Page 1

RAWS-H Remote

Automated Weather Station

Revision: 4/12

Copyright © 2006-2012

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell's obligation under this warranty is

limited to repairing or replacing (at Campbell's option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a "Statement of Product Cleanliness

and Decontamination" form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer's expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

RAWS-H Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction.................................................................. 1

2. Getting Started.............................................................3

3. Station Siting and Orientation .................................... 3

3.1 General Description..................................................................................3

3.2 Air Temperature and Relative Humidity ..................................................3

3.3 Precipitation..............................................................................................3

3.4 Solar Radiation .........................................................................................3

3.5 Wind Speed and Direction........................................................................4

3.6 Barometric Pressure..................................................................................4

3.7 Fuel Moisture and Fuel Temperature........................................................4

4. Sensor Wiring ..............................................................4

4.1 Air Temperature and Relative Humidity ..................................................4

4.2 Rain Gage .................................................................................................4

4.3 Solar Radiation .........................................................................................5

4.4 Wind Speed and Direction........................................................................5

4.4.1 SDI-12 Sensor.................................................................................5

4.5 Fuel Moisture and Fuel Temperature........................................................5

4.6 Barometric Pressure..................................................................................6

5. Equipment Wiring and Troubleshooting ...................6

5.1 Solar Panels ..............................................................................................6

5.1.1 General Description, Solar Panel....................................................6

5.1.2 Wiring, Solar Panel.........................................................................6

5.1.3 Troubleshooting, Solar Panel..........................................................7

5.2 Charger/Regulator ....................................................................................7

5.2.1 General Description, 12 V Charger/Regulator (part #CH100) .......7

5.2.2 Wiring, 12 V Charger/Regulator (part #CH100) ............................7

5.2.3 Troubleshooting, 12 V Charger/Regulator (part #CH100) .............8

5.3 Battery ......................................................................................................8

5.3.1 General Description, Battery...........................................................8

5.3.2 Wiring, Battery ...............................................................................8

5.3.3 Troubleshooting, Battery ................................................................9

5.4 GOES Transmitter ....................................................................................9

5.4.1 General Description, GOES Transmitter (part #TX320) ................9

5.4.2 Wiring, GOES Transmitter (part #TX320)...................................10

5.4.3 Troubleshooting, GOES Transmitter (part #TX320)....................10

5.5 Voice Radio Interface.............................................................................11

5.5.1 General Description, Voice Radio Interface (part #VSP3)...........11

5.5.2 Wiring, Voice Radio Interface (part #VSP3)................................11

5.5.3 Troubleshooting, Voice Radio Interface (part #VSP3).................12

i

Page 6

RAWS-H Table of Contents

6. Desiccant ....................................................................14

7. Sensor and Equipment Maintenance .......................14

8. References..................................................................15

5.6 CR1000 Keyboard/Display.................................................................... 12

5.6.1 General Description, CR1000 Keyboard/Display (part

#CR1000KD) ...................................................................................... 12

5.6.2 Wiring, CR1000 Keyboard/Display (part #CR1000KD)............. 13

5.6.3 Troubleshooting, CR1000 Keyboard/Display (part

#CR1000KD) ...................................................................................... 13

5.7 CR1000 Datalogger ............................................................................... 13

5.7.1 General Description, CR1000 Datalogger.................................... 13

5.7.2 Wiring, CR1000 Datalogger ........................................................ 14

5.7.3 Troubleshooting, CR1000 Datalogger ......................................... 14

6.1 When to Replace Desiccant ................................................................... 14

6.2 Reusing Desiccant.................................................................................. 14

7.1 Sensor and Equipment Maintenance...................................................... 14

8.1 RAWS Orientation................................................................................. 15

8.1.1 Determining True North and Sensor Orientation......................... 15

8.1.2 USGS Web Calculator ................................................................. 18

Appendix

A. Equipment Wiring and Connector Panel

Jumper Location................................................. A-1

Figures

1-1. Color coded, keyed connector panel....................................................... 1

1-2. Inside Environmental Enclosure (optional equipment shown)............... 2

5.2-1. 12 volt charger/regulator ..................................................................... 7

5.4-1. GOES Transmitter ............................................................................. 10

5.5-1. Voice Radio Interface........................................................................ 11

5.6-1. CR1000 Keyboard/Display................................................................ 12

5.7-1. CR1000 and printed circuit wiring panel........................................... 13

8.1-1. Magnetic declination for the contiguous United States ..................... 16

8.1-2. A declination angle East of True North (positive) is subtracted

from 360 (0) degrees to find True North .................................................. 17

8.1-3. A declination angle West of True North (negative) is subtracted

from 0 (360) degrees to find True North .................................................. 17

8.1-4. USGS Web Calculator....................................................................... 18

A-1. RAWS-H equipment wiring ..............................................................A-1

A-2. RAWS-H connector panel schematic 1 of 2...................................... A-2

A-3. RAWS-H connector panel schematic 2 of 2...................................... A-3

A-4. RAWS-H connector panel jumper location ....................................... A-4

ii

Page 7

RAWS-H Remote Automated Weather

Station

1. Introduction

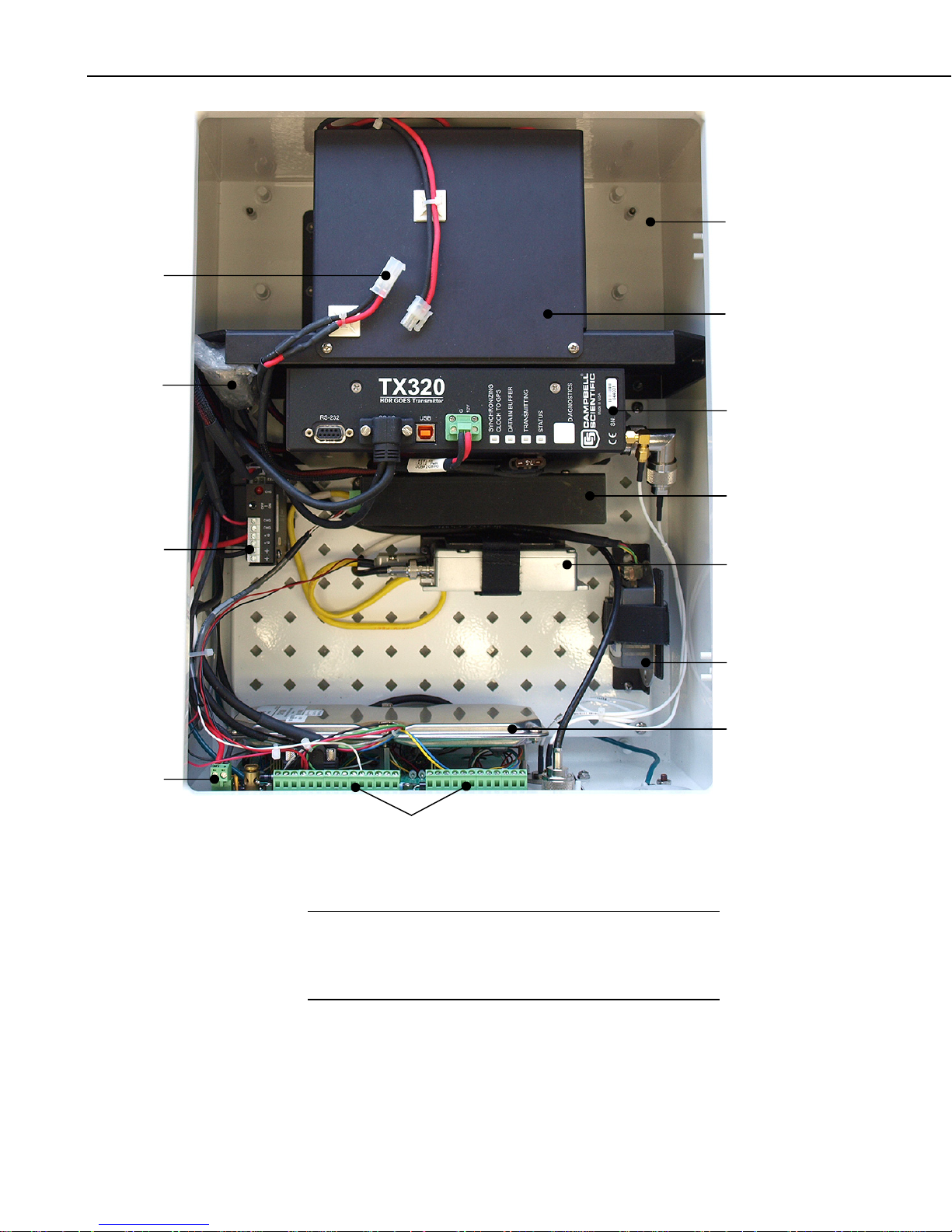

The RAWS environmental enclosure can be used for configuring a custom

Remote Automated Weather Station (RAWS) that matches the requirements of

your application. The aluminum environmental enclosure houses a 12 V

rechargeable battery and a CR1000 datalogger. The outside of the enclosure

has color-coded, keyed connectors (Figure 1-1) for attaching the sensors.

Besides the connectors, a wiring panel is included that allows the measurement

of additional sensors. Communication options include satellite transmitter and

voice radio interface module. Additional communication equipment

(telephone, cellular phone, radio) can be added to the station. The RAWS data

collection platform is ideal for configuring a custom remote automated weather

station.

NOTE

FIGURE 1-1. Color coded, keyed connector panel

Keep this manual and the CR1000KD Keyboard Display

with the RAWS. Review the station siting and orientation

section before field deployment. If a problem is encountered,

review the troubleshooting sections in this manual and Appendix

A Equipment Wiring and Connector Panel Jumper Location.

1

Page 8

RAWS-H Remote Automated Weather Station

(1)

Connect

battery

SC12

Cable

CR1000KD

packed in foam

(may go here)

Battery

TX320

GOES

Transmitter

VSP3

Vosponder

(2)

Turn on

CH100

CR1000

power in

NOTE

RF Radio

CS100

Barometer

CR1000

Datalogger

CR1000 Wiring Panel

FIGURE 1-2. Inside Environmental Enclosure (optional equipment

shown)

Customized Handar sensor programming can be developed for a

nominal fee. Program development will require datalogger

support software (LoggerNet or PC400) purchased from

Campbell Scientific, Inc.

2

Page 9

2. Getting Started

RAWS-H Remote Automated Weather Station

NOTE

NOTE

NOTE

Set up and test your station before field deployment.

Keep this manual and the CR1000KD Keyboard Display

with the RAWS. Review the station siting and orientation

section before field deployment. If a problem is encountered,

review the equipment wiring and troubleshooting sections in this

manual.

After siting and leveling the RAWS station, open the enclosure and

(1) connect the battery cable and (2) verify the CH100 switch is in

the ‘on’ position. When this equipment is not in use (i.e.,

transport or storage), disconnect battery cable to the CH100.

3. Station Siting and Orientation

3.1 General Description

Selecting an appropriate site for the RAWS is critical in order to obtain

accurate meteorological data. In general, the site should be representative of

the general area of interest and away from the influence of obstructions such as

buildings and trees.

WARNING

If any part of the weather station comes in contact with

power lines, you could be killed. Contact local utilities

for the location of buried utility lines before digging or

driving ground rods.

3.2 Air Temperature and Relative Humidity

A temperature and relative humidity sensor should be located over an open

level area at least 9 m in diameter (EPA). The surface should be covered by

short grass, or where grass does not grow, the natural earth surface. The sensor

must be housed inside a radiation shield and adequately ventilated.

Situations to avoid include: 1) large industrial heat sources, 2) rooftops, 3)

steep slopes, 4) sheltered hollow, 5) high vegetation, 6) shaded areas,

7) swamps, 8) areas where snow drifts occur, and 9) low places holding

standing water after rains.

3.3 Precipitation

A rain gauge should be located over an open level area covered by short grass,

or where grass does not grow, the natural earth surface. Level the rain gage.

3.4 Solar Radiation

A solar radiation sensor should be located to avoid shadows on the sensor at

any time. Orient the solar radiation sensor where the solar radiation sensor

3

Page 10

RAWS-H Remote Automated Weather Station

faces south (northern hemisphere) minimizing the chance of shading from

other weather station structures. Reflective surfaces and sources of artificial

radiation should be avoided. Level the solar radiation sensor.

3.5 Wind Speed and Direction

A wind sensor should be located over open level terrain and at a distance of at

least ten times (EPA) the height of any nearby building, tree, or other

obstruction.

3.6 Barometric Pressure

The CS100 barometric pressure sensor can be mounted to the back plate inside

the RAWS environmental enclosure.

3.7 Fuel Moisture and Fuel Temperature

The fuel moisture and fuel temperature sensor should be left outside at the field

site continually exposed to the same conditions as forest fuels. The fuel

moisture and fuel temperature dowel rods absorb and desorb moisture from its

surroundings. Install the probes horizontally on the mounting stake and face

the sensors south (northern hemisphere) above a representative forest floor duff

layer. Place the sensor away from foot traffic areas.

4. Sensor Wiring

4.1 Air Temperature and Relative Humidity

The temp/RH sensor is connected to the RAWS connector panel “TEMP/RH”

connector COLOR CODED ORANGE. This sensor is internally wired from

the RAWS connector panel to the CR1000 datalogger.

Connector Panel “TEMP/RH” connector COLOR CODED ORANGE

Connector Pin A Temp Hi to CR1000 1L

Connector Pin B Sensor excitation to CR1000 EX1

Connector Pin C Sensor signal Lo/AG to CR1000 AG

Connector Pin D Power ground to CR1000 Ground

Connector Pin E RH signal to CR1000 1H

Connector Pin F SW_12V to CR1000 SW_12V

4.2 Rain Gage

The rain gage is connected to the RAWS connector panel “PRECIP” connector

COLOR CODED BLUE. This sensor is internally wired from the RAWS

connector panel to the CR1000 datalogger.

Connector Panel “PRECIP” connector COLOR CODED BLUE

Connector Pin A Tipping Bucket to CR1000 C6

Connector Pin B 5V to CR1000 5V

Connector Pin C Ground to CR1000 Ground

4

Page 11

4.3 Solar Radiation

The solar radiation sensor is connected to the RAWS connector panel “SOLAR

RAD SDI-12” connector COLOR CODED GREEN. The pyranometer sensor

is internally wired from the RAWS connector panel to the CR1000 datalogger.

RAWS-H Remote Automated Weather Station

Connector Panel “SOLAR RAD SDI-12” connector COLOR CODED GREEN

Connector Pin A Solar Sensor + to CR1000 3H

Connector Pin B Solar Sensor - to CR1000 3L/AG (3L shorted to AG)

Connector Pin C Solar Sensor Gnd to CR1000 AG

Connector Pin D SDI-12 Ground to CR1000 Ground*

Connector Pin E SDI-12 Signal to CR1000 C5* (*Note: 2

Connector Pin F SDI-12 12V to CR1000 12V*

4.4 Wind Speed and Direction

The windset sensor is connected to the RAWS connector panel “WS/WD”

connector COLOR CODED RED. The wind speed probe is internally wired

from the RAWS connector panel to the CR1000 datalogger.

Connector Panel “WS/WD” connector COLOR CODED RED

Connector Pin A Sensor ground to CR1000 AG

Connector Pin B Wind dir. Excitation to CR1000 Ex2

Connector Pin C Wind dir. Signal to CR1000 2H

Connector Pin D Power ground to CR1000 Ground

Connector Pin E +12V power to CR1000 +12V

Connector Pin F Wind speed signal to CR1000 P1

4.4.1 SDI-12 Sensor

An SDI-12 Sensor can be connected to the RAWS connector panel “SDI-12”

connector COLOR CODED YELLOW. The wind sensor is internally wired

from the RAWS connector panel to the CR1000 datalogger.

sensor)

nd

SDI-12

Connector Panel “SDI-12” connector COLOR CODED YELLOW

Connector Pin A Signal + to CR1000 C7

Connector Pin B 12V to CR1000 12V

Connector Pin C Power ground to CR1000 Ground

Connector Pin D Open to CR1000

4.5 Fuel Moisture and Fuel Temperature

The Campbell Scientific CS506 and CS205 sensors are combined into one

connector (part#CS516-LQ). This sensor is internally wired from the RAWS

connector panel to the CR1000 datalogger. This sensor is connected to the

RAWS connector panel “FM/FT” connector COLOR CODED BROWN.

Connector Panel “FM/FT” connector COLOR CODED BROWN

Connector Pin A CS205 Temp. Signal to CR1000 4L

Connector Pin B Sensor Ground to CR1000 Ground

Connector Pin C CS205 Temp. Excitation to CR1000 EX1

Connector Pin D CS506 FM Enable to CR1000 C8

Connector Pin E CS506 FM Signal to CR1000 4H

Connector Pin F CS506 FM +12V power to CR1000 +12V

5

Page 12

RAWS-H Remote Automated Weather Station

4.6 Barometric Pressure

The barometric pressure sensor (part #CS100-QD) is mounted inside the

RAWS environmental enclosure and the sensor wires are attached to the

CR1000 printed circuit board wiring panel.

CS100 Barometric Pressure Sensor wires attached to CR1000 Wiring

Panel

CS100 Blue wire to CR1000 wiring panel 5H

CS100 Yellow wire to CR1000 wiring panel AG

CS100 Red wire to CR1000 wiring panel 12V

CS100 Clear wire to CR1000 wiring panel Ground

CS100 Black wire to CR1000 wiring panel Ground

CS100 Green wire to CR1000 wiring panel C4

CAUTION

The CS100 is sensitive to static when the back plate is

removed. To avoid damage, take adequate anti-static

measures when handling this sensor.

5. Equipment Wiring and Troubleshooting

5.1 Solar Panels

5.1.1 General Description, Solar Panel

The RAWS Solar Panel is a photovoltaic power source used for charging lead

acid batteries. The SP20-Handar 20 watt solar panel is used for system

configurations that have higher-than-average power requirements. It is also

recommended for use at higher elevations and latitudes. The solar panel

should be mounted facing south if located in the northern hemisphere, or facing

north in the southern hemisphere.

The SP10-Handar 10 watt solar panel is recommended for a RAWS where NO

communication equipment is used. The SP20-Handar 20 watt solar panel is

recommended for a RAWS where communication equipment is used (i.e.,

GOES, voice, cell phone, or radio).

NOTE

If the user supplies a solar panel for the RAWS, use an

unregulated solar panel. The solar panel size depends on the

station power requirements, specifically the communication

equipment selected for the station.

The SP10-Handar solar panel outputs 0.59 Amps, 8.9 Watts typical peak

power.

The SP20-Handar solar panel outputs 1.17 Amps, 18 Watts typical peak power.

5.1.2 Wiring, Solar Panel

The RAWS-Solar Panel attaches to the connector panel labeled “BATT

CHARGER/SOLAR PANEL”. Inside the RAWS environmental enclosure the

“BATT CHARGER/SOLAR PANEL” connector pin A and pin B are wired to

the CH100 charger/regulator “CHG” and “CHG” ports. Polarity does not

6

Page 13

RAWS-H Remote Automated Weather Station

matter; either lead can be connected to either terminal. The CH100

charger/regulator has two functions: 1) blocks any current flow from the

battery to the solar panel, and 2) limits the source current to the battery.

5.1.3 Troubleshooting, Solar Panel

If a problem with the solar panel is suspected, the solar panel may be checked

by measuring the voltage output from the solar panel. Check the voltage with a

voltmeter connected between the two leads going to the CH100

charger/regulator “CHG” “CHG” terminals located inside the environmental

enclosure (15 VDC to 28 VDC). There must be solar radiation incident on the

panel and there must be a load connected to the solar panel. The load can be

the datalogger, other equipment, or a 75 ohm resistor capable of dissipating

solar panel power between the two leads. No voltage output implies a bad

solar panel, regulator, or cable. The magnitude of the voltage output depends

on the incident solar radiation. Check the sensor cable. Disconnect the

connector and look for damaged pins.

5.2 Charger/Regulator

5.2.1 General Description, 12 V Charger/Regulator (part #CH100)

The 12 volt charger/regulator (part #CH100) is a charging regulator for 12 V

rechargeable batteries. The CH100 is connected to an external charging source

such as an unregulated solar panel (part # SP20-Handar or SP10-Handar) or a

wall charger (part #9591-Handar). The CH100 charger/regulator has two

functions: 1) blocks any current flow from the battery to the solar panel, and 2)

limits the source current to the battery.

5.2.2 Wiring, 12 V Charger/Regulator (part #CH100)

FIGURE 5.2-1. 12 volt charger/regulator

The leads from the RAWS connector panel “BATT CHARGER/SOLAR

PANEL” connector COLOR CODED PURPLE are wired to the CH100

“CHG” terminals. Polarity does not matter; either lead can be connected to

either terminal. The charge indicating diode should be “ON” when voltage to

the charging circuitry (CHG Terminals) is present.

An internal and/or external battery can be connected to the CH100

Charger/Regulator by means of the INT (Internal) or EXT (External)

7

Page 14

RAWS-H Remote Automated Weather Station

connectors. The battery red lead connects to the positive battery terminal and

the black lead connects to the negative terminal.

Connect 12 V power to the datalogger and/or peripherals using the “+12

and Ground” terminals. The ON-OFF switch applies power to these 12 V

terminals.

WARNING

CAUTION

CAUTION

Reversal of battery polarity will damage the CH100 or

battery.

A battery must be attached for the CH100 to function

correctly as a power supply.

It is possible to leave two batteries connected. The battery

connections are diode isolated; however, if one of the

batteries fails, it could draw all the charging current and the

other battery will be discharged.

5.2.3 Troubleshooting, 12 V Charger/Regulator (part #CH100)

If a problem with the charger/regulator (part #CH100) is suspected, the CH100

may be checked by measuring: 1) input voltage (CHG terminals) from the solar

panel (15 VDC to 28 VDC) or input voltage from the AC adapter (part #9591Handar) about 18 VAC RMS, 2) charging output voltage (BATT INT or EXT

terminal) with battery disconnected about 13.5 VDC to 14 VDC, and 3) power

out (+12 terminals) about 11 VDC to 14 VDC. No voltage output implies a

bad solar panel, regulator, or battery. Power out (+12 terminals) is controlled

by the CH100 ON-OFF switch position.

NOTE

Power out (+12 terminals) is controlled by the CH100 ON-OFF

switch position.

8

5.3 Battery

5.3.1 General Description, Battery

The RAWS battery is a rechargeable 12 volt battery. The battery requires a

regulated charging source provided by the RAWS Charger/Regulator (part

#CH100) connected to an unregulated solar panel or a wall charger.

WARNING

5.3.2 Wiring, Battery

RAWS rechargeable batteries are designed to be float

charged. Permanent damage occurs and battery life is

shortened if the battery is allowed to discharge below

10.5 volts.

The RAWS rechargeable battery should be connected to the CH100

charger/regulator INT (Internal) connector. The battery red lead connects to

the positive battery terminal and the black lead connects to the negative

terminal. If desired, an external battery can be connected to the CH100

charger/regulator EXT (External) connector. It is possible to leave two

Page 15

RAWS-H Remote Automated Weather Station

batteries connected. The battery connections are diode isolated; however, if

one of the batteries fails, it could draw all the charging current and the other

battery will be discharged.

WARNING

CAUTION

Reversal of battery polarity will damage the CH100 or

battery.

It is possible to leave two batteries connected. The battery

connections are diode isolated; however, if one of the

batteries fails, it could draw all the charging current and the

other battery will be discharged.

5.3.3 Troubleshooting, Battery

Measure the +12 V and Ground terminal on the CR1000 printed circuit board

wiring panel. Acceptable readings are +11 VDC to +14 VDC. Use PC200W

software to collect the 1-HR data table from the CR1000 datalogger and review

the historical record of battery voltage.

5.4 GOES Transmitter

5.4.1 General Description, GOES Transmitter (part #TX320)

The High Data Rate GOES transmitter (part #TX320) shown in Figure 5.4-1

supports one-way communication, via satellite, from a Campbell Scientific

datalogger to a ground receiving station. Satellite telemetry offers a convenient

communication alternative for field stations where phone systems or RF

systems are impractical or rendered unreliable after a tragedy to the local

infrastructure. Data transmission rates of 100, 300, and 1200 bps are

supported. Because clock accuracy is critically important for GOES satellite

telemetry, the TX320 includes a robust, TCXO-based real-time clock and a

GPS receiver.

NOTE

The TX320 transmitter has two siting requirements for proper operation. The

GOES antenna must have a clear view of the spacecraft. The GOES antenna is

directional and should be aimed at the spacecraft. Both elevation and azimuth

are unique to the location of the planet and must be set. A poorly aimed

antenna will cause a drop in signal strength or possibly prevent successful

transmission.

For more information on the GOES transmitter (part #TX320) and antenna

siting, go to our website at www.campbellsci.com

“Search” box on the website mentioned above, and go the equipment manual.

The GOES transmitter (part #TX320) manual is also provided on the

ResourceDVD which ships with the RAWS Quick Deployment Weather

Station.

The spacecraft specific DCP-Setup parameters for the GOES

transmitter must be entered in the CR1000 program.

, enter the “TX320” in the

9

Page 16

RAWS-H Remote Automated Weather Station

FIGURE 5.4-1. GOES Transmitter

5.4.2 Wiring, GOES Transmitter (part #TX320)

The GOES transmitter (part #TX320) is mounted inside the RAWS

environmental enclosure and the transmitter connections are described below;

GOES Transmitter TX320 Connection inside the RAWS environmental

enclosure

GOES TX320 “CSI/O” Port --to-- CR1000 PC Board “CSI/O” Port using

an *SC12 Cable

GOES TX320 “GPS Port” --to-- GPS Antenna Cable

GOES TX320 “RF Out” --to-- GOES Antenna Cable

GOES TX320 “Power Port” --to-- Battery Cable Junction Connector

*Note: The SC12 Cable ships with the RAWS Weather Station.

5.4.3 Troubleshooting, GOES Transmitter (part #TX320)

If a problem with the GOES transmitter (part #TX320) is suspected, the TX320

may be checked by measuring the +12 V and Ground terminal on the CR1000

PC-board wiring panel. Acceptable readings are +11 VDC to +14 VDC.

Check the SC12 cable connection between the CR1000 wiring panel and the

TX320. Press the TX320 diagnostic button to query the state of the

transmitter.

10

Page 17

RAWS-H Remote Automated Weather Station

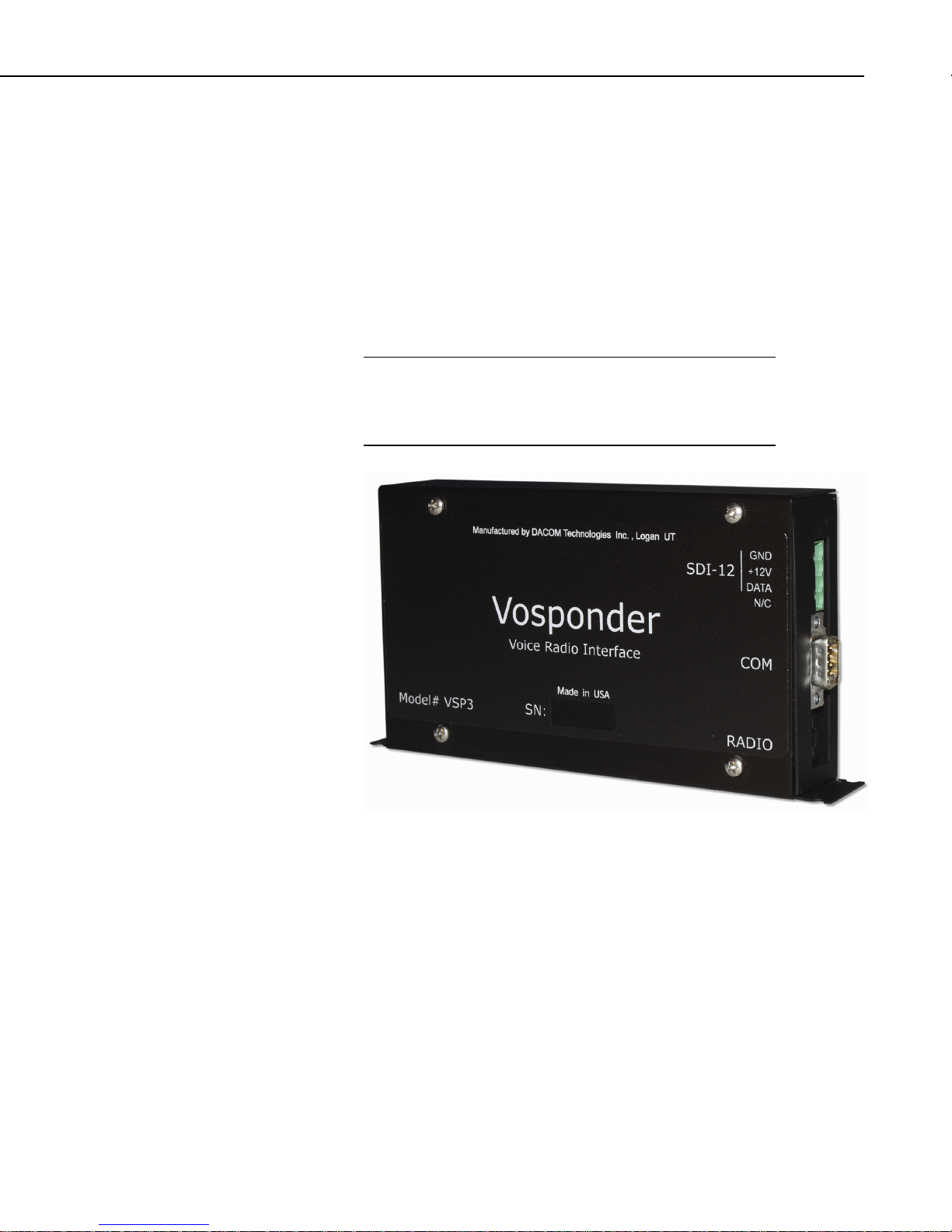

5.5 Voice Radio Interface

5.5.1 General Description, Voice Radio Interface (part #VSP3)

The DACOM Voice Radio Interface (part #VSP3) shown in Figure 5.5-1 is

mounted inside the RAWS environmental enclosure. The VSP3 converts data

into voice messages that can be transmitted via UHF or VHF transceiver. The

VSP3 Vosponder uses phonetic native text string to speech conversion, which

provides for an unlimited vocabulary. The Vosponder communicates with a

datalogger using the SDI-12 protocol. The VSP3 Vosponder can be integrated

into an existing UHF/VHF radio network. A minimum of two radios with

matching frequencies is required. The VSP3 ships preprogrammed with a

voice image file for the fire weather market.

NOTE

A minimum of two radios with matching frequencies is required

to transmit voice messages. To activate the voice file, hold down

the radio microphone button and press 9 on the radio keypad.

Radios can be purchased from Campbell Scientific.

5.5.2 Wiring, Voice Radio Interface (part #VSP3)

FIGURE 5.5-1. Voice Radio Interface

The Voice Radio Interface (part #VSP3) is mounted inside the RAWS

environmental enclosure and the VSP3 connections are described below.

Voice Radio Interface (part #VSP3) inside the RAWS environmental

enclosure

VSP3 “Ground” terminal contact --to-- CR1000 PC Board “G”

VSP3 “+12V” terminal contact --to-- CR1000 PC Board “+12V”

VSP3 “DATA” terminal contact --to-- CR1000 PC Board “C1”

VSP3 “RADIO” RJ45 Connector --to-- UHF/VHF Radio*

*Note: Maxon and Bendix King Radio cables are available from Campbell

Scientific.

11

Page 18

RAWS-H Remote Automated Weather Station

5.5.3 Troubleshooting, Voice Radio Interface (part #VSP3)

If a problem with the voice radio interface (part #VSP3) is suspected, the VSP3

may be checked by measuring the +12 V and Ground terminal on the VSP3.

Acceptable readings are +11 VDC to +14 VDC. Verify the sensor wires are

securely fastened to the VSP3 connector and the CR1000 printed circuit board

wiring panel. If problems persist, try a substitute.

5.6 CR1000 Keyboard/Display

5.6.1 General Description, CR1000 Keyboard/Display (part #CR1000KD)

The CR1000 Keyboard/Display (part #CR1000KD) shown in Figure 5.6-1 is

used to check datalogger status, display or plot sensor readings and stored

values, and to enter numeric data or change port/flag state. The CR1000KD is

powered from the CR1000 printed circuit board “CS I/O” connector via a

standard 9-pin serial cable (part #10873) that ships with the RAWS station.

Power Up Screen

Press any key for Power up Screen

Press ^ to turn on/off backlight

Press <> to adjust contrast

RAWS-H Setup Screen

Press up/down arrow to select menu item

Press Enter to see menu choices

Press up/down arrow to highlight menu choice

Press Enter to select menu choice

Press Esc to move up a menu

Press Enter to move down a menu

FIGURE 5.6-1. CR1000 Keyboard/Display

12

Page 19

RAWS-H Remote Automated Weather Station

5.6.2 Wiring, CR1000 Keyboard/Display (part #CR1000KD)

The CR1000 Keyboard/Display (part #CR1000KD) connects to the CR1000

PC board “CSI/O” 9-Pin connector using a standard RS-232 serial cable (part

#10873) that ships with the RAWS station.

5.6.3 Troubleshooting, CR1000 Keyboard/Display (part #CR1000KD)

If a problem with the CR1000 Keyboard/Display is suspected, the CR1000KD

may be checked by connecting the CR1000KD to the CR1000 PC board 9-Pin

“CS I/O” connector using the 9-pin serial cable (part #10873). The

CR1000KD display should be visible. Check the CH100 on/off switch. If the

display is not visible, check the CR1000 wiring panel for 12 volt power. If the

CR1000 is unresponsive to CR1000KD key strokes, then there might be a

problem with the CR1000 datalogger.

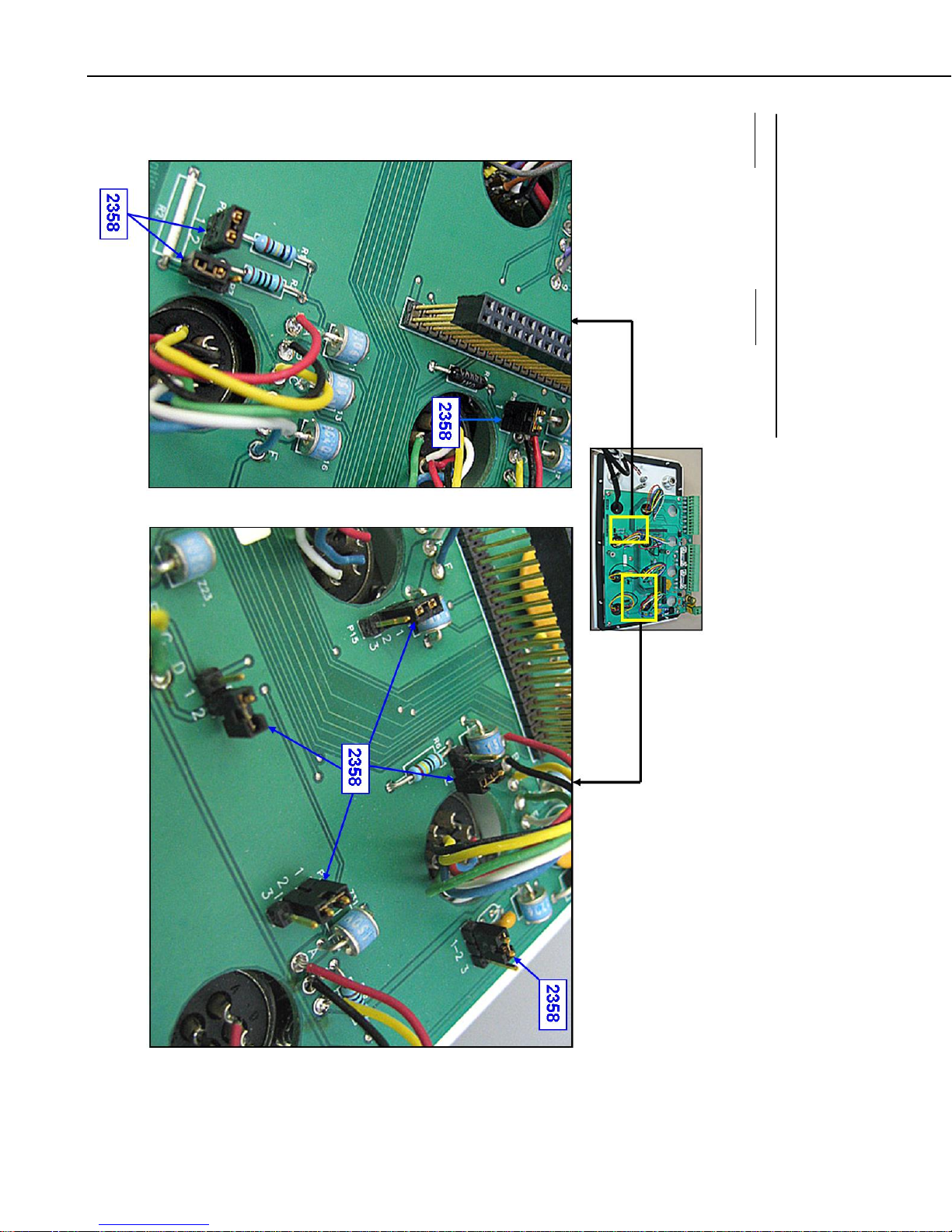

5.7 CR1000 Datalogger

5.7.1 General Description, CR1000 Datalogger

The CR1000 shown in Figure 5.7-1 provides sensor measurement,

timekeeping, data reduction, data/program storage and control

functions. The RAWS CR1000 datalogger includes 2 Mbytes of

memory for data and program storage. A lithium battery backs up the

RAM and real-time clock. The CR1000 also suspends execution

when primary power drops below 9.6 V, reducing the possibility of

inaccurate measurements.

FIGURE 5.7-1. CR1000 and printed circuit wiring panel

13

Page 20

RAWS-H Remote Automated Weather Station

5.7.2 Wiring, CR1000 Datalogger

The CR1000 datalogger is mounted inside the RAWS environmental enclosure

and fastened to the CR1000 printed circuit board wiring panel. Connect 12 V

power to the CR1000 printed circuit board wiring panel green power

connector. The CH100 ON-OFF switch applies power to the 12 V terminals.

5.7.3 Troubleshooting, CR1000 Datalogger

If a problem with the CR1000 datalogger is suspected, the CR1000 may be

checked by connecting the CR1000KD to the CR1000 printed circuit board 9Pin “CSI/O” connector using the 9-pin serial cable (part #10873). The

CR1000KD display should be visible. If the display is not visible, check the

CR1000 printed circuit board for 12 volt power. If the CR1000 is unresponsive

to CR1000KD key strokes, then there might be a problem with the CR1000

datalogger.

6. Desiccant

6.1 When to Replace Desiccant

A humidity indicator card and desiccant packs are provided with the weather

station. Place the humidity indicator card and 2 ea. desiccant packs inside the

enclosure. Desiccant packets inside the enclosure should be replaced with

fresh packets when the upper dot on the indicator begins to turn pink. The

indicator tab does not need to be replaced unless the colored circles overrun. A

humidity indicator card (part #6571) and desiccant pack (part # 4905) may be

ordered through Campbell Scientific. Desiccant packs inside of the datalogger

do not require replacement under normal conditions.

6.2 Reusing Desiccant

Customers can reactivate saturated desiccant packets. Care must be taken. If

the heating process is too rapid, water vapor is released too quickly causing too

much pressure to build up inside the packets so that the packets burst.

Standard Oven Method:

1. Bake at an oven temperature of 125ºF for 2 hours.

2. Increase the oven temperature to 175ºF and bake for 2 hours.

3. Increase the oven temperature from 245ºF to 250ºF and bake for 12 hours.

The optimum situation for reactivation is to use a recalculating oven that has a

ramping temperature. The desiccant should bake for 16 hours, and the final

temperature should be 245ºF to 250ºF.

7. Sensor and Equipment Maintenance

7.1 Sensor and Equipment Maintenance

Proper maintenance of weather station components is essential to obtain

accurate data. Equipment must be in good operating condition, which requires

a program of regular inspection and maintenance. Routine and simple

maintenance can be accomplished by the person in charge of the weather

14

Page 21

RAWS-H Remote Automated Weather Station

station. More difficult maintenance, such as sensor calibration, sensor

performance testing (i.e., bearing torque), and sensor component replacement,

generally requires a skilled technician, or send the instrument to Campbell

Scientific. A station log should be maintained for each weather station that

includes equipment model and serial numbers and maintenance that was

performed.

NOTE

NOTE

8. References

8.1 RAWS Orientation

8.1.1 Determining True North and Sensor Orientation

Consult the equipment manual for routine maintenance

procedures.

Contact Campbell Scientific, Inc., phone (435) 227-9000, for a

RMA number before returning sensor or equipment for service.

Orientation of the wind direction sensor is done after the datalogger has been

programmed and the location of True North has been determined. True North

is usually found by reading a magnetic compass and applying the site-specific

correction for magnetic declination; where the magnetic declination is the

number of degrees between True North and Magnetic North. Magnetic

declination for a specific site can be obtained from a USGS map, local airport,

or through the web calculator offered by the USGS (Section 8.1.2). A general

map showing magnetic declination for the contiguous United States is shown

in Figure 8.1-1.

Declination angles are always subtracted from the compass reading to find

True North. A declination angle East of True North is reported as positive a

value and is subtracted from 360 (0) degrees to find True North as shown

Figure 8.1-2. A declination angle West of True North is reported as a negative

value and is also subtracted from 0 (360) degrees to find True North as shown

in Figure 8.1-3. Note that when a negative number is subtracted from a

positive number, the resulting arithmetic operation is addition.

For example, the declination for Longmont, CO is 10.1°, thus True North is

360° - 10.1°, or 349.9° as read on a compass. Likewise, the declination for Mc

Henry, IL is -2.6°, and True North is 0° - (-2.6°), or 2.6° as read on a compass.

15

Page 22

RAWS-H Remote Automated Weather Station

FIGURE 8.1-1. Magnetic declination for the contiguous United States

16

Page 23

RAWS-H Remote Automated Weather Station

FIGURE 8.1-2. A declination angle East of True North (positive) is

subtracted from 360 (0) degrees to find True North

FIGURE 8.1-3. A declination angle West of True North (negative) is

subtracted from 0 (360) degrees to find True North

17

Page 24

RAWS-H Remote Automated Weather Station

8.1.2 USGS Web Calculator

The USGS provides an easy way of determining declination of a specific site.

Since magnetic declination fluctuates with time, it should be adjusted each time

the wind sensor orientation is adjusted. The calculator can be accessed at:

www.ngdc.noaa.gov/geomagmodels/Declination.jsp

example for Logan, UT.

. Figure 8.1-4 shows an

FIGURE 8.1-4. USGS Web Calculator

In the example above the declination for Logan, UT is 12º 24′ or 12.4º. As

shown in Figure 8.1-4, the declination for Utah is East (positive), so True

North for this site is 360 – 12.4 = 347.6 degrees. The annual change is 7

minutes West per year or -7 minutes/year.

18

Page 25

Appendix A. Equipment Wiring and

Connector Panel Jumper Location

FIGURE A-1. RAWS-H equipment wiring

A-1

Page 26

Appendix A. Equipment Wiring and Connector Panel Jumper Location

FIGURE A-2. RAWS-H connector panel schematic 1 of 2

A-2

Page 27

Appendix A. Equipment Wiring and Connector Panel Jumper Location

FIGURE A-3. RAWS-H connector panel schematic 2 of 2

A-3

Page 28

Appendix A. Equipment Wiring and Connector Panel Jumper Location

P7 Open 1 to 2

P6 Jumper 1 to 2

Open

P8 Ju

P19 Open

P22 Jumper 1 to

Page A-2

Default Jumper Locations

mper 1 to 2

1 to 2

2 to 3

Open 2 to 3

P20 Jum

2

Page A-3

P15 Jumper 1 to 2

Op

P13 Op

en 1 to 2

per 1 to 2

en 2 to 3

FIGURE A-4. RAWS-H connector panel jumper location

A-4

Page 29

Page 30

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br • suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...