then

SendVariables (Result,ComSDC7,0,4094,0000,0,"Public","Callback",Scratch,1)

CallBackFlag = false

EndIf

'Call Output Tables

CallTable Test

NextScan

EndProg

A-9

Page 42

Appendix A. Installation Scenarios

A-10

Page 43

Appendix B. Settings Editor

The Settings Editor of DevConfig provides access to additional settings not

shown on the Deployment Tab. Most RF450 networks do not need to make

changes through the Settings Editor.

B-1

Page 44

Appendix B. Settings Editor

4

New Zealand

921-928 MHz

Radios deployed outside of the United States must use a Hop Table Version

other than zero (the default). This setting can be changed through the Settings

Editor tab.

The Hop Table Version setting allows the user to choose the portion of the

band in which the transceiver will operate.

0 Standard Full 902-928 MHz

1 Australia 915-928 MHz

2 International 902-928 MHz, 16 fewer frequencies than full U.S. set

3 Taiwan 916-920 MHz

5 Notch

Uses 902-928 MHz with center frequencies of 911-919

MHz notched out

6 Brazil 902-915 MHz

B-2

Page 45

Page 46

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific (Beijing) Co., Ltd.

8B16, Floor 8 Tower B, Hanwei Plaza

7 Guanghua Road

Chaoyang, Beijing 100004

P.R. CHINA

www.campbellsci.com • info@campbellsci.com.cn

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

14532 – 131 Avenue NW

Edmonton AB T5L 4X4

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (CSL France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Ltd. (CSL Germany)

Fahrenheitstraße 13

28359 Bremen

GERMANY

www.campbellsci.de • info@campbellsci.de

Campbell Scientific Spain, S. L. (CSL Spain)

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Loading...

Loading...