Page 1

CR5000 Measurement and

Control System Overview

Revision: 11/06

Copyright © 2000-2006

Campbell Scientific, Inc.

Page 2

Page 3

CR5000 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

TABLE OF CONTENTS

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

PAGE

OV1. PHYSICAL DESCRIPTION

OV1.1 Measurement Inputs ........................................................................................................... OV-1

OV1.2 Communication and Data Storage...................................................................................... OV-4

OV1.3 Power Supply and AC Adapter ........................................................................................... OV-5

OV2. MEMORY AND PROGRAMMING CONCEPTS

OV2.1 Memory ............................................................................................................................... OV-5

OV2.2 Measurements, Processing, Data Storage ......................................................................... OV-5

OV2.3 Data Tables......................................................................................................................... OV-6

OV3. PC9000 APPLICATION SOFTWARE

OV3.1 Hardware and Software Requirements .............................................................................. OV-6

OV3.2 PC9000 Installation............................................................................................................. OV-6

OV3.3 PC9000 Software Overview................................................................................................ OV-7

OV4. KEYBOARD DISPLAY

OV4.1 Data Display...................................................................................................................... OV-12

OV4.2 Run/Stop Program ............................................................................................................ OV-16

OV4.3 File Display........................................................................................................................ OV-17

OV4.4 Configure Display.............................................................................................................. OV-19

OV5. SPECIFICATIONS.......................................................................................................... OV-20

i

Page 4

CR5000 OVERVIEW TABLE OF CONTENTS

This is a blank page.

ii

Page 5

CR5000 Overview

The CR5000 provides precision measurement capabilities in a rugged, battery-operated

package. The system makes measurements at a rate of up to 5,000 samples/second with

16-bit resolution. The CR5000 includes CPU, keyboard display, power supply, and analog

and digital inputs and outputs. The on-board, BASIC-like programming language includes

data processing and analysis routines. PC9000 Software provides program generation

and editing, data retrieval, and realtime monitoring.

19 20

17 18

15 16

13 14

11 12

910

56

34

12

SE

2

1

HL

HL

HL

DIFF

25

24

23

22

21

SE

12

11

H

L

H

L

H

DIFF

VX1

VX3

VX2

VX4

G

C6

C5

C7

G

C8

C

O

N

TR

O

L

I/O

PO

L

o

g

a

n

, U

ta

h

CR5000 MICROLOGGER

78

4

3

HL

28

27

26

14

13

HL

L

CAO1

CAO2

IX1

IX2

>2.0V

G

<0.8V

5V

5V

W

E

R

U

P

7

6

5

HL

HL

HL

34

33

32

31

30

29

17

16

15

L

H

HL

HL

CONTRO

IX3

IX4

IXR

P1

P1

C1C2C3

G

SDI-12

12V

G

SDM-C2

SDM-C1

SDM-C3

G

12V

P

O

W

'

,

_

A B C

D E F

H

m

P

gU

p

1

2

3

G H I

J K L

M N O

Graph/

char

4

5

6

P R S

T U V

W X Y

E

n

d

P

gD

n

7

8

9

- + (

* / )

< = >

D

el

Ins

ESC

0

SN:

E

HL

35

H

G

R

O

U

8

36

18

L

L I/O

C4

SW-12

SW-12

T

CURSOR

ALPHA

SHIFT

Spc Cap

BKSPC

$ Q Z

ENTER

HL

37

H

G

G

POWER IN

11 - 16 VDC

9

38

19

L

CAUTION

DC ONLY

12V

G

12V

MADE IN USA

10

HL

CS I/O

40

39

20

L

H

RS-232

COMPUTER

(OPTICALLY ISOLATED)

GROUND

LUG

pc card

status

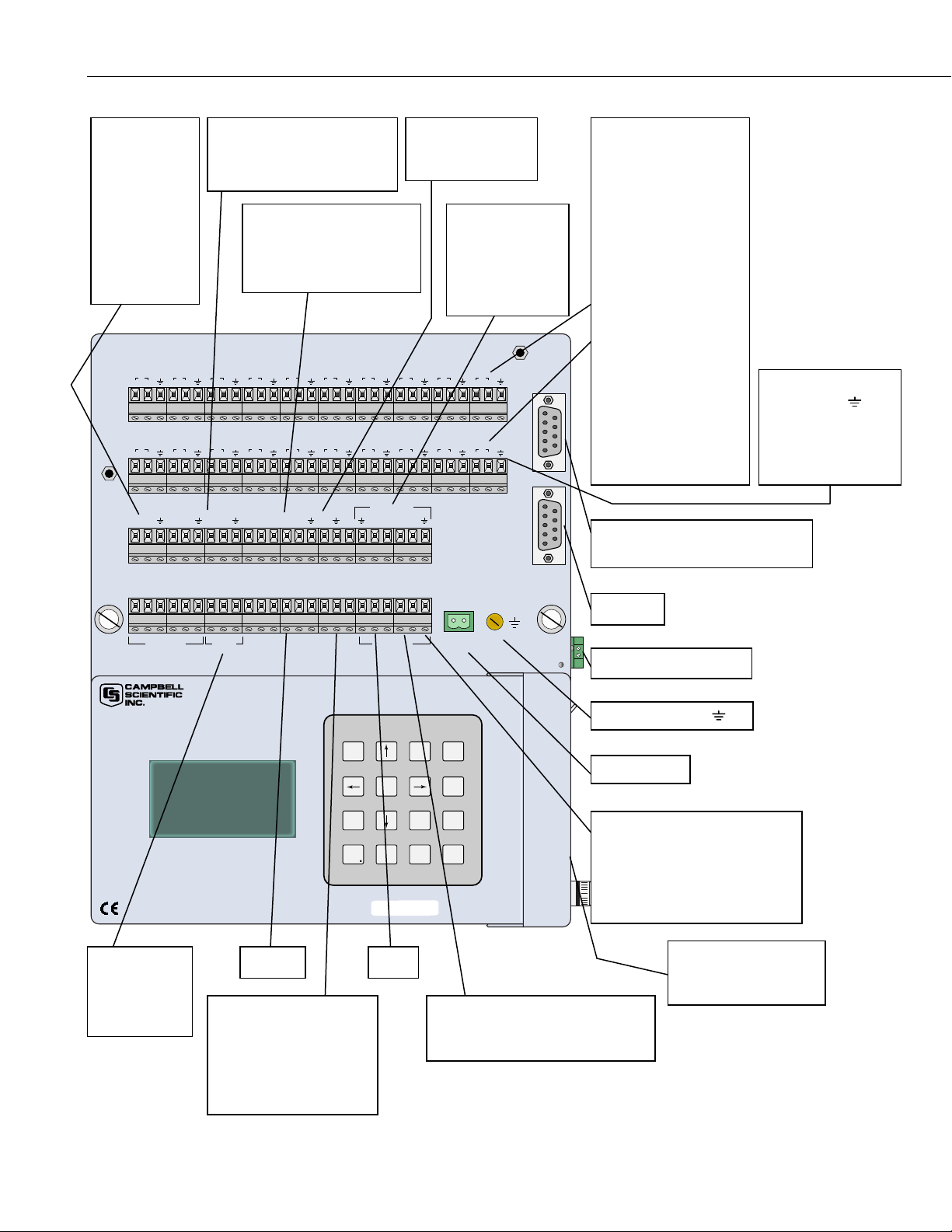

FIGURE OV1-1. CR5000 Measurement and Control System

OV1. Physical Description

Figure OV1-2 shows the CR5000 panel and the associated program

instructions. Unless otherwise noted, they are measurement instructions

(Section 7).

OV1.1 Measurement Inputs

OV1.1.1 Analog Inputs

There are 20 differential or 40 single-ended inputs for measuring voltages up

to ±5 V. A thermistor installed in the wiring panel can be used to measure the

reference temperature for thermocouple measurements, and a heavy copper

grounding bar and connectors combine with the case design to reduce

temperature gradients for accurate thermocouple measurements. Resolution on

the most sensitive range is 0.67 µV

OV-1

Page 6

CR5000 Overview

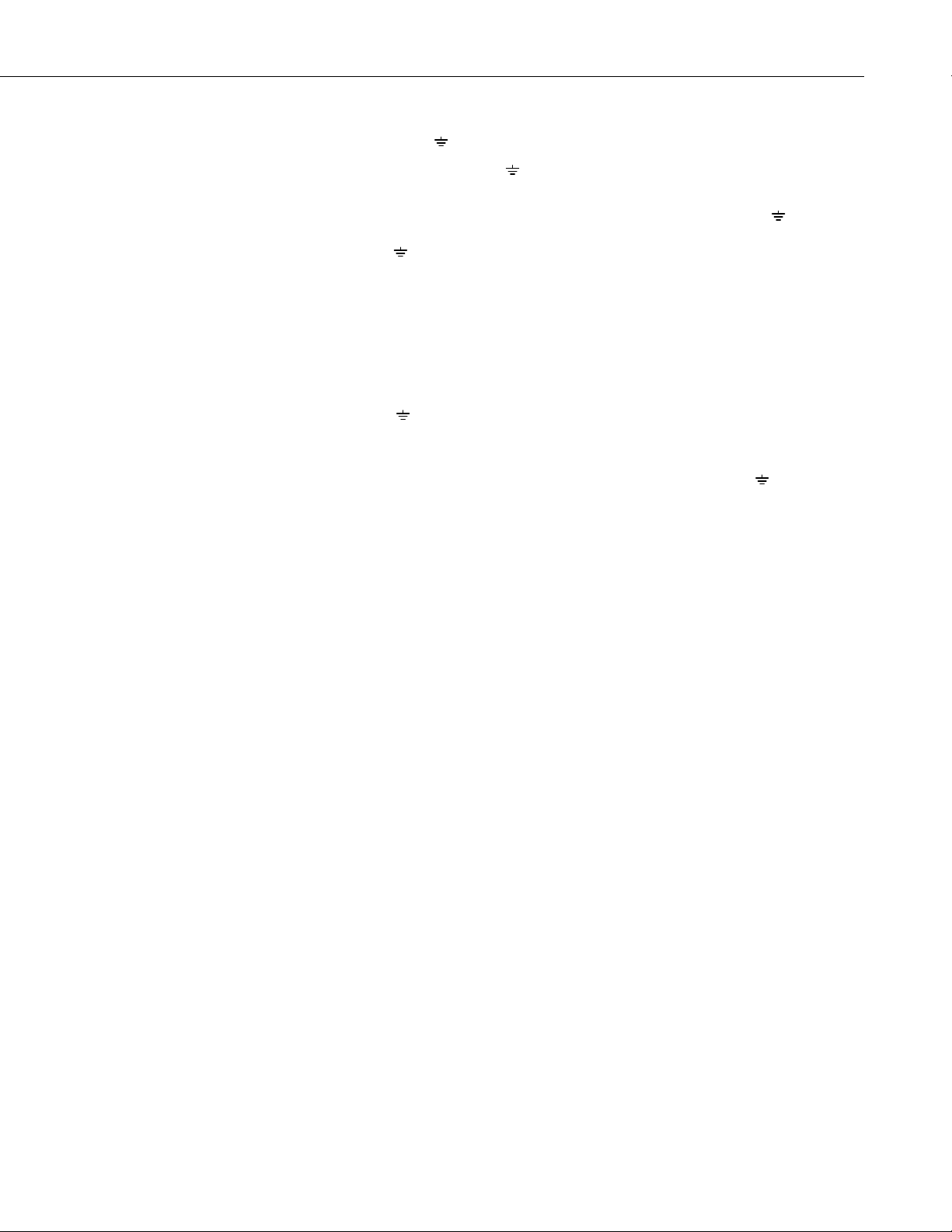

t

SWITCHED

VOLTAGE

EXCITATION

(VX)

Excite

BrFull

BrFull6w

BrHalf

BrHalf3W

BrHalf4W

12

1

HL

21

11

HL

VX1

34

2

HL

22

23 24

12

HL

VX2

VX3

SE

DIFF

SE

DIFF

CONTINUOUS ANALOG

OUTPUTS (CAO)

ExciteCAO

SWITCHED CURRENT

EXCITATION (IX)

ExciteI

Resistance

56

78

910

3

4

HL

HL

25 26

27 28

13

14

HL

HL

VX4

CAO1

CAO2

IX1

IX2

IX3

5

HL

29 30

15

HL

IX4

11 12

6

HL

31 32

16

HL

IXR

P1

P2

13 14

7

HL

33 34

17

HL

PULSE INPUTS

PulseCount

PulseCountRese

15 16

17 18

8

HL

HL

35 36

37 38

18

HL

HL

CONTROL I/O

C1C2C3

C4

CONTROL I/O

PortGet

PortSet

ReadIO

TimerIO

WriteIO

19 20

9

10

HL

39 40

19

20

HL

COMPUTER RS-232

CS I/O

(OPTICALLY ISOLATED)

ANALOG INPUTS

Voltage

VoltDiff

VoltSE

Thermocouple

TCDiff

TCSE

Bridge measurements

(use VX)

BrFull

BrFull6W

BrHalf

BrHalf3W

BrHalf4W

Others

Resistance

PanelTemp

PeriodAvg

AM25T

SIGNAL

GROUND (

FOR

Analog

Pulse

Excitation

CS I/O

DSP4 (Data Tables and Output)

),

GC5C6C7C8G>2.0VG>0.8V5V5VGSDI-12

CONTROL I/O POWER

Logan, U

CR5000 MICROLOGGER

POWER UP

PowerOff

(program

control)

UP

tah

SDI-12 12 V

SDM CONNECTIONS

CS7500

CSAT3

SDMINT8

SDMSpeed

SDMTrigger

12VGSDM-C1

SDM-C2

SDM-C3G12VGSW-12

POWER OUT

'

_

,

A

Hm

1

I

H

G

J K

Graph/

char

4

S

R

T

P

End

7

(

- +

Del

SN:

SW-12

G

CAUTION

DC ONLY

G12V

POWER IN

11 - 16 VDC

GROUND

LUG

pc card

status

RS-232

CHARGER INPUT

GROUND LUG

F

C

E

B

D

CURSOR

PgUp

ALPHA

3

2

O

L

N

M

X

W

PgDn

< = >

ESC

6

Y

9

SHIFT

ap

pc C

S

BKSPC

Z

$ Q

ENTER

5

V

U

8

* / )

Ins

0

POWER IN

POWER GROUND (G),

FOR

5V

SW-12

12V

MADE IN USA

PCMCIA PC CARD

CardOut (Data Tables

and Output)

SWITCHED 12 VOLTS SW-12

PortSet

SW12

OV-2

FIGURE OV1-2. CR5000 Panel and Associated Instructions.

Page 7

OV1.1.2 Signal Grounds ( )

The Signal Grounds ( ) should be used as the reference for Single-ended

Analog inputs, Excitation returns, and sensor shield wires.

Signal returns from the CAO and Pulse channels should use the

located on the CAO and Pulse terminal strip to minimize current flow through

grounds on the analog terminal strips.

the

OV1.1.3 Power Grounds (G)

The Power Grounds (G) should be used as the returns for the 5V, SW12, 12V,

and C1-C8 outputs. Use of the G grounds for these outputs with potentially

large currents will minimize current flow through the analog section, which

can cause Single-ended voltage measurement errors.

OV1.1.4 Ground Lug

The large ground lug is used to connect a heavy gage wire to earth ground. A

good earth connection is necessary fix the ground potential of the datalogger

and to send to earth transients that come in on either the G or

are shunted to ground via the spark gaps protecting other inputs.

CR5000 Overview

terminals

terminals or

OV1.1.5 Power In

The G and 12V terminals on the unplugable Power In connector are for

connecting power from an external battery to the CR5000. These are the only

terminals that can be used to input battery power; the other 12V and SW-12V

terminals are out only. Power from this input will not charge internal CR5000

batteries. Power to charge the internal batteries (17-28 VDC or 18 VRMS AC)

must be connected to the charger input on the side of the LA battery back.

OV1.1.6 Switched 12 Volts SW-12

The SW-12 terminals provide an unregulated 12 volts that can be switched on

and off under program control.

OV1.1.7 Switched Voltage Excitation (VX)

Four switched excitation channels provide precision programmable voltages

within the ±5 Volt range for bridge measurements. Each analog output will

provide up to 50 mA between ±5 V.

OV1.1.8 Switched Current Excitation (IX)

Four Switched Current Excitation channels provide precision current

excitations programmable within ±2.5 mA for resistance or bridge

measurements.

OV1.1.9 Continuous Analog Outputs (CAO)

Two Continuous Analog Outputs (CAO) with individual outputs under

program control for proportional control (e.g., PID algorithm) and waveform

generation. Each analog output will provide up to 15 mA between ±5 V.

OV-3

Page 8

CR5000 Overview

OV1.1.10 Control I/O

OV1.1.11 Pulse Inputs

OV1.1.12 Power Up

There are 8 digital Input/Output channels (0 V low, 5 V high) for frequency

measurement, digital control, and triggering.

Two Pulse input channels can count pulses from high-level (5 V square wave),

switch closure, or low-level A/C signals.

The CR5000 allows shutting off power under program control. The Power Up

inputs allow an external signal to awaken the CR5000 from a powered down

state (PowerOff, Section 9). When the CR5000 is in this power off state the

ON Off switch is in the on position but the CR5000 is off. If the "<0.5 " input

is switched to ground or if the ">2" input has a voltage greater than 2 volts

applied, the CR5000 will awake, load and run the “run on power-up” program.

If the "< 0.5" input continues to be held at ground while the CR5000 is

powered on and goes through its 2-5 second initialization sequence, the

CR5000 will not run “run on power-up” program.

OV1.1.13 SDM Connections

The Synchronous Device for Measurement (SDM) connections C1,C2, and C3

along with the adjacent 12 volts and ground terminals are used to connect

SDM sensors and peripherals.

OV1.2 Communication and Data Storage

OV1.2.1 PCMCIA PC Card

One slot for a Type I/II/III PCMCIA card. The keyboard display is used to

check card status. The card must be powered down before removing it. The

card will be reactivated if not removed.

CAUTION

OV1.2.2 CS I/O

OV1.2.3 Computer RS-232

Removing a card while it is active can cause garbled data

and can actually damage the card. Do not switch off the

CR5000 power while the card is present and active.

A 9-pin serial I/O port supports CSI peripherals.

OV-4

RS-232 Port

Page 9

OV1.3 Power Supply and AC Adapter

The CR5000 has two base options the low profile without any power supply

and the lead acid battery power supply base. The low profile base requires an

external DC power source connected to the Power In terminal on the panel.

The battery base has a 7 amp hour battery with built in charging regulator and

includes an AC adapter for use where 120 VAC is available (18 VAC RMS

output). Charging power can also come from a 17-28 VDC input such as a

solar panel. The DCDC18R is available for stepping the voltage up from a

nominal 12 volt source (e.g., vehicle power supply) to the DC voltage required

for charging the internal battery.

OV2. Memory and Programming Concepts

OV2.1 Memory

The CR5000 has 2MB SRAM and 1MB Flash EEPROM. The operating

system and user programs are stored in the flash EEPROM. The memory that

is not used by the operating system and program is available for data storage.

The size of available memory may be seen in the status file. Additional data

storage is available by using a PCMCIA card in the built in card slot.

CR5000 Overview

OV2.2 Measurements, Processing, Data Storage

The CR5000 divides a program into two tasks. The measurement task

manipulates the measurement and control hardware on a rigidly timed

sequence. The processing task processes and stores the resulting

measurements and makes the decisions to actuate controls.

The measurement task stores raw Analog to Digital Converter (ADC) data

directly into memory. As soon as the data from a scan is in memory, the

processing task starts. There are at least two buffers allocated for this raw

ADC data (more under program control), thus the buffer from one scan can be

processed while the measurement task is filling another.

When a program is compiled, the measurement tasks are separated from the

processing tasks. When the program runs, the measurement tasks are

performed at a precise rate, ensuring that the measurement timing is exact and

invariant.

Processing Task: Measurement Task:

Digital I/O task

Read and writes to digital I/O ports

(ReadI/O, WriteI/O)

Processes measurements

Determines controls (port states) to set next scan

Stores data

Analog measurement and excitation sequence and

timing

Reads Pulse Counters

Reads Control Ports (GetPort)

Sets control ports (SetPort)

OV-5

Page 10

CR5000 Overview

OV2.3 Data Tables

The CR5000 can store individual measurements or it may use its extensive

processing capabilities to calculate averages, maxima, minima, histogams,

FFTs, etc., on periodic or conditional intervals. Data are stored in tables such

as listed in Table OV2-1. The values to output are selected when running the

program generator or when writing a datalogger program directly.

Table OV2-1. Typical Data Table

TOA4 StnName Temp

TIMESTAMP RECORD RefTemp_Avg TC_Avg(1) TC_Avg(2) TC_Avg(3) TC_Avg(4) TC_Avg(5) TC_Avg(6)

TS RN degC degC degC degC degC degC degC

Avg Avg Avg Avg Avg Avg Avg

1995-02-16 15:15:04.61 278822 31.08 24.23 25.12 26.8 24.14 24.47 23.76

1995-02-16 15:15:04.62 278823 31.07 24.23 25.13 26.82 24.15 24.45 23.8

1995-02-16 15:15:04.63 278824 31.07 24.2 25.09 26.8 24.11 24.45 23.75

1995-02-16 15:15:04.64 278825 31.07 24.21 25.1 26.77 24.13 24.39 23.76

OV3. PC9000 Application Software

PC9000 is a Windows™ application for use with the CR5000. The software

supports CR5000 program generation, real-time display of datalogger

measurements, graphing, and retrieval of data files.

OV3.1 Hardware and Software Requirements

The following computer resources are necessary:

• IBM PC, Portable or Desktop

• 8 Meg of Ram

• VGA Monitor

• Windows 95 or newer

• 30 Meg of Hard Drive Space for software

• 40 Meg of Hard Drive Space for data

• RS232 Serial Port

OV-6

The following computer resources are recommended:

• 16 Meg of Ram

• 33 MHz 486 or faster

• Mouse

OV3.2 PC9000 Installation

To install the PC9000 Software:

• Start Microsoft Windows

• Insert diskette 1 (marked 1 of 2) in a disk drive.

• From the Program Manager, select F

• Type (disk drive):\setup and press Enter e.g. a:\setup<Enter>

• The setup routine will prompt for disk 2.

ile menu and choose Run

Page 11

You may use the default directory of PC9000 or install the software in a

different directory. The directory will be created for you.

To abort the installation, type Ctrl-C or Break at any time.

OV3.3 PC9000 Software Overview

This overview points out the main PC9000 functions and where to find them.

PC9000 has extensive on-line help to guide the user in its operation, run

PC9000 to get the details. A CR5000 is not necessary to try out the

programming and real time display options; a demo uses canned data for

viewing. Without a CR5000, there are no communications with the

datalogger; operations such as downloading programs and retrieving data will

not function.

Figures OV3-1 and OV3-2 show the main PC9000 menus. The primary

functions of PC9000 are accessed from the File, Comm, Realtime, and

Analysis selections on the main menu (Figure OV3-1).

CR5000 Overview

OV-7

Page 12

CR5000 Overview

File Edit Realtime Analysis Tools Collect Display Windows Help

CommLink

Alarms List . . .

ield Monitor . . .

F

Virtual M

Virtual O

-Y Plotter . . .

X

istogram . . .

H

Fast Fourier T

Level Crossing Histogram . . .

et/Set Variable . . .

G

Display Data Graph 1 . . .

Display Data Graph 2

ID2000 . . . Ctrl + I

eter . . .

'Scope . . .

ransform . . .

Select S

Select P

Logger C

Logger Status . . .

D

ownload . . .

Save and Download

Logger F

Di

agnostics

Data Retrieval . . .

cheduled Data Retrieval . . .

S

eries Linked Station . . .

arallel Linked Station . . .

lock . . .

iles . . .

. . .

Realtime Display

& Graphing

Display Data in Tables Collected From CR5000.

Graphing requires no special processing of the data

and provides rapid feedback to the operator.

Collect data from CR5000

PC to CR5000

communications.

CR9000 Program Generator

000 Program Generator

CR5

CR9000 Program Editor . . .

CR5000 Program Editor . . .

Open W

Open Data Table I

Open D

Convert Binary to ASCII File . . .

P

Printer Setup . . .

D

File Manager . . .

E

Exit PC9000

iring Diagram . . .

ata File . . .

rint . . .

OS Shell . . .

xplorer . . .

nfo File . . .

Menu-driven Program Generation.

Direct Editing of Program

View/Edit Wiring Diagram & DataTable

Information (Created by Program Generator)

View Data Collected from CR5000

OV3-1. PC9000 Primary Functions

OV-8

Page 13

CR5000 Overview

File Edit Realtime Analysis Tools Collect Display Windows Help

Undo Ctrl + Z

Date & Time

Select All

Strip Remarks and Spaces Ctrl + S

Cut Ctrl + X

Copy Ctrl + C

Paste Ctrl + V

Delete

Delete Line Ctrl + Y

Wrap Text Ctrl + W

Go To Line . . .

Find Ctrl + F

Replace Ctrl + R

OV3-2. PC9000 Editing, Help, and User Preferences

Editing Options for

Active Windows

Colors . . .

Fonts . . .

Defaults . . .

Change fonts

and/or Colors for

Active Windows.

Tile Horizontal . . .

Tile Vertical . . .

Cascade . . .

Arrange Icons . . .

ork Area Setup . . .

W

List of Windows

PC9000 Help Contents . . .

earch PC9000 Help . . .

S

CRBasic Help Contents . . .

Search CR

Obtaining Technical Support . . .

A

bout PC9000 . . .

Software Versions . . .

Basic Help . . .

OV3.3.1 File

OV3.3.2 Edit

Program Generator

Guides the user through a series of menus to configure the measurement types:

thermocouple, voltage, bridge, pulse counting, frequency, and others. Creates

a CR5000 program, wiring diagram, output table, description, and

configuration file.

Program Editor

Create programs directly or edit those created by the program generator or

retrieved from the CR5000. Provides context-sensitive help for the CR5000's

BASIC-like language.

REALTIME

Virtual Meter

Updates up to five displays simultaneously. Choices include analog meter,

horizontal and vertical bars, independent scaling/offset, multiple alarms, and

rapid on-site calibration of sensors

OV-9

Page 14

CR5000 Overview

OV3.3.3 Analysis

OV3.3.4 Tools

OV3.3.5 Collect

Virtual Oscilloscope

Displays up to six channels. Time base variable from milliseconds to hours.

X-Y Plotter

Allows comparison of any two measurements in real time.

Data Graphing

Displays up to 16 fields simultaneously as strip charts or two multi-charts with

up to 8 traces each. Includes 2D/3D bars, line, log/linear, area, and scatter.

Line statistics available for max/min, best fit, mean, and standard deviation.

Handles files of unlimited size. Historical graphing requires no special

processing of the data and provides rapid feedback to the operator.

Control and Communications

Supports PC to CR5000 communications: clock read/set, status read, program

download, and program retrieval.

OV3.3.6 Display

OV3.3.7 Windows

OV3.3.8 Help

Collect data from CR5000 data tables

Configure the font and color scheme in an active window.

Size and arrange windows.

On-line help for PC9000 software.

OV-10

Page 15

OV4. Keyboard Display

CR5000 Overview

Power Up Screen

Press any key

CAMPBELL

SCIENTIFIC

CR5000 Datalogger

06/18/2000, 18:24:35

CPU: TRIG.CR5

Running.

for Main Menu

(except < >)

Data

Run/Stop Program

File

Status

Configure, Settings

Adjust contrast with < >

< lighter darker >

Real Time Tables

Real Time Custom

Final Storage Data

Reset Data Tables

Graph Setup

New

Edit

Copy

Delete

Run Options

Directory

Format

ROM Version : xxxx

OS Version : xxxx

OS Date : xxxx

OS Signature

Serial Number

Rev Board

Station Name : xxxx

Program Name : xxxxx

StartTime : xxxxx

Run Signature

DLD Signature

Battery : xxxx

Set Time/Date

Settings

Display

OV-11

Page 16

CR5000 Overview

OV4.1 Data Display

Data

Run/Stop Program

File

Status

Configure, Settings

Cursor to Data

and Press

Enter

Real Time Tables

Real Time Custom

Final Storage Data

Reset Data Table

Graph Setup

List of Data Tables created by

active program

List of Data Tables created by

active program

List of Data Tables created by

active program

OV-12

All Tables

List of Data Tables created by

active program

Graph Type: Scope

Scaler: Manual

Upper: 0.000000

Lower: 0.000000

Display Val Off

Display Max Off

Display Min Off

Page 17

OV4.1.1 Real Time Tables

List of Data Tables created by

active program. For Example,

Table1

Temps

Public

Cursor to desired

Table and press

Enter

Tref : 23.0234

TCTemp(1) : 19.6243

TCTemp(2) : 19.3429

TCTemp(3) : 21.2003

TCTemp(3) :

Flag(1) : -1.0000

Flag(2) : 0.00000

Flag(3) : 0.00000

Flag(4) : 0.00000

Public Table values

can be changed.

Cursor to value and

press Enter to edit

value.

CR5000 Overview

Tref : 23.0234

TCTemp(1) : 19.6243

TCTemp(2) : 19.3429

TCTemp(3) : 21.2003

TCTemp(3)

2

Flag(1) : -1.0000

Flag(2) : 0.00000

Flag(3) : 0.00000

Flag(4) : 0.00000

Press Graph/ Char

for Graph of

selected field

30.0 22.35

_____

___ ____

__

20.00

New values are displayed as they

are stored.

Scaler Manual

Press Ins for

Graph Setup

Upper: 30.000000

Lower: 20.000000

Display Val On

Display Max On

Display Min On

Graph Type Roll

OV-13

Page 18

CR5000 Overview

)

OV4.1.2 Setting up Real Time Custom Display

List of Data Tables created by

active program. For Example,

Table1

Temps

Public

Cursor to desired

Table and Press

Enter

Tref

TCTemp(1)

TCTemp(2)

TCTemp(3)

TCTemp(3

Flag(1)

Flag(2)

Flag(3)

Flag(4)

Cursor to position for next value

and Press Enter

Cursor to desired

Field and Press

Enter

TCTemp(3) : 24.9496

New values are displayed as they

are stored.

:

:

:

:

:

:

:

OV-14

Page 19

OV4.1.3 Final Storage Tables

_

List of Data Tables created by

active program. For Example:

Table1

Temps

CR5000 Overview

Cursor to desired

Table and Press

Enter

Use Hm (oldest), End (newest),

PgUp (older), PgDn (newer),

←, →, ↑

, and ↓ to move around

in data table.

TimeStamp Record Tref TC(1) TC(2) TC(3)

"2000-01-03 00:12:38" 0 21.934 22.8419

"2000-01-03 00:12:39" 1 24.1242 21.8619 21.9173 22.8364

"2000-01-03 00:12:40" 2 24.1242 21.8786 21.9229 22.8364

"2000-01-03 00:12:41" 3

"2000-01-03 00:12:42" 4

"2000-01-03 00:12:43" 5

"2000-01-03 00:12:44" 6

"2000-01-03 00:12:45" 7

"2000-01-03 00:12:46" 8

5 :2000-01-03 00:12:43

Tref TC(1)

24.1242 : 21.8786

24.1242 : 21.8786

24.1242 : 21.8675

21.8675

24.1242 : 21.8675

24.1242 : 21.8675

24.1242 : 21.8398

21.9173 22.8419

21.9173 22.8253

21.9118 22.8364

21.9173 22.8087

21.9173 22.8142

21.9395 22.8253

"2000-01-03 00:12:47" 9 24.1242 21.8176 21.9118 22.8308

"2000-01-03 00:12:48" 10 24.1242 21.8342 21.945 22.8364

"2000-01-03 00:12:49" 11 24.1242 21.8453 21.9506 22.8364

Press Ins for Jump To screen.

Go to Record:

Press Graph/ Char for

Graph of selected field.

←, →

Use

, PgUp, PgDn

to move cursor and

window of data graphed.

5

press Ins to edit

Table Size:

1000

Current Record:

759

30.0 21.87

______

______ _______

____ ___ ____

__

20.00

Press Ins for

Graph Setup

Scaler Manual

Upper: 30.000000

Lower: 20.000000

Display Val On

Display Max On

Display Min On

Graph Type Roll

OV-15

Page 20

CR5000 Overview

OV4.2 Run/Stop Program

PCCard Display

Data

Run/Stop Program

File

Status

Configure, Settings

Cursor to

PCCard and

Press Enter

Remove Card

Format Card

Table Status

Card Status

CPU:

List of Programs

No Program

CRD:

List of Programs

You may now

remove the Card.

CR5000 closes tables first.

All Card Data

Will be Lost!

Proceed?

Yes

No

List of Data Tables on card

created by active program

PC Card Status:

Battery OK

5Volt Card

WP Disabled

OV-16

Page 21

OV4.3 File Display

Data

Run/Stop Program

File

Status

Configure, Settings

Cursor to

File and

Press Enter

New

Edit

Copy

Delete

Run Options

Directory

Format

CR5000 Overview

New File Name:

CPU: .CR5

CRD: .CR5

CPU:

CRD:

Copy

From

To

Execute

List of files on

CPU or Card.

CPU: Program

No Program

CRD: Program

CPU:

All programs and other files

will be lost!

Proceed?

Yes List of Programs

No

OV-17

Page 22

CR5000 Overview

D

p

)

p

OV4.3.1 File: Edit

List of Program files on CPU: or

CRD: For Example:

CPU:

TCTEMP.CR5 0

RACE.CR5 0

Cursor to desired Program

and Press Enter

The Program Editor in PC9000 is recommended for writing and editing

datalogger programs. Changes in the field can be made with the keyboard

display.

Save Changes?

Yes

No

ESC

CR5000

' TCTemp.CR5

Public TREF,TC(3),FLAG(8)

D ataTable (Temps,1,1000)

Sample (1,TREF,IEEE4)

Sample (3,TC(),IEEE4)

Edit Directly or Cursor to first

character of line and Press

Enter

ENTER

Edit Instruction

Blank Line

Create Block

DataTable (Temps,1,1000)

DataTable (Temps,1,1000

Sample (1,TREF,IEEE4)

Sample (3,TC(),IEEE4)

EndTable

Press Ins

Edit Instruction parameters with

Cursor down to

highlight desired

block and press

Enter

INSERT

Instruction

Function

Blank Line

Block

Insert Off

arameter names and some pick lists:

DataTable

TableName

> Temps

TrigVar

1

Size

1000

Insert blank line

Block Commands

Copy

Cut

Delete

BeginProg

Scan(1,sec,3,0)

To insert a block created by this

operation, cursor to desired place in

rogram and press Ins.

OV-18

Page 23

OV4.4 Configure Display

Data

Run/Stop Program

File

Status

Configure, Settings

Cursor to

Configure,

Settings and

Press Enter

Set Time/Date

Settings

Display

CR5000 Overview

05/24/2000, 15:10:40

Year 2000

Month 5

Day 24

Hour 15

Minute 10

Set

Cancel

Security Enable

RS-232 Time Out: No

CR5000 Off

Light Dark

<- * ->

Enter Passwords:

Level 1:

Level 2:

Level 3:

click

Enter

Num

Password

Turn off display

Back Light

Contrast Adjust

Display Time Out: No, Yes (if yes)

Time out (min) 1

OV-19

Page 24

CR5000 Overview

OV5. Specifications

Electrical specifications are valid over a -25° to +50°C range unless otherwise specified; testing over -40° to +85°C available as

an option, excludes batteries. Non-condensing environment required. Yearly calibrations are recommended to maintain electrical specifications.

PROGRAM EXECUTION RATE

The CR5000 can measure one channel and store the

result in 500 µs; all 40 SE* channels can be measured

in 8 ms (5 kHz aggregate rate).

ANALOG INPUTS

DESCRIPTION: 20 DF* or 40 SE, individually

configured. Channel expansion provided through

AM16/32, AM416, and AM25T Multiplexers.

RANGES, RESOLUTION, AND TYPICAL INPUT

NOISE: Basic Resolution (Basic Res) is the A/D

resolution of a single conversion. Resolution of

DFM* with input reversal is half the Basic Res.

Noise values are for DFM with input reversal; noise

is greater with SEM.*

Input Basic 0 Int. 250 µs Int. 20/16.7 ms Int.

Rng (mV) Res (µV) (µV RMS) (µV RMS) (µV RMS)

±5000 167 70 60 30

±1000 33.3 30 12 6

±200 6.67 8 2.4 1.2

±50 1.67 3.0 0.8 0.3

±20 0.67 1.8 0.5 0.2

ACCURACY

MINIMUM TIME BETWEEN MEASUREMENTS:

COMMON MODE RANGE: ±5 V

DC COMMON MODE REJECTION: >100 dB with

NORMAL MODE REJECTION: 70 dB @ 60 Hz

SUSTAINED INPUT VOLTAGE WITHOUT DAMAGE:

INPUT CURRENT: ±2 nA typ., ±10 nA max. @ 50°C

INPUT RESISTANCE: 20 GΩ typical

ACCURACY OF INTERNAL THERMOCOUPLE

REFERENCE JUNCTION:

†

:

±(0.05% of Reading + Offset) 0° to 40°C

±(0.075% of Reading + Offset) -25° to 50°C

±(0.10% of Reading + Offset) -40° to 85°C

Offset for DFM w/input reversal =

Offset for DFM w/o input reversal =

Offset for SEM = 2Basic Res + 10 µV

Zero Integration: 125 µs

250 µs Integration: 475 µs

16.7 ms Integration: 19.9 ms

20 ms Integration: 23.2 ms

input reversal (>80 dB without input reversal)

when using 60 Hz rejection

±16 Vdc

±0.25°C, 0° to 40°C

±0.5°C, -25° to 50°C

±0.7°C, -40° to 85°C

Basic Res +1 µV

2Basic Res + 2 µV

ANALOG OUTPUTS

DESCRIPTION: 4 switched voltage; 4 switched cur-

rent; 2 continuous voltage; switched outputs active

only during measurements, one at a time.

RANGE: Voltage (current) outputs programmable

between ±5 V (±2.5 mA)

RESOLUTION: 1.2 mV (0.6 µA) for voltage (current)

outputs

ACCURACY: ±10 mV (±10 µA) for voltage (current)

outputs

CURRENT SOURCING: 50 mA for switched voltage;

15 mA for continuous

CURRENT SINKING: 50 mA for switched voltage;

5 mA for continuous (15 mA w/selectable option)

COMPLIANCE VOLTAGE: ±5 V for switched current

excitation

RESISTANCE MEASUREMENTS

Provides voltage ratio measurements of 4- and 6-wire

full bridges, and 2-, 3-, 4-wire half bridges. Direct

resistance measurements available with current excitation. Dual-polarity excitation is recommended.

VOLTAGE RATIO ACCURACY

excitation reversal and an excitation voltage of at

least 2000 mV.

±(0.04% Reading + Basic Res/4) 0° to 40°C

±(0.05% Reading + Basic Res/4) -25° to 50°C

±(0.06% Reading + Basic Res/4) -40° to 85°C

ACCURACY

†

WITH CURRENT EXCITATION:

Assumes input and excitation reversal, and an

excitation current, I

±(0.075% Reading + Basic Res/2I

±(0.10% Reading + Basic Res/2I

±(0.12% Reading + Basic Res/2I

†

: Assumes input and

, of at least 1 mA.

x

x

x

) 0° to 40°C

x

) -25° to 50°C

) -40° to 85°C

PERIOD AVERAGING MEASUREMENTS

DESCRIPTION: The average period for a single

cycle is determined by measuring the duration of a

specified number of cycles. Any of the 40 SE

analog inputs can be used; signal attenuation and

ac coupling may be required.

INPUT FREQUENCY RANGE:

Input Signal (peak to peak) Min. Max.

Rng (mV) Min. Max.

±5000 600 mV 10 V 2.5 µs 200 kHz

±1000 100 mV 2.0 V 5.0 µs 100 kHz

±200 4 mV 2.0 V 25 µs 20 kHz

1

Maximum signals must be centered around

datalogger ground.

RESOLUTION: 70 ns/number of cycles measured

ACCURACY: ±(0.03% of Reading + Resolution)

1

Pulse W. Freq

PULSE COUNTERS

DESCRIPTION: Two 16-bit inputs selectable for switch

closure, high frequency pulse, or low-level ac.

MAXIMUM COUNT: 4 x 10

SWITCH CLOSURE MODE:

Minimum Switch Closed Time: 5 ms

Minimum Switch Open Time: 6 ms

Maximum Bounce Time: 1 ms open without

being counted.

HIGH FREQUENCY PULSE MODE:

Maximum Input Frequency: 400 kHz

Maximum Input Voltage: ±20 V

Voltage Thresholds: Count upon transition

from below 1.5 V to above 3.5 V at low frequencies. Larger input transitions are required at high

frequencies because of 1.2 µs time constant filter.

LOW LEVEL AC MODE:

Internal ac coupling removes dc offsets up to

±0.5 V.

Input Hysteresis: 15 mV

Maximum ac Input Voltage: ±20 V

Minimum ac Input Voltage (sine wave):

(mV RMS) Range (Hz)

20 1.0 to 1000

200 0.5 to 10,000

1000 0.3 to 16,000

9

counts per scan

DIGITAL I/O PORTS

DESCRIPTION: 8 por ts selectable as binary inputs or

control outputs.

OUTPUT VOLTAGES (no load): high 5.0 V ±0.1 V;

low < 0.1 V

OUTPUT RESISTANCE: 330 Ω

INPUT STATE: high 3.0 to 5.3 V; low -0.3 to 0.8 V

INPUT RESISTANCE: 100 kΩ

EMI and ESD PROTECTION

The CR5000 is encased in metal and incorporates

EMI filtering on all inputs and outputs. Gas discharge

tubes provide robust ESD protection on all terminal

block inputs and outputs. The following European

standards apply.

EMC tested and conforms to BS EN61326:1998.

Details of performance criteria applied are available

upon request.

Warning: This is a Class A product. In a domestic

environment this product may cause radio interference

in which case the user may be required to correct the

interference at the user’s own expense.

CPU AND INTERFACE

PROCESSOR: Hitachi SH7034

MEMORY: Battery-backed SRAM provides 2 Mbytes

for data and operating system use with

128 kbytes reserved for program storage.

Expanded data storage with PCMCIA type I,

type II, or type III card.

DISPLAY: 8-line-by-21 character alphanumeric or

128 x 64 pixel graphic LCD display w/backlight.

SERIAL INTERFACES: Optically isolated RS-232

9-pin interface for computer or modem. CSI/O

9-pin interface for peripherals such as CSI

modems.

BAUD RATES: Selectable from 1,200 to 115,200 bps.

ASCII protocol is eight data bits, one start bit, one

stop bit, no parity.

CLOCK ACCURACY: ±1 minute per month

SYSTEM POWER REQUIREMENTS

VOLTAGE: 11 to 16 Vdc

TYPICAL CURRENT DRAIN: 400 µA software power

off; 1.5 mA sleep mode; 4.5 mA at 1 Hz (200 mA

at 5 kHz) sample rate.

INTERNAL BATTERIES: 7 Ahr rechargeable base

(optional); 1650 mAhr lithium battery for clock and

SRAM backup, 10 years of service typical, less at

high temperatures.

EXTERNAL BATTERIES: 11 to 16 Vdc; reverse

polarity protected.

PHYSICAL SPECIFICATIONS

SIZE: 9.8” x 8.3” x 4.5” (24.7 cm x 21.0 cm x 11.4 cm)

WEIGHT: 4.5 lbs (2.0 kg) with low-profile base;

Terminal strips extend 0.4” (1.0 cm).

12.2 lbs (5.5 kg) with rechargeable base

WARRANTY

Three years against defects in materials and

workmanship.

*SE(M): Single-Ended (Measurement)

*DF(M): Differential (Measurement)

†

Sensor and measurement noise not included.

We recommend that you confirm system

configuration and critical specifications with

Campbell Scientific before purchase.

OV-20

Page 25

This is a blank page.

Page 26

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com

info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za

cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au

info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br

suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca

dataloggers@campbellsci.ca

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk

sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr

campbell.scientific@wanadoo.fr

Campbell Scientific Spain, S. L.

Psg. Font 14, local 8

08013 Barcelona

SPAIN

www.campbellsci.es

info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...