Page 1

CS475, CS476 and C477 Radar

Water Level Sensor

Revision: 1/10

Copyright © 2009-2010

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The CS475, CS476, and CS477 RADAR WATER LEVEL SENSOR is

warranted by CAMPBELL SCIENTIFIC, INC. to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless specified otherwise. Batteries have no

warranty. CAMPBELL SCIENTIFIC, INC.'s obligation under this warranty is

limited to repairing or replacing (at CAMPBELL SCIENTIFIC, INC.'s option)

defective products. The customer shall assume all costs of removing,

reinstalling, and shipping defective products to CAMPBELL SCIENTIFIC,

INC. CAMPBELL SCIENTIFIC, INC. will return such products by surface

carrier prepaid. This warranty shall not apply to any CAMPBELL

SCIENTIFIC, INC. products which have been subjected to modification,

misuse, neglect, accidents of nature, or shipping damage. This warranty is in

lieu of all other warranties, expressed or implied, including warranties of

merchantability or fitness for a particular purpose. CAMPBELL SCIENTIFIC,

INC. is not liable for special, indirect, incidental, or consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company

serves your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container.

CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Declaration of Hazardous Material

and Decontamination” form and comply with the requirements specified in it.

The form is available from our website at

completed form must be either emailed to repair@campbellsci.com

435-750-9579. Campbell Scientific will not process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

www.campbellsci.com/repair

. A

or faxed to

Page 3

CS475, CS476, CS477 Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. Overview.......................................................................1

2. Specifications ..............................................................2

3. Installation....................................................................4

3.1 General Safety Instructions.......................................................................4

3.2 Unpacking Equipment..............................................................................4

3.3 Components and Hardware.......................................................................4

3.4 Installation Recommendations..................................................................6

3.4.1 Site Selection ..................................................................................6

3.5 Sensor Mounting.......................................................................................7

3.5.1 Vertical Alignment..........................................................................7

3.5.2 Azimuth Alignment.........................................................................7

3.6 Instrument Housing Adjustment...............................................................8

4. Wiring............................................................................9

4.1 Datalogger Connection.............................................................................9

4.2 Multiple Sensors Connection....................................................................9

4.3 Built-in Self Test (BIST)..........................................................................9

5. Configuration.............................................................10

5.1 Default Settings ......................................................................................10

5.2 Startup Procedure ...................................................................................10

5.2.1 Start False Echo Learn..................................................................10

5.2.2 Set Water Stage.............................................................................11

6. Programming .............................................................12

6.1 CRBasic..................................................................................................12

6.1.1 Example Program..........................................................................13

6.2 Edlog.......................................................................................................14

6.2.1 Example Program..........................................................................15

7. Diagnostics, Repair, and Maintenance....................16

7.1 Testing Procedure................................................................................... 16

7.1.1 Start Measurement Command.......................................................16

7.1.2 Check Unit Response....................................................................17

7.1.3 Check for Valid Data....................................................................17

7.1.4 Cyclic Redundancy Check (CRC) ................................................18

7.1.4.1 Check CRC for Valid Data..................................................18

7.1.5 Get Units.......................................................................................19

7.1.6 Get Water Conditions ...................................................................19

7.1.7 Get Power Operation Mode..........................................................19

i

Page 4

CS475, CS476, CS477 Table of Contents

7.2 Diagnostics and Repair ..........................................................................20

7.2.1 No Measured Value Available - Error E013................................ 20

7.2.2 No Measured Value Available - Error E041, E042, E043........... 20

7.2.2.1 Exchange Electronics Module............................................ 20

7.3 Maintenance........................................................................................... 23

Appendices

A. Replacing the Cable................................................A-1

B. Entering SDI-12 Commands/Changing Settings ..B-1

B.1 Changing Settings ............................................................................... B-3

B.1.1 Query/Set the Address............................................................... B-3

B.1.2 Set Units .................................................................................... B-3

B.1.3 Set Water Conditions................................................................. B-4

B.1.4 Set Power Operation Mode........................................................ B-4

C. FCC/IC Equipment Authorization...........................C-1

List of Figures

1-1. CS475, CS476, and CS477..................................................................... 2

3-1. Components and Hardware .................................................................... 5

3-2. Polarization Markings............................................................................. 8

7-1. Changing the Electronics...................................................................... 22

A-1. Connecting the Instrument Housing..................................................A-2

List of Tables

3-1. Description of Components and Hardware Labels................................. 5

3-2. Radiation Beam Spread for CS475 (10° Beam Angle)........................... 7

3-3. Radiation Beam Spread for CS476/CS477 (8° Beam Angle)................. 7

3-4. Description of Polarization Markings Labels......................................... 8

4-1. Wiring Diagram...................................................................................... 9

5-1. Default Settings .................................................................................... 10

5-2. Example of a Start False Echo Learn Command.................................. 11

5-3. Example for Setting Water Stage ......................................................... 12

6-1. SDI-12 Command Codes...................................................................... 13

7-1. Example of Start Measurement Command........................................... 17

7-2. Acknowledge Active Command........................................................... 17

7-3. Send Identification Command.............................................................. 18

7-4. Checking CRC Example....................................................................... 19

7-5. Description of Changing the Electronics Labels ..................................22

A-1. Description of Instrument Housing Labels........................................A-2

B-1. SDI-12 Commands............................................................................. B-2

B-2. SDI-12 Command for Querying the Address..................................... B-3

B-3. Example of Setting Address............................................................... B-3

B-4. Example of Setting Units................................................................... B-3

B-5. Example for Setting Water Conditions.............................................. B-4

B-6. Example for Setting Power Operation Mode..................................... B-5

ii

Page 5

CS475, CS476, and CS477 Radar Water

Level Sensor

1. Overview

The CS475, CS476, and CS477 are radar ranging sensors typically used for

water-level applications. They emit short microwave pulses and then measure

the elapsed time between the emission and return of the pulses. The elapsed

time measurement is used to calculate the distance between the sensor face and

the target (e.g., water, grain, slurry). The distance value can then be used to

determine depth.

These radar sensors output a digital SDI-12 signal to indicate distance and

stage. This output is acceptable for recording devices with SDI-12 capability

including Campbell Scientific dataloggers. Compatible dataloggers include

our CR200(X)-series, CR800-series, CR1000, CR3000, CR5000, CR510, and

CR10X.

Three sensor models are available that differ in their measurement range and

accuracy. The CS475 can measure distances up to 65 feet with an accuracy of

±0.2 inches; the CS476 can measure up to 98 feet with an accuracy of ±0.1

inches; and the CS477 can measure up to 230 feet with an accuracy of ±0.6

inches.

The -L after the model name indicates that the cable length is user specified.

1

Page 6

CS475, CS476, and CS477 Radar Water Level Sensor

FIGURE 1-1. CS475, CS476, and CS477

2. Specifications

Measurement Range

CS475: 2 inch to 65 ft (50 mm to 20 m)

CS476: 2 inch to 98 ft (50 mm to 30 m)

CS477: 16 inch to 229 ft (400 mm to 70 m)

Accuracy

CS475 (20 inch to 65 ft): ±0.2 inch (±5 mm)

CS476 (20 inch to 98 ft): ±0.1 inch (±3 mm)

CS477 (20 inch to 230 ft): ±0.6 inch (±15 mm)

Resolution: 0.0033 ft (1 mm)

Output Protocol: SDI-12

2

Page 7

CS475, CS476, and CS477 Radar Water Level Sensor

Radar Unit

Frequency: ~26 GHz

Electromagnetic Compatibility: Emission to EN 61326;

Electrical Equipment Class B

Pulse E nergy: 1 mW maxi mum

Beam angle

CS475: 10° (3-in dia horn)

CS476, CS477: 8° (4-in dia horn)

Power Requirements

Input Voltage: 9.6 to 16 Vdc

Surge Protection: 1.5 KVA

Typical Current Drain with 12 V power supply

Sleeps: 4.7 mA

Measurement: 14 mA

Environmental

Operating Temperature Range: -40° to +80°C

Storage Ranges

Temperature: -40° to +80°C

Relative Humidity: 20% to 80% RH

Temperature Sensitivity: average TK: 2 mm/10 K,

max 5 mm over the entire

temperature range of

-40°to +80°C

Vibration Resistance: Mechanical vibrations with 4 g

and 5 to 100 Hz

Mechanical

Rating: NEMA 4x

Housing: Aluminum, coated IP66/68

Face Diameter: 0.625 inches (16 mm)

Horn Length

CS475: 5.4 inches (137 mm)

CS476, CS477: 16.9 inches (430 mm)

Horn Material: 316L stainless steel

3

Page 8

CS475, CS476, and CS477 Radar Water Level Sensor

3. Installation

3.1 General Safety Instructions

Observe standard regulations and guidelines while installing and operating the

radar sensors. You should follow country-specific installation standards,

prevailing safety regulations, accident prevention rules, and this manual’s

safety instructions.

Depending on the model, the emitting frequencies of these radar sensors are

either in the C or K band range. Their low transmitting power is well below

the internationally permitted limits. When used correctly, the radar sensors

present no danger to people.

It is the responsibility of the user to ensure that the sensors are maintained and

functioning properly.

3.2 Unpacking Equipment

When unpacking the equipment, do the following:

• Unpack the unit in a clean, dry area.

• Inspect the equipment for any damage that occurred during shipping or

storage.

• If the equipment is damaged, file a claim against the carrier and report the

damage in detail.

3.3 Components and Hardware

The radar sensor consists of an integrated microwave transmitter and sensor

together with a horn antenna (see Figure 3-1 and Table 3-1). The horn antenna

serves to focus the transmitted signal and to receive the reflected echo. A builtin SDI-12 interface provides data processing and SDI-12 communications with

the datalogger.

4

Page 9

CS475, CS476, and CS477 Radar Water Level Sensor

(A)

1

(B)

3

2

4

5

3

2

4

5

6

7

8

9

12

13

14

15

(C)

10

11

(D)

FIGURE 3-1. Components and Hardware

(see Table 3-1 for description of labels)

TABLE 3-1. Description of Components and Hardware Labels

(A) CS475

(B) CS476 or CS477

(C) Optional Mounting Base

(D) Optional Protective Shield

1 Mounting Loop

2 PULS Housing Side Cap

3 PULS Housing Cap

4 PULS Unit Secondary 1/2” NPT Cable Port, Primary Port on Opposite

Side

5 PULS Instrument Horn

6 5/8” Hex Head Cap Screw & Lock Washer

7 Swivel Mounting Flange

8 Upper Shield

9 Upper Shield Twist Lock Tab (3x)

10 Mounting Base

11 1/2” NPT, Mounting Base, Cable Entry Port

12 Lower Shield Locking Tab

13 Notch in Lower Shield Mounting Plate for Twist Lock Upper Shield

14 Lower Shield Mounting Stud, 5/8-11 (2x)

15 Lower Shield

5

Page 10

CS475, CS476, and CS477 Radar Water Level Sensor

3.4 Installation Recommendations

Before installing the radar sensor, you must consider all the suggested

guidelines for site and maintenance issues. Do not attempt to install the sensor

unless you are qualified to perform the installation. The sensor is designed for

safe operation in accordance with the current technical, safety and ANSI

standards.

CAUTION

If you are uncertain of the safe installation and operation of

this unit, read and understand all the instructions included

in this manual before attempting any installation or

operation.

3.4.1 Site Selection

1. Handle the sensor carefully, since it is a precision instrument.

2. Mount the sensor high enough to prevent submersion during flooding

3. Ensure that the sensor is mounted securely to prevent any movement.

WARNING

NOTE

Since the sensor is commonly installed over water

from tall structures, use appropriate safety equipment

such as a safety harness or a life preserver when you

install or perform maintenance on the sensor.

4. Install the sensor above the smoothest part of the water surface.

The smoothest part of the water surface is typically found

halfway between bridge piers. However, bridges with long

spans between the piers experience more vibration. For these

bridges, vibration can be minimized by mounting the sensor a

quarter to a third of the distance to the next pier.

conditions.

5. Align the antenna horn within 1° of vertical to prevent trigonometric

6. Avoid mounting near horizontal structural surfaces such as beams,

7. Center the sensor beam a minimum of 2.5 m from any obstruction in the

NOTE

6

Usually the beam path is 10° for the CS475, and 8° for the

CS476/CS477.

measurement errors. (A level indicator is provided on the top cap of the

sensor for zero bubble).

brackets, and sidewall joints because these surfaces reflect a strong signal.

If these structures cannot be avoided, use the false echo learn command to

map out the interfering structures in the beam profile (see Section 5.2.1).

measurement range. Obstructions to be aware of include excessive waves,

splashing, pipes, wires, and logs. Note that the radiation beam spreads as

it leaves the sensor (see Tables 3-2 and 3-3).

Page 11

CS475, CS476, and CS477 Radar Water Level Sensor

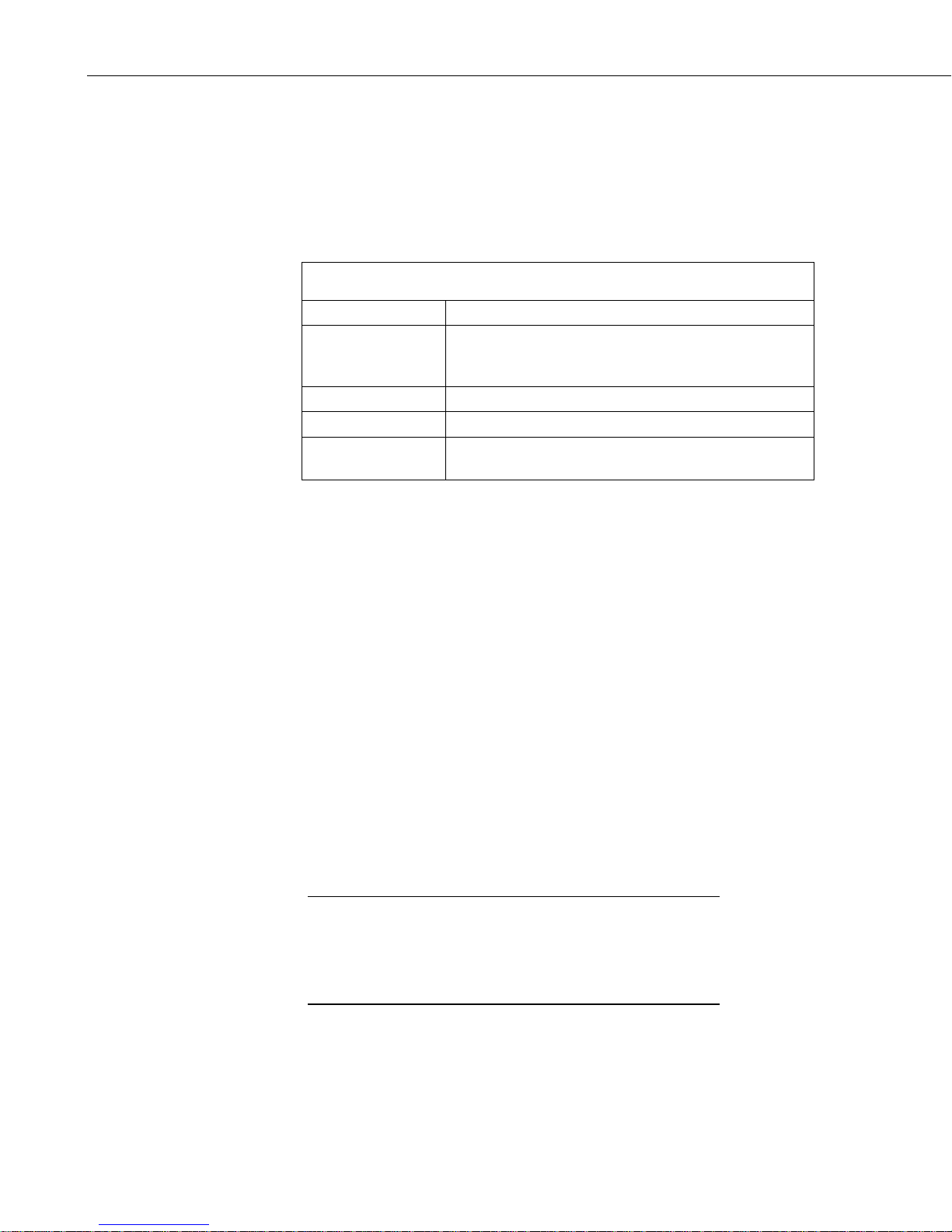

TABLE 3-2. Radiation Beam Spread for CS475

(10° Beam Angle)

Distance in

Meters

1 0.18

5 0.87

10 1.76

15 2.64

20 3.53

TABLE 3-3. Radiation Beam Spread for CS476/CS477

Distance in Meters Diameter of Footprint in Meters

1 0.14

5 0.70

10 1.41

15 2.11

20 2.81

30 4.216

70 (CS477 only) 9.84

Diameter of Footprint in

Meters

(8° Beam Angle)

8. Be aware that bridges contract and expand with temperature changes.

Traffic loads or trucks can also cause changes to the bridge height.

9. Do not install the sensor where submerged obstructions such as rocks or

bridge piers can distort or disturb water level.

3.5 Sensor Mounting

3.5.1 Vertical Alignment

Use a user-supplied bubble level or the 25619 bubble level to make certain the

antenna horn is aligned within 1° of vertical. The cap needs to be removed

when using the 25619. If the antenna is not vertical, a trigonometric

measurement error can occur with respect to the water. The maximum range is

reduced because of the off-axis return signal.

3.5.2 Azimuth Alignment

The sensor’s radar beam is polarized so that it emits radar waves in an elliptical

or football shape. You should orient the unit so the lobes are parallel to, and do

not intersect the pier, when you install on a wall or close to a bridge pier. The

radar housing has a large hex nut on its mount stem. Two drill marks below the

7

Page 12

CS475, CS476, and CS477 Radar Water Level Sensor

hex nut indicate which direction the lobes extend the least. Orient the sensor

such that one of the marks is aligned towards the wall or pier (see Figure 3-2

and Table 3-4).

CS475 CS476/CS477

1

FIGURE 3-2. Polarization Markings

(see Table 3-4 for label descriptions)

TABLE 3-4. Description of Polarization Markings Labels

Sensor Description

1 CS475 Polarization marks are designated by the mounting loop

screws.

2 CS476/CS477 Polarization mark is machine-tooled.

3.6 Instrument Housing Adjustment

2

After mounting, you can rotate the housing up to 350° to simplify access to the

conduit entry and terminal compartment. Proceed as follows to rotate the

housing to the desired position:

1. Loosen the set screw on the housing.

2. Rotate the housing as desired.

3. Tighten the set screw.

8

Page 13

4. Wiring

4.1 Datalogger Connection

CS475, CS476, and CS477 Radar Water Level Sensor

As shipped from Campbell Scientific, the sensor is fitted with a cable for

connection with the datalogger. Appendix A describes replacing this cable.

Connections to Campbell Scientific dataloggers are given in Table 4-1. When

Short Cut is used to create the datalogger program, the sensor should be wired

to the channels shown on the wiring diagram created by Short Cut.

CAUTION

Color

white SDI-12 Signal Odd Numbered

clear Chassis ground

red +12V (power

black ground G G

Description

supply for

sensor)

Connect the wires in the order shown in Table 4-1.

TABLE 4-1. Wiring Diagram

CR800,

CR850,

CR1000,

CR3000,

Control Port

(C1, C3…)

12V 12V 12V 12V Battery+

CR10(X),

CR510, CR500

Odd Numbered

Control Port

(C1, C3…)

G

4.2 Multiple Sensors Connection

CR23X

Odd Numbered

Control Port

(C1, C3…)

CR5000

SDI-12 C1/SDI-12

G G

CR200(X)

4.3 Built-in Self Test (BIST)

To use more than one probe per datalogger, you can either connect the

different probes to different SDI-12 compatible ports on the datalogger or

change the SDI-12 addresses of the probes and let them share the same

connection. Using the SDI-12 address minimizes the use of ports on the

datalogger and also allows probes to be connected in a “daisy-chain” fashion

which can minimize cable runs in some applications.

After connecting the sensor to the datalogger’s power terminals, the sensor

performs a BIST (built-in self test) for approximately 80 seconds (factory

default). During this self-check, an internal check of the electronics occurs.

9

Page 14

CS475, CS476, and CS477 Radar Water Level Sensor

5. Configuration

5.1 Default Settings

In most circumstances, the default settings (see Table 5-1) should be used.

Refer to Appendix B for other setting options and SDI-12 commands.

Setting Default Setting

SDI-12 Address 0 (You only need to change this if two sensors are

connected to the same port; valid addresses are 0

through 9, A through Z, and a through z.)

Units of Measure 1 = feet

Water Conditions 1 = smooth; (typical peak to trough of wave ≤4 inches)

Power Operation

Mode

1=on (Sensor is always on until a new power operation

mode command is received.)

TABLE 5-1. Default Settings

5.2 Startup Procedure

The basic startup procedure for the radar sensor is as follows:

1. Mount, wire, and install the sensor (see Sections 3 and 4).

2. Do a Start False Echo Learn command followed by a Send Data

command. The Start False Echo Learn command is an essential function

during the setup of the sensor (see Section 5.2.1).

3. Enter the current water level using the Set Water Stage command followed

by a Send Data command (see Section 5.2.2).

4. Refer to Appendix B if you want to change defaults for the address, units

of measure, water conditions, and power operation mode.

5. Program the datalogger to measure the sensor (see Section 6).

5.2.1 Start False Echo Learn

NOTE

The settings are changed using the 25616 Adjustment/Display

Module or the terminal emulator in LoggerNet or PC400.

During normal communication, the datalogger sends the address,

together with a command, to the sensor. The sensor then replies

with a “response”.

The Start False Echo Learn command is an essential function during the

startup of the sensor. It is also used during testing if a problem is encountered.

The command allows the unit to learn about false echoes (noise) in the area.

With the False Echo Learn command, you enter the actual distance to the water

surface, as measured in meters or feet, depending on the Unit setting. The

10

Page 15

CS475, CS476, and CS477 Radar Water Level Sensor

radar sensor then emits the short microwave pulses. Any echo occurring 0.5 m

(1.6 ft) short of the distance you entered will be considered noise.

To start false echo learn, do the aXSFEL+nnn.nnn! command (where nnn.nnn

= the actual distance to the water) followed by the aD0! (Send Data) command.

Table 5-2 shows an example of the command and response.

TABLE 5-2. Example of a Start False Echo Learn Command

Initial Command Response

0XSFEL+2.500!

Where (from left to right),

0—sensor’s address;

2.500—the water surface distance.

02001<cr><If>

Where (from left to right),

0—sensor’s address;

200—the amount of time (in seconds)

that you must wait before sending the

send data command;

1—the number of values that will be

placed in the buffer.

Subsequent Command Response

0D0!

Where the first zero is the sensor

address.

This is the send data command.

0+2.500<cr><lf>

Where (from left to right),

0—sensor’s address;

2.500—the water surface distance.

5.2.2 Set Water Stage

NOTE

The settings are changed using the 25616 Adjustment/Display

Module or the terminal emulator in LoggerNet or PC400.

During normal communication, the datalogger sends the address,

together with a command, to the sensor. The sensor then replies

with a “response”.

With the Set Water Stage command, you enter the initial depth of the water,

and the sensor will automatically measure the distance between the sensor and

the water surface. The water stage setting and the initial distance measurement

are used to calculate subsequent water stage measurements. Correct stage

measurements require that the water stage setting be in the same units as the

Units of Measure setting. You can find out if the sensor is set to meters or feet

by using the aXGU! (Get Unit) command.

To set the water stage, do an aXSS+nnn.nnn! command (where nnn.nnn = the

initial water depth) followed by the aD0! (send data) command. Table 5-3

shows an example of the command and response for entering this setting.

11

Page 16

CS475, CS476, and CS477 Radar Water Level Sensor

TABLE 5-3. Example for Setting Water Stage

Initial Command Response

0XSS+7.010!

Where (from left to right),

0—sensor’s address;

7.010—the initial water depth value

used to calculate subsequent stage

measurements

Subsequent Command Command Response

0D0!

Where the first zero is the sensor

address.

This is the send data command.

00011<cr><If>

Where (from left to right),

0—sensor’s address;

001—the amount of time (in seconds)

that you must wait before sending the

send data command;

1—the number of values that will be

placed in the buffer.

0+7.010<cr><If>

Where (from left to right),

0—sensor’s address;

7.010—the initial water depth value

used to calculate subsequent stage

measurements

6. Programming

6.1 CRBasic

This section is for users who write their own datalogger programs. A

datalogger program to measure this sensor can be created using Campbell

Scientific’s Short Cut Program Builder software. You do not need to read this

section to use Short Cut.

The radar sensor’s output is measured using a standard SDI-12 instruction to

read the data from an SDI-12 sensor. If using the sensor with other SDI-12

recorders, please refer to your system’s documentation. Further details of the

SDI-12 commands can be found at: www.sdi-12.org.

Dataloggers that are programmed with CRBasic include the CR200(X) series,

CR800, CR850, CR1000, CR3000, and CR5000. These dataloggers use the

SDI12Recorder instruction to read the sensor. The SDI12Recorder instruction

should only be ran in the sequential mode.

The values returned from the SDI12Recorder( ) instruction are different

depending on the SDI12 measurement command issued. The SDI12Recorder

instruction sends the command specified by the SDI12Command parameter as

(address)SDI12Command!.

SDI12Recorder (Dest, SDIPort, SDIAddress, "SDICommand", Multiplier,

Offset)

12

Page 17

CS475, CS476, and CS477 Radar Water Level Sensor

The SDI12Recorder instruction has the following parameters:

Dest The Dest parameter is a variable in which to store the results

of the measurement. Dest must have enough elements to

store all the data that is returned by the sensor or a 'variable

out of range' error will result during the execution of the

instruction.

SDIPort The SDIPort parameter is the port to which the SDI-12

sensor is connected. A numeric value is entered:

Description

Code

1 Control Port 1

3 Control Port 3

5 Control Port 5

7 Control Port 7

SDIAddress The SDIAddress parameter is the address of the sensor that

will be affected by this instruction. Valid addresses are 0

through 9, A through Z, and a through z. Alphabetical

characters should be enclosed in quotes (e.g., "0").

SDICommand The SDICommand parameter is used to specify the

command strings that will be sent to the sensor. The

command should be enclosed in quotes. See Table 6-1

shows the specific SDI-12 Command Codes and their

returned values.

TABLE 6-1. SDI-12 Command Codes

SDI12 Measurement Command Returned Values

M! 1) Stage in meters or feet

6.1.1 Example Program

‘CR1000 Series Datalogger

‘Declare the variable for the water level measurement

Public CS475(3)

‘Rename the variable names

Alias CS475(1)=Stage

Alias CS475(2)=Distance

Alias CS475(3)=Error_Code

2) Distance in meters or feet

3) Error Code (see Section 7)

13

Page 18

CS475, CS476, and CS477 Radar Water Level Sensor

‘Define a data table for 60 minute maximum and minimums

DataTable (Hourly,True,-1)

DataInterval(0,60,Min,10)

Maximum(1,Distance,FP2,0,0)

Minimum(1,Distance,FP2,0,0)

Average(1,Distance,FP2,False)

StdDev(1,Distance,FP2,False)

Maximum(1,Stage,FP2,0,0)

Minimum(1,Stage,FP2,0,0)

Average(1,Stage,FP2,False)

StdDev(1,Stage,FPs,False)

Sample (1,Error_Code,UINT2)

EndTable

‘Read sensor every 60 seconds

BeginProg

Scan(60,sec,1,0)

‘Code for SDI-12 measurements:

SDI12Recorder(CS475,1,0,”M!”,1,0)

‘Call the data table:

CallTable(Hourly)

NextScan

EndProg

6.2 Edlog

Dataloggers that are programmed with Edlog include the CR500, CR510,

CR10(X), and CR23X. These dataloggers use Instruction 105 to read the

sensor.

Instruction 105 allows data to be collected from the radar sensor; each sensor

requires a separate Instruction 105.

Instruction 105 has the following parameters:

Parameter 1 - Address. Valid addresses are 0 through 9; 65 through 90

(decimal value for ASCII upper-case letters); and 97 through 122 (decimal

values for ASCII lower-case letters). Refer to Table xx for a list of the decimal

values for the upper- or lower-case letters.

Parameter 2 - Command. Refer to the Edlog help for the command codes used

with this instruction.

Parameter 3 - Port. Enter the datalogger port in which the datalogger is

connected.

Parameter 4 - Location. Enter the input location in which to store the results.

Parameter 5 - Multiplier

Parameter 6 - Offset

14

Page 19

CS475, CS476, and CS477 Radar Water Level Sensor

NOTE

Edlog allocates only one of the input locations needed for this

instruction. Three input locations are required for this sensor.

The additional input locations must be inserted manually using

the Input Location Editor. For information on manually inserting

input locations, refer to Manually Inserting Input Locations in

the Edlog help.

6.2.1 Example Program

Below is a portion of a CR10X program that measures the radar sensor.

NOTE

;{CR10X}

;

*Table 1 Program

01: 60 Execution Interval (seconds)

1: SDI-12 Recorder (P105)

1: 0 SDI-12 Address

2: 0 Start Measurement (aM0!)

3: 1 Port ;this is where the white wire is connected

4: 1 Loc[Data_1 ]

5: 1.0 Mult

6: 0.0 Offset

*Table 2 Program

02: 0.000 Execution Interval (seconds)

*Table 3 Subroutines

End Program

The instructions below do not store data in final storage.

Instruction 92, Instruction 77 and processing instructions such as

Instruction 70 are required to store the data permanently.

After Instruction 105 is executed, the input location called “Data_1” will hold

the measured stage, reported in feet or meters (depending on the Unit of

Measure setting). The input location called Data_2 will hold the distance

measurement, reported in feet or meters (depending on the Unit of Measure

setting). The input location called Data_3 will hold the error code; an error

code of 0 indicates that the sensor is functioning properly (see Section 7).

Note that Port 1 specifies that the SDI-12 data line is to be connected to the

Port C1.

15

Page 20

CS475, CS476, and CS477 Radar Water Level Sensor

7. Diagnostics, Repair, and Maintenance

7.1 Testing Procedure

The test procedures for the sensor require the following steps:

1. Double check all wiring connections.

2. Connect the sensor to your datalogger and apply +12V power.

3. Compare the Output Stage versus the Actual Stage using the Start

Measurement command followed by the Send Data command (see Section

7.1.1)

4. Send the Acknowledge Active command (see Section 7.1.2). This

command is used to check the presence of the sensor on the bus. Only the

address is sent back in response.

5. Send the Identification command (see Section 7.1.3).

6. Send the Start Verification command followed by the Get Data command

(see Section 7.1.4).

7. Use the Get Unit command to ensure the units are what you want (see

Section 7.1.5).

8. Use the Get Water Condition command to ensure that the water condition

fit the body of water you are monitoring (see Section 7.1.6).

9. Use the Get Power Operation mode to ensure that the power mode is what

you want (see Section 7.1.7).

10. Use the False Echo Learn command if you encounter a problem that could

be caused by noise (see Section 5.2.1).

7.1.1 Start Measurement Command

NOTE

The 25616 Adjustment/Display Module or the terminal emulator

in LoggerNet or PC400 can be used to enter this command. The

Start Measurement command is also used in CRBasic or Edlog

programming. Refer to the Edlog help for the appropriate

command code entry.

The aM! command requests measurement values from the sensor. This

command is always followed by the aD0! (Send Data) command (see Table

7-1). As a response of the Send Data command, the following information will

be returned.

• Stage--the water level as measured in meters or feet. This measurement is

16

calculated using the Water Stage Setting and the Units setting.

Page 21

CS475, CS476, and CS477 Radar Water Level Sensor

• Distance--the distance between the sensor and water surface. This value

will be reported in either meters or feet, depending on the Units setting.

• Diagnostic Values—an error code. For example, Code 0 = OK, Code 13 =

error E013 (see Section 7.2).

TABLE 7-1. Example of Start Measurement Command

Initial Command Response

0M!

Where zero is the

sensor address

Subsequent

Command

0D0!

Where the first zero is

the sensor address

00023<cr><If>

Where (from left to right),

0—sensor’s address;

002—the amount of time (in seconds) that you must

wait before sending the send data command;

3—the number of values that will be placed in the

buffer.

Response

0+100.050+25.000+0<cr><If>

Where (from left to right),

0—sensor’s address;

100.050—the stage in meters or feet;

25.000—the distance in meters or feet

0—error code

7.1.2 Check Unit Response

The Acknowledge Active command is used to check the presence of the sensor

on the bus (see Table 7-2).

Initial Command Response

a! a<cr><If!>

7.1.3 Check for Valid Data

The aI! command gets the following identification information in response to

sending al! (see Table 7-3).

• Compatibility level: Version of SDI-12 protocol version. For example, 1.3

• Manufacturer’s Name: VEGA

TABLE 7-2. Acknowledge Active Command

Only the address is sent back in response.

17

Page 22

CS475, CS476, and CS477 Radar Water Level Sensor

• Manufacturer’s Model Number: PS61 (CS475), PS62 (CS476), or PS63

(CS477)

• Three Digit Firmware Version Number.

• Eight Digit Serial Number of Sensor.

TABLE 7-3. Send Identification Command

Initial Command Response

aI! a13VEGAbbbbPS6233212345678<cr><If>

Where (from left to right),

a—sensor address

13—SDI-12 compatibility number

VEGA = manufacturer’s Name

PS62=Manufacturer’s Model Number

3.32Sensor Version Number =

Serial Number = 12345678

7.1.4 Cyclic Redundancy Check (CRC)

A cyclic redundancy check (CRC) is used to produce and send a small, fixedsize checksum of a larger block of data to the datalogger. This checksum

detects errors after transmission or storage. The CRC is computed and added

before any transmission or storage. The CRC is also authenticated by the

recipient, after the transmission, to confirm that no alterations occurred. CRCs

are very good at identifying errors caused by noise in transmission channels.

7.1.4.1 Check CRC for Valid Data

The aV! command requests three verification values from the sensor. This

command is always followed by the aD0! (Send Data) command.

The verification values that will be returned are:

• CRC check (error check)—values are 0 (OK) or 1 (failed)

• SDI-12 Radar firmware version number

• HART Sensor firmware version

18

Page 23

CS475, CS476, and CS477 Radar Water Level Sensor

Table 7-4 shows an example of checking the CRC.

TABLE 7-4. Checking CRC Example

Initial Command Response

0V!

where 0=the sensor’s address

Subsequent Command Response

0D0!

Where the first zero is the

sensor’s address.

00013<cr><If>

Where (from left to right),

0—sensor’s address;

001—the amount of time (in seconds) that

you must wait before sending the send data

command;

3—the number of values that will be

placed in the buffer.

0+0+1610000+3320000<cr><If>

Where (from left to right),

0—sensor’s address;

0—CRC check (0 = OK)

1610000—adapter version (1.61.00.00)

3320000—sensor version (3.32.00.00)

7.1.5 Get Units

Use the aXGU! command to get the current units setting of the sensor. The

units can be either feet or meters. If the units are feet, a 1 will be returned, and

if the units are meters, a 0 will be returned.

7.1.6 Get Water Conditions

The aXGWC! command returns the current setting of the water conditions.

Possible water conditions are:

1 = smooth (default)

2 = medium

3 = rough

0 = undefined (custom settings)

7.1.7 Get Power Operation Mode

The 0XGPOM! command provides the current power operation mode setting

of the sensor.

19

Page 24

CS475, CS476, and CS477 Radar Water Level Sensor

7.2 Diagnostics and Repair

The radar sensor is extremely reliable, but problems can occur during

operation. Most of these problems are caused by the following:

• Sensor

• Environmental Conditions

• Power Supply

• Signal Processing

When you encounter a problem with the radar sensor, check the error messages

from the aM!, followed by the aD0! command to help evaluate the issue.

NOTES

1. During the initial power-up or resumption of supply voltage

to the sensor, some SDI-12 commands, such as the I command,

will not yield the expected responses.

2. A typical response to the aD0! command results in a response

of 108003 where approximately 80 seconds is the required time

to complete the BIST (Built in Self Test) of the instrument.

After power-up is complete, normal SDI-12 communication

starts.

7.2.1 No Measured Value Available - Error E013

If you are unable to find a measured value, check the following:

• Sensor in boot phase

• Update the Start False Echo Learn (aXSFEL).

7.2.2 No Measured Value Available - Error E041, E042, E043

If you have a hardware error or have defective electronics, try cycling the

power to the sensor. If the sensor recovers, no further steps are required. If the

sensor does not recover, do one of the following:

• Exchange the electronics module (see Section 7.2.2.1)

• Return the equipment for repair (an RMA is required)

7.2.2.1 Exchange Electronics Module

If you do not have an electronics module onsite, order one from Campbell

Scientific.

20

Page 25

CS475, CS476, and CS477 Radar Water Level Sensor

The electronics module is replaced by doing the following steps (see Figure 71 and Table 7-5):

1. Unscrew the housing cap (cap is not shown in Figure 7-1).

2. Remove all wires that are attached or plugged into the electronics and note

their location for reassembly.

3. Loosen the two (2) screws “A” securing the electronics to the housing.

These screws are captive screws and will remain nested with the

electronics.

4. Gently remove the electronics “B” from the housing.

NOTE

NOTE

Some friction is normal when removing the electronics because a

seal is between the electronics and the lower portion of the

housing.

5. Replace the electronics with a new module.

Make sure the two (2) screws holding the electronics module in

are tight, but do not over tighten. Over tightening these screws

can strip the threads.

6. Tighten the two (2) screws “A” to secure the electronics to the housing.

7. Re-assemble all wires that were originally attached or plugged into the

electronics.

8. Tighten the housing cap.

21

Page 26

CS475, CS476, and CS477 Radar Water Level Sensor

1

2

3

3

4

5

Description

1 Red Wire

2 Housing Top View

3 Screws to Secure Electronics to Housing

4 Electronics

5 Housing Side View

22

FIGURE 7-1. Changing the Electronics

(see Table 7-5 for label descriptions)

TABLE 7-5. Description of Changing the Electronics

Labels

Page 27

7.3 Maintenance

The sensors are maintenance free under normal operation.

CS475, CS476, and CS477 Radar Water Level Sensor

23

Page 28

CS475, CS476, and CS477 Radar Water Level Sensor

24

Page 29

Appendix A. Replacing the Cable

The sensor is fitted with a cable for connection to the dataogger. The

following procedure is for replacing the original cable (see Figure A-1 and

Table A-1).

1. Unscrew the housing side compartment screw cap.

2. Loosen the cord grip on the cable entry.

3. Remove approximately 4 inches (10 cm) of the cable mantle.

4. Strip approximately 0.4 inches (1 cm) of the insulation from the end of the

individual wires.

5. Insert the cable into the sensor through the cable entry.

6. Lift the opening levers of the terminals with a screwdriver.

7. Insert the wire ends into the open terminals.

• Connect the Power Supply +12 Vdc to the terminals marked 1 (+).

• Connect the Power Supply Ground to the terminals marked 2(-).

• Connect the Data Line to the terminals marked 3 (data).

8. Press the opening lever of the terminal down. You will hear the terminal

spring closed.

9. Check that the wires are firmly connected in the terminal by lightly pulling

on them.

10. Connect the screen to the internal ground terminal and the external gr ound

terminal to potential equalization (ground).

11. Tighten the cord grip on the cable entry. The seal ring must completely

encircle the cable.

12. Place the housing side compartment screw cap on and tighten to ensure a

mechanical seal.

A-1

Page 30

Appendix A. Replacing the Cable

(A)

(C)

1

2

3

4

5

6

7

8

9

18

17

16

13

12

10

FIGURE A-1. Connecting the Instrument Housing

(see Table A-1 for description of labels)

(B)

15

14

(D)

11

TABLE A-1. Description of Instrument Housing Labels

Connections Description

(A) Side Chamber SDI-12 Wiring

(B) Top Chamber Inner Housing C on nect i o ns

(C) Typical SDI-12 Network Configuration

(D) DIS61 (Optional) (Reference V-2799S0)

1 Inner Housing Connections (Modular Plu g M ou nt ed in D u al

Chamber Housing), Plugs into Back of SDI-12 Board

2 SDI-12 Data

3 Ground Connection

4 Data Acquisition Device

5 Serial Data Line

6 12V (-) Ground

7 12V (+) Line

8 SDI-12 Sensor #1

9 SDI-12 Sensor #2

10 Ground Connection

11 To Instrument

12 Remote Display

13 Ground Connection

14 Dig ital Output (To Optional Remote Display)

15 Plug for Laptop Connection

16 Remote Display

17 Red

18 Other

A-2

Page 31

Appendix B. Entering SDI-12

Commands/Changing Settings

The SDI-12 commands are entered using the 25616 Adjustment/Display

Module or the terminal emulator in LoggerNet or PC400. These commands are

also used in CRBasic or Edlog programming (see Section 6).

During normal communication, the datalogger sends the address, together with

a command, to the sensor. The sensor then replies with a “response”.

SDI-12 command codes that are used with the radar sensor are listed in Table

B-1. The SDI-12 address and the command/response terminators are defined

as follows:

Initial Command Response

a Is the sensor address. The following ASCII Characters

are valid addresses: 0-9, AZ, a-z, *, ?. Sensors are

initially programmed at the factory with the address of 0

for use in single sensor systems. Addresses 1 to 9 and A

to Z or a to z are used for additional sensors connected

to the same port.

Where:

NOTES

a is the sensor address (0-9, A-Z, a-z, *, ?)

M is an upper-case ASCII character ! Is the last character of a command block

<cr><lf> Are carriage return (0D) hex and line feed (0A) hex characters. They

are the last two characters of a response block

• All commands/responses are upper-case printable ASCII

characters.

• Commands must be terminated with a ! character.

• Responses are terminated with <cr><lf> characters.

• The command string must be transmitted in a contiguous block

with no gaps of more than 1.66 milliseconds between characters

B-1

Page 32

Appendix B. Entering SDI-12 Commands/Changing Settings

TABLE B-1. SDI-12 Commands

Function SDI-12 Command

Address Query

Send Identification

Acknowledge Active

Change Address

Start Verification

Start Measurement

Start Measurement and

Request CRC

Send Data

Additional Measurements

Additional Measurement and

Request CRC

Start Concurrent Measurement

Start Concurrent Measurement

and Request CRC

Additional Concurrent

Measurements

Additional Concurrent

Measurements and Request

CRC

Start False Echo Learn

Set Power n Operation Mode

(ON, OFF, AUTO)

Get Power Operation Mode

(ON, OFF, AUTO)

Get Water Conditions

Set Water Conditions

Where n is the new Water

Condition

Set Water Stage

Where n is the new Water

Stage

Get Unit

Set Unit

Where n is the new unit of

measurement

Reset Sensor

Resets the sensor to its factory

settings

?!

aI!

a!

aAb!

Where a is the current address and b is the

new address

aV!

aM!

aMC!

aD0!...aD9!

aM1!...aM9!

aMC1!...aMC9!

aC!

aCC!

aC1!...aC9!

aCC1!...aCC9!

aXSFEL+n!

n=distance necessary to clear the obstruction

aXSPOM+n!

n=2 (auto), 1 (on), or 0 (off)

aXGPOM!

2=auto; 1=on; 0=off

aXGWC!

n=0 (auto), 1 (smooth) 2 (medium), or 3

(rough)

aXSWC+n!

n=0 (auto), 1 (smooth) 2 (medium), or 3

(rough)

aXSS+n!

n=floating point number that is the initial

distance between the sensor and the water

surface.

aXGU!

0=meters; 1=feet

aXSU+n!

n= 0 (meters) or 1 (feet)

aXRS!

0=reset unsuccessful; 1=reset successful

B-2

Page 33

Appendix B. Entering SDI-12 Commands/Changing Settings

B.1 Changing Settings

B.1.1 Query/Set the Address

Valid addresses are 0 to 9; A through Z; and a through z. The factory default

address is set to 0. The address can be verified by sending the sensor the

Address Query command (see Table B-2).

TABLE B-2. SDI-12 Command for Querying the Address

Initial Command Response

?!

Change the sensor’s address by sending the sensor the aAb! command, where a

is the original address and b is the new address. Table B-3 shows an examp le

of the command and response for setting the address.

a<cr><If>

Where a is the current address of the sensor.

TABLE B-3. Example of Setting Address

B.1.2 Set Units

Initial Command Response

0A1!

Where 0 is the original address

and 1 is the new address

The distance measurement can be reported in feet (default) or meters. Change

the units by first using the aXSU+n! command (where n=1 (feet) or 0 (meters))

followed by the aXGU! (Get Units) command. Table B-3 shows an example of

the command and response for changing this setting.

TABLE B-4. Example of Setting Units

Initial Command Response

0XSU+0!

Where the first zero is the sensor

address and the second zero sets the

units to meters

Subsequent Command Response

0XGU!

Where zero is the sensor address.

This is the get units command.

1<cr><If>

The new address (1) is set in response.

00011<cr><If>

Where (from left to right),

0—sensor’s address;

001—the amount of time (in seconds)

that you must wait before sending

another command;

1—the number of values that will be

placed in the buffer.

0+0<cr><If>

Where the first zero is the sensor

address and the second zero indicates

that the units are now meters

B-3

Page 34

Appendix B. Entering SDI-12 Commands/Changing Settings

B.1.3 Set Water Conditions

The Set Water Conditions command adapts the sensor to different water

conditions.

There are four different settings:

• 0 (custom setting)

• 1 (smooth--typical peak to trough of wave < 4”)

• 2 (medium--typical peak to trough of wave < 8”)

• 3 (rough--typical peak to trough of wave > 8”)

The factory default water conditions are set to 1, which is smooth. The water

condition settings should closely mimic the actual water conditions during

normal river flow.

Change this setting by first using the aXSWC+n! command (where n=0

(custom), 1 (smooth), 2 (medium), or 3 (rough)) followed by the aXG W C !

(Get Water Conditions) command. Table B-5 shows an example of the

command and response for changing this setting.

TABLE B-5. Example for Setting Water Conditions

Initial Command Response

0XSWC+2!

Where,

0—sensor’s address;

2—the new water condition setting

(2=medium)

Subsequent Command Response

0XGWC!

Where zero is the sensor address.

This is the send water conditions

command.

B.1.4 Set Power Operation Mode

The following three power operation modes are available:

00011<cr><If>

Where (from left to right),

0—sensor’s address;

001—the amount of time (in seconds)

that you must wait before sending

another command;

1—the number of values that will be

placed in the buffer.

0+2<cr><If>

Where,

0—sensor’s address;

2—the new water condition setting

(2=medium)

• 1 (ON--sensor is always on until a new set power command is received.)

• 2 (Auto--sensor is powered by an incoming request from the SDI-12 bus

B-4

and sends back a response including the information on power up time.)

Page 35

Appendix B. Entering SDI-12 Commands/Changing Settings

• 0 (OFF—this mode is typically not recommended; sensor is completely off

until a new set power command is received)

CAUTION

The OFF power mode should only be used by advanced users

who want to turn the sensor off for extended time periods. In this

mode the sensor is completely off and only responds to a new set

power command.

The factory default Power Operation Mode is 1 (ON). In this mode of

operation, the instrument is continuously making measurements and draws

approximately 13.5 mA. The AUTO Power Operation Mode puts the

instrument in quiescent mode between measurement request queries.

Change this setting by first using the aXSPOM+n! command (where n=1 (on),

2 (auto), or 0 (off)) followed by the aXGPOM! (Get Power Mode) command.

Table B-6 shows an example of the command and response for changing this

setting.

TABLE B-6. Example for Setting Power Operation Mode

Initial Command Response

0XSPOM+2!

Where,

0—sensor’s address;

2—the new power mode setting

(2=auto).

00011<cr><If>

Where (from left to right),

0—sensor’s address;

001—the amount of time (in seconds)

that you must wait before sending

another data command;

1—the number of values that will be

placed in the buffer.

Subsequent Command Response

aXGPOM!

Where zero is the sensor address.

This is the get power mode

command.

0+2<cr><If>

Where,

0—sensor’s address;

2—the new power mode setting

(2=auto).

B-5

Page 36

Appendix B. Entering SDI-12 Commands/Changing Settings

B-6

Page 37

Appendix C. FCC/IC Equipment

Authorization (USA/Canada only)

The CS475, CS476, and CS477 are FCC approved. Modifications to the

sensors must have express agreement from Campbell Scientific. Any

modifications not approved by Campbell Scientific will cause the expiration of

the operating license issued by the FCC/IC. The radar sensor is in conformity

with Part 15 of the FCC directives and fulfills the RSS-210 regulations.

Regulations for operation include:

• These devices must not cause any interfering emissions.

• These devices must accept any interfering emissions received, including

interference that may cause unwanted operating conditions.

C-1

Page 38

Page 39

Page 40

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br • suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Psg. Font 14, local 8

08013 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...