Page 1

OPERATOR'S MANUAL

Revision: 12/16

Want to get going? Go to the Quickstart

section.

Copyright © 2000 – 2016

(p. 35)

CR800 Series Dataloggers

Campbell Scientific, Inc.

Page 2

Page 3

3

Warranty

The CR800 Measurement and Control Datalogger is warranted for three (3) years

subject to this limited warranty:

Limited Warranty: Products manufactured by CSI are warranted by CSI to be free

from defects in materials and workmanship under normal use and service for

twelve months from the date of shipment unless otherwise specified in the

corresponding product manual. (Product manuals are available for review online

at www.campbellsci.com.) Products not manufactured by CSI, but that are resold

by CSI, are warranted only to the limits extended by the original manufacturer.

Batteries, fine-wire thermocouples, desiccant, and other consumables have no

warranty. CSI's obligation under this warranty is limited to repairing or replacing

(at CSI's option) defective Products, which shall be the sole and exclusive remedy

under this warranty. The Customer assumes all costs of removing, reinstalling,

and shipping defective Products to CSI. CSI will return such Products by surface

carrier prepaid within the continental United States of America. To all other

locations, CSI will return such Products best way CIP (port of entry) per

Incoterms ® 2010. This warranty shall not apply to any Products which have been

subjected to modification, misuse, neglect, improper service, accidents of nature,

or shipping damage. This warranty is in lieu of all other warranties, expressed or

implied. The warranty for installation services performed by CSI such as

programming to customer specifications, electrical connections to Products

manufactured by CSI, and Product specific training, is part of CSI's product

warranty. CSI EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. CSI hereby disclaims, to the fullest extent allowed by

applicable law, any and all warranties and conditions with respect to the Products,

whether express, implied or statutory, other than those expressly provided herein.

Page 4

Page 5

5

Assistance

Products may not be returned without prior authorization. The following contact

information is for US and International customers residing in countries served by

Campbell Scientific, Inc. directly. Affiliate companies handle repairs for

customers within their territories. Please visit www.campbellsci.com to determine

which Campbell Scientific company serves your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After a support engineer determines

the nature of the problem, an RMA number will be issued. Please write this

number clearly on the outside of the shipping container. Campbell Scientific's

shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a "Statement of Product Cleanliness and

Decontamination" form and comply with the requirements specified in it. The

form is available from our web site at www.campbellsci.com/repair. A completed

form must be either emailed to repair@campbellsci.com or faxed to 435-227-

9106. Campbell Scientific is unable to process any returns until we receive this

form. If the form is not received within three days of product receipt or is

incomplete, the product will be returned to the customer at the customer's

expense. Campbell Scientific reserves the right to refuse service on products that

were exposed to contaminants that may cause health or safety concerns for our

employees.

Page 6

Page 7

7

Precautions

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING,

USING, MAINTAINING, AND WORKING ON OR AROUND TRIPODS,

TOWERS, AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH

AS SENSORS, CROSSARMS, ENCLOSURES, ANTENNAS, ETC. FAILURE

TO PROPERLY AND COMPLETELY ASSEMBLE, INSTALL, OPERATE,

USE, AND MAINTAIN TRIPODS, TOWERS, AND ATTACHMENTS, AND

FAILURE TO HEED WARNINGS, INCREASES THE RISK OF DEATH,

ACCIDENT, SERIOUS INJURY, PROPERTY DAMAGE, AND PRODUCT

FAILURE. TAKE ALL REASONABLE PRECAUTIONS TO AVOID THESE

HAZARDS. CHECK WITH YOUR ORGANIZATION'S SAFETY

COORDINATOR (OR POLICY) FOR PROCEDURES AND REQUIRED

PROTECTIVE EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for

which they are designed. Do not exceed design limits. Be familiar and comply

with all instructions provided in product manuals. Manuals are available at

www.campbellsci.com or by telephoning 435-227-9000 (USA). You are

responsible for conformance with governing codes and regulations, including

safety regulations, and the integrity and location of structures or land to which

towers, tripods, and any attachments are attached. Installation sites should be

evaluated and approved by a qualified engineer. If questions or concerns arise

regarding installation, use, or maintenance of tripods, towers, attachments, or

electrical connections, consult with a licensed and qualified engineer or

electrician.

General

• Prior to performing site or installation work, obtain required approvals

and permits. Comply with all governing structure-height regulations,

such as those of the FAA in the USA.

• Use only qualified personnel for installation, use, and maintenance of

tripods and towers, and any attachments to tripods and towers. The use of

licensed and qualified contractors is highly recommended.

• Read all applicable instructions carefully and understand procedures

thoroughly before beginning work.

• Wear a hardhat and eye protection, and take other appropriate safety

precautions while working on or around tripods and towers.

• Do not climb tripods or towers at any time, and prohibit climbing by

other persons. Take reasonable precautions to secure tripod and tower

sites from trespassers.

• Use only manufacturer recommended parts, materials, and tools.

Page 8

8

Utility and Electrical

• You can be killed or sustain serious bodily injury if the tripod, tower, or

attachments you are installing, constructing, using, or maintaining, or a

tool, stake, or anchor, come in contact with overhead or underground

utility lines.

• Maintain a distance of at least one-and-one-half times structure height, or

20 feet, or the distance required by applicable law, whichever is greater,

between overhead utility lines and the structure (tripod, tower,

attachments, or tools).

• Prior to performing site or installation work, inform all utility companies

and have all underground utilities marked.

• Comply with all electrical codes. Electrical equipment and related

grounding devices should be installed by a licensed and qualified

electrician.

Elevated Work and Weather

• Exercise extreme caution when performing elevated work.

• Use appropriate equipment and safety practices.

• During installation and maintenance, keep tower and tripod sites clear of

un-trained or non-essential personnel. Take precautions to prevent

elevated tools and objects from dropping.

• Do not perform any work in inclement weather, including wind, rain,

snow, lightning, etc.

Maintenance

• Periodically (at least yearly) check for wear and damage, including

corrosion, stress cracks, frayed cables, loose cable clamps, cable

tightness, etc. and take necessary corrective actions.

• Periodically (at least yearly) check electrical ground connections.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST

DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS, THE

CUSTOMER ASSUMES ALL RISK FROM ANY INJURY RESULTING

FROM IMPROPER INSTALLATION, USE, OR MAINTENANCE OF

TRIPODS, TOWERS, OR ATTACHMENTS TO TRIPODS AND TOWERS

SUCH AS SENSORS, CROSSARMS, ENCLOSURES, ANTENNAS, ETC.

Page 9

9

Table of Contents

1. Introduction ............................................................... 29

1.1 HELLO .............................................................................................. 29

1.2 Typography ....................................................................................... 30

1.3 Capturing CRBasic Code .................................................................. 30

2. Precautions ................................................................ 31

3. Initial Inspection ........................................................ 33

4. Quickstart .................................................................. 35

4.1 Sensors — Quickstart ...................................................................... 35

4.2 Datalogger — Quickstart ................................................................... 36

4.2.1 CR800 Module ........................................................................... 36

4.2.1.1 Wiring Panel — Quickstart.............................................. 36

4.3 Power Supplies — Quickstart ........................................................... 37

4.3.1 Internal Battery — Quickstart .................................................... 38

4.4 Data Retrieval and Comms — Quickstart ......................................... 38

4.5 Datalogger Support Software — Quickstart ...................................... 39

4.6 Tutorial: Measuring a Thermocouple ................................................ 39

4.6.1 What You Will Need .................................................................. 40

4.6.2 Hardware Setup .......................................................................... 40

4.6.2.1 Connect External Power Supply ...................................... 40

4.6.2.2 Connect Comms .............................................................. 41

4.6.3 PC200W Software Setup ............................................................ 41

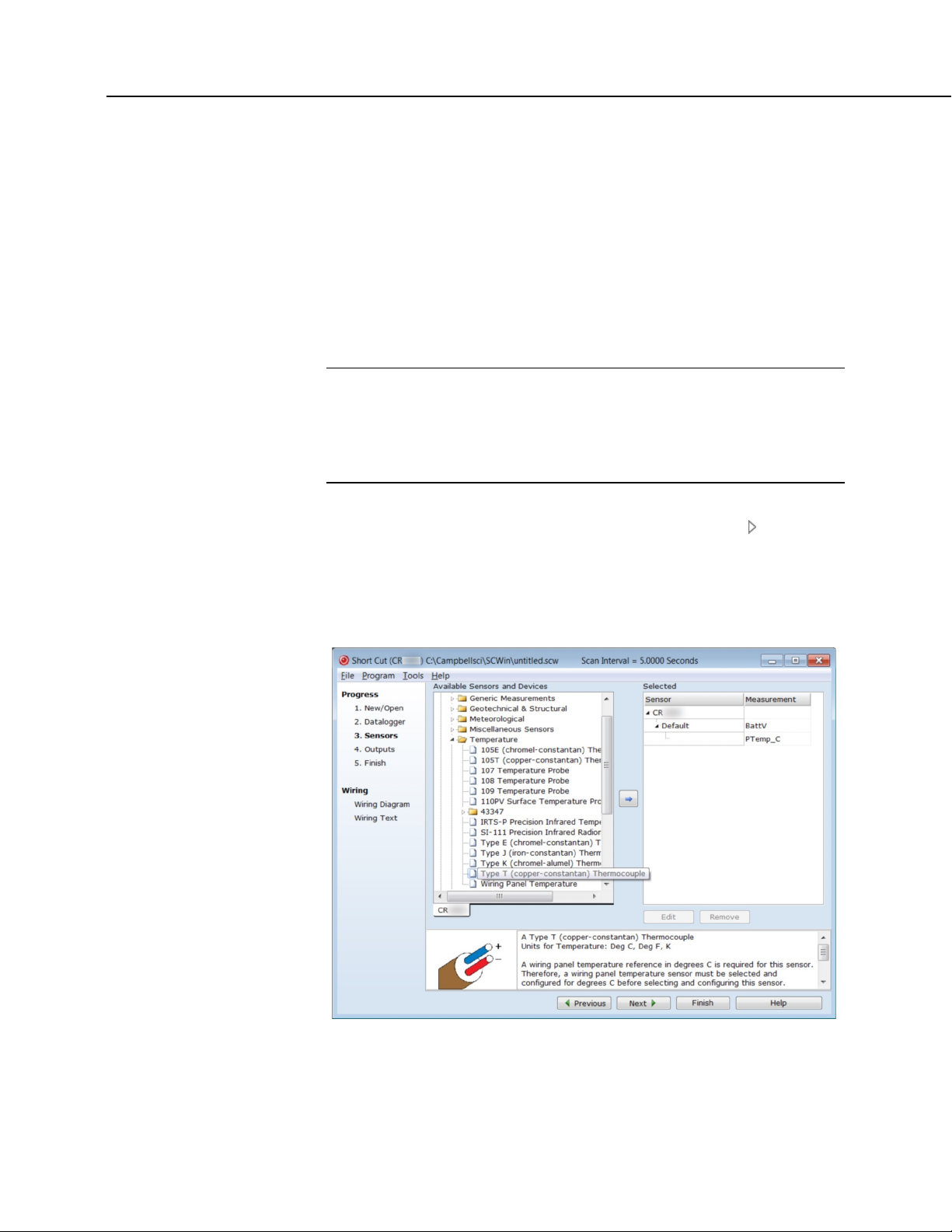

4.6.4 Write CRBasic Program with Short Cut .................................... 43

4.6.4.1 Procedure: (Short Cut Steps 1 to 5) ................................. 44

4.6.4.2 Procedure: (Short Cut Steps 6 to 7) ................................. 45

4.6.4.3 Procedure: (Short Cut Step 8) .......................................... 45

4.6.4.4 Procedure: (Short Cut Steps 9 to 12) ............................... 45

4.6.4.5 Procedure: (Short Cut Steps 13 to 14) ............................. 46

4.6.5 Send Program and Collect Data ................................................. 46

4.6.5.1 Procedure: (PC200W Step 1) ........................................... 47

4.6.5.2 Procedure: (PC200W Steps 2 to 4) .................................. 47

4.6.5.3 Procedure: (PC200W Step 5) ........................................... 48

4.6.5.4 Procedure: (PC200W Step 6) ........................................... 49

4.6.5.5 Procedure: (PC200W Steps 7 to 10) ................................ 50

4.6.5.6 Procedure: (PC200W Steps 11 to 12) .............................. 51

4.6.5.7 Procedure: (PC200W Steps 13 to 14) .............................. 51

4.7 Data Acquisition Systems — Quickstart ........................................... 52

5. Overview .................................................................... 55

5.1 Datalogger — Overview.................................................................... 56

5.1.1 Wiring Panel — Overview ......................................................... 57

5.1.1.1 Switched Voltage Output — Overview ........................... 59

Voltage Excitation — Overview .................................. 60

5.1.1.2

5.1.1.3 Power Terminals .............................................................. 61

5.1.1.3.1 Power In Terminals ............................................... 61

5.1.1.3.2 Power Out Terminals ............................................ 61

Page 10

Table of Contents

10

5.1.1.4 Communication Ports — Overview ................................. 61

5.1.1.4.1 RS-232 Ports ......................................................... 62

5.1.1.4.2 SDI-12 Ports ......................................................... 63

5.1.1.4.3 SDM Port .............................................................. 63

5.1.1.4.4 CPI Port and CDM Devices — Overview ............ 63

5.1.1.4.5 Ethernet Port ......................................................... 64

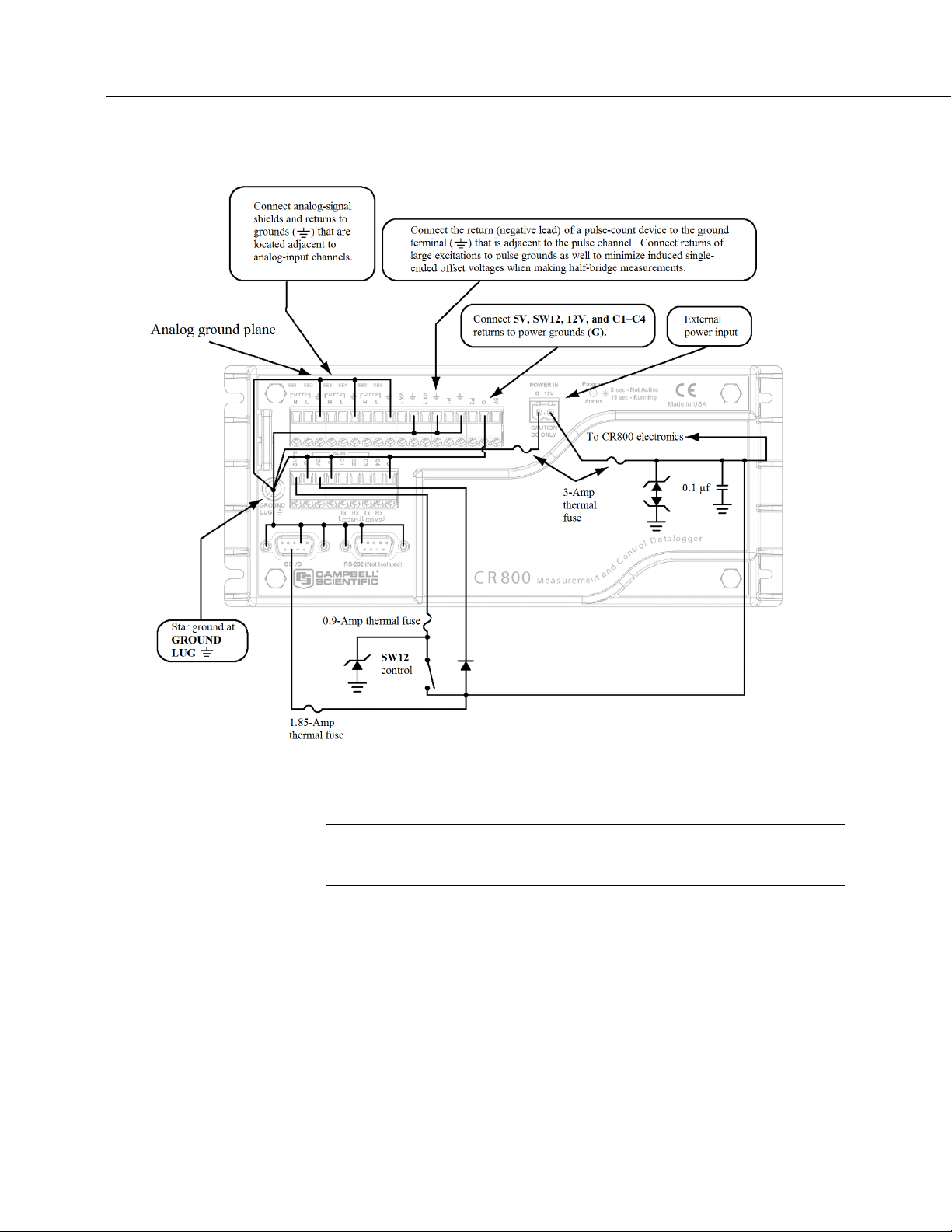

5.1.1.5 Grounding — Overview .................................................. 64

5.2 Measurements — Overview .............................................................. 64

5.2.1 Time Keeping — Overview ....................................................... 65

5.2.2 Analog Measurements — Overview .......................................... 65

5.2.2.1 Voltage Measurements — Overview ............................... 65

5.2.2.1.1 Single-Ended Measurements — Overview ........... 67

5.2.2.1.2 Differential Measurements — Overview .............. 68

5.2.2.2 Current Measurements — Overview ............................... 68

5.2.2.3 Resistance Measurements — Overview .......................... 69

5.2.2.3.1 Voltage Excitation ................................................ 69

5.2.2.4 Strain Measurements — Overview .................................. 70

5.2.3 Pulse Measurements — Overview ............................................. 70

5.2.3.1 Pulses Measured .............................................................. 71

5.2.3.2 Pulse Input Channels ....................................................... 71

5.2.3.3 Pulse Sensor Wiring......................................................... 72

5.2.4 Period Averaging — Overview .................................................. 73

5.2.5 Vibrating Wire Measurements — Overview .............................. 73

5.2.6 Reading Smart Sensors — Overview ......................................... 74

5.2.6.1 SDI-12 Sensor Support — Overview .............................. 74

5.2.6.2 RS-232 — Overview ....................................................... 75

5.2.7 Field Calibration — Overview ................................................... 75

5.2.8 Cabling Effects — Overview ..................................................... 76

5.2.9 Synchronizing Measurements — Overview ............................... 76

5.2.9.1 Synchronizing Measurements in the CR800 —

Overview ...................................................................... 76

5.2.9.2 Synchronizing Measurements in a Datalogger

Network — Overview .................................................. 76

5.3 Data Retrieval and Comms — Overview .......................................... 76

5.3.1 Data File Formats in CR800 Memory ........................................ 77

5.3.2 Data Format on Computer .......................................................... 77

5.3.3 Mass-Storage Device .................................................................. 77

5.3.4

Comms Protocols ....................................................................... 77

5.3.4.1 PakBus Comms — Overview .......................................... 77

5.3.5 Alternate Comms Protocols — Overview .................................. 78

5.3.5.1 Modbus — Overview....................................................... 78

5.3.5.2 DNP3 — Overview .......................................................... 79

5.3.5.3 TCP/IP — Overview ........................................................ 79

5.3.6 Comms Hardware — Overview ................................................. 80

5.3.7 Keyboard/Display — Overview ................................................. 80

5.3.7.1 Integrated/Keyboard Display ........................................... 81

5.3.7.2 Character Set .................................................................... 81

5.3.7.3 Custom Menus — Overview ........................................... 82

5.4 Measurement and Control Peripherals — Overview ......................... 82

5.5 Power Supplies — Overview ............................................................ 83

5.6 CR800 Setup — Overview ................................................................ 83

5.7 CRBasic Programming — Overview ................................................ 84

5.8 Security — Overview ........................................................................ 84

5.9 Maintenance — Overview ................................................................. 85

5.9.1 Protection from Moisture — Overview ...................................... 85

Page 11

Table of Contents

11

5.9.2 Protection from Voltage Transients — Overview ...................... 85

5.9.3 Factory Calibration — Overview ............................................... 86

5.9.4 Internal Battery — Overview ..................................................... 86

5.10 Datalogger Support Software — Overview ....................................... 86

5.11 PLC Control — Overview ................................................................. 87

5.12 Auto Self-Calibration — Overview ................................................... 89

5.13 Memory — Overview ....................................................................... 89

6. Specifications ............................................................ 91

7. Installation ................................................................. 93

7.1 Enclosures — Details ........................................................................ 93

7.2 Power Supplies — Details ................................................................. 94

7.2.1 CR800 Power Requirement ........................................................ 94

7.2.2 Calculating Power Consumption ................................................ 95

7.2.3 Power Sources ............................................................................ 95

7.2.3.1 Vehicle Power Connections ............................................. 95

7.2.4 Uninterruptable Power Supply (UPS) ........................................ 96

7.2.5 External Power Supply Installation ............................................ 96

7.2.6 External Alkaline Power Supply ................................................ 96

7.3 Grounding — Details ........................................................................ 96

7.3.1 ESD Protection ........................................................................... 97

7.3.1.1 Lightning Protection ........................................................ 98

7.3.2 Single-Ended Measurement Reference ...................................... 99

7.3.3 Ground Potential Differences ................................................... 100

7.3.3.1 Soil Temperature Thermocouple ................................... 100

7.3.3.2 External Signal Conditioner........................................... 100

7.3.4 Ground Looping in Ionic Measurements .................................. 101

7.4 Protection from Moisture — Details ............................................... 102

7.5 CR800 Setup — Details .................................................................. 102

7.5.1 Tools — Setup .......................................................................... 103

7.5.1.1 DevConfig — Setup Tools ............................................ 103

7.5.1.2 Network Planner — Setup Tools ................................... 104

7.5.1.2.1 Overview — Network Planner ............................ 105

7.5.1.2.2 Basics — Network Planner ................................. 106

7.5.1.3 Info Tables and Settings — Setup Tools ....................... 107

7.5.1.4 CRBasic Program — Setup Tools ................................. 108

7.5.1.5 Executable CPU: Files — Setup Tools .......................... 108

7.5.1.5.1 Default.cr8 File ................................

7.5.1.5.2 "Include" File ...................................................... 109

7.5.1.5.3 Executable File Run Priorities ............................ 112

7.5.2 Setup Tasks .............................................................................. 113

7.5.2.1 Operating System (OS) — Details ................................. 113

7.5.2.1.1 OS Update with DevConfig Send OS Tab .......... 114

7.5.2.1.2 OS Update with File Control .............................. 115

7.5.2.1.3 OS Update with Send Program Command ......... 116

7.5.2.1.4 OS Update with External Memory and

PowerUp.ini File ............................................. 117

7.5.2.2 Factory Defaults — Installation ..................................... 118

7.5.2.3 Saving and Restoring Configurations — Installation .... 118

7.6 CRBasic Programming — Details ................................................... 119

7.6.1 Program Structure .................................................................... 119

7.6.2 Writing and Editing Programs .................................................. 122

................... 109

Page 12

Table of Contents

12

7.6.2.1 Short Cut Programming Wizard .................................... 122

7.6.2.2 CRBasic Editor .............................................................. 122

7.6.2.2.1 Inserting Comments into Program ...................... 123

7.6.2.2.2 Conserving Program Memory ............................. 124

7.6.3 Programming Syntax ................................................................ 124

7.6.3.1 Program Statements ....................................................... 124

7.6.3.1.1 Multiple Statements on One Line ....................... 125

7.6.3.1.2 One Statement on Multiple Lines ....................... 125

7.6.3.2 Single-Statement Declarations ....................................... 125

7.6.3.3 Declaring Variables ....................................................... 126

7.6.3.3.1 Declaring Data Types ......................................... 127

7.6.3.3.2 Dimensioning Numeric Variables ....................... 131

7.6.3.3.3 Dimensioning String Variables ........................... 132

7.6.3.3.4 Declaring Flag Variables .................................... 132

7.6.3.4 Using Variable Pointers ................................................. 133

7.6.3.5 Declaring Arrays ............................................................ 134

7.6.3.5.1 Advanced Array Declaration .............................. 135

7.6.3.6 Declaring Local and Global Variables ........................... 136

7.6.3.7 Initializing Variables...................................................... 136

7.6.3.8 Declaring Constants ....................................................... 137

7.6.3.8.1 Predefined Constants .......................................... 138

7.6.3.9 Declaring Aliases and Units........................................... 138

7.6.3.10 Numerical Formats ........................................................ 139

7.6.3.11 Multi-Statement Declarations ........................................ 140

7.6.3.11.1 Declaring Data Tables ......................................... 141

7.6.3.11.2 Declaring Subroutines ......................................... 148

7.6.3.11.3 Declaring Subroutines ......................................... 149

7.6.3.11.4 Declaring Incidental Sequences .......................... 149

7.6.3.12 Execution and Task Priority........................................... 150

7.6.3.12.1 Pipeline Mode ..................................................... 151

7.6.3.12.2 Sequential Mode ................................................. 152

7.6.3.13 Execution Timing .......................................................... 153

7.6.3.13.1 Scan() / NextScan ............................................... 153

7.6.3.13.2 SlowSequence / EndSequence ............................ 154

7.6.3.13.3 SubScan() / NextSubScan ................................... 155

7.6.3.13.4 Scan Priorities in Sequential Mode ..................... 155

7.6.3.14 Programming Instructions .............................................. 157

7.6.3.14.1 Measurement and Data Storage Processing ........ 157

7.6.3.14.2 Argument Types.................................................. 158

7.6.3.14.3 Names in Arguments ........................................... 158

7.6.3.15 Expressions in Arguments ............................................. 159

7.6.3.16 Programming Expression Types .................................... 160

7.6.3.16.1 Floating-Point Arithmetic ................................... 160

7.6.3.16.2 Arithmetic Operations ......................................... 161

7.6.3.16.3 Expressions with Numeric Data Types ............... 161

7.6.3.16.4 Logical Expressions

............................................ 163

7.6.3.16.5 String Expressions .............................................. 166

7.6.3.17 Programming Access to Data Tables ............................. 167

7.6.3.18 Programming to Use Signatures .................................... 169

7.6.3.19 Functions (with a capital F) ........................................... 169

7.6.4 Sending CRBasic Programs ..................................................... 170

7.6.4.1 Preserving Data at Program Send .................................. 170

7.7 Programming Resource Library ...................................................... 171

7.7.1 Advanced Programming Techniques........................................ 171

7.7.1.1 Capturing Events ........................................................... 171

Page 13

Table of Contents

13

7.7.1.2 Conditional Output ........................................................ 173

7.7.1.3 Groundwater Pump Test ................................................ 173

7.7.1.4 Miscellaneous Features .................................................. 176

7.7.1.5 PulseCountReset Instruction .......................................... 178

7.7.1.6 Scaling Array ................................................................. 179

7.7.1.7 Signatures: Example Programs ...................................... 180

7.7.1.7.1 Text Signature ..................................................... 180

7.7.1.7.2 Binary Runtime Signature................................... 180

7.7.1.7.3 Executable Code Signatures ............................... 180

7.7.1.8 Use of Multiple Scans .................................................... 181

7.7.2 Data Input: Loading Large Data Sets ....................................... 182

7.7.3 Data Input: Array-Assigned Expression ................................... 183

7.7.4 Data Output: Calculating Running Average ............................. 187

7.7.5 Data Output: Two Intervals in One Data Table ........................ 191

7.7.6 Data Output: Triggers and Omitting Samples .......................... 192

7.7.7 Data Output: Using Data Type Bool8 ...................................... 193

7.7.8 Data Output: Using Data Type NSEC ...................................... 198

7.7.8.1 NSEC Options ............................................................... 198

7.7.9 Data Output: Wind Vector ....................................................... 201

7.7.9.1 OutputOpt Parameters ................................................... 202

7.7.9.2 Wind Vector Processing ................................................ 202

7.7.9.2.1 Measured Raw Data ............................................ 203

7.7.9.2.2 Calculations ........................................................ 204

7.7.10 Displaying Data: Custom Menus — Details ............................ 207

7.7.11 Field Calibration — Details ..................................................... 214

7.7.11.1 Field Calibration CAL Files .......................................... 214

7.7.11.2 Field Calibration Programming ..................................... 215

7.7.11.3 Field Calibration Wizard Overview ............................... 215

7.7.11.4 Field Calibration Numeric Monitor Procedures............. 215

7.7.11.4.1 One-Point Calibrations (Zero or Offset) ............. 216

7.7.11.4.2 Two-Point Calibrations (gain and offset) ............ 217

7.7.11.4.3 Zero Basis Point Calibration ............................... 217

7.7.11.5 Field Calibration Examples ........................................... 217

7.7.11.5.1 FieldCal() Zero or Tare (Opt 0) Example ........... 218

7.7.11.5.2 FieldCal() Offset (Opt 1) Example ..................... 220

7.7.11.5.3 FieldCal() Slope and Offset (Opt 2) Example ..... 223

7.7.11.5.4 FieldCal() Slope (Opt 3) Example ...................... 225

7.7.11.5.5 FieldCal() Zero Basis (Opt 4) Example .............. 228

7.7.11.6 Field Calibration Strain Examples ................................. 228

7.7.11.6.1 FieldCalStrain() Shunt Calibration Concepts...... 228

7.7.11.6.2 FieldCalStrain() Shunt Calibration Example ...... 229

7.7.11.6.3 FieldCalStrain() Quarter-Bridge Shunt

Example ........................................................... 231

7.7.11.6.4 FieldCalStrain() Quarter-Bridge Zero ................. 232

7.7.12 Measurement: Fast Analog Voltage ......................................... 233

7.7.12.1

Tips — Fast Analog Voltage ......................................... 237

7.7.13 Measurement: Excite, Delay, Measure ..................................... 239

7.7.14 Serial I/O: SDI-12 Sensor Support — Details .......................... 240

7.7.14.1 SDI-12 Transparent Mode ............................................. 240

7.7.14.1.1 SDI-12 Transparent Mode Commands ............... 241

7.7.14.2 SDI-12 Recorder Mode .................................................. 246

7.7.14.2.1 Alternate Start Concurrent Measurement

Command ........................................................ 248

7.7.14.2.2 SDI-12 Extended Command Support ................. 253

7.7.14.3 SDI-12 Sensor Mode ..................................................... 253

Page 14

Table of Contents

14

7.7.14.4 SDI-12 Power Considerations........................................ 255

7.7.15 Compiling: Conditional Code................................................... 256

7.7.16 Measurement: RTD, PRT, PT100, PT1000 .............................. 258

7.7.16.1 Measurement Theory (PRT) .......................................... 259

7.7.16.2 General Procedure (PRT) ............................................... 260

7.7.16.3 Example: 100 Ω PRT in Four-Wire Half Bridge with

Voltage Excitation (PT100 / BrHalf4W() ) ................ 262

7.7.16.4 Example: 100 Ω PRT in Three-Wire Half Bridge with

Voltage Excitation (PT100 / BrHalf3W() ) ................ 266

7.7.16.5 Example: 100 Ω PRT in Four-Wire Full Bridge with

Voltage Excitation (PT100 / BrFull() ) ...................... 270

7.7.16.6 PRT Callendar-Van Dusen Coefficients ........................ 275

7.7.16.7 Self-Heating and Resolution .......................................... 279

7.7.17 Serial I/O: Capturing Serial Data ............................................. 279

7.7.17.1 Introduction.................................................................... 279

7.7.17.2 I/O Ports ......................................................................... 280

7.7.17.3 Protocols ........................................................................ 281

7.7.17.4 Glossary of Serial I/O Terms ......................................... 281

7.7.17.5 Serial I/O CRBasic Programming .................................. 284

7.7.17.5.1 Serial I/O Programming Basics ........................... 284

7.7.17.5.2 Serial I/O Input Programming Basics ................. 286

7.7.17.5.3 Serial I/O Output Programming Basics ............... 288

7.7.17.5.4 Serial I/O Translating Bytes ................................ 289

7.7.17.5.5 Serial I/O Memory Considerations ..................... 289

7.7.17.5.6 Serial I/O Example I ........................................... 290

7.7.17.6 Serial I/O Application Testing ....................................... 292

7.7.17.6.1 Configure HyperTerminal ................................... 292

7.7.17.6.2 Create Send-Text File ......................................... 294

7.7.17.6.3 Create Text-Capture File ..................................... 294

7.7.17.6.4 Serial I/O Example II .......................................... 295

7.7.17.7 Serial I/O Q & A ............................................................ 300

7.7.18 String Operations ...................................................................... 303

7.7.18.1 String Operators ............................................................. 303

7.7.18.2 String Concatenation...................................................... 304

7.7.18.3 String NULL Character ................................................. 306

7.7.18.4 Inserting String Characters ............................................ 307

7.7.19 Subroutines ............................................................................... 307

8. Operation ................................................................. 311

8.1 Measurements — Details................................................................. 311

8.1.1 Time Keeping — Details .......................................................... 311

8.1.1.1 Time Stamps .................................................................. 311

8.1.2 Analog Measurements — Details ............................................. 313

8.1.2.1 Voltage Measurement Quality ....................................... 314

8.1.2.2 Thermocouple Measurements — Details ....................... 331

8.1.2.3 Resistance Measurements — Details ............................. 332

8.1.2.3.1 Ac Excitation ...................................................... 335

8.1.2.3.2 Accuracy — Resistance Measurements .............. 335

8.1.2.4 Auto Self-Calibration — Details ................................... 337

8.1.2.4.1 Auto Self-Calibration Process ............................. 337

8.1.2.5 Strain Measurements — Details .................................... 343

8.1.2.6 Current Measurements — Details .................................. 344

8.1.2.7 Voltage Measurements — Details ................................. 345

8.1.2.7.1 Voltage Measurement Limitations ...................... 345

Page 15

Table of Contents

15

8.1.2.7.2 Voltage Measurement Mechanics ....................... 348

8.1.2.7.3 Voltage Measurement Quality ............................ 351

8.1.3 Pulse Measurements — Details ................................................ 369

8.1.3.1 Pulse Measurement Terminals ....................................... 372

8.1.3.2 Low-Level Ac Measurements — Details ...................... 372

8.1.3.3 High-Frequency Measurements ..................................... 373

8.1.3.3.1 Frequency Resolution ......................................... 374

8.1.3.3.2 Frequency Measurement Q & A ......................... 375

8.1.3.4 Switch Closure and Open-Collector Measurements ...... 375

8.1.3.5 Edge Timing .................................................................. 376

8.1.3.6 Edge Counting ............................................................... 377

8.1.3.7 Timer Input on I/O NAN Conditions ............................. 377

8.1.3.8 Pulse Measurement Tips ................................................ 377

8.1.3.8.1 Pay Attention to Specifications ........................... 379

8.1.3.8.2 Input Filters and Signal Attenuation ................... 380

8.1.4 Vibrating Wire Measurements — Details ................................ 382

8.1.4.1 Time-Domain Measurement .......................................... 382

8.1.5 Period Averaging — Details .................................................... 383

8.1.6 Reading Smart Sensors — Details ........................................... 384

8.1.6.1 RS-232 and TTL — Details ........................................... 384

8.1.6.2 SDI-12 Sensor Support — Details ................................. 385

8.1.7 Field Calibration — Overview ................................................. 385

8.1.8 Cabling Effects — Details ........................................................ 386

8.1.8.1 Analog Sensor Cabling .................................................. 386

8.1.8.2 Pulse Sensor Cabling ..................................................... 386

8.1.8.3 RS-232 Sensor Cabling .................................................. 386

8.1.8.4 SDI-12 Sensor Cabling .................................................. 386

8.1.9 Synchronizing Measurements — Details ................................. 387

8.1.9.1 Synchronizing Measurement in the CR800 —

Details ........................................................................ 387

8.1.9.2 Synchronizing Measurements in a Datalogger

Network — Details .................................................... 387

8.2 Switched-Voltage Output — Details ............................................... 388

8.2.1 Switched-Voltage Excitation .................................................... 389

8.2.2 Continuous-Regulated (5V Terminal) ...................................... 390

8.2.3 Continuous-Unregulated Voltage (12V Terminal) ................... 390

8.2.4 Switched-Unregulated Voltage (SW12 Terminal) ................... 391

8.3 PLC Control — Details ................................................................... 391

8.3.1 Terminals Configured for Control ............................................

392

8.4 Measurement and Control Peripherals — Details ........................... 393

8.4.1 Analog Input Modules .............................................................. 393

8.4.2 Analog Output Modules ........................................................... 394

8.4.3 PLC Control Modules — Overview ......................................... 394

8.4.3.1 Relays and Relay Drivers .............................................. 394

8.4.3.2 Component-Built Relays ............................................... 394

8.4.4 Pulse Input Modules ................................................................. 395

8.4.4.1 Low-Level Ac Input Modules — Overview .................. 395

8.4.5 Serial I/O Modules — Details .................................................. 396

8.4.6 Terminal-Input Modules .......................................................... 396

8.4.7 Vibrating Wire Modules ........................................................... 396

8.5 Datalogger Support Software — Details ......................................... 396

8.6 Program and OS File Compression Q and A ................................... 397

8.7 Security — Details .......................................................................... 400

8.7.1 Vulnerabilities .......................................................................... 401

8.7.2 Pass-Code Lockout ................................................................... 402

Page 16

Table of Contents

16

8.7.2.1 Pass-Code Lockout By-Pass .......................................... 403

8.7.3 Passwords ................................................................................. 404

8.7.3.1 .csipasswd ...................................................................... 404

8.7.3.2 PakBus Instructions ....................................................... 404

8.7.3.3 TCP/IP Instructions........................................................ 404

8.7.3.4 Settings — Passwords .................................................... 405

8.7.4 File Encryption ......................................................................... 405

8.7.5 Communication Encryption...................................................... 405

8.7.6 Hiding Files .............................................................................. 405

8.7.7 Signatures ................................................................................. 406

8.7.8 Read Only Variables ................................................................ 406

8.8 Memory — Details .......................................................................... 406

8.8.1 Storage Media .......................................................................... 406

8.8.1.1 Memory Drives — On-Board ........................................ 409

8.8.1.1.1 Data Table SRAM............................................... 409

8.8.1.1.2 CPU: Drive ......................................................... 409

8.8.1.1.3 USR: Drive ......................................................... 410

8.8.1.1.4 USB: Drive ......................................................... 410

8.8.2 Data File Formats ..................................................................... 411

8.8.3 Resetting the CR800 ................................................................. 415

8.8.3.1 Full Memory Reset ........................................................ 415

8.8.3.2 Program Send Reset ....................................................... 416

8.8.3.3 Manual Data-Table Reset .............................................. 416

8.8.3.4 Formatting Drives .......................................................... 416

8.8.4 File Management in CR800 Memory ....................................... 416

8.8.4.1 File Attributes ................................................................ 418

8.8.4.2 Files Manager ................................................................ 419

8.8.4.3 Data Preservation ........................................................... 420

8.8.4.4 Powerup.ini File — Details ........................................... 421

8.8.4.4.1 Creating and Editing Powerup.ini ....................... 422

8.8.4.5 File Management Q & A ............................................... 424

8.8.5 File Names................................................................................ 424

8.8.6 File System Errors .................................................................... 425

8.9 Data Retrieval and Comms — Details ............................................. 426

8.9.1 Protocols ................................................................................... 426

8.9.2 Conserving Bandwidth ............................................................. 427

8.9.3 Initiating Comms (Callback) .................................................... 427

8.10 Alternate Comms Protocols ............................................................. 428

8.10.1 TCP/IP — Details ..................................................................... 428

8.10.1.1 FYIs — OS2; OS28 ................................

....................... 429

8.10.1.2 DHCP ............................................................................. 429

8.10.1.3 DNS ............................................................................... 430

8.10.1.4 FTP Server ..................................................................... 430

8.10.1.5 FTP Client ...................................................................... 430

8.10.1.6 HTTP Web Server ......................................................... 430

8.10.1.6.1 Default HTTP Web Server .................................. 430

8.10.1.6.2 Custom HTTP Web Server ................................. 431

8.10.1.7 Micro-Serial Server........................................................ 434

8.10.1.8 Modbus TCP/IP ............................................................. 434

8.10.1.9 PakBus Over TCP/IP and Callback ............................... 434

8.10.1.10 Ping (IP) ......................................................................... 435

8.10.1.11 SNMP ............................................................................ 435

8.10.1.12 Telnet ............................................................................. 435

8.10.1.13 SMTP ............................................................................. 435

8.10.1.14 Web API ........................................................................ 435

Page 17

Table of Contents

17

8.10.1.15 Web API — Details ....................................................... 435

8.10.2 DNP3 — Details....................................................................... 436

8.10.3 Modbus — Details ................................................................... 436

8.10.3.1 Modbus Terminology .................................................... 437

8.10.3.1.1 Glossary of Modbus Terms ................................. 437

8.10.3.2 Programming for Modbus .............................................. 438

8.10.3.2.1 Declarations (Modbus Programming) ................. 438

8.10.3.2.2 CRBasic Instructions (Modbus) .......................... 439

8.10.3.2.3 Addressing (ModbusAddr) ................................. 439

8.10.3.2.4 Supported Modbus Function Codes .................... 440

8.10.3.2.5 Reading Inverse Format Modbus Registers ........ 440

8.10.3.2.6 Timing................................................................. 441

8.10.3.3 Troubleshooting (Modbus) ............................................ 441

8.10.3.4 Modbus over IP ............................................................. 441

8.10.3.5 Modbus Security ............................................................ 441

8.10.3.6 Modbus Over RS-232 7/E/1 .......................................... 442

8.10.3.7 Converting Modbus 16-Bit to 32-Bit Longs .................. 442

8.11 Keyboard/Display — Details .......................................................... 443

8.11.1 Character Set ............................................................................ 444

8.11.2 Data Display ............................................................................. 446

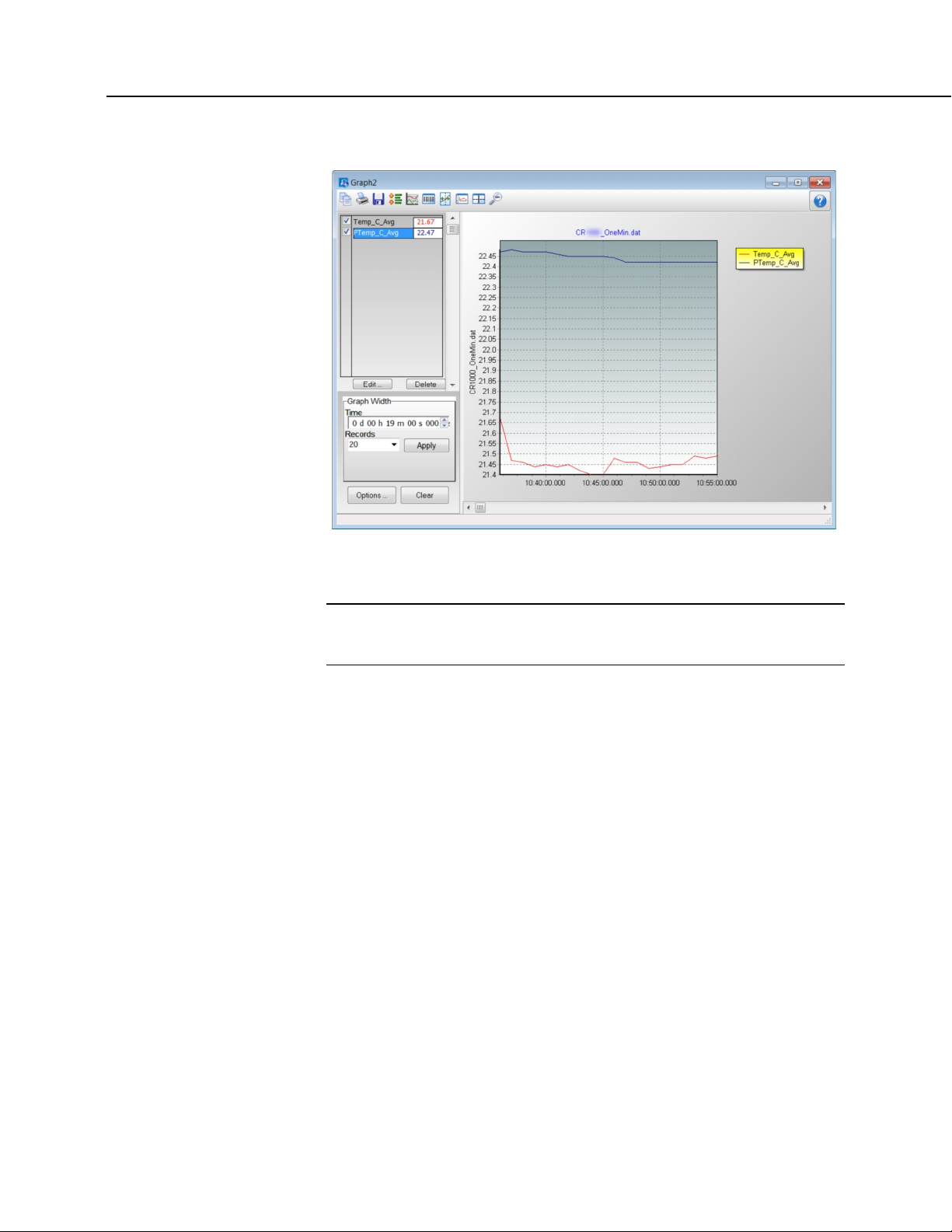

8.11.2.1 Real-Time Tables and Graphs ....................................... 447

8.11.2.2 Real-Time Custom ......................................................... 447

8.11.2.3 Final-Storage Data ......................................................... 449

8.11.3 Run/Stop Program .................................................................... 450

8.11.4 File Management ...................................................................... 451

8.11.4.1 File Edit ......................................................................... 451

8.11.5 Port Status and Status Table ..................................................... 453

8.11.6 Settings ..................................................................................... 454

8.11.6.1 CR1000KD: Set Time / Date ......................................... 454

8.11.6.2 CR1000KD: PakBus Settings ........................................ 454

8.11.7 Configure Display .................................................................... 455

8.12 CPI Port and CDM Devices — Details ........................................... 455

9. Maintenance — Details ........................................... 457

9.1 Protection from Moisture — Details ............................................... 457

9.2 Internal Battery — Details ............................................................... 457

9.3 Factory Calibration or Repair Procedure ......................................... 461

10. Troubleshooting ..................................................... 463

10.1 Troubleshooting — Essential Tools ................................................ 463

10.2 Troubleshooting — Basic Procedure ............................................... 463

Troubleshooting — Error Sources ................................................... 464

10.3

10.4 Troubleshooting — Status Table ..................................................... 465

10.5 Troubleshooting — CRBasic Programs .......................................... 465

10.5.1 Program Does Not Compile ..................................................... 465

10.5.2 Program Compiles / Does Not Run Correctly .......................... 466

10.5.3 NAN and ±INF ......................................................................... 466

10.5.3.1 Measurements and NAN ................................................ 466

10.5.3.1.1 Voltage Measurements ....................................... 467

10.5.3.1.2 SDI-12 Measurements ........................................ 467

10.5.3.2 Floating-Point Math, NAN, and ±INF ........................... 467

10.5.3.3 Data Types, NAN, and ±INF ......................................... 467

10.5.3.4 Output Processing and NAN.......................................... 469

Page 18

Table of Contents

18

10.5.4 Status Table as Debug Resource .............................................. 470

10.5.4.1 CompileResults .............................................................. 471

10.5.4.2 SkippedScan .................................................................. 472

10.5.4.3 SkippedSystemScan ....................................................... 473

10.5.4.4 SkippedRecord ............................................................... 473

10.5.4.5 ProgErrors ...................................................................... 473

10.5.4.6 MemoryFree .................................................................. 473

10.5.4.7 VarOutOfBounds ........................................................... 473

10.5.4.8 Watchdog Errors ............................................................ 474

10.5.4.8.1 Status Table WatchdogErrors ............................. 474

10.5.4.8.2 Watchdoginfo.txt File ......................................... 475

10.6 Troubleshooting — Operating Systems ........................................... 475

10.7 Troubleshooting — Auto Self-Calibration Errors ........................... 475

10.8 Troubleshooting — Communications .............................................. 476

10.8.1 RS-232 ...................................................................................... 476

10.8.2 Communicating with Multiple PCs .......................................... 476

10.8.3 Comms Memory Errors ............................................................ 477

10.9 Troubleshooting — Power Supplies ................................................ 477

10.9.1 Troubleshooting Power Supplies — Overview ........................ 477

10.9.2 Troubleshooting Power Supplies — Examples ........................ 478

10.9.3 Troubleshooting Power Supplies — Procedures ...................... 478

10.9.3.1 Battery Test .................................................................... 478

10.9.3.2 Charging Regulator with Solar Panel Test ..................... 479

10.9.3.3 Charging Regulator with Transformer Test ................... 481

10.9.3.4 Adjusting Charging Voltage .......................................... 482

10.10 Troubleshooting — Using Terminal Mode ..................................... 483

10.10.1 Serial Talk Through and Comms Watch .................................. 486

10.11 Troubleshooting — Using Logs ...................................................... 486

10.12 Troubleshooting — Data Recovery ................................................. 486

10.13 Troubleshooting — Miscellaneous Errors ....................................... 487

10.13.1 Voltage Calibration Error! ........................................................ 487

10.14 Troubleshooting — Rebooting ........................................................ 488

11. Glossary.................................................................. 489

11.1 Terms ............................................................................................... 489

11.2 Concepts .......................................................................................... 522

11.2.1 Accuracy, Precision, and Resolution ........................................ 522

12. Attributions ............................................................. 525

Appendices

A. Info Tables and Settings ......................................... 527

A.1 Info Tables and Settings Directories ................................................ 529

A.1.1.1 Info Tables and Settings: Frequently Used

A.1.1.2 Info Tables and Settings: Keywords .............................. 530

A.1.1.3 Info Tables and Settings: Accessed by Keyboard/

Display ....................................................................... 532

A.1.1.4 Info Tables and Settings: Communications ................... 534

A.1.1.5 Info Tables and Settings: Programming......................... 535

A.1.1.6 Info Tables and Settings: Other ..................................... 535

A.2 Info Tables and Settings Descriptions ............................................. 536

.................... 529

Page 19

Table of Contents

19

B. Serial Port Pinouts .................................................. 553

B.1 CS I/O Communication Port ........................................................... 553

B.2 RS-232 Communication Port .......................................................... 554

B.2.1 Pin Outs .................................................................................... 554

B.2.2 Power States ............................................................................. 555

C. FP2 Data Format ...................................................... 557

D. Endianness .............................................................. 559

E. Supporting Products — List ................................... 561

E.1 Dataloggers — List ......................................................................... 561

E.2 Measurement and Control Peripherals — List ................................ 562

E.3 Sensor-Input Modules — List ......................................................... 562

E.3.1 Analog Input Modules — List .................................................. 562

E.3.2 Pulse Input Modules — List ..................................................... 562

E.3.3 Serial I/O Modules — List ....................................................... 563

E.3.4 Vibrating Wire Input Modules — List ..................................... 563

E.3.5 Passive Signal Conditioners — List ......................................... 563

E.3.5.1 Resistive-Bridge TIM Modules — List ......................... 564

E.3.5.2 Voltage Divider Modules — List .................................. 564

E.3.5.3 Current-Shunt Modules — List ..................................... 564

E.3.5.4 Transient Voltage Suppressors — List .......................... 564

E.3.6 Terminal Strip Covers — List .................................................. 565

E.4 PLC Control Modules — Lists ........................................................ 565

E.4.1 Digital-I/O Modules — List ..................................................... 565

E.4.2 Continuous-Analog Output (CAO) Modules — List ............... 565

E.4.3 Relay-Drivers — List ............................................................... 566

E.4.4 Current-Excitation Modules — List ......................................... 566

E.5 Sensors — Lists ............................................................................... 567

E.5.1 Wired-Sensor Types — List ..................................................... 567

E.5.2 Wireless-Network Sensors — List ........................................... 568

E.6 Cameras — List ............................................................................... 568

E.7 Data Retrieval and Comms Peripherals — List ............................... 568

E.7.1 Keyboard/Display — List ........................................................ 569

E.7.2 Hardwire, Single-Connection Comms Devices — List ............ 569

E.7.3

E.7.4 TCP/IP Links — List ................................................................ 570

E.7.5 Telephone Modems — List ...................................................... 570

E.7.6 Private-Network Radios — List ............................................... 570

E.7.7 Satellite Transceivers — List ................................................... 571

E.8 Data Storage Devices — List .......................................................... 571

E.9 Datalogger Support Software — List .............................................. 571

E.9.1 Starter Software — List ............................................................ 572

E.9.2 Datalogger Support Software — List ....................................... 572

E.9.3 Software Tools — List ............................................................. 574

E.9.4 Software Development Kits — List ......................................... 575

E.10 Power Supplies — List .................................................................... 576

E.10.1 Battery / Regulator Combinations — List ................................ 576

E.10.2 Batteries — List ....................................................................... 577

E.10.3 Regulators — List .................................................................... 577

Hardwire, Networking Devices — List .................................... 570

E.9.2.1 LoggerNet Suite — List ................................................. 573

Page 20

Table of Contents

20

E.10.4 Primary Power Sources — List ................................................ 577

E.10.5 24 Vdc Power Supply Kits — List ........................................... 578

E.11 Enclosures — List ........................................................................... 578

E.12 Tripods, Towers, and Mounts — List .............................................. 579

E.13 Protection from Moisture — List .................................................... 580

Index ............................................................................. 581

List of Figures

FIGURE 1: Wiring Panel .............................................................................. 37

FIGURE 2: Connect Power and Comms ....................................................... 41

FIGURE 3: PC200W Main Window ............................................................. 42

FIGURE 4: Short Cut Temperature Sensor Folder ....................................... 44

FIGURE 5: Short Cut Outputs Tab ............................................................... 45

FIGURE 6: Short Cut Compile Confirmation Window and Results Tab ...... 46

FIGURE 7: PC200W Main Window ............................................................. 47

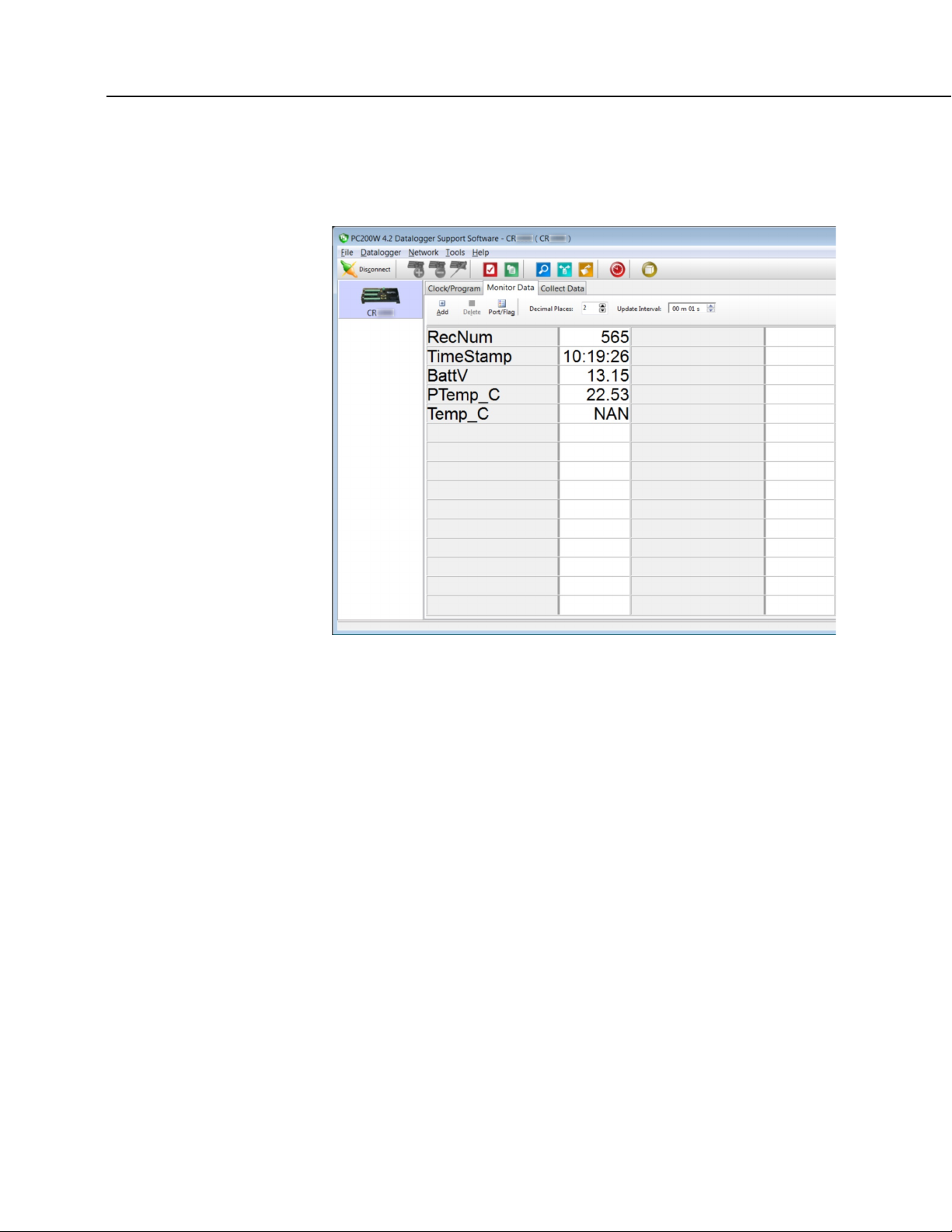

FIGURE 8: PC200W Monitor Data Tab – Public Table ............................... 48

FIGURE 9: PC200W Monitor Data Tab — Public and OneMin Tables ...... 49

FIGURE 10: PC200W Collect Data Tab....................................................... 49

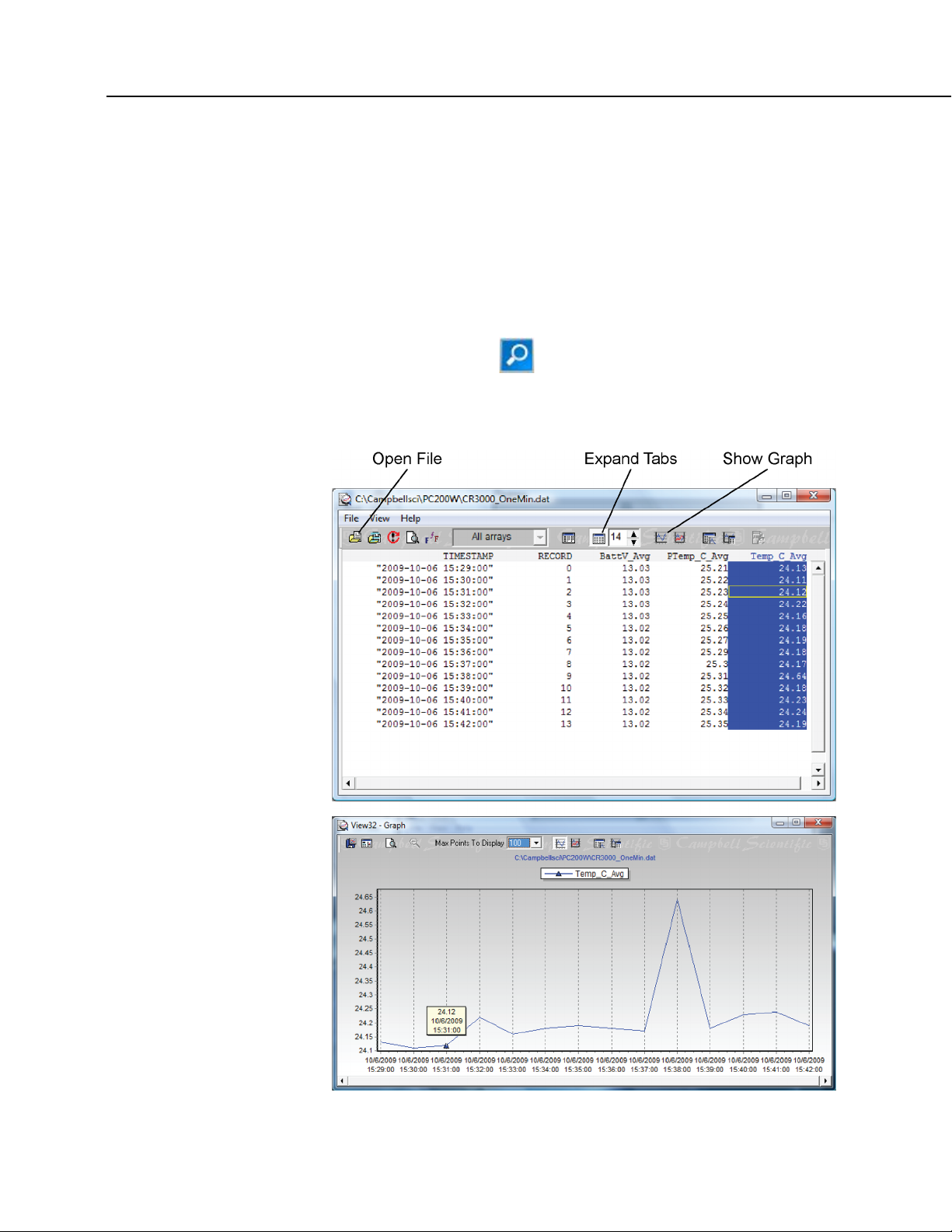

FIGURE 11: PC200W View Data Utility ..................................................... 50

FIGURE 12: PC200W View Data Table....................................................... 51

FIGURE 13: PC200W View Line Graph ...................................................... 52

FIGURE 14: Data-Acquisition System Components .................................... 53

FIGURE 15: Data Acquisition System — Overview .................................... 56

FIGURE 16: Wiring Panel ............................................................................ 58

FIGURE 17: Control and Monitoring with C Terminals............................... 60

FIGURE 18: Analog Sensor Wired to Single-Ended Channel #1 ................. 66

FIGURE 19: Analog Sensor Wired to Differential Channel #1 .................... 67

FIGURE 20: Half-Bridge Wiring Example — Wind Vane Potentiometer ... 69

FIGURE 21: Full-Bridge Wiring Example — Pressure Transducer ............. 70

FIGURE 22: Pulse Sensor Output Signal Types ........................................... 71

FIGURE 23: Pulse Input Wiring Example — Anemometer ......................... 72

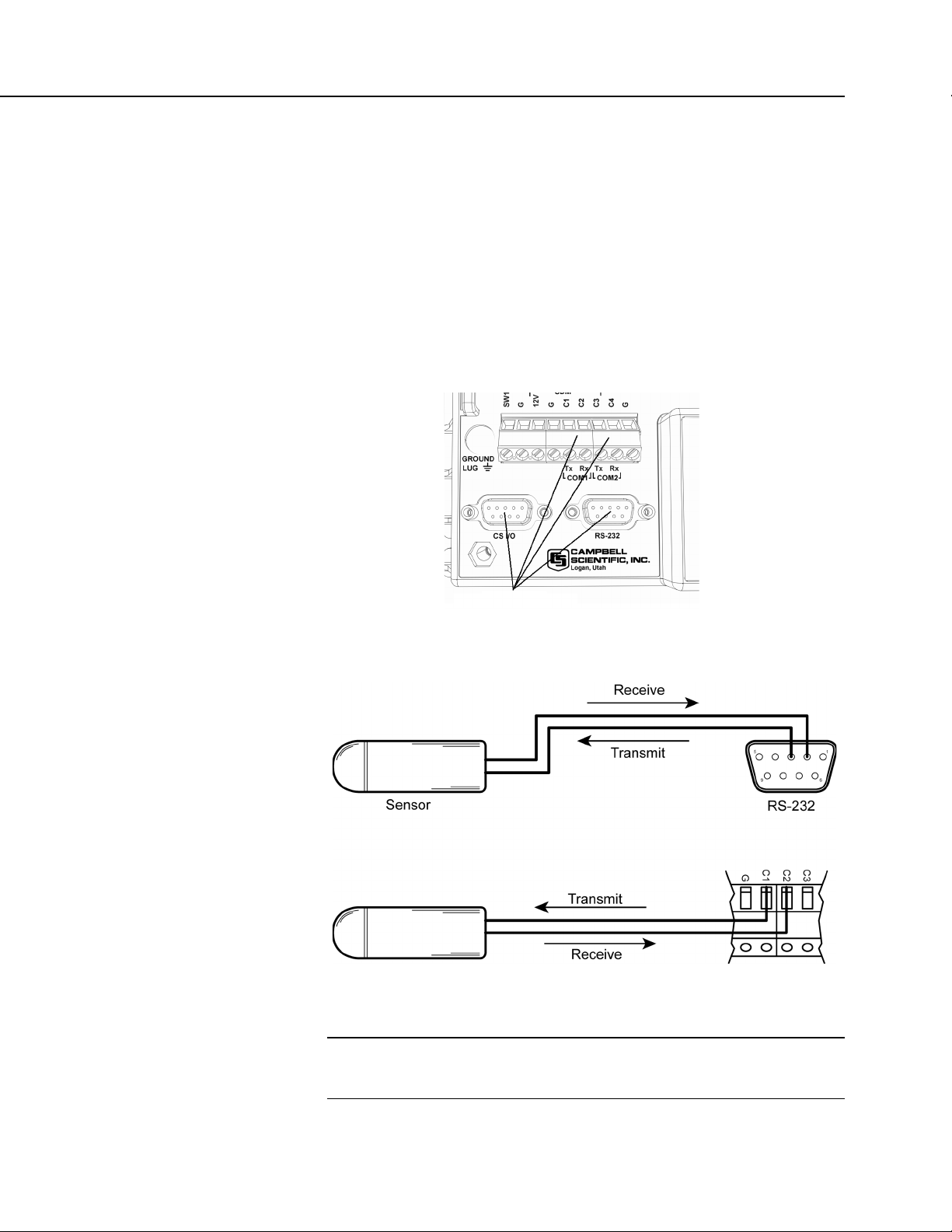

FIGURE 24: Terminals Configurable for RS-232 Input ............................... 75

FIGURE 25: Use of RS-232 and Digital I/O when Reading RS-232

Devices ................................................................................................... 75

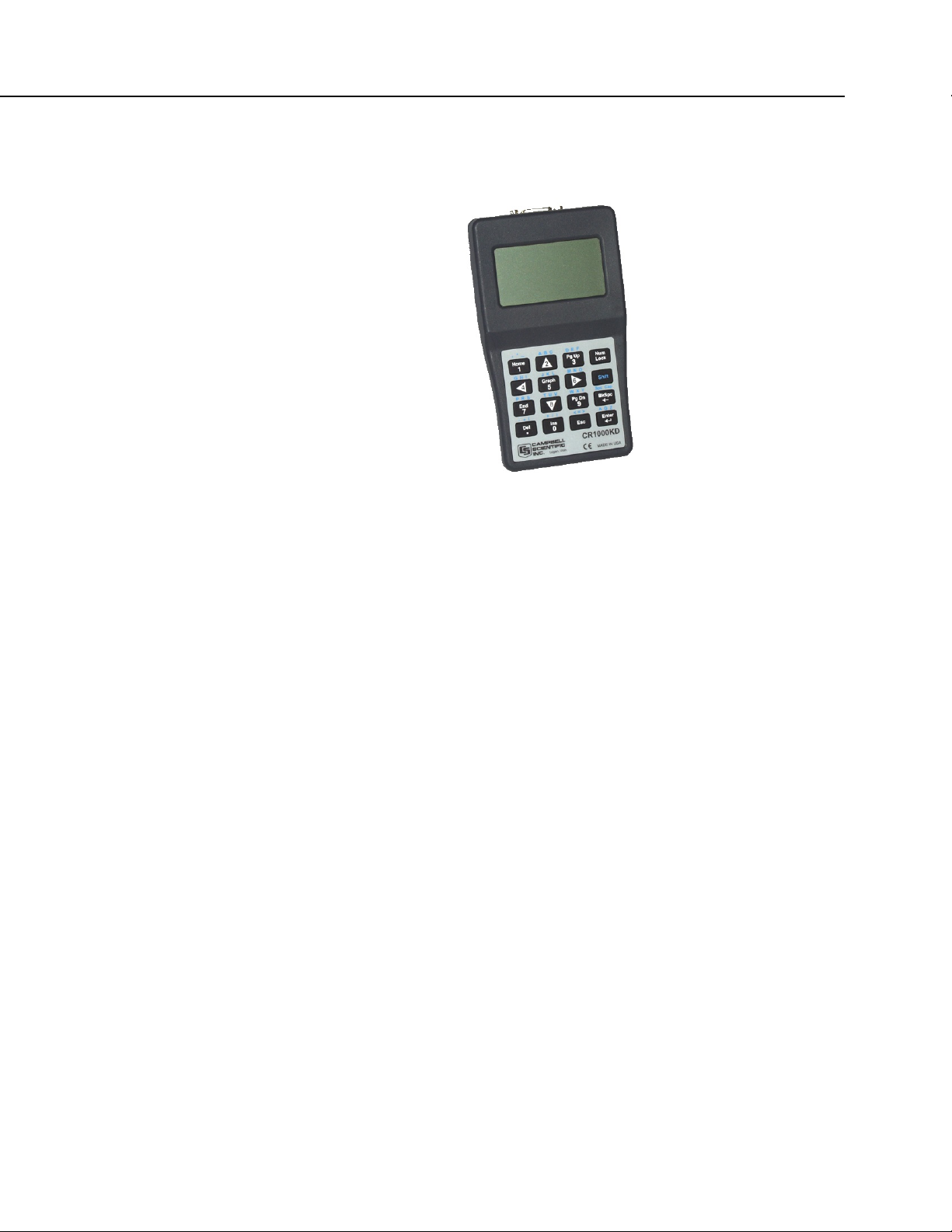

FIGURE 26: CR1000KD Keyboard/Display ................................................ 81

FIGURE 27: Custom Menu Example............................................................ 82

FIGURE 28: Enclosure ................................................................................. 93

FIGURE 29: Connecting to Vehicle Power Supply ...................................... 96

FIGURE 30: Schematic of Grounds .............................................................. 98

FIGURE 31: Lightning Protection Scheme ................................................... 99

FIGURE 32: Model of a Ground Loop with a Resistive Sensor ................. 102

FIGURE 33: Device Configuration Utility (DevConfig) ............................ 104

FIGURE 34: Network Planner Setup .......................................................... 105

FIGURE 35: "Include" File Settings With DevConfig................................ 110

FIGURE 36: "Include" File Settings With PakBusGraph ........................... 111

FIGURE 37: Summary of CR800 Configuration ........................................ 119

FIGURE 38: Sequential-Mode Scan Priority Flow Diagrams .................... 157

FIGURE 39: CRBasic Editor Program Send File Control window............. 171

FIGURE 40: Running-Average Frequency Response ................................. 190

FIGURE 41: Running-Average Signal Attenuation .................................... 190

FIGURE 42: Data from TrigVar Program................................................... 193

FIGURE 43: Alarms Toggled in Bit Shift Example.................................... 195

Page 21

Table of Contents

21

FIGURE 44: Bool8 Data from Bit Shift Example (Numeric Monitor) ....... 195

FIGURE 45: Bool8 Data from Bit Shift Example (PC Data File) .............. 196

FIGURE 46: Input Sample Vectors ............................................................ 204

FIGURE 47: Mean Wind-Vector Graph ..................................................... 205

FIGURE 48: Standard Deviation of Direction ............................................ 206

FIGURE 49: Standard Deviation of Direction ............................................ 206

FIGURE 50: Custom Menu Example — Home Screen .............................. 209

FIGURE 51: Custom Menu Example — View Data Window .................... 209

FIGURE 52: Custom Menu Example — Make Notes Sub Menu ............... 209

FIGURE 53: Custom Menu Example — Predefined Notes Pick List ......... 210

FIGURE 54: Custom Menu Example — Free Entry Notes Window .......... 210

FIGURE 55: Custom Menu Example — Accept / Clear Notes Window .... 210

FIGURE 56: Custom Menu Example — Control Sub Menu ...................... 211

FIGURE 57: Custom Menu Example — Control LED Pick List ............... 211

FIGURE 58: Custom Menu Example — Control LED Boolean Pick

List ....................................................................................................... 211

FIGURE 59: Quarter-Bridge Strain Gage with RC Resistor Shunt ............ 230

FIGURE 60: Strain Gage Shunt Calibration Start ....................................... 231

FIGURE 61: Strain Gage Shunt Calibration Finish .................................... 232

FIGURE 62: Zero Procedure Start .............................................................. 232

FIGURE 63: Zero Procedure Finish ............................................................ 232

FIGURE 64: Entering SDI-12 Transparent Mode ....................................... 241

FIGURE 65: PT100 BrHalf4W() Four-Wire Half-Bridge Schematic ......... 262

FIGURE 66: PT100 BrHalf3W() Three-Wire Half-Bridge Schematic ....... 266

FIGURE 67: PT100 BrFull() Four-Wire Full-Bridge Schematic ................ 270

FIGURE 68: HyperTerminal New Connection Description ....................... 292

FIGURE 69: HyperTerminal Connect-To Settings ..................................... 293

FIGURE 70: HyperTerminal COM Port Settings Tab: Click File |

Properties | Settings | ASCII Setup... and set as shown. ....................... 293

FIGURE 71: HyperTerminal ASCII Setup ................................................. 294

FIGURE 72: HyperTerminal Send-Text File Example ............................... 294

FIGURE 73: HyperTerminal Text-Capture File Example .......................... 295

FIGURE 74: Ac Power Noise Rejection Techniques .................................. 317

FIGURE 75: Input voltage rise and transient decay .................................... 319

FIGURE 76: Settling Time for Pressure Transducer .................................. 321

FIGURE 77: Example voltage measurement accuracy band, including

the effects of percent of reading and offset, for a differential

measurement with input reversal at a temperature between 0 to

40 °C. ................................................................................................... 329

FIGURE 78: PGIA with Input Signal Decomposition ................................ 348

FIGURE 79: Simplified voltage measurement sequence. ........................... 348

FIGURE 80: Programmable Gain Input Amplifier (PGIA): H to V+, L

to V–, VH to V+, VL to V– correspond to text. ................................... 349

FIGURE 81: Ac Power Noise Rejection Techniques .................................. 354

FIGURE 82: Input voltage rise and transient decay .................................... 357

FIGURE 83: Settling Time for Pressure Transducer .................................. 359

FIGURE 84: Example voltage measurement accuracy band, including

the effects of percent of reading and offset, for a differential

measurement with input reversal at a temperature between 0 to

40 °C. ................................................................................................... 368

FIGURE 85: Pulse Sensor Output Signal Types ......................................... 370

FIGURE 86: Switch Closure Pulse Sensor ................................................. 370

FIGURE 87: Terminals Configurable for Pulse Input ................................ 371

FIGURE 88: Amplitude reduction of pulse count waveform (before and

after 1 µs µs time-constant filter) ......................................................... 381

Page 22

Table of Contents

22

FIGURE 89: Vibrating Wire Sensor ........................................................... 382

FIGURE 90: Input Conditioning Circuit for Period Averaging .................. 384

FIGURE 91: Circuit to Limit C Terminal Input to 5 Vdc ........................... 385

FIGURE 92: Current-Limiting Resistor in a Rain Gage Circuit ................. 386

FIGURE 93: Current sourcing from C terminals configured for control .... 393

FIGURE 94: Relay Driver Circuit with Relay ............................................ 395

FIGURE 95: Power Switching without Relay ............................................. 395

FIGURE 96: Preconfigured HTML Home Page ......................................... 431

FIGURE 97: Home Page Created Using WebPageBegin() Instruction ...... 432

FIGURE 98: Customized Numeric-Monitor Web Page .............................. 432

FIGURE 99: CR1000KD: Navigation ........................................................ 445

FIGURE 100: CR1000KD: Displaying Data .............................................. 446

FIGURE 101: CR1000KD Real-Time Tables and Graphs. ......................... 447

FIGURE 102: CR1000KD Real-Time Custom ........................................... 448

FIGURE 103: CR1000KD: Final Storage Data .......................................... 449

FIGURE 104: CR1000KD: Run/Stop Program .......................................... 450

FIGURE 105: CR1000KD: File Management ............................................ 451

FIGURE 106: CR1000KD: File Edit .......................................................... 452

FIGURE 107: CR1000KD: Port Status and Status Table ........................... 453

FIGURE 108: CR1000KD: Settings ........................................................... 454

FIGURE 109: CR1000KD: Configure Display ........................................... 455

FIGURE 110: Remove Retention Nuts ....................................................... 459

FIGURE 111: Pull Edge Away from Panel ................................................. 459

FIGURE 112: Remove Nuts to Disassemble Canister ................................ 460

FIGURE 113: Remove and Replace Battery ............................................... 460

FIGURE 114: Potentiometer R3 on PS100 and CH100 Charger /

Regulator .............................................................................................. 483

FIGURE 115: DevConfig Terminal Tab ..................................................... 485

FIGURE 116: Relationships of Accuracy, Precision, and Resolution ........ 523

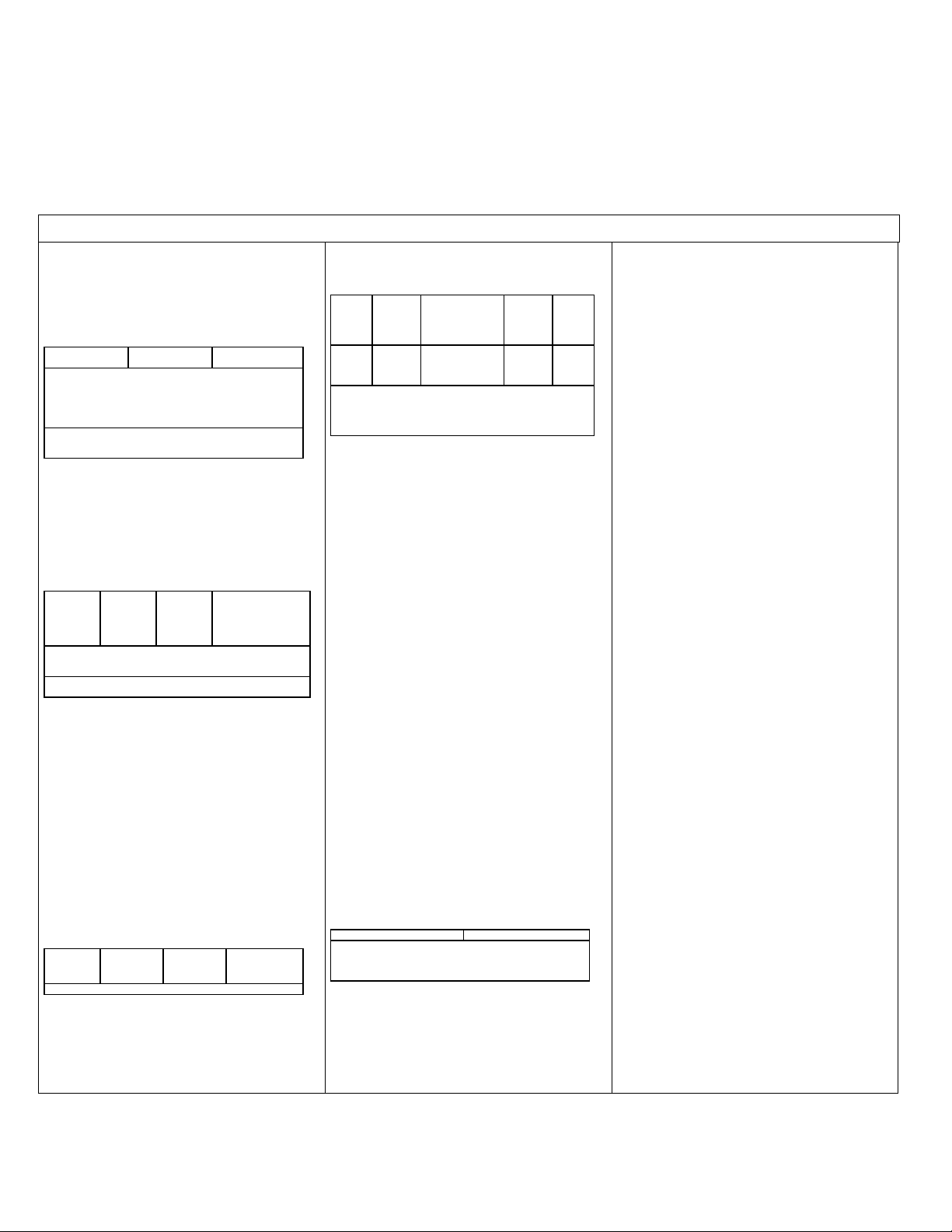

List of Tables

PC200W EZSetup Wizard Prompts ............................................ 43

CR800 Wiring Panel Terminal Definitions ............................... 58

Differential and Single-Ended Input Terminals .......................... 67

Pulse Input Terminals and Measurements ................................... 72

Info Tables and Settings Interfaces ........................................... 107

Common Configuration Actions and Tools ............................... 113

Program Send Command Locations .......................................... 116

CRBasic Program Structure ...................................................... 119

Data Types in Variable Memory ............................................... 127

Data Types in Final-Storage Memory ..................................... 128

Formats for Entering Numbers in CRBasic ............................. 139

Typical Data Table .................................................................. 142

TOA5 Environment Line ......................................................... 142

DataInterval() Lapse Parameter Options ................................. 146

Program Tasks ......................................................................... 151

Program Timing Instructions ................................................... 153

Rules for Names ...................................................................... 159

Binary Conditions of TRUE and FALSE ................................ 164

Logical Expression Examples ................................................. 165

Data Process Abbreviations ..................................................... 168

Program Send Options That Reset Memory1........................... 171

WindVector() OutputOpt Options ........................................... 202

FieldCal() Codes...................................................................... 216

Page 23

Table of Contents

23

Calibration Report for Relative Humidity Sensor ................... 218

Calibration Report for Salinity Sensor .................................... 221

Calibration Report for Flow Meter .......................................... 223

Calibration Report for Water Content Sensor ......................... 226

Maximum Measurement Speeds Using VoltSE() ................... 233

Voltage Measurement Instruction Parameters for Dwell

Burst ..................................................................................................... 237

SDI-12 Commands for Transparent Mode .............................. 242

SDI-12 Commands for Programmed (SDIRecorder())

Mode .................................................................................................... 246

SDI-12 Sensor Configuration CRBasic Example —

Results .................................................................................................. 255

Example Power Usage Profile for a Network of SDI-12

Probes................................................................................................... 256

PRT Measurement Circuit Overview ...................................... 260

PT100 Temperature and ideal resistances (RS); α =

1

0.00385

............................................................................................... 261

Callandar-Van Dusen Coefficients for PT100, α = 0.00385 ... 261

Input Ranges (mV) .................................................................. 261

Input Limits (mV) ................................................................... 261

Excitation Ranges .................................................................... 262

BrHalf4W() Four-Wire Half-Bridge Equations ...................... 262

Bridge Resistor Values (mΩ) .................................................. 262

BrHalf3W() Three-Wire Half-Bridge Equations ..................... 266

Bridge Resistor Values (mΩ) .................................................. 266

PRTCalc() PRTType = 1, α = 0.003851 .................................. 276

PRTCalc() PRTType = 2, α = 0.003921 ................................ 277

PRTCalc() PRTType = 3, α = 0.003911 .................................. 277

PRTCalc() PRTType = 4, α = 0.0039161 ................................ 277

PRTCalc() PRTType = 5, α = 0.003751 .................................. 278

PRTCalc() PRTType = 6, α = 0.0039261 ................................ 278

ASCII / ANSI Equivalents ...................................................... 279

CR800 Serial Ports .................................................................. 281

String Operators ...................................................................... 303

String Concatenation Examples .............................................. 304

String NULL Character Examples .......................................... 306

Analog Measurement Integration ............................................ 316

Ac Noise Rejection on Small Signals1 .................................... 317

Ac Noise Rejection on Large Signals1 .................................... 318

CRBasic Measurement Settling Times .................................... 319

First Six Values of Settling Time Data .................................... 322

Range-Code Option C Over-Voltages ..................................... 323

Offset Voltage Compensation Options .................................... 326

Analog Voltage Measurement Accuracy1 ............................... 328

Analog Voltage Measurement Offsets .................................... 328

Analog Voltage Measurement Resolution ............................... 329

Resistive-Bridge Circuits with Voltage Excitation ................. 333

Ratiometric-Resistance Measurement Accuracy ..................... 336

CalGain() Field Descriptions ................................................... 339

CalSeOffset() Field Descriptions ............................................ 340

CalDiffOffset() Field Descriptions .......................................... 340

Calibrate() Instruction Results ................................................. 341

StrainCalc() Instruction Equations .......................................... 343

Analog Voltage Input Ranges and Options ............................. 346

Page 24

Table of Contents

24

Parameters that Control Measurement Sequence and

Timing .................................................................................................. 350

Analog Measurement Integration ............................................ 354

Ac Noise Rejection on Small Signals1 .................................... 355

Ac Noise Rejection on Large Signals1 .................................... 355