Page 1

USER MANUAL

CS650 & CS655

Soil Water Content

Reflectometers

Issued: 24.6.15

Copyright © 2011-2015 Campbell Scientific, Inc.

Printed under licence by Campbell Scientific Ltd.

CSL 912

Page 2

Page 3

Guarantee

This equipment is guaranteed against defects in materials and workmanship.

This guarantee applies for 24 months from date of delivery. We will repair or

replace products which prove to be defective during the guarantee period

provided they are returned to us prepaid. The guarantee will not apply to:

Equipment which has been modified or altered in any way without the

written permission of Campbell Scientific

Batteries

Any product which has been subjected to misuse, neglect, acts of God or

damage in transit.

Campbell Scientific will return guaranteed equipment by surface carrier

prepaid. Campbell Scientific will not reimburse the claimant for costs incurred

in removing and/or reinstalling equipment. This guarantee and the Company’s

obligation thereunder is in lieu of all other guarantees, expressed or implied,

including those of suitability and fitness for a particular purpose. Campbell

Scientific is not liable for consequential damage.

Please inform us before returning equipment and obtain a Repair Reference

Number whether the repair is under guarantee or not. Please state the faults as

clearly as possible, and if the product is out of the guarantee period it should

be accompanied by a purchase order. Quotations for repairs can be given on

request. It is the policy of Campbell Scientific to protect the health of its

employees and provide a safe working environment, in support of this policy a

“Declaration of Hazardous Material and Decontamination” form will be

issued for completion.

When returning equipment, the Repair Reference Number must be clearly

marked on the outside of the package. Complete the “Declaration of

Hazardous Material and Decontamination” form and ensure a completed copy

is returned with your goods. Please note your Repair may not be processed if

you do not include a copy of this form and Campbell Scientific Ltd reserves

the right to return goods at the customers’ expense.

Note that goods sent air freight are subject to Customs clearance fees which

Campbell Scientific will charge to customers. In many cases, these charges are

greater than the cost of the repair.

Campbell Scientific Ltd,

80 Hathern Road,

Shepshed, Loughborough, LE12 9GX, UK

Tel: +44 (0) 1509 601141

Fax: +44 (0) 1509 601091

Email: support@campbellsci.co.uk

www.campbellsci.co.uk

Page 4

Page 5

PLEASE READ FIRST

About this manual

Please note that this manual was originally produced by Campbell Scientific Inc. primarily for the North

American market. Some spellings, weights and measures may reflect this origin.

Some useful conversion factors:

Area: 1 in2 (square inch) = 645 mm2

Length: 1 in. (inch) = 25.4 mm

1 ft (foot) = 304.8 mm

1 yard = 0.914 m

1 mile = 1.609 km

Mass: 1 oz. (ounce) = 28.35 g

In addition, while most of the information in the manual is correct for all countries, certain information

is specific to the North American market and so may not be applicable to European users.

Differences include the U.S standard external power supply details where some information (for

example the AC transformer input voltage) will not be applicable for British/European use. Please note,

however, that when a power supply adapter is ordered it will be suitable for use in your country.

Reference to some radio transmitters, digital cell phones and aerials may also not be applicable

according to your locality.

Some brackets, shields and enclosure options, including wiring, are not sold as standard items in the

European market; in some cases alternatives are offered. Details of the alternatives will be covered in

separate manuals.

Part numbers prefixed with a “#” symbol are special order parts for use with non-EU variants or for

special installations. Please quote the full part number with the # when ordering.

1 lb (pound weight) = 0.454 kg

Pressure: 1 psi (lb/in2) = 68.95 mb

Volume: 1 UK pint = 568.3 ml

1 UK gallon = 4.546 litres

1 US gallon = 3.785 litres

Recycling information

At the end of this product’s life it should not be put in commercial or domestic refuse but

sent for recycling. Any batteries contained within the product or used during the

products life should be removed from the product and also be sent to an appropriate

recycling facility.

Campbell Scientific Ltd can advise on the recycling of the equipment and in some cases

arrange collection and the correct disposal of it, although charges may apply for some

items or territories.

For further advice or support, please contact Campbell Scientific Ltd, or your local agent.

Campbell Scientific Ltd, 80 Hathern Road, Shepshed, Loughborough, LE12 9GX, UK

Tel: +44 (0) 1509 601141 Fax: +44 (0) 1509 601091

Email: support@campbellsci.co.uk

www.campbellsci.co.uk

Page 6

Page 7

Precautions

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON

OR AROUND TRIPODS, TOWERS, AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS,

CROSSARMS, ENCLOSURES, ANTENNAS, ETC. FAILURE TO PROPERLY AND COM P LE TE LY ASS E M BLE ,

INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS, TOWERS, AND ATTACHMENTS, AND FAILURE TO HEED

WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS INJURY, PROPERTY DAMAGE, AND

PRODUCT FAILURE. TAKE ALL REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS. CHECK WITH YOUR

ORGANIZATION'S SAFETY COORDINATOR (OR POLICY) FOR PROCEDURES AND REQUIRED PROTECTIVE

EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not

exceed design limits. Be familiar and comply with all instructions provided in product manuals. Manuals are

available at www.campbellsci.eu or by telephoning +44(0) 1509 828 888 (UK). You are responsible for conformance

with governing codes a nd regulations, including safety regulations , and the integrity and location o f structures o r land

to which towers, tripods, and any attachments are attached. Installation sites should be evaluated and approved by a

qualified engineer. If questions or co ncerns arise regarding installation, use, or maintenance of tripods, towers,

attachments, or electrical connections, consult with a licensed and qualified engineer or electrician.

General

• Prior to performing site or installation work, obtain required approvals and permits. Comply with all

governing structure-height regulations, such as those of the FAA in the USA.

• Use only qualified personnel for installation, use, and maintenance of tripods and towers, and any

attachments to tripods and towers. The use of licensed and qualified contractors is highly recommended.

• Read all applicable instructions carefully and understand procedures thoroughly before beginning work.

• Wear a hardhat and eye protection, and take other appropriate safety precautions while working on or

around tripods and towers.

• Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take reasonable

precautions to secure tripod and tower sites from trespassers.

• Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

• You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are installing,

constructing, using, or maintaining, or a tool, stake, or anchor, come in contact with overhead or

underground utility lines.

• Maintain a distance of at least one-and-one-half times structure height, or 20 feet, or the distance

required by applicable law, whichever is greater, between overhead utility lines and the structure (tripod,

tower, attachments, or tools).

• Prior to performing site or installation work, inform all utility companies and have all underground utilities

marked.

• Comply with all electrical codes. Electrical equipment and related grounding devices should be installed

by a licensed and qualified electrician.

Elevated Work and Weather

• Exercise extreme caution when performing elevated work.

• Use appropriate equipment and safety practices.

• During installation and maintenance, keep tower and tripod sites clear of un-trained or non-essential

personnel. Take precautions to prevent elevated tools and objects from dropping.

• Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

• Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks, frayed cables,

loose cable clamps, cable tightness, etc. and take necessary corrective actions.

• Periodically (at least yearly) check electrical ground connections.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL

SCIENTIFIC PRODUCTS, THE CUSTOMER ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER

INSTALLATION, USE, OR MAINTENANCE OF TRIPODS, TOWERS, OR ATTACHMENTS TO TRIPODS AND TOWERS

SUCH AS SENSORS, CROSSARMS, ENCLOSURES, ANTENNAS, ETC.

Page 8

Page 9

Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction ................................................................ 1

2. Cautionary Statements .............................................. 1

3. Initial Inspection ........................................................ 1

4. Quickstart ................................................................... 2

5. Overview ..................................................................... 4

6. Specifications ............................................................ 6

6.1 Electrical Specifications ....................................................................... 7

6.1.1 Current .......................................................................................... 7

6.2 Operational Specifications ................................................................... 8

7. Installation .................................................................. 9

7.1 Orientation and Placement ................................................................... 9

7.2 Proper Insertion .................................................................................. 10

7.3 Datalogger Wiring.............................................................................. 10

7.4 Programming ...................................................................................... 11

8. Operation .................................................................. 12

8.1 A200 and Device Configuration Utility ............................................. 12

8.1.1 Using the A200 ........................................................................... 12

8.1.1.1 Driver Installation ............................................................ 12

8.1.1.2 RS-232 Wiring ................................................................. 12

8.1.1.3 Powering the Sensor ......................................................... 13

8.1.1.4 Determining which COM Port the A200 has been

Assigned ....................................................................... 13

8.1.2 Device Configuration Utility (DevConfig) .................................. 13

8.1.2.1 Settings Editor Tab ........................................................... 15

8.1.2.2 Send OS Tab..................................................................... 16

8.1.2.3 Terminal Tab .................................................................... 17

8.2 SDI-12 Measurements ........................................................................ 19

8.2.1 Use of Multiplexers .................................................................... 19

8.3 Water Content Reflectometer Method for Measuring Volumetric

Water Content ................................................................................. 20

8.3.1 Description of Measurement Method.......................................... 20

8.3.2 The Topp Equation ..................................................................... 20

8.3.3 Electrical Conductivity ............................................................... 21

8.3.3.1 Soil Electrical Conductivity ............................................. 21

8.3.3.2 Temperature Correction of Soil Electrical Conductivity .. 22

8.3.4 Error Sources in Water Content Reflectometer Measurement .... 22

8.3.4.1 Probe-to-Probe Variability Error ...................................... 22

8.3.4.2 Insertion Error .................................................................. 22

i

Page 10

8.3.5 Temperature Dependence and Correction ................................ ... 22

8.3.5.1 Accurate Soil Temperature Measurement ........................ 23

8.4 Water Content Reflectometer User-Calibration ................................. 23

8.4.1 Need for Soil Specific Calibration Equation ............................... 23

8.4.2 User-Derived Calibration Equation ............................................ 23

8.4.3 Collecting Laboratory Data for Calibration ................................ 24

8.4.4 Collecting Field Data for Calibration.......................................... 26

8.4.5 Calculations ................................................................................ 27

9. Maintenance and Troubleshooting ......................... 29

10. References ............................................................... 30

Appendices

A. Importing Short Cut Code into a Program

Editor .................................................................... A-1

B. Example Programs ................................................ B-1

B.1 CR1000 Programs ............................................................................ B-1

B.1.1 CR1000 with One CS650 Probe ............................................... B-1

B.1.2 CR1000 with Two CS650 Probes on Same Control Port ......... B-1

B.1.3 CR1000 with 12 CS650 Probes on Multiplexer ........................ B-2

B.2 CR200X with Three CS650 Probes ................................................. B-3

C. Discussion of Soil Water Content ......................... C-1

D. SDI-12 Sensor Support .......................................... D-1

D.1 SDI-12 Command Basics ................................................................. D-1

D.2 Changing the SDI-12 Address Using Terminal Emulator and a

Datalogger .................................................................................... D-3

D.2.1 SDI-12 Transparent Mode ........................................................ D-3

D.2.2 CR200(X) Series Datalogger Example ..................................... D-4

D.2.3 CR1000 Datalogger Example ................................................... D-5

Figures

5-1. CS650 Water Content Reflectometer ................................ ................... 5

6-1. CS650 and CS655 average current drain ............................................. 8

7-1. CS650G Insertion Guide Tool ........................................................... 10

8-1. A200 Sensor-to-PC Interface ............................................................. 12

D-1. SDI-12 transparent mode on CR200(X)-series datalogger using

control port C1/SDI12 and changing SDI-12 address from 0

to 1 ................................................................................................ D-4

D-2. SDI-12 transparent mode on CR1000 datalogger using control

port 1 and changing SD1-12 address from 3 to 1 ......................... D-5

ii

Page 11

Tables

6-1. Size Specifications ............................................................................... 6

6-2. Relative Dielectric Permittivity Specifications .................................... 8

7-1. CS650 Wiring Code for SDI-12 ......................................................... 11

8-1. CS650 Wiring Code for RS-232 and A200 ........................................ 13

8-2. Real-Time Measurements .................................................................. 16

8-3. CS650 Terminal Commands .............................................................. 18

8-4. CS650 SDI-12 Commands ................................ ................................. 19

9-1. Symptom, Cause, and Solutions ......................................................... 29

B-1. CR1000 Wiring for One Probe Example Program ........................... B-1

B-2. CR1000 Wiring for Two Probe Example Program .......................... B-1

B-3. CR1000 Wiring For Multiplexer Example Program ........................ B-2

B-4. CR200(X) Wiring for Example Program ......................................... B-3

D-1. CS650 SDI-12 Command and Response Set .................................. D-1

iii

Page 12

iv

Page 13

NOTE

CS650 and CS655 Water Content

Reflectometers

1. Introduction

The CS650 and CS655 are multiparameter smart sensors that use innovative

techniques to monitor soil volumetric water content, bulk electrical conductivity,

and temperature. They output an SDI-12 signal that many of our dataloggers can

measure.

The CS650 has 30 cm length rods, whereas the CS655 has 12 cm length rods.

This manual uses CS650 to reference model numbers CS650 and CS655. Unless

specifically stated otherwise, information in the manual applies equally to both

models.

This manual provides information only for CRBasic dataloggers. It

is also compatible with most of our retired Edlog dataloggers. For

Edlog datalogger support, see an older manual at

www.campbellsci.com/old-manuals or contact a Campbell Scientific

application engineer for assistance.

2. Cautionary Statements

READ AND UNDERSTAND the Precautions section at the front of this

manual.

Although the CS650 is rugged, it should be handled as precision scientific

instrument.

External RF sources can affect the probe’s operation. Therefore, the probe

should be located away from significant sources of RF such as ac power lines

and motors.

3. Initial Inspection

Upon receipt of the CS650, inspect the packaging and contents for damage.

File damage claims with the shipping company.

The model number and cable length are printed on a label at the connection

end of the cable. Check this information against the shipping documents to

ensure the expected product and cable length are received.

1

Page 14

CS650 and CS655 Water Content Reflectometers

4. Quickstart

Short Cut is an easy way to program your datalogger to measure the CS650 and

assign datalogger wiring terminals. The following procedures show using Short

Cut to program the CS650.

1. Install Short Cut by clicking on the install file icon. Get the install file from

either www.campbellsci.com, the ResourceDVD, or find it in installations of

LoggerNet, PC200W, PC400, or RTDAQ software.

2. The Short Cut installation should place a shortcut icon on the desktop of your

computer. To open Short Cut, click on this icon.

3. When Short Cut opens, select New Program.

2

Page 15

User Manual

4. Select Datalogger Model and Scan Interval (default of 5 seconds is OK for

most applications). Click Next.

5. Under the Available Sensors and Devices list, select the Sensors |

Meteorological | Soil Moisture | CS650/CS655 Water Content

Reflectometer. Four options are available that monitor different parameters.

In this tutorial, we’ll select CS650/CS655 Water Content Reflectometer

(VWC, EC, T, P, PA, and VR). Click to move the selection to the

Selected device window. The soil temperature defaults to degree C, and the

sensor is measured hourly. These can be changed by clicking the

Temperature or Measure sensor box and selecting one of the other options.

3

Page 16

CS650 and CS655 Water Content Reflectometers

6. After selecting the sensor, click at the left of the screen on Wiring Diagram

to see how the sensor is to be wired to the datalogger. The wiring diagram

can be printed out now or after more sensors are added.

5. Overview

7. Select any other sensors you have, then finish the remaining Short Cut steps

to complete the program. The remaining steps are outlined in Short Cut Help,

which is accessed by clicking on Help | Contents | Programming Steps.

8. If LoggerNet, PC400, RTDAQ, or PC200W is running on your PC, and the

PC to datalogger connection is active, you can click Finish in Short Cut and

you will be prompted to send the program just created to the datalogger.

9. If the sensor is connected to the datalogger, as shown in the wiring diagram in

step 6, check the output of the sensor in the datalogger support software data

display to make sure it is making reasonable measurements.

The CS650 measures volumetric water content, electrical conductivity, dielectric

permittivity, and temperature of soils or other porous media. These values are

reported through SDI-12 communication.

4

Page 17

User Manual

Figure 5-1. CS650 Water Content Reflectometer

Volumetric water content information is derived from the probe’s sensitivity to the

dielectric permittivity of the medium surrounding the probe stainless-steel rods.

The CS650 is configured as a water content reflectometer, with the two parallel

rods forming an open-ended transmission line. A differential oscillator circuit is

connected to the rods, with an oscillator state change triggered by the return of a

reflected signal from one of the rods. The two-way travel time of the

electromagnetic waves that are induced by the oscillator on the rod varies with

changing dielectric permittivity. Water is the main contributor to the bulk

dielectric permittivity of the soil or porous media, so the travel time of the

reflected wave increases with increasing water content and decreases with

decreasing water content, hence the name water content reflectometer.

Electrical conductivity is determined by exciting the rods with a known nonpolarizing waveform and measuring the signal attenuation.

Temperature is measured with a thermistor in contact with one of the rods.

It is well known that transmission line oscillators used for water content

measurements suffer from unwanted increases in oscillation period as increasing

electrical conductivity causes transmission line signal attenuation. The CS650

handles this problem by making an electrical conductivity measurement and then

correcting the oscillator period accordingly. On-board processing within the

sensor head calculates electrical conductivity from the signal attenuation

measurement and combines the result with the oscillation period measurement to

calculate the dielectric permittivity of the media and finally applies the Topp

equation (Topp et al. 1980) to estimate volumetric water content.

Probe electronics are encapsulated in the rugged epoxy probe head.

A five conductor cable including the drain or shield wire is used to provide power

and ground as well as serial communication with the CS650. The CS650 is

intended to communicate with SDI-12 recorders, including Campbell Scientific

dataloggers. The orange Rx wire can be used to communicate by means of RS232 Tx/Rx. The A200 USB-to-Serial Module allows RS-232 serial

communication between a computer and the CS650 by means of Campbell

Scientific’s Device Configuration Utility (DevConfig) software.

5

Page 18

CS650 and CS655 Water Content Reflectometers

Table 6-1. Size Specifications

CS650

CS655

Rods

300 mm long

3.2 mm diameter

32 mm spacing

120 mm long

3.2 mm diameter

32 mm spacing

Probe Head

L 85 mm

W 63 mm

D 18 mm

L 85 mm

W 63 mm

D 18 mm

Probe Weight

280 g

240 g

Cable Weight

35 g m-1

35 g m-1

The CS650’s cable can terminate in:

Connector that attaches to a prewired enclosure (option –PW). Refer to

www.campbellsci.com/prewired-enclosures for more information.

Campbell Scientific also offers the CS650-LC, CS655-LC, and CWS655. The

CS650-LC and CS655-LC include a connector for attaching the sensor to an

ET107 weather station. The CWS655 is a wireless version of our CS655; refer to

the Wireless Sensor Network manual for more information.

6. Specifications

Features:

Larger sample volume reduces error

Measurement corrected for effects of soil texture and electrical

conductivity

Estimates soil-water content for a wide range of mineral soils

Versatile sensor—measures dielectric permittivity, bulk electrical

conductivity (EC), and soil temperature

Compatible with Campbell Scientific CRBasic dataloggers: CR6,

CR200(X) series, CR800 series, CR1000, CR3000, and CR5000

Table 6-1 compares the size of the CS650 and CS655 reflectometers.

6

Page 19

6.1 Electrical Specifications

Sensor Output:

SDI-12

Serial RS-232

Warmup Time:

3 s

Measurement Time:

3 ms to measure

600 ms to complete SDI-12 command

Power Supply

Requirements:

6 Vdc to 18 Vdc

Must be able to supply 45 mA @ 12 Vdc

Maximum Cable Length:

610 m (2000 ft) combined length for 1 – 10

sensors connected to the same datalogger

control port

Electromagnetic

Compatibility:

Πcompliant (EMC compliant performance

criteria available upon request)

Meets EN61326 requirements for protection

against electrostatic discharge and surge

External RF sources can affect CS650

measurements. CS650 circuitry should be

located away from radio transmitter aerials and

cables, or measurements ignored during RF

transmissions.

Active (3 ms):

45 mA typical @ 12 Vdc

(80 mA @ 6 Vdc, 35 mA @ 18 Vdc)

Quiescent:

135 A @ 12 Vdc

Average Current Drain:

I = 0.09n + [3.5 + 0.024(n-1)]n/s

I = average current in milliamps

n = number of CS650’s

s = number of seconds between measurements

(see Figure 6-1)

User Manual

6.1.1 Current

7

Page 20

CS650 and CS655 Water Content Reflectometers

Table 6-2. Relative Dielectric Permittivity Specifications

CS650

CS655

Relative Dielectric Permittivity

Range

1 to 81

Accuracy†

1 to 40:

40 to 80:

(2% of reading + 0.6)

for solution EC

3 dS/m

1.4 for solution EC

3 dS/m

(3% of reading + 0.8)

for solution EC

8 dS/m

2 for solution EC

2.8 dS/m

Precision‡

<0.02

Figure 6-1. CS650 and CS655 average current drain

Figure 6-1 shows average current drain for different measurement rates and

quantities of CS650 probes. If the time between measurements is five minutes or

longer, average current drain may be approximated at 0.15 milliamps per sensor.

6.2 Operational Specifications

Table 6-2 provides the operational specifications.

8

Page 21

User Manual

Volumetric Water Content using Topp Equation (m3/m3)

Range

5% to 50%

Accuracy†

3% VWC typical in

mineral soils where

solution EC 3 dS/m

3% VWC typical in

mineral soils where

solution EC 10 dS/m

Precision‡

<0.05%

Electrical Conductivity

Range Solution EC

0 to 3 dS/m

0 to 8 dS/m

Range Bulk EC

0 to 3 dS/m

0 to 8 dS/m

Accuracy†

(5% of reading + 0.05 dS/m)

Precision‡

0.5% of BEC

Temperature

Soil Measurement Range

–10 to 70 °C

Operational Range

0 to 70 °C

Accuracy†

0.5 C for probe body buried in soil

Precision‡

0.02 °C

Sensing Volume*

7800 cm3

3600 cm3

*Sensing Volume approximately 7.5 cm radius around each probe rod and 4.5 cm

beyond the end of the rods

†Accuracy specifications are based on laboratory measurements in a series of

solutions with dielectric permittivities ranging from 1 to 81 and solution electrical

conductivities ranging from 0 to 3 dS/m.

‡Precision describes the repeatability of a measurement. It is determined for the

CS650 by taking repeated measurements in the same material. The precision of the

CS650 is better than 0.05 % volumetric water content and 0.01 dS/m electrical

conductivity.

7. Installation

If you are programming your datalogger with Short Cut, skip Section 7.3,

Datalogger Wiring (p. 10), and Section 7.4, Programming (p. 11). Short Cut does this

work for you. See Section 4, Quickstart (p. 2), for a Short Cut tutorial.

7.1 Orientation and Placement

The CS650 measures the bulk dielectric permittivity, average volumetric water

content, and bulk EC along the length of the rods, which is 30 cm for the CS650

and 12 cm for the CS655. The probe rods may be inserted vertically into the soil

surface or buried at any orientation to the surface. The probe may be installed

horizontal to the surface to detect the passing of wetting fronts or other vertical

water fluxes.

The sensitive volume depends on the surrounding media. In soil, the sensitive

volume extends approximately 7.5 cm (3 in) from the rods along their length and

4.5 cm (1.8 in) beyond the end of the rods. Consequently, if the probe is buried

horizontally closer than 7.5 cm from the soil surface, it will include air above the

surface in its measurements and underestimate soil water content.

9

Page 22

CS650 and CS655 Water Content Reflectometers

The thermistor used to measure temperature is in contact with one of the stainless

steel rods at the base of the epoxy probe body. Because of the low thermal

conductivity of stainless steel, the thermistor does not measure the average

temperature along the rod, but instead provides a point measurement of the

temperature within the epoxy. For a valid soil temperature reading, the probe

body must be in thermal equilibrium with the soil. If the probe is installed

vertically with the epoxy probe body above the surface, then the probe body must

be shielded from solar radiation and in direct contact with the soil or media of

interest.

7.2 Proper Insertion

The method used for probe installation can affect the accuracy of the

measurement. The probe rods should be kept as close to parallel as possible when

installed to maintain the design wave guide geometry. The probe is more

sensitive to permittivity close to the rods so probes inserted in a manner which

generates air voids around the rods will have reduced measurement accuracy. In

most soils, the soil structure will recover from the disturbance during probe

insertion.

In some applications, installation can be improved by using the CS650G insertion

guide tool (Figure 7-1). The CS650G is inserted into the soil and then removed.

This makes proper installation of the water content reflectometer easier in dense or

rocky soils.

10

Figure 7-1. CS650G Insertion Guide Tool

7.3 Datalogger Wiring

Our dataloggers typically use SDI-12 to measure the sensor because RS-232

communication requires more control ports per CS650 and RS-232 programming

is more complicated than SDI-12 programming. SDI-12 communication also

allows up to ten probes to be given different addresses and then share a single

control port.

Page 23

User Manual

Table 7-1. CS650 Wiring Code for SDI-12

Colour

Function

Datalogger Connection

Green

SDI-12 Data

SDI-12 Input, Control Port,

or U* configured for SDI-12

measurement

Red

SDI-12 Power

12 V

Black

SDI-12 Reference

G

Clear

Shield

G

Orange

Not Used

G

NOTE

NOTE

Table 7-1 shows the SDI-12 wiring for the CS650 water content reflectometer.

SDI-12 data is transmitted to a CRBasic datalogger odd numbered control port or

U terminal. Wiring information for RS-232 communications is provided in

Section 8.1.1.2, RS-232 Wiring (p. 12).

The orange Rx wire is only used for RS-232 Tx/Rx communication,

and should be grounded when using SDI-12.

7.4 Programming

Short Cut is the best source for up-to-date datalogger programming code.

Programming code is needed,

If your data acquisition requirements are simple, you can probably create and

maintain a datalogger program exclusively with Short Cut. If your data

acquisition needs are more complex, the files that Short Cut creates are a great

source for programming code to start a new program or add to an existing custom

program.

Short Cut cannot edit programs after they are imported and edited in

CRBasic Editor.

A Short Cut tutorial is available in Section 4, Quickstart (p. 2). If you wish to

import Short Cut code into CRBasic Editor to create or add to a customized

program, follow the procedure in Appendix A, Importing Short Cut Code into a

Program Editor (p. A-1). Programming basics for CRBasic dataloggers are

provided here. Complete program examples for select CRBasic dataloggers can

be found in Appendix B, Example Programs (p. B-1). Programming basics and

programming examples for Edlog dataloggers are provided at

www.campbellsci.com\old-manuals.

when creating a program for a new datalogger installation

when adding sensors to an existing datalogger program

The SDI12Recorder() measurement instruction programs CRBasic dataloggers

(CR6, CR200(X)-series, CR800-series, CR1000, CR3000, and CR5000) to

measure the sensor. This instruction sends a request to the sensor to make a

measurement and then retrieves the measurement from the sensor. See Section

8.2, SDI-12 Measurements (p. 19), for more information.

When using a CR200(X), the SDI12Recorder() instruction has the following

syntax:

11

Page 24

CS650 and CS655 Water Content Reflectometers

NOTE

SDI12Recorder(Destination,OutString,Multiplier,Offset)

For the other CRBasic dataloggers, the SDI12Recorder() instruction has the

following syntax:

SDI12Recorder(Destination, SDIPort, SDIAddress, “SDICommand”, Multiplier,

Offset)

8. Operation

8.1 A200 and Device Configuration Utility

The A200 Sensor-to-PC Interface allows communication between a CS650 and a

PC, allowing sensor settings to be changed through Device Configuration Utility

(DevConfig) software.

8.1.1 Using the A200

8.1.1.1 Driver Installation

If the A200 has not been previously plugged into your PC and your PC operating

system is not Windows 7, the A200 driver needs to be loaded onto your PC.

8.1.1.2 RS-232 Wiring

Drivers should be loaded before plugging the A200 into the PC.

The A200 drivers can be downloaded, at no charge, from:

www.campbellsci.com/downloads.

One end of the A200 has a terminal block while the other end has a type B female

USB port. The terminal block provides 12V, G, Tx, and Rx terminals for

connecting the sensor (see Figure 8-1 and Table 8-1).

12

Figure 8-1. A200 Sensor-to-PC Interface

A data cable, pn #17648, ships with the A200. This cable has a USB type-A male

connector that attaches to a PC’s USB port, and a type B male connector that

attaches to the A200’s USB port.

Page 25

Table 8-1. CS650 Wiring Code

for RS-232 and A200

Colour

Function

A200 Terminal

Orange

RxD

Rx

Green

TxD

Tx

Red

Power

+12 Vdc

Black

Reference

G

Clear

Shield

G

8.1.1.3 Powering the Sensor

The A200 provides power to the sensor when it is connected to a PC’s USB port.

An internal DC/DC converter boosts the 5 Vdc supply from the USB connection

to a 12 Vdc output that is required to power the sensor.

8.1.1.4 Determining which COM Port the A200 has been Assigned

When the A200 driver is loaded, the A200 is assigned a COM port number. This

COM port number is needed when using DevConfig. Often, the assigned COM

port will be the next port number that is free. However, if other devices have been

installed in the past (some of which may no longer be plugged in), the A200 may

be assigned a higher COM port number.

User Manual

To check which COM port has been assigned to the A200, you can monitor the

appearance of a new COM port in the list of COM ports offered in your software

package such as LoggerNet before and after the installation, or look in the

Windows Device Manager list under the ports section (access via the control

panel).

8.1.2 Device Configuration Utility (DevConfig)

DevConfig may be downloaded from the Campbell Scientific website,

www.campbellsci.com/downloads.

Connect the CS650 to the A200 as shown in Table 8-1. Connect the PC to the

A200 USB port with the supplied USB cable.

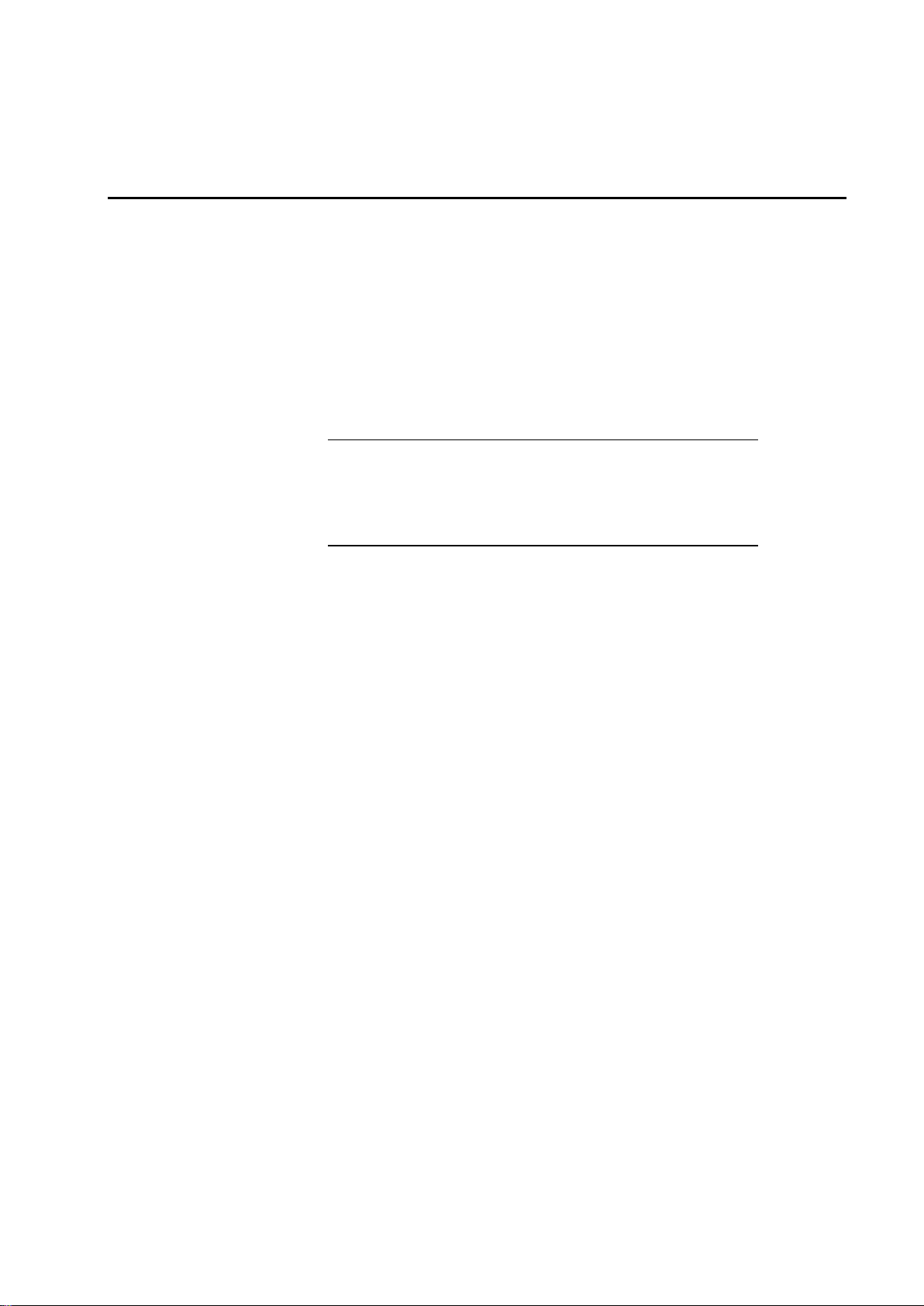

Launch DevConfig and select CS650 Series from the Device Type menu on the

left. Select 9600 from the Baud Rate drop-down menu.

13

Page 26

CS650 and CS655 Water Content Reflectometers

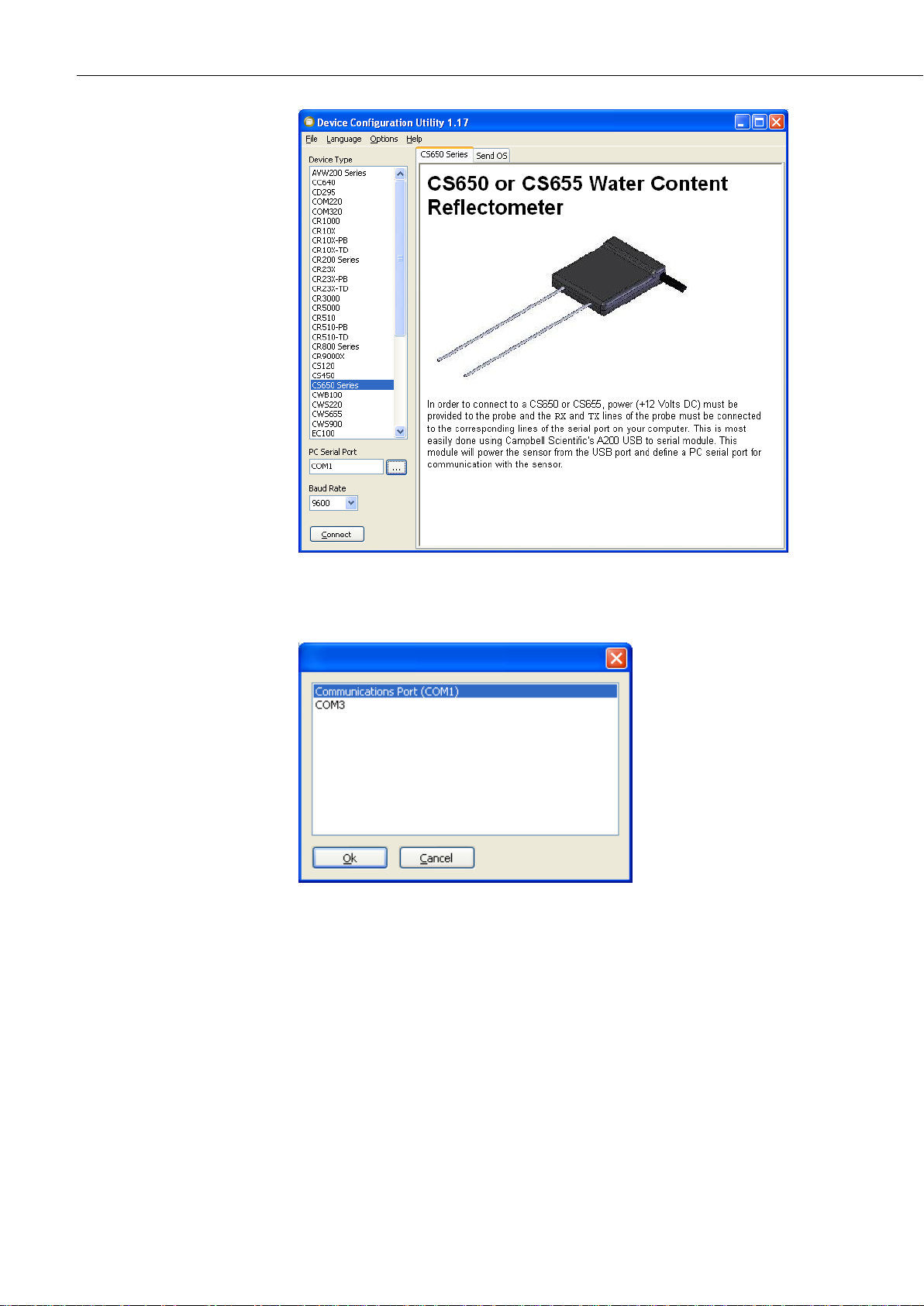

Select the appropriate PC serial port from the list of available COM ports shown

when the browse button on the lower left is selected (see Section 8.1.1.4,

Determining which COM Port the A200 has been Assigned (p. 13)).

Select Ok and then Connect to begin communication with the CS650.

14

Page 27

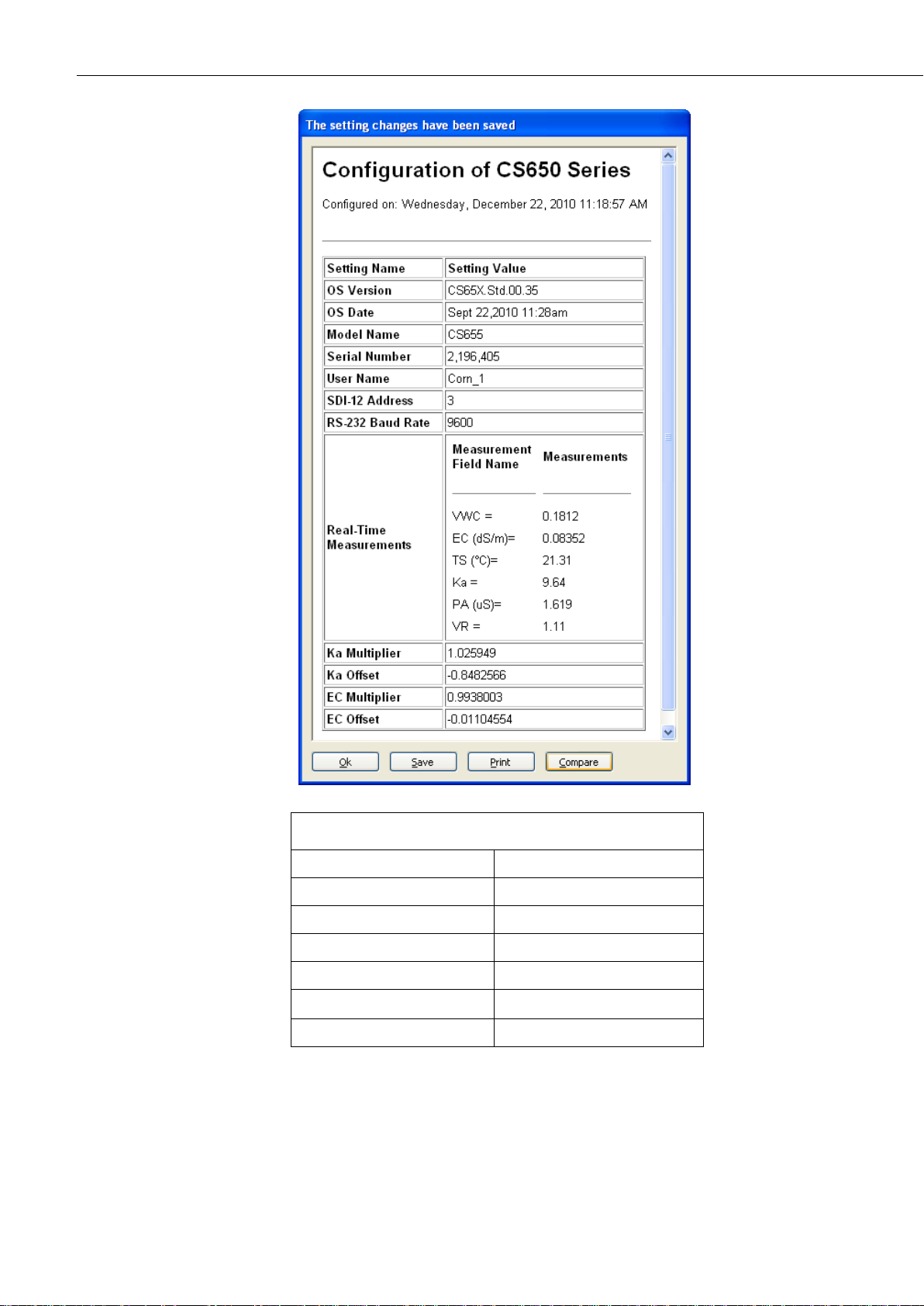

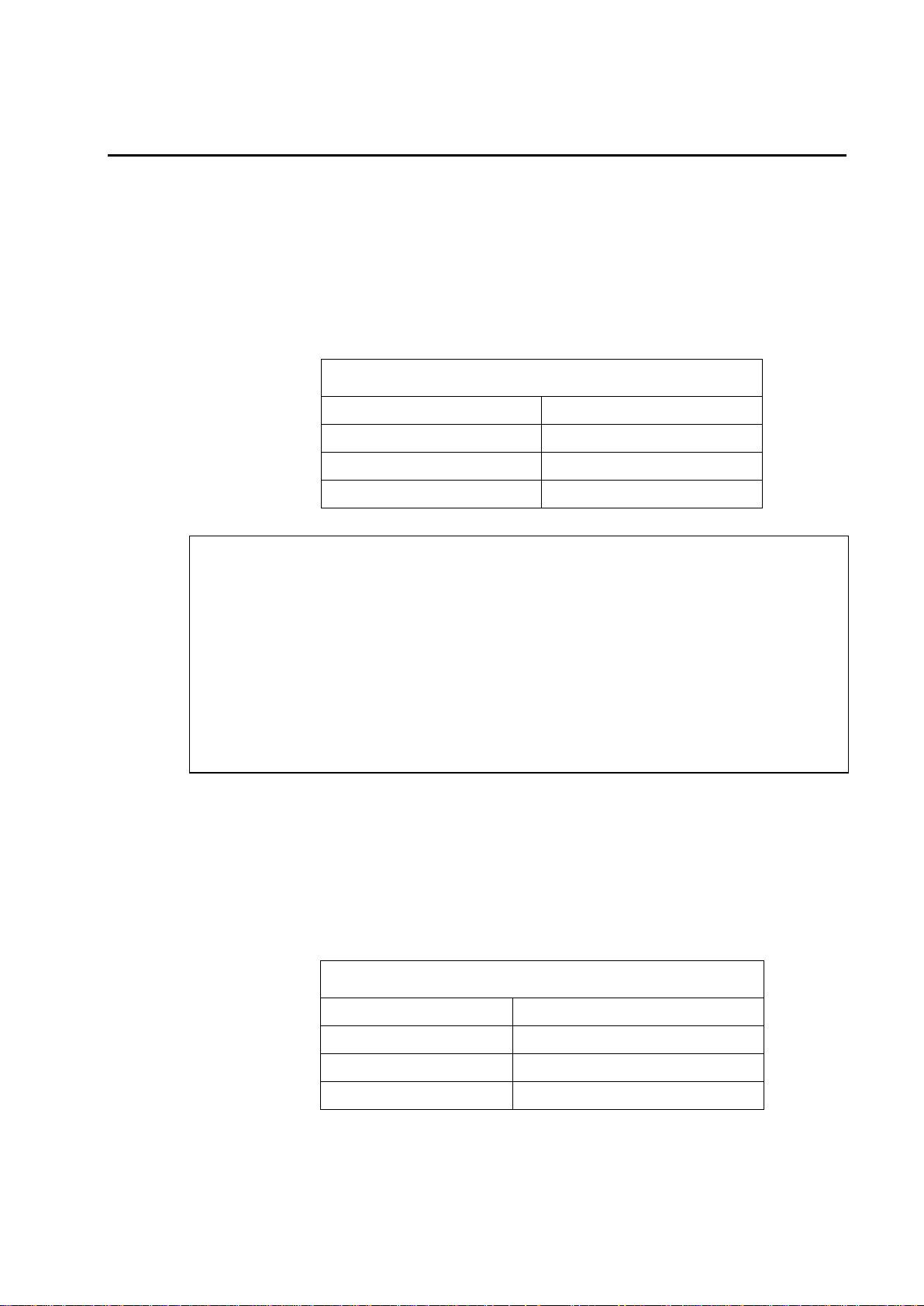

8.1.2.1 Settings Editor Tab

The Settings Editor tab shows settings stored in the CS650 firmware. Settings

that may be modified include User Name, SDI-12 Address, and RS-232 Baud

Rate. Attempts to change any of the other settings will result in a “Commit failed.

Unrecognized error condition” error message. DevConfig polls the CS650 every

two seconds while connected and the results are displayed in the Real-Time

Measurements field (Table 8-2). This is useful for verifying probe performance.

User Manual

Default communication settings are 9600 baud, no parity, 1 stop bit, 8 data bits,

and no error checking. After any changes to CS650 settings, select Apply to write

the changes to the CS650 firmware. A configuration summary is then shown.

The summary may be printed or saved electronically for future reference.

15

Page 28

CS650 and CS655 Water Content Reflectometers

Table 8-2. Real-Time Measurements

Measurement Field Name

Meaning

VWC

Volumetric Water Content

EC (dS/m)

Bulk Electrical Conductivity

TS (°C)

Soil Temperature

Ka

Bulk Dielectric Permittivity

PA (S)

Period Average

VR

Voltage Ratio

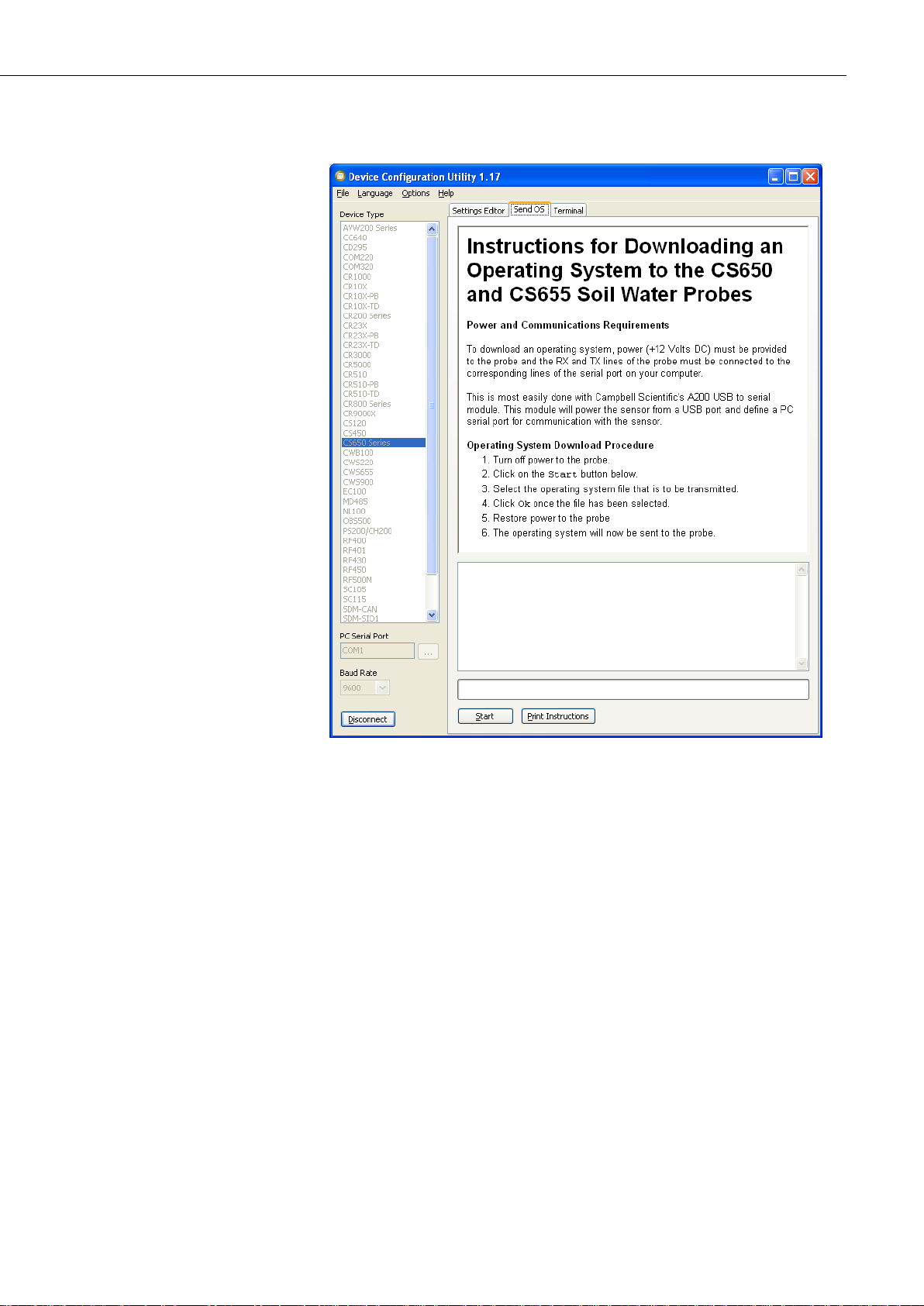

8.1.2.2 Send OS Tab

The Send OS tab is used to update the firmware in the CS650. The firmware is

available at www.campbellsci.com/downloads. The file to send will have a

filename extension of .a43, such as CS65X.Std.00.36.a43. Sending a new

operating system will not affect any of the user-modified settings or probe specific

multiplier and offset settings.

16

Page 29

User Manual

To download a new operating system, follow the Operating System Download

Procedure listed on the Send OS tab.

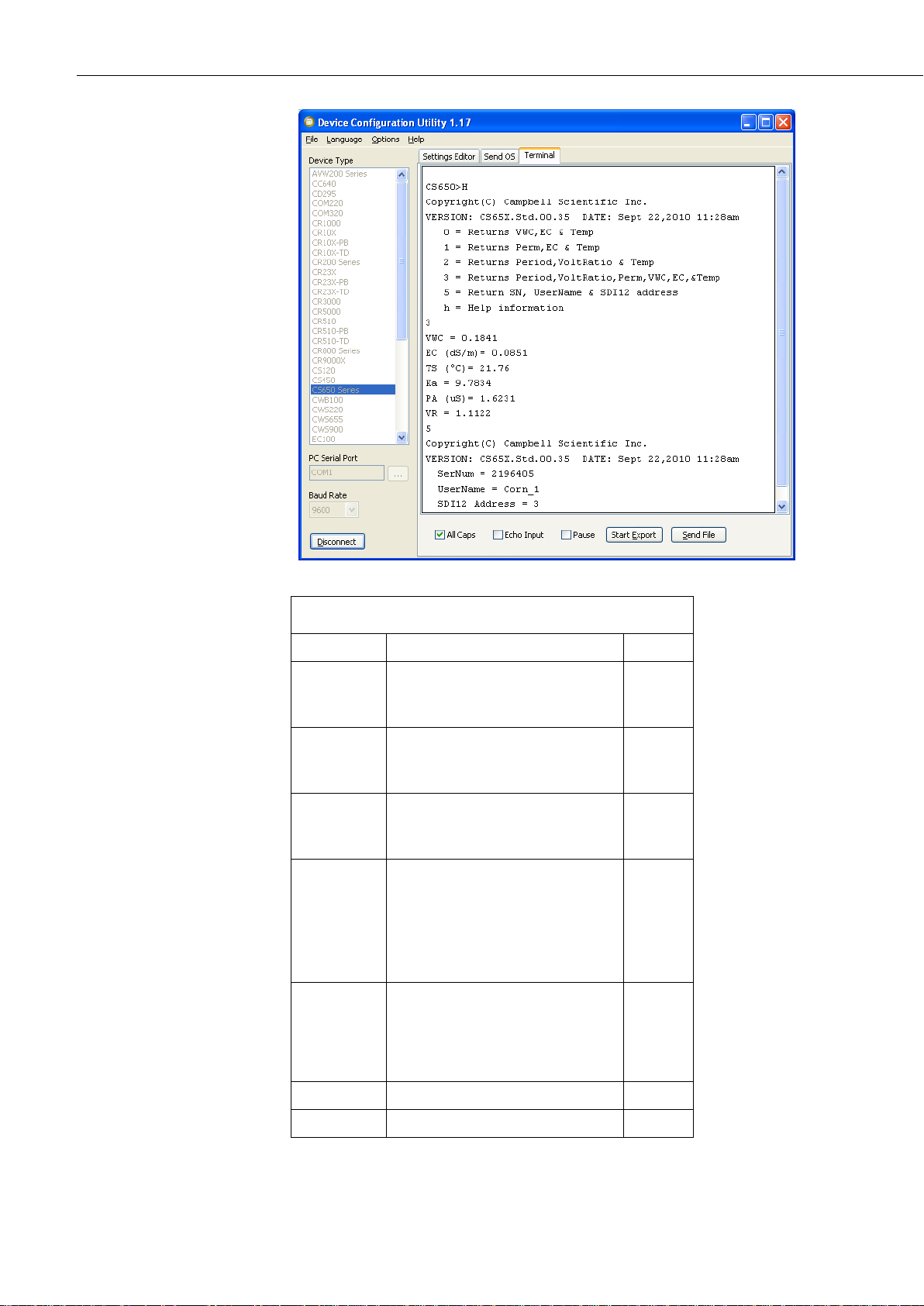

8.1.2.3 Terminal Tab

The Terminal tab may be used to send serial commands directly to the CS650.

See Table 8-3 for a list of serial interface commands.

To send a command from the Terminal tab, left click in the field to get a flashing

black cursor, then press <Enter> several times until the CS650> prompt is shown.

At the prompt, type in the command then <Enter>.

17

Page 30

CS650 and CS655 Water Content Reflectometers

Table 8-3. CS650 Terminal Commands

Command

Values Returned

Units

0

1) Volumetric Water Content,

2) Electrical Conductivity,

3) Temperature

m3/m3

dS/m

°C

1

1) Permittivity,

2) Electrical Conductivity,

3) Temperature

dS/m

°C

2

1) Period,

2) Voltage Ratio,

3) Temperature

Sec

°C

3

1) Volumetric Water Content,

2) Electrical Conductivity,

3) Temperature

4) Permittivity,

5) Period,

6) Voltage Ratio,

m3/m3

dS/m

°C

Sec

5

1) Copyright information

2) OS version and Date

3) Product Serial Number

4) Product User Name

5) SDI-12 Address

H or h

Help Menu

18

Page 31

8.2 SDI-12 Measurements

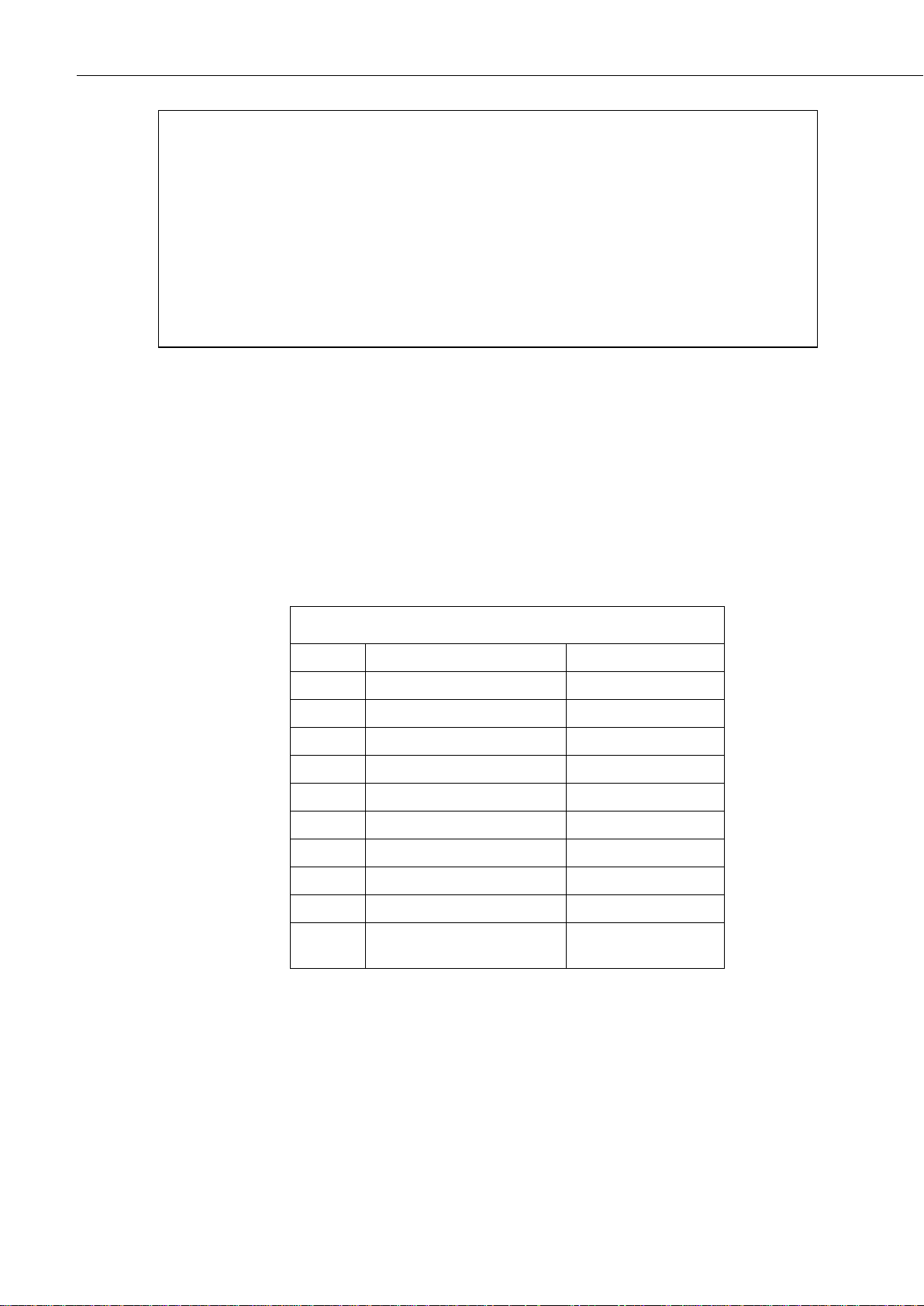

Table 8-4. CS650 SDI-12 Commands

SDI-12 command

(“a” is the sensor

address)

Values Returned

Units

aM!

1) Volumetric Water Content,

2) Electrical Conductivity,

3) Temperature

m3/m3

dS/m

°C

aM1!

1) Permittivity,

2) Electrical Conductivity,

3) Temperature

dS/m

°C

aM2!

1) Period,

2) Voltage Ratio,

3) Temperature

Sec

°C

aM3!

1) Volumetric Water Content,

2) Electrical Conductivity,

3) Temperature

4) Permittivity,

5) Period,

6) Voltage Ratio,

m3/m3

dS/m

°C

Sec

aM4! .. aM9!

No Values Returned

?!

Returns the SDI-12 Address

aI!

CampbellSci, OS version, Product

Serial Number

NOTE

The CS650 responds to SDI-12 commands M!, M1!, M2!, M3!, ?!, and I!. Table

8-4 shows the values returned for each of these commands.

See Section 7.3, Datalogger Wiring (p. 10), for SDI-12 wiring details.

This section briefly describes using the SDI-12 commands.

Additional SDI-12 information is available at Appendix D, SDI-12

Sensor Support (p. D-1), www.sdi-12.org, or

www.youtube.com/user/CampbellScientific.

User Manual

8.2.1 Use of Multiplexers

Up to 10 CS650 probes may be connected to the same datalogger control port as

long as each one has a unique SDI-12 address. The CS650 ships with a default

SDI-12 address of 0 unless otherwise specified at the time of ordering. The SDI12 address may be changed through DevConfig software (see Section 8.1, A200

and Device Configuration Utility (p. 12)) or with a terminal emulator in SDI-12

transparent mode (see Appendix D, SDI-12 Sensor Support (p. D-1)).

SDI-12 communication is established using the SDI12Recorder() CRBasic

instruction. See Appendix D, SDI-12 Sensor Support (p. D-1), for more detail on

SDI-12 communication.

Multiplexers such as Campbell Scientific’s AM16/32B may be used to connect up

to 32 CS650 probes to a single control port. When using multiplexers, the

simplest configuration is for all probes to have the same SDI-12 address.

19

Page 32

CS650 and CS655 Water Content Reflectometers

CAUTION

When multiplexing CS650 probes, the switched 12V channel should be used so

that power to the sensor may be turned off under program control before the

multiplexer switches to the next channel.

Failure to turn off the switched 12 volt channel before clocking

the multiplexer will result in damage to the multiplexer relays.

The proper sequence in the datalogger program for measuring CS650 probes on a

multiplexer is:

1. Set RES control port high to enable multiplexer

2. Pulse CLK control port to advance to next multiplexer channel

3. Set switched 12 volt channel high to supply power to CS650

4. Send SDI-12 command(s) to CS650

5. Set switched 12 volt channel low to remove power from CS650

6. Repeat steps 2 through 5 for each CS650 connected to the multiplexer

7. Set RES control port low to disable multiplexer

Program examples in Appendix B, Example Programs (p. B-1), show the commands

used in CRBasic.

8.3 Water Content Reflectometer Method for Measuring Volumetric Water Content

8.3.1 Description of Measurement Method

For the water content measurement, a differential emitter-coupled logic (ECL)

oscillator on the circuit board is connected to the two parallel stainless steel rods.

The differentially driven rods form an open-ended transmission line in which the

wave propagation velocity is dependent upon the dielectric permittivity of the

media surrounding the rods. An ECL oscillator state change is triggered by the

return of a reflected signal from the end of one of the rods.

The fundamental principle for CS650 water content measurement is that the

velocity of electromagnetic wave propagation along the probe rods is dependent

on the dielectric permittivity of the material surrounding the rods. As water

content increases, the propagation velocity decreases because of increasing

dielectric permittivity. Therefore, the two-way travel time of the rod signal is

dependent upon water content, hence the name water content reflectometer.

Digital circuitry scales the high-speed oscillator output to an appropriate

frequency for measurement by an on-board microprocessor. Increases in

oscillation period resulting from signal attenuation are corrected using an

electrical conductivity measurement. A calibration equation converts period and

electrical conductivity to bulk dielectric permittivity. The Topp equation is used

to convert from permittivity to volumetric water content.

20

8.3.2 The Topp Equation

The relationship between dielectric permittivity and volumetric water content in

mineral soils has been described by Topp et al. (1980) in an empirical fashion

using a 3rd degree polynomial. With v the volumetric water content and Ka the

bulk dielectric permittivity of the soil, the equation presented by Topp et al. is

Page 33

User Manual

bulk solution

v solid

v = -5.3*10-2 + 2.92*10-2Ka – 5.5*10-4K

It has been shown in numerous research efforts that this equation works well in

most mineral soils, so a soil specific calibration of the CS650 probe is usually not

necessary. If a soil specific calibration is desired, the user can generate an

equation relating Ka to v following the methods described in Section 8.4, Water

Content Reflectometer User-Calibration (p. 23).

8.3.3 Electrical Conductivity

8.3.3.1 Soil Electrical Conductivity

The quality of soil water measurements which apply electromagnetic fields to

wave guides is affected by soil electrical conductivity. The propagation of

electromagnetic fields in the configuration of the CS650 is predominantly affected

by changing dielectric permittivity due to changing water content, but it is also

affected by electrical conductivity. Free ions in soil solution provide electrical

conduction paths which result in attenuation of the signal applied to the

waveguides. This attenuation both reduces the amplitude of the high-frequency

signal on the probe rods and reduces the bandwidth. The attenuation reduces

oscillation frequency at a given water content because it takes a longer time to

reach the oscillator trip threshold.

It is important to distinguish between soil bulk electrical conductivity and soil

solution electrical conductivity. Soil solution electrical conductivity refers to the

conductivity of the solution phase of soil. Soil solution electrical conductivity,

the solution from the solid and then measuring the electrical conductivity of the

extracted solution.

can be determined in the laboratory using extraction methods to separate

solution

2

+ 4.3*10-6K

a

3

a

The relationship between solution and bulk electrical conductivity can be

described by (Rhoades et al., 1976)

with

solution;

being the electrical conductivity of the bulk soil;

bulk

, the solid constituents; v, the volumetric water content; and, a

solid

solution

, the soil

soil-specific transmission coefficient intended to account for the tortuosity of the

flow path as water content changes. See Rhoades et al., 1989 for a form of this

equation which accounts for mobile and immobile water. This publication also

discusses soil properties related to CS650 operation such as clay content and

compaction. The above equation is presented here to show the relationship

between soil solution electrical conductivity and soil bulk electrical conductivity.

Most expressions of soil electrical conductivity are given in terms of solution

conductivity or electrical conductivity from extract since it is constant for a soil.

Bulk electrical conductivity increases with water content so comparison of the

electrical conductivity of different soils must be at the same water content.

The calibration equation in the CS650 firmware corrects the oscillation frequency

for the effects of

10 dS m-1 for the CS655. This is equivalent to

dS m-1 and 2.7 dS m-1 respectively. If

up to 3 dS m-1 for the CS650 and up to

solution

bulk

exceeds these limits, the CS650 probe

bulk

values of approximately 0.8

will return 99999 for dielectric permittivity and volumetric water content. The

measured period average and voltage ratio values will continue to be reported

even if the bulk EC is outside the operational range of the probe.

21

Page 34

CS650 and CS655 Water Content Reflectometers

8.3.3.2 Temperature Correction of Soil Electrical Conductivity

The EC value reported by the CS650 is bulk electrical conductivity. This value is

temperature dependent, changing by 2% per degree Celsius. To compensate for

the effect of temperature, EC readings may be converted to a standard

temperature, such as 25 °C using the following equation:

where EC25 is the

temperature T

(°C).

soil

EC25 = ECT / (1 + 0.02*(T

value at 25 °C and ECT is the

bulk

soil

-25)

bulk

value at soil

8.3.4 Error Sources in Water Content Reflectometer Measurement

8.3.4.1 Probe-to-Probe Variability Error

All manufactured CS650s/CS655s are checked in standard media to develop a

probe specific span and offset value for electrical conductivity and dielectric

permittivity measurements. These probe specific values are written to the probe’s

firmware and minimize probe-to-probe variability.

8.3.4.2 Insertion Error

The method used for probe insertion can affect the accuracy of the measurement.

The probe rods should be kept as close to parallel as possible when inserted to

maintain the design wave guide geometry. The sensitivity of this measurement is

greater in the regions closest to the rod surface than at distances away from the

surface. Probes inserted in a manner that generates air voids around the rods will

indicate lower water content than actual. In some applications, installation can be

improved by using insertion guides or a pilot tool. Campbell Scientific offers the

CS650G insertion tool.

8.3.5 Temperature Dependence and Correction

The two temperature dependent sources of error in CS650 water content

measurements are the effect of temperature on the operation of the probe

electronics and the effect of temperature on the dielectric permittivity of the soil.

The effect of temperature on probe electronics is minimal with period average

readings varying by less than 0.5% of the 20 °C reading over the range of 10 to 30

°C and less than 2% of the 20 °C reading over the range of –10 to 70 °C.

The larger error is caused by the change in dielectric permittivity of soil with

temperature. This is mostly due to the high temperature dependence of the

permittivity of water, which varies from a value of 88 at 0 °C to 64 at 70 °C.

Since water is the major contributor to bulk dielectric permittivity of soil,

temperature related changes to the permittivity of water will lead to

overestimation of volumetric water content at temperatures below 20 °C and

underestimation of volumetric water content at temperatures above 20 °C.

The Topp equation does not account for soil temperature. The effect of

temperature on the soil permittivity is related to soil specific properties such as

porosity and the permittivity of the soil solid phase with temperature.

Consequently, a general equation that corrects volumetric water content for

temperature for all soils is not available.

A temperature correction equation that works well in quartz sand is given by:

= - 0.0044*T3 + 0.0014*T2 + 0.0029*T – 0.0002*T + 2.4*3 – 1.6*2 +

Corr

0.32* – 0.046

22

Page 35

User Manual

where

is the temperature corrected volumetric water content, T is soil

Corr

temperature in °C, and is the volumetric water content value at soil temperature

T.

8.3.5.1 Accurate Soil Temperature Measurement

The thermistor used for measuring soil temperature is located in the probe head

and is in contact with one of the stainless steel rods. In order to make an accurate

soil temperature measurement, the probe head should be buried in the soil so that

it is insulated from diurnal temperature fluctuations.

8.4 Water Content Reflectometer User-Calibration

8.4.1 Need for Soil Specific Calibration Equation

While the Topp equation has been determined to work well in a wide range of

mineral soils, there are soils for which a user-derived calibration will optimize

accuracy of the volumetric water content measurement. The Topp equation

underestimates the water content of some organic, volcanic, and fine textured

soils. Additionally, porous media with porosity greater than 0.5 or bulk density

greater than 1.55 g cm–3 may require a media-specific calibration equation.

In these cases, the user may develop a calibration equation to convert CS650

permittivity to volumetric water content over the range of water contents the probe

is expected to measure.

8.4.2 User-Derived Calibration Equation

The relationship between soil permittivity and volumetric water content may be

described by a quadratic equation or a 3rd order polynomial. In many applications,

a linear equation similar to Ledieu et al (1986) gives required accuracy.

Quadratic form:

v(Ka) = C0 + C1*Ka + C2*K

with v the volumetric water content, Ka the bulk dielectric permittivity of the soil,

and Cn , the calibration coefficient.

3rd degree polynomial form:

v(Ka) = C0 + C1*Ka + C2*K

with v the volumetric water content, Ka the bulk dielectric permittivity of the soil,

and Cn , the calibration coefficient.

Linear form:

with v the volumetric water content, Ka the bulk dielectric permittivity of the soil,

and Cn , the calibration coefficient.

v(Ka) = C0 + C1*K

2

+ C3*K

a

0.5

a

2

a

3

a

Two data points from careful measurements can be enough to derive a linear

calibration. A minimum of three data points are needed for a quadratic

calibration. With three evenly spaced water contents covering the expected range,

the middle water content data point will indicate whether a linear or polynomial

calibration equation is needed.

23

Page 36

CS650 and CS655 Water Content Reflectometers

A minimum of four data points are required for derivation of a 3rd degree

polynomial. Data points should be spaced as evenly as practical over the expected

range of water content and include the wettest and driest expected values.

8.4.3 Collecting Laboratory Data for Calibration

Water content reflectometer data needed for CS650 calibration are the CS650

permittivity reading and an independently determined volumetric water content.

From this data, the probe response to changing water content can be described by

a linear or polynomial function as described in Section 8.4.2, User-Derived

Calibration Equation (p. 23).

Required equipment:

CS650 connected to datalogger programmed to measure permittivity

Cylindrical sampling devices to determine sample volume for bulk

density, such as copper tubing with diameter of 2.5 cm (1 in) and

length at about 5 cm (2 ins).

Containers and scale to measure soil sample mass

Oven to dry samples (microwave oven can also be used)

The calibration coefficients are derived from a curve fit of known water content

and probe permittivity output. The number of data sets needed to derive a

calibration depends on the form of the calibration equation. At least three data

sets should be generated to determine whether the linear form is valid. If a

polynomial is to be used, four data sets will determine whether the function is a

quadratic or third order polynomial. Accuracy requirements may require

additional data sets. Consider the expected range of soil water content and include

data sets from the highest and lowest expected water contents.

The measurement sensitive volume around the probe rods must be completely

occupied by the calibration soil. Only soil should be in the region within

10 cm (4 in) of the rod surface. The probe rods can be buried in a tray of soil that

is dry or nearly dry. The soil will be homogeneous around the probe rods if it is

poured around the rods while dry. Also, a 20 cm diameter PVC pipe with length

about 35 cm can be closed at one end and used as the container.

It is important that the bulk density of the soil used for calibration be similar to the

bulk density of the undisturbed soil. Using dry soil without compaction will give

a typical bulk density, 1.1 to 1.4 g cm–3. This is especially important when bulk

density is greater than 1.55 g cm–3. Compaction of the calibration soil to similar

bulk density at the field site is necessary for an accurate calibration.

The typically used method for packing a container of soil to uniform bulk density

is to roughly separate the soil into three or more equal portions and add one

portion to the container with compaction. Evenly place the first loose soil layer in

the bottom of the container. Compact by tamping the surface to a level in the

container that is correct for the target bulk density. Repeat for the remaining

layers. Prior to placing successive layers, scarify (loosen) the top of the existing

compacted layer.

24

The container to hold the soil during calibration should be non-metal and large

enough that the rods of the probe are no closer than about 10 cm from any

container surface.

Pack the container as uniformly as possible in bulk density with relatively dry soil

(volumetric water content <10%).

Page 37

User Manual

g

wet dry

dry

m m

m

bulk

dry

cylinder

m

volume

Probe rods can be buried in a tray or inserted into a column. When using a

column, insert the rods carefully through surface until rods are completely

surrounded by soil. Movement of rods from side-to-side during insertion can form

air voids around rod surface and lead to measurement error.

Collect the probe permittivity output. Repeat previous step and this step three or

four times.

Determine volumetric water content by subsampling soil column after removing

probe or using mass of column. If subsampling is used, remove soil from column

and remix with samples used for water content measurement. Repack column.

Water can then be added to the top of the container. It must be allowed to

equilibrate. Cover the container during equilibration to prevent evaporation. The

time required for equilibration depends on the amount of water added and the

hydraulic properties of the soil. Equilibration can be verified by frequently

observing the CS650 permittivity output. When permittivity is constant,

equilibration is achieved. Collect a set of calibration data values and repeat the

water addition procedure again if needed.

With soil at equilibrium, record the CS650 permittivity.

Take subsamples of the soil using containers of known volume. This is necessary

for measurement of bulk density. Copper tubing of diameter 2.5 cm (1 in) and

length about 5 cm (2 ins) works well. The tubes can be pressed into the soil

surface.

It is good to take replicate samples. Three carefully handled samples will provide

good results.

The sample tubes should be pushed evenly into the soil. Remove the tube and

sample and gently trim the ends of excess soil. Remove excess soil from outside

of tube.

Remove all the soil from tube to a tray or container of known mass that can be put

in oven or microwave. Weigh and record the wet soil mass.

Water is removed from the sample by heating with oven or microwave. Oven

drying requires 24 hours at 105 °C. Microwave drying typically takes 20 minutes

depending on microwave power and sample water content. ASTM Method

D4643-93 requires heating in microwave for 3 minutes, cooling in desiccator then

weighing and repeating this process until measured mass is constant.

Gravimetric water content is calculated after the container mass is accounted for.

For the bulk density

the dry mass of the sample is divided by the sample tube volume.

The volumetric water content is the product of the gravimetric water content and

the bulk density

25

Page 38

CS650 and CS655 Water Content Reflectometers

v g bulk

*

The average water content for the replicates and the recorded CS650 permittivity

are one datum pair to be used for the calibration curve fit.

8.4.4 Collecting Field Data for Calibration

Required equipment:

CS650 connected to datalogger programmed to measure probe

permittivity

Cylindrical sampling devices to determine sample volume for bulk

density, such as copper tubing with diameter of 2.5 cm (1 in) and

length about 5 cm (2 ins).

Containers and scale to measure soil sample mass

Oven to dry samples (microwave oven can also be used)

Data needed for CS650 calibration are the CS650 permittivity output and an

independently determined volumetric water content. From this data, the probe

response to changing water content can be described by a function as described in

Section 8.4.2, User-Derived Calibration Equation (p. 23).

The calibration coefficients are derived from a curve fit of known water content

and probe permittivity output. The number of data sets needed to derive a

calibration depends on the form of the calibration equation. At least three data

sets should be generated to determine whether the linear form is valid. If a

polynomial is to be used, four data sets will determine whether the function is a

quadratic or third order polynomial. Accuracy requirements may require

additional data sets. Consider the expected range of soil water content and include

data sets from the highest and lowest expected water contents.

Collecting measurements of CS650 permittivity and core samples from the

location where the probe is to be used will provide the best on-site soil-specific

calibration. However, intentionally changing water content in soil profiles can be

difficult.

A vertical face of soil can be formed with a shovel. If the CS650 is to be used

within about 0.5 metres of the surface, the probe can be inserted into the face and

water added to the surface with percolation. After adding water, monitor the

CS650 permittivity to determine if the soil around the rods is at equilibrium.

With soil at equilibrium, record the CS650 permittivity.

Soil hydraulic properties are spatially variable. Obtaining measurements that are

representative of the soil on a large scale requires multiple readings and sampling.

The average of several core samples should be used to calculate volumetric water

content. Likewise, the CS650 should be inserted at least 3 times into the soil

recording the permittivitys following each insertion and using the average.

Remove the CS650 and take core samples of the soil where the probe rods were

inserted. This is necessary for measurement of bulk density. Copper tubing of

diameter 2.5 cm (1 in) and length about 5 cm (2 ins) works well. The tubes can

be pressed into the soil surface.

It is good to take replicate samples at locations around the soil surface. Three

carefully handled samples will provide good results.

26

Page 39

User Manual

g

wet dry

dry

m m

m

bulk

dry

cylinder

m

volume

v g bulk

*

volume

d

h

* *

2

2

The sample tubes should be pushed evenly into the soil surface. Remove the tube

and sample and gently trim the ends of excess soil. Remove excess soil from

outside of tube.

Remove all the soil from tube to a tray or container of known mass that can be put

in oven or microwave. Weigh and record the wet soil mass. If samples must be

stored prior to weighing, seal the container with tape or inside a plastic bag to

prevent water loss and store away from direct sunlight.

Water is removed from the sample by heating with oven or microwave. Oven

drying requires 24 hours at 105 °C. Microwave drying typically takes 20 minutes

depending on microwave power and sample water content. ASTM Method

D4643-93 requires heating in microwave for 3 minutes, cooling in desiccator then

weighing and repeating this process until mass is constant.

Gravimetric water content is calculated after the container mass is accounted for.

For the bulk density,

8.4.5 Calculations

the dry mass of the sample is divided by the sample tube volume.

The volumetric water content is the product of the gravimetric water content and

the bulk density

The average water content for the replicates and the recorded CS650 period are

one datum pair to be used for the calibration curve fit.

The empty cylinders used for core sampling should be clean and both empty mass

and volume are measured and recorded. For a cylinder, the volume is

where d is the inside diameter of the cylinder and h is the height of the cylinder.

During soil sampling it is important that the cores be completely filled with soil

but not extend beyond the ends of the cylinder.

Once soil core samples are obtained, place the soil-filled cylinder in a small tray

of known empty mass. This tray will hold the core sample during drying in an

oven.

To obtain m

, subtract the cylinder empty mass and the container empty mass

wet

from the mass of the soil filled cylinder in the tray. Remove all the soil from the

cylinder and place this soil in the tray. Dry the samples using oven or microwave

methods as described above.

27

Page 40

CS650 and CS655 Water Content Reflectometers

g

wet dry

dry

m m

m

bulk

dry

cylinder

m

volume

v g bulk

*

To obtain m

for m

dry

, weigh the tray containing the soil after drying. Subtract tray mass

dry

. Calculate gravimetric water content, g, using

To obtain soil bulk density, use

Volumetric water content is calculated using

28

Page 41

9. Maintenance and Troubleshooting

Table 9-1. Symptom, Cause, and Solutions

Symptom

Possible Cause

Solution

All CS650 output

values read 0

No SDI12Recorder

instruction in datalogger

program

Conditional statement

that triggers reading is

not evaluating as true

Add SDI12Recorder

instruction to datalogger

program

Check logic of conditional

statement that triggers

readings

First value reads NAN

and all other values read

0* or never change

from one measurement

to another

CS650 SDI-12 address

does not match address

specified in datalogger

program

Change probe address or

modify program so that

they match

(*or all values read

NAN if the program

examples in this manual

are followed)

CS650 green wire not

attached to SDI port

specified in datalogger

program

Connect wire to correct

control port or modify

program to match wiring

CS650 not being

powered

Make sure red wire is

connected to 12V or

SW12V and black wire to

G.

If using SW12 to power

sensor, make sure red wire

is connected and datalogger

program switches SW12 on.

VWC reading is

9999999

Soil bulk permittivity is

outside probe’s

operational range

Modify program to collect

permittivity value and try

soil specific calibration

EC reading is 9999999

Soil bulk electrical

conductivity is outside

probe’s operational

range

If using CS650, try CS655

Readings erratic,

including NAN’s and

9999999’s

Multiple probes with

same SDI-12 address

sharing same control

port

Give probes unique

addresses or put on separate

control ports

The CS650 does not require periodic maintenance. Table 9-1 provides

troubleshooting information.

User Manual

29

Page 42

CS650 and CS655 Water Content Reflectometers

10. References

Ledieu, J., P. De Ridder, P. De Clerck, and S. Dautrebande. 1986. “A method of

measuring soil moisture by time-domain reflectometry,” J. Hydrol. 88:319-

328.

Rhoades, J.D., P.A.C. Raats, and R.J. Prather. 1976. Effects of liquid-phase

electrical conductivity, water content and surface conductivity on bulk soil

electrical conductivity. Soil Sci. Soc. Am. J., 40: 651-653.

Rhoades, J.D., N.A. Manteghi, P.J. Shouse, W.J. Alves. 1989. Soil electrical

conductivity and soil salinity: New formulations and calibrations. Soil Sci.

Soc. Am. J., 53:433-439.

Topp, G.C., J.L. Davis & A.P. Annan. 1980. “Electromagnetic determination of

soil water content: measurements in coaxial transmission lines,” Water

Resources Research, v. 16, No. 3:574-582.

30

Page 43

NOTE

Appendix A. Importing Short Cut Code into a Program Editor

This tutorial shows:

How to import a Short Cut program into a program editor for additional

refinement

How to import a wiring diagram from Short Cut into the comments of a

custom program

Short Cut creates files that can be imported into either CRBasic Editor program

editor. These files normally reside in the C:\campbellsci\SCWin folder and have

the following extensions:

.DEF (wiring and memory usage information)

.CR6 (CR6 datalogger code)

.CR2 (CR200(X) datalogger code)

.CR1 (CR1000 datalogger code)

.CR8 (CR800 or CR850 datalogger code)

.CR3 (CR3000 datalogger code)

.CR5 (CR5000 datalogger code)

Use the following procedure to import Short Cut code into CRBasic Editor

(CR200(X), CR1000, CR800, CR3000, CR5000 dataloggers).

1. Create the Short Cut program following the procedure in Section 4,

Quickstart (p. 2). Finish the program and exit Short Cut. Make note of the file

name used when saving the Short Cut program.

2. Open CRBasic Editor.

3. Click File | Open. Assuming the default paths were used when Short Cut was

installed, navigate to C:\CampbellSci\SCWin folder. The file of interest has a

“.CR6”, “.CR2”, “.CR1”, “.CR8”, “.CR3, or “.CR5” extension, for CR6,

CR200(X), CR1000, CR800, CR3000, or CR5000 dataloggers, respectively.

Select the file and click Open.

4. Immediately save the file in a folder different from \Campbellsci\SCWin, or

save the file with a different file name.

Once the file is edited with CRBasic Editor, Short Cut can no longer

be used to edit the datalogger program. Change the name of the

program file or move it, or Short Cut may overwrite it next time it is

used.

5. The program can now be edited, saved, and sent to the datalogger.

6. Import wiring information to the program by opening the associated .DEF

file. Copy and paste the section beginning with heading “-Wiring for

CRXXX–” into the CRBasic program, usually at the head of the file. After

pasting, edit the information such that a ' character (single quotation mark)

begins each line. This character instructs the datalogger compiler to ignore

the line when compiling the datalogger code.

A-1

Page 44

Appendix A. Importing Short Cut Code

A-2

Page 45

Table B-1. CR1000 Wiring for One Probe Example Program

CR1000

CS650

12V

Red

C1

Green

G

Black, Orange, Clear

Table B-2. CR1000 Wiring for Two Probe Example Program

CR1000

CS650’s (wiring same for both)

12V

Red

C1

Green

G

Black, Orange, Clear

Appendix B. Example Programs

B.1 CR1000 Programs

B.1.1 CR1000 with One CS650 Probe

This CRBasic example program measures one CS650 probe on a CR1000 every

15 minutes, storing hourly averages of volumetric water content, electrical

conductivity, and soil temperature and samples of permittivity, period average and

voltage ratio. The CS650 has an SDI-12 address of 0. Wiring for the example is

shown in Table B-1.

Public CS650(6)

'Assign aliases to the public array

Alias CS650(1)=VWC: Alias CS650(2)=EC: Alias CS650(3)=TSoil

Alias CS650(4)=Perm: Alias CS650(5)=PerAvg: Alias CS650(6)=VoltR

Units VWC = m^3/m^3: Units EC = dS/m: Units TSoil = deg C

DataTable (DatoutCS650,1,-1)

DataInterval (0,60,Min,2)

Average (3,CS650(1),FP2,False)

Sample(3,CS650(4),IEEE4)

EndTable

BeginProg

Scan (15,Min,0,0)

SDI12Recorder (CS650(1),1,0,"M3!",1.0,0)

CallTable DatoutCS650 'Call Data Table

NextScan

EndProg

B.1.2 CR1000 with Two CS650 Probes on Same Control Port

This CRBasic example program measures two CS650 probes on a CR1000 every

15 minutes, storing hourly averages of volumetric water content, electrical

conductivity, and soil temperature and samples of permittivity, period average and

voltage ratio. The first CS650 has an SDI-12 address of 0 and the second has an

address of 1. Wiring for the example is shown in Table B-2. Assignment of

aliases and units is not shown in this example.

B-1

Page 46

Appendix B. Example Programs

Table B-3. CR1000 Wiring For Multiplexer Example Program

CR1000

AM16/32B (2x32 mode)

CS650

12V

12V

G GND

C2

RES

C3

CLK

SW12

COM ODD H

C1

COM ODD L

G

COM Ground

High Channels 1H – 12H

Red

Low Channels 1L – 12L

Green

Ground Channels to Left of

Low Channels

Black, Orange, Clear

Public CS650(6)

Public CS650_2(6)

DataTable (DatoutCS650,1,-1)

DataInterval (0,60,Min,2)

Average (3,CS650(1),FP2,False)

Sample(3,CS650(4),IEEE4)

Average (3,CS650_2(1),FP2,False)

Sample(3,CS650_2(4),IEEE4)

EndTable

BeginProg

Scan (15,Min,0,0)

SDI12Recorder (CS650(1),1,0,"M3!",1.0,0)

SDI12Recorder (CS650_2(1),1,1,"M3!",1.0,0)

CallTable DatoutCS650 'Call Data Table

NextScan

EndProg

B.1.3 CR1000 with 12 CS650 Probes on Multiplexer

This CRBasic example program measures 12 CS650 probes on a AM16/32B

multiplexer every 15 minutes, storing hourly averages of volumetric water