Page 1

PC208W DATALOGGER SUPPORT SOFTWARE

INSTRUCTION MANUAL

REVISION: 4/01

COPYRIGHT (c) 1996-2001 CAMPBELL SCIENTIFIC, INC.

Page 2

This is a blank page.

Page 3

License for Use

This software is protected by both United States copyright law and

international copyright treaty provisions. The installation and use of this

software constitutes an agreement to abide by the provisions of this license

agreement.

You may copy this software onto a computer to be used and you may make

archival copies of the software for the sole purpose of backing-up CAMPBELL

SCIENTIFIC, INC. software and protecting your investment from loss. This

software may not be sold, included or redistributed in any other software, or

altered in any way without prior written permission from Campbell Scientific.

All copyright notices and labeling must be left intact.

This software may be used by any number of people, and may be freely moved

from one computer location to another, so long as there is not a possibility of it

being used at one location while it's being used at another. The software, under

the terms of this license, cannot be used by two different people in two

different places at the same time.

Page 4

Page 5

Limited Warranty

CAMPBELL SCIENTIFIC, INC. warrants that the installation media on which

the accompanying computer software is recorded and the documentation

provided with it are free from physical defects in materials and workmanship

under normal use. CAMPBELL SCIENTIFIC, INC. warrants that the

computer software itself will perform substantially in accordance with the

specifications set forth in the instruction manual published by CAMPBELL

SCIENTIFIC, INC. CAMPBELL SCIENTIFIC, INC. warrants that the

software is compatible with computers running Microsoft Windows 3.1, 95, 98,

NT and 2000.

CAMPBELL SCIENTIFIC, INC. will either replace or correct any software

that does not perform substantially according to the specifications set forth in

the instruction manual with a corrected copy of the software or corrective code.

In the case of significant error in the installation media or documentation,

CAMPBELL SCIENTIFIC, INC. will correct errors without charge by

providing new media, addenda or substitute pages.

If CAMPBELL SCIENTIFIC, INC. is unable to replace defective media or

documentation, or if CAMPBELL SCIENTIFIC, INC. is unable to provide

corrected software or corrected documentation within a reasonable time,

CAMPBELL SCIENTIFIC, INC. will either replace the software with a

functionally similar program or refund the purchase price paid for the software.

The above warranties are made for ninety (90) days from the date of original

shipment.

CAMPBELL SCIENTIFIC, INC. does not warrant that the software will meet

licensee’s requirements or that the software or documentation are error free or

that the operation of the software will be uninterrupted. The warranty does not

cover any diskette or documentation that has been damaged or abused. The

software warranty does not cover any software that has been altered or changed

in any way by anyone other than CAMPBELL SCIENTIFIC, INC.

CAMPBELL SCIENTIFIC, INC. is not responsible for problems caused by

computer hardware, computer operating systems or the use of CAMPBELL

SCIENTIFIC, INC.’s software with non-CAMPBELL SCIENTIFIC, INC.

software.

ALL WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE DISCLAIMED AND EXCLUDED.

CAMPBELL SCIENTIFIC, INC. SHALL NOT IN ANY CASE BE LIABLE

FOR SPECIAL, INCIDENTAL, CONSEQUENTIAL, INDIRECT, OR

OTHER SIMILAR DAMAGES EVEN IF CAMPBELL SCIENTIFIC HAS

BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

CAMPBELL SCIENTIFIC, INC. IS NOT RESPONSIBLE FOR ANY COSTS

INCURRED AS A RESULT OF LOST PROFITS OR REVENUE, LOSS OF

USE OF THE SOFTWARE, LOSS OF DATA, COST OF RE-CREATING

LOST DATA, THE COST OF ANY SUBSTITUTE PROGRAM, CLAIMS

BY ANY PARTY OTHER THAN LICENSEE, OR FOR OTHER SIMILAR

COSTS.

Page 6

LICENSEE’S SOLE AND EXCLUSIVE REMEDY IS SET FORTH IN THIS

LIMITED WARRANTY. CAMPBELL SCIENTIFIC, INC.’S AGGREGATE

LIABILITY ARISING FROM OR RELATING TO THIS AGREEMENT OR

THE SOFTWARE OR DOCUMENTATION (REGARDLESS OF THE

FORM OF ACTION; E.G., CONTRACT, TORT, COMPUTER

MALPRACTICE, FRAUD AND/OR OTHERWISE) IS LIMITED TO THE

PURCHASE PRICE PAID BY THE LICENSEE.

815 W. 1800 N.

Logan, UT 84321-1784

USA

Phone (435) 753-2342

FAX (435) 750-9540

www.campbellsci.com

Campbell Scientific Canada Corp.

11564 -149th Street

Edmonton, Alberta T5M 1W7

CANADA

Phone (780) 454-2505

FAX (780) 454-2655

Campbell Scientific Ltd.

Campbell Park

80 Hathern Road

Shepshed, Loughborough

LE12 9GX, U.K.

Phone +44 (0) 1509 601141

FAX +44 (0) 1509 601091

Page 7

What's New!

PC208W 3.3 is being released to enhance Edlogw's programming capabilities

by adding new instructions:

• Instruction 126, Data Transfer to HDR GOES (CR510, CR10X, CR23X) -

Communication and control for our SAT HDR GOES transmitter.

• Instruction 127, HDR GOES Status (CR510, CR10X, CR23X) -

Diagnostic tool for SAT HDR GOES transmitter communication.

• Instruction 137, Pulse Width Modulation (CR23X) - Instruction to

generate a continuous pulse width on a control port.

In addition to these new instructions, an issue has been resolved that was seen

when using call-back over telephone modems. Some modems require a longer

power-down period after a call-back attempt to reset and return to a callwaiting state. An improvement has been made in PC208W 3.3 to increase this

power-down period to help ensure that most modems will be reset properly

after call-back.

Note for Windows ME Users: Microsoft has confirmed a problem with its

Windows ME Internet Protocol Helper API component (Iphlpapi.dll) that can

result in an error message when a 16-bit program makes a call to the Winsock

connect() function. This problem affects PC208W. Refer to Microsoft's web

site at http://support.microsoft.com/support/kb/articles/Q279/8/66.ASP to

download a fix for this problem prior to running PC208W.

For Users Upgrading from PC208W 2.3 or earlier

If you are upgrading from PC208W 2.3 or earlier, you may also be interested

in some of the new features and improvements which were implemented in

PC208W 3.0, 3.1, and 3.2.

Changes in PC208W 3.2

PC208W 3.2 implements the ability to use TCP/IP communication protocol to

communicate with Campbell Scientific dataloggers. This version of software is

required to communicate with a datalogger over an Ethernet network (Internet

or Intranet) using Campbell Scientific's NL100/105 Network Link Interface.

Changes in PC208W 3.1

Setup

Scheduled data collection has been improved to better handle instances of

failed calls. Retry attempts are now synch r onized with the original Calling

Interval to help prevent drif t wh en in retry mode. This new feature is impor tant

to those who have a critical time window during which calls should be made,

Page 8

Connect

Edlog

such as cell phone users who power their communication equipment only

during certain times of the day.

PC208W has been updated to include the improved telecommunications

commands supported by newer datalogger operating systems (see Note below).

These commands help to prevent ports or flags from being inadvertently

toggled to another state because of noisy communication links.

When PC208W connects to a datalogger, a command is sent to determine the

operating system in the datalogger. PC208W then sends the appropriate

commands for the datalogger's communications protocol. Integrity measures

with this newer protocol include error-checking of input locations and setting

ports and flags high or low (rather than toggling the ports or flags between

states as in older operating systems).

Instructions have been added in support of some of the newer devices available

from Campbell Scientific: TDR100 Time Domain Reflectometer, SDM-CAN

CAN-bus interface, and the LI-COR 7500 Gas Analyzer.

Support has been added to the measurement instructions for the newer

datalogger operating systems which take advantage of Autoranging (see Note

below). With Autoranging, the datalogger tests and determines the correct

voltage range for the sensor being measured. Note that Autoranging can

significantly increase program execution time; therefore, it should be used with

caution. Refer to the Edlog help file or the datalogger User's Manual for

additional information .

Report

The runtime version of Split (Splitr) can now be run minimized from a

command line using the /H switch.

Storage Module Communication

Support has been added to SMS for the new 4M (SM4M) and 16M (SM16M)

storage modules. These modules store 2 million and 8 million data points,

respectively, and take advantage of Flash memory technology.

SMS now uses View to take a quick look at data stored on the module. Using

View, the user can print quick reports and select up to two elements for

graphing.

Page 9

NOTE

The features are available only in the following operating

systems:

CR10X Default OS Revision 10 and greater

CR10X Modbus OS Revision 06 and greater

CR10X Alert OS Revision 03 and greater

CR10X Toro OS Revision 03 and greater

CR510X OS (all options) Revision 03 and greater

CR23X OS (all options) Revision 07 and greater

Refer to the datalogger operator's manual for information on

accessing the *B mode to determine the datalogger's OS version

and revision number. Contact Campbell Scientific for upgrade

information if your datalogger does not support the required

features.

Changes in PC208W 3.0

Setup

Improved Modem Communication - Setting up remote communications is

easier with PC208W's new modem configurations. PC208W uses hardware

flow control, verbose result codes (looking for “CONNECT” back from the

modem rather than a number), and error correction which is consistent with the

newer, faster modems. Just pick your modem from a list, and you should be

ready to communicate. If your modem is not in the list, the default modem

will work in most instances.

Connect

NOTE

If you used a custom modem string in a previous version of

PC208W, please refer to the special upgrade information

provided in Section 1.4, Installation.

User-determined FSA 2 Data File Names - PC208W now lets you specify

different names for data files from Final Storage Areas 1 and 2.

New Clock Offset - A clock offset feature has been added to make it easier to

set the datalogger time for different time zones or daylight savings.

Updated Scheduling Capability - Datalogger schedules can now be copied to

one or more datalogger stations. When you have one station's schedule set up,

simply click a button to apply those settings to other stations. This helps you

set up your data collection schedules in less time and with less effort.

Datalogger Call-back - If you use call-back with your dataloggers, you’ll

notice that PC208W automatically tries to initialize the COM port. Check the

Help on “Call-back” for details on properly setting up the network.

New Numeric Monitor - The Numeric Monitor is now a stand-alone window

that is opened separately from the other Connect screen views. This 17-column

Page 10

View

by 15-cell display has room for assigning 254 input locations. It can be sized to

view one to four columns (up to 60 input locations) at one time. This new

design allows you to monitor your real-time data with a small screen while

minimizing the rest of PC208W so you can work on other tasks.

Enhanced Graphing Capability - You can now save any of the three realtime graphs to disk in a WMF (Windows metafile) format for printing or

importing into other programs.

New Graphing Capability - View now plots up to two array elements on one

graph. This is especially useful to quickly identify potential problems in your

data (or sensors) either in the field or office. Use the zoom feature for a closer

look at the graph, or click on a data point to display its numeric value.

Enhanced Ease of Use - Graphical icons have been added to the user interface

for easier and more efficient use of the program. For instance, you can view

your data in comma separated, columnar, or hexadecimal format just by

clicking a button.

Enhanced Printing Capability - You can now preview your data or graph

before printing. Headings have been added to the printed page for quicker

identification of printed data. Margins can be adjusted by entering numerical

values or by simply "dragging" them in Print Preview mode.

Report

Start Offsets - A negative value can now be entered as an offset on the Input

File tab. This directs Split to begin reading X bytes from the end of the file

(positive values begin reading f r om the beginning of the file). This makes

using the time sync functions to process the tail end of a data file much faster

when that data file is very large.

SplitR - Multiple copies of SplitR, the comma n d-line version of Split, can be

run at once using the /M switch.

New Start-up Feature!

Command Line Capabilities - Command line arguments can be entered from

a Windows command prompt or Windows short cut to open PC208W and

perform a specific task automatically. Collecting data, setting the clock,

invoking the Numeric Monitor or graphs, and toggling ports or flags can all be

accomplished using command line arguments. Administrators can set up

complex tasks for associates to run without training them on the entire

package.

You can find a comprehensive list of these command line entries in the Help

(search for “command line” ) and in Section 1.5 of this manual.

Page 11

PC208W Datalogger Support Software

Table of Contents

PC208W 3.3 Introduction................................................ 1

I.1 Please Read This....................................................................................... 1

I.2 Overview................................................................................................... 1

I.3 Other Software of Interest......................................................................... 2

I.4 Installation ................................................................................................ 3

I.4.1 Floppy Disk Installation.................................................................. 4

I.4.2 For Users Upgrading from PC208W Versions 2.3 and Earlier....... 4

I.5 Uninstall.................................................................................................... 6

I.6 Some Notes on System Resources ............................................................ 6

I.7 Getting Help.............................................................................................. 7

1. Setting Up the Network and Communicating

with the Datalogger ............................................. 1-1

1.1 Getting Started ......................................................................................1-1

1.2 Setup .....................................................................................................1-1

1.2.1 General Information....................................................................1-1

1.2.2 Setup Procedures.........................................................................1-1

1.2.3 Device Map Notes.......................................................................1-3

1.2.4 Example Device Maps.................................................................1-5

1.2.5 Notes on Data Collection and Formats........................................1-9

1.2.6 Setup Safety Tips.......................................................................1-10

1.3 Connect...............................................................................................1-11

1.3.1 Handy Things That May Not Be Obvious.................................1-11

1.3.2 Connect Safety Tips ..................................................................1-13

1.4 Status...................................................................................................1-13

1.4.1 Device Map and Station Map....................................................1-13

1.4.2 Low Level I/O...........................................................................1-14

1.4.3 COMM SWF Messages.............................................................1-15

1.4.4 Pause..........................................................................................1-15

1.5 Command Line Parameters.................................................................1-16

2. Program: EDLOG................................................... 2-1

2.1 Introduction...........................................................................................2-1

2.2 Getting Started ......................................................................................2-4

2.2.1 Creating a New EDLOG Program...............................................2-4

2.2.2 Editing an Existing Program .......................................................2-4

2.2.3 Documenting a DLD File............................................................2-4

2.2.4 The Program Development Template .........................................2-4

2.3 Comments .............................................................................................2-5

2.4 Instructions............................................................................................2-6

2.4.1 Entering Parameters ....................................................................2-6

2.4.2 Data Entry Warning.....................................................................2-7

i

Page 12

PC208W Datalogger Support Software Table of Contents

2.5 Expressions............................................................................................2-7

2.5.1 Rules for Creating Expressions....................................................2-7

2.5.2 Examples .....................................................................................2-9

2.6 Editing EDLOG Programs ..................................................................2-10

2.6.1 Editing Comments, Instructions, and Expressions....................2-10

2.6.2 Cut, Copy, Paste, and Clipboard Options..................................2-11

2.6.3 Library Files ..............................................................................2-11

2.6.4 Renumbering the Instructions.................................................... 2-11

2.6.5 Compress View..........................................................................2-11

2.7 Input Locations....................................................................................2-12

2.7.1 Entering Input Locations...........................................................2-12

2.7.2 REPS..........................................................................................2-12

2.7.3 Input Location Editor.................................................................2-13

2.7.4 Input Location Anomalies.........................................................2-15

2.8 Indention..............................................................................................2-15

2.9 File Types............................................................................................2-16

2.9.1 Program Documentation, *.CSI.................................................2-16

2.9.2 Download Files, *.DLD.............................................................2-16

2.9.3 Final Storage Label Files, *.FSL...............................................2-16

2.9.4 Program Trace Information Files, *.PTI....................................2-16

2.9.5 Printer Output Files, *.TXT.......................................................2-17

2.9.6 Library Files, *.LBR..................................................................2-17

3. Report: SPLIT......................................................... 3-1

3.1 Overview...............................................................................................3-1

3.2 Getting Started.......................................................................................3-1

3.3 SPLIT Parameter File Entries................................................................3-7

3.3.1 Input Files....................................................................................3-7

3.3.2 Start Condition........................................................................... 3-10

3.3.3 Stop Condition...........................................................................3-14

3.3.4 Copy ..........................................................................................3-17

3.3.5 Select .........................................................................................3-18

3.3.6 Output Files ...............................................................................3-33

3.4 Help Option.........................................................................................3-37

3.5 Editing Commands..............................................................................3-37

3.6 Running SPLIT From a Command Line.............................................3-37

3.6.1 Processing Alternate Files .........................................................3-37

3.6.2 Processing Multiple Files with One Command Line.................3-38

3.6.3 Using SPLITR.EXE in Batch Files............................................3-38

3.6.4 Command Line Switches...........................................................3-39

4. View.......................................................................... 4-1

4.1 Introduction...........................................................................................4-1

4.2 Menu Items............................................................................................4-1

4.3 Icon Items..............................................................................................4-1

4.4 Running View as a Stand-Alone Program.............................................4-4

4.5 Assigning Data Files to View................................................................4-4

ii

Page 13

PC208W Datalogger Support Software Table of Contents

5. Stg Module: SMS - Storage Module Software...... 5-1

5.1 Introduction...........................................................................................5-1

5.2 Getting Started ......................................................................................5-2

5.2.1 The Setup Screen.........................................................................5-3

5.2.2 Establishing Communications.....................................................5-4

5.3 Status Information .................................................................................5-7

5.3.1 Status Box/Update Status............................................................5-7

5.3.2 Advanced Status Information......................................................5-7

5.4 Programs .............................................................................................5-10

5.4.1 Program Location......................................................................5-11

5.4.2 Clear..........................................................................................5-11

5.4.3 Store ..........................................................................................5-12

5.4.4 Read...........................................................................................5-12

5.5 Data.....................................................................................................5-12

5.5.1 File Format................................................................................5-13

5.5.2 File Naming Options.................................................................5-14

5.5.3 Show Card/Module Directory and Viewing Data.....................5-15

5.5.4 Get All.......................................................................................5-15

5.5.5 Get New.....................................................................................5-15

5.5.6 Get One .....................................................................................5-16

5.6 Erase....................................................................................................5-16

5.6.1 Erase Data .................................................................................5-16

5.6.2 Erase Data and Programs ..........................................................5-16

5.6.3 Erase and Test Card/Module.....................................................5-16

5.7 The Menu Bar .....................................................................................5-16

5.7.1 File.............................................................................................5-17

5.7.2 Options......................................................................................5-17

5.7.3 Data ...........................................................................................5-18

5.7.4 Tools..........................................................................................5-18

5.7.5 Help...........................................................................................5-18

5.8 Abort...................................................................................................5-19

6. Program Conversion............................................... 6-1

6.1 CR10 Programs to CR10X....................................................................6-1

6.2 Xlate......................................................................................................6-1

6.2.1 File Menu ....................................................................................6-1

6.2.2 Options Menu..............................................................................6-2

6.2.3 Using Translated Files.................................................................6-3

A. Frequently Asked Questions.................................A-1

A.1 Setup, Connect, and Status..................................................................A-1

A.2 EDLOG.EXE.......................................................................................A-3

iii

Page 14

PC208W Datalogger Support Software Table of Contents

B. Modems...................................................................B-1

B.1 Phone Modems ....................................................................................B-1

B.2 Generic Modem Dialing Strings..........................................................B-2

B.3 MD9 Multidrop Interface.....................................................................B-3

B.4 Short Haul Modems.............................................................................B-3

B.5 NL100/105 (Network Link Interface)..................................................B-3

B.6 Datalogger Initiated Communications (Call-back)..............................B-4

C. PC208W Error Messages .......................................C-1

C.1 SPLIT Error Messages.........................................................................C-1

C.2 EDLOG Expression Errors..................................................................C-3

C.2.1 Causes........................................................................................C-3

D. Card Services Driver Software Notes ...................D-1

D.1 General ................................................................................................D-1

D.2 Driver Version Numbers .....................................................................D-1

D.2.1 Microsoft Windows...................................................................D-2

D.2.2 CSL_CS.DLL ............................................................................D-2

D.3 Setting Up Card Services.....................................................................D-2

D.3.1 How to Choose Which Area of Memory to Allocate to

Card Services ........................................................................D-4

E. Glossary of Common Windows Terminology.......E-1

Glossary

iv

Page 15

PC208W 3.3 Introduction

I.1 Please Read This

Welcome to PC208W 3.3, Campbell Scientific’s Windows compatible

support software for the CR10X, CR10, CR500, CR510, 21X, CR7, and

CR23X dataloggers. Please take time to read the Introduction and Frequently

Asked Questions (Appendix A) sections of this manualwe’ve tried hard to

keep them short and direct. We have designed the PC208W windows and help

screens to make learning the sof twar e as intuitive as possible, and have

intentionally kept these sections short.

We hope that the use of most controls and features will be obvious, but for

those that are not, there are several ways to get help. First check the

hint lines

which are displayed on the bottom of most screens. These provide a one line

summary of the control under the mouse cursor. For more help, select a

control with the mouse pointer or <Tab> key and press the <F1> key. In some

instances clicking the right mouse b utton will bring up options that will he lp.

I.2 Overview

This manual assumes that the user is familiar with the Microsoft Windows

interface. If you need help with some of Windows' features (double-clicking,

cutting and pasting, etc.) refer to Appendix E.

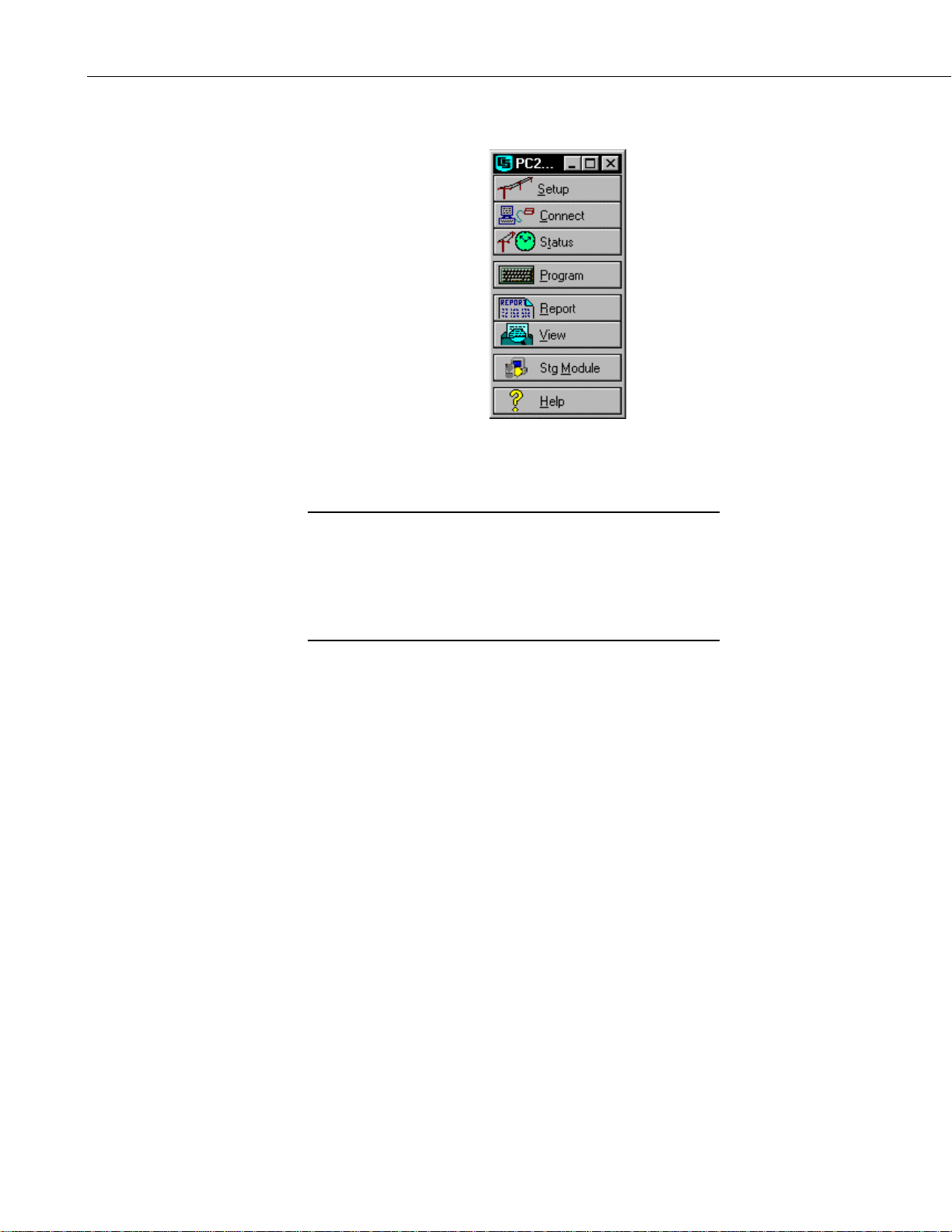

There are eight buttons on the PC208W toolbar. Here is what they are used

for:

Setup: Configure the devices (including modems, dataloggers, COM

•

ports, and tasks) that you use, with separate tabs for hardware, data

collection, and collection schedules.

Connect: Go on-line with a datalogger to set the clock, send programs,

•

collect data, view and graph measurements, etc.

Status: Check the communication and data collection status of all devices

•

you work with, and trigger manual data collection.

Program: Create and edit datalogger programs with EDLOG.

•

Report: Process the data files and create reports using SPLIT.

•

View: View ASCII files in comma separated, columnar, or hexadecimal

•

format. Quickly graph up to two elements in your data file.

Stg Module: Retrieve files from (and reset, program, etc.) Storage

•

Modules either directly using an SC532 or via a CR10(X), CR500, CR510,

or CR23X, and from PCMCIA (PC) Cards via the CSM1/MCR1 interface

or directly from a PCMCIA slot in the PC.

PC208W, Version 3.3, Instruction Manual 1

Page 16

PC208W 3.3 Introduction

Help: Enter the PC208W help system.

•

Each of these buttons launches its own window which gives you access to all

of PC208W’s functions all the time. The details of each screen are described

further in the rest of this man ual and in the Help.

NOTE

Reading Card Storage Module cards directly in a PCMCIA slot

requires compliant drivers. Some computers may require the

purchase of drivers from a software vendor. Windows NT and

Windows 2000 do not support 16-bit card services; therefore,

accessing CSI formatted PC cards via a PCMCIA card slot in a

computer is not available.

I.3 Other Software of Interest

There are other programs available from Campbell Scientific that you may find

useful. These packages are free and are available from our Internet site

(www.campbellsci.com) or on disk (call 435-753-2342 and ask for an

Applications Engineer):

Short Cut Program Generato r ( SCWI N): An alternative to EDLOG for

•

creating simple programs. Short Cut guides the user through the selection

and setup of sensors (including wiring) and data storage for many

meteorological, hydrological, and industrial applications. Short Cut

supports the CR10(X) , CR500, CR510, CR23X, and 21X dataloggers.

(You can then download the program to the datalogger and retrieve data

with PC208W.)

PC TOUR: A computer-based tutorial that introduces a new user to basic

•

datalogger and datalogger support software use. It provides an overview

of a CR10X datalogger wiring panel, discusses the concepts behind a data

acquisition system, and presents an overview of PC208W.

PC200W: PC200W is Campbell Scientific's starter software for datalogger

•

communication. You can connect to a datalogger over a direct link and

collect data, set the clock, and send programs, as well as generate simple

reports and view collected data files.

2 PC208W, Version 3.3, Instruction Manual

Page 17

I.4 Installation

PC208W 3.3 Introduction

SMS: SMS Storage Module Software is shipped with PC208W, but the

•

latest version can also be downloaded from our web site. The SMS install

utility is included in the PC200W installation.

CAUTION

As with all software, Campbell Scientific strongly

recommends that a back-up of critical files be performed

before software installation. In addition, periodic back-ups

should be performed on files in the PC208W directory.

These files include: PC208W.DND (datalogger network

map), WMODEM3.INI (modem setup information), Edlog

program files (*.DLD, *.CSI), Split Parameter files (*.PAR),

and collected data files (*.DAT).

PC208W requires Windows 3.1, Windows 95, Windows 98, Windows

, or Windows 2000. We recommend at least a 486 computer with 16 M

NT

RAM. Though PC208W may run on slower systems, better performance will

be seen with faster systems. A mouse is also required. A minimum of 16 M of

hard disk space is required for software installation . Additional disk space

may be required for I/O log files if you choose to log these files to disk (refer

to Section 1.4.2 and Appendix A for more information on log files).

Insert the PC208W disk into your computer's CD-ROM drive. If your system is

configured for Autorun, the installation procedure will begin automatically. If

it does not begin automatically, go into Windows Explorer and double-click on

the file named Setup.exe that is in th e Disk1 folder. Follow the instructions

given on the screen. PC208W lets you choose a working directory name and

installs most of the software into a subdirectory named BIN.

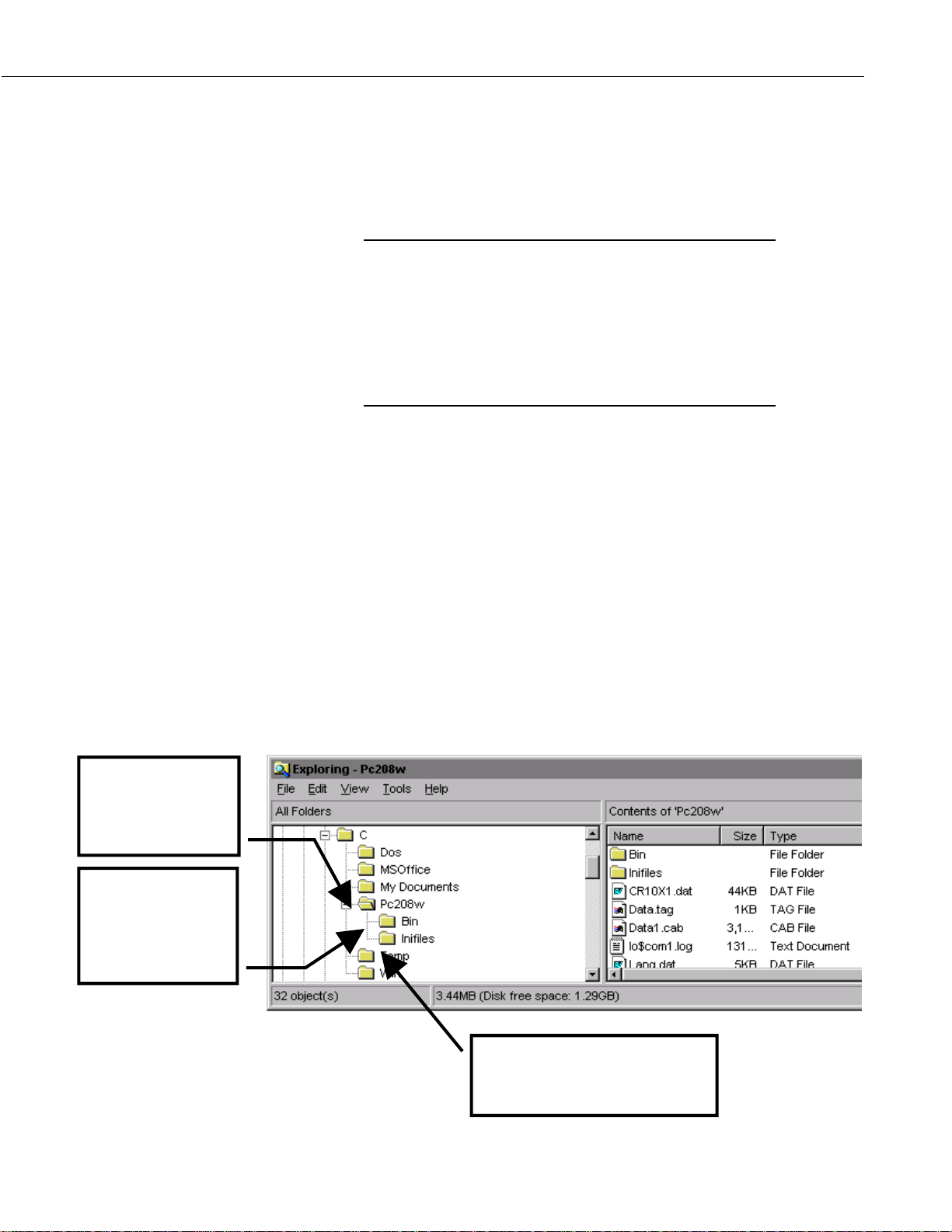

In the example below, PC208W was installed to the C:\PC208W directory.

Working Directory:

Programs

•

Data files

•

etc.

•

PC208W Software

and templates:

pc208w.exe

•

edlogw.exe

•

etc.

•

PC208W, Version 3.3, Instruction Manual 3

“ini” files for the main PC208W

screens and Connect screen setting

for each datalogger.

Page 18

PC208W 3.3 Introduction

I.4.1 Floppy Disk Installation

I.4.2 For Users Upgrading from PC208W Versions 2.3 and

Earlier

PC208W is shipped only on CD-ROM. However, the CD-ROM includes

folders that can be used to create a set of disks for floppy disk installation. To

create a set of disks, copy the contents of each folder named Disk1, Disk2, etc.,

to a 1.44 MB 3.5" floppy.

To install the program from floppy disk, insert the floppy disk with the

contents of Disk1 into your computer's drive. In Windows 95, 98, NT, or 2000,

select RUN from the Start button. Type in SETUP and press OK. (In Windows

3.1, select FILE and then RUN from the Program Manager menu. Enter

A:SETUP and select the OK button.) The installation process should begin;

follow the instructions given o n the screen to complete software installation.

Modem Configurations

PC208W 3.0 and greater use a newer configuration for modem setups, which

should provide for more reliable communication and fewer problems in

establishing remote communication links. If your station setup uses a modem

that is included in PC208W's modem list, you won't need to make any changes

after installing PC208W.

NOTE

However, if you previously set up a custom modem instead of using an

existing modem configuration, PC208W will leave the modem pick list field

blank. Choose the default modem; in most instances, this setup should work.

If the default settings will not work with your modem, you will need to refer to

your modem's user's manual to enter valid strings (refer to Appendix B). Some

items to look for when developing a custom modem string are: hardware flow

control enabled, verbose result codes (looking for “CONNECT” back from the

modem rather than a number), and error correction enabled.

PC208W won’t find your custom modem on its WMODEM3.INI

list so it will display a blank field for the Modem Pick List field

and a warning in the SWF log until you actually pick "default

modem".

Directory Structures

In version 2.1 and greater, the main PC208W directory is PC208W (unless you

manually change the default directory during software installation). Two

subdirectories exist under PC208W: BIN and INIFILES. The BIN directory is

used to store nearly all of the files essential to the operation of the PC208W

program (executable files, help files, etc.). The INIFILES directory is used to

store all of the *.INI files associated with datalogger setups and PC208W

software execution.

Datalogger *.INI files are created/updated each time a communication session

with a datalogger is closed, and PC208W's INI file is updated each time it is

closed. The files provide the PC208W program with specific information so

4 PC208W, Version 3.3, Instruction Manual

Page 19

PC208W 3.3 Introduction

your devices or program defaults do not have to be configured before each

PC208W session.

Versions of software prior to 2.3 stored the PC208W.INI file in the working

directory. This INI file included information on all of the dataloggers in the

device map and setup information on PC208W. If you are upgrading from

Version 2.2 or earlier, when the program is installed, your existing

PC208W.INI file will be moved into the INIFILES directory. Then, the first

time a connection is made to each datalogger that was set up in your original

INI file, the program accesses the INI file and creates a new file from the

information in the old INI. This change in directory structure was made to

accommodate an INI file size limitation inherent to the Windows operating

system.

Datalogger Network Configuration Files (*.DND files)

PC208W keeps the setup information in the working directory in a DND file.

(In PC208W 1.x and earlier, this file was named TCOM.DND. In versions later

than 1.x, it was named PC208W.DND.) If an existing DND file is found during

an upgrade installation, this file will be renamed, if necessary, and updated to

the current DND format.

During the upgrade installation, you may choose to install the new PC208W in

a different directory. If so, you can copy the old DND file into the new

directory. If the old file is named TCOM.DND, rename it to PC208W.DND.

By copying this DND file, you will not have to set up new network

configurations (the device map) for your existing datalogger stations.

Existing Data, Edlog, and Split Files

Your existing PC208W files can be used without modification in PC208W 3.3

These file types include: *.DAT, *.PAR, *.CSI, *.FSL, *.DLD. (Refer to

Section 2.9 for more information on Edlog file types.)

For users upgrading from DOS PC208

You will have to recreate the setup information and batch routines. Edlog .CSI

and .DLD files and Split .PAR files will work without modification. However,

if your previous version of Edlog used .DOC files, they will need to be

converted using DOC2CSI (see Section 6).

If you are connecting to one or more dataloggers via an MD9 network, and have

been using PC208 for DOS, you will have to change the ID switch settings on

your base MD9. The DOS software uses an address between 1 and 254;

PC208W uses address 255.

If the base MD9 ID is set to 255, you can still use PC208 DOS software, if

needed, without changing the setting back to a number between 1 and 254.

Simply add a pound sign (#) to the end of the MD9 dialing path in the station

file.

PC208W, Version 3.3, Instruction Manual 5

Page 20

PC208W 3.3 Introduction

I.5 Uninstall

Should you need to remove PC208W from a computer, an uninstall program is

provided. With Windows 95, 98, NT, or 2000, select SETTINGS from the

Start button then select CONTROL PANEL. Double click on

ADD/REMOVE programs. Select PC208W from the list and select the

Add/Remove button.

With Windows 3.1, double click on the UNINSTALL PC208W icon in the

PC208W program group.

I.6 Some Notes on System Resources

COM Ports and Interrupts

PC208W is capable of running in the background while you are doing other

work with other programs. To do this, it uses the system’s idle time for some

of its serial communications. Some other applications may be so resource

intensive that PC208W does not receive sufficient time for its communications.

PC208W will not run reliably with these applications loaded.

NOTE

The Windows environment provides access to the COM ports via a COM port

driver. Many computers have COM ports which share interrupts with other

COM ports. (Typically COM1 and COM3 share IRQ 4 and COM2 and COM4

share IRQ 3.) This can be checked by examining the ‘Ports’

(Settings/Advanced) setting in the Windows Control Panel. A COM port

sharing an interrupt with another device can prevent Windows from reliably

performing communications using that port, particularly if the COM port and

device are used concurrently. This shared interrupt problem would also affect

operation of PC208W.

If you appear to be experiencing communication problems when

using external modules, always check the COM ports setting in

the Windows Control Panel, using the ‘Ports’

(Settings/Advanced) option, and check for any shared interrupts.

Other programs may also try to use the COM ports, and some may leave the

COM ports “open” even when not active. This is especially true of DOS

based communications programs. If PC208W has trouble connecting to a

datalogger when you believe the setup and connections are correct, check to

make sure other programs that use the same COM ports are closed.

For Windows 3.1 and 95 Users

A problem which is inherent to Windows 3.1 and 95 may surface when

scheduling Tasks which call DOS programs. When a DOS command is

executed, a certain amount of system resources are allocated to this command.

Windows 95 does not free up this resource when the command has been

executed and control is returned to Windows. This memory is freed, however,

once your computer system is rebooted.

6 PC208W, Version 3.3, Instruction Manual

Page 21

I.7 Getting Help

PC208W 3.3 Introduction

If your Windows 3.1/95 system remains on-line for long periods of time (such

as a week or more without being powered down), it is suggested that the

system be rebooted every few days if DOS commands are being executed. If

not, your system may run out of system resources and fail to respond. The

only solution to this system “lock-up” is to reboot the computer. Any files

which have not been saved to disk will be lost.

We’ve tried hard to make PC208W 3.3 as intuitive as possible and follow

common Windows conventions. There are several sources of help for you

including:

This manual.

•

Hint lines which appear at the bottom of each screen.

•

Context-sensitive Help in each program available when you press <F1>.

•

General help from the Help pull down menu.

•

The datalogger manuals. These are thick and more for reference than to

•

be read cover-to-cover. The Overview chapter, however, is a good one,

and you should be sure to read it carefully.

From Anywhere:

Campbell Scientific, Inc.

815 West 1800 North

Logan, UT 84321-1784

Tel: (435) 753-2342

Fax: (435) 750-9540

E-mail: support@campbellsci.com

WWW: http://www.campbellsci.com

From Australia, Fiji, Indonesia, Malaysia, Papua New Guinea, Philippines,

Singapore, and Thailand:

Campbell Scientific Australia Pty Ltd

PO Box 444 Thuringowa Central

Townsville QLD 4817 AUSTRALIA

Phone: 61-7-4772-0444

Fax: 61-7-4772-0555

E-mail: info@campbellsci.com.au

WWW: http://www.campbellsci.com.au

From Canada:

Campbell Scientific Canada

11564 - 149th Street

Edmonton, Alberta T5M 1W7

Phone: 780-454-2505

Fax: 780-454-2655

E-mail: dataloggers@campbellsci.ca

PC208W, Version 3.3, Instruction Manual 7

Page 22

PC208W 3.3 Introduction

From Austria, Belgium, Denmark, Finland, France, Germany, Greece, Ireland,

Italy, Luxembourg, Netherlands, Northern Ireland, Norway, Poland, Portugal,

Spain, Sweden, Switzerland, and United Kingdom:

Campbell Scientific Ltd.

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

Phone: 44-(0)1509-601141

Fax: 44-(0)1509-601091

E-mail: sales@campbellsci.co.uk

Technical Support: support@campbellsci.co.uk

WWW: http://www.campbellsci.com/europe /

From South Africa:

Campbell Scientific Africa

Box 2450

Somerset West 7129

Republic of South Africa

Phone: 2721-880-1252

Fax: 2721-880-0240

E-mail: jvisagie@mbv.co.za

From Brazil:

Campbell Scientific do Brazil Ltda

Rua Mateus Grou n°152 - Pinheiros

05417-010

Sao Paulo SP

Brazil

Phone: 011-55-11-306-10916

Fax: 011-55-11-306-89945

E-mail: ghfamb@sti.com.br

8 PC208W, Version 3.3, Instruction Manual

Page 23

Section 1. Setting Up the Network and Communicating with the Datalogger

1.1 Getting Started

With the software installed, you are probably anxious to start using the

datalogger. If at all possible, prior to deploying the equipment in the field,

make sure you can establish a telecommunication link with your datalogger

even if you have to create a temporary setup in your office. Getting familiar

with datalogger programming and the support software in the comfort of your

office will be a lot less frustrating than trying to resolve problems in the field.

If your datalogger is already deployed and working, then establishing

communications with the datalogger is the place to start.

The first step in interfacing your PC and the PC208W software with your

equipment is to set up your datalogger and other devices. SETUP is used to

accomplish this. Once your network is configured, direct connection can be

made to the logger through the CONNECT screens. After telecommunication

has been established you can use the other features of PC208W to create and

download programs, collect data, view raw data or prepare more sophisticated

reports, monitor equipment status, and interact with storage devices.

1.2 Setup

1.2.1 General Information

1.2.2 Setup Procedures

opens a window in which you edit the Device Map, a

diagram of all the various dataloggers, modems and

other communications devices which you are using.

Three different pages on this screen show up as tabs to

let you configure Hardware, Data Collection, and

Scheduled Communications settings. Whether you work with one

datalogger (or “station”) on your desk or hundreds of dataloggers over

elaborate telecommunications networks, PC208W’s Device Map keeps track of

the type of devices, addresses and phone numbers, data collection pointers, and

collection schedules. You can also add “Tasks” to the Device Map to execute

other programs, such as DOS batch files, SPLIT (PC208W’s data processing

utility), or any other executable pr o gram.

The first step in setting up telecommunications is to add the necessary

component to the Device Map by choosing one of the Add... options from the

toolbar. Some of the necessary entries include which serial communication

port (e.g., COM1 or Socket 1) you will use, modems (if any), type of

datalogger, etc.

PC208W, Version 3.3, Instruction Manual 1-1

Page 24

Section 1. Setting Up the Network and Communicating with the Datalogger

The Setup window consists of three tabs: HARDWARE, DATA

COLLECTION, and SCHEDULE. Each device will have these three tabs

but only parameters relevant to that type of device will be shown on the tabs.

1.2.2.1 Hardware Setting

PC208W inserts default values for most parameters, but some it can’t know.

Therefore, once you add devices to the Device Map, click on the

HARDWARE tab for each device to enter settings unique for that device, such

as baud rates for COM ports, brand of telephone modem (for initialization

strings), telephone numbers, radio IDs or paths for dataloggers, etc.

1.2.2.2 Data Collection Settings

You will also need to set up what data you want to collect and how you want to

collect and store it. This information goes on the DATA COLLECTION tab

for the datalogger. Note that PC208W will suggest a filename for the data, but

you can Browse to choose a different name, directory, or even a different

computer if you’re on a network.

1.2.2.3 Schedule Settings

PC208W can be configured to call one or more dataloggers and collect data on

a predefined schedule. Once all data has been collected from a datalogger, the

call is automatically terminated. This function is set up on the Schedule tab for

the datalogger.

The first field to set up is the Calling Interv al. The Calling Interval is how

often PC208W should call the datalogger to collect data. When the schedule is

first set up, the initial starting time for scheduled data collection should be

entered into the Next Time to Call field. Once th e schedule is implemented,

this field will be updated each time the scheduled call is successful to reflect

the next time that PC208W will attempt to make a scheduled call.

The Next Time to Call will be determined based upon entries in the Primary

Retry Interval, the Retries Using Primary Interval, and the Secondary Retry

Interval fields. The Primary Retry Interval is an interval at which calls will be

made if a scheduled call fails. The Retries Using Primary Interval field is the

number of times calls will be attempted using this interval. The Secondary

Retry Interval is an interval that will be used if all of the Primary Retries fail.

Following are some of the rules PC208W will follow for scheduled data

collection.

• If a scheduled call for a device is successful, the "Next Time to Call" will

be incremented one "Calling Inter val". For instance, if the Calling Interval

is set at 1 hour and a successful call occurs at 8:00 a.m., the "Next Time to

Call" will be set to 9:00 a.m.

• If a scheduled call fails and the "Retries Using Primary Interval" is set to

something other than 0, and this number of Primary Retries has not been

exhausted, the "Next Time to Call" will be incremen ted by the Primary

Retry Interval value, plus the time that the call actually took to fail (this

allows time for a hardware reset). For in stance, if the original time for a

1-2 PC208W, Version 3.3, Instruction Manual

Page 25

Section 1. Setting Up the Network and Communicating with the Datalogger

failed call was 9:00 a.m. and the Primar y Retry Interval was set to 5

minutes, on the first retry the "Next Time to Call" will be set to 9:05 a.m.,

plus the few seconds it took for PC208W to determine the call failed.

• If a scheduled call fails and the "Retries Using Primary Interval" is set to 0

or the number of Primary Retries has been exhausted, the "Next Time to

Call" will be some multiple of the "Secondary Retry Interval" added to the

regularly scheduled "Next Time to Call", such that the "Next Time to Call"

is in the future.

• If the "Primary Retry Interval" is 0 and "Retries Using Primary Interval"

have not been exhausted, the "Next Tim e to Call" is set for the time the

last call failed (i.e., zero seconds after the failure, and the next primary

retry may begin immediately).

• If the "Retries Using Primary Interval" is set to 0, no primary retries will

be attempted and the next time to call is determined by the "Secondary

Retry Interval."

• If the "Secondary Retry Interval" is set to 0, once the Primary Retries are

exhausted, the "Next Time to Call" is set by add ing some multiple of the

"Calling Interval" to the last time a regularly scheduled call was to begin,

such that the “Next Time to Call” is in the future.

PC208W also allows you to set up other DOS or Windows programs to be run

at scheduled times. These programs are referred to as TASKS. To set up a task

to be run, press the Add Task button. On the HARDWARE tab, you can enter

a unique name for the task to be run in the "Task Name" field. In the "Name of

Program to Start" field, enter the command line for the program, batch file, or

DOS command you want to execute. On the SCHEDULE tab, enter the

"Calling Interval" for the task and ensure the "Schedule On" box is checked.

You will notice a list-box on all of the SCHEDULE tabs called “After Call Do”.

If you select the name of a device or Task from the Device Map, that device will

be called or Task executed after the first Device is called (only for Scheduled

Calls). In this way, you can set up a sequence of calls to dataloggers, or run

other programs after that call (such as data processing applications like SPLITR).

Note that the After Call Do function is executed regardless of whether the first

call is “su ccessful”.

1.2.3 Device Map Notes

The Device Map provides a pictorial representation of how each device is

connected in your communications link. "Parent" and "child" connections are

shown by right angle lines which connect the components, and the child

components are indented beneath the parent component to help depict the

logical order of the connection.

PC208W, Version 3.3, Instruction Manual 1-3

Page 26

Section 1. Setting Up the Network and Communicating with the Datalogger

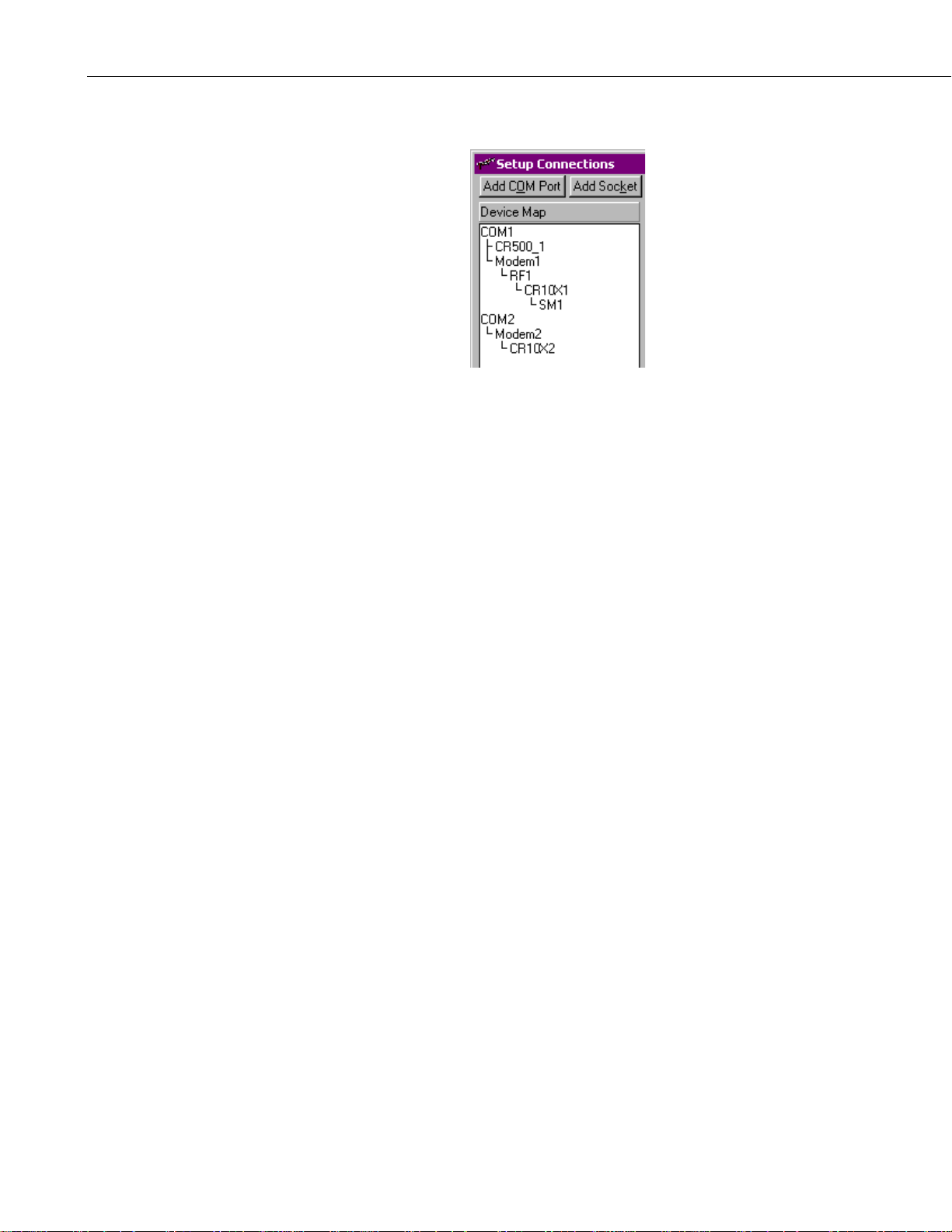

Review the example below:

The first item shown on the Device Map above is COM1it is considered a

parent component. The CR500 under it is a child. This communications link

could be for direct connection from a desktop PC's COM1 port to the CR500.

The Modem1 connection is a link from the PC's COM1 port that has a phone

modem connected to it, an RF modem connected to the phone modem, and a

CR10X at the other end (remote RF modem is assumed) and a storage module

connected to the CR10X. COM2 is a similar example, with a CR10X

connected to COM2 through a phone modem (remote phone modem is

assumed).

Following are some hints which may help when setting up your Device Map.

• When you choose Add Device, a two column popup screen appears. The

device which you want to add should be chosen from the left-hand

column; the component which you want for the parent device should be

chosen from the right hand column. PC208W will only allow you to

choose valid parent components for each device; other devices are grayed

out.

• Add your COM port first, and then attach each component in the order that

it physically appears in your communications link.

• PC208W recognizes that modems are used in pairsone at the computer

and one at the datalogger. Therefore, once you attach a modem to the

COM port, you do not have to add another modem for the datalogger site.

• Each device can be given a unique name. This can be helpful if you have a

large network of datalogger sites and you want to remember which

connections are for which sites. Device names can be edited by typing in a

new entry directly in the device’s Name field on the Hardware, Data

Collection, or Schedule tab.

• If you need to change the logical order of a site's communication link, you

can select a component with the mouse pointer and drag it to a new

location. If PC208W is unclear of the connection to be made it will ask

you to select whether the device should be connected as a child component

or on the same level. If the device you are moving has child components,

these will be moved along with their parent device.

1-4 PC208W, Version 3.3, Instruction Manual

Page 27

Section 1. Setting Up the Network and Communicating with the Datalogger

• If you delete a component with child components attached, the child

components also will be deleted.

• If you inadvertently delete a communications link, it can be refreshed by

choosing Cancel Edits (as long as you have not chosen Save Edits since

the deletion).

1.2.4 Example Device Maps

Refer to the examples below for help in setting up your own Device Map.

Step-by-step examples are provided in the PC208W help file. These can be

accessed from the content page, by a right click on the device map in the Setup

screen, or by searching for Cue Cards in the help file index.

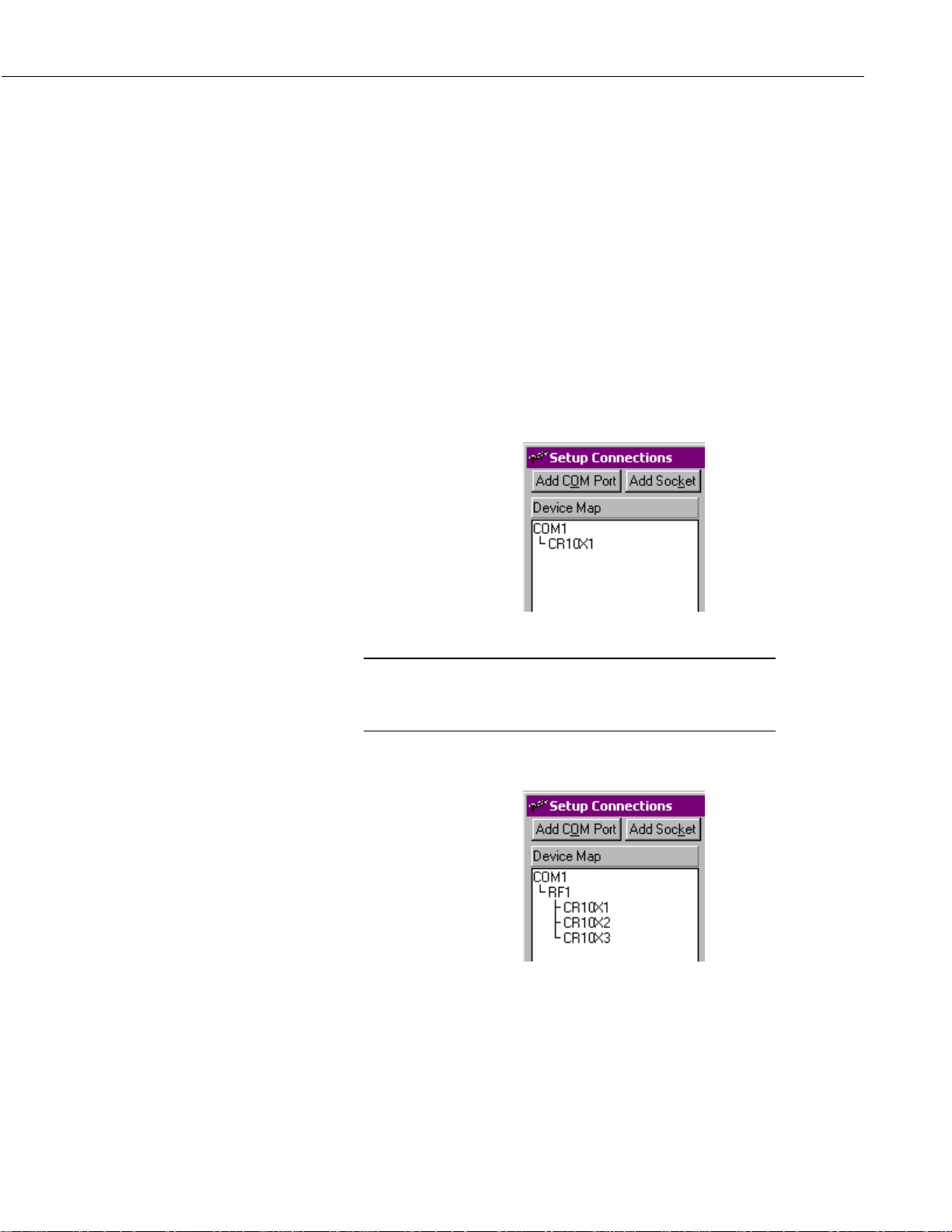

Direct Connect via an SC32A or RAD Short Haul Modem Pairs to a CR1 0X:

NOTE

Older short haul modems (SC95) are set up as generic modems

with the datalogger attached. Refer to Appendix B for more

information.

RF (Radiotelemetry) Connection to Three CR10Xs:

PC208W, Version 3.3, Instruction Manual 1-5

Page 28

Section 1. Setting Up the Network and Communicating with the Datalogger

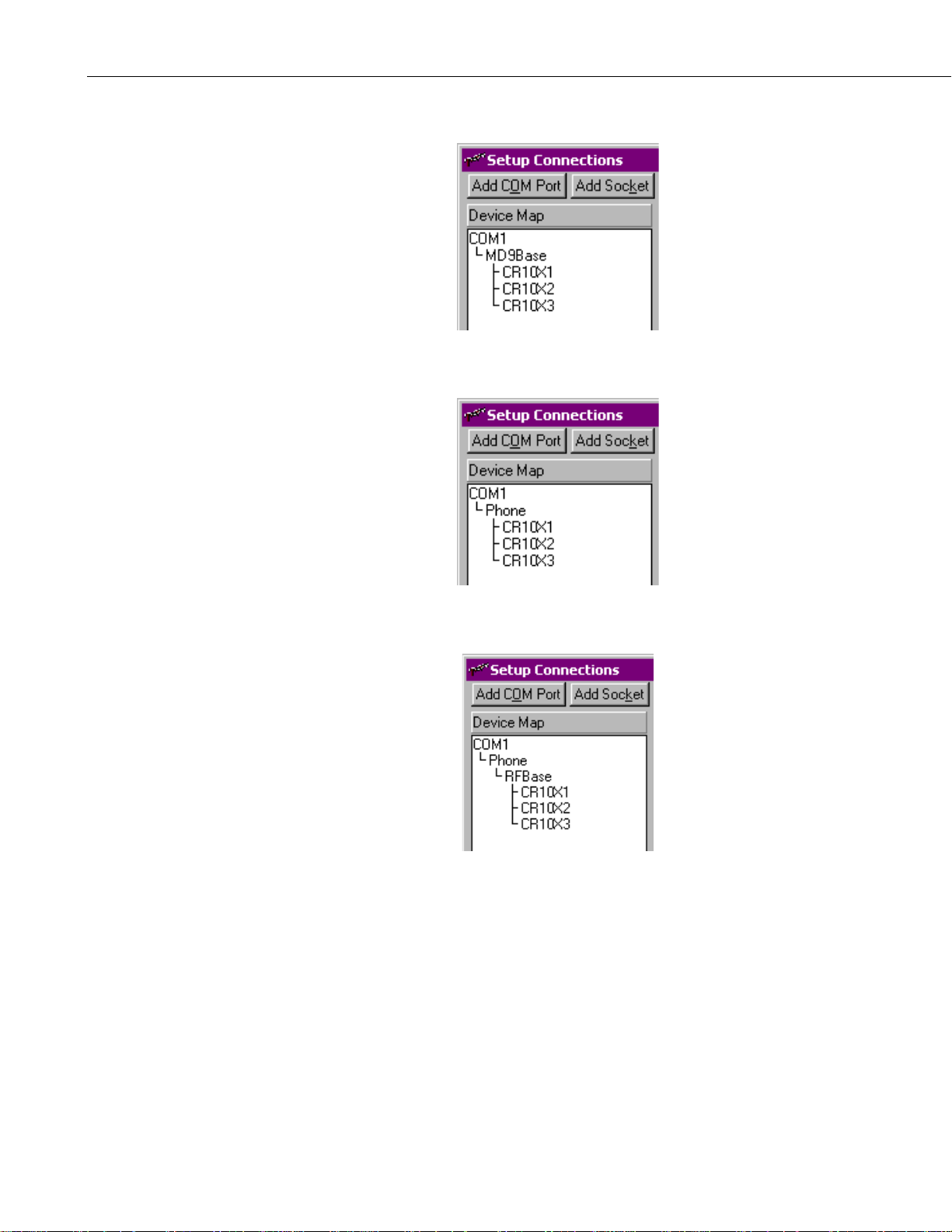

MD9 (Coax Multi-drop) Connection to Three CR10Xs:

Phone Modem Connection to Three CR10Xs:

Phone to RF (or MD9) Connection to Three CR10Xs:

1-6 PC208W, Version 3.3, Instruction Manual

Page 29

Section 1. Setting Up the Network and Communicating with the Datalogger

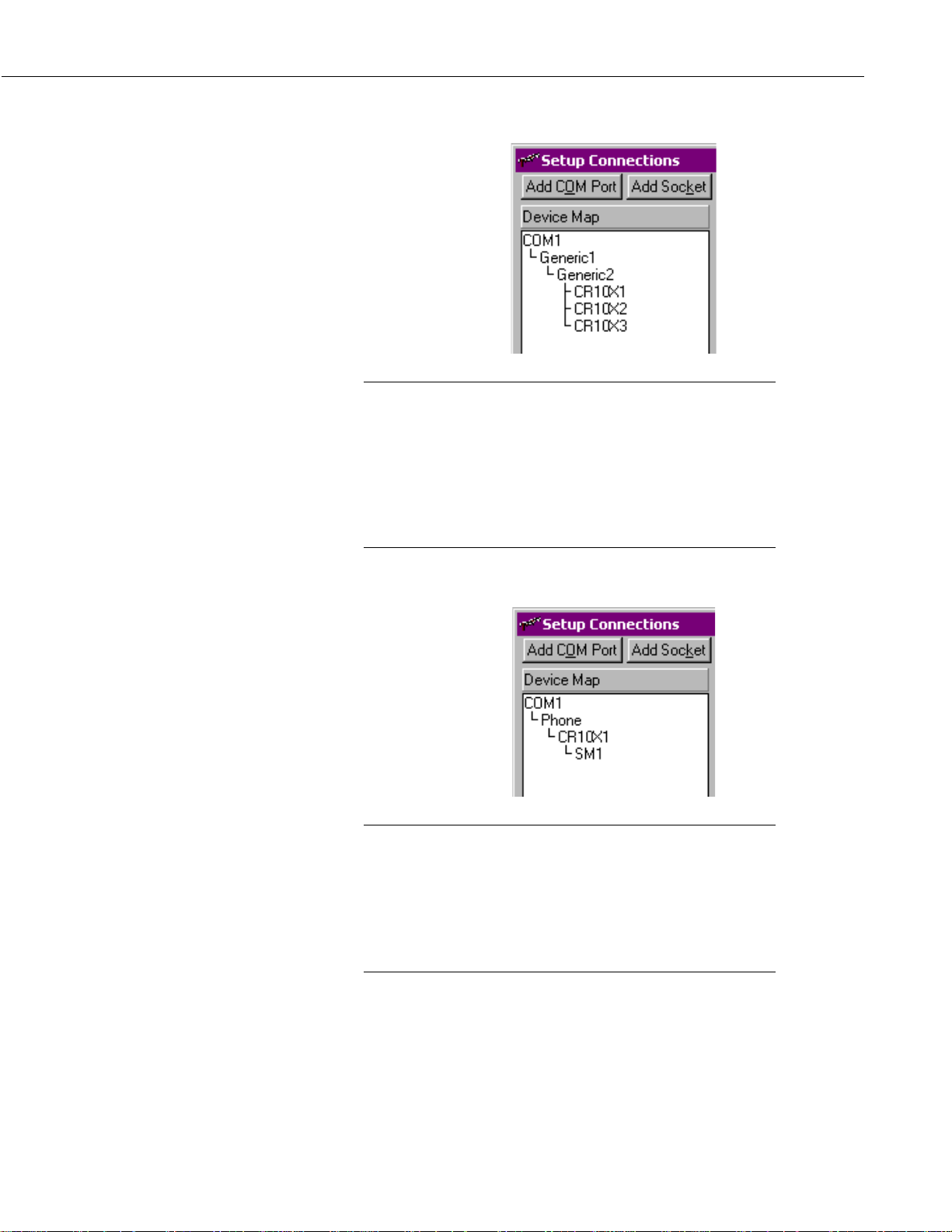

Generic Modem Connection to Three CR10Xs:

NOTE

Generic modems are used for connections or modems otherwise

not supported by PC208W (such half-duplex modems from other

vendors or SC95 short haul modems). Generic modems require

that the users specify the dialing and response strings needed to

dial the modem. The user must also specify the delays and

resolve timing issues. (See Appendix B.) It is possible to chain

several generic modems if multiple strings and responses are

required.

Modem Connection to CR10X with Storage Device:

NOTE

In reality, you can connect Campbell Scientific storage modules

or PC card drives to most dataloggers. However, PC208W only

allows valid connections in the Device Map where data can be

retrieved from a storage module through a datalogger over

telecommunications. PC208W allows remote data collection

from SM192, SM716, SM4M and SM16M storage modules

connected to CR10(X), CR500, CR510, or CR23X dataloggers.

PC208W, Version 3.3, Instruction Manual 1-7

Page 30

Section 1. Setting Up the Network and Communicating with the Datalogger

Tasks (Scheduled Execution of DOS or Windows Programs):

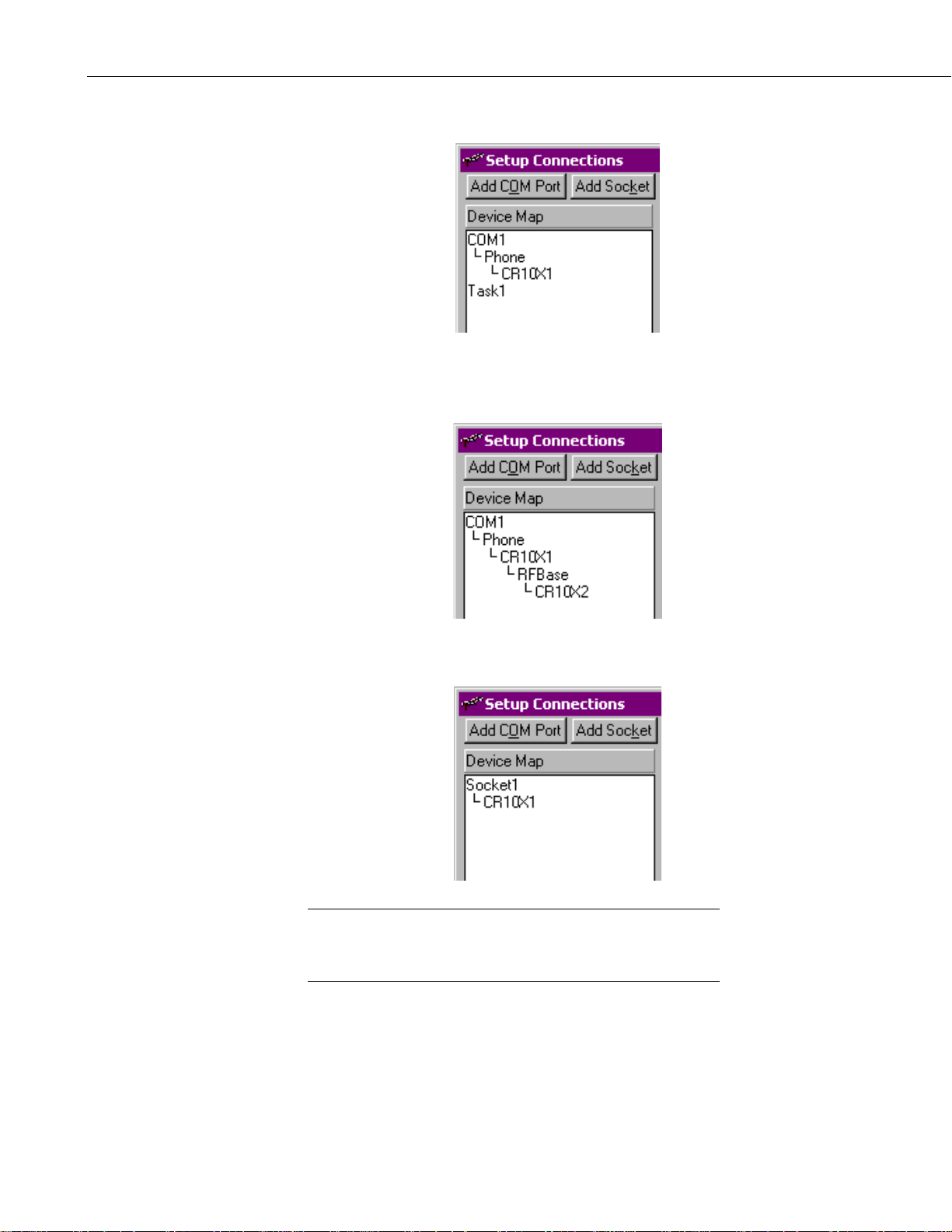

Phone Modem to RF Connection to a Remote CR10X, with a CR10X at the

Phone-to-RF Base:

TCP/IP Connection - NL100/105 to Datalogger:

NOTE

Extra response time (3000 to 4000 ms) may need to be added to

the Socket and/or the datalogger to account for network traffic

delays over a TCP/IP connection.

1-8 PC208W, Version 3.3, Instruction Manual

Page 31

Section 1. Setting Up the Network and Communicating with the Datalogger

TCP/IP Connection - NL100/105 to Phone (or RF or MD9) to Datalogger:

NOTE

The modem peripheral should be connected to the RS232 port of

the NL100/105. When an RF modem is used, the pin that carries

the RTS signal should be disabled in the cable (pin 7 on a 9-pin

connector or pin 4 on a 25-pin connector).

1.2.5 Notes on Data Collection and Formats

As noted in Section 1.2.2, you must define how the datalogger should collect

data and what file format to store the d ata. This information is entered on the

Data Collection tab of the Setup window.

There are two basic options for specifying what data is collected: collect all

the new data since the last collection or collect a fixed number of arrays on

each call. Use the Data Logged Since Last Call option to build a complete

archive. Use the Most Recently Logged Arrays option to collect a fixed

number of the most recent arrays for each call.

When the Most Recently Logged Arrays option is chosen, the number of

arrays to be collected is entered in the Arrays to Collect on each call field.

Enter 0 if you want to collect all data on each call.

Data File Names for Areas 1 and 2

All dataloggers have a Final Storage area 1. The CR10, CR10X, and CR23X

can be configured with two final storage areas. The default filenames for a

device's Final Storage areas are taken from the device name. If a CR10X is

named LOG1, the default files names are LOG1.DAT and LOG12.DAT.

These default names can be changed by selecting the Browse button and

entering a new name.

NOTE

PC208W, Version 3.3, Instruction Manual 1-9

By default, only Final Storage area 1 is set up for CR10s,

CR510s, CR10Xs, and CR23Xs. For data to be stored in Final

Storage area 2, memory must be allocated in the datalogger, and

the program must write data to this area.

Page 32

Section 1. Setting Up the Network and Communicating with the Datalogger

File Format

PC208W supports three formats for the collected data:

• ASCII, Comma Separated - This is the best choice for most applications.

Data values are separated by commas with no leading zeros and with each

array on a new line. This is the easiest format for importing into other

software; it’s reasonably compact and can be viewed directly.

• ASCII, Printable - Numbers are aligned in columns and preceded by a 2-

digit ID indicating the array position. The column IDs repeat after 100

columns. Each row in the data file has up to eight columns before a new

line is started. This format is easiest to read manually (i.e., printed copy)

but is difficult to import into spreadsheets and other application s. SPLIT

can be used to convert to other formats. This format is ambiguous for data

arrays of 100 or more and should be avoided for purposes other than

printing.

• Binary - This format is the most compact on the PC but must be converted

before it can be used. SPLIT can be used to convert to other formats.

1.2.6 Setup Safety Tips

You can freely move between the different PC208W windows. This means

you can open the SETUP screen while you are communicating with a

datalogger or using one of the other PC208W programs. However, if you

change the setup, PC208W may hang up calls in process and not call again

until the changes are saved. It does this to prevent data storage pointer s f r om

being corrupted. Therefore, it is better to avoid changing the setup while

communicating with a datalogger that will be affected by the change.

You must click on Save Edits for the device settings to take effect and continue

any scheduled communications. You will also be prompted to Save Edits if

you close the Setup window or PC208W if you have not yet saved the new

device settings. If you find you have made a mistake while changing device

settings but have not yet saved the edits, you can return to the previous

configuration by clicking Cancel Edits. This only works for one previous

setup because otherwise, PC208W may have called a datalogger and changed

data storage pointers, making a return to previous settings unreliable.

You may drag and drop devices from one connection to another. If the place

where you drop a device is ambiguous, PC208W will ask whether to place the

moved device as a child or at the same level.

PC208W uses the computer clock to control some of its timing. Changing the

PC clock while connected to a datalogger may cause unexpected results in

PC208W.

1-10 PC208W, Version 3.3, Instruction Manual

Page 33

1.3 Connect

Section 1. Setting Up the Network and Communicating with the Datalogger

brings up a window which gives you real time access to

any of the dataloggers in your Device Map.

You can transfer programs to a datalogger, set the datalogger clock, collect

data from the datalogger, collect data from the storage module, and display or

graph datalogger measurements. From the CONNECT window you may

connect to only one datalogger or storage module at any given time.

Only dataloggers and storage modules are shown on the CONNECT screen.

You can switch to a different device by clicking on it with the mouse pointer.

If you are connected to a device, PC208W will warn you and ask if it should

close the current connection.

PC208W assumes a double click on a different datalogger means you want to

switch regardless of the current connection. It will close the connection in an

orderly fashion and switch to the new CONNECT screen. Note that PC208W

saves the location and appearance of the screen for each datalogger, so

switching to a new one may appear to make the screen “jump” from one

position to another.

1.3.1 Handy Things That May Not Be Obvious

TOOLS Tab

• Check the Pause Clk Update to stop the clock display. This can speed up

manual data collection on a slow communication link. Be careful; if you

pause the clock display AND the numeric d isplay, there will be no visual

clues as to when you are connected. In fact, PC208W may not stay

connected as there is nothing to do. If you pause everything for more than

about 40 seconds, the datalogger may time out and hang up the link from

its end to conserve power.

• If you associate a datalogger program (.DLD file) in which you labeled

your Input Locations, then you will have labels in the Numeric Display

and Graphs.

• The Pause Both checkbox stops updating the numeric displays and

graphs. This can speed up manual data collection on a slow

communication link.

Ports/Flags

• A port or flag can be given a unique label. Right click on the port or flag

and type in a new label. Labels are saved individually in an *.ILL file in

the Inifiles subdirectory for each datalogger in the Device Map.

PC208W, Version 3.3, Instruction Manual 1-11

Page 34

Section 1. Setting Up the Network and Communicating with the Datalogger

Numeric Display

• Right click on any cell in the Numeric Display to invoke a pop-up box.

From this box you can choose to Add locations to the display; Delete

locations from the display; Setup the Numeric Display's update interval,

delete options, or decimal place settings.

• Double click on value labels to edit them. Changing the labels only

affects the Numeric display and will not change the datalogger program.

• Double click on a value, then edit it and press <Enter> to send the new

value to the datalogger’s Input Location.

• You can drag and drop individual Input Locations to different locations on

the display.

• Press and hold the <Ctrl> key before starting to drag an Input Location

cell, and the cell will be inserted when you drop it. If <Ctrl> is not held,

the dragged cell will replace the destination cell.

• You can drag an Input Location from the ADD Inloc List and drop it on

the numeric display instead of using the Paste button. You can drag and

drop multiple locations at once by first highlighting labels using

conventional <Ctrl>-click and <Shift>-click keystrokes.

Graphs

TERMINAL Tab

• A cell must be highlighted on the numeric display in order to paste new

input locations.

• <Ctrl>-click and <Shift>-click allow you to highlight multiple Input

Locations for a subsequent DELETE.

• If you are using the “power of 10 autoscaling” and a trace goes off scale,

select the Rescale button to scale the value back to the Y-axis again.

• You can leave one or more graphs up with all other PC208W windows

minimized, but if you close the CONNECT screen or the main PC208W

toolbar, the connections are dropped and the graphs are also closed.

• Use the Capture button to save a graph to a WMF (Windows Metafile)

format. This file can be printed or imported into other programs.

• If you are not connected to a datalogger, the Open Port button will allow

you to manually dial and work with the communication devices. If you

are connected, selecting the TERMINAL tab will stop all other

communication with the datalogger until you return to the TOOLS tab.

To enter the Remote Keyboard Mode on the datalogger press <Enter> to

get an “*” and then press “7H <Enter>” (CR10(X), CR500, or CR23X)

or “2718H <Enter>” (any datalogger). BE CAREFUL! This mode

1-12 PC208W, Version 3.3, Instruction Manual

Page 35

Section 1. Setting Up the Network and Communicating with the Datalogger

allows you to delete program instructions and may result in erasing the

datalogger’s memory!

• If you enter the Remote Keyboard Mode, be sure to press the ‘ *0 ’ keys

sequence to get a LOG1 message from the datalogger before you leave the

TERMINAL screen so the datalogger is left in a known state.

1.3.2 Connect Safety Tips

• Leaving PC208W connected to a datalogger keeps the communication link

to the datalogger open and may prevent scheduled collection or callback

from other dataloggers which use the same COM port.

• If you pause the clock display and the numeric display, there will be no

visual clues as to when you are connected. In fact, PC208W may not stay

connected as there is nothing to do. If you pause communication for more

than 40 seconds, the datalogger may time out and hang up the link.

• If you are connected, selecting the TERMINAL tab will stop all other

communication with the datalogger until you return to the TOOLS tab. If

communication between the computer and datalogger remains idle for

more than 40 seconds, the datalogger may time out and hang up the link.

When the datalogger times out, you may get odd characters on the screen.

1.4 Status

1.4.1 Device Map and Station Map

• During data collection if the disk or other storage devices become full, an

error will be written to the SWF log and the data collection attempt will be

halted. Once space is freed up on the disk or a new storage device is

attached, data collection will be resumed, though some duplicate data may

be written to the file.

displays information for all the dataloggers on the

Device Map at one glance. You can check the status of

data collection including scheduled calls, errors, retries,

and how much data was collected. You can also

launch windows displaying SWF (Status, Warning, and

Fault) messages or Low Level I/O (input/output) to monitor the binary traffic

between the PC and datalogger. Buttons are also provided to conveniently

collect data, stop data collection, turn on scheduled calls or reset retries.

The top portion of the Status window shows a summary for all the devices you

have set up. Information is displayed on data collection attempts and the next

scheduled call. A checkbox in the lower left portion of the screen allows you to

choose between viewing all the devices or just the stations (dataloggers). You

can also highlight one or more dataloggers to manually collect data or manually

terminate a collection in progress.

When a device is highlighted, you can press the right mouse button to bring up

a list of data collection related options. You can Toggle On/Off the device's

schedule; Collect Data from the device; Collect Data and Do Task (that is,

PC208W, Version 3.3, Instruction Manual 1-13

Page 36

Section 1. Setting Up the Network and Communicating with the Datalogger

perform any "After Call Do" items); Reset Retries to 0, or Discontinue the

current data collection process.

This display gives a variety of diagnostic information summarized below.

On-line

O - the device is currently on-line or being dialed.

T - the device, usually a modem, has been dialed and is currently transparent

(active but not the end of the link).

M - the COM port is being monitored for datalogger initiated communication

(call-back).

Error Rate

This is a running average of the errors in the last 20 communication attempts.

(n) will appear following the error nu m ber if the last attempt to communicate

failed. “n” is the number of successive failures. Typically the higher the error

rate number, the worse the communication link.

Last Call

Indicates when the last call or attempt to call finished (even if it failed).

Collected

Indicates the last area collected, how many Final Storage locations were

collected, and how many Final Storage locations should have been collected.

(The CR10, CR10X, CR510, and CR23X are the only supported dataloggers with

a Final Storage area 2.) For example, Area1 7/7 indicates that seven Final

Storage locations were collected from Area 1 on the last call. Area1 0/0

indicates that no locations where collected on the last call, probably because

there was no new data. Area1 0/10 would indicate that 10 locations were

attempted but none were collected, possibly due to a link failure.

Next Call

Indicates the next time to call. This is based on the scheduling and retry

parameters entered on the SCHEDULE tab for the datalogger in the SETUP

window. If no date and time are displayed, scheduling is not enabled. If a date

and time are displayed, but are grayed out, the schedule has been paused by

checking the Pause Schedule check box at the bottom of the Status screen. A

device's schedule can be toggled on or off by selecting the device, pressing the

right mouse button, and choosing Toggle On/Off or by pressing the Toggle

On/Off button.

1.4.2 Low Level I/O

Logging low level I/O is typically used to troubleshoot a communication

problem.

Select the View I/O button to display the actual serial communications for all

the serial ports. The columns on th e lef t co ntain the characters transmitted by

PC208W and those on the right indicate characters received. Binary

(unprintable) characters are displayed as a period “.” character. Since

1-14 PC208W, Version 3.3, Instruction Manual

Page 37

Section 1. Setting Up the Network and Communicating with the Datalogger

communication for all serial ports is displayed and can occur concurrently, it

may be helpful to turn scheduling off for all other sites when troubleshooting a

particular site.

The Log I/O to Disk checkbox is used to enable logging to a file in PC208W's

working directory. The files are named IO$COM1.LOG for COM1,

IO$COM2.LOG for COM2, and so on for COM ports, and IO$SOCKE.LOG

for socket connections. A separate file is used for each COM port, but all

socket activity is contained in one log. These files use a hexadecimal format so

binary characters can be viewed.

Information is saved to the IO$COMX.log file until it reaches 1 . 2 M . Once it