Page 1

l

Open Path Eddy Covariance System

Operator’s Manua

CSAT3, LI-7500, and KH20

9/06

Copyright © 2004-2006

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The OPEN PATH EDDY COVARIANCE (OPEC) SYTEM is warranted

by CAMPBELL SCIENTIFIC, INC. to be free from defects in materials and

workmanship under normal use and service for twelve (12) months from date

of shipment unless specified otherwise. Batteries have no warranty.

CAMPBELL SCIENTIFIC, INC.'s obligation under this warranty is limited to

repairing or replacing (at CAMPBELL SCIENTIFIC, INC.'s option) defective

products. The customer shall assume all costs of removing, reinstalling, and

shipping defective products to CAMPBELL SCIENTIFIC, INC. CAMPBELL

SCIENTIFIC, INC. will return such products by surface carrier prepaid. This

warranty shall not apply to any CAMPBELL SCIENTIFIC, INC. products

which have been subjected to modification, misuse, neglect, accidents of

nature, or shipping damage. This warranty is in lieu of all other warranties,

expressed or implied, including warranties of merchantability or fitness for a

particular purpose. CAMPBELL SCIENTIFIC, INC. is not liable for special,

indirect, incidental, or consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company

serves your country. To obtain a Returned Materials Authorization (RMA),

contact CAMPBELL SCIENTIFIC, INC., phone (435) 753-2342. After an

applications engineer determines the nature of the problem, an RMA number

will be issued. Please write this number clearly on the outside of the shipping

container. CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

CAMPBELL SCIENTIFIC, INC. does not accept collect calls.

Page 3

Open Path Eddy Covariance System

Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. System Description .....................................................1

1.1 OPEC (CSAT3 Only) ...............................................................................1

1.2 Basic OPEC ..............................................................................................1

1.3 Extended OPEC........................................................................................1

1.4 Additional Fast Response Sensors............................................................2

2. Installation and Mounting ...........................................2

2.1 Fetch and Sensor Height...........................................................................3

2.2 Mounting ..................................................................................................4

2.2.1 Measure CSAT3 Azimuth...............................................................9

2.3 Wiring.......................................................................................................9

2.4 Power........................................................................................................9

3. System Datalogger Program ....................................10

3.1 Generic Program Flowchart....................................................................12

3.2 Program Configuration ...........................................................................13

3.2.1 CSAT3 Azimuth ...........................................................................14

3.2.2 Sensor Configuration ....................................................................15

3.3 Loading a Program to the Datalogger.....................................................16

3.3.1 Direct Connection via LoggerNet.................................................16

3.3.2 Remote via PC/CF Card................................................................16

3.4 System Operation....................................................................................17

3.4.1 Monitoring Data............................................................................17

3.4.2 Status Table...................................................................................18

4. Data.............................................................................18

4.1 Data Retrieval .........................................................................................19

4.1.1 Direct Connection Data Retrieval via LoggerNet.........................20

4.1.2 File Management with Baler.........................................................23

4.1.3 Remote Data Retrieval via a PC/CF Card.....................................24

4.1.4 File Management with CardConvert.............................................25

4.1.4.1 Collecting Data with One Card ...........................................29

4.1.4.2 Collecting Data with Two Cards .........................................30

4.2 Data Processing ......................................................................................31

4.2.1 Online Processing .........................................................................32

4.2.2 Off-line Processing with EdiRe ....................................................32

4.2.2.1 Creating Raw File Format and Processing Lists..................33

4.2.2.2 Example EdiRe Raw File Format and Processing Lists ......35

5. Eddy Covariance Theory 101....................................39

i

Page 4

Open Path Eddy Covariance System Table of Contents

A. CSAT3 Orientation ..................................................A-1

A.1 Determining True North and Sensor Orientation................................ A-1

A.2 Online Magnetic Declination Calculator............................................. A-3

B. Sensible Heat Flux without a FW05 .......................B-1

B.1 Speed of Sound and Sonic Temperature ............................................. B-1

B.2 Sonic Temperature, Temperature, and Humidity ................................ B-2

B.3 Sensible Heat and Specific Humidity Flux ......................................... B-3

B.4 Sensible and Latent Heat Flux............................................................. B-4

Appendix C. References..............................................C-1

Figures

1. Eddy Covariance Sensors Mounted on a CM10 Tripod ............................ 3

2. Side View of the CSAT3 and LI-7500 (mounted underneath CSAT3) ..... 5

3. Side View of the CSAT3 and LI-7500 (mounted beside CSAT3)............. 5

4. CM110 Enclosure Mounting Hardware Attached to the LI-7500

Electronics Box .......................................................................................... 6

5. Close Up View p/n 17716, configured for ENC 10/12, Locking

Mechanism ................................................................................................. 6

6. CSAT3 Electronics Box and p/n 17813 Enclosure Hanger Kit on

CM110 Tripod Body .................................................................................. 7

7. CSAT3 and LI-7500 Electronics Boxes Mounted on the CM110

Tripod Body ............................................................................................... 7

8. ENC12/14 Enclosure Mounted on the CM110 Tripod Base ..................... 8

9. HMP45C 10-plate Radiation Shield Mounted on the Body of the

CM110 and on the CM204 Horizontal Crossarm....................................... 8

10. Terminal Strip Adapters for Power Connection to External Battery ..... 10

11. CSAT3 Right Hand Coordinate System, Horizontal Wind Vector

Angle is 0 Degrees.................................................................................... 14

12. Compass Coordinate System, Compass Wind Direction is 140

Degrees..................................................................................................... 15

13. LoggerNet Station Setup for the “flux” table......................................... 21

14. LoggerNet Station Setup for the “ts_data” Table .................................. 21

15. LoggerNet Station Data Collection Schedule ........................................ 22

16. LoggerNet Station Status Monitor ......................................................... 22

17. Baler Station Setup for the “flux” Table................................................ 23

18. Baler Station Setup for the “ts_data” Table ........................................... 24

19. File Format Flow.................................................................................... 26

20. Destination File Option Screen .............................................................. 27

21. Fully Configured CardConvert Start Up Screen .................................... 28

22. List of Files Created by CardConvert .................................................... 28

23. List of Files Created by CardConvert with Duplicates .......................... 29

24. List of Files Where the Duplicate Files are Renamed to *.bak.............. 30

25. List of Files Collected the First Time Using Two Cards ....................... 31

26. List of Files Collected the Second time Using Two Cards .................... 31

27. Interpreter Settings to Read a Campbell Scientific, Inc. TOB1

Data File ................................................................................................... 34

28. Folder that Contains the Raw TOB1 Time Series Data Files................. 34

29. Competed Interpreter Screen ................................................................. 35

30. Estimated Sample Frequency and Correct Sample Frequency .............. 35

ii

Page 5

Tables

Open Path Eddy Covariance System Table of Contents

31. Default EdiRe Processing List Created by the Interpreter......................36

32. Output File Location as Part of the Processing List ...............................37

33. Output File Location as Part of the Processing List ...............................37

34. Processing U

35. Computing CO

and CO2 with 1 Chn Statistics Instruction........................38

z

Flux with 2 Chn Statistics and Graphing Uz Statistic

2

with Plot Value Instruction .......................................................................38

36. Ideal Vertical Profiles of Virtual Potential Temperature and Specific

Humidity Depicting All the Layers o the Atmospheric Boundary Layer..39

A-1. Magnetic Declination for the Conterminous United States (2004) ... A-1

A-2. A Declination Angle East of True North (Positive) is Subtracted

from 360 (0) degrees to Find True North............................................... A-2

A-3. A Declination Angle West of True North (Negative) is Subtracted

from 0( 360) degrees to Find True North............................................... A-2

A-4. Online Magnetic Declination Calculator with Inputs and Output

for Longmont, CO.................................................................................. A-3

1. Nominal Sensor Power Requirements ........................................................9

2. Nominal Datalogger Power Requirements with the Display Off and

No RS-232 Communications ......................................................................9

3. Nominal Datalogger Power Requirements with the Display and

Backlight On, and No RS-232 Communications ........................................9

iii

Page 6

Open Path Eddy Covariance System Table of Contents

This is a blank page.

iv

Page 7

Open Path Eddy Covariance System

This document will serve as a guide to properly install and operate a Campbell Scientific,

Inc. Open Path Eddy Covariance System (OPEC). The OPEC is composed of various

products, e.g. dataloggers, fast response turbulence sensors, slow response meteorological

sensors, and software. These products are manufactured by Campbell Scientific, Inc. and

other vendors. Manuals for each of these sensors shipped with the system. It is time well

spent reviewing these documents.

The literature contains information that spans 50 years on eddy covariance (correlation)

theory and measurements. Section 5ever so briefly touches eddy covariance theory. For

more details on eddy covariance measurements and data analysis, see the literature.

1. System Description

The Campbell Scientific, Inc. eddy covariance systems measure sonic sensible

heat flux, momentum flux, and the flux of other scalars between the

atmosphere and earth’s surface. The system consists of a datalogger, fast

response three-dimensional sonic anemometer, and fast response scalar

sensors. An independent measure of temperature and humidity from a slow

response sensor is also measured to calculate background meteorological

variables. Horizontal wind speed and direction are computed by the datalogger

from the three-dimensional measurements of wind made by the sonic

anemometer.

1.1 OPEC (CSAT3 Only)

The minimum components required for eddy covariance measurements are a

datalogger, a CSAT3 three-dimensional sonic anemometer, and a HMP45C

temperature and humidity probe. This system configuration measures sonic

sensible heat flux, momentum flux, temperature, humidity, horizontal wind

speed, and wind direction. This system configuration is used to compute eddy

diffusivity required to compute fluxes of trace gases measured with a gradient

system like the TGA100A (Warland, et al., 2001).

1.2 Basic OPEC

A more typical eddy covariance system consists of a datalogger, a CSAT3

three-dimensional sonic anemometer, a LI-7500 open path infrared gas

analyzer (IRGA), and a HMP45C temperature and humidity probe. With this

configuration, the system can measure carbon dioxide flux, latent heat flux,

sonic sensible heat flux, momentum flux, a computed sensible heat flux (see

Appendix B), temperature, humidity, horizontal wind speed, and wind

direction.

1.3 Extended OPEC

Energy balance sensors can be added to a basic OPEC system to also measure

the net radiation, soil heat flux, soil temperature, and soil water content. The

sensors required for these additional measurements are a Q7.1, NR-LITE, or

CNR1 net radiometer, two to four HFT3 or SHF01-SC soil heat flux plates,

1

Page 8

Open Path Eddy Covariance System

one or two TCAV averaging soil temperature probes, and one or two CS616

soil moisture reflectometers.

1.4 Additional Fast Response Sensors

If the application requires a direct measurement of sensible heat flux, a FW05

can be added to the system. In the absence of a FW05 or if the FW05 breaks,

the sensible heat flux can be found from the sonic sensible heat flux and the

latent heat flux (see Equation 36 in Appendix B).

A KH20 Krypton hygrometer, instead of the LI-7500, can be used to measure

the latent heat flux. The KH20 can not be used to measure an absolute

concentration of water vapor, because of scaling on the source tube windows

caused by disassociation of atmospheric continuants by the ultra violet photons

(Campbell and Tanner, 1985 and Buck, 1976). The rate of scaling is a function

of the atmospheric humidity. In high humidity environments, scaling can

occur within a few hours. That scaling attenuates the signal and can cause

shifts in the calibration curve. However, the scaling over a typical flux

averaging period is small. Thus, water vapor fluctuation measurements can

still be made with the hygrometer. The effects of the scaling can be easily

reversed by wiping the windows with a moist swab.

To measure other trace gases, a TGA100A Trace Gas Analyzer can be added to

the system. The TGA100A can measure methane, carbon dioxide isotope,

water vapor isotope, ammonia, and nitrous oxide flux.

2. Installation and Mounting

When making eddy covariance measurements near the surface (less than 3

meters), mount the datalogger enclosure between the legs of the CM11x tripod,

on a separate tripod, or user-supplied drive stake. Also, mount any sensor

electronics boxes as far from the fast response sensors as possible and always

use the tripod guy kit. This will minimize potential flow distortions and tower

sway caused by wind blowing against the fiberglass enclosure. See the tripod

manuals for detailed installation instructions.

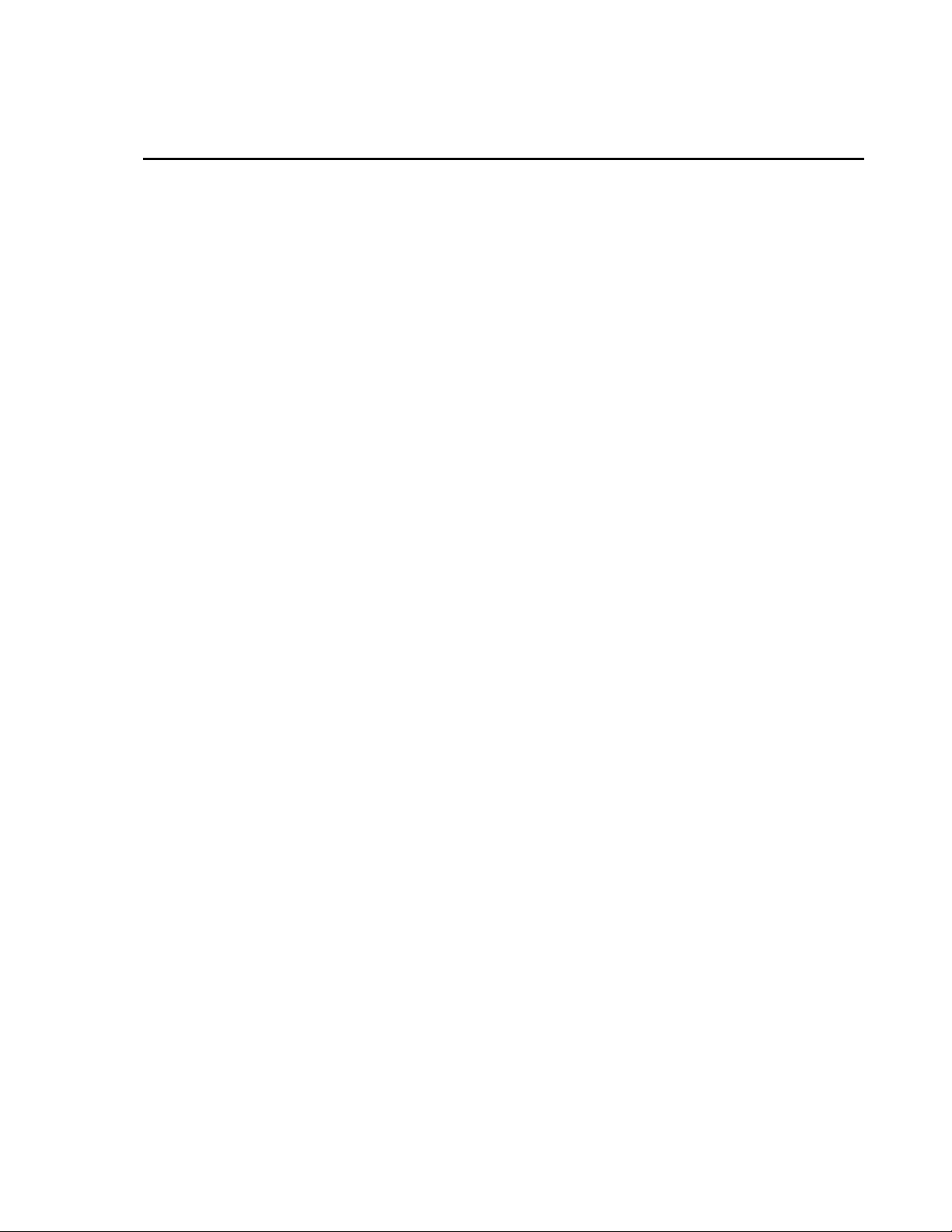

Figure 1 depicts a typical eddy covariance station. Point the eddy covariance

sensors into the prevailing wind to minimize the flow distortion from the

tower, mounting hardware, and other sensors.

TIP

Keep a log book for each station. Record the date and personnel

name for all site visits, as well as all maintenance and work that

is performed during the site visit.

2

Page 9

Open Path Eddy Covariance System

FIGURE 1. Eddy Covariance Sensors Mounted on a CM10 Tripod;

the Datalogger Enclosure is on a Separate Tripod (not pictured)

2.1 Fetch and Sensor Height

The eddy covariance sensors must be mounted at some height to ensure that the

measurements are made within the local surface layer. The local surface layer

grows at a rate of approximately 1 vertical meter per 100 horizontal meters.

Thus, a height to fetch (horizontal distance traveled) ratio of 1:100 may be used

as an absolute bare minimum rough rule of thumb for determining the

measurement height. The following references discuss fetch requirements in

detail: Brutsaert (1982); Dyer and Pruitt (1962); Gash (1986); Schuepp, et al.

(1990); and Shuttleworth (1992).

The fetch should be homogenous and flat, and no abrupt changes in vegetation

height should exist (Tanner, 1988). Consider two adjacent fields, the first

planted with 1 m tall corn and the second with 0.5 m soybean. Eddy

covariance sensors mounted at 2 m above the corn field should have a

minimum of 200 m of fetch in all the directions that the data is of interest,

3

Page 10

Open Path Eddy Covariance System

particularly between the eddy covariance sensors and the interface between the

corn and soybean field.

2.2 Mounting

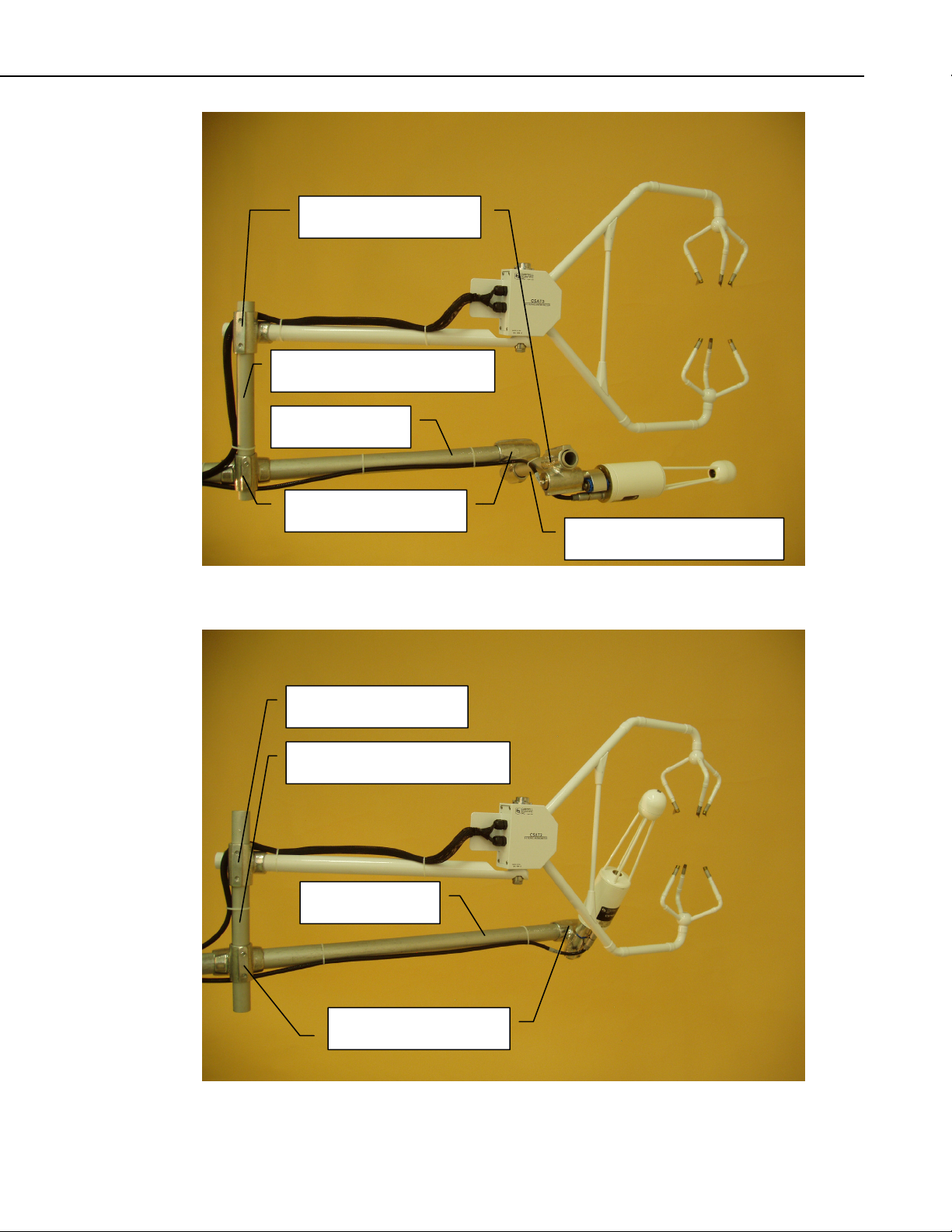

The CSAT3, LI-7500, and HMP45C are mounted to a tripod or tower using a

horizontal mounting arm, several Nu-Rail crossover fittings, and short lengths

of pipe.

The CSAT3 is attached to the CM204 (OPEC standard), CM206, or CM208

horizontal mounting arm by a 0.75 inch by 0.75 inch crossover Nu-Rail (p/n

1017), a 1.0 inch by 0.75 inch crossover Nu-Rail (p/n 1049), and a 30.48 cm

(12 inch) length of 0.75 inch diameter pipe (p/n 18048) (Figures 2 and 3).

The LI-7500 can be mounted two ways, underneath the CSAT3 (Figure 2) or

slightly behind the CSAT3 measurement volume (Figure 3) with a separation

of about 15 to 20 cm. The IRGA should be set back from the anemometer to

minimize flow distortions. Tilt the IRGA sensor head about 60 degrees from

horizontal to minimize the amount of precipitation that accumulates on the

windows.

The LI-7500 is attached to the CM204 horizontal mounting arm by a 1.0 inch

by 0.75 inch crossover NU-Rail (p/n 1049), and the Head Mounting Kit

(LI-COR p/n 9975-010), or a 1.0 inch by 0.75 inch crossover NU-Rail

(p/n 1049), a 0.75 inch by 0.75 inch crossover Nu-Rail (p/n1017), a 25.4 cm

(10 inch) length of 0.75 inch diameter pipe (p/n 6332), and the Head Mounting

Kit (LI-COR p/n 9975-010) (Figure 2 and Figure 3).

Attach the enclosure mounting hardware, p/n 17716, to the LI-7500 electronics

enclosure (Figures 4 and 5). Mount the enclosure hanger kit, p/n 17813, and

the CSAT3 electronics as shown in Figures 6 and 7. Finally, mount the

ENC12/14 enclosure on the tripod base as shown in Figure 8.

Mount the HMP45C radiation shield at the same height as the fast response

sensors. The HMP45C radiation shield is mounted to the either the tripod body

or the end of the horizontal cross arm (Figure 9).

4

Page 11

p/n 1017 0.75 inch by 0.75 inch

crossover Nu-Rail fitting

p/n 18048 0.75 inch diameter by 30.48

cm (12 inch) long aluminium pipe

CM204 Crossarm with

bracket, 1.3 m (4 ft)

p/n 1049 1.0 inch by 0.75 inch

crossover Nu-Rail fitting

Open Path Eddy Covariance System

p/n 6332 0.75 inch diameter by 25.4

cm (10 inch) long aluminium pipe

FIGURE 2. Side View of the CSAT3 and LI-7500 (mounted underneath CSAT3)

p/n 1017 0.75 inch by 0.75 inch

crossover Nu-Rail fitting

p/n 18048 0.75 inch diameter by 30.48

cm (12 inch) long aluminium pipe

CM204 Crossarm with

bracket,1.3 m (4 ft)

p/n 1049 1.0 inch by 0.75 inch

crossover Nu-Rail fitting

FIGURE 3. Side View of the CSAT3 and LI-7500 (mounted beside CSAT3)

5

Page 12

Open Path Eddy Covariance System

FIGURE 4. CM110 Enclosure Mounting Hardware (p/n 17716 configured for ENC 10/12)

Attached to the LI-7500 Electronics Box

6

FIGURE 5. Close Up View p/n 17716, configured for ENC 10/12, Locking Mechanism

Page 13

Open Path Eddy Covariance System

FIGURE 6. CSAT3 Electronics Box and p/n 17813

Enclosure Hanger Kit on CM110 Tripod Body

FIGURE 7. CSAT3 and LI-7500 Electronics Boxes Mounted on

the CM110 Tripod Body

7

Page 14

Open Path Eddy Covariance System

FIGURE 8. ENC12/14 Enclosure Mounted on the CM110 Tripod Base

8

FIGURE 9. HMP45C 10-plate Radiation Shield Mounted on

the Body of the CM110 (left) and on the CM204 Horizontal Crossarm (right)

Page 15

2.2.1 Measure CSAT3 Azimuth

To compute the correct compass wind direction, the station operator must enter

the negative x-axis azimuth of the CSAT3 into the datalogger program. If the

CSAT3 is installed such that it points into the prevailing wind, the negative

x-axis is pointing into the prevailing wind. Take a compass azimuth of the

negative x-axis (prevailing wind) and record it into the station log book for

later use.

2.3 Wiring

A Campbell Scientific, Inc. eddy covariance system can take on several

configurations and utilize several different dataloggers. It is impractical to

document the different wiring schemes in this manual. However, do not

despair; each datalogger program (p/n 18442 or 18443) contains a complete

and detailed wiring diagram. See the datalogger program for wiring

instructions.

2.4 Power

The system requires about 1.5 to 14 W continuous power, depending on the

datalogger and sensor configuration. The approximate power requirements of

various key components, for a system running at 10 Hz, are listed in Tables 1,

2, and 3.

Open Path Eddy Covariance System

TABLE 1. Nominal Sensor Power Requirements

Sensor Power (mW)

CSAT3 67 mA @ 12.5 Vdc

LI-7500 850 mA @ 12.5 Vdc (after warmup)

KH20 10 - 20 mA @ 12.5 Vdc

HMP45C <3.8 mA @ 12.5 Vdc

TABLE 2. Nominal Datalogger Power Requirements with

the Display Off and No RS-232 Communications

Datalogger Power (mW)

CR1000 w/ CFM100 & CF card 8 mA @ 12.5 Vdc

CR3000 w/ CFM100 & CF card 39 mA @ 12.5 Vdc

CR5000 w/ PC/CF card 63 mA @ 12.5 Vdc

TABLE 3. Nominal Datalogger Power Requirements with

the Display and Backlight On, and No RS-232 Communications

Datalogger Power (mW)

CR1000 w/ CFM100 & CF card 109 mA @ 12.5 Vdc

CR3000 w/ CFM100 & CF card 75 mA @ 12.5 Vdc

CR5000 w/ PC/CF card 170 mA @ 12.5 Vdc

9

Page 16

Open Path Eddy Covariance System

The CSAT3 and LI-7500 are powered by an external battery. Typically, so is

the datalogger. If a CR3000/CR5000 is to be powered from a base with a

sealed rechargeable battery, connect the datalogger ground lug to the negative

post of the external battery. Ensure that the rechargeable battery is trickle

charged by a solar panel or mains power.

A user-supplied 70 Ahr deep cycle RV battery (degraded by 30%) will run the

system for approximately two days. The battery will have to be charged by a

trickle charger connected to mains power or solar panels. In some

environments, additional batteries or solar panels may be required (see the

Power Supply Application Note 5-F at http://www.campbellsci.com/

documents/apnotes/pow-sup.pdf and the solar panel manual at

http://www.campbellsci.com/documents/manuals/msx.pdf).

The CSAT3 and LI-7500 power cables are connected directly to the battery

terminals by means of two terminal strips (p/n 4386), one for the positive post

and the other the negative post (Figure 10).

FIGURE 10. Terminal Strip Adapters for Power Connection

to External Battery

Power connections are listed in the programs (p/n 18442 or 18443). Be sure

the datalogger has a good earth ground to protect against primary and

secondary lightning strikes. Campbell Scientific, Inc. recommends that all

dataloggers in the field be earth grounded. All components of the system

(datalogger, sensors, external power supplies, mounts, housing, etc.) must be

referenced to one common earth ground. When long cables are used or a site

has frequent lightning strikes, spark gaps may be required to protect the

datalogger from transient voltages.

3. System Datalogger Program

The eddy covariance datalogger program is the single component that

integrates all of the sensors in an eddy covariance station into a single system.

Part number 18442 is a program for a basic system and p/n 18443 is a program

for an extended system (with energy balance sensors). If your order did not

include either p/n 18442 or 18443 as a line item on the order, contact Campbell

Scientific, Inc. to purchase the appropriate datalogger program for your eddy

covariance system.

10

Page 17

Open Path Eddy Covariance System

The library of programs covers a variety of sensors and is continuously

growing. If your system has sensors that are not part of any program in the

library, simply add the appropriate measurement and processing instructions to

the program or contact Campbell Scientific, Inc. for assistance. Campbell

Scientific, Inc. charges for custom datalogger programming with a one hour

minimum and one hour resolution; call for current Application Engineering

time rates.

The datalogger programs align the measurements in time from the CSAT3,

LI-7500, KH20, and FW05. The CSAT3 has a fixed two scan delay and

LI-7500s shipped from Campbell Scientific, Inc. are programmed with a fixed

300 milliseconds (297.25 milliseconds) delay. These sensor delays are

removed before the time series data is saved to Final Storage and before they

are used to compute the online fluxes.

Depending on the system configuration, the datalogger programs compute

carbon dioxide flux, latent heat flux, sonic sensible heat flux, sensible heat

flux, momentum flux, and friction velocity, along with all the second moment

covariances, standard deviations, and means. The program will also compute a

sensible heat flux from the sonic sensible heat flux and latent heat flux (see

Appendix B). Each datalogger program is shipped with a Microsoft

®

Excel

workbook (tab) that describes the datalogger program outputs. There is one

worksheet (tab) per output data table.

11

Page 18

Open Path Eddy Covariance System

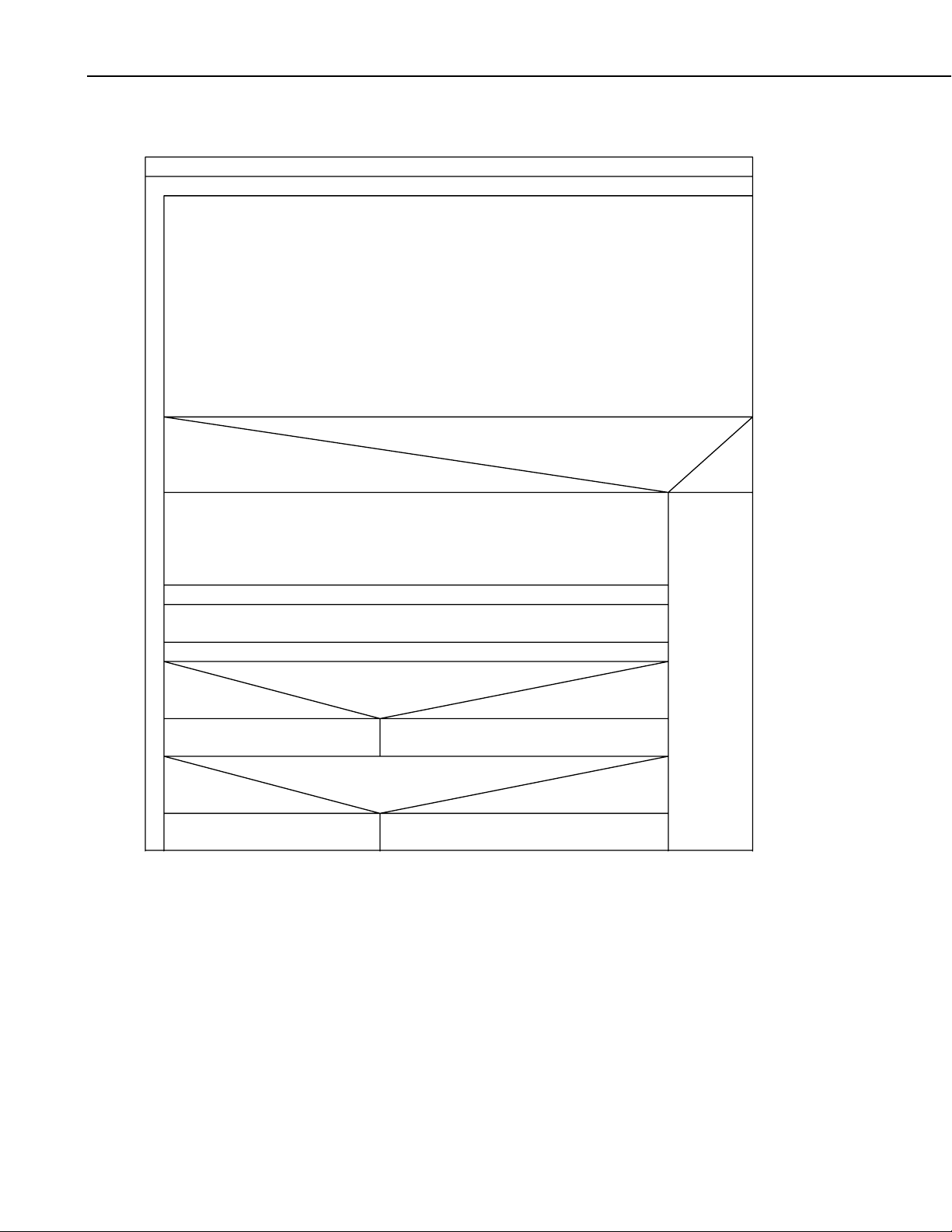

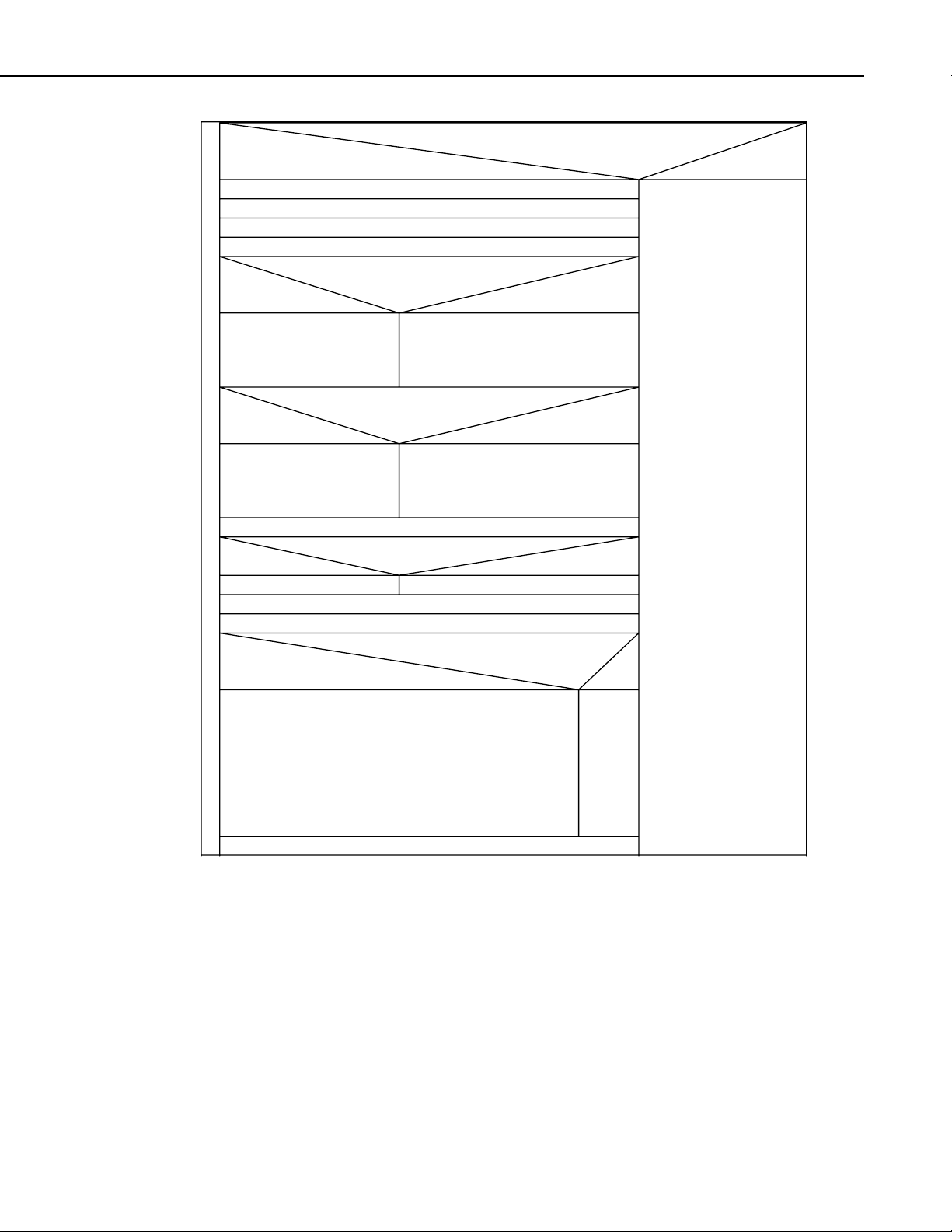

3.1 Generic Program Flowchart

Set default values for all variables:

Scan every 0.1 or 0.05 seconds

Measure Sensors:

- datalogger panel temperature

- FW05

- KH20

- CSAT3

- LI-7500

- HMP45C

- battery voltage

- Q7.1/NRLite/CNR1

- HFP01SC/HFT3

- TCAV

- CS616

Are enough data buffered to undo sensor lags? (scan_count

>= offset?)

TRUE

Retrieve buffered data and apply the appropriate lag:

- Load the CSAT3 data from (OFFSET - 2) scans back

- Load the LI-7500 data from (OFFSET - 1) scans back

- Load the KH20 data from (OFFSET - 0) scans back

- Load the FW05 data from (OFFSET - 0) scans back

Convert CSAT3 data for WindVector (): wind_east = -Uy, wind_north = Ux

Convert LI-7500 data from molar density to mass density

Convert LI-7500 data from molar density to molar fraction

Convert CSAT3 diagnostic word into seperate warning flags

Are any CSAT3 warning flags set?

TRUE

Disable covariance processing

(disable_flag_on(1) = TRUE)

Is the CSAT3 warning not a diagnostic code?

TRUE

Disable count of warning flags

(disable_flag_on(3) = TRUE)

Enable covariance processing

(disable_flag_on(1) = FALSE)

Enable count of warning flags

(disable_flag_on(3) = FALSE)

FALSE

FALSE

FALSE

12

Page 19

Open Path Eddy Covariance System

continuation of scan_count >= offset?

TRUE

Save the 4 most significant bits of the CSAT3 diagnostic word

Flip the diagnostic bits in the LI-7500 diagnostic

Compute LI-7500 AGC

Convert LI-7500 diagnostic word into seperate warning flags

Are any LI-7500 warning flags true?

TRUE

Disable covariance

processing

(disable_flag_on(2) =

TRUE)

LI-7500 CO2 = NAN or SDM error?

TRUE

Disable count of LI-7500

warning flags

(disable_flag_on(4) =

TRUE)

Save the 4 most significant bits of the LI-7500 diagnostic word

Is it even minute?

TRUE

Call time series data table (delay adjusted)

Call the online covariance calculation data table (comp_cov)

TRUE

Perform online processing:

- Load the calculated covariances

- Calculate the compass wind direction

- Calculate the CSAT3 wind direction

- Compute the fluxes from the covariance values

- Calculate Webb et al. term

- Calculate a computed sensible heat flux

- Calculate the oxygen correction

Call flux data table

Enable covariance processing

(disable_flag_on(2) = FALSE)

Enable count of LI-7500 warning

flags (disable_flag_on(4) = FALSE)

save_ts_flag_on = FALSEsave_ts_flag_on = TRUE

Have new covarianc es been

calculated?

FALSE

scan_count =

scan_count+1

FALSE

FALSE

FALSE

FALSE

3.2 Program Configuration

The site attendant must enter unique calibration coefficients or site-specific

information into the datalogger program. This information includes, but is not

limited to, the CSAT3 azimuth, calibration coefficients for the net radiometer

and soil heat flux plates, or site pressure. To find the section of the program

where these changes are made, search for the text “Unique value”.

13

Page 20

Open Path Eddy Covariance System

3.2.1 CSAT3 Azimuth

The example programs report the wind direction in both the CSAT3 coordinate

system (a right-handed coordinate system) and in the compass coordinate

system (a screwball left-handed coordinate system). The CSAT3 coordinate

system is relative to the CSAT3 itself and does not depend on the CSAT3’s

orientation (azimuth of the negative x-axis). The compass coordinate system is

fixed to the earth. In order for the programs to compute the correct compass

wind direction, the azimuth of the CSAT3 negative x-axis must be entered into

the program. The program default value for CSAT3_AZIMUTH is 0. This

assumes that the prevailing wind is from the North, e.g. the CSAT3 is mounted

such that the negative x-axis points to the North.

As described in Section 2 and 2.2.1, orient the CSAT3 so that it is pointing into

the prevailing wind direction. If you have done so, the CSAT3 negative

x-axis will point into the prevailing wind direction. Enter this prevailing wind

direction for the constant CSAT3_AZIMUTH (see the station log book for this

bearing).

NOTE

Don’t forget to account for the magnetic declination at the site;

see Appendix A for details.

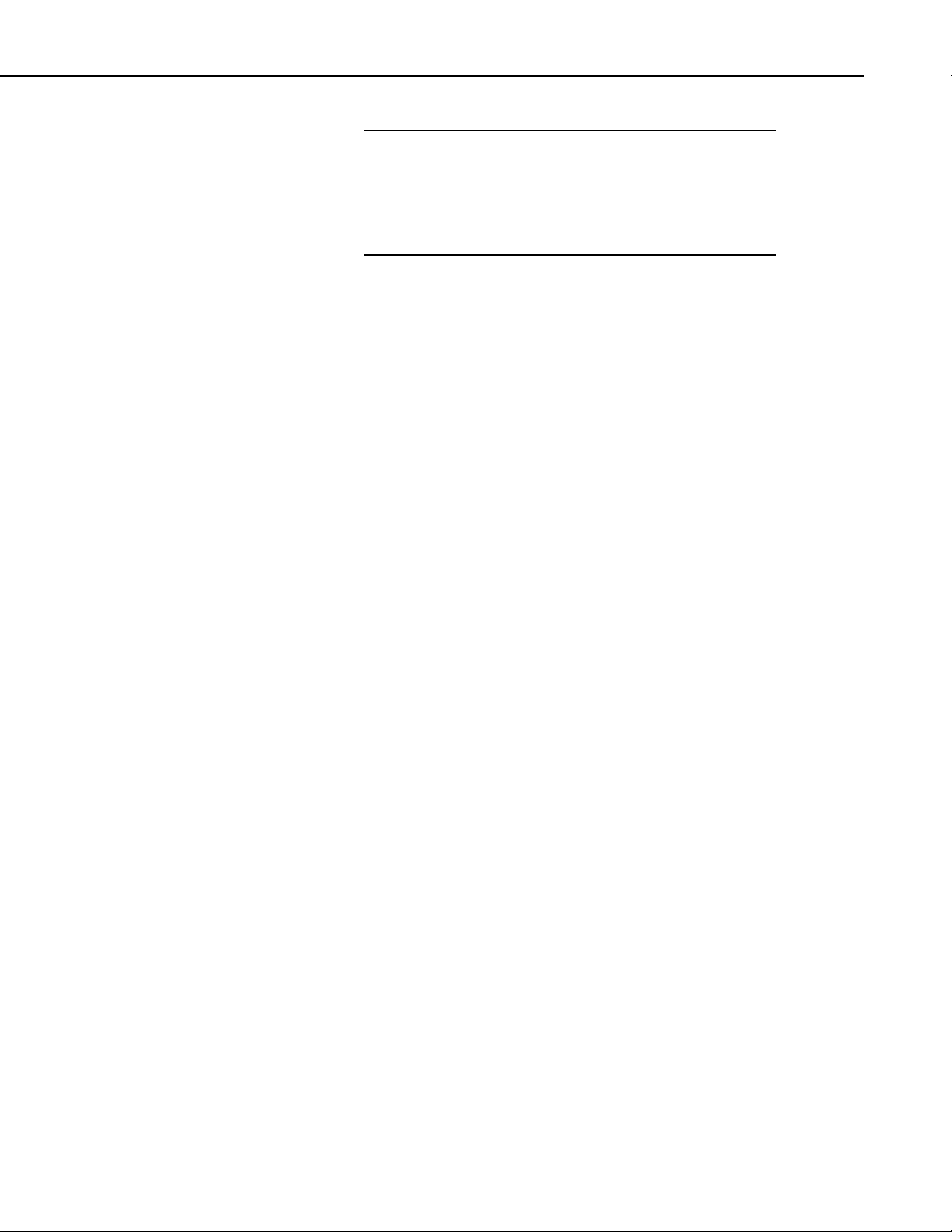

Figures 11 and 12 show the orientation of a CSAT3 with a compass bearing of

140 degrees, e.g. the negative x-axis is pointing into 140 degrees. If the wind

is blowing into the CSAT3, from the negative x-axis to the positive x-axis

(from the transducers to the block), the horizontal wind vector angle

(wind_dir_csat3) is 0 degrees (wind vector) and the compass wind direction

(wnd_dir_compass) is 140 degrees (wind vane).

Y

X

14

Wind Vane

Wind Vector

North

FIGURE 11. CSAT3 Right Hand Coordinate System,

Horizontal Wind Vector Angle is 0 Degrees

Page 21

Open Path Eddy Covariance System

North

X

Y

FIGURE 12. Compass Coordinate System,

Compass Wind Direction is 140 Degrees

Wind Vane

Wind Vector

3.2.2 Sensor Configuration

The CSAT3 and LI-7500 communicate with Campbell Scientific, Inc.

dataloggers using a proprietary digital communication protocol called

Synchronous Device for Measurement (SDM). Each sensor connected to the

SDM bus has a unique address. A maximum of 15 addresses are allowed by

the protocol and each sensor must have a unique SDM address.

CAUTION

Do not use SDM address F (15) because it is reserved for

use with the Group Trigger instruction.

The CSAT3 is shipped from the factory with a default SDM address of 3. The

CSAT3 address is set by a 16 position thumb switch located on the CPU circuit

board (see the CSAT3 manual for details).

The LI-7500 shipped from Campbell Scientific, Inc. is set with an SDM

address of 7. This address is set in software and can be changed using the

LI-7500 PC support software and the LI-7500 serial cable and port. In addition

to the SDM address, Campbell Scientific, Inc. sets the LI-7500 delay to 300

milliseconds (297.25 milliseconds). At a measurement rate of 10 Hz, this

programmed delay is a 3 scan delay and at 20 Hz it is a 6 scan delay. Finally,

the LI-7500 bandwidth is set to 20 Hz to limit the amount of numeric filtering

of high frequency information.

If the LI-7500 delay and bandwidth are not set correctly, the carbon dioxide

and latent heat fluxes will be underestimated. LI-7500s purchased directly

through LI-COR may or may not have the correct settings for use in a

Campbell Scientific, Inc. eddy covariance system. The only way to know for

sure is to check the settings. Contact LI-COR for information on changing

these settings or see Section 3, Outputs Page - Setting DAC and SDM Outputs

of the LI-COR published LI-7500 manual.

15

Page 22

Open Path Eddy Covariance System

CAUTION

If you loan a CSAT3 or LI-7500 to a colleague, verify that

the addresses are 3 and 7, respectively, before deploying

the system into the field.

3.3 Loading a Program to the Datalogger

Before the datalogger can begin to make measurements, a program must be

transferred into its CPU. The program can be transferred using a PC and

LoggerNet or using PC/CF cards. Without a working datalogger program, the

collection of eddy covariance sensors is just that, a collection of sensors. It is

the datalogger program and this document that integrates the sensors and

makes them an Open Path Eddy Covariance Flux System.

3.3.1 Direct Connection via LoggerNet

The datalogger program can be transferred to a datalogger using a PC,

LoggerNet, and some sort of interface. In the eddy covariance application, the

most common interface is the RS-232 cable.

NOTE

CR3000 OS v3.0, CR1000 OS v10.0, and CR5000 OS v2.1 or

greater support a 32 bit File Allocation Table (FAT32). Before a

card is used for the first time with a CRBasic datalogger, format

it on a Windows XP computer using FAT32. If a Windows XP

computer is unavailable, the 16 bit File Allocation Table (FAT)

is also supported with the above CRBasic dataloggers.

TIP

To avoid potential problems (mixed data and connectivity

issues), configure LoggerNet with one station file per datalogger,

even if the data is retrieved using cards and the computer is

connected to multiple dataloggers for monitoring purposes only.

See the LoggerNet manual Section 4.2.

Set up a station in the LoggerNet network map; see Section 4.1 in the

LoggerNet manual for details. To transfer a program to the datalogger, start

LoggerNet. Click on the “Connect” button in the Toolbar. Select the station

and click on the “Connect” button. Check the datalogger time, it is located in

the upper right hand side of the Connect Screen. If the datalogger and PC time

differ by more than a few seconds, set the datalogger time by clicking on the

“Set Station’s Clock” button. To download a program, click on the “Send”

button. Navigate to the folder where the program is saved, select it, and click

on “OK”.

3.3.2 Remote via PC/CF Card

The datalogger program can be transferred to a datalogger using a PC/CF card.

The CRBasic dataloggers reserve 10% or 80 Kbytes of space, whichever is

smaller, on cards to store programs. Copy the program onto the card using

Windows Explorer.

16

Page 23

Open Path Eddy Covariance System

CAUTION

Use only SanDisk Industrial Grade or Silicon Systems

PC/CF Cards. Although consumer versions of PC/CF

cards will fit into the card slot and operate, for a short time,

only the SanDisk Industrial Grade or Silicon Systems

PC/CF cards have passed our temperature and ESD

testing.

The following instructions assume a basic familiarity in the operation of a

CRBasic datalogger keyboard; see the datalogger manual for details on using

the keyboard.

Insert the card into the datalogger card slot. Press the enter key. If necessary,

select the “System Menu” menu and press the <Enter> key. Select the “File”

menu and press the <Enter> key. Select the “Copy” menu and press the

<Enter> key. The cursor should be at the “From” line. Press the <Enter> key,

select “CRD:” and again press the <Enter> key. The datalogger will now

display a list of program files on the card.

Navigate to the eddy covariance program and press the <Enter> key. The

cursor will jump to the “To” line. Press the <Enter> key and then the right

arrow, select CPU:filename. Press the <Esc> key and down arrow. Finally,

press the <Enter> key to execute the copy from the card to the CPU.

To start the program, press the <Esc> key until the main menu appears and

Campbell Scientific, Inc. logo appear in the upper left hand side. Press the

<Enter> key, if necessary, select the “System Menu” and press the <Enter>

key. Select the “Run/Stop Program” menu and press the <Enter> key. Tag the

“Restart, Delete Data” option, navigate to “Execute” and press the <Enter>

key. Select “Yes” and press the <Enter> key.

CAUTION

Do not run a program from the PC/CF card if the card will

be removed and replaced with another.

3.4 System Operation

Once the program is downloaded to the datalogger, compiled, and the PC/CF

card has been formatted, the datalogger will begin to communicate with the

SDM sensors and measure the analog sensors. At the top of the next minute, it

will start writing the raw time series data to the PC/CF card (the LED will

begin to flash at a steady frequency). Verify that all the sensors are wired and

measured correctly by monitoring the Public data table. Check the Status data

table for compile and runtime errors (See Section 3.4.2).

3.4.1 Monitoring Data

Monitor the instantaneous measurements by viewing the Public table. The

“Public” table can be monitored using either LoggerNet (see the LoggerNet

manual for details) or via the keyboard and display (see the datalogger manual

for details). The online flux computations can be viewed by monitoring the

“Flux” table with either LoggerNet or the keyboard and display. The historical

online “Flux” data can be monitored in “Final Storage Data” menu.

17

Page 24

Open Path Eddy Covariance System

3.4.2 Status Table

The “Status” table contains useful information about the performance and

status of the system (see Appendix A in the datalogger manual). To view the

“Status” table with LoggerNet, go to the Connect Screen and select the

Tools|Status Table … menu (see Section 5.1.10 in the LoggerNet manual).

With the keyboard display, follow this menu path System Menu|Status. Useful

information in the “Status” table includes, but is not limited to:

OSVersion: Version and revision of the CRBasic datalogger operating

system. As of the printing of this document, Campbell Scientific, Inc.

recommends using, CR3000 OS v3.0, CR1000 OS v10.0, or CR5000 OS v2.1

or greater.

WatchdogErrors: Number of times the watch dog timer reset the datalogger.

Normally, this count should be 0.

CompileResults: Reports compile errors.

VarOutOfBound: An element of an array was referenced that does not exist,

e.g. a VarOutOfBound is reported if element wind(9) is referenced in the

program, but the array was defined with 5 elements.

SkippedScan: If the maximum number of buffered scans is exceeded (defined

in the third parameter of the Scan () instruction), the Processing and

Measurement tasks are resynchronized. The resynchronization results in a

number of SkippedScan equal to the buffer depth.

DataFillDays(): The number of days to fill a table in both the CPU and CRD

memory. The number of days to fill a table is reported in the same order they

are found in the “Status” table, e.g. the same order they are defined in the

program.

CardStatus: Indicates if a card is used by the program or not.

ProcessTime: Time, in microseconds, it takes the datalogger to complete all

the processing. In the Sequential mode, this value must always be less than the

Scan Interval. In the PipeLine mode, this value can occasionally be greater

than the Scan Interval, e.g. when the 30 minute fluxes are computed. With the

eddy covariance systems, always use the Pipeline mode.

BuffDepth: The current number of Scans that the datalogger Processing tasks

have fallen behind the Measurement tasks. In the Pipeline Mode, the

datalogger processing task can periodically fall behind the Scan Interval.

MaxBuffDepth: The maximum number of Scans that the Processing tasks

have fallen behind the Measurement tasks.

4. Data

18

Each system requires an eddy covariance program (p/n 18442 or 18443). The

data table outputs of the programs are described in a Microsoft

document (shipped with the program). The description includes the variable

name and units. There is one sheet (tab) per output.

®

Excel

Page 25

Open Path Eddy Covariance System

NOTE

CAUTION

The datalogger programs are protected under U.S. and

International copyright laws. Do not distribute the datalogger

programs. See the End User License Agreement (EULA) shipped

with the programs for more information on your rights and

obligations.

Data is saved on the PC/CF card as a binary file in a Campbell Scientific, Inc.

format called Table Oriented Binary Format 3 (TOB3). TOB3 incorporates

features to improve reliability of the card and allows for the accurate

determination of each record’s time without the space required for individual

time stamps.

Use only SanDisk Industrial Grade or Silicon Systems

PC/CF Cards. Although consumer versions of PC/CF card

will fit into the card slot and operate, for a short time, only

the SanDisk Industrial Grade or Silicon Systems PC/CF

cards have passed our temperature and ESD testing.

Before the data can be used, it must be converted to a Table Oriented Binary

Format 1 (TOB1), Table Oriented ASCII Format 5 (TOA5), or Array

Compatible CSV file. In all of these formats, the time stamp is written to each

record. In the TOB1 format, the time stamp is reported as the number of

seconds and nanoseconds since 0000 hrs, 1 Jan 1990. In the TOA5 format, the

time stamp is a quoted string, similar to that used in Microsoft

®

Excel. In the

Array Compatible CSV, time is reported as elements of the array, e.g. in the

same format as the Campbell Scientific, Inc. mixed array dataloggers.

NOTE

Campbell Scientific, Inc. recommends the use of TOB1 file

format. This file format can be readily read into third party post

processing software, e.g. EdiRe (“e-dE rE”), MatLab, or

DADiSP. If required, a TOB1 flux file can be converted into a

TOA5 flux file using CardConvert. A TOA5 file is comma

separated values and easily read into Microsoft

file.

Both the TOB1 and TOA5 formats contain an ASCII header. This header

contains information about the datalogger used to collect the data. The header

also describes the data with variable names and units. For more information on

the file formats, see Section 2.4 in the datalogger manual.

For backwards compatibility with mixed array dataloggers, comma separated

values, without header information, is also supported with LoggerNet and

CardConvert. Elements that contain an array ID, day of year, hour and

minutes, can be added to the first few columns of the data file. This format is

supported in LoggerNet version 3.3 and CardConvert version 1.2 or greater.

4.1 Data Retrieval

Data can be collected from a datalogger using both LoggerNet and a direct

connection, or by physically moving the card from the datalogger to the

computer. Using LoggerNet and a PC as a data retrieval option is only

®

Excel as a CSV

19

Page 26

Open Path Eddy Covariance System

practical if the PC will be located at the site and is continuously polling the

datalogger because the volume of data is such that it takes about 8% to 25% of

real time to download 10 Hz time series data.

Transferring data using the PC/CF card is relatively fast; however, it does

require manual intervention to manage the files. A 1024 Mbyte file (about 30

days of 10 Hz time series from a Basic Eddy Covariance system) will take

about 15 minutes to copy from the card to a PC hard drive.

A Basic Eddy Covariance system will collect about 40 Mbytes of 10 Hz time

series data per day. A strategy for maintaining manageable file sizes is to

break them up into smaller files that cover time periods ranging from 1 hour to

1 day. This can be achieved with LoggerNet and the Baler, or using

CardConvert. Both the Baler and CardConvert support naming these smaller

files using the time stamp of the first record in the file.

TIP

A group file renaming utility can be useful to manage files from

multiple stations. These utilities are commonly used in the

photography industry to manage image files and are readily

available on the web, ranging from freeware, shareware, and

commercial versions. Any one of these will meet the data file

management needs, as long as it can find and replace text within

a file name.

4.1.1 Direct Connection Data Retrieval via LoggerNet

LoggerNet can be used to automatically collect and organize data from an eddy

covariance system. This approach is some what limited because of the slow

throughput into the PC’s RS-232 port. For all practical purposes, the PC must

remain continuously connected to the datalogger. It will take about 8% to 25%

of real time to collect 10 Hz time series data, e.g. it will take between 5 to 15

minutes to download 60 minutes of 10 Hz time series data. Using a PC and

LoggerNet to “milk” data from remote sites is not practical.

For sites where a PC is continuously connected to the datalogger via RS-232,

MD-485 short haul modems, Freewave spread spectrum radios, Ethernet

connection, or other “direct connection”, LoggerNet and the Baler can be used

to collect and manage the data.

To create a new station file see Section 4.2 of the LoggerNet manual.

Configure the station’s “Data Files” tab as shown in Figures 13 and 14. Note

that the “File Output Option” is “No Output File”. LoggerNet will collect the

data from the data table and place it in the cache. The cache is where data

collected from the datalogger is stored and made available for use by client

software, e.g. the Baler. Client software is run on the host PC or a remote PC.

For more information, see Section 13.1 of the LoggerNet manual.

20

Page 27

Open Path Eddy Covariance System

FIGURE 13. LoggerNet Station Setup for the “flux” Table

FIGURE 14. LoggerNet Station Setup for the “ts_data” Table

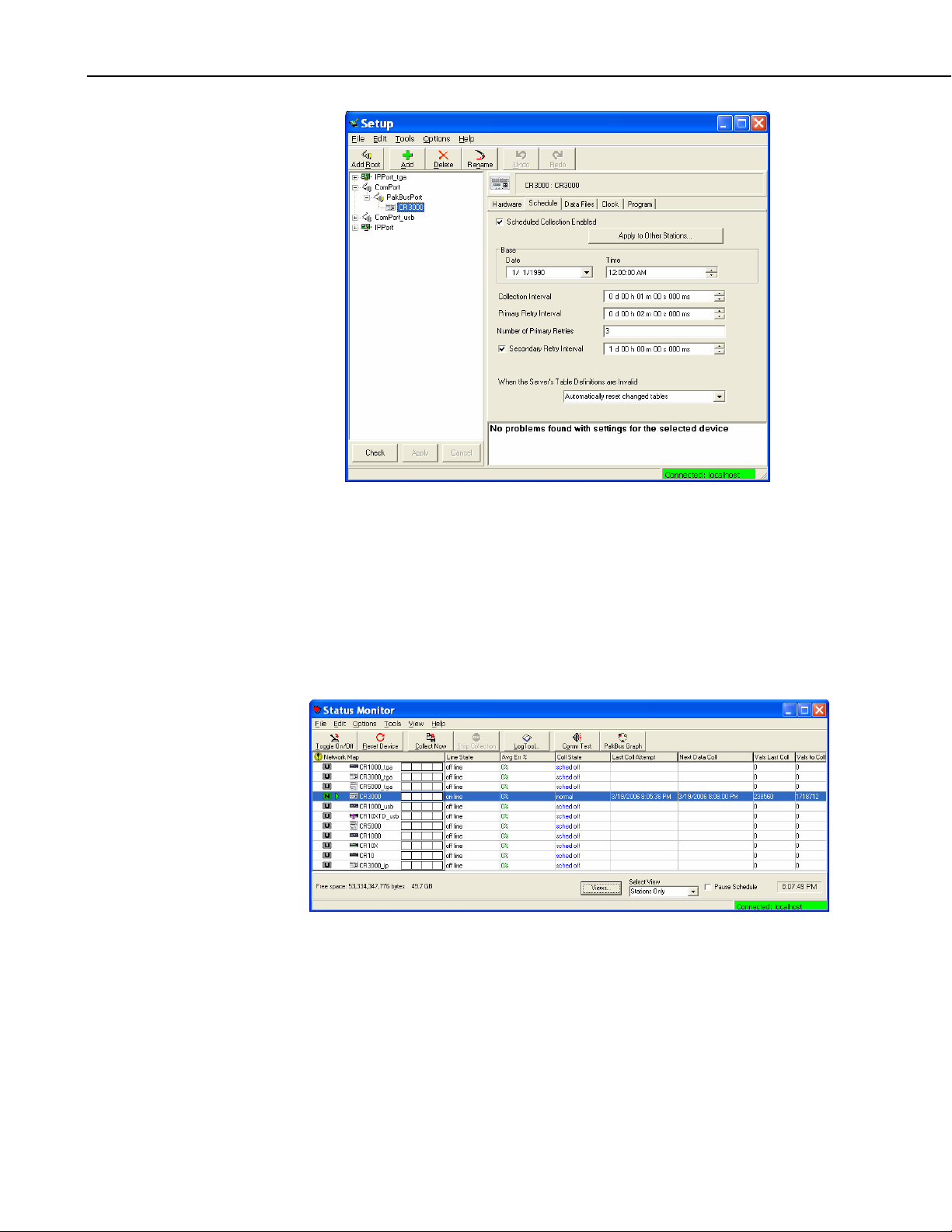

In the “Schedule” tab, configure the station’s data collection as shown in

Figure 15. Modify the Primary Retry Interval, Number of Primary Retries, and

the Secondary Retry interval as needed for the specific telecommunications

option used at the station. For example, a site using Freewave spread spectrum

radios or an Ethernet connection may require a long interval between retries or

more frequent retry attempts because of other background traffic.

21

Page 28

Open Path Eddy Covariance System

FIGURE 15. LoggerNet Station Data Collection Schedule

To enable LoggerNet’s data collection, click on the Status Monitor button in

the Toolbar. Select the station and click on the “Toggle On/Off” button. The

time of the next data collection will appear in the “Next Data Call” column (see

Figure 16). To display additional station information, right click on any

column header and then Select “Column…”. For more information, see

Section 6.1 Status in the LoggerNet manual.

FIGURE 16. LoggerNet Station Status Monitor

22

Page 29

4.1.2 File Management with Baler

The data is collected by LoggerNet and placed in the LoggerNet cache. Two

instances of the Baler, one for the time series data and the other for the flux

data, will pull the data from the cache and “bale” it into a user specified file

size (see Figures 17 and 18). Campbell Scientific, Inc. recommends using a

one hour bale size for time series data that will be post processed by EdiRe and

a 1 day bale size for the flux data. To run more than one instance of the Baler,

use the “/WorkDir=pathname” switch and two shortcuts, one for the time series

data and the other for the flux data (see Section 6.5 in the Baler manual).

Open Path Eddy Covariance System

TIP

While the system is set up in the lab or outside near the lab,

practice not only operating the system and data collection, but

also file management and data processing. Only through this

type of experimentation will you determine the file sizes and

procedures that work best for you.

FIGURE 17. Baler Station Setup for the “flux” Table

23

Page 30

Open Path Eddy Covariance System

FIGURE 18. Baler Station Setup for the “ts_data” Table

4.1.3 Remote Data Retrieval via a PC/CF Card

To transfer data manually from the PC/CF card to the PC, remove the card

from the datalogger following the proper card removal procedure (see the

appropriate datalogger manual for details). Insert a fresh card into the

datalogger or copy the data from the card to a working directory on the

computer. Transferring data using the PC/CF card is relatively fast. A 1024

Mbyte file (about 30 days of 10 Hz time series from a Basic Eddy Covariance

system) will take about 15 minutes to copy from the card to a PC hard drive.

While the PC/CF card is not in the datalogger, the datalogger will continue to

collect and save the data in the CPU. When the card is returned to the

datalogger, the data will be transferred automatically from the CPU to the card.

NOTE

When a card is inserted into a CRBasic datalogger, the

datalogger will transfer all the data that was collected since the

card was removed. It is good practice to avoid keyboard and

RS-232 activity during this time. After the datalogger is finished

transferring the data to the card, the LED will blink at a steady

frequency.

The amount of CPU storage, for time series data, varies from data logger to

datalogger. The Status Table reports the time it takes to fill the CPU and CRD

DataTables in the “DataFillDays” fields. The third DataFillDays field is the

fill time for the CPU time series data table. The fill time of the CPU time

series data table can be increased by decreasing the size of the CPU flux data

table, e.g. decrease the variable NUM_DAY_CPU from its default value.

24

Page 31

Open Path Eddy Covariance System

CAUTION

Never remove a PC/CF card from the datalogger or turn off

power to the datalogger without first shutting down the

card. With a CR3000 or CR1000, press the “Removal

Button” on the CFM100 Compact Flash/NL115

Ethernet/Compact Flash module. With a CR5000 select

the PCCard|Remove Card menu.

Data can be retrieved from a datalogger using one or two cards. If a single card

is used, and data on the card is not deleted after copying it to the PC, the data

from the CPU will be appended to the file on the card when it is returned to the

datalogger. Using a single card in this fashion allows the site attendant to

create files of uniform size.

The disadvantage of this approach, if the time between site visits is

significantly less than the DataTable file time, is that there will be redundant

data copied, along with the new data. This approach is not practical if the PC

can not be brought to the site or the time it takes to copy the data from the card

to the PC is greater than the time it takes to fill the CPU time series DataTable.

As an alternative, two cards can be used. The site attendant will remove the

card in the datalogger and replace it with a fresh one. This method is fast and

does not require a PC at the site. The disadvantage of this approach is that it

will create non-uniform file sizes around the time that the cards are exchanged.

If the time series data is processed by EdiRe, nonuniform file sizes are not an

issue. The files could be spliced together with a binary editor for TOB1 files or

a text editor TOA5 files.

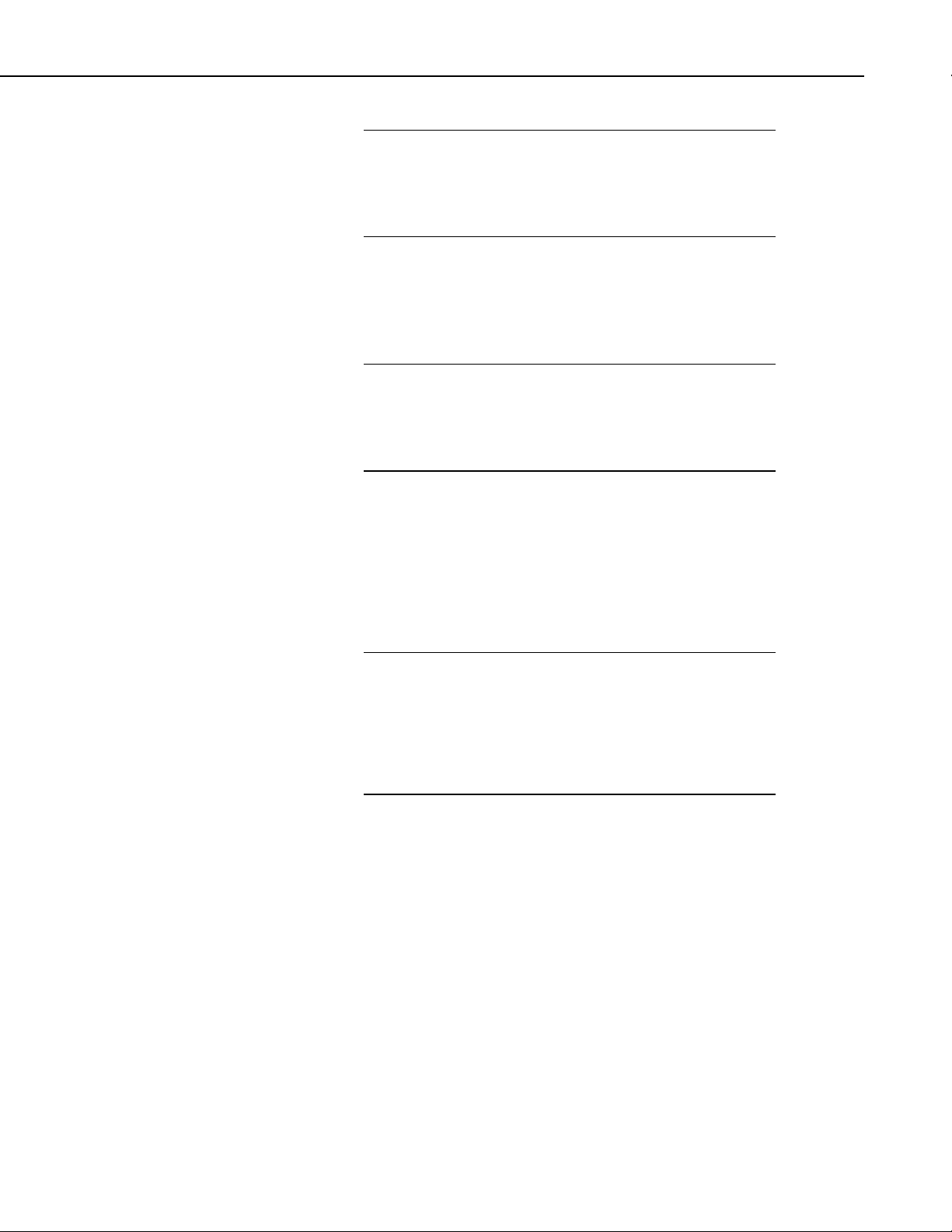

4.1.4 File Management with CardConvert

CardConvert is an utility that is shipped with LoggerNet and is used to convert

the files on a card from the compact file format TOB3 to a TOB1, TOA5, or

Array Compatible CSV (see Figure 19). This utility is installed on the PC

under the Start menu in the LoggerNet|Utilities group. To take advantage of all

the functionality described in this section, use CardConvert version 1.2 or later.

Copy the data from the PC/CF card onto the computer using Windows

Explorer. Place the file in a temporary working directory, e.g C:\Temporary.

It will take about 15 minutes to copy a 1024 Mbyte file (about 30 days of

10 Hz time series from a Basic Eddy Covariance system).

TIP

It is good practice to archive the raw data as copied from the

PC/CF card. Use a zip utility to compress the file, before

archiving it to a CD. Compressing a 1024 Mbyte time series file

will take about 2 minutes using the built-in Windows XP zip

utility.

25

Page 32

Open Path Eddy Covariance System

TOB1

Binary File

TOB3

File from

PC/CF Card

TIP

TOA5

ASCII file

with header

Array

Compatible

ASCI

Arrays without

header

FIGURE 19. File Format Flow

Start the CardConvert utility. When CardConvert is started, a summary of its

current settings is displayed in the lower right hand screen. There are four

screens/parameters to setup and configure in CardConvert. Once configured,

CardConvert will save these settings in the Windows Registry. In subsequent

runs, only the default Output File name must be changed.

• Click on the “Select Card Drive” button and navigate to the temporary

directory that contains the raw time series and flux data files. Select

the drive and click on the “OK” button.

Since it is likely that the online flux and time series files will be

broken down into different sizes based on time, process the time

series and flux data with multiple passes through CardConvert.

26

• Click on the “Change Output Dir” button and navigate to the folder to

store the processed data. Select the drive and click on the “OK”

button.

• Click on the “Destination File Options” button, the Destination File

Option screen will appear. Configure the screen as shown in Figure

20 and then click on the “OK” button.

Page 33

Open Path Eddy Covariance System

FIGURE 20. Destination File Option Screen

TIP

TIP

NOTE

To create an EdiRe raw format file list using the Interpreter, save

the data in the TOB1 file format. If another format is needed at a

later date, convert the TOB1 files into the other file format (see

Figure 19).

• Set the file size (Bale size) in the “Time Settings” screen. For the

time series files, use a one hour file size and for the online flux data,

use a one day file size.

Practice converting the data from the card and processing it with

your off-line tools. Only through this type of experimentation

will you determine the file sizes that work best for you.

• Finally, change the output file name. The default output file name is

TOB1_stationname.ts_data.dat, where stationname is the datalogger’s

station name and can be set using DevConfig.exe (part of LoggerNet).

The factory default station name is the datalogger serial number.

Right click on the stationname.ts_data file and select “Change Output

File”.

If any other parameters are later changed, CardConvert will

return to the default output file name.

• Click on the “Start Conversion” to start the conversion process

(Figure 21).

27

Page 34

Open Path Eddy Covariance System

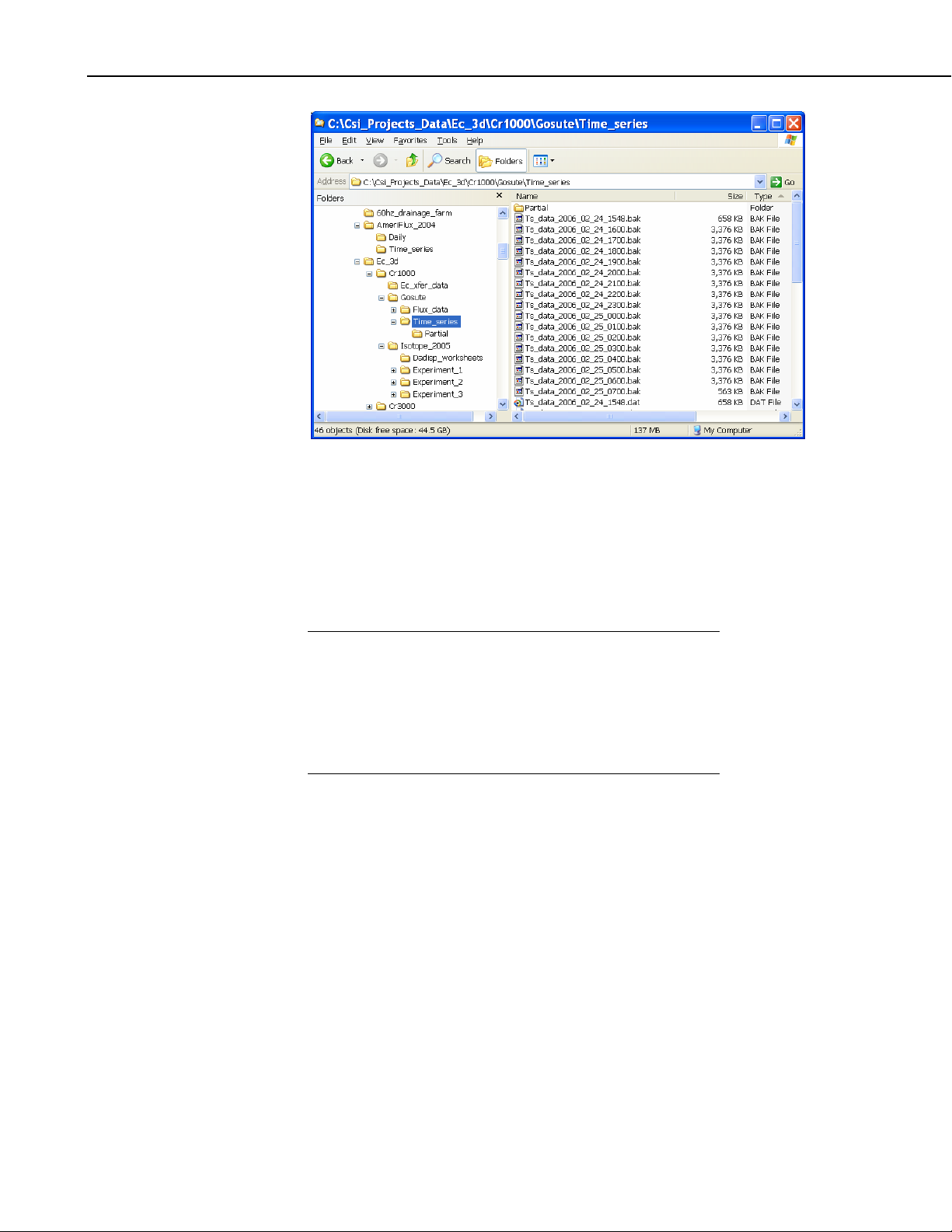

The converted files will look something like the 20 Hz files shown in Figure

22. Each file name with consist of a user specified file name and the time

stamp of the first record in each file with a one minute resolution. Note that

the first file and last file in the folder are smaller than the rest. This is because

they do not contain a complete hour of data.

FIGURE 21. Fully Configured CardConvert Start Up Screen

28

FIGURE 22. List of Files Created by CardConvert

Page 35

4.1.4.1 Collecting Data with One Card

If a single card is used to collect the data and the data on the card is not deleted

after copying it to the PC, the datalogger will append the data collected since

the card was removed to the data file on the card. This means that the next

time data is collected and converted from the PC/CF card, the last file in Figure

22 will contain a complete hour of data.

Before collecting data for the second and subsequent time, rename the last

partial file from …_0700.dat to …_0700_1.dat. This will ensure that the

complete version of this file is saved to the folder.

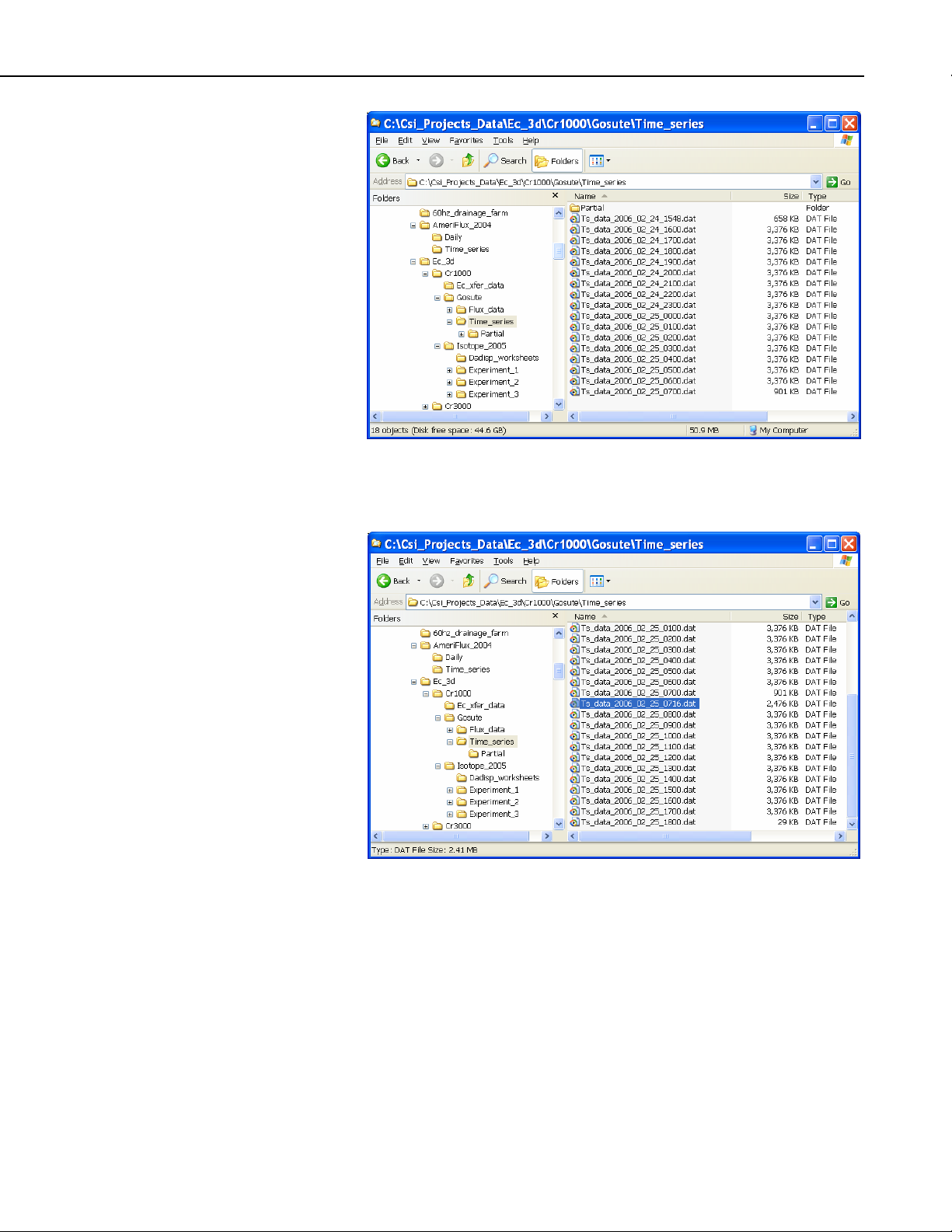

CardConvert will not overwrite existing files within a folder. Instead, it will

append a “_n” to the filename, where n is a numeral. Figure 23 shows the

name change to duplicate files. Note that the duplicate files get mixed in with

the original files within the folder. Rename the duplicate file using a group file

renaming utility. Specifically, find and replace the text “_1.dat” with “.bak”.

Sort the files in the folder by extension and delete the “bak” files (see Figure

24).

Open Path Eddy Covariance System

FIGURE 23. List of Files Created by CardConvert with Duplicates

29

Page 36

Open Path Eddy Covariance System

FIGURE 24. List of Files Where

the Duplicate Files are Renamed to *.bak

4.1.4.2 Collecting Data with Two Cards

Data can be collected using two cards. The card in the datalogger is removed

and replaced with an empty one. The data from the original card is copied to

the computer at some later time.

NOTE

Using two or more cards is a fast and efficient method of

collecting data. Only new data is collected; however, two partial

files within a “baling” period are created. Variable file lengths

are not an issue with EdiRe, but maybe for some other post

processing software. Two partial files can be appended to one

another using a hexadecimal editor for TOB1 files or a text

editor for TOA5 files.

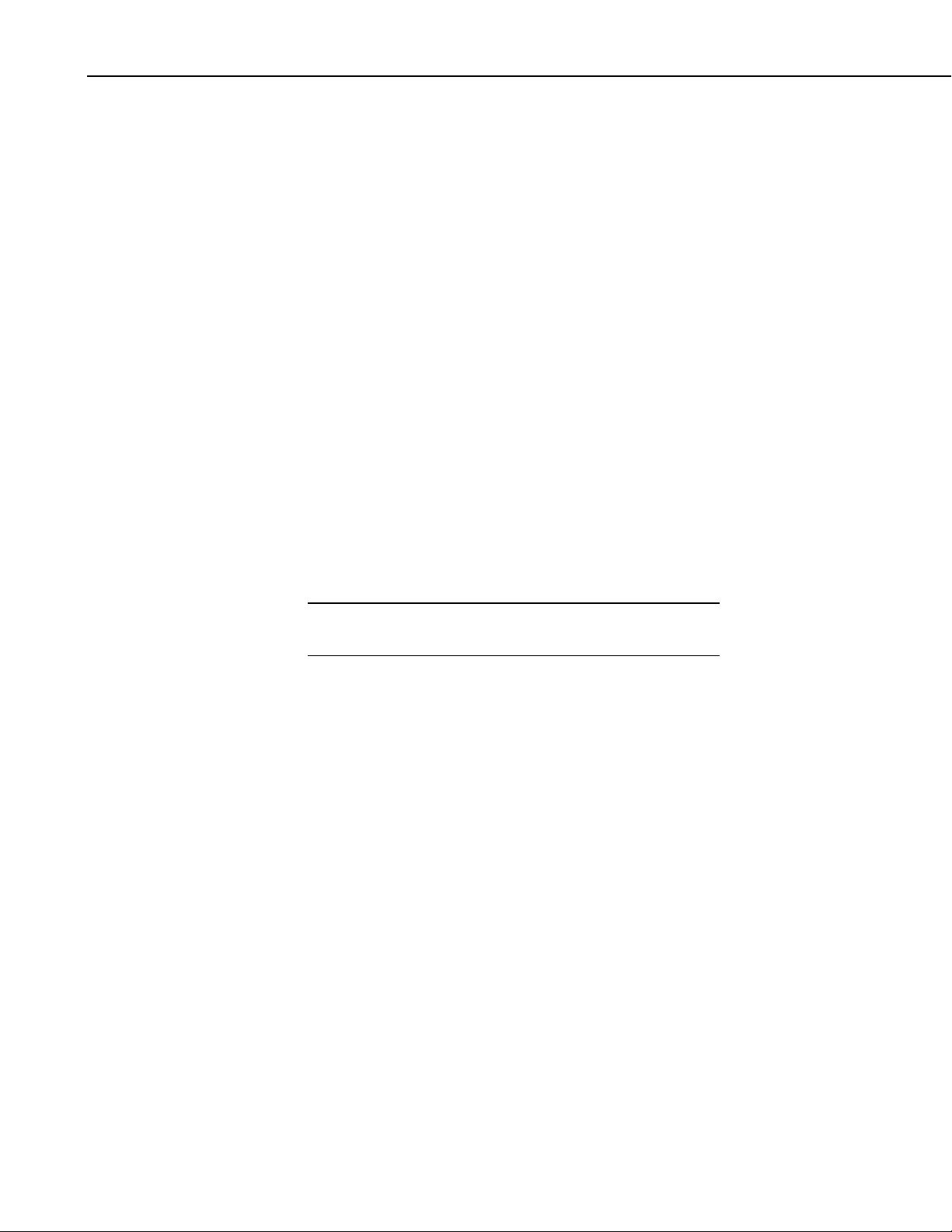

Again, note that the first and last files (Figure 25) are smaller than the rest of

the files. The next time data is retrieved from the datalogger, the file

Ts_data_2000_02_25_0700.dat will be continued in another file (see Figure

26).

30

Page 37

Open Path Eddy Covariance System

FIGURE 25. List of Files Collected the First Time Using Two Cards

FIGURE 26. List of Files Collected the Second Time Using Two Cards

4.2 Data Processing

There are several ways to process the raw time series data collected by the

system. Some of these are considered standard by the community and others

are subject to much debate. To gain a better understanding of the issues,

review the literature.

31

Page 38

Open Path Eddy Covariance System

4.2.1 Online Processing

The eddy covariance datalogger programs perform the processing listed below

online and in real time. In many cases, no further processing of the data is

required.

• Thirty minute statistics for the turbulence and meteorological

variables, these include fluxes, means, and standard deviations. The

output period can be changed by changing the Constant

OUTPUT_PERIOD.

• Compute the mean moist air density, temperature, and vapor pressure

from the HMP45C. Air density is used to compute the sensible heat

and momentum flux.

• Webb et al. (1980) term for latent heat flux and CO

separated into its two components, e.g. one term for temperature and

the other for vapor density.

• Wind direction and wind speed from the CSAT3.

• Compute the KH20 Krypton Hygrometer oxygen correction.

• Cross-products (second moments) required for an off-line coordinate

rotation following Kaimal and Finnigan (1994) and Tanner and

Thurtell (1969).

NOTE

The datalogger programs do not apply a coordinate rotation to

the data.

4.2.2 Off-line Processing with EdiRe

EdiRe is a powerful and flexible software package for processing eddy

covariance data collected by a Campbell Scientific, Inc. system. Best of all, it

is available at no charge from the University of Edinburgh’s ftp site

(http://www.geos.ed.ac.uk/abs/research/micromet/EdiRe/Downloads.html).

EdiRe can, using the Interpreter, read TOB1 data files. EdiRe will sort the

input data files by date and time, and can deal with files that are not the same

size, e.g. collected using two cards.

flux. This term is

2

32

Some of the available EdiRe processing functions are:

• Statistics for the turbulence and meteorological variables, these

include means, standard deviations, and covariances.

• Filtering the data (detrending, recursive, FIR, exponential).

• Spatial separation correction or maximum covariance.

• Coordinate rotation (mean vertical wind = 0 or planar fit).

• Spectral analysis.

Page 39

• Wavelet analysis.

Open Path Eddy Covariance System

NOTE

• Webb et al. (1980) term for latent heat flux and CO

flux. This term is

2

separated into its components due to temperature and to vapor density

fluctuations.

• Wind direction and wind speed from the CSAT3.

• KH20 Krypton Hygrometer oxygen correction.

There is a certain level of complexity inherent in any software package with

EdiRe’s flexibility. At the University of Edinburgh ftp site you will find an

online user forum (http://www.geos.ed.ac.uk/abs/research/micromet/

EdiRe/EdiReForum/), FAQ (http://www.geos.ed.ac.uk/abs/research/

micromet/EdiRe/Help_information.html), and tutorials (http://www.geos.ed.

ac.uk/abs/research/micromet/EdiRe/Tutorials/).

Along with the information on the University of Edinburgh’s ftp site, see the

EdiRe online help and the Campbell Scientific, Inc. Application Note on using

EdiRe. EdiRe lends itself to experimentation. The best way to learn how to

use EdiRe is to experiment with it.

EdiRe is not a Campbell Scientific, Inc. product. Campbell

Scientific, Inc. provides limited support of EdiRe, specifically in

reading in TOB1 data files. If further support is required, contact

the support personnel listed at http://www.geos.ed.ac.uk/

abs/research/micromet/edisol/edicontact.htm.

4.2.2.1 Creating Raw File Format and Processing Lists

Start EdiRe, select the Processing|Interpreter menu. Fill out the Interpreter

screen as shown in Figure 27. In the “Sample file” pull down menu, navigate

to the folder that contains the raw time series data and select one of the TOB1

files (Figure 28). Do the same for the “Format list file name” and “Processing

List file name”. After the Interpreter screen is filled out, it should look

something like Figure 29. Now click on the “Create” button.

EdiRe will estimate the data collection frequency and display this estimate in a

pop-up window. The estimate will be wrong because EdiRe includes the

header information as data records in the file. Enter the correct data collection

frequency (Figure 30). Now, click on “OK” and then “OK” again. EdiRe will

create and load the format and processing lists.

33

Page 40

Open Path Eddy Covariance System

FIGURE 27. Interpreter Settings to Read

a Campbell Scientific, Inc. TOB1 Data File

34

FIGURE 28. Folder that Contains the Raw TOB1

Time Series Data Files

Page 41

Open Path Eddy Covariance System

FIGURE 29. Competed Interpreter Screen

FIGURE 30. Estimated Sample Frequency and

Correct Sample Frequency

4.2.2.2 Example EdiRe Raw File Format and Processing Lists

To view the Lists in EdiRe, select the Processing|Options menu. The “Raw

File Format” list. The default “Processing Steps” list must be modified for

your specific application.

35

Page 42

Open Path Eddy Covariance System

The Processing Steps list has the default instructions needed to extract the data

from the TOB1 file (Figure 31). Additional instructions can be found in the

“Processing Items” list. To configure the instruction, select the instruction

parameter and enter values either from the “Processing Item Parameter” pull

down menu, or enter output variable names in the “Processing Item Parameter”

field using the keyboard.

The location of the output files, as comma separated values, can be specified in

the “Output Files” tab or as part of the processing list with the “Location

Output Files” instruction (Figure 32).

TIP

Campbell Scientific, Inc. recommends incorporating the output

file destination as part of the processing list rather than changing

the output file name in the “Output File” tab. This will prevent

the accidental merger of results from multiple stations.

The mean and standard deviation of a variable is found using the “1 Chn

Statistics” instruction, covariances and fluxes are found using the “2 Chn

Statistics” instruction. The results of the processing can be plotted with the

“Plot Value” instruction, see Figures 33 through 35.

Other useful instructions are: Rotation Coefficients, Rotation, Remove Lag,

Cross Correlate, Wind Direction, Raw Subset, Set Value, Comments, User

Defined, User Defined Fast, and Webb Correction. For additional information

on EdiRe and its use, see the online help and the EdiRe application note

published by Campbell Scientific, Inc.

36

FIGURE 31. Default EdiRe Processing List Created by the Interpreter

Page 43

Open Path Eddy Covariance System

FIGURE 32. Output File Location as Part of the Processing List

FIGURE 33. Output File Location as Part of the Processing List

37

Page 44

Open Path Eddy Covariance System

FIGURE 34. Processing U

and CO2 with 1 Chn Statistics Instruction

z

38

FIGURE 35. Computing CO

Graphing U

Statistic with Plot Value Instruction

z

Flux with 2 Chn Statistics and

2

Page 45

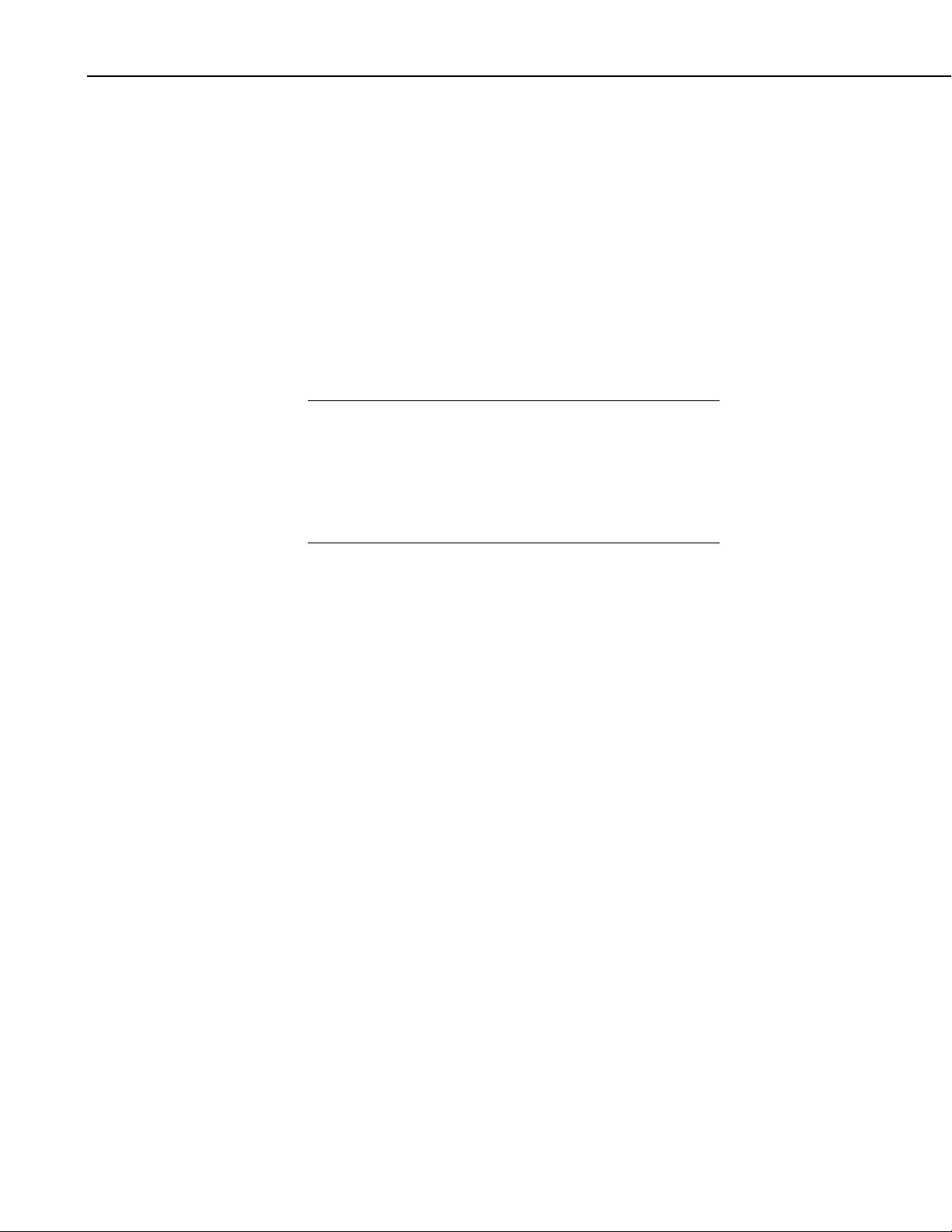

5. Eddy Covariance Theory 101

Open Path Eddy Covariance System

FIGURE 36. Ideal Vertical Profiles of Virtual Potential Temperature and Specific Humidity Depicting

All the Layers of the Atmospheric Boundary Layer.

The surface layer (Figure 36) is comprised of approximately the lower 10% of

the atmospheric boundary layer (ABL). The fluxes of water vapor and heat

within this layer are nearly constant with height when the following criteria are

met: the surface has approximate horizontal homogeneity; and the relationship

z/h << 1 << z/z

is true, where z

om

height of the ABL, and z

is the roughness length of momentum. When the

om

is the height of the surface layer, h is the

sfc

above conditions are met, the flux of carbon dioxide, water vapor and heat,

within the surface layer, may be written as:

UF′′=

ρ

(1)

zcc

ULLE′′=

ρ

(2)

zvv

UTCH′′=

ρ

(3)

zpa

39

Page 46

Open Path Eddy Covariance System

′

+

where F

is the carbon dioxide flux,

c

carbon dioxide density from the mean,

vertical wind speed from the mean, LE is the latent heat flux, L

heat of vaporization,

ρ′

is the instantaneous deviation of the water vapor

v

density from the mean, H is the sensible heat flux,

the heat capacity of air at a constant pressure, T

ρ′

is the instantaneous deviation of the

c

U

is the instantaneous deviation of

z

is the latent

v

ρ

is the density of air, Cp is

a

′

is the instantaneous deviation

of air temperature from the mean (Stull, 1988; Massman et al., 2004).

The quantities

′′

U

ρ

zc

′′

,

U

ρ

, and,

zv

′′

UT

are the covariances between vertical

z

wind speed and carbon dioxide density; vertical wind speed and vapor density;

and vertical wind speed and temperature. These quantities are computed online

by the CRBasic datalogger as are the cross products (second order moments)

required to apply a post processing coordinate rotation following Kaimal and

Finnigan (1994) and Tanner and Thurtell (1969).

The eddy covariance system directly measures latent and sensible heat flux. If

net radiation and soil heat flux are also measured, energy balance closure may

be examined using the surface energy balance equation:

LEHGR

=− (4)

n

where R

defined as positive away from the surface and R

F

is the net radiation and G is the total soil heat flux. H, LE, and G are

n

is positive toward the surface;

n

is defined, following the micrometeorological sign convention, as positive

c

away from the surface.

If a FW05 finewire thermocouple is not part of the system, the sensible heat

flux (H

) can be computed from the sonic sensible heat flux (Hs) and the latent

c

heat flux (LE) with equation (5). Appendix B gives a detailed derivation of

equation (5).

⎡

⎢

−=

CHH

ρ

⎢

⎣

psc

2

LE

L

⎤

T

⎥

(5)

⎥

T

v

s

⎦

TR

51.0

d

P

40

Page 47

Appendix A. CSAT3 Orientation

A.1 Determining True North and Sensor Orientation

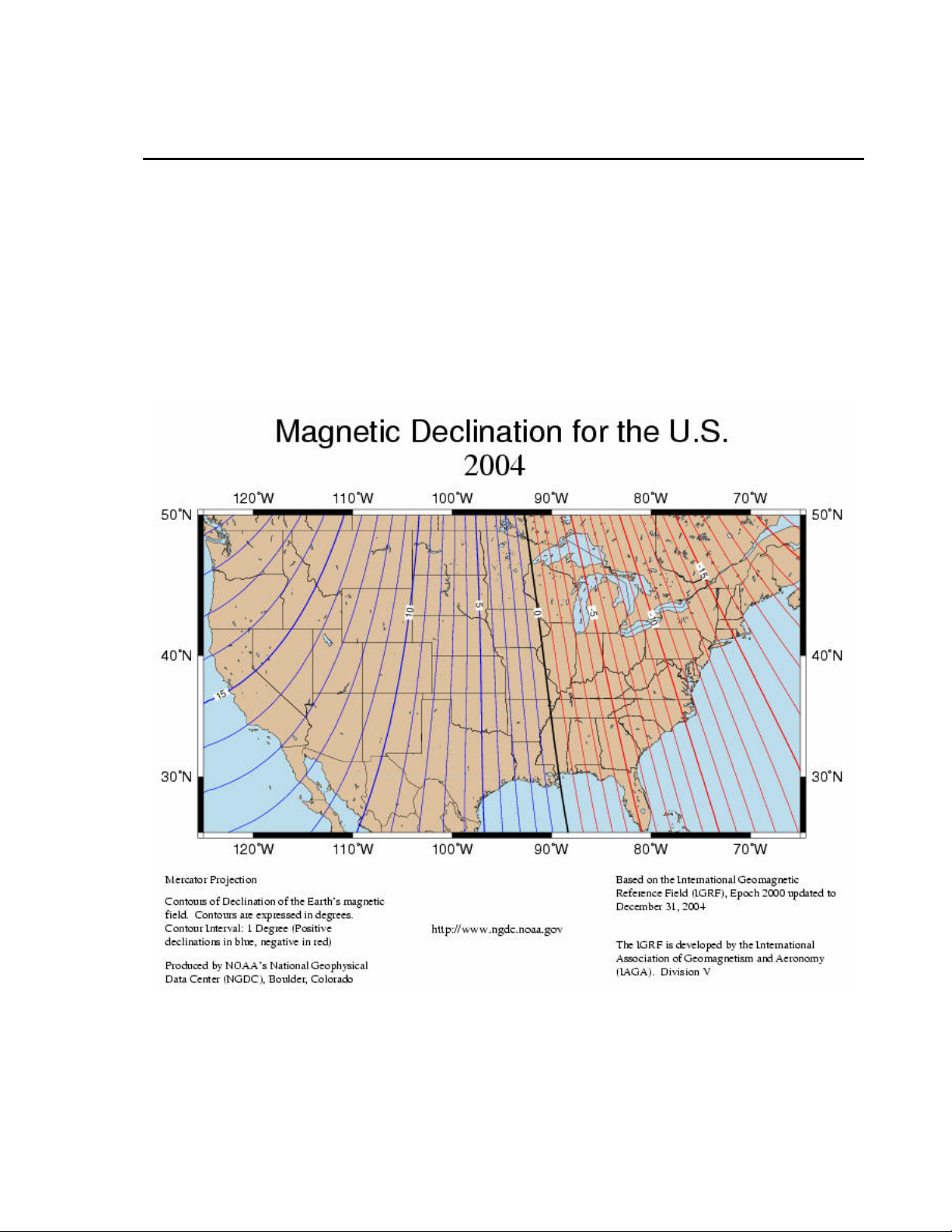

The orientation of the CSAT3 negative x-axis is found by reading a magnetic

compass and applying the site-specific correction for magnetic declination;

where the magnetic declination is the number of degrees between True North

and Magnetic North. Magnetic declination for a specific site can be obtained

from a USGS map, local airport, or through a NOAA web calculator (Section

A.2). A general map showing magnetic declination for the Conterminous

United States in 2004 is shown in Figure A-1.

FIGURE A-1. Magnetic Declination for the Conterminous United States (2004)

A-1

Page 48

Appendix A. Sensor Orientation

Declination angles are always subtracted from the compass reading to find

True North. A declination angle East of True North is reported as positive a

value and is subtracted from 360 (0) degrees to find True North as shown

Figure A-2. A declination angle West of True North is reported as a negative

value and is also subtracted from 0 (360) degrees to find True North as shown

in Figure A-3. Note that when a negative number is subtracted from a positive

number, the resulting arithmetic operation is addition.

For example, the declination for Longmont, CO (10 June 2006) is 9.67°, thus

True North is 360° - 9.67°, or 350.33° as read on a compass. Likewise, the

declination for Mc Henry, IL (10 June 2006) is -2.68°, and True North is

0° - (-2.68°), or 2.68° as read on a compass.

FIGURE A-2. A Declination Angle East of True North (Positive) is

Subtracted from 360 (0) degrees to Find True North

FIGURE A-3. A Declination Angle West of True North (Negative) is

Subtracted from 0 (360) degrees to Find True North

A-2

Page 49

Appendix A. Sensor Orientation

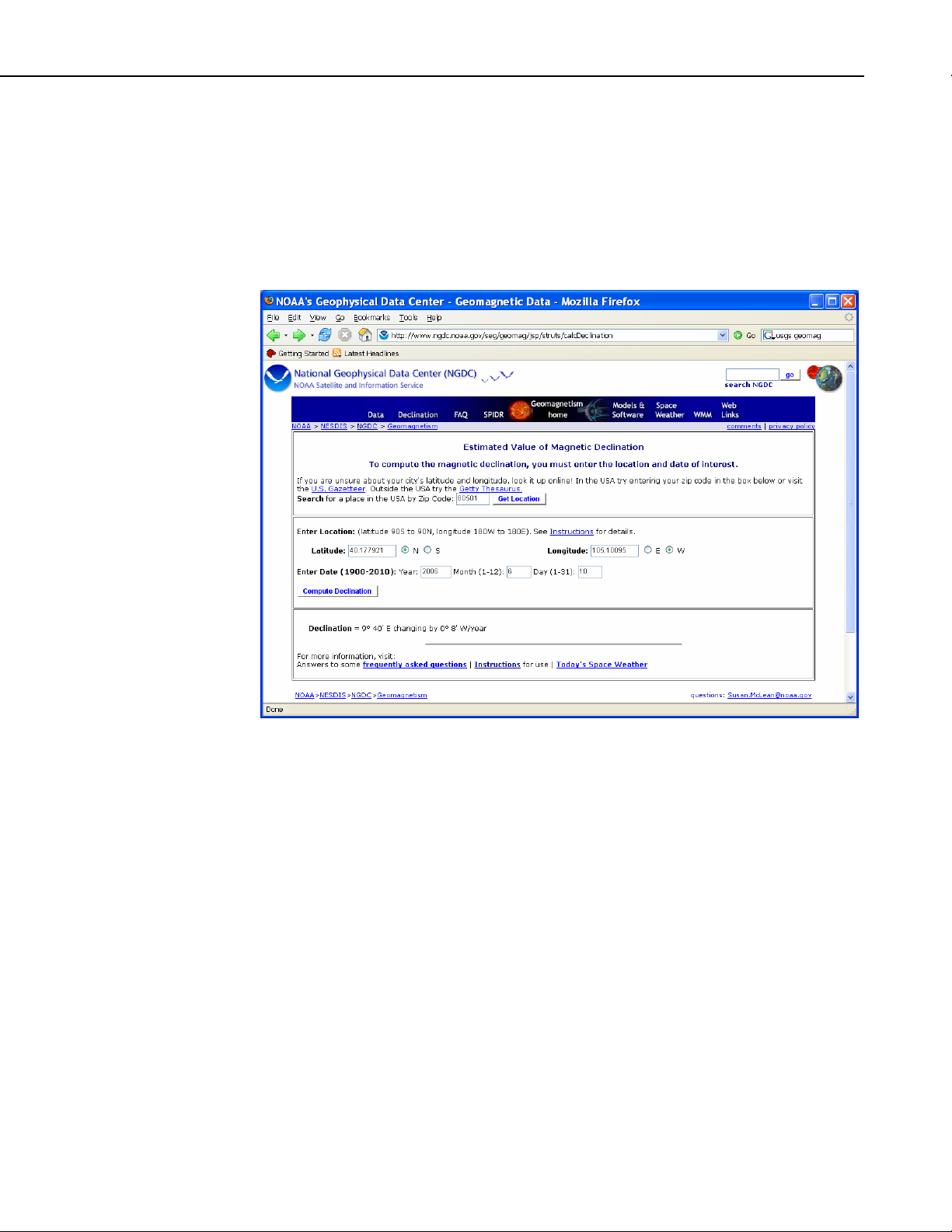

A.2 Online Magnetic Declination Calculator

The magnetic declination calculator web calculator published by NOAA’s

Geophysical Data Center is available at the following url

http://www.ngdc.noaa.gov/seg/geomag/jsp/struts/calcDeclination. After the

web page loads, enter the site zip code, or longitude and latitude, then click on

the “Compute Declination” button (Figure A-4).

FIGURE A-4. Online Magnetic Declination Calculator with Inputs and

Output for Longmont, CO.

The declination for Longmont, CO is 9.67 degrees (10 June 2006). As shown

in Figure A-4, the declination for Colorado is positive (east of north), so true

north for this site is 360 - 9.67, or 350.33 degrees. The annual change is -8

minutes/year or 8 minutes west per year.

A-3

Page 50

Appendix A. Sensor Orientation

This is a blank page.

A-4

Page 51

Appendix B. Sensible Heat Flux without

v

()(

()(

(

dvd

v

a FW05

B.1 Speed of Sound and Sonic Temperature

In the following section the speed of sound will be expressed as a sonically

measured temperature. The effects of humidity, on the speed of sound, will be

combined into this temperature.

This temperature, T

sonic temperature and is related to the speed of sound by two well known

constants.

The speed of sound (c) is defined by:

P

2

c

=

γ

(B-1)

, is defined as the sonic virtual temperature or simply the

s

ρ

C

where P is atmospheric pressure,

the ratio of the specific heats of moist air. The specific heats of moist air can

be written as:

CqC qC C q

=+− =+11084. (B-2)

pp pp

CqC qC C q

vv vv