Page 1

PONDVIEW 4.0

CSI AQUACULTURE

AUTOMATED MONITORING AND CONTROL SUPPORT SOFTWARE

INSTRUCTION MANUAL

REVISION: 6/02

COPYRIGHT (c) 2000-2002 CAMPBELL SCIENTIFIC, INC.

Page 2

This is a blank page.

Page 3

Limited Warranty

CAMPBELL SCIENTIFIC, INC. warrants that the media on which the accompanying

computer software is recorded and the documentation provided with it are free from

physical defects in materials and workmanship under normal use. CAMPBELL

SCIENTIFIC, INC. warrants that the computer software itself will perform substantially

in accordance with the specifications set forth in the Operator’s Manual published by

CAMPBELL SCIENTIFIC, INC. CAMPBELL SCIENTIFIC, INC. warrants that the

software is compatible with Windows 2000, Windows NT 4.0 Service Pack 4 or

greater. CAMPBELL SCIENTIFIC, INC. is not responsible for incompatibility of this

software running under any operating system other than those specified in

accompanying data sheets or Operator’s Manuals.

The above warranties are made for ninety (90) days from the date of original shipment.

CAMPBELL SCIENTIFIC, INC. will replace any media or documentation which

proves defective in materials or workmanship without charge.

CAMPBELL SCIENTIFIC, INC. will either replace or correct any software that does

not perform substantially according to the specifications set forth in the Operator’s

Manual with a corrected copy of the software or corrective code. In the case of

significant error in the documentation, CAMPBELL SCIENTIFIC, INC. will correct

errors in the documentation without charge by providing addenda or substitute pages.

If CAMPBELL SCIENTIFIC, INC. is unable to replace defective documentation or

media, or if CAMPBELL SCIENTIFIC, INC. is unable to provide corrected software or

corrected documentation within a reasonable time, CAMPBELL SCIENTIFIC, INC.

will either replace the software with a functionally similar program or refund the

purchase price paid for the software.

CAMPBELL SCIENTIFIC, INC. does not warrant that the software will meet

licensee’s requirements or that the software or documentation are error free or that the

operation of the software will be uninterrupted. The warranty does not cover any media

or documentation which has been damaged or abused. The software warranty does not

cover any software which has been altered or changed in any way by anyone other than

CAMPBELL SCIENTIFIC, INC. CAMPBELL SCIENTIFIC, INC. is not responsible

for problems caused by computer hardware, computer operating systems or the use of

CAMPBELL SCIENTIFIC, INC.’s software with non-CAMPBELL SCIENTIFIC,

INC. software.

ALL WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE DISCLAIMED AND EXCLUDED. CAMPBELL

SCIENTIFIC, INC. SHALL NOT IN ANY CASE BE LIABLE FOR SPECIAL,

INCIDENTAL, CONSEQUENTIAL, INDIRECT, OR OTHER SIMILAR DAMAGES

EVEN IF CAMPBELL SCIENTIFIC HAS BEEN ADVISED OF THE POSSIBILITY

OF SUCH DAMAGES.

CAMPBELL SCIENTIFIC, INC. is not responsible for any costs incurred as result of

lost profits or revenue, loss of use of the software, loss of data, cost of re-creating lost

data, the cost of any substitute program, claims by any party other than licensee, or for

other similar costs.

LICENSEE’S SOLE AND EXCLUSIVE REMEDY IS SET FORTH IN THIS

LIMITED WARRANTY. CAMPBELL SCIENTIFIC, INC.’S AGGREGATE

LIABILITY ARISING FROM OR RELATING TO THIS AGREEMENT OR THE

SOFTWARE OR DOCUMENTATION (REGARDLESS OF THE FORM OF

ACTION; E.G., CONTRACT, TORT, COMPUTER MALPRACTICE, FRAUD

AND/OR OTHERWISE) IS LIMITED TO THE PURCHASE PRICE PAID BY THE

LICENSEE.

Page 4

License for Use

This software is protected by both the United States copyright law and

international copyright treaty provisions. You may copy it onto a computer to

be used and you may make archival copies of the software for the sole purpose

of backing-up CAMPBELL SCIENTIFIC, INC. software and protecting your

investment from loss. All copyright notices and labeling must be left intact.

This software may be used by any number of people, and may be freely moved

from one computer location to another, so long as there is not a possibility of it

being used at one location while it’s being used at another. The software,

under the terms of this license, cannot be used by two different people in two

different places at the same time.

815 W. 1800 N.

Logan, UT 84321-1784

USA

Phone (435) 753-2342

FAX (435) 750-9540

www.campbellsci.com

Campbell Scientific Canada Corp.

11564 -149th Street

Edmonton, Alberta T5M 1W7

CANADA

Phone (780) 454-2505

FAX (780) 454-2655

Campbell Scientific Ltd.

Campbell Park

80 Hathern Road

Shepshed, Loughborough

LE12 9GX, U.K.

Phone +44 (0) 1509 601141

FAX +44 (0) 1509 601091

Page 5

PondView Table of Contents

PondView Introduction

I.1 Please Read This........................................................................................1

I.2 Overview ...................................................................................................1

I.3 Installation.................................................................................................1

I.4 Uninstall ....................................................................................................3

I.5 Some Notes on System Resources.............................................................3

....................................................1

1. Setting Up the Network and Communicating

1.1 Getting Started ...................................................................................... 1-1

1.2 Setup ..................................................................................................... 1-1

1.2.1 Start the Server............................................................................ 1-1

1.2.2 Configure Communication.......................................................... 1-2

1.3 Device Configuration Settings.............................................................. 1-4

1.3.1 Serial Port.................................................................................... 1-4

1.3.2 PakBusPort.................................................................................. 1-4

1.3.3 CR10X-TD.................................................................................. 1-4

2. PondView Display Screen

2.1 Enable the Display................................................................................ 2-1

2.2 Overview Page...................................................................................... 2-1

2.3 Pond Page ............................................................................................. 2-2

2.4 Temperature Thermometer ................................................................... 2-3

2.5 Trends ................................................................................................... 2-3

.......................................2-1

........1-1

3. Control Set Points and Alarms

3.1 Control Set Points ................................................................................. 3-1

3.1.1 Aerator Control ........................................................................... 3-1

3.2 Alarms .................................................................................................. 3-2

3.2.1 Aerator Alarms............................................................................ 3-2

3.2.2 Dissolved Oxygen Alarm............................................................ 3-3

3.2.3 Communication Alarm................................................................ 3-3

4. Manual Control

4.1 Aerator Control..................................................................................... 4-1

5. Timer Aerator Control

6. DO Probe Calibration

6.1 Dissolved Oxygen Calibration.............................................................. 6-1

6.2 Air Calibration ...................................................................................... 6-1

6.3 Hand Calibration................................................................................... 6-1

.........................................................4-1

..............................................5-1

...............................................6-1

i

...............................3-1

Page 6

PondView Table of Contents

7. Communication Status

8. Remote Buoy

8.1 Wireless Dissolved Oxygen Probe........................................................ 8-1

8.2 Buoy Parameters ................................................................................... 8-1

9. Troubleshooting

........................................................... 8-1

...................................................... 9-1

........................................... 7-1

ii

Page 7

PondView Introduction

I.1 Please Read This

Welcome to PondView, Campbell Scientific’s Windows compatible support

software for CR10X-TD Monitoring and Control Systems. Please take time to

read this manual thoroughly before installing your software. We have

designed PondView to be as intuitive as possible, so have intentionally kept

this manual short.

This manual assumes that the user is familiar with the Microsoft Windows

interface. If you need help with some of Windows’ features, please call a

Campbell Scientific Applications Engineer.

I.2 Overview

PondView is a combination of two separate software programs that interface

together to provide complete monitoring and control support of your

Automated Monitoring and Control System via the personal computer.

Initial setup will be supported through LoggerNet, while regular monitoring

and control will be a function of the PondView screen.

I.3 Installation

For most applications LoggerNet will be used very infrequently; however, it

will always be running in the background. For some modifications and

troubleshooting LoggerNet may be required.

As with all software, Campbell Scientific strongly recommends that a back-up

of critical files be performed before software installation. In addition, periodic

back-ups should be performed on files in the Campbellsci directory.

PondView requires Windows NT, Windows 2000 or Windows XP operating

systems. The computer should have at least a Pentium II processor with 128

MB RAM.

The following instructions assume that drive D: is a CD-ROM drive on the

computer from which the software is being installed. If the drive letter is

different, substitute the appropriate drive letter.

Install the LoggerNet CD by inserting the CD into the CD slot of the computer;

this will initiate the installation process. DO NOT change the default locations

for the directories and file locations. Follow this installation by installing the

PondView CD. As with the LoggerNet CD, this will automatically initiate the

installation process. DO NOT change the default locations for directories and

file locations. Simply select Next.

1

Page 8

PondView Introduction

If remote PCs are being used to network with the main server computer, then

PondView is the only installation that is required. Installation of LoggerNet is

only required on the server PC.

When prompted to restart the computer select Yes. If insertion of the CD does

not initiate the installation process, proceed as follows: From the Windows

system menu, select Start | Run.

Type D:\Setup.exe in the Open field or use the Browse button to access the

CD-ROM drive and select the setup executable in the folder.

This activates the PondView Installation Utility. Follow the prompts on the

screen to complete the installation.

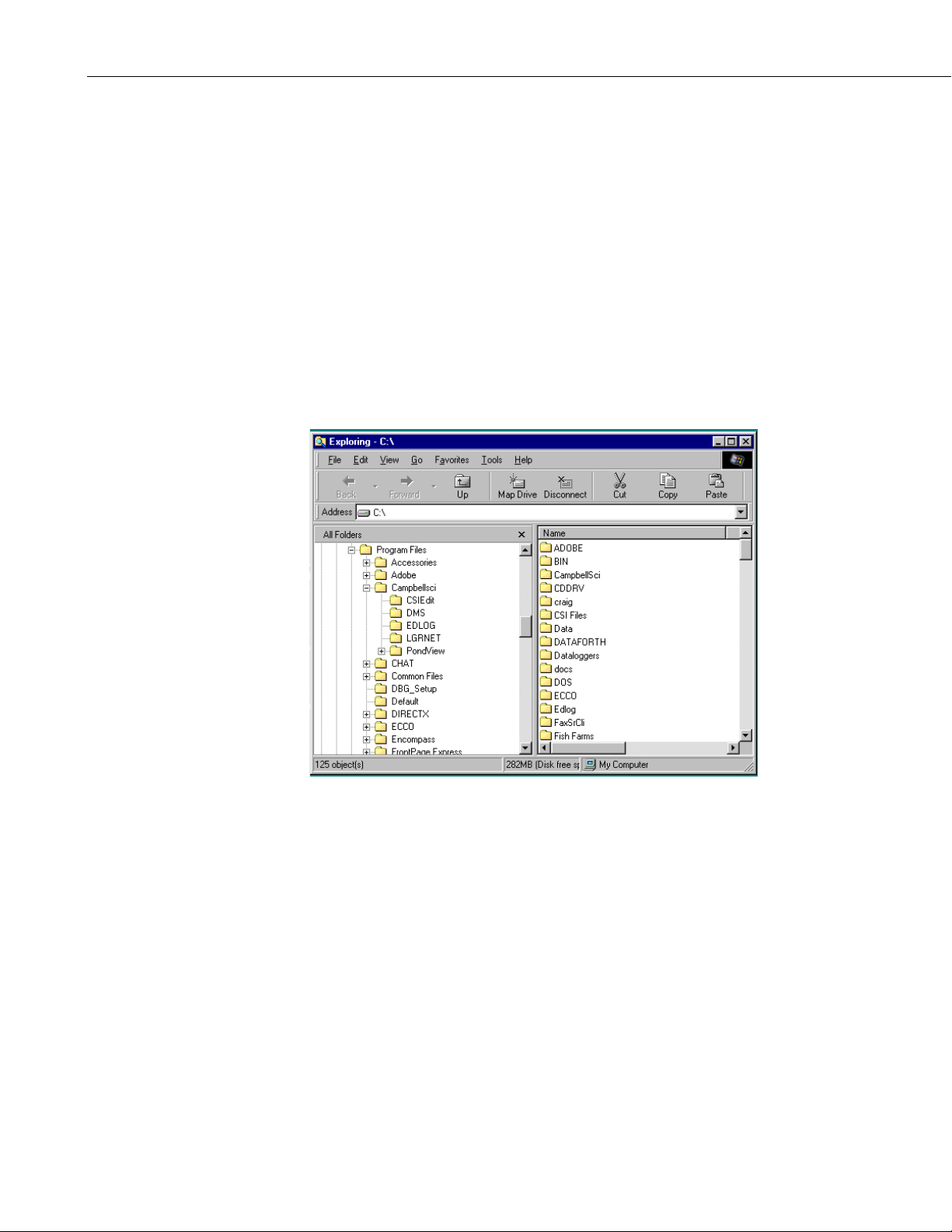

The file Campbellsci will be loaded into the C:\Program Files directory. All

of the LoggerNet and PondView files will be found in the Campbellsci file.

Each PondView software package also includes a customized Application File.

This program is found on the 3 ½ floppy disk.

To install this file, insert the floppy disk into your A: drive. Using Windows

Explorer select the A: drive. Click the right mouse button and select Copy on

PondView.ini. Paste this file to the C:/Program File/Campbellsci/PondView

folder. This file already exists in the PondView folder so you will be asked if

you would like to replace it. Select yes. This will load the proper files to

operate your individualized program.

If a remote PC is used to network with the server running LoggerNet, the

network path needs to be specified as part of the PondView path.

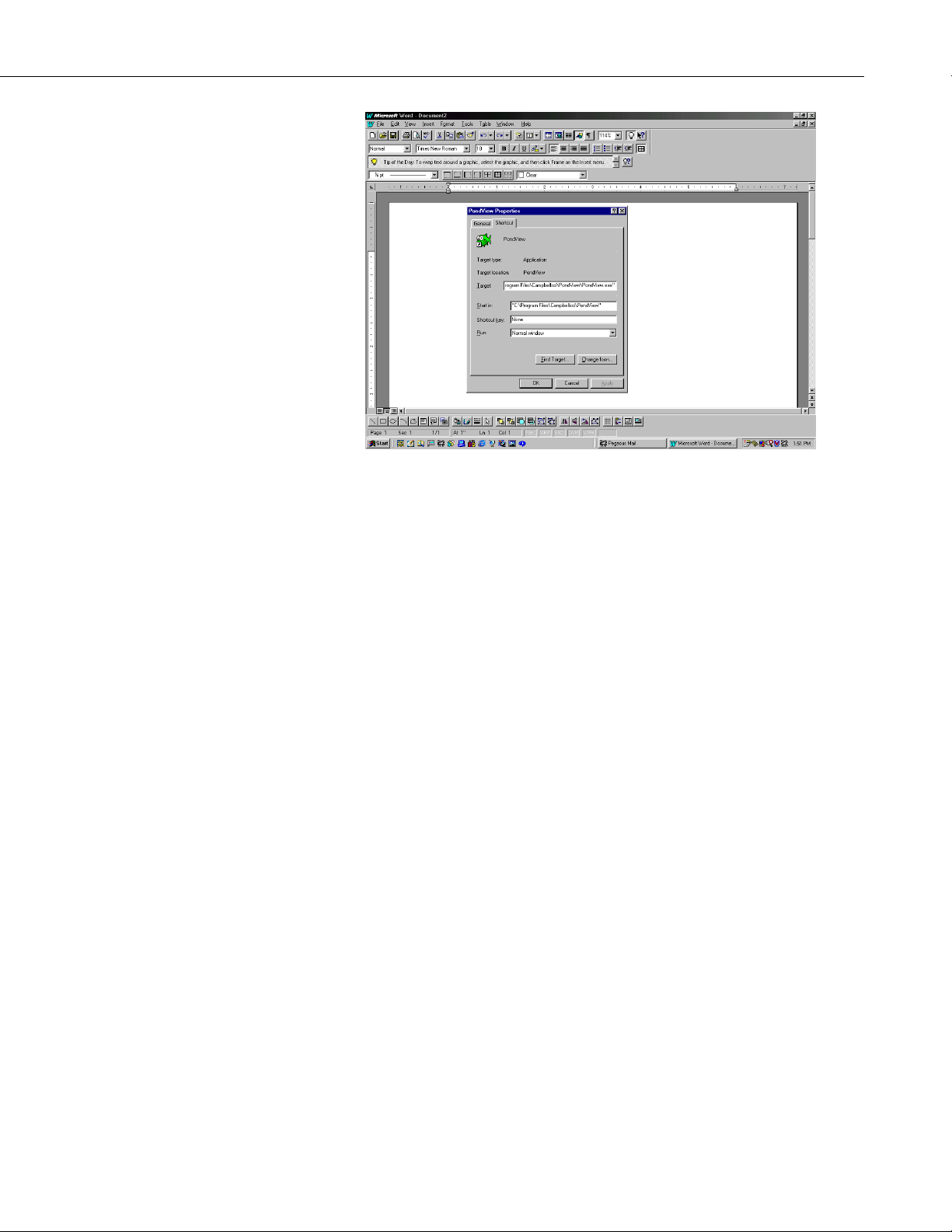

Right click on PondView, found in START | PROGRAMS. A menu will

appear. Select Properties.

2

Page 9

PondView Introduction

The Path should read: “C:\Program Files\Campbellsci\PondView\

PondView.exe” 192.168.22.131 username password 6789

The 192.168.22.131 is the IP address of the server computer. This will be

different for every computer.

If a username or password is not used, then any word can be substituted.

I.4 Uninstall

Should you need to remove PondView from a computer, an uninstall program

is provided. Select SETTINGS from the Start button then select CONTROL

PANEL. Double click on ADD/REMOVE programs. Select PondView from

the list and select the Add/Remove button.

I.5 Some Notes on System Resources

PondView is capable of running in the background while you are doing other

work with other programs. To do this, it uses the system’s idle time for some

of its serial communications. Some other applications may be so resource

intensive that PondView does not receive sufficient time for its

communication. PondView will not run reliably with these applications

loaded.

3

Page 10

PondView Introduction

This is a blank page.

4

Page 11

Section 1. Setting Up the Network and Communicating

1.1 Getting Started

With the software installed, you are probably anxious to start using PondView.

If at all possible, prior to deploying the equipment in the field, make sure you

can establish a telecommunication link with the CR10X-TD—even if you have

to create a temporary setup in your office. Getting familiar with PondView

and your CR10X-TD in the comfort of your office will be a lot less frustrating

than trying to resolve problems in the field. If your CR10X-TD is already

deployed and working, then establishing communications with the CR10X-TD

is the place to start. RF radio telecommunication should not be operated at

close distances. Damage to your radios can occur.

1.2 Setup

The LoggerNet communications server is the application that provides the

software interface between the computer applications and the CR10X-TD

network. The server software must be running on the computer for data

monitoring and control to occur and to allow any of the applications to be

used to access information from the CR10X-TD.

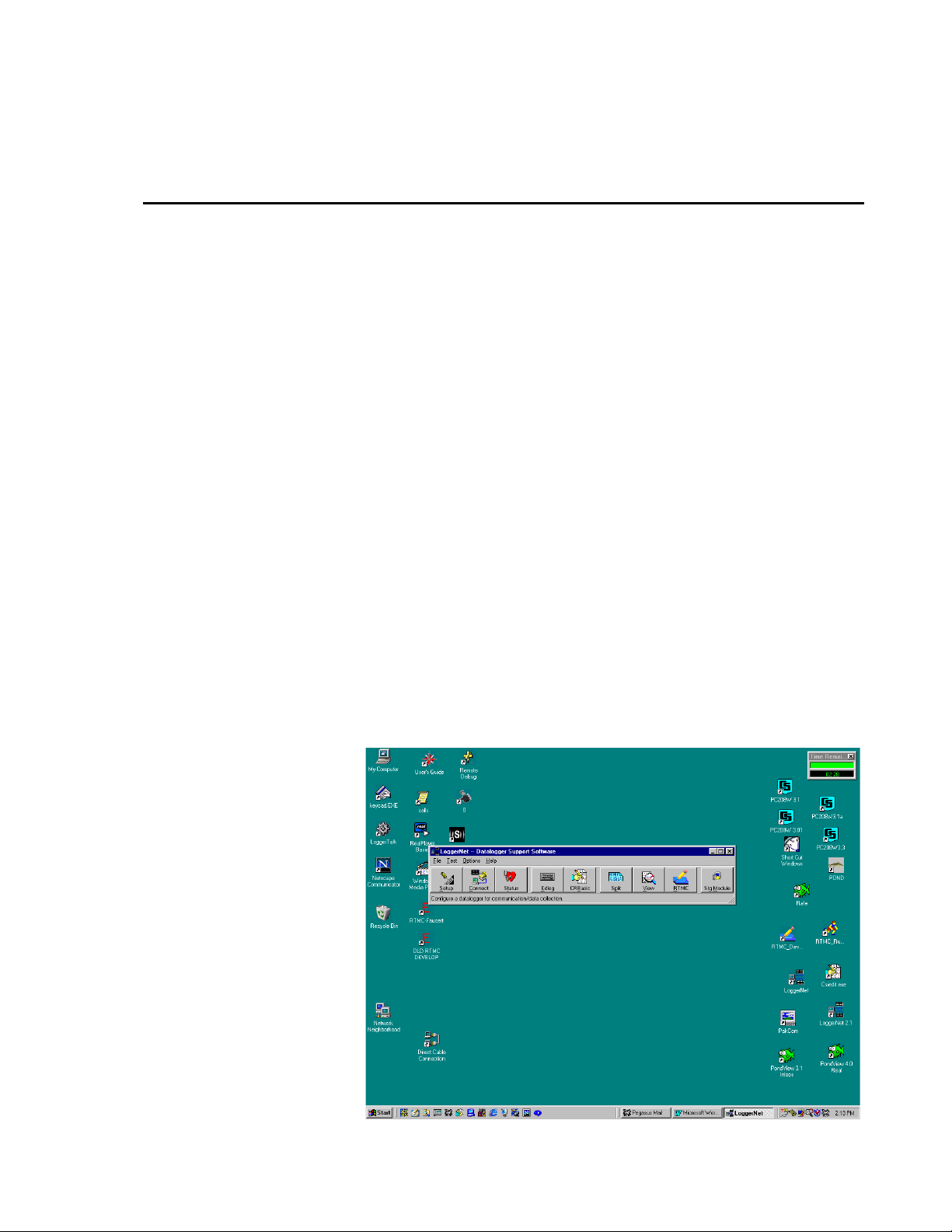

1.2.1 Start the Server

The Server is accessed through the PROGRAMS directory. From the Start

button select PROGRAMS. From the PROGRAMS menu select LoggerNet.

A bar menu will be displayed.

1-1

Page 12

Section 1. Setting Up the Network and Communicating

1.2.2 Configure Communication

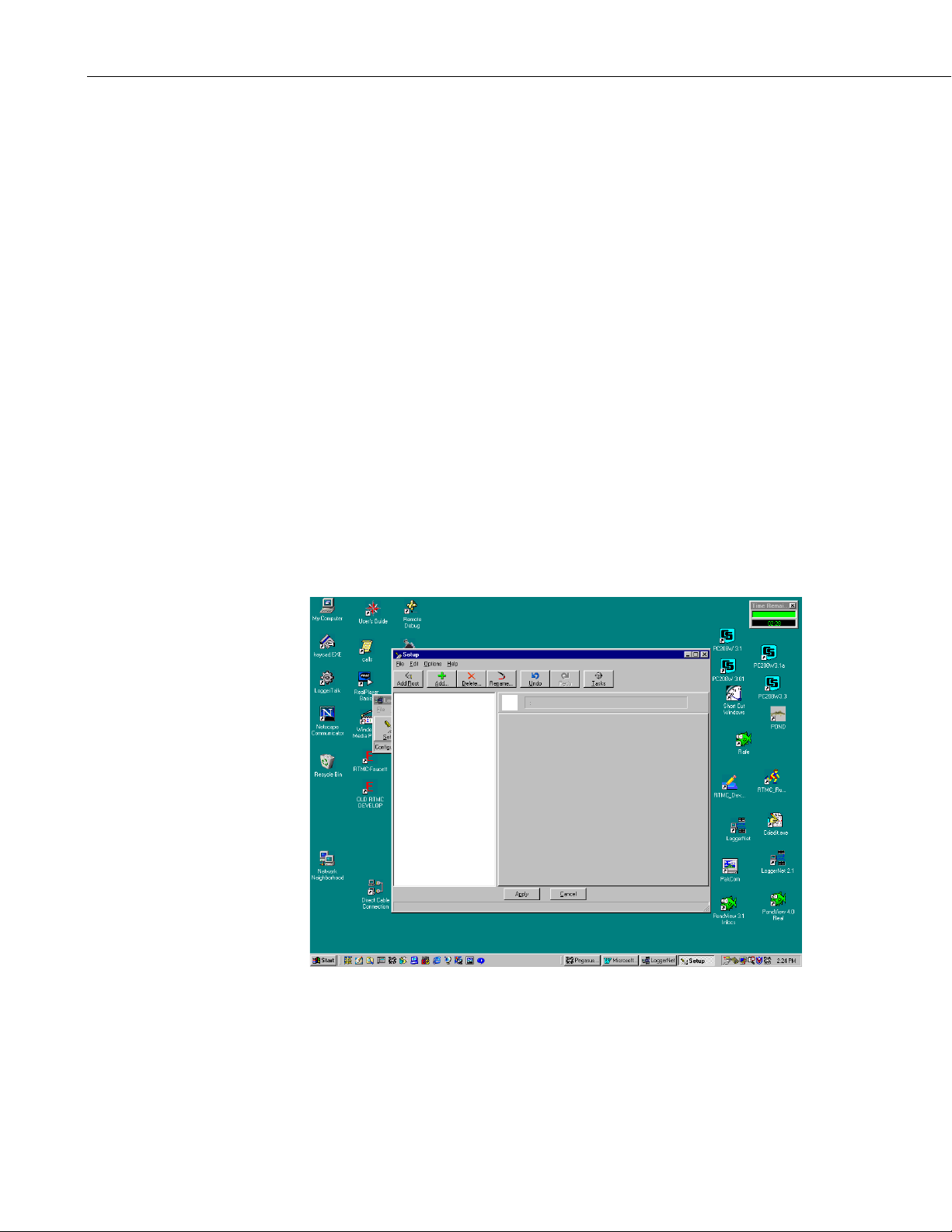

The Setup Screen is used to configure your CR10X-TD network, define the

communication link that exists between the computer and the CR10X-TD, and

to set up the data collection schedule.

Although many different methods are used for communication between the

monitoring system and the PC, the following are the most common methods

used.

• Direct Connect - Simple serial communication or RAD Short-Haul

Modem communication.

• Spread Spectrum Radio - Connection using Campbell Scientific RF400 or

other spread spectrum radios. These radios do not require FCC licenses.

Distance for communication is limited.

• Radio Frequency (RF) - Connection over specific frequencies require an

FCC license. Distances are generally greater than for the RF400 although

both require line-of-site paths.

The Setup Screen is accessed through the LoggerNet Menu Bar. The Setup

button is the first button from the left of the Menu Bar.

When you first select the Setup button, the dialog box should appear as:

The Setup Screen is divided into two parts: the device map (left side of the

screen) and the set up tabs (right side of the screen).

1-2

Begin adding devices to the device map in the order that they appear in your

communication link. For example, let’s assume your CR10X-TD is connected

to the computer via an RF400 radio link. You would first add a Serial Port,

Page 13

Section 1. Setting Up the Network and Communicating

then the PakBusPort, then the CR10X-PB, this is the path of communication

from the PC to the CR10X-PB.

A new device can be added to the network device map by choosing Edit | Add

from the Setup menu. The Add Device Window will appear.

When you select an item from the left side of the Add Device window, valid

connections will be displayed in the right-hand column. Highlight the item to

which you want to attach the device and select the Add Now button. Continue

to add devices in this manner until your network map is complete.

For direct connection to the CR10X using short RS232 connection, RAD Short

Haul Modems, or RF400 Spread Spectrum Radio the device map would be:

1-3

Page 14

Section 1. Setting Up the Network and Communicating

Once all devices are added to the device map, complete the forms associated

with each device. Refer to the sections that immediately follow for

information on setting up devices. The CR10X-PB is a default label and must

be edited. The PondView Software will be looking for a label called

CR10XTD_1. After all settings are configured, apply the Setup program by

selecting the Apply button; this saves all settings.

1.3 Device Configuration Settings

When you highlight any device on the network shown on the left side of the

Setup screen, forms appear on the right side with the relevant settings. These

settings are different for different devices and are described in detail below.

1.3.1 Serial Port

The serial port has only a Hardware tab to configure.

Communication Enable - Before communication can take place, all devices in

the communications chain must be enabled. The default setting for this check

box is Enabled.

Call-Back Enable - Leave unchecked.

Com Port Connection - This field designates the communications port through

which you will be connecting to the CR10X-TD or RF232T Base Station.

Select the arrow to the right of the field with a mouse to display Com 1

through Com 8. For most computers Com 1 will be used.

Extra Response Time - Leave this set at the default rate. Additional time may

be needed in instances where the communications link is noisy or network

traffic is heavy.

1.3.2 PakBusPort

Communication Enabled - Must be checked.

PakBus Port is Dialed - Leave unchecked.

Extra Response Time - Leave default value of 000s.

Beacon Interval - Leave default value of 060s.

1.3.3 CR10X-TD

The CR10X-TD has four different tabs. Similar to a serial port, a hardware tab

is completed to specify communication settings. There are also tabs to define

the method of data collection, how often data should be collected, and whether

to automatically update the CR10X-TD’s clock.

1-4

Page 15

1.3.3.1 Hardware Tab

Communication Enable - Before communications can take place, all devices in

the chain must be enabled.

Maximum Time On-Line - Set to 5 min.

Maximum Packet Size - Default 2048 bytes should be used.

Extra Response Time - Default 0 ms should be used.

Maximum Baud Rate - Default of 9600.

Security Code - The CR10X-TD can have a security code to restrict access to

the system. This helps prevent inadvertent changes to the CR10X-TD’s

program or memory. Leave this value set to 0. If a security code is needed,

the CR10X-TD program must also be changed.

PakBus Address - This must correspond with the value set in the CR10X.

Default is 1. Each logger in the network must have individual numbers.

Section 1. Setting Up the Network and Communicating

1.3.3.2 Data Collection Tab

The data collection tab is used to define what data tables will be copied from

the CR10X-TD. The tables available will not be shown until Scheduled

Collection has been enabled. Skip to the 1.3.2.3 Scheduled Collection Tab

before Data Collection Tab. Tables selected and checked with the green check

mark should only include REAL and HIST. All other tables should be marked

with the red X, excluding them from the Tables section.

All other parameters should be left as the default value.

1-5

Page 16

Section 1. Setting Up the Network and Communicating

1.3.3.3 Scheduled Collection Tab

The Scheduled Collection tab defines when PondView will automatically

collect data from the CR10X-TD.

Scheduled Collection Enabled - This check box activates the data collection

schedule defined on this tab. This box must be checked.

Initial Date - Leave as default date.

Initial Time - Set this 10 seconds after the hour. This allows all wireless

probes to respond to the CR10X before data collection begins.

Collection Interval - This is the interval at which the CR10X-TD will be

queried for new data. If this interval is set at 10 minutes, new data will be

collected from the CR10X-TD every 10 minutes. One minute is generally

quick enough for most data collection. Longer times or shorter times may be

set depending upon how frequently data must be updated.

Primary Retry Interval- If a data collection attempt is made but fails, you can

specify an interval on which another attempt will be made. The Primary Retry

Interval should always be greater than the Collection Interval.

Number of Primary Retries - The number entered into this field is the number

of times PondView will attempt to contact the CR10X-TD on the Primary

Retry Interval. If the number of collection attempts specified are unsuccessful,

then the server will revert to calling on the Secondary Retry Interval.

Secondary Retry Interval - The Secondary Retry Interval is a calling interval

that will be attempted if all Primary Retries have failed. The Connection

Status Screen Alarm on the PondView screen will be activated if the

Secondary Retry Interval is reached. Data collection attempts will continue on

the Secondary Interval until a data collection attempt is successful, at which

time all retry statistics are reset.

1-6

Page 17

1.3.3.4 Clock Check/Set Tab

Automated Clock Check - Enable this to compare the CR10X-TD clock to the

server computer’s clock based on the schedule defined by the other parameters

on this tab. If the CR10X-TD’s time differs from the PC time by more than a

specified amount, the CR10X-TD clock will be set automatically. Enable

should be checked. Set the clock initial time to 15 seconds after the hour. All

other settings should be left at the default value.

Section 1. Setting Up the Network and Communicating

1-7

Page 18

Section 1. Setting Up the Network and Communicating

This is a blank page.

1-8

Page 19

Section 2. PondView Display Screen

2.1 Enable the Display

PondView is activated by selecting Start|Programs|PondView.

When PondView is first started, please be patient. The initialization may take

a few minutes.

2.2 Overview Page

The Overview Page provides a quick summary of the dissolved oxygen

readings in each pond. Ponds are arranged in sections corresponding to the

stations that monitor the pond. Each station group includes a time stamp of

when the data was collected.

In addition to the dissolved oxygen value, an alarm light is displayed along the

right side of each DO value. If the alarm condition occurs, the light will be

red; if the alarm is not active, then the light will be green.

A smaller light will be displayed along the left side of the pond label. This

alarm light represents communication of the remote buoy to the monitoring

station. A green light indicates successful communication between the buoy

and monitoring station. A red light indicates communication has been lost.

2-1

Page 20

Section 2. PondView Display Screen

2.3 Pond Page

The Pond Page provides a desktop display for real-time dissolved oxygen and

motor amps, and is used for entering set points for alarms, control of aeration,

and sensor calibration.

2-2

Page 21

2.4 Temperature Thermometer

The temperature thermometer can be use to monitor temperature in degrees

Fahrenheit or Celsius. Using the mouse, click on the thermometer the degree

units will change to either Celsius or Fahrenheit.

2.5 Trends

Seven days of historical data is displayed on the Trends Graph. Select the

Trends Graph by using the mouse left button to open the Trends Button

A specific value with time stamp can be viewed by selecting the data point on

the graph with the mouse arrow, then clicking the left mouse button. The

selected value will be displayed in the upper right hand corner of the graph.

The associated time stamp will be displayed in the upper left hand corner of the

graph.

The graph can be sent to a printer by clicking the graph icon in the upper right

corner of the graph.

Section 2. PondView Display Screen

.

This is only a sample of the data that is being collected and stored by the

CR10X-TD. If more data is needed, the PondView Graph can be customized

for specific application, or call a Campbell Scientific, Inc. Applications

Engineer for help.

2-3

Page 22

Section 2. PondView Display Screen

This is a blank page.

2-4

Page 23

Section 3. Control Set Points and Alarms

3.1 Control Set Points

3.1.1 Aerator Control

The CR10X-TD automatically controls each aerator. If the dissolved oxygen

in the pond is below a user-determined value, then the aerator is switched on.

If the dissolved oxygen raises to a high set point, the aerator is switched off.

Double-click on the pond label (example Pond 1). This will pull up a slider

switch that is used to set the low and high points for each aerator in Pond 1.

The set point can be changed in two ways. To use the slider bar, point the

mouse arrow to the colored bar on the slider. While holding the left button on

the mouse slide the bar up to the value desired.

Use the edit box by highlighting the value to be changed and enter the new

value. This value will not be sent to the CR10X-TD until the ENTER key on

the PC keypad is pushed.

The aerator will switch on when the DO value is less than the value selected

with the DO ON slider. The aerator will switch off when the DO value is equal

to or greater than the value selected with the DO OFF slider. When changing

this value, the bar to show the status by turning black temporarily. At this

point the value has been sent to the CR10X-TD and the slider box can be

closed (select the X in the upper right corner).

3-1

Page 24

Section 3. Control Set Points and Alarms

3.2 Alarms

PondView provides audio and visual alarms to indicate when critical levels

have been reached. These alarms indicate critical levels of dissolved oxygen,

aerator motor amps, and communication.

To acknowledge the alarm, point to the visual alarm with the mouse and push

the right mouse button. An ALARM ACKNOWLEDGE button will appear.

Select this button and the audio alarm will be deactivated. Alarms will switch

off if the alarm condition on longer exists.

3.2.1 Aerator Alarms

Aerator status is being monitored by the CR10X-TD. Aerator alarms can be

activated on two conditions. If the aerator is supposed to be on but if the amps

being monitored indicate a value that is lower than expected, the amp alarm

will be activated. Also, if the amps being drawn are higher than is expected,

the alarm will be activated.

The high set point will also disable the aerator if the condition is met. For

example, if the amps high set point on aerator 1 in pond 1 is set at 40 amps,

and the amps being monitored indicate 41 amps, then the alarm will be

activated and the aerator will be switched off.

These two set points are selected by clicking with the mouse on the aerator that

is desired. Alarms have both a visual display and an audio sound. They are

activated every 30 seconds.

3-2

Page 25

3.2.2 Dissolved Oxygen Alarm

To select the slider bars for DO alarm set points, double click on the CLICK

FOR ALARMS SET POINT box found in the lower right corner. Like the

other slider bars, move the bar until the desired set point is found. This enables

the alarms for the dissolved oxygen in the ponds. If the DO is lower than the

set point, the alarms are activated. These alarms are acknowledged by using

the mouse to select the alarm and pressing the right mouse key.

Section 3. Control Set Points and Alarms

3.2.3 Communication Alarm

If communication between the CR10X-TD and PC is disrupted, the

Communication Status light will turn red and alarm sounds are activated.

Disable this alarm by selecting the acknowledge button.

3-3

Page 26

Section 3. Control Set Points and Alarms

This is a blank page.

3-4

Page 27

Section 4. Manual Control

The automated feature of the CR10X-TD can be overridden using the

PondView monitor. Switching aerators on or off can also be accomplished

using the on-screen display.

4.1 Aerator Control

Click the desired aerator with a right mouse. The Control button will be

displayed. Selecting turn on will override the automated conditions of aerator

control and turn the aerator on.

To switch off aerators that have been switched on, click the desired aerator

with the right mouse button. The Control button will be displayed. Selecting

Turn Off will return control of the aerator back to the automated function

controlled by the CR10X-TD. The aerator will turn off if the High-Off SetPoint for that aerator is less than the current dissolved oxygen reading.

4-1

Page 28

Section 4. Manual Control

This is a blank page.

4-2

Page 29

Section 5. Timer Aerator Control

In addition to the aerators being controlled automatically be the condition of

the dissolved oxygen, and manually by the operator, they can also be

controlled by a timer.

Like the manual mode of control, the time mode of control overrides the

automated control based on the condition of the dissolved oxygen. The timers

will turn the aerator on and off at a user specified time regardless of the

condition of the dissolved oxygen.

Click on the desired aerator. Click on the Timer Status button; this will pop up

the Paddle Wheel Timer Select screen. In this screen enter the desired start and

stop times. These must be entered in military times. After a value is entered in

the Set Start Time and Set Stop Time locations, the corresponding button must

be pressed in order to send these values to the CR10X-TD.

Even with the start and stop values sent to the CR10X-TD, the timer function is

not active until the Timer Status Button is turned ON. To turn the button on,

click the Timer Status button with the right mouse. Select ON. The timer is

now active and will control the aerators based on the times entered.

5-1

Page 30

Section 5. Timer Aerator Control

This is a blank page.

5-2

Page 31

Section 6. DO Probe Calibration

6.1 Dissolved Oxygen Calibration

The CR10X-TD is programmed to allow for both automatic dissolved oxygen

air calibration and automatic hand calibration of the dissolved oxygen probes.

Use whichever method is best for your application.

6.2 Air Calibration

Before the air calibration process is enabled the dissolved oxygen probes and

temperature sensor must be removed from the water. Since sunlight can

greatly heat these probes, which will adversely effect the accuracy of the

calibrated value, this process is best performed when the sun is clouded or at

dusk or dawn.

Once the probes are out of the water use the right mouse button to select the

calibration mode. An on/off button will be displayed. Click the button with

the mouse. The line will change on the Calibration Knob to indicate the

calibration status. Give the probes 10 to 15 minutes to stabilize before setting

the calibration process off. The Calibration status should be in the off position

for normal operations.

6.3 Hand Calibration

Hand calibration allows calibrating the submersed dissolved oxygen probe to a

value obtained using an accurate hand-held dissolved oxygen meter. Click on

the Hand Calibration button. Edit the box corresponding to the DO probe that

6-1

Page 32

Section 6. DO Probe Calibration

is to be calibrated. Enter the value obtained using the hand dissolved oxygen

meter. Press the Enter key on the PC keypad to send this new value to the

CR10X-TD. Once all of the corrected values have been entered into the edit

boxes, click the calibration status button with the right mouse. Select Turn On.

The CR10X-TD will remain in the Hand Calibration mode for 30 seconds,

after which it will automatically return to the Normal operation mode.

6-2

Page 33

Section 7. Communication Status

Communication Status (Status Monitor) provides a way to monitor

communication statistics for the CR10X-TD network. Information can be

viewed on data collection attempts and communication failures. This program

is especially useful when using RF communication.

From the LoggerNet Tool Bar button select STATUS.

Status Monitor is customized to display only those columns containing

communication data of interest. To add columns to the Status Monitor

window, select Edit | Select Columns. The Column Modifications window

appears.

Entries in the Statistics Not Visible field will not be displayed on the main

Status Monitor screen. Entries in the Statistics Visible field will be displayed

on the screen.

7-1

Page 34

Section 7. Communication Status

This is a blank page.

7-2

Page 35

Section 8. Remote Buoy

8.1 Wireless Dissolved Oxygen Probe

PondView provides data to view the current conditions of the wireless

dissolved oxygen probe. The Buoy is only displayed on your screen if you are

using the wireless system.

8.2 Buoy Parameters

Use the mouse and right click on the yellow buoy to view the critical

parameters of the wireless probe.

8-1

Page 36

Section 8. Remote Buoy

This is a blank page.

8-2

Page 37

Section 9. Troubleshooting

Problem Solution

PondView Screen does not represent

my pond lay out.

The program on the CR10X-TD has

been changed and now the PondView

Screen will not communicate.

PondView is shipped with a

standard .INI file that represents a

generic pond lay out. You must

replace this generic lay out with one

that has been created for your farm.

This file is found on the 3-1/2” disk

shipped with your equipment.

The server is looking for a specific

list of labels found on the CR10XTD. If the program has been

modified this list may have been

changed. To ensure the server is

looking for the current labels go the

START button on the computer.

Select Programs|LoggerNet|Control

Panel. Select the appropriate station.

Select Options|Advanced|Update

Table Definitions.

9-1

Page 38

Section 9. Troubleshooting

This is a blank page.

9-2

Loading...

Loading...