Page 1

INSTRUCTION MANUAL

CRVW3 3-Channel

Copyright © 2015

Campbell Scientific, Inc.

Vibrating-Wire Datalogger

Preliminary: 1/30/15

Page 2

Page 3

Limited Warranty

“Products manufactured by CSI are warranted by CSI to be free from defects in

materials and workmanship under normal use and service for twelve months

from the date of shipment unless otherwise specified in the corresponding

product manual. (Product manuals are available for review online at

www.campbellsci.com.) Products not manufactured by CSI, but that are resold

by CSI, are warranted only to the limits extended by the original manufacturer.

Batteries, fine-wire thermocouples, desiccant, and other consumables have no

warranty. CSI’s obligation under this warranty is limited to repairing or

replacing (at CSI’s option) defective Products, which shall be the sole and

exclusive remedy under this warranty. The Customer assumes all costs of

removing, reinstalling, and shipping defective Products to CSI. CSI will return

such Products by surface carrier prepaid within the continental United States of

America. To all other locations, CSI will return such Products best way CIP

(port of entry) per Incoterms ® 2010. This warranty shall not apply to any

Products which have been subjected to modification, misuse, neglect, improper

service, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied. The warranty for installation services

performed by CSI such as programming to customer specifications, electrical

connections to Products manufactured by CSI, and Product specific training, is

part of CSI's product warranty. CSI EXPRESSLY DISCLAIMS AND

EXCLUDES ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. CSI hereby disclaims,

to the fullest extent allowed by applicable law, any and all warranties and

conditions with respect to the Products, whether express, implied or

statutory, other than those expressly provided herein.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an application engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Precautions

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON OR AROUND

TRIPODS, TOWERS, AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES,

ANTENNAS, ETC. FAILURE TO PROPERLY AND COMPLETELY ASSEMBLE, INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS,

TOWERS, AND ATTACHMENTS, AND FAILURE TO HEED WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS

INJURY, PROPERTY DAMAGE, AND PRODUCT FAILURE. TAKE ALL REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS.

CHECK WITH YOUR ORGANIZATION'S SAFETY COORDINATOR (OR POLICY) FOR PROCEDURES AND REQUIRED PROTECTIVE

EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not exceed design

limits. Be familiar and comply with all instructions provided in product manuals. Manuals are available at www.campbellsci.com or

by telephoning (435) 227-9000 (USA). You are responsible for conformance with governing codes and regulations, including safety

regulations, and the integrity and location of structures or land to which towers, tripods, and any attachments are attached. Installation

sites should be evaluated and approved by a qualified engineer. If questions or concerns arise regarding installation, use, or

maintenance of tripods, towers, attachments, or electrical connections, consult with a licensed and qualified engineer or electrician.

General

• Prior to performing site or installation work, obtain required approvals and permits. Comply

with all governing structure-height regulations, such as those of the FAA in the USA.

• Use only qualified personnel for installation, use, and maintenance of tripods and towers, and

any attachments to tripods and towers. The use of licensed and qualified contractors is

highly recommended.

• Read all applicable instructions carefully and understand procedures thoroughly before

beginning work.

• Wear a hardhat and eye protection, and take other appropriate safety precautions while

working on or around tripods and towers.

• Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take

reasonable precautions to secure tripod and tower sites from trespassers.

• Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

• You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are

installing, constructing, using, or maintaining, or a tool, stake, or anchor, come in contact

with overhead or underground utility lines.

• Maintain a distance of at least one-and-one-half times structure height, 20 feet, or the

distance required by applicable law, whichever is greater, between overhead utility lines and

the structure (tripod, tower, attachments, or tools).

• Prior to performing site or installation work, inform all utility companies and have all

underground utilities marked.

• Comply with all electrical codes. Electrical equipment and related grounding devices should

be installed by a licensed and qualified electrician.

Elevated Work and Weather

• Exercise extreme caution when performing elevated work.

• Use appropriate equipment and safety practices.

• During installation and maintenance, keep tower and tripod sites clear of un-trained or non-

essential personnel. Take precautions to prevent elevated tools and objects from dropping.

• Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

• Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks,

frayed cables, loose cable clamps, cable tightness, etc. and take necessary corrective actions.

• Periodically (at least yearly) check electrical ground connections.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS,

THE CUSTOMER ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER INSTALLATION, USE, OR

MAINTENANCE OF TRIPODS, TOWERS, OR ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS,

ENCLOSURES, ANTENNAS, ETC.

Page 6

Page 7

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction ................................................................. 1

2. Cautionary Statements ............................................... 2

3. Initial Inspection ......................................................... 3

4. Quickstart .................................................................... 4

5. Overview ...................................................................... 5

5.1 Measurement Theory ........................................................................... 5

5.2 About This Manual .............................................................................. 7

6. Specifications ............................................................. 8

7. Installation ................................................................... 9

7.1 Individual Devices and Radio Considerations ................................... 10

7.2 Software Requirements ...................................................................... 10

8. Installation of Individual CRVW3 Stations .............. 10

8.1 Lab Connection and Configuration .................................................... 11

8.1.1 Preparing the Windows Computer (PC) ..................................... 11

8.1.1.1 Device Configuration Utility (DevConfig) ....................... 11

8.1.1.2 Install the CRVW3 USB Driver ....................................... 12

8.1.1.3 Network Planner ............................................................... 12

8.1.2 Wiring Temporary Sensors to the CRVW3 ................................ 13

8.1.3 Providing Temporary Power to the CRVW3 .............................. 15

8.1.4 Connecting to the CRVW3 ......................................................... 15

8.1.5 Configuring the CRVW3 ............................................................ 18

8.1.5.1 Key Settings ..................................................................... 18

8.1.5.2 Managing Changes to Settings ......................................... 21

8.1.6 Testing the Measurement Operation of the CRVW3 .................. 22

8.1.7 Validating Radio Connectivity in the Lab .................................. 24

8.1.7.1 Configuring the RF450 Radio .......................................... 25

8.1.7.2 Configuring the CRVW3-RF451 ..................................... 25

8.1.7.3 Using DevConfig to Connect to the CRVW3-RF451

Over the Radio .............................................................. 26

8.2 Field Deployment of the CRVW3 ...................................................... 26

8.2.1 Connecting Sensors to the CRVW3 ............................................ 27

8.2.2 Providing Power to the CRVW3 ................................................. 29

8.2.2.1 Alkaline D-Cell Option (–ALK) ...................................... 29

8.2.2.2 Rechargeable Battery Option (–RC) ................................ 31

8.2.2.3 Grid Power ....................................................................... 32

8.2.3 Humidity Monitoring and Control .............................................. 33

8.2.4 Mounting the CRVW3 Enclosure ............................................... 33

i

Page 8

Table of Contents

8.2.5 Installing the CRVW3 Antenna ................................................. 34

8.2.6 Connecting the CRVW3 Electrical System to Earth Ground ..... 35

8.2.7 Validating and Fine-Tuning CRVW3 Settings ........................... 35

8.2.8 Confirming CRVW3 Sensor Measurement Operation ............... 36

8.2.8.1 LED Operation ................................................................ 36

8.2.8.2 Validation with DevConfig .............................................. 38

8.2.9 Validating CRVW3 Radio Operation ......................................... 40

8.2.10 Sealing the CRVW3 Enclosure .................................................. 40

8.3 On-site Manual Data Collection ........................................................ 41

9. Radio Networks ......................................................... 41

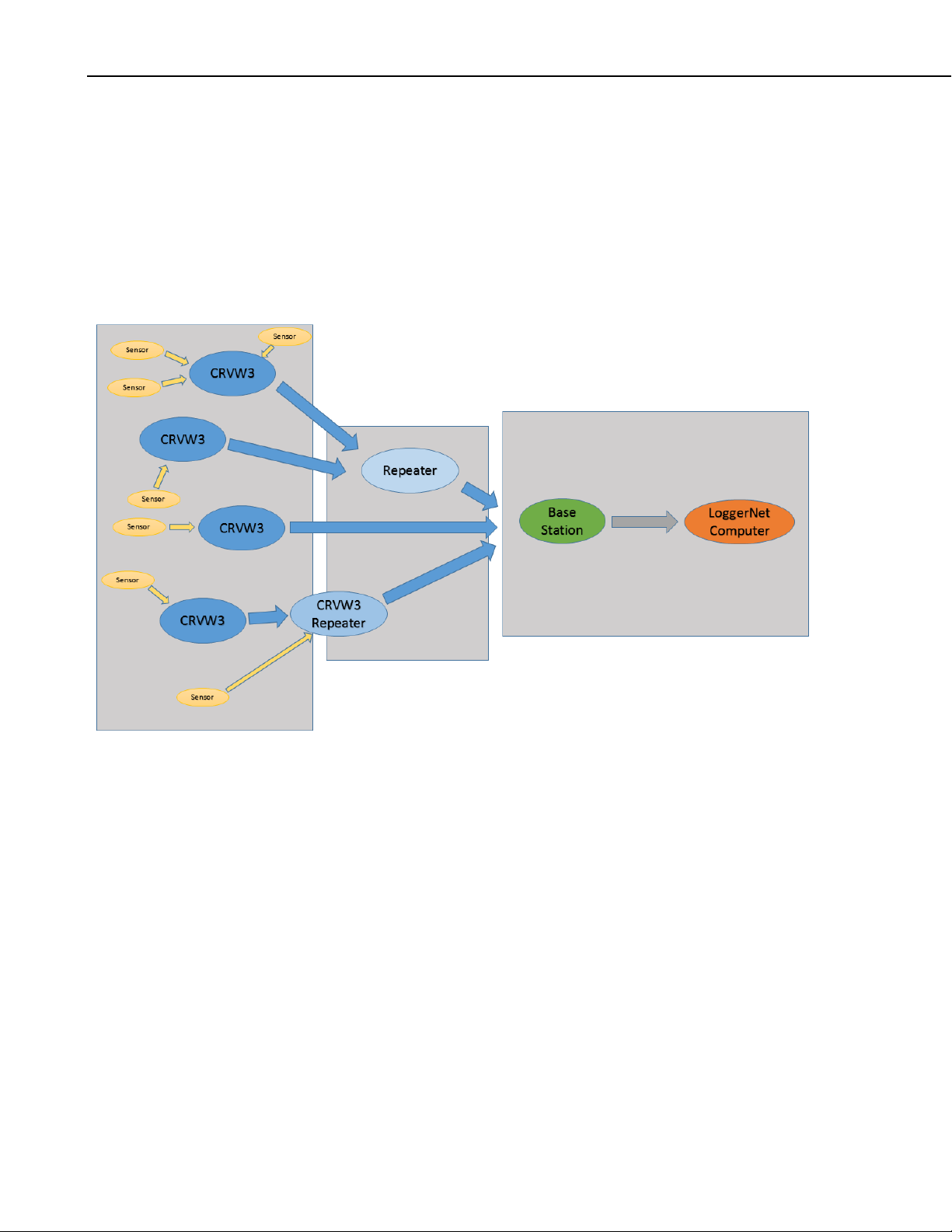

9.1 Simple Radio Network Definition ..................................................... 42

9.2 Simple Network Installation Overview ............................................. 43

9.3 CRVW3-RF451 Simple Network Installation ................................... 43

9.3.1 Deploying CRVW3 End-node Stations, Confirming Radio

Connectivity ............................................................................ 44

9.3.2 Base Station Installation and Validation .................................... 44

9.3.3 Configuring LoggerNet for Connectivity and Scheduled

Collection ................................................................................ 45

10. Complex (Large) Radio Networks ............................ 46

10.1 Radio Network Station Types ........................................................... 46

10.1.1 LoggerNet Computer Station ..................................................... 46

10.1.2 Base Radio Station ..................................................................... 47

10.1.3 CRVW3 End-node Station ......................................................... 48

10.1.4 CRVW3 Repeater Station .......................................................... 48

10.1.5 Dedicated Repeater Station ........................................................ 48

10.1.6 Aggregating Datalogger Station ................................................. 49

10.2 Planning the Radio Network ............................................................. 49

10.2.1 Sensor Planning .......................................................................... 51

10.2.2 Planning for CRVW3 End-node Stations ................................... 52

10.2.3 Repeater Planning ...................................................................... 53

10.2.4 LoggerNet Station Planning ....................................................... 53

10.2.5 Planning the Base Station ........................................................... 54

10.2.6 Planning RF451 Radio Networks ............................................... 55

10.2.6.1 Base Station Design for RF451 Radio Networks ............ 56

10.2.7 Plan Validation and Hardware Procurement .............................. 57

10.2.7.1 Pre-procurement Field Visits ........................................... 57

10.2.7.2 Plan Validation with Others ............................................. 58

10.2.7.3 Hardware Procurement .................................................... 58

10.3 Deployment Strategy ......................................................................... 58

10.3.1 Radio Network Lab Validation .................................................. 58

10.3.2 Field Deployment Considerations .............................................. 59

10.4 Deployment of CRVW3 Radio Stations ............................................ 60

10.4.1 CRVW3-RF451 Deployment ..................................................... 60

10.5 Base Station Deployment .................................................................. 61

10.5.1 Base Station on the RF451 Network .......................................... 62

10.6 Repeater Station Deployment ............................................................ 63

10.6.1 Repeaters on RF451 Networks ................................................... 63

10.7 LoggerNet Configuration .................................................................. 64

10.7.1 Physical Connection to the Base Station .................................... 64

10.7.2 Configuring the Network Map of LoggerNet ............................. 64

10.7.3 Connecting to CRVW3 Stations ................................................ 69

10.7.4 Setting up Automatic Data Collection ........................................ 71

ii

Page 9

11. Operation of CRVW3 Networks ............................... 71

11.1 Monitoring Automatic Data Collection .............................................. 72

11.2 Manual Data Collection ..................................................................... 74

11.2.1 Manual Data Collection From the LoggerNet Station ................ 74

11.2.2 Manual Data Collection at the CRVW3 Site .............................. 75

11.3 Station Health Monitoring ................................................................. 76

11.4 Processing Collected Data ................................................................. 77

11.4.1 Monitoring Data Influx Using Real-time Displays ..................... 77

11.4.2 Analyzing and Publishing Historical Data .................................. 77

12. Maintenance of CRVW3 Networks ........................... 79

12.1 CRVW3 Maintenance with LoggerNet .............................................. 79

12.1.1 Battery Monitoring ..................................................................... 79

12.1.2 Sensor Spectrum Checks ............................................................. 80

12.1.3 Adjusting Device Settings ........................................................... 82

12.2 CRVW3 On-site Maintenance Visits ................................................. 83

13. Troubleshooting CRVW3 Networks ........................ 84

13.1 Troubleshooting Problems Remotely Using LoggerNet .................... 85

13.2 Troubleshooting Problems by Visiting the CRVW3 Site ................... 85

Appendices

Updating CRVW3 Firmware ................................... A-1

A.

B. Terminal Mode from Connect Screen or

DevConfig .............................................................. B-1

C. Aggregating Dataloggers ....................................... C-1

C.1 Aggregator Station Configuration .................................................... C-1

C.2 Programming the Aggregator ........................................................... C-2

D. GetDataRecord Sample Program .......................... D-1

E. Engineering Output and Calibration ..................... E-1

E.1 Engineering Output .......................................................................... E-1

E.2 Calibration of Sensors ...................................................................... E-2

Figures

1-1. The CRVW3 3-Channel Vibrating-Wire Datalogger ........................... 1

3-1. Contents of the enclosure manufacturer parts bag ............................... 3

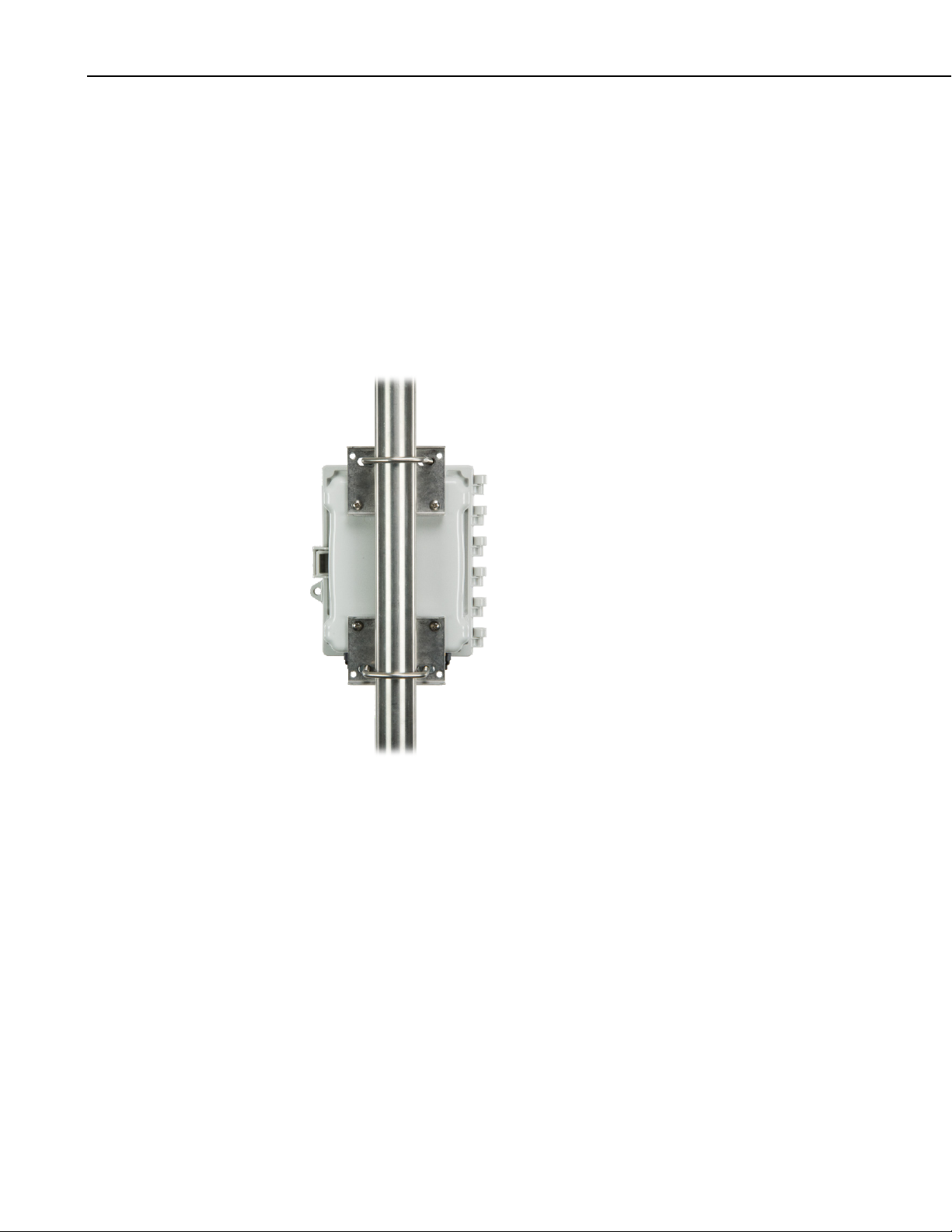

3-2. CRVW3 with the –UM mounting option ............................................. 4

5-1. Basic Parts of the CRVW3 ................................................................... 5

5-2. CRVW3 Cable Connection and Entry Points ...................................... 5

5-3. Internal View of a Typical Vibrating-Wire Piezometer Sensor ........... 6

5-4. Time-Series and Frequency Response of a Vibrating-Wire Sensor ..... 7

8-1. Wiring Panel of the CRVW3 ............................................................. 14

8-2. Typical Vibrating-Wire Sensor Lead Colors and Connections .......... 14

Page 10

Table of Contents

8-3. Power Source Connection to the CRVW3 Charge Terminals ........... 15

8-4. CRVW3 USB Connection Location .................................................. 16

8-5. Typical Vibrating-Wire Sensor Lead Colors and Connections ......... 28

8-6. CRVW3 Cable Connection and Entry Points .................................... 28

8-7. Wiring Panel of the CRVW3 ............................................................. 29

8-8. –ALK Battery Pack Connector Cable and CRVW3 Battery

Connection ..................................................................................... 30

8-9. Bumpers Used to Secure the -ALK Battery Pack .............................. 30

8-10. Power Source Connection to the CRVW3 Charge Terminals ........... 32

8-11. –RC Battery Connector Cable and CRVW3 Battery Connection ..... 32

8-12. CRVW3 with the –UM mounting option .......................................... 33

8-13. Proper Field-Installed Orientation of the CRVW3 ............................ 34

8-14. Properly Weather-proofed Antenna Cable Connection with Surge

Protection ....................................................................................... 35

8-15. CRVW3 Ground Lug Location ......................................................... 35

8-16. LED Viewing Locations on the CRVW3 .......................................... 37

8-17. CRVW3 Latch Closure and Lock Location ...................................... 41

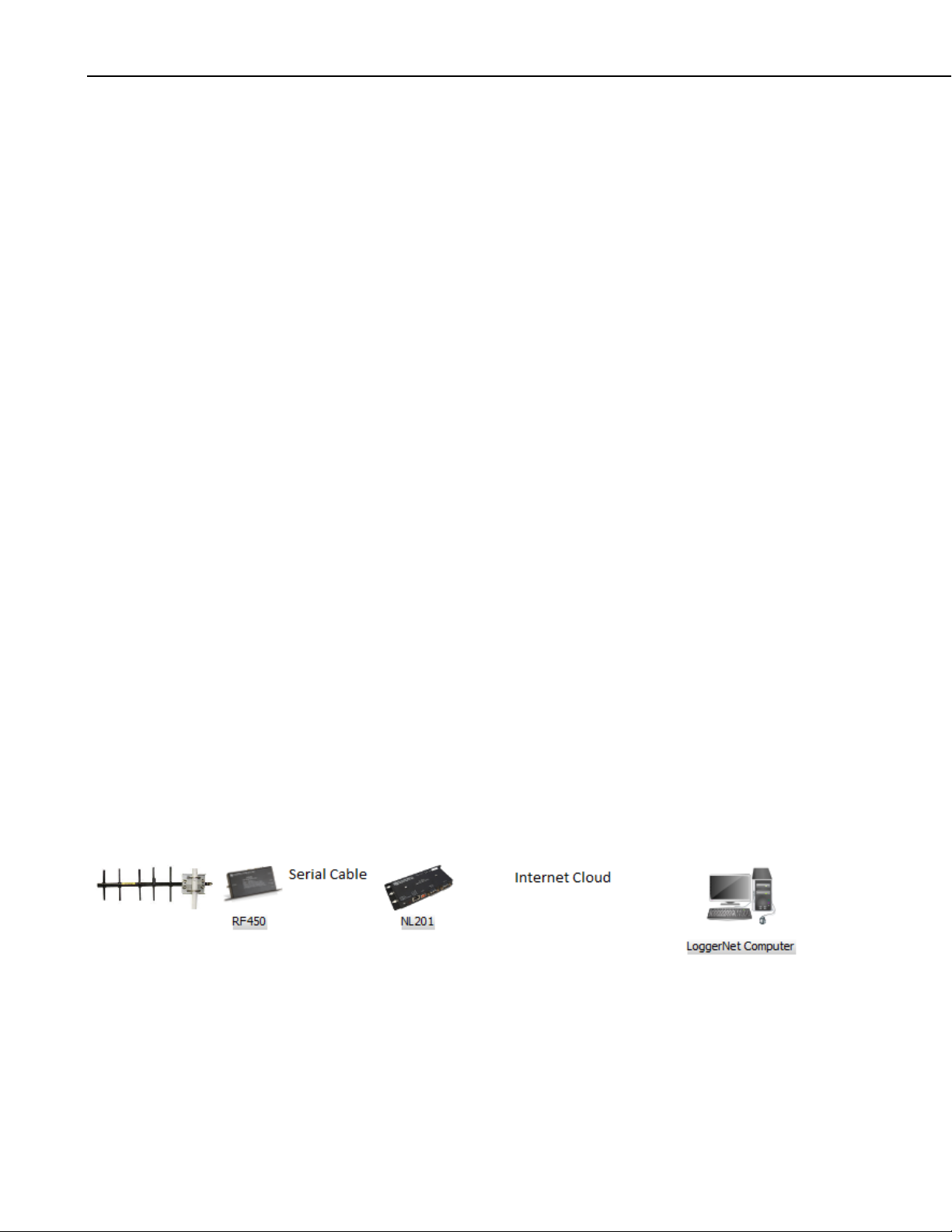

9-1. CRVW3 Radio Network ................................................................... 42

9-2. RF451 Network Base Station Configured for Remote LoggerNet

Connectivity ................................................................................... 44

10-1. CRVW3 Radio Network and Base Station Operation ....................... 47

10-2. CRVW3 Collected Data Flow ........................................................... 49

10-3. Sensor Side and LoggerNet Side of a CRVW3 Network .................. 50

10-4. Each Sensor Connects to a CRVW3 ................................................. 52

Table

8-1. CRVW3 LED Behavior..................................................................... 37

iv

Page 11

CRVW3 3-Channel Vibrating-Wire

Datalogger

1. Introduction

The CRVW3 is a datalogger (Campbell recorder) that measures and stores

readings from up to three vibrating-wire sensors. A temperature measurement

(usually obtained from a thermistor built-in to the sensor) is also available for

each of these three channels. Standard, single-coil-circuit vibrating-wire

sensors are supported (purchased separately). Common vibrating-wire

measurements include water depth (pressure or column height), strain of

structural members, loading, crack/gap extension, earth pressure, and tilt.

FIGURE 1-1. The CRVW3 3-Channel Vibrating-Wire Datalogger

The use of patented VSPECT™ technology helps to eliminate unwanted noise

interference and results in high-resolution output. Measurements may be taken

as often as once every 1 to 3 seconds (1 second per active channel) and as

infrequently as once per day. Measurement history is preserved on the device

enabling data collection at reasonable intervals, and protecting against data loss

due to periods of intermittent radio connectivity.

Each CRVW3 is packaged inside a protective enclosure. On-board power

support for a rechargeable battery (including a built-in charge regulator) or

non-rechargeable D-cells is included. Built-in radio options, including repeater

capability, are available to enable the creation of wireless networks.

1

Page 12

CRVW3 3-Channel Vibrating-Wire Datalogger

Configuration of devices and automated data collection can be performed

remotely using the wireless options.

CRVW3 operation is controlled by software-configured settings made on the

device. No CRBasic programming is required. Frequency and temperature

measurements are obtained at the specified measurement interval. Optional

engineering output can be calculated using advanced settings.

Additional information about the CRVW3 (pn 30243) can be found on the

Campbell Scientific website:

www.campbellsci.com/crvw3

Before using the CRVW3, please refer to the following:

• Quick Deploy Guide

o a folded card stored within the CRVW3 that contains summarized

deployment and use instructions

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

2. Cautionary Statements

• READ AND UNDERSTAND the Precautions section at the front of this

manual.

• DANGER: As with all electrical devices, ensure proper grounding using

the ground lug of the device. Observe polarity (+/–) markings on the

charge connector, and do not apply voltages over 28 V.

• Carefully install any solar panels, other power supply devices, antennae,

and cabling according to manufacturer recommendations. Use surge

suppression where possible. Consider the use of the Basic Grounding Kit

(pn 31163), the Bulkhead Surge Suppressor Kit (pn 31312), and Selfvulcanizing Shrink Tape (pn 21212).

2

• WARNING: Close the lid of the enclosure and secure the latch when the

CRVW3 is deployed. This will help avoid unwanted entry of water, and

provide isolation from other environmental factors. IP66 protection is

available when using the four screws provided by the enclosure

manufacturer to seal the lid properly. Wipe off any water from the outside

of the enclosure before opening the enclosure lid.

Page 13

When using multiple CRVW3 devices in an RF451 radio network

NOTE

NOTE

or in an RF407 radio network, it may be necessary to deploy an

RF450, RF451, or RF407 radio+modem device (in addition to

those built-in to the CRVW3) to operate as the base radio station

in the network. Please consult with your local Campbell Scientific

support representative regarding the use of radio options. Also

refer to Section

(Large) Radio Networks, for more information relating to the

design and configuration of radio networks.

3. Initial Inspection

Ensure that the following standard items were included with your shipment of

the CRVW3:

• USB 2.0 Cable Type A Male to Micro B Male (pn 27555)

• Flat-bladed Screwdriver (pn 1113)

• Quick Deploy Guide (folded card, pn 31174)

• Desiccant Bag (pn 4905)

• Humidity Indicator Card w/ Mounting Tape (pn 28878)

• Original Enclosure Manufacturer Parts bag including (4) Lid-securing

CRVW3 3-Channel Vibrating-Wire Datalogger

9, Radio Networks, and Section 10, Complex

Screws

Most of these items are shipped from the factory inside a bag

stored within the enclosure.

The contents of the enclosure manufacturer parts bag are shown in FIGURE

3-1.

FIGURE 3-1. Contents of the enclosure manufacturer parts bag

3

Page 14

CRVW3 3-Channel Vibrating-Wire Datalogger

Examine the outside label on the device to ensure that the correct

communication option was provided (–RF451 radio, –RF407 radio, No radio).

Confirm that the appropriate battery option is installed within the CRVW3

enclosure. For the –ALK option, this is an 8-cell battery pack along with 8

D-cell alkaline batteries. For the –RC option, this is a single rechargeable leadacid 7 Ahr battery. If you received a CRVW3 with the –RC option, you should

begin charging your rechargeable battery as soon as possible after receiving

your shipment. See Section 8.1.3, Providing Temporary Power to the CRVW3,

for details about how this is done.

If the –UM mounting option was selected, ensure that the corresponding

mounting hardware was included with your shipment.

4. Quickstart

4

FIGURE 3-2. CRVW3 with the –UM mounting option

Find the packing list that came with your shipment and ensure that all other

related accessories included in your order are present and in good condition.

Typical accessories include solar panels, other power equipment, antennae,

cabling, grounding kits, and related items. Thoroughly check the packaging

material for items that may be trapped inside. In case of damage, file claims

with the shipping company. Contact Campbell Scientific to facilitate repair or

replacement of damaged items.

For Quickstart information, refer to the Quick Deploy Guide included with

each CRVW3 as a folded card inside the enclosure (pn 31174). You can also

view and download the Quick Deploy Guide from the Campbell Scientific

website:

s.campbellsci.com/documents/us/manuals/crvw3-quick-deploy-guide.pdf

Page 15

5. Overview

CRVW3 3-Channel Vibrating-Wire Datalogger

The CRVW3 is a rugged, field-ready datalogger for measuring vibrating-wire

sensors. It provides built-in power options, including a charge regulator that

enables direct solar panel connections. Built-in radio options are available to

enable wireless communications, and the system comes inside an

environmentally protective enclosure as a standard option. The basic parts of

the CRVW3 are shown in FIGURE 5-1.

FIGURE 5-1. Basic Parts of the CRVW3

5.1 Measurement Theory

The CRVW3 uses Campbell Scientific VSPECT™ technology (U.S. Patent

No. 7,779,690 ) to measure standard, single-coil-circuit vibrating-wire sensors.

FIGURE 5-2. CRVW3 Cable Connection and Entry Points

5

Page 16

CRVW3 3-Channel Vibrating-Wire Datalogger

A vibrating-wire sensor is designed by its manufacturer so that its output

corresponds to changes of the phenomenon in the environment being

measured. This is done by converting environmental changes into changes of

the tension on a suspended metal wire which is located inside the sensor. The

wire’s natural frequency changes as the tension changes, therefore a change in

frequency may be detected as changes in the measured phenomenon. A

magnetic coil circuit is placed near the suspended wire and senses the motion

of the wire by picking up the changes in the magnetic field caused by wire

vibrations.

To measure a vibrating-wire sensor, three main steps are taken by the

measurement system: 1) Electrical energy is inserted into the coil circuit,

creating a changing magnetic field that excites (plucks, or inserts energy into)

the wire. 2) The excitation terminates so that the wire is left to vibrate at its

characteristic resonant frequency (natural frequency). The coil circuit is used

to electrically capture the motion of the wire’s vibrations during this stage.

3) The measurement system processes the time-series waveform captured from

the coil to assess the frequency of the wire’s vibration. The basic output of a

vibrating-wire sensor is frequency in Hz. Conversion from frequency to

engineering units is possible based on a knowledge of how the sensor operates,

and that is provided by the sensor manufacturer.

FIGURE 5-3. Internal View of a Typical Vibrating-Wire Piezometer

Sensor

The CRVW3 excites vibrating-wire sensors with a swept excitation

(frequency-rich) waveform. The lowest frequency and highest frequency used

in that excitation are customizable by the user. This frequency range represents

all expected natural frequencies that the sensor should produce, including those

expected when it measures the most extreme conditions in the environment

(highest and lowest frequencies). By exciting the sensor in only a certain

range, interference from unwanted signals on the wire is reduced. The level of

the excitation (12 V, 5 V, 2 V) can also be controlled by the user.

The patented VSPECT™ process uses frequency-domain analysis (including

the use of Fourier transforms), interpolation, and digital signal processing

(DSP) to identify and eliminate unwanted noise from the measurement, and

produces a very high resolution frequency output.

6

Page 17

CRVW3 3-Channel Vibrating-Wire Datalogger

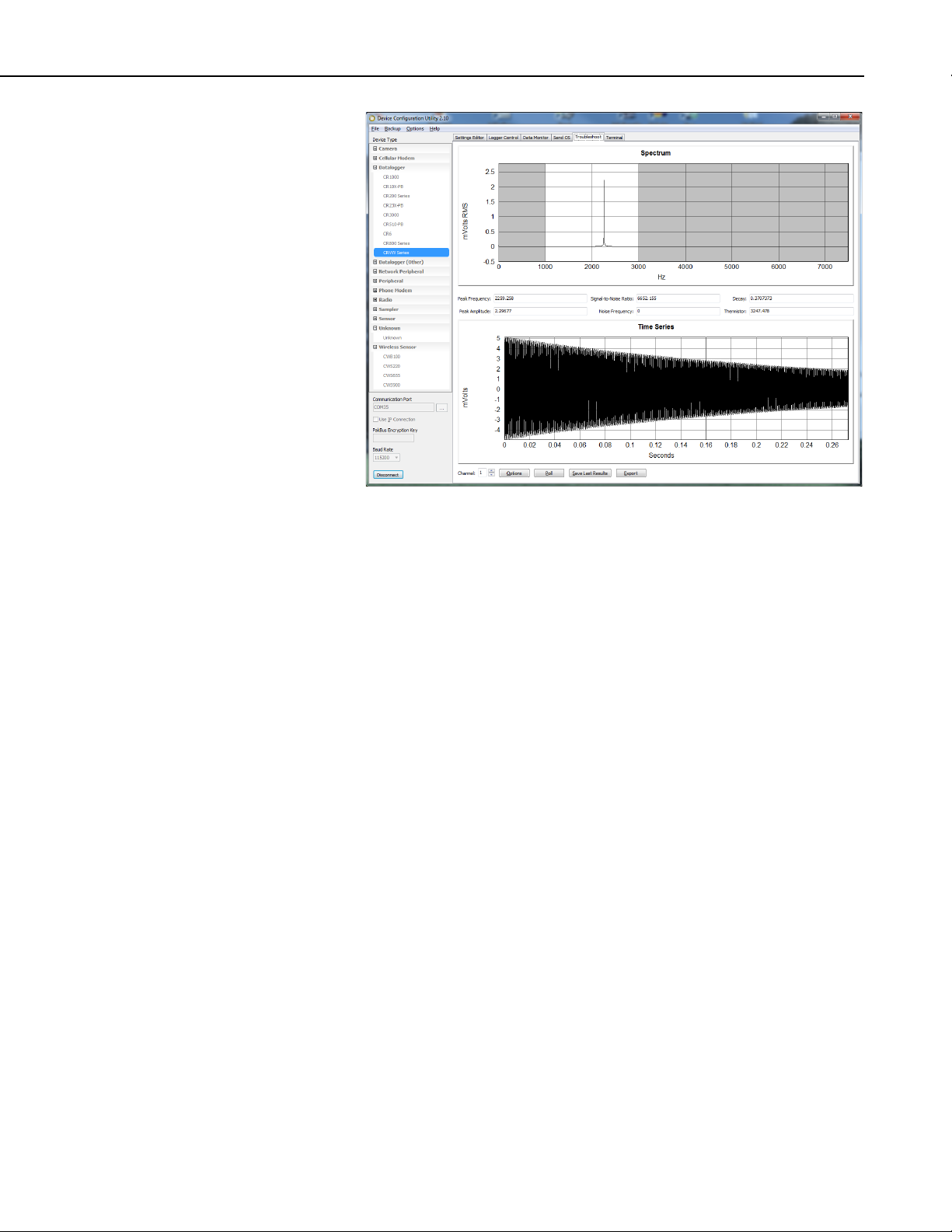

FIGURE 5-4. Time-Series and Frequency Response of a Vibrating-

Wire Sensor

Since changes in temperature can impact the density of the vibrating-wire

element of the sensor, a slight change in frequency is expected on the sensor as

temperature changes occur. To compensate for this effect, many vibrating-wire

sensors contain a built-in thermistor or other resistive temperature device. The

resistance of the device is measured and converted to temperature. The

temperature at the time of measurement is recorded and can then be used

together with the frequency reading to calculate the value of the output

phenomenon in engineering units (i.e., measured value given with its

dimensions or units of measure).

5.2 About This Manual

Please study the remaining sections of this manual to obtain maximum benefit

from your CRVW3 dataloggers.

Section 6, Specifications, contains key specifications relevant to the

measurement and use of the CRVW3.

Section 7, Installation, introduces the main installation issues applicable to the

CRVW3.

Section 8, Installation of Individual CRVW3 Stations, focuses on the

installation of individual CRVW3 stations.

7

Page 18

CRVW3 3-Channel Vibrating-Wire Datalogger

Section 9, Radio Networks, and Section 10, Complex (Large) Radio Networks,

discuss the planning and implementation of networks containing multiple

CRVW3 stations that communicate with each other using radio telemetry.

Section 11, Operation of CRVW3 Networks, Section 12, Maintenance of

CRVW3 Networks, and Section 13, Troubleshooting CRVW3 Networks, provide

guidance for the operation, maintenance, and troubleshooting required when

administering CRVW3 measurement systems.

Appendices are also provided containing supplemental information.

6. Specifications

Datalogger

Processor: ST ARM CORTEX-M4 (32-bit with

Data Storage: 16 MB serial flash, up to 420,000 records

Clock Accuracy: ±3 minutes per year

hardware FPU, running at 144 MHz)

(single channel), up to 160,000 records (3

channels)

Measurement

Interval Range: 1 s to 1 day

USB Micro B: Direct connect to PC (supplies power for

configuration and data collection), 2.0 full

speed, 12 Mbps

Configuration: Software configurable, no programming

required

Measurements

Channel Count: 3 vibrating wire (VW) and 3 thermistor/RTD

(temperature) measurements

Measurement Speed: 1 s per sensor (VW and temperature)

Vibrating Wire

Measurement

Excitation Options: 2 V (±1 V), 5 V (±2.5 V), 12 V (±6 V)

Measurement

(Frequency) Resolution: 0.001 Hz RMS (–40 to 70 °C)

Time-series

Basic Resolution: 24-bit ADC

Measurement Accuracy: ±0.005% of reading

8

Measurement Method: VSPECT (Spectral Analysis), U.S. Patent

No. 7,779,690, includes diagnostic data

Page 19

CRVW3 3-Channel Vibrating-Wire Datalogger

Temperature (Resistance)*

Measurement Method: Half-bridge ratiometric, 24-bit ADC, built-in

completion resistor 4.99 kΩ 0.1%

Resolution: 0.01 Ω RMS (–40 to +70 °C)

Accuracy: ±0.15% of reading (–40 to +70 °C)

Wireless Communications

–RF451 Option

Internal Radio Description: 1 W, 902 to 928 MHz license-free band,

frequency hopping spread spectrum radio

FCC ID: KNYAMM0300AT

IC: 2329B-FGR2

Radio Repeater: Devices with the –RF451 option can be

setup as a radio repeater

Power

Charge Terminal: 16 to 28 Vdc from solar panel or dc power

converter

7. Installation

Battery Options: Rechargeable 7 Ah or 8 D-cell alkaline

Physical

Weight: 4.2 kg (9.2 lb) with rechargeable battery, 3.0

kg (6.6 lb) with alkaline batteries

Operating

Temperature Range: –40 to 70 °C

Compliance: CE, RoHS

Enclosure Dimensions: 24.1 x 22.9 x 14.0 cm (9.5 x 9.0 x 5.5 in)

Weather-proof

Enclosure Rating: NEMA 4X (IP66) with proper use of cable

entry points

Enclosure Mounting: Stainless steel universal mount for pole/ wall

mount (optional) or plastic mounting tabs

(included)

* Thermistor or RTD resistance can be scaled to Temperature (°C) per manufacturer

specifications. The resulting temperature can be used as a correction factor for the

sensor’s output.

For summarized installation information, refer to the Quick Deploy Guide (pn

31174) included with each CRVW3 as a folded card inside the enclosure. You

can also view and download the Quick Deploy Guide from the Campbell

Scientific website:

s.campbellsci.com/documents/us/manuals/crvw3-quick-deploy-guide.pdf

9

Page 20

CRVW3 3-Channel Vibrating-Wire Datalogger

Campbell Scientific Field-Deployment Philosophy

Pre-configure and test your measurement system before taking it to the field.

Issues that are unresolved before placing instrumentation in the field will

usually be more difficult to resolve once in-field. Campbell Scientific

equipment and software are among the best available, but the integration

process can be demanding and involves trial and error; contingencies should be

developed to address possible problems. Perform the bulk of the integration

work in a comfortable and dry location that has a communications link with

Campbell Scientific during regular business hours. If you are experienced with

field deployments, set aside at least a full day for pre-configuration work.

Otherwise, set aside three to seven days for system development before

traveling to the field.

7.1 Individual Devices and Radio Considerations

Each CRVW3 device can be deployed to the field as an independent data

collection station. Additionally, radio communication options are provided to

allow CRVW3 devices to communicate with each other, with repeater stations,

and with a base radio station. This enables CRVW3 devices to interact from

the field with LoggerNet software running in the lab or office, or other IThosted location. Automatic data collection (i.e., collection without technician

field visits) is one of the most useful benefits provided by a radio network

configuration of multiple CRVW3 devices.

When installing CRVW3 devices, consider the deployment issues for both

individual stations (Section 8, Installation of Individual CRVW3 Stations) and

also the planning and configuration of radio communications within a multiCRVW3 network (Section 9, Radio Networks, and Section 10, Complex

(Large) Radio Networks).

7.2 Software Requirements

To use the computer software described in this manual, you must have a

version that includes CRVW3 support. These software versions are:

• LoggerNet version 4.3 or higher (MS-Windows or Linux platforms)

• PC400 version 4.3 or higher (MS-Windows only)

• PC200W version 4.3 or higher (MS-Windows only)

• DevConfig version 2.10 or higher (MS-Windows only)

You should periodically check the Campbell Scientific website for updates to

these software packages, and also for updates to the firmware/OS of the

CRVW3:

www.campbellsci.com/downloads

8. Installation of Individual CRVW3 Stations

The installation of an individual CRVW3 station includes two critical steps:

10

1. Connecting with and configuring the CRVW3 device in the lab or

office (Section 8.1, Lab Connection and Configuration)

Page 21

CRVW3 3-Channel Vibrating-Wire Datalogger

NOTE

2. Deployment of the CRVW3 device to a permanent location in the

field (Section 8.2, Field Deployment of the CRVW3)

Both steps are usually performed on each device. In unusual situations, or

when installation personnel have sufficient deployment experience, it is

conceivable that step 1 could be omitted. When that step is bypassed, some of

its elements will still need to be performed at the field location. If a station is

deployed as an independent collection station (i.e., with no radio links), its data

can be manually collected using a USB cable connection from the CRVW3 to a

laptop or similar computer.

When deploying a system of multiple CRVW3 devices using

radio-based communication options (such as the CRVW3RF451), also refer to Section

9, Radio Networks.

8.1 Lab Connection and Configuration

When using a CRVW3 device in the lab or office, there are several key tasks to

perform. A Microsoft Windows-based laptop or desktop computer (Personal

Computer, i.e., PC) should be available. Electrical outlets or other power

options, as well as vibrating-wire sensors for testing the device should also be

on-hand. During this process, the proper software and drivers will be installed

on the PC, the device will be wired to one or more sensors, and then it will be

powered. A connection between the device and the PC will be established, the

device will be configured, and the device’s measurement operation will be

validated.

8.1.1 Preparing the Windows Computer (PC)

For CRVW3 lab operations, you will need a desktop or laptop computer

running Microsoft Windows. This document also refers to that computer as a

PC (Personal Computer). When installing software, you should have

administrative privileges on the account used to log in to the computer at

startup. Consider the benefits of configuring and using a laptop in the lab —

once it is configured, it can then be taken into the field to facilitate efficient

deployment of CRVW3 devices (see Section 8.2, Field Deployment of the

CRVW3).

8.1.1.1 Device Configuration Utility (DevConfig)

You should first install the Device Configuration Utility (a.k.a., DevConfig).

The CRVW3 requires version 2.10 or later of this software. If you have

installed LoggerNet 4.3, PC400 4.3, or PC200W 4.3 on your computer, then

this software is already available. This software is also available as a free

download from the Campbell scientific website

(www.campbellsci.com/downloads, www.campbellsci.com/19_1_9999_83).

Check the version of any previously installed DevConfig software to ensure it

is version 2.10 or later. If it is an earlier version, it will need to be upgraded

using a newer installation program. The installation program can also be found

on the Resource DVD which is included with most hardware orders shipped

from Campbell Scientific.

11

Page 22

CRVW3 3-Channel Vibrating-Wire Datalogger

NOTE

If you upgrade your LoggerNet, PC400, or PC200W software

from an earlier version to version 4.3, then version 2.10 of

DevConfig should automatically be installed during that process.

8.1.1.2 Install the CRVW3 USB Driver

In order to make a wired communications connection between the CRVW3 and

the PC, it is necessary to use a USB cable. This requires a driver to be installed

on Windows in order to operate correctly.

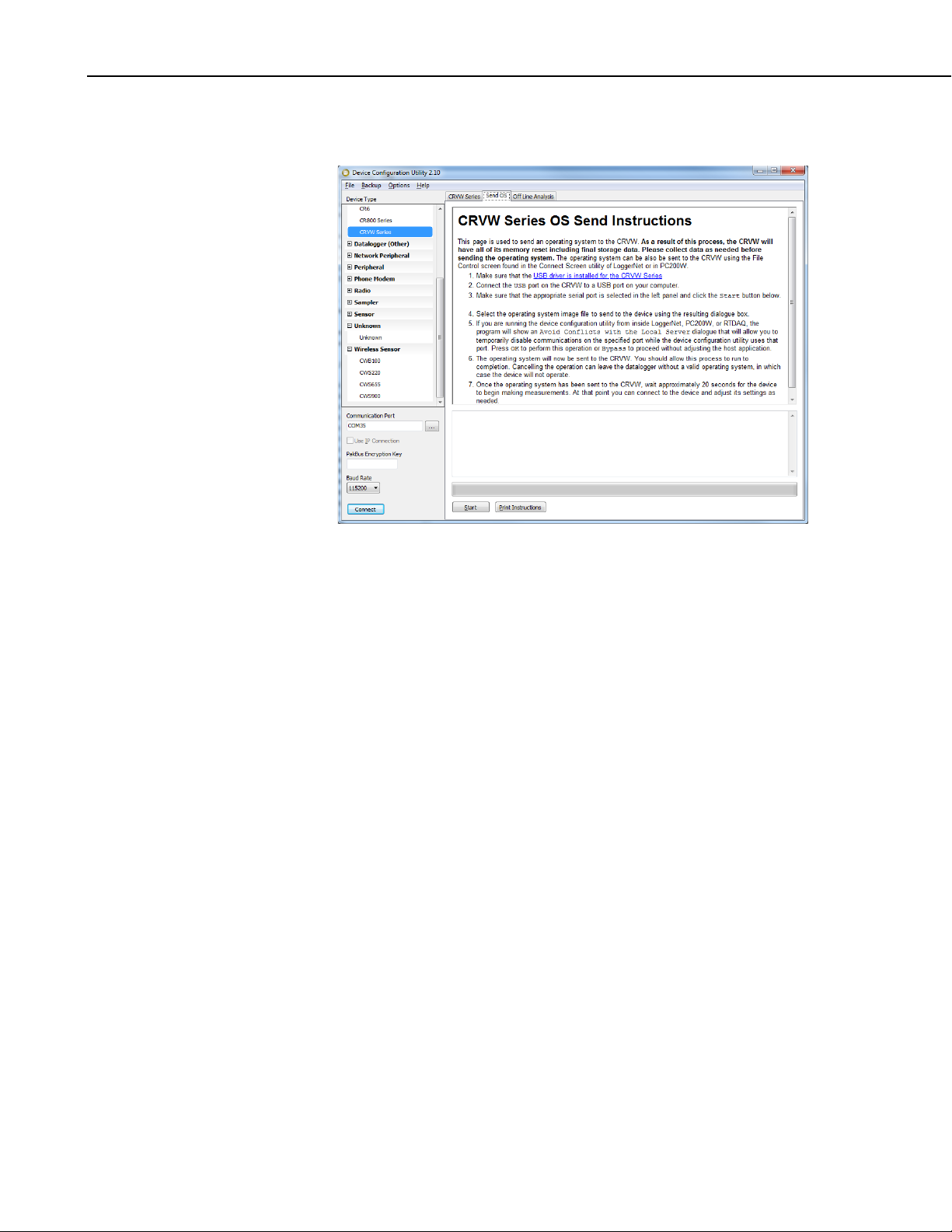

Start DevConfig, and then scroll down and highlight the CRVW Series device

and you will see a screen like this:

12

Install the USB driver by clicking on the link entitled “install the USB driver

onto your computer”.

8.1.1.3 Network Planner

If you have installed the LoggerNet software, you can use the Network Planner

tool to make network design decisions and configure devices before they are

deployed to the field. The Network Planner is found in the Tools section of the

LoggerNet toolbar.

Page 23

CRVW3 3-Channel Vibrating-Wire Datalogger

The Network Planner allows you to plan out which measurement stations,

repeater stations, and base station will be used in your deployed system. You

can place hardware device icons onto a canvas (with an optional background

graphic in place, such as map), and explore how connections are made between

each station. Many of the settings are automatically set by the software as each

device is added to the canvas (such as unique PakBus addresses). Details about

the computer running LoggerNet are also worked out. After a design is

complete, the Network Planner can be used to automatically configure each

device that is a part of the system. Using a checklist showing each device that

requires configuration (Configure Devices), screens similar to those found in

DevConfig are used to prepare each device for field use.

For more information about the Network Planner, refer to the LoggerNet

Manual, Section 4.3.

For more information about the design of radio telemetry networks, see Section

9, Radio Networks, and Section 10, Complex (Large) Radio Networks.

8.1.2 Wiring Temporary Sensors to the CRVW3

Wiring sensors temporarily to the CRVW3 is necessary while in the lab to

validate measurement operation. You can use the actual sensors (or similar)

that will be used when the device is deployed to the field. Consider that any

sensors connected in the lab may need to be disconnected from the CRVW3

when the system is transported to the field location.

When wiring sensors to the CRVW3, it is recommended that the device be

powered down. Note that this includes removing any USB cable that may be

connected, since a USB cable provides enough power for the device to operate

(for configuration or data collection purposes).

A vibrating-wire sensor may contain a built-in thermistor or other resistive

temperature measurement device. If so, it will have five wire leads. Sensors

without built-in temperature monitoring have only three leads. Refer to the

sensor manufacturer’s documentation to determine what sensor type you have.

13

Page 24

CRVW3 3-Channel Vibrating-Wire Datalogger

NOTE

FIGURE 8-1. Wiring Panel of the CRVW3

Two of the sensor leads are for the main vibrating-wire measurement, and they

are wired internally to the coil-circuit of the sensor. This connection is used

for both sensor excitation (energy input) and for reading out the current

measurement (measurement output). These two leads should be connected to

the two VW terminals on the CRVW3 corresponding to the desired

measurement channel. The shield wire should be connected to the ground

associated with that channel (located in between the VW terminals and the T

terminals). If the sensor has a built-in temperature measurement device, then

those two leads should be connected to the two T terminals.

Sensor manufacturers often color-code the leads so you can easily identify

which leads are for the coil-circuit and which are for the temperature device.

Polarity does not need to be considered when wiring the two leads for the VW

terminals and the two leads for the T terminals.

FIGURE 8-2. Typical Vibrating-Wire Sensor Lead Colors and

Connections

Use the provided screwdriver (pn 1113) to wire the leads securely into the

terminal blocks. Ensure a good connection between the metal lead and the

inside of the terminal.

If the built-in temperature device isn’t a thermistor, measure only

the resistance of the device in Ohms. If it is a thermistor that

follows the Steinhart-Hart conversion formula, then you have the

option to convert the thermistor resistance output into Degrees

Celsius. Refer to the sensor manual to know which kind of

temperature device you have.

14

Page 25

CRVW3 3-Channel Vibrating-Wire Datalogger

8.1.3 Providing Temporary Power to the CRVW3

To provide temporary power to the CRVW3 while in the lab, it is

recommended that you use pn 29796 (Power Supply 24 Vdc, 5 ft Cable). You

can also use any power supply with a 16 to 28 volt DC output. Connect the

power leads to the charge terminals located on the CRVW3.

FIGURE 8-3. Power Source Connection to the CRVW3 Charge

Terminals

If your CRVW3 uses the –ALK option, you can disconnect that power source

to preserve battery life while power is applied to the charge terminals. When

using the –RC option, you can leave the rechargeable battery connected and the

charge circuit will charge the battery while the device is powered. You can

also power the device through the terminals when no battery is present.

A USB cable will also provide power to the CRVW3. However, the USB

connection alone does not provide enough power to operate the radio or make

measurements. USB power should only be used to configure the device or to

collect data. A power source other than USB should be provided for the

CRVW3 to make measurements properly and to enable radio communications.

For CRVW3 devices with the radio option, the RX/TX LED is solid red when

only USB power is provided to remind the user that the radio is not operating.

The Status LED shows a red flash when no radio is used and only USB power

is provided to the device. Measurements made while powered only with USB

will result in NAN (invalid) for measurement output.

8.1.4 Connecting to the CRVW3

Before connecting to the CRVW3 via USB, you must ensure that the USB

driver is installed as described above. After the driver is installed on a

particular PC, it should be in-place for all future connections. Connect

pn 27555 USB cable (included with the CRVW3 shipment) between the PC

and the powered CRVW3.

15

Page 26

CRVW3 3-Channel Vibrating-Wire Datalogger

FIGURE 8-4. CRVW3 USB Connection Location

Start the Device Configuration Utility software (DevConfig). Find the CRVW

Series device item in the Datalogger category (subtree) and select it. If the

Show Device Type Categories item in the Options menu is not selected, the

devices will be listed alphabetically. Once selected, you should see a picture of

the CRVW3 and connection instructions as shown below:

16

Press the ellipsis button (…) next to the Communication Port box. This will

list available COM ports on your system. With the USB driver properly

installed, one of these items should include CRVWx in the name. Choose that

COM port and press OK. Now press the Connect button in the lower left

corner of the DevConfig window.

Page 27

CRVW3 3-Channel Vibrating-Wire Datalogger

After a few moments, you should see the Settings Editor and Main tabs for

the CRVW3 device, as shown here:

If you are having trouble when pressing Connect, refer to Section 13,

Troubleshooting CRVW3 Networks.

The top set of tabs should include: Settings Editor, Logger Control, Data

Monitor, Send OS, Troubleshoot, and Terminal. With the Settings Editor

tab selected, the tabs should include: Main, PakBus, Channel 1, Channel 2,

and Channel 3. When using the –RF451 option you should see Radio and

Radio Advanced tabs.

Ensure you have selected the Settings Editor and Main tabs. The Model

setting for your CRVW3 should be shown. This should show CRVW3–RF451

if you have the –RF451 communications option. If you have the –RF407

communications option, you should see the value CRVW3-RF407. For the

-NoRadio option, you should simply see CRVW3 for the model.

You can use the OS Version box to determine which version of the device’s

firmware (operating system) is currently loaded in the device. For details on

how to update the firmware of the device, see Appendix A, Updating CRVW3

Firmware.

The Serial Number box shows the factory serial number of your device. The

Company box should read as Campbell Scientific, Inc.

Choose the Logger Control tab. You should see the Station Time update once

every second. This behavior confirms that you have a good connection with

the CRVW3 device. You may update the device’s clock to match the clock on

the computer by using the Set Clock button.

17

Page 28

CRVW3 3-Channel Vibrating-Wire Datalogger

8.1.5 Configuring the CRVW3

Once you have successfully connected to the CRVW3 using DevConfig (see

above), you can configure the device. This is an important installation activity

that cannot be overlooked. Key settings must be configured before (or when) a

device is deployed to the field.

Use the Settings Editor tab that is available when DevConfig is connected to

make configurations to the CRVW3. The following sub-tabs will appear:

Main, PakBus, Channel 1, Channel 2, and Channel 3. For devices with the

–RF451 option, two additional sub-tabs will appear: Radio and Radio

Advanced.

Key settings whose values you should review and set are listed below. As you

place the cursor in the box for each setting, the frame in the lower right corner

of the DevConfig screen shows text that describes the setting and how it is used

(online help).

18

8.1.5.1 Key Settings

[TabName – SettingName]

Main- Station Name

You can give a name to each CRVW3 station and store it in the device. When

planning a network of multiple devices, station naming can assist you in the

organization of your system. (See Planning your Network in Section 10.2,

Planning the Radio Network.)

Main – Measurement interval

This setting specifies how often the CRVW3 should measure the sensors

connected to its active channels. The CRVW3 will repeatedly and

automatically make these measurements at this interval and store the results

until powered down, or re-configured.

Page 29

CRVW3 3-Channel Vibrating-Wire Datalogger

NOTE

NOTE

For 1 active channel the smallest (fastest) measurement interval is 1 second.

For two channels, 2 seconds is required, and for three channels, 3 seconds is

the smallest interval. The longest interval between measurements that can be

used is 24 hours.

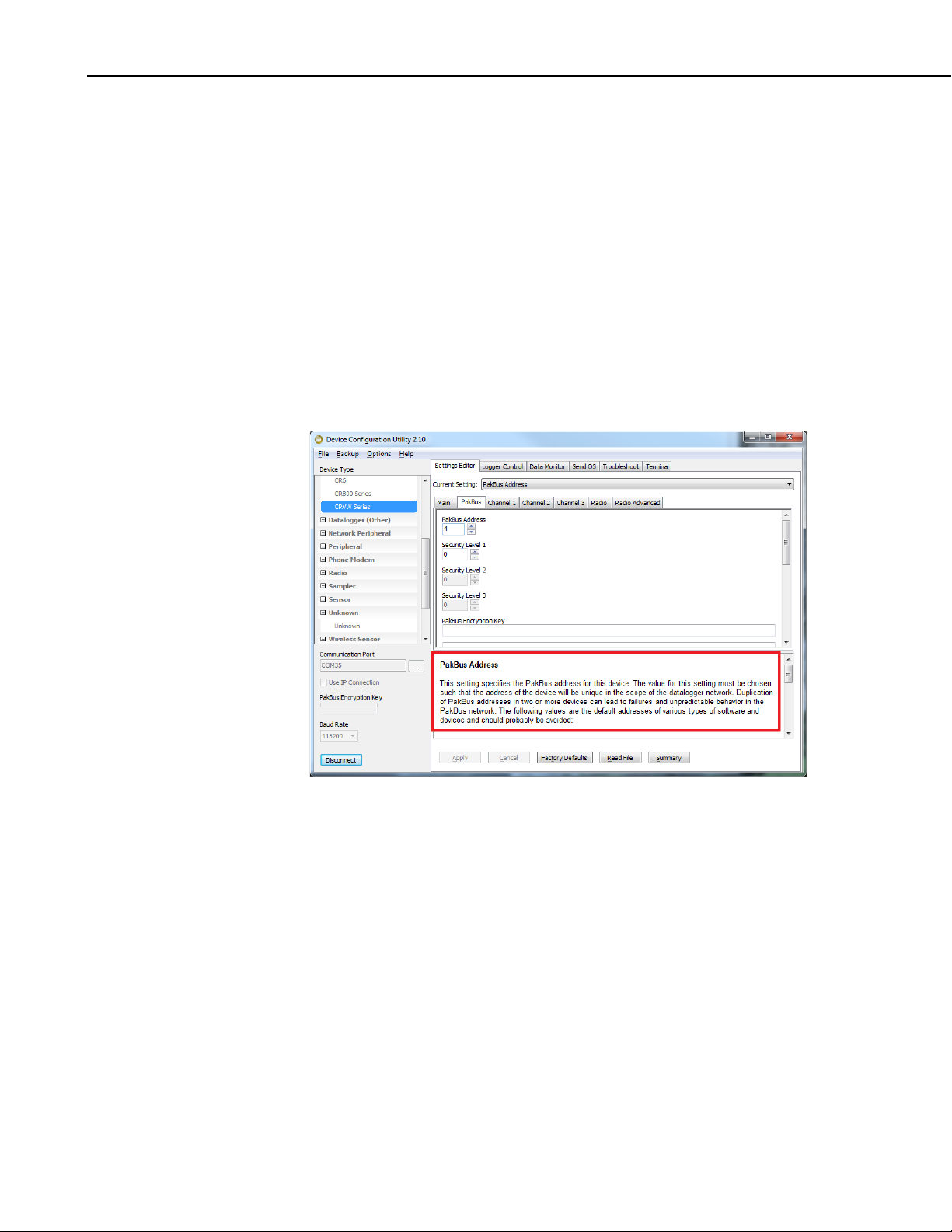

PakBus – PakBus Address

If multiple CRVW3 devices will communicate with each other in the field or

communicate to LoggerNet from the field, then each CRVW3 station requires a

unique PakBus address. You may wish to give a unique address to each

CRVW3 even if it currently won’t be deployed as part of a radio network in

case your communications usage on the device changes in the future. Set this

address to a value between 1 and 3999. Addresses between 4000 and 4094 are

reserved for use by specialized PakBus server tools such as LoggerNet or

DevConfig.

When deploying multiple devices to the field, plan carefully so that no two

devices share the same address.

The Network Planner can be used to manage PakBus Addresses

and ensure that each device has a unique value for this setting.

PakBus – Is Router

Sometimes, a CRVW3 is not only used to make measurements, but it is also

used as a communications relay device in a radio network. This can extend the

spatial range of the network by allowing distant stations to communicate back

to a base station via multiple radio links or “hops”. When a CRVW3 station

performs these relay functions it is known as a radio repeater, and also

functions as a PakBus router. Set the Is Router setting to true when the

CRVW3 station will be used in this way.

Since a station configured as a router must communicate with

multiple remote stations, an omnidirectional antenna is usually

required instead of a directional antenna. For more information

about repeater stations and routing, refer to Section

10, Complex

(Large) Radio Networks.

Channel 1, Channel 2, Channel 3 – Name

Each measurement channel (sensor) can be given a name. This helps to

distinguish data from multiple sensors as it is stored in the final storage table

and eventually collected into data files by LoggerNet or other means.

Sometimes a name more descriptive than just the channel number is helpful.

Channel 1, Channel 2, Channel 3 – Enabled

This setting is used to specify whether the channel will be actively measured or

not. When set to False, any sensor connected to the channel will be ignored.

19

Page 30

CRVW3 3-Channel Vibrating-Wire Datalogger

Channel 1, Channel 2, Channel 3 – Excitation Voltage

This setting controls how much electrical excitation energy is inserted into the

vibrating-wire sensor just before being measured for its natural frequency. The

excitation waveform is a frequency-rich sweep, containing frequencies from

the lowest to the highest desired frequencies required for the sensor being

measured. The amplitude of the input sweep waveform is controlled by this

setting. Amplitudes of 2 V, 5 V, and 12 V can be selected. Longer cable

lengths between a sensor and the CRVW3 may require a higher voltage setting.

Sensors measured on a 3 second or shorter interval may require the lowest

(2 V) voltage setting to avoid loss of resolution.

Channel 1, Channel 2, Channel 3 – Begin Frequency

This setting controls the lower frequency boundary that is used for the

excitation sweep waveform. It also controls the high-pass digital filtering that

is used on the measurement of the sensor. Any frequency detected on the

sensor lower than this value will be ignored during processing.

Refer to your sensor documentation for guidance on what frequencies can be

expected from your sensor during both usual and extreme environmental

conditions. Sensors measured on a 3 second or shorter interval should use as

narrow of a window as possible (i.e., minimize the range between Begin

Frequency and End Frequency) to avoid a loss of resolution.

Channel 1, Channel 2, Channel 3 – End Frequency

This setting controls the higher frequency boundary that is used for the

excitation sweep waveform. It also controls the low-pass digital filtering that

is used on the measurement of the sensor. Any frequency detected on the

sensor higher than this value will be ignored during processing.

Channel 1, Channel 2, Channel 3 – Thermistor Enabled

Set this setting to True if you have connected a built-in resistive temperature

device from your sensor. If the temperature sensor is a thermistor that follows

the Steinhart-Hart scaling equation, you can also specify the proper coefficients

A, B, and C (given as the three settings following the Thermistor Enabled

setting). This will result in a temperature output in units of Degrees Celsius.

Setting the three coefficient values to zero will result in only the resistance in

Ohms being given as an output from the temperature sensor. Refer to your

sensor documentation to confirm whether the temperature sensor follows the

Steinhart-Hart equation, and also to obtain the three coefficients to be used

(A,B,C).

Channel 1, Channel 2, Channel 3 – Calculate Engineering Output

Use this setting if output in engineering units is desired. The basic

measurement outputs given by the CRVW3 are sensor frequency (including

digits) and sensor temperature (if a thermistor is used). It is possible to

calculate a reading or output that is specified in engineering units (units of

measure or dimensions) using frequency/digits and temperature as the inputs.

The CRVW3 implements a polynomial that works with most vibrating-wire

sensors. Configuration of the polynomial can be an involved process and

requires knowledge of the sensor’s measurement factors, as well as an

20

Page 31

understanding of the multiple settings that are set within DevConfig. For

NOTE

NOTE

details about this polynomial-based calculation process, refer to Appendix E,

Engineering Output and Calibration.

If you wish to use a current barometric pressure reading as part of

the calculation of water height, pressure, or related measurements,

refer to

Appendix E, Engineering Output and Calibration.

Radio (–RF451 option)

When using the –RF451 option, there are some key settings on the Radio and

Radio Advanced tabs that should be set. See Section 8.1.7, Validating Radio

Connectivity in the Lab, for more details about these settings.

8.1.5.2 Managing Changes to Settings

Once you have made changes to the CRVW3’s settings, the Apply button at the

bottom of the DevConfig screen becomes active. Press Apply to execute the

changes on the device. The CRVW3 will be busy for up to 20 seconds to

complete the changes. During that time you will not be able to connect to the

CRVW3. Watch the LEDs on the device to determine when the device has

completed its reconfiguration and has begun making measurements again.

CRVW3 3-Channel Vibrating-Wire Datalogger

Applying changes to certain CRVW3 settings may cause the

CRVW3 to reset its operating mode, change its table structure, and

can result in data being erased. Please be certain that you have

collected all required data from the CRVW3 before making

changes to its settings. Changes to the following settings will reset

the final storage data on the CRVW3:

• Measurement Interval

• Channel Enabled

• Channel Name (when channel is enabled)

• Thermistor Enabled

• Thermistor Coefficients ABC (when changed from all zeroes

or changed to all zeroes)

• Calculate Engineering Output

• Use Baseline Offsets

• Use Ambient Pressure Correction

• Engineering Units (string setting)

• Use Digits

If you want to abandon the changes that have been made since connecting to

the CRVW3, use the Cancel button.

Press the Factory Defaults button to set all settings to their default values. It is

necessary to press Apply to execute these settings and place them into the

device.

Once you have used the Settings Editor tab to configure a device with a

certain settings, the current state can be saved to a file on the PC. You can use

the Summary button to display a summary of the current settings. Press the

Save button to save these settings onto the computer as an xml file (*.xml). A

filename is suggested which includes the device type and the date. You can

21

Page 32

CRVW3 3-Channel Vibrating-Wire Datalogger

change the name of the file to something different if you wish. Later on, you

can use the Read File button to retrieve the device settings that were saved to

an xml file, and re-apply them to the device with the Apply button.

When applying settings to a device using the Apply button, the Save screen

appears, allowing you to review and save the settings. Use the Save button to

save the *.xml file at that time, if desired.

8.1.6 Testing the Measurement Operation of the CRVW3

You can use the Device Configuration Utility in the lab to confirm the

measurement operations of the CRVW3. Once you have configured the

CRVW3 as desired, the CRVW3 will restart itself and automatically begin

measuring its sensors at the interval you have specified. The data is stored

immediately as each measurement is made.

When you first connect to the CRVW3, the following tabs are available:

Settings Editor, Logger Control, Data Monitor, Send OS, Troubleshoot,

and Terminal. If any changes are made to settings within the Settings Editor

tab and its sub-tabs, then all of these tabs except Settings Editor will disappear

until those changes are either applied or canceled.

Use the LoggerControl tab to check the real-time clock of the device. The

CRVW3’s clock can be synchronized with the PC clock using the Set Clock

button. If the LoggerControl tab is unable to obtain the time from the

CRVW3, then there are connectivity problems that need to be resolved (see

Section 13, Troubleshooting CRVW3 Networks).

Use the Data Monitor tab to examine the data being stored in the final storage

tables and utility tables of the device. Click on a table’s name in the left pane,

and its latest stored record will be displayed in the right pane. The Status table

shows general information about the CRVW3 and its operation. The Public

table shows information about specific variables in use by the current program

configuration. The VW_Data table is the main storage table. This is where a

permanent history of sensor readings is stored. The DataTableInfo table gives

details about final storage tables in use by the device. If calibration settings are

used (baseline values), then a CalHist table will also appear showing

calibration values captured during the latest calibration event.

22

Page 33

CRVW3 3-Channel Vibrating-Wire Datalogger

To ensure proper operation of the CRVW3, you should confirm that the

RecordNo field of the VW_Data table is incrementing at the proper

measurement interval, and that the measurement data (frequency, temperature)

is correct. The Time Stamp field should also get updated as each

measurement is made. By confirming this operation in the lab, you have the

opportunity to resolve any problems as early as possible and in an environment

more favorable for troubleshooting.

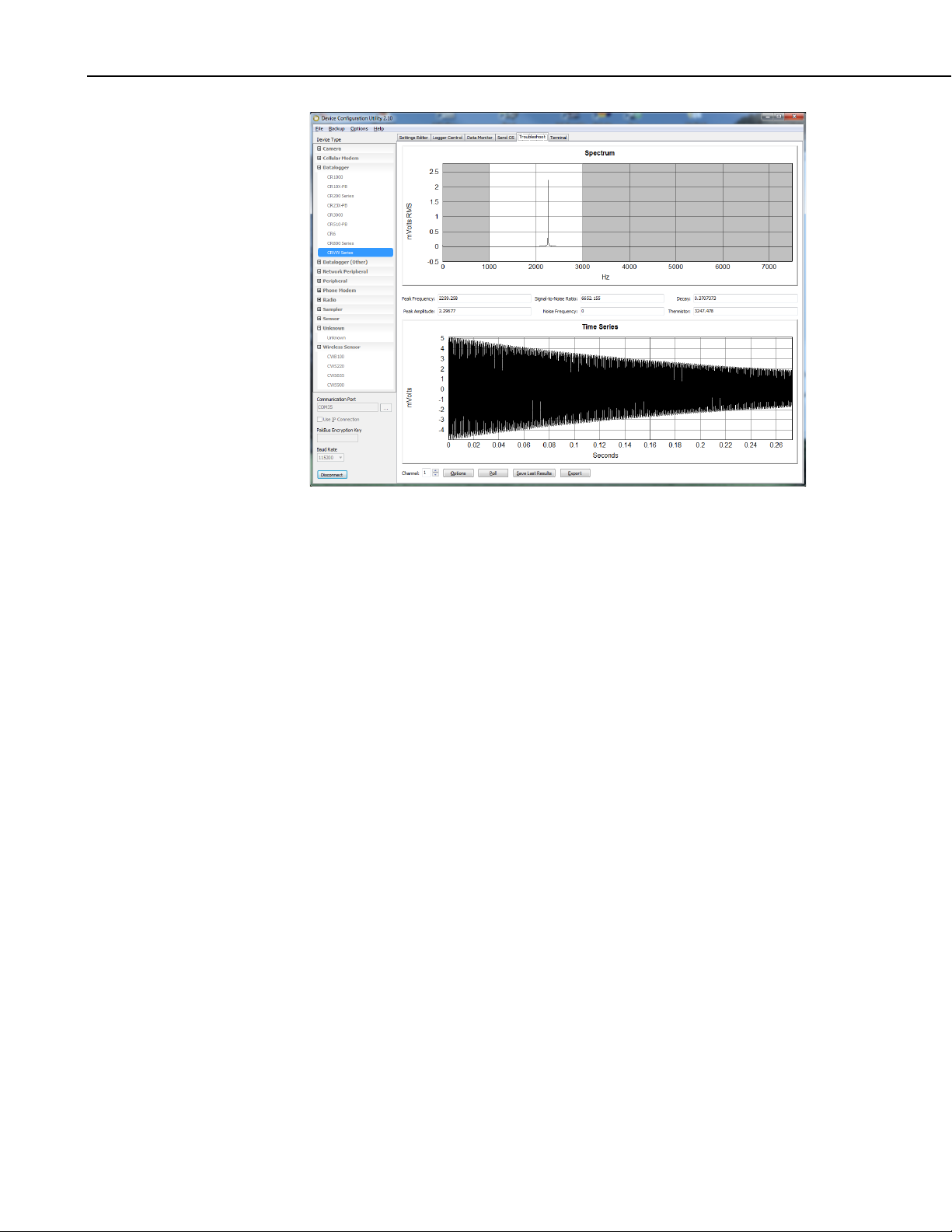

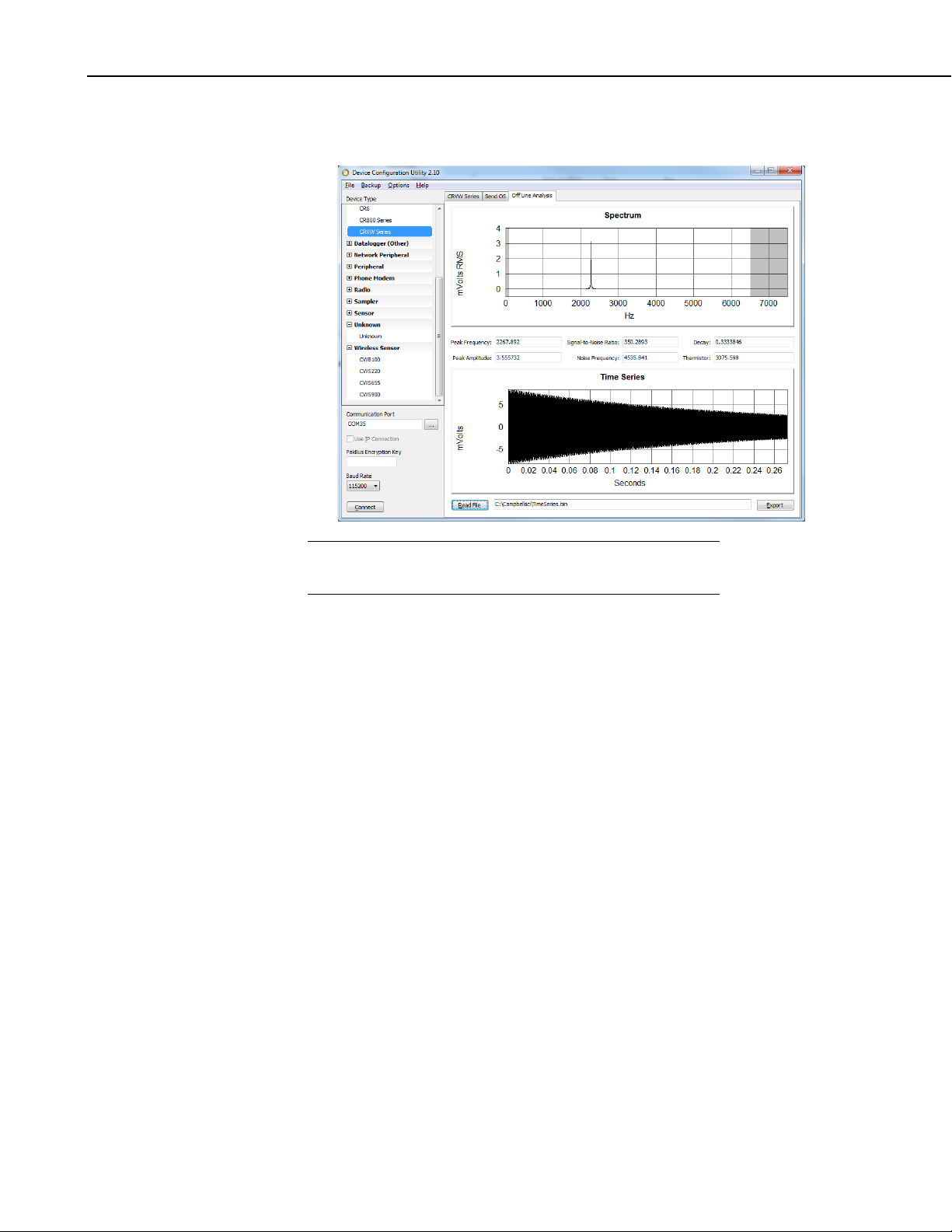

The Troubleshoot tab is provided so you can see detailed information about

the vibrating-wire sensor measurements made by the CRVW3. You can

manually trigger a measurement test and see diagnostic results within a few

seconds. Select your channel of interest in the Channel selection box. Use the

Options button to set the sweep excitation and frequency filtering window, and

also to set the excitation voltage level to be used during the test. Press the Poll

button to initiate the test. Within a few seconds the results will be displayed on

the screen.

The Spectrum window shows the frequency domain response of the vibratingwire sensor. Peaks in the spectrum indicate the main frequencies at which the

sensor’s wire vibrated during the measurement. The strength of the peaks are

shown in the millivolt scale. Drag a rectangle on the viewing area to zoom in.

Press the Undo Zoom button to return to the initial scale.

The Time Series window shows the motion of the sensor’s wire (in millivolts)

during the measurement period as given by the changing magnetic field sensed

by the coil circuitry. Drag a rectangle on the viewing area to zoom in. Press

the Undo Zoom button to return to the initial scale.

The main frequency reading is given in the Peak Frequency box in units of

Hertz (Hz). Other diagnostic readings are given to help assess the quality of

the reading:

• Signal-to-Noise Ratio: The amplitude (mV) of the strongest

frequency peak in the spectrum divided by the amplitude (mV) of the

nd

strongest frequency peak.

2

• Decay (Decay Ratio): The amplitude (mV) of the time-series motion

of the wire at the beginning of the measurement divided by the

amplitude (mV) of the wire motion at the end of the measurement.

This can also be approximately discerned by a study of the results in

the Time Series window.

• Peak Amplitude: The amplitude in millivolts (mV) of the strongest

frequency peak in the spectrum.

nd

• Noise Frequency: The frequency (Hz) of the 2

strongest frequency

peak in the spectrum.

• Thermistor: The measurement of the thermistor’s electrical resistance

in units of Ohms.

23

Page 34

CRVW3 3-Channel Vibrating-Wire Datalogger

Use the Save Last Results button to save the results of the test to a binary file

(*.bin). This file can be sent to Campbell Scientific support personnel (or to

others) and then opened within DevConfig using the Offline Analysis tab that

is shown when not connected to the CRVW3. This will allow others to assess

the condition of your sensor measurement in detail. Use the Export button to

save the results of the test into a text file that is readable using standard text

editor programs.

The Send OS tab is used when updated firmware (an operating system) is

installed into the CRVW3. Campbell Scientific will periodically provide

firmware updates for the CRVW3 on its website. (see

www.campbellsci.com/downloads). Once a newer firmware file is obtained

from the website, follow the installation instructions that are displayed when

this tab is selected.

You can use the Terminal tab to make a terminal mode connection to the

CRVW3. This is typically used under the direction of Campbell Scientific

support personnel or by advanced users. See Appendix B, Terminal Mode

from Connect Screen or DevConfig, for more information.

8.1.7 Validating Radio Connectivity in the Lab

For CRVW3 devices with the –RF451 or –RF407 communications option, you

should verify while still in the lab that the radio is working and has been

configured to be reasonably ready for field operation.

When using CRVW3-RF451 devices, the simplest way to confirm this is to use

an RF450 radio (www.campbellsci.com/rf450) connected to your lab computer.

The RF450 operates as the master radio device and the base station. The

CRVW3-RF451 device is configured as a slave device. (See Section 10.2.6,

Planning RF451 Radio Networks, for more details about master/slave radio

configurations and base station considerations.)

24

Page 35

The RF450 and CRVW3-RF451 can usually communicate easily in lab

NOTE

conditions, if they are within about 100 feet of each other, and if the RF450 is

using a small 1/2 wave antenna (pn 19512). When the RF450 uses an antenna,

then usually no antenna is required on the CRVW3-RF451 (while in the lab).

You can use the Device Configuration Utility (DevConfig) to test radio

connectivity. For details about using LoggerNet to test the radio connectivity,

see Section 10.7, LoggerNet Configuration.

If you are testing the radio connectivity of multiple CRVW3RF451 devices, only one of those devices at a time should be

powered up and tested when using this test method.

8.1.7.1 Configuring the RF450 Radio

Power the RF450 using an adapter with the DC POWER connection, or use a

CS I/O connection to a datalogger or A100/PS100 using an SC12 or other

serial cable. Connect the RS-232 port of the RF450 to the serial COM port on

your DevConfig computer. Select RF450 for the device in the radio section of

DevConfig. Just before you press Connect in DevConfig, physically press the

SETUP button on the side of the RF450. The CTS and CD LEDS should turn

green.

CRVW3 3-Channel Vibrating-Wire Datalogger

Set these settings with DevConfig:

• Active Interface : RS-232

• Baud Rate : 115.2K

• Radio Operation Mode: Multi-Point Master

• Repeaters Used : leave unchecked

• Network ID : This value should match the CRVW3 ID exactly ( 0 to

4095)

• Frequency Key : Leave at 5

• Transmit Power : Leave at 10

• Receive SubNet ID: Leave at 15

• Transmit SubNet ID : Leave at 15

• Radio ID: This must be unique for each radio device: Use “1”

(CRVW3 will use 0)

Press Apply. Leave the RF450 powered during the test. Leave the serial COM

port cable on the RS-232 port of the RF450 connected to the computer.

8.1.7.2 Configuring the CRVW3-RF451

Provide power to the CRVW3 per Section 8.1.3, Providing Temporary Power

to the CRVW3. Connect the USB cable between the CRVW3 and the

computer. In DevConfig, choose CRVW Series, select the port that was created

when the USB driver was activated, and press Connect. In the Settings Editor

tab, choose the Radio sub-tab.

Set the following settings:

• Radio Enabled : True

• Radio Operation Mode : Point to MultiPoint Slave

• Frequency Key : 5 (matches RF450)

• RF Transmit Power : Leave at 10

25

Page 36

CRVW3 3-Channel Vibrating-Wire Datalogger

NOTE

NOTE

• Low Power Mode : Leave at 2

• Repeater Frequency : Leave at “Use Master Frequency Key”

• Receive SubNet ID : 15 (matches RF450)

• Transmit SubNet ID : 15 (matches RF450)

• Network ID : Same value as given for RF450 – must match (0 to

4095)

• Radio ID: Leave at zero (must be unique/different from RF450 radio

ID, which should be 1).

Press Apply. Disconnect the USB cable from the CRVW3.

When testing deployed devices in the field, you may have already

assigned different Radio ID, Network ID, and Frequency Key

values than those shown above. Make sure the Network ID and

Frequency Key values match between both (all) devices and that

the Radio ID is unique for each device.

8.1.7.3 Using DevConfig to Connect to the CRVW3-RF451 Over the Radio

Position the RF450 and computer to be at least 25 feet away from the CRVW3.

The CRVW3 should no longer be wired to any device. Highlight CRVW Series

in DevConfig (not RF450). Choose the port on the computer that is connected

to the RF450 radio. Now Press Connect. Confirm red and green flashes on the

RX/TX LED of the CRVW3 and on the RF450 as radio communications now

occur.

If no other CRVW3-RF451 devices are on the radio network (i.e., powered or

in range), then DevConfig connects only to the CRVW3 device that is powered

and available, using the RF450/COM port on the computer as a transparent

link. The DevConfig screens should act just as they do when the computer has

a wired connection to the CRVW3. You should be able to view and set all the

settings of the CRVW3 over the radio connection. Confirm that the Serial

Number and Station Name in the Main tab are correct and correspond to the

CRVW3 station being tested. Use the Data Monitor tab to confirm proper

CRVW3 operation.

If multiple CRVW3 devices need to be powered and located

within radio range of the RF450 base station computer, then you

must use LoggerNet to test their radio connectivity. LoggerNet

can distinguish between CRVW3 devices based on PakBus

address. Each CRVW3 should have a unique Radio ID setting

and a unique PakBus address. Follow the steps outlined in Section

10.7, LoggerNet Configuration, to perform multiple CRVW3

radio testing using LoggerNet.

8.2 Field Deployment of the CRVW3

When a CRVW3 is deployed to its permanent location in the field, there are

several key considerations which help to ensure that it works properly. This

section discusses how to get each device individually installed at its planned

location.

26

Page 37

CRVW3 3-Channel Vibrating-Wire Datalogger

NOTE

When using a CRVW3 with a radio option (–RF451 or –RF407),

it is recommend that you design the radio network before

deploying any device to the field. Radio connectivity is a factor

that can impact the geographic location of a CRVW3 site. See

Section

Radio Networks, for more information about the use of radios. It

is also recommended that at least some of the configuration of the

CRVW3 be done in the office or lab (Section 8.1

and Configuration) before deploying it into the field.

Bring a laptop with DevConfig installed when you travel to the installation site

(see Section 8.1.1, Preparing the Windows Computer (PC), and Section 8.1.4,

Connecting to the CRVW3). Consider the following tasks when installing a

CRVW3 station:

9, Radio Networks, and Section 10, Complex (Large)

, Lab Connection

• Connecting Sensors to the CRVW3

• Providing Power to the CRVW3

• Monitoring and Controlling Humidity Within the CRVW3 Enclosure

• Mounting the CRVW3 Enclosure

• Installing the CRVW3 Antenna (for devices with a radio option)

• Connecting the CRVW3 Electrical System to Earth Ground, Surge

Protection

• Validating and Fine-Tuning CRVW3 Settings

• Confirming CRVW3 Sensor Measurement Operation

• Validating Radio communications (when applicable)

• Sealing the CRVW3 Enclosure

Details about these tasks are provided in this section.

When installing devices with a radio option, bring a radio device into the field

that can operate as a radio base station. For the CRVW3-RF451 this is the

RF450 device configured as the master radio and LoggerNet software running

on a laptop computer.

8.2.1 Connecting Sensors to the CRVW3

Selection of the proper vibrating-wire sensors to meet your data acquisition

needs is a process that is beyond the scope of this document. Contact an

application engineer at your local Campbell Scientific support office for

guidance regarding sensor selection and purchase. Campbell Scientific, Inc.

also provides training related to the measurement of several kinds of vibratingwire sensors.

The vibrating-wire sensors to be measured should be located within a

reasonable distance of the CRVW3. Install the sensors according to

manufacturer supplied instructions. A 5-wire or 3-wire cable will connect

between each sensor and the CRVW3. Longer cable distances (more than

500 m or 1500 feet) may require the use of 12 volt excitation instead of 5 volt

excitation (see Excitation Voltage in Section 8.1.5, Configuring the CRVW3).

Since 12 volt excitation uses more power, consider how that excitation level

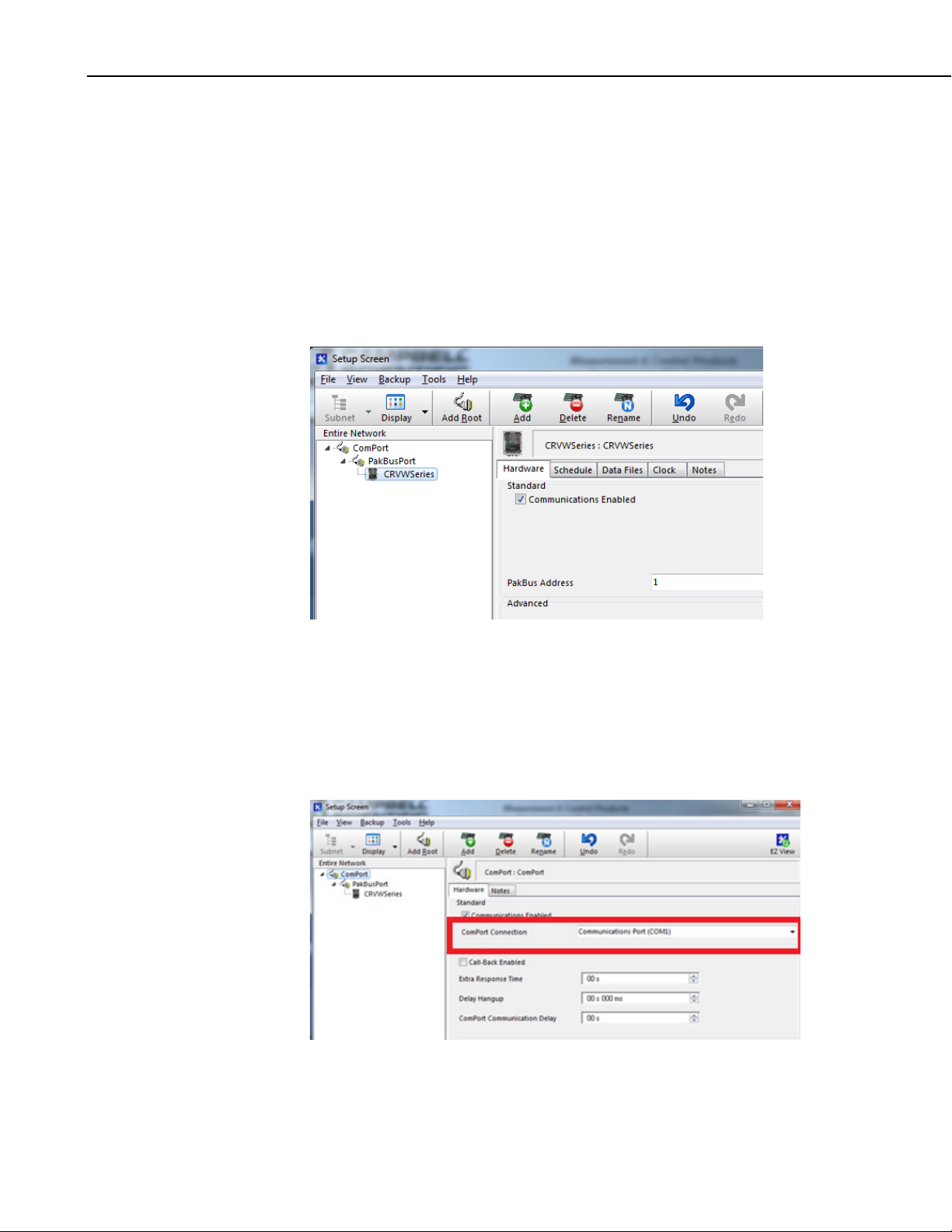

may impact your power storage. Vibrating-wire sensor connections can