Page 1

OPERATOR'S MANUAL

Revision: 12/16

Want to get going? Go to the Quickstart

section.

Copyright © 2000 – 2016

(p. 37)

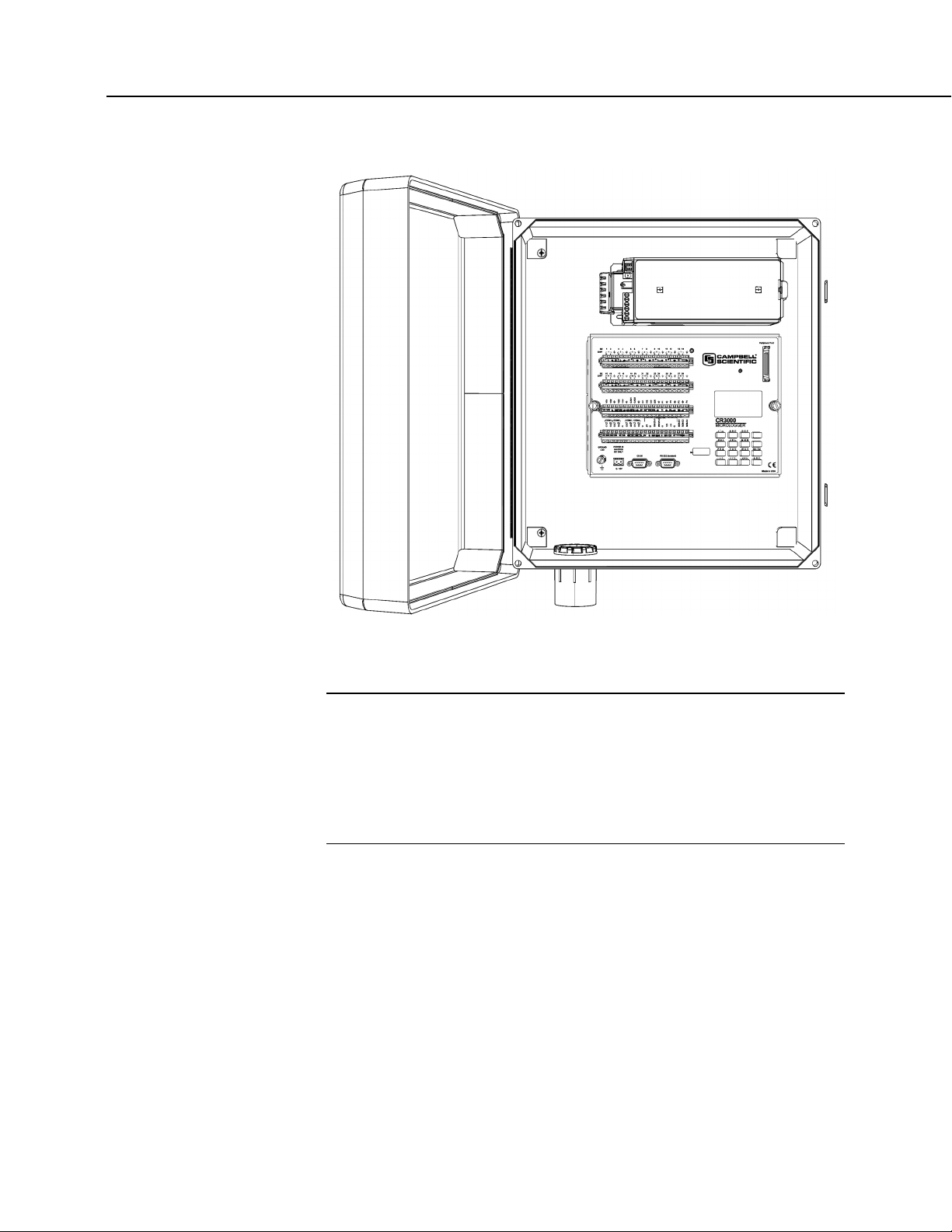

CR3000 Micrologger®

Campbell Scientific, Inc.

Page 2

Page 3

Page 4

Page 5

Assistance

Products may not be returned without prior authorization. The following

contact information is for Canadian and international clients residing in

countries served by Campbell Scientific (Canada) Corp. directly. Affiliate

companies handle repairs for clients within their territories. Please visit

www.campbellsci.ca to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC (CANADA) CORP., phone (780) 454-2505. After a

measurement consultant determines the nature of the problem, an RMA

number will be issued. Please write this number clearly on the outside of the

shipping container. Campbell Scientific’s shipping address is:

CAMPBELL SCIENTIFIC (CANADA) CORP.

RMA#_____

14532 131 Avenue NW

Edmonton, Alberta T5L 4X4

Canada

For all returns, the client must fill out a “Statement of Product Cleanliness and

Decontamination” form and comply with the requirements specified in it. The

form is available from our web site at www.campbellsci.ca/repair. A

completed form must be either emailed to repair@campbellsci.ca or faxed to

(780) 454-2655. Campbell Scientific (Canada) Corp. is unable to process any

returns until we receive this form. If the form is not received within three days

of product receipt or is incomplete, the product will be returned to the client at

the client’s expense. Campbell Scientific (Canada) Corp.f reserves the right to

refuse service on products that were exposed to contaminants that may cause

health or safety concerns for our employees.

Page 6

Page 7

Precautions

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON OR AROUND

TRIPODS, TOWERS, AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES,

ANTENNAS, ETC. FAILURE TO PROPERLY AND COMPLETELY ASSEMBLE, INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS,

TOWERS, AND ATTACHMENTS, AND FAILURE TO HEED WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS

INJURY, PROPERTY DAMAGE, AND PRODUCT FAILURE. TAKE ALL REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS.

CHECK WITH YOUR ORGANIZATION'S SAFETY COORDINATOR (OR POLICY) FOR PROCEDURES AND REQUIRED PROTECTIVE

EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not exceed design

limits. Be familiar and comply with all instructions provided in product manuals. Manuals are available at www.campbellsci.ca or by

telephoning (780) 454-2505 (Canada). You are responsible for conformance with governing codes and regulations, including safety

regulations, and the integrity and location of structures or land to which towers, tripods, and any attachments are attached. Installation

sites should be evaluated and approved by a qualified personnel (e.g. engineer). If questions or concerns arise regarding installation,

use, or maintenance of tripods, towers, attachments, or electrical connections, consult with a licensed and qualified engineer or

electrician.

General

Prior to performing site or installation work, obtain required approvals and permits.

Use only qualified personnel for installation, use, and maintenance of tripods and towers, and

any attachments to tripods and towers. The use of licensed and qualified contractors is

highly recommended.

Read all applicable instructions carefully and understand procedures thoroughly before

beginning work.

Wear a hardhat and eye protection, and take other appropriate safety precautions while

working on or around tripods and towers.

Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take

reasonable precautions to secure tripod and tower sites from trespassers.

Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are

installing, constructing, using, or maintaining, or a tool, stake, or anchor, come in contact

with overhead or underground utility lines.

Maintain a distance of at least one-and-one-half times structure height, 6 meters (20 feet), or

the distance required by applicable law, whichever is greater, between overhead utility lines

and the structure (tripod, tower, attachments, or tools).

Prior to performing site or installation work, inform all utility companies and have all

underground utilities marked.

Comply with all electrical codes. Electrical equipment and related grounding devices should

be installed by a licensed and qualified electrician.

Elevated Work and Weather

Exercise extreme caution when performing elevated work.

Use appropriate equipment and safety practices.

During installation and maintenance, keep tower and tripod sites clear of un-trained or non-

essential personnel. Take precautions to prevent elevated tools and objects from dropping.

Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks,

frayed cables, loose cable clamps, cable tightness, etc. and take necessary corrective actions.

Periodically (at least yearly) check electrical ground connections.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS,

THE CLIENT ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER INSTALLATION, USE, OR MAINTENANCE OF

TRIPODS, TOWERS, OR ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES, ANTENNAS,

ETC.

Page 8

PLEASE READ FIRST

About this manual

Please note that this manual was originally produced by Campbell Scientific Inc. (CSI) primarily

for the US market. Some spellings, weights and measures may reflect this origin.

Some useful conversion factors:

Area: 1 in

Length: 1 in. (inch) = 25.4 mm

1 ft (foot) = 304.8 mm

1 yard = 0.914 m

1 mile = 1.609 km

Mass: 1 oz. (ounce) = 28.35 g

1 lb (pound weight) = 0.454 kg

Pressure: 1 psi (lb/in2) = 68.95 mb

Volume: 1 US gallon = 3.785 litres

In addition, part ordering numbers may vary. For example, the CABLE5CBL is a CSI part

number and known as a FIN5COND at Campbell Scientific Canada (CSC). CSC Technical

Support will be pleased to assist with any questions.

2

(square inch) = 645 mm

2

About sensor wiring

Please note that certain sensor configurations may require a user supplied jumper wire. It is

recommended to review the sensor configuration requirements for your application and supply the jumper

wire is necessary.

Page 9

9

Table of Contents

1. Introduction .............................................................. 31

1.1 HELLO .............................................................................................. 31

1.2 Typography ....................................................................................... 32

1.3 Capturing CRBasic Code .................................................................. 32

2. Precautions .............................................................. 33

3. Initial Inspection ....................................................... 35

4. Quickstart ................................................................. 37

4.1 Sensors — Quickstart ...................................................................... 37

4.2 Datalogger — Quickstart ................................................................... 38

4.2.1 CR3000 Module ......................................................................... 38

4.2.1.1 Wiring Panel — Quickstart.............................................. 38

4.3 Power Supplies — Quickstart ........................................................... 39

4.3.1 Internal Battery — Quickstart .................................................... 40

4.4 Data Retrieval and Comms — Quickstart ......................................... 40

4.5 Datalogger Support Software — Quickstart ...................................... 41

4.6 Tutorial: Measuring a Thermocouple ................................................ 42

4.6.1 What You Will Need .................................................................. 42

4.6.2 Hardware Setup .......................................................................... 42

4.6.2.1 Connect Internal Power Supply ....................................... 43

4.6.2.2 Connect External Power Supply ...................................... 43

4.6.2.3 Connect Comms .............................................................. 44

4.6.3 PC200W Software Setup ............................................................ 44

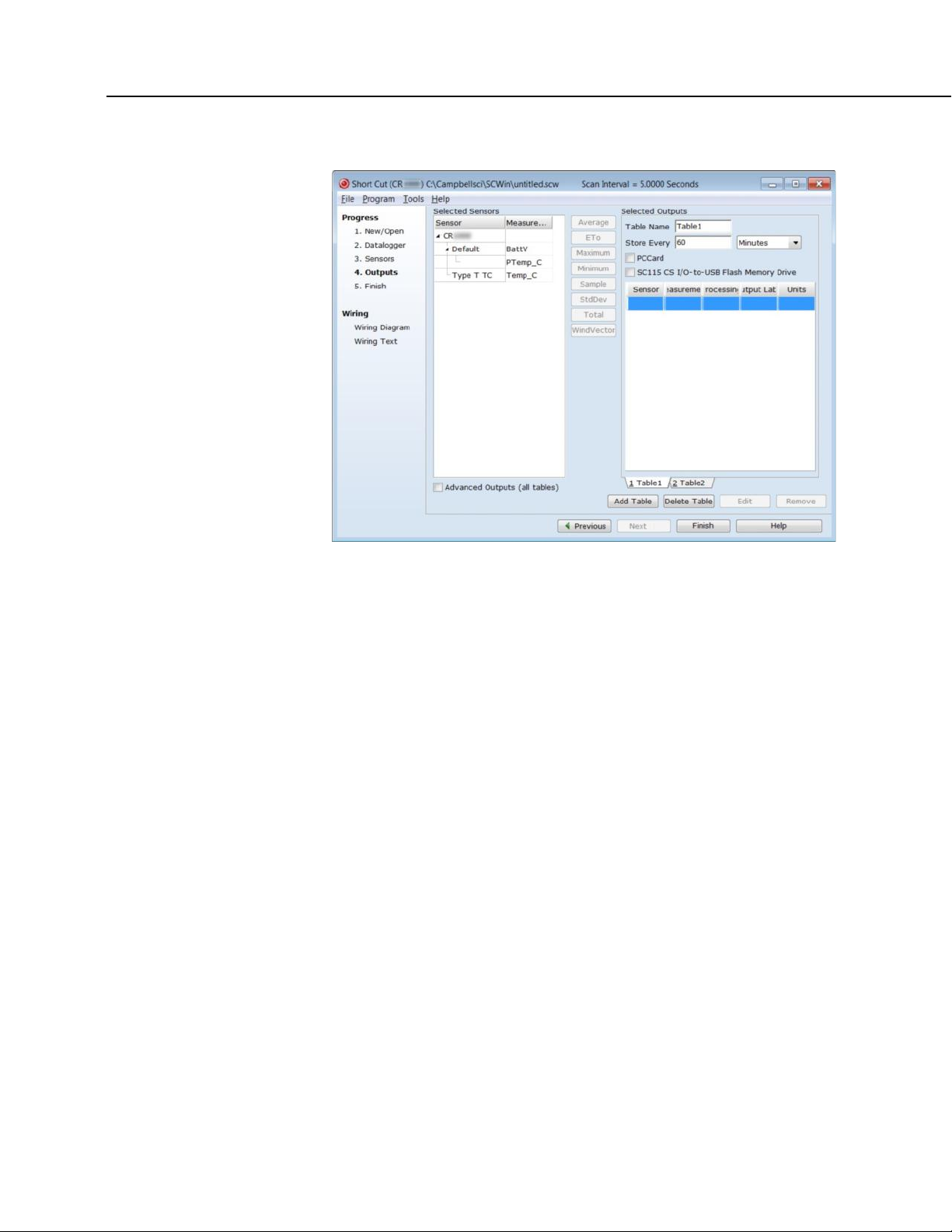

4.6.4 Write CRBasic Program with Short Cut .................................... 46

4.6.4.1 Procedure: (Short Cut Steps 1 to 5) ................................. 46

4.6.4.2 Procedure: (Short Cut Steps 6 to 7) ................................. 47

4.6.4.3 Procedure: (Short Cut Step 8) .......................................... 47

4.6.4.4 Procedure: (Short Cut Steps 9 to 12) ............................... 48

4.6.4.5 Procedure: (Short Cut Steps 13 to 14) ............................. 48

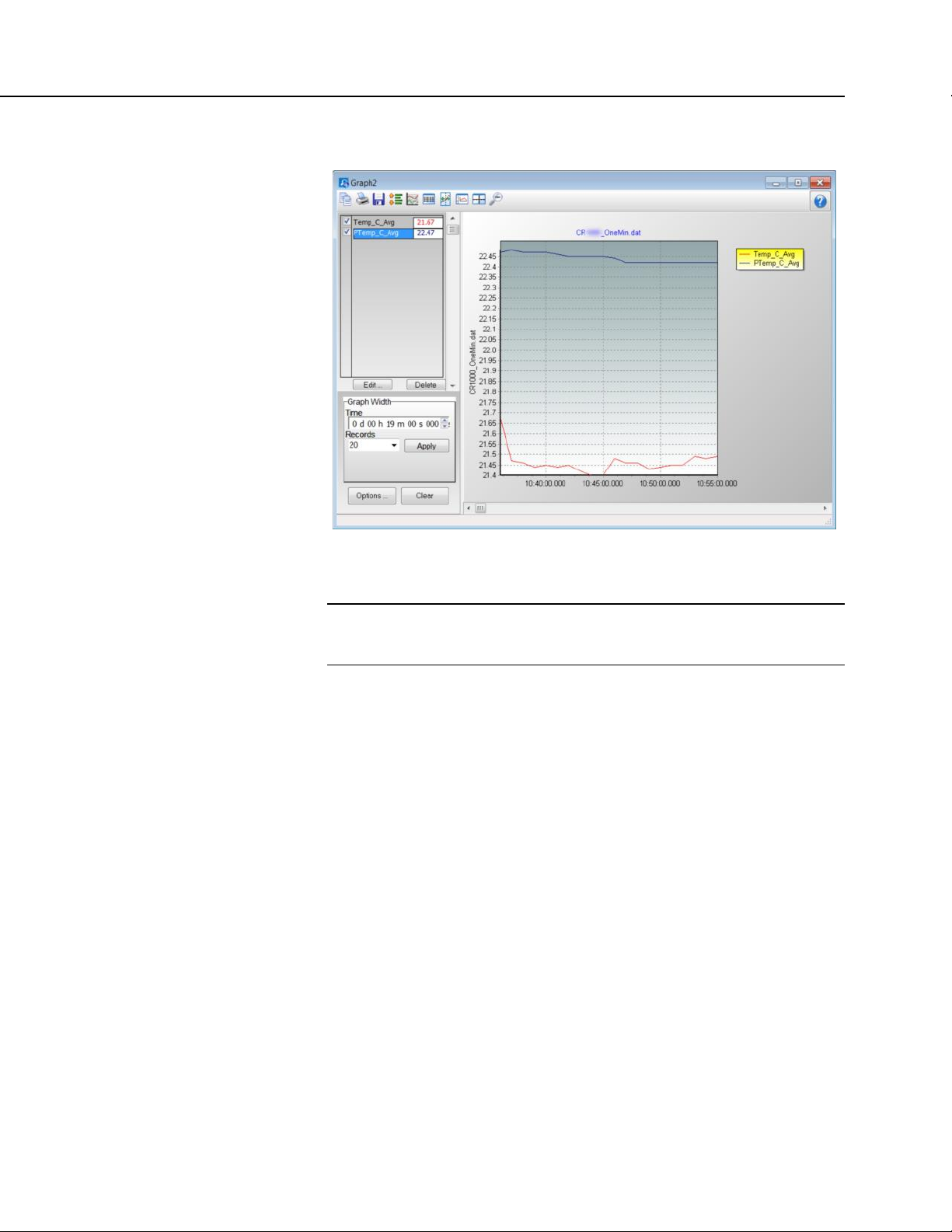

4.6.5 Send Program and Collect Data ................................................. 49

4.6.5.1 Procedure: (PC200W Step 1) ........................................... 49

4.6.5.2 Procedure: (PC200W Steps 2 to 4) .................................. 50

4.6.5.3 Procedure: (PC200W Step 5) ........................................... 51

4.6.5.4 Procedure: (PC200W Step 6) ........................................... 52

4.6.5.5 Procedure: (PC200W Steps 7 to 10) ................................ 53

4.6.5.6 Procedure: (PC200W Steps 11 to 12) .............................. 54

4.6.5.7 Procedure: (PC200W Steps 13 to 14) .............................. 54

4.7 Data Acquisition Systems — Quickstart ........................................... 55

5. Overview ................................................................... 57

5.1 Datalogger — Overview.................................................................... 58

5.1.1 Wiring Panel — Overview ......................................................... 59

5.1.1.1 Switched Voltage

5.1.1.2 Voltage and Current Excitation — Overview ................ 62

5.1.1.3 Power Terminals .............................................................. 63

5.1.1.3.1 Power In Terminals ............................................... 63

Output — Overview ........................... 62

Page 10

Table of Contents

10

5.1.1.3.2 Power Out Terminals ............................................ 63

5.1.1.4 Communication Ports — Overview ................................. 64

5.1.1.4.1 CS I/O Port............................................................ 65

5.1.1.4.2 RS-232 Ports ......................................................... 65

5.1.1.4.3 Peripheral Port ...................................................... 65

5.1.1.4.4 SDI-12 Ports ......................................................... 65

5.1.1.4.5 SDM Port .............................................................. 66

5.1.1.4.6 CPI Port and CDM Devices — Overview ............ 66

5.1.1.4.7 Ethernet Port ......................................................... 66

5.1.1.5 Grounding — Overview .................................................. 66

5.2 Measurements — Overview .............................................................. 67

5.2.1 Time Keeping — Overview ....................................................... 67

5.2.2 Analog Mea s urements — Overview .......................................... 67

5.2.2.1 Voltage Measurements — Overview ............................... 68

5.2.2.1.1 Single-Ended Measurements — Overview ........... 70

5.2.2.1.2 Differential Measurements — Overview .............. 71

5.2.2.2 Current Measurements — Overview ............................... 72

5.2.2.3 Resistance Measurements — Overview .......................... 72

5.2.2.3.1 Voltage Excitation ................................................ 72

5.2.2.3.2 Current Excitation ................................................. 73

5.2.2.4 Strain Measurements — Overview .................................. 74

5.2.3 Pulse Measurements — Overview ............................................. 74

5.2.3.1 Pulses Measured .............................................................. 74

5.2.3.2 Pulse Input Channels ....................................................... 75

5.2.3.3 Pulse Sensor Wiring......................................................... 75

5.2.4 Period Averaging — Overview .................................................. 76

5.2.5 Vibrating Wire Measurements — Overview .............................. 77

5.2.6 Reading Smart Sensors — Overview ......................................... 77

5.2.6.1 SDI-12 Sensor Support — Overview .............................. 78

5.2.6.2 RS-232 — Overview ....................................................... 78

5.2.7 Field Calibration — Overview ................................................... 79

5.2.8 Cabling Effects — Overview ..................................................... 79

5.2.9 Synchronizing Measurements — Overview ............................... 79

5.2.9.1 Synchronizing Measurements in the CR3000 —

Overview ...................................................................... 80

5.2.9.2 Synchronizing Measurements in a Datalogger

Network — Overview .................................................. 80

5.3 Data Retrieval and Comms — Overview .......................................... 80

5.3.1 Data File Formats in CR3000 Memory ...................................... 80

5.3.2 Data Format on Computer .......................................................... 80

5.3.3 Mass-Storage Device .................................................................. 80

5.3.4 Memory Card (CRD: Drive) — Overview ................................. 81

5.3.4.1 Comms ............................................................................. 81

5.3.4.2 Direct with Adapter to PC ............................................... 81

5.3.5 Comms Protocols ....................................................................... 82

5.3.5.1 PakBus Comms — Overview .......................................... 82

5.3.6 Alternate Comms Protocols — Overview .................................. 82

5.3.6.1 Modbus — Overview....................................................... 83

5.3.6.2 DNP3 — Overview .......................................................... 83

5.3.6.3 TCP/IP — Overview ........................................................ 84

5.3.7 Comms Hardware — Overview ................................................. 84

5.3.8 Keyboard/Display — Overview ................................................. 84

5.3.8.1 Integrated Keyboard/Display ........................................... 85

5.3.8.2 Character Set .................................................................... 85

5.3.8.3 Custom Menus — Overview ........................................... 85

Page 11

Table of Contents

11

5.4 Measurement and Control Peripherals — Overview ......................... 86

5.5 Power Supplies — Overview ............................................................ 86

5.6 CR3000 Setup — Overview .............................................................. 87

5.7 CRBasic Programming — Overview ................................................ 87

5.8 Security — Overview ........................................................................ 88

5.9 Maintenance — Overview ................................................................. 89

5.9.1 Protection from Moisture — Overview ...................................... 89

5.9.2 Protection from Voltage Trans ie nts — Overview ...................... 89

5.9.3 Factory Calibration — Overview ............................................... 89

5.9.4 Internal Battery — Overview ..................................................... 90

5.10 Datalogger Support Software — Overview ....................................... 90

5.11 PLC Control — Overview ................................................................. 91

5.12 Auto Self-Calibration — Overview ................................................... 92

5.13 Memory — Overview ....................................................................... 93

6. Specifications ........................................................... 95

7. Installation ................................................................ 97

7.1 Enclosures — Details ........................................................................ 97

7.2 Power Supplies — Details ................................................................. 98

7.2.1 CR3000 Power Requirement ...................................................... 99

7.2.2 Calculating Power Consumption ................................................ 99

7.2.3 Power Sources ............................................................................ 99

7.2.3.1 Vehicle Power Connections ........................................... 100

7.2.4 Uninterrup table Po wer Supply (UP S ) ...................................... 101

7.2.5 External Power Supply Installation .......................................... 101

7.2.6 External Al kaline Po wer Supply .............................................. 101

7.2.7 Integrated Batteries .................................................................. 101

7.2.7.1 Alkaline-Battery Base .................................................... 102

7.2.7.2 Sealed Rechargeable-Battery Base ................................ 103

7.2.7.3 Low Profile (No Battery) Base ...................................... 106

7.3 Grounding — Details ...................................................................... 106

7.3.1 ESD Protection ......................................................................... 107

7.3.1.1 Lightning Protection ...................................................... 108

7.3.2 Single-Ended Measurement Reference .................................... 109

7.3.3 Ground Potential Differences ................................................... 110

7.3.3.1 Soil Temperature Thermocouple ................................... 110

7.3.3.2 External Signal Conditioner........................................... 110

7.3.4 Ground Looping in Ionic Measurements ..................................

7.4 Protection from Moisture — Details ............................................... 112

7.5 CR3000 Setup — Details ................................................................ 112

7.5.1 Tools — Setup .......................................................................... 113

7.5.1.1 DevConfig — S etup Tools ............................................ 113

7.5.1.2 Network Pla nner — Setup Tools ................................... 114

7.5.1.2.1 Overview — Network Planner ............................ 115

7.5.1.2.2 Basics — Network Planner ................................. 116

7.5.1.3 Info Tables and Settings — Setup Tools ....................... 117

7.5.1.4 CRBasic Program — Setup Tools ................................. 118

7.5.1.5 Executable CPU: Files — Set up Tools .......................... 118

7.5.1.5.1 Default.cr3 File ................................................... 119

7.5.1.5.2 "Include" File ...................................................... 119

7.5.1.5.3 Executable File Run Priorities ............................ 122

111

Page 12

Table of Contents

12

7.5.2 Setup Tasks .............................................................................. 123

7.5.2.1 Operating System (OS) — Details ................................. 123

7.5.2.1.1 OS Update with DevConfig Send OS Tab .......... 124

7.5.2.1.2 OS Update with File Control .............................. 125

7.5.2.1.3 OS Update with Send Program Command .......... 126

7.5.2.1.4 OS Update with External Memory and

PowerUp.ini File.............................................. 127

7.5.2.2 Factory Defaults — Installation ..................................... 128

7.5.2.3 Saving and Restoring Configurations — Installation .... 128

7.6 CRBasic Programming — Details ................................................... 129

7.6.1 Program Structure..................................................................... 129

7.6.2 Writing and Editing Programs .................................................. 132

7.6.2.1 Short Cut Programming Wizard .................................... 132

7.6.2.2 CRBasic Editor .............................................................. 132

7.6.2.2.1 Inserting C omments into Program ...................... 133

7.6.2.2.2 Conserving Program Memory ............................. 134

7.6.3 Programmi ng S yntax ................................................................ 134

7.6.3.1 Program Statements ....................................................... 134

7.6.3.1.1 Multiple Statements on One Line ....................... 135

7.6.3.1.2 One Statement on Multiple Lines ....................... 135

7.6.3.2 Single-Statement Declarations ....................................... 135

7.6.3.3 Declaring Variables ....................................................... 136

7.6.3.3.1 Declaring Data Types ......................................... 137

7.6.3.3.2 Dimensioning Numeric Variables ....................... 141

7.6.3.3.3 Dimensioning String Variables ........................... 142

7.6.3.3.4 Declaring Flag Variables .................................... 142

7.6.3.4 U sin g Variable Pointers ................................................. 143

7.6.3.5 Declaring Arrays ............................................................ 144

7.6.3.5.1 Advanced Array Declaration .............................. 145

7.6.3.6 Declaring Local and Global Variables ........................... 146

7.6.3.7 Initializing Variables...................................................... 146

7.6.3.8 D e c la r ing Constants ....................................................... 147

7.6.3.8.1 Predefined Constants .......................................... 148

7.6.3.9 D e c la r ing Aliases and Units........................................... 148

7.6.3.10 Numerical Formats ........................................................ 149

7.6.3.11 Multi-Statement Declarations ........................................ 150

7.6.3.11.1 Declaring Data Tables ......................................... 151

7.6.3.11.2 Declaring S ubroutines ......................................... 158

7.6.3.11.3 Declaring S ubroutines ......................................... 159

7.6.3.11.4 Declaring Incidental Sequences .......................... 159

7.6.3.12 Execution and Task Priority........................................... 160

7.6.3.12.1 Pipeline Mode ..................................................... 161

7.6.3.12.2 Sequential Mode ................................................. 162

7.6.3.13 Execution Timing .......................................................... 163

7.6.3.13.1 Scan() / NextScan ............................................... 163

7.6.3.13.2 SlowSequence / EndSequence ............................ 164

7.6.3.13.3 SubScan() / NextSubScan ................................... 165

7.6.3.13.4 Scan Priorities in Sequential M ode ..................... 165

7.6.3.14 Programming Instructions .............................................. 167

7.6.3.14.1 Measurement and Data Storage Processing ........ 167

7.6.3.14.2 Argument Types.................................................. 168

7.6.3.14.3 Names in Arguments ........................................... 168

7.6.3.15 Expressions in Arguments ............................................. 169

7.6.3.16 Programming Expression Types .................................... 170

7.6.3.16.1 Floating-Point Arithmetic ................................... 170

Page 13

Table of Contents

13

7.6.3.16.2 Arithmetic Operations ......................................... 171

7.6.3.16.3 Expressions with Numeric Data Types ............... 171

7.6.3.16.4 Logical Exp ressions ............................................ 173

7.6.3.16.5 String Expr essions .............................................. 176

7.6.3.17 Programming Access to Data Tables ............................. 177

7.6.3.18 Programming to Use Sig natures .................................... 179

7.6.3.19 Functions (with a capital F) ........................................... 179

7.6.4 Sending CRBasic Programs ..................................................... 180

7.6.4.1 Preserving Data at Program Send .................................. 180

7.7 Programming Resource Library ...................................................... 181

7.7.1 Advanced Programming Techniques ....................................... 181

7.7.1.1 C apturing Eve nts ........................................................... 181

7.7.1.2 Co nd itional Output ........................................................ 182

7.7.1.3 Gr o undwater Pump Test ................................................ 183

7.7.1.4 Miscellaneous Features .................................................. 186

7.7.1.5 PulseCountReset Instruction .......................................... 188

7.7.1.6 Sc aling Arra y ................................................................. 189

7.7.1.7 Signatures: Example Programs ...................................... 190

7.7.1.7.1 Text Signat ure ..................................................... 190

7.7.1.7.2 Binary Runt ime Signatur e................................... 190

7.7.1.7.3 Executable Code Signatures ............................... 190

7.7.1.8 U se of Multiple Scans .................................................... 191

7.7.2 Data Input: Loading Large Data Sets ....................................... 192

7.7.3 Data Input: Array-Assig ne d Expression ................................... 193

7.7.4 Data Output : Calculating Running Average ............................. 197

7.7.5 Data Output: Two Intervals in One Data Table ........................ 201

7.7.6 Data Output: Triggers and Omittin g Samples .......................... 202

7.7.7 Data Output: Using Data Type B ool8 ...................................... 203

7.7.8 Data Output: Using Data Type NSEC ...................................... 208

7.7.8.1 NSEC Options ............................................................... 208

7.7.9 Data Output: Wind Vector ....................................................... 211

7.7.9.1 O utputOpt Parameters ................................................... 212

7.7.9.2 Wind Vector Processing ................................................ 212

7.7.9.2.1 Measured Raw Data ............................................ 213

7.7.9.2.2 Calculations ........................................................ 214

7.7.10 Data Output: Writing High-Frequency Data to Memory

Cards ..................................................................................... 217

7.7.10.1 TableFile() with Option 64 ............................................ 218

7.7.10.2 TableFile() with Option 64 Replaces CardOut()............ 218

7.7.10.3 TableFile() with Option 64 Programming ..................... 219

7.7.10.4 Converting TOB3 Files with CardConvert .................... 220

7.7.10.5 TableFile() with Option 64 Q & A ................................ 220

7.7.11 Displaying Data: Custom Menus — Details ............................ 222

7.7.12 Field Calibration — Details ..................................................... 229

7.7.12.1 Field Calibration CAL Files ..........................................

229

7.7.12.2 Field Calibration Programming ..................................... 229

7.7.12.3 Field Calibration Wiza rd Overview ............................... 230

7.7.12.4 Field Calibration N umeric Monitor Procedures............. 230

7.7.12.4.1 One-Point Calibrations (Zero or Offset) ............. 231

7.7.12.4.2 Two-Point Calibrations (gain and o ffset) ............ 232

7.7.12.4.3 Zero Basis Point Calibration ............................... 232

7.7.12.5 Field Calibration Examples ........................................... 232

7.7.12.5.1 FieldCal() Zero or Tare (Opt 0) Example ........... 233

7.7.12.5.2 FieldCal() Offset (Opt 1) Example ..................... 235

Page 14

Table of Contents

14

7.7.12.5.3 FieldCal() Slope and Offset (Op t 2) Example ..... 238

7.7.12.5.4 FieldCal() Slope (Opt 3) Example ...................... 240

7.7.12.5.5 FieldCal() Zero Basis (Opt 4) Example .............. 243

7.7.12.6 Field Calibration Strain Examples ................................. 243

7.7.12.6.1 FieldCalStrain() Shunt Calibra tion Concepts ...... 243

7.7.12.6.2 FieldCalStrain() Shunt Calibra tion Example ...... 244

7.7.12.6.3 FieldCalStrain() Quarter-Bridge Shunt

Example ........................................................... 246

7.7.12.6.4 FieldCalStrain() Quarter-Bridge Zero ................. 247

7.7.13 Measurement: Fast Analog Voltage ......................................... 248

7.7.13.1 Tips — Fast Analog Voltage ......................................... 252

7.7.14 Measurement: Excite, Delay, Measure ..................................... 254

7.7.15 Serial I/O: SDI-12 Sensor Support — Details .......................... 255

7.7.15.1 SDI-12 Transparent Mode ............................................. 255

7.7.15.1.1 SDI-12 Transparent Mode Commands ............... 256

7.7.15.2 SDI-12 Recorder Mode .................................................. 261

7.7.15.2.1 Alternate Start Concurrent Measurement

Command ........................................................ 263

7.7.15.2.2 SDI-12 Extended Command Support.................. 267

7.7.15.3 SDI-12 Sensor Mode ..................................................... 268

7.7.15.4 SDI-12 Power Considerations........................................ 270

7.7.16 Compiling: Conditional Code................................................... 271

7.7.17 Measurement: RTD, PRT, PT100, PT1000 .............................. 273

7.7.17.1 Measurement Theory (PRT) .......................................... 274

7.7.17.2 General Procedure (PRT) ............................................... 275

7.7.17.3 Example: 100 Ω PRT in Four-Wire Half Bridge with

Voltage Excitation (PT100 / BrHalf4W() ) ................ 277

7.7.17.4 Example: 100 Ω PRT in Three-Wire Half Bridge with

Voltage Excitation (PT100 / BrHalf3W() ) ................ 281

7.7.17.5 Example: 100 Ω PRT in Four-Wire Full Bridge with

Voltage Excitation (PT100 / BrFull() ) ...................... 285

7.7.17.6 Example: 100 Ω PRT in Four-Wire Basic Circuit

(PT100 / Basic Resistance() ) ..................................... 290

7.7.17.7 Example: 100 Ω PRT in Four-Wire Full Bridge with

Current Excitation (PT100 / Full-Bridge

Resistance() ).............................................................. 296

7.7.17.8 PRT Callendar-Van Dusen Coefficients ........................ 300

7.7.17.9 Self-Heating and Resolution .......................................... 303

7.7.18 Serial I/O: Capturing Serial Data ............................................. 303

7.7.18.1 Introduction.................................................................... 304

7.7.18.2 I/O Ports ......................................................................... 305

7.7.18.3 Protocols ........................................................................ 306

7.7.18.4 Glossary of Serial I/O Terms ......................................... 306

7.7.18.5 Serial I/O CRBasic Pr ogramming .................................. 308

7.7.18.5.1 Serial I/O Programming Basics ........................... 309

7.7.18.5.2 Serial I/O Input Programming Basics ................. 311

7.7.18.5.3 Serial I/O Output Progra mming Basics ............... 312

7.7.18.5.4 Serial I/O Translating B ytes ................................

313

7.7.18.5.5 Serial I/O Memory Considerations ..................... 314

7.7.18.5.6 Serial I/O Example I ........................................... 315

7.7.18.6 Serial I/O Application Testing ....................................... 316

7.7.18.6.1 Configure HyperTerminal ................................... 316

7.7.18.6.2 Create Send-Text File ......................................... 319

7.7.18.6.3 Create Text-Capture File ..................................... 319

7.7.18.6.4 Serial I/O Example II .......................................... 319

Page 15

Table of Contents

15

7.7.18.7 Serial I/O Q & A ............................................................ 325

7.7.19 String Operations...................................................................... 327

7.7.19.1 String Operator s ............................................................. 328

7.7.19.2 String Concatenation ..................................................... 329

7.7.19.3 String NULL Character ................................................. 331

7.7.19.4 Inserting String C haracters ............................................ 332

7.7.20 Subroutines ............................................................................... 332

8. Operation ................................................................ 335

8.1 Measurements — Details ................................................................ 335

8.1.1 Time Keeping — Details .......................................................... 335

8.1.1.1 Time Stamps .................................................................. 335

8.1.2 Analog Mea s urements — Details ............................................. 337

8.1.2.1 Vo ltage Measurement Quality ....................................... 337

8.1.2.2 Thermocouple Measurements — Details ....................... 355

8.1.2.2.1 Thermocouple Error Analysis ............................. 356

8.1.2.2.2 Use of External Reference Junction .................... 366

8.1.2.3 Resistance Measurements — Details ............................. 367

8.1.2.3.1 Ac Excitation ...................................................... 371

8.1.2.3.2 Accuracy — Resistance Measurements .............. 371

8.1.2.4 Auto Self-Calibration — Details ................................... 373

8.1.2.4.1 Auto Self-Calibr a tion Process ............................. 373

8.1.2.5 Strain Measurements — Details .................................... 378

8.1.2.6 Current Measurements — Details .................................. 380

8.1.2.7 Vo ltage Measurements — Details ................................. 380

8.1.2.7.1 Voltage Measurement Limitatio ns ...................... 380

8.1.2.7.2 Voltage Measurement Mechanics ....................... 383

8.1.2.7.3 Voltage Measurement Quality ............................ 386

8.1.3 Pulse Measurements — Details ................................................ 404

8.1.3.1 Pulse Measurement Terminals ....................................... 407

8.1.3.2 Low-Level Ac Measurements — Details ...................... 407

8.1.3.3 High-Frequency Measurements ..................................... 408

8.1.3.3.1 Frequency Resolution ......................................... 409

8.1.3.3.2 Frequency Measurement Q & A ......................... 410

8.1.3.4 Switch Closure and Open-Collector Measurements ...... 410

8.1.3.5 Edge Timing .................................................................. 411

8.1.3.6 Edge Counting ............................................................... 412

8.1.3.7 Timer Input on I/O NAN Conditions ............................. 412

8.1.3.8 Pulse Measurement Tips ................................................ 412

8.1.3.8.1 Pay Attention to Specifications ........................... 414

8.1.3.8.2 Input Filters and Signal Attenuatio n ................... 415

8.1.4

8.1.5 Period Averaging — Details .................................................... 418

8.1.6 Reading Smart Sensors — Details ........................................... 419

8.1.7 Field Calibration — Overview ................................................. 420

8.1.8 Cabling Effects — Details ........................................................ 421

Vibrating Wire Measurements — Details ................................ 417

8.1.4.1 Time-Domain Measurement .......................................... 417

8.1.6.1 RS-232 and TTL — Details ........................................... 419

8.1.6.2 SDI-12 Sensor Support — Details ................................. 420

8.1.8.1 Analog Sensor Cabling .................................................. 421

8.1.8.2 Curr e nt Excitation Cabling ............................................ 421

8.1.8.3 Pulse Sensor Cabling ..................................................... 421

8.1.8.4 RS-232 Sensor Cabling .................................................. 422

Page 16

Table of Contents

16

8.1.8.5 SDI-12 Sensor Cabling .................................................. 422

8.1.9 Synchronizing Measurements — Details ................................. 422

8.1.9.1 Synchronizing Measurement in the CR3000 —

Details ........................................................................ 422

8.1.9.2 Synchronizing Measurements in a Datalogger

Network — Details .................................................... 422

8.2 Switched-Voltage Output — Details ............................................... 424

8.2.1 Switched-Voltage Excitation .................................................... 425

8.2.2 Switched-Current Excitation (IX Terminals) ........................... 425

8.2.3 Continuous-Regulated (5V Terminal) ...................................... 426

8.2.4 Continuous-Analog Out ( CAO Ter minal ) ................................ 426

8.2.5 Continuous-Unregulated Voltage (12V Terminal) ................... 426

8.2.6 Switched-Unregulated Voltage (SW12 Terminal) ................... 426

8.3 PLC Control — Details ................................................................... 427

8.3.1 Terminals Configured for Control ............................................ 428

8.4 Measurement and Control Peripherals — Details ........................... 429

8.4.1 Analog Input Modules .............................................................. 429

8.4.2 Analog Output Modules ........................................................... 430

8.4.3 PLC Control Modules — Overview ......................................... 430

8.4.3.1 R elays and Rel ay Drivers .............................................. 430

8.4.3.2 Component-Built Rela ys ................................................ 430

8.4.4 Pulse Input M odules ................................................................. 431

8.4.4.1 Low-Level Ac Input Modules — Overview .................. 431

8.4.5 Serial I/O Modules — Details .................................................. 432

8.4.6 Terminal-Input Modules ........................................................... 432

8.4.7 Vibrating Wire Modules ........................................................... 432

8.5 Datalogger Support Software — Details ......................................... 432

8.6 Program and OS File Compression Q and A ................................... 433

8.7 Security — Details .......................................................................... 436

8.7.1 Vulnerabilities .......................................................................... 437

8.7.2 Pass-Code Lockout ................................................................... 438

8.7.2.1 Pass-Code Lockout By-Pass .......................................... 439

8.7.3 Passwords ................................................................................. 440

8.7.3.1 .csipasswd ...................................................................... 440

8.7.3.2 PakBus Instr uctions ....................................................... 440

8.7.3.3 TCP/IP Instructions........................................................ 440

8.7.3.4 Settings — Passwords .................................................... 441

8.7.4 File Encryption ......................................................................... 441

Communication Encryption...................................................... 441

8.7.5

8.7.6 Hiding Files .............................................................................. 441

8.7.7 Signatures ................................................................................. 442

8.7.8 Read Only Variables ................................................................ 442

8.8 Memory — Details .......................................................................... 442

8.8.1 Storage Media .......................................................................... 442

8.8.1.1 Memory Drives — On-Board ........................................ 445

8.8.1.1.1 Data Table SRAM............................................... 446

8.8.1.1.2 CPU: Drive ......................................................... 446

8.8.1.1.3 USR: Drive ......................................................... 446

8.8.1.1.4 USB: Drive ......................................................... 447

8.8.1.2 Memory Card (CRD: Drive) .......................................... 447

8.8.2 Data File Formats ..................................................................... 449

8.8.3 Memory Cards and Record Numbers ....................................... 453

8.8.4 Resetting the CR3000 ............................................................... 454

8.8.4.1 Full Memory Reset ........................................................ 455

8.8.4.2 Program Send R eset ....................................................... 455

Page 17

Table of Contents

17

8.8.4.3 Manual Data-Table Reset .............................................. 455

8.8.4.4 Formatting Dr ives .......................................................... 456

8.8.5 File Management in CR3000 Memory ..................................... 456

8.8.5.1 File Attributes ................................................................ 457

8.8.5.2 Files Manager ................................................................ 458

8.8.5.3 Data Preservation ........................................................... 459

8.8.5.4 Powerup.ini File — Details ........................................... 460

8.8.5.4.1 Creating and Editing Powerup.ini ....................... 461

8.8.5.5 File Management Q & A ............................................... 464

8.8.6 File Names ............................................................................... 464

8.8.7 File System Errors .................................................................... 464

8.8.8 Memo ry Q & A ........................................................................ 466

8.9 Data Retrieval and Comms — Details ............................................ 466

8.9.1 Protocols ................................................................................... 466

8.9.2 Conserving Bandwidth ............................................................. 466

8.9.3 Initiating Comms (Callback) .................................................... 467

8.10 Alternate Comms Protocols ............................................................. 468

8.10.1 TCP/IP — Details..................................................................... 468

8.10.1.1 FYIs — OS2; OS28 ....................................................... 469

8.10.1.2 DHCP ............................................................................ 469

8.10.1.3 DNS ............................................................................... 469

8.10.1.4 FTP Server ..................................................................... 469

8.10.1.5 FTP Client...................................................................... 470

8.10.1.6 HTTP Web Server ......................................................... 470

8.10.1.6.1 Default HTTP Web Server.................................. 470

8.10.1.6.2 Custom HTTP Web Server ................................. 471

8.10.1.7 Micro-Serial Server ....................................................... 473

8.10.1.8 Modbus TCP/IP ............................................................. 473

8.10.1.9 PakBus Over TCP/IP and Callback ............................... 474

8.10.1.10 Ping (IP) ......................................................................... 474

8.10.1.11 SNMP ............................................................................ 474

8.10.1.12 Telnet ............................................................................. 474

8.10.1.13 SMTP ............................................................................. 475

8.10.1.14 Web API ........................................................................ 475

8.10.1.15 Web API — Details ....................................................... 475

8.10.2 DNP3 — Details....................................................................... 475

8.10.3 Modbus — Details ................................................................... 476

8.10.3.1 Modbus Terminology .................................................... 476

8.10.3.1.1 Glossary of Modbus Terms ................................. 477

8.10.3.2 Programming for Modbus .............................................. 477

8.10.3.2.1 Declarations (Modbus Programming)

................. 477

8.10.3.2.2 CRBasic Instr uc t i ons (Modbus) .......................... 478

8.10.3.2.3 Addressing (ModbusAddr) ................................. 479

8.10.3.2.4 Supported Modbus Function Codes .................... 479

8.10.3.2.5 Reading Inverse Format Modbus Registers ........ 480

8.10.3.2.6 Timing................................................................. 480

8.10.3.3 Troubleshooting (Modbus) ............................................ 480

8.10.3.4 Modbus over IP ............................................................. 480

8.10.3.5 Modbus Security ............................................................ 481

8.10.3.6 Modbus Over RS-232 7/E/1 .......................................... 482

8.10.3.7 Converting Modbus 16-Bit to 32-Bit Longs .................. 482

8.11 Keyboard/Display — Details .......................................................... 483

8.11.1 Character Set ............................................................................ 483

8.11.2 Data Display ............................................................................. 485

Page 18

Table of Contents

18

8.11.2.1 Real-Time Tables and Graphs ....................................... 486

8.11.2.2 Real-Time Custom ......................................................... 486

8.11.2.3 Final-Storage Data ......................................................... 488

8.11.3 Run/Stop Program .................................................................... 489

8.11.4 File Management ...................................................................... 490

8.11.4.1 File Edit ......................................................................... 490

8.11.5 PCCard (Memory Card) Management ..................................... 492

8.11.6 Port Status and Status Table ..................................................... 492

8.11.7 Settings ..................................................................................... 493

8.11.7.1 CR1000KD: Set Time / Date ......................................... 494

8.11.7.2 CR1000KD: PakBus Settings ........................................ 494

8.11.8 Configure Display .................................................................... 494

8.12 CPI Port and CDM Devices — Details ........................................... 494

9. Maintenance — Details .......................................... 497

9.1 Protection from Moisture — Details ............................................... 497

9.2 Internal Battery — Details ............................................................... 497

9.3 Factory Calibration or Repair Procedure ......................................... 500

10. Troubleshooting ..................................................... 503

10.1 Troubleshooting — Essential Tools ................................................ 503

10.2 Troubleshooting — Basic Procedure ............................................... 503

10.3 Troubleshooting — Error Sources ................................................... 504

10.4 Troubleshooting — Status Table ..................................................... 505

10.5 Troubleshooting — CRBasic Pro gr ams .......................................... 505

10.5.1 Program Does Not Compile ..................................................... 505

10.5.2 Program Compiles / Does Not Run Correctly .......................... 506

10.5.3 NAN and ±INF ......................................................................... 506

10.5.3.1 Measurements and NAN ................................................ 507

10.5.3.1.1 Voltage Measurements ........................................ 507

10.5.3.1.2 SDI-12 Measurements ........................................ 507

10.5.3.2 Floating-Point Math, NAN, and ±INF ........................... 507

10.5.3.3 Data Types, NAN, and ±INF ......................................... 507

10.5.3.4 Output Processing and NAN .......................................... 509

10.5.4 Status Table as Debug Resource .............................................. 510

10.5.4.1 CompileResults .............................................................. 510

10.5.4.2 SkippedScan .................................................................. 512

10.5.4.3 SkippedSystemScan ....................................................... 513

10.5.4.4 SkippedRecord ............................................................... 513

10.5.4.5 ProgErrors ...................................................................... 513

10.5.4.6 MemoryFree .................................................................. 513

10.5.4.7

10.5.4.8 Watchdog Errors ............................................................ 514

10.6 Troubleshooting — Operating Systems ........................................... 515

10.7 Troubleshooting — Auto Self-Calibration Errors ........................... 515

10.8 Troubleshooting — Communications .............................................. 516

10.8.1 RS-232 ...................................................................................... 516

10.8.2 Communicating with Multiple PCs .......................................... 516

10.8.3 Comms Memory Errors ............................................................ 517

10.9 Troubleshooting — Power Supplies ................................................ 517

10.9.1 Troubleshooting Power Supplies — Overview ........................ 517

VarOutOfBounds ........................................................... 513

10.5.4.8.1 Status Table WatchdogErrors ............................. 514

10.5.4.8.2 Watchdoginfo.txt File ......................................... 515

Page 19

Table of Contents

19

10.9.2 Troubleshooting Power Supplies — Examples ........................ 518

10.9.3 Troubleshooting Power Supplies — Procedures ...................... 518

10.9.3.1 Battery Test.................................................................... 518

10.9.3.2 Charging R egulator with Solar P anel Test ..................... 519

10.9.3.3 Charging R egulator with Transformer Test ................... 521

10.9.3.4 Adjusting Charging Vo ltage .......................................... 522

10.10 Troubleshooting — Using Terminal Mode ..................................... 523

10.10.1 Serial Talk Through and Comms Watch .................................. 526

10.11 Troubleshooting — Using Logs ...................................................... 526

10.12 Troubleshooting — Data Recovery ................................................. 526

10.13 Troubleshooting — Miscellaneous Errors ....................................... 527

10.13.1 Voltage Calibration Error!........................................................ 527

10.14 Troubleshooting — Rebooting ........................................................ 528

11. Glossary ................................................................. 529

11.1 Terms ............................................................................................... 529

11.2 Concepts .......................................................................................... 563

11.2.1 Accuracy, Precision, and Resolution ........................................ 563

12. Attributions ............................................................. 565

Appendices

A. Info Tables and Settings ........................................ 567

A.1 Info Tables and Settings Directories ............................................... 569

A.1.1.1 Info Tables and Settings: Frequently Used .................... 569

A.1.1.2 Info Tables and Settings: Keywords .............................. 570

A.1.1.3 Info Tables and Settings: Accessed by Keyboard/

Display ....................................................................... 572

A.1.1.4 Info Tables and Settings: Communications ................... 574

A.1.1.5 Info Tables and Settings: Programming ........................ 575

A.1.1.6 Info Tables and Settings: Other ..................................... 575

A.2 Info Tables and Settings Descr iptions ............................................. 576

B. Serial Por t Pinout s ................................................. 595

B.1 CS I/O Communication Port ........................................................... 595

B.2 RS-232 Communication Port .......................................................... 596

B.2.1 Pin Outs .................................................................................... 596

B.2.2 Power States ............................................................................. 597

C. FP2 Data Format .................................................... 599

D. Endianness ............................................................. 601

E. Supporting Pr oduc t s — List .................................. 603

E.1 Dataloggers — List ......................................................................... 603

E.2 Measurement and Control Peripherals — List ................................ 604

E.3 Sensor-Input Modules — List ......................................................... 604

Page 20

Table of Contents

20

E.3.1 Ana log Input Modules — List .................................................. 604

E.3.2 Pulse Input Mod ules — List ..................................................... 604

E.3.3 Serial I /O M odules — List ....................................................... 605

E.3.4 Vibr a ting Wir e Input Modules — List ..................................... 605

E.3.5 Pa ssive Si gnal Conditioners — List ......................................... 605

E.3.5.1 Resistive-Bridge TIM Modules — List ......................... 606

E.3.5.2 Voltage Divider Modules — List .................................. 606

E.3.5.3 Current-Shunt Modules — List ..................................... 606

E.3.5.4 Transient Voltage Suppressors — List .......................... 606

E.3.6 Terminal Strip Covers — List .................................................. 607

E.4 PLC Control Modules — Lists ........................................................ 607

E.4.1 Digital-I/O M odules — List ..................................................... 607

E.4.2 Continuous-Analog Output (CAO) Modules — List ............... 607

E.4.3 Relay-Drivers — List ............................................................... 608

E.4.4 Current-Excitation Modules — List ......................................... 608

E.5 Sensors — Lists ............................................................................... 609

E.5.1 Wired-Sensor Types — List ..................................................... 609

E.5.2 Wireless-Network Se ns ors — List ........................................... 610

E.6 Cameras — List ............................................................................... 610

E.7 Data Retrieval and Comms Peripherals — List ............................... 610

E.7.1 Keyboard/Display — List ........................................................ 611

E.7.2 Ha rdwire, Single-Connection Comms Devices — List ............ 611

E.7.3 Ha rdwire, Networking Devic es — List .................................... 612

E.7.4 TCP/IP Links — List ................................................................ 612

E.7.5 Telephone Modems — List ...................................................... 612

E.7.6 Private-Network Radios — List ............................................... 613

E.7.7 Satellite Transceivers — List ................................................... 613

E.8 Data Storage Devices — List .......................................................... 613

E.9 Datalogger Support Software — List .............................................. 614

E.9.1 Starter Software — List ............................................................ 614

E.9.2 Datalogger Support Software — List ....................................... 615

E.9.2.1 LoggerNet Suite — List ................................

E.9.3 Software Tools — List ............................................................. 617

E.9.4 Software D evelopment Kits — List ......................................... 617

E.10 Power Supplies — List .................................................................... 618

E.10.1 Battery / Regulator Combinations — List ................................ 618

E.10.2 Batteries — List ....................................................................... 619

E.10.2.1 CR3000 Batte ry Bases — List ....................................... 619

E.10.3 Regulators — List .................................................................... 620

E.10.4 Primary Power Sources — List ................................................ 620

E.10.5 24 Vdc Power Supply Kits — List ........................................... 621

E.11 Enclosures — List ........................................................................... 621

E.12 Tripods, Towers, and Mounts — List .............................................. 622

E.13 Protection from Moisture — List .................................................... 622

................. 616

Index ............................................................................. 625

List of Figures

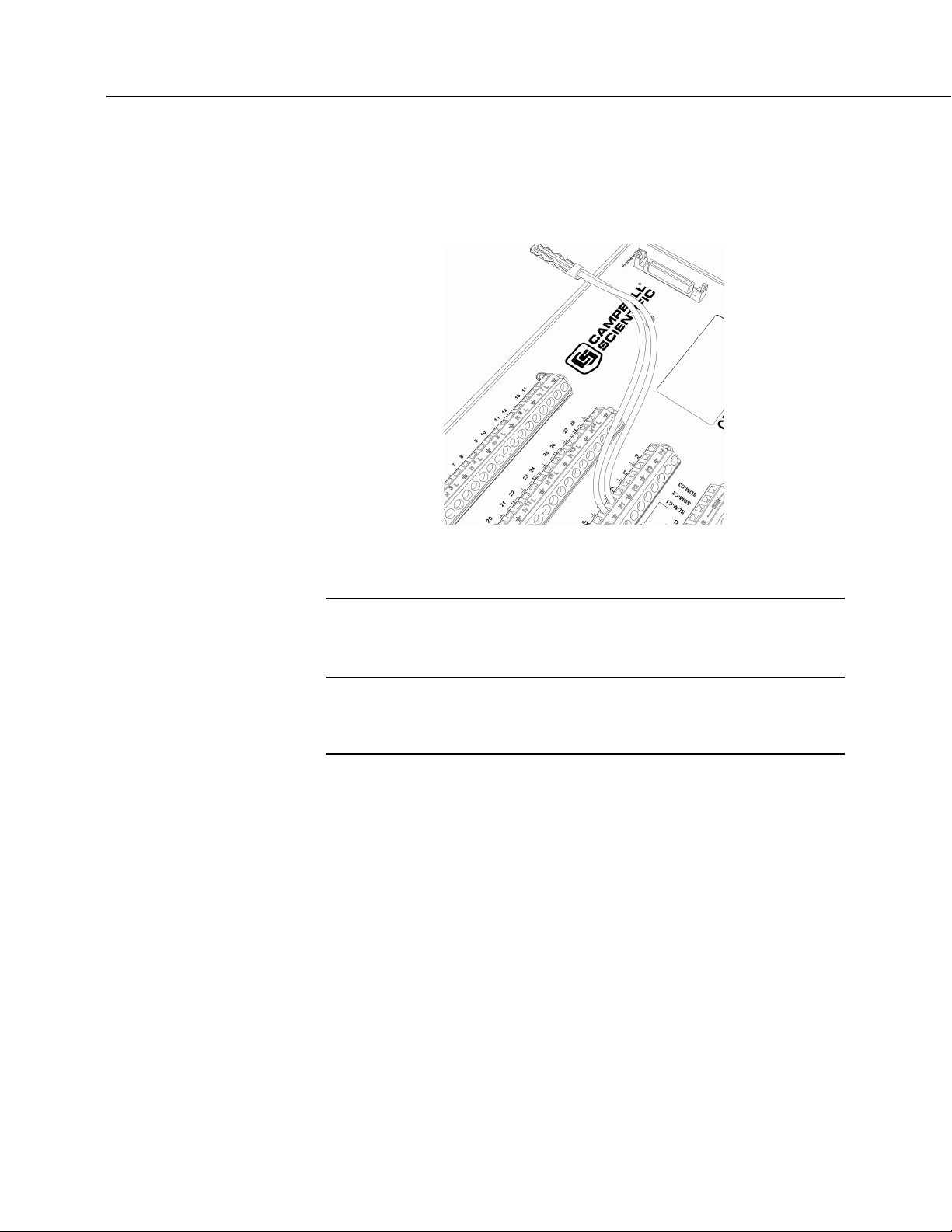

FIGURE 1: Wiring Panel .............................................................................. 39

FIGURE 2: Connect Power and Comms (Internal-Power Supply) ............... 43

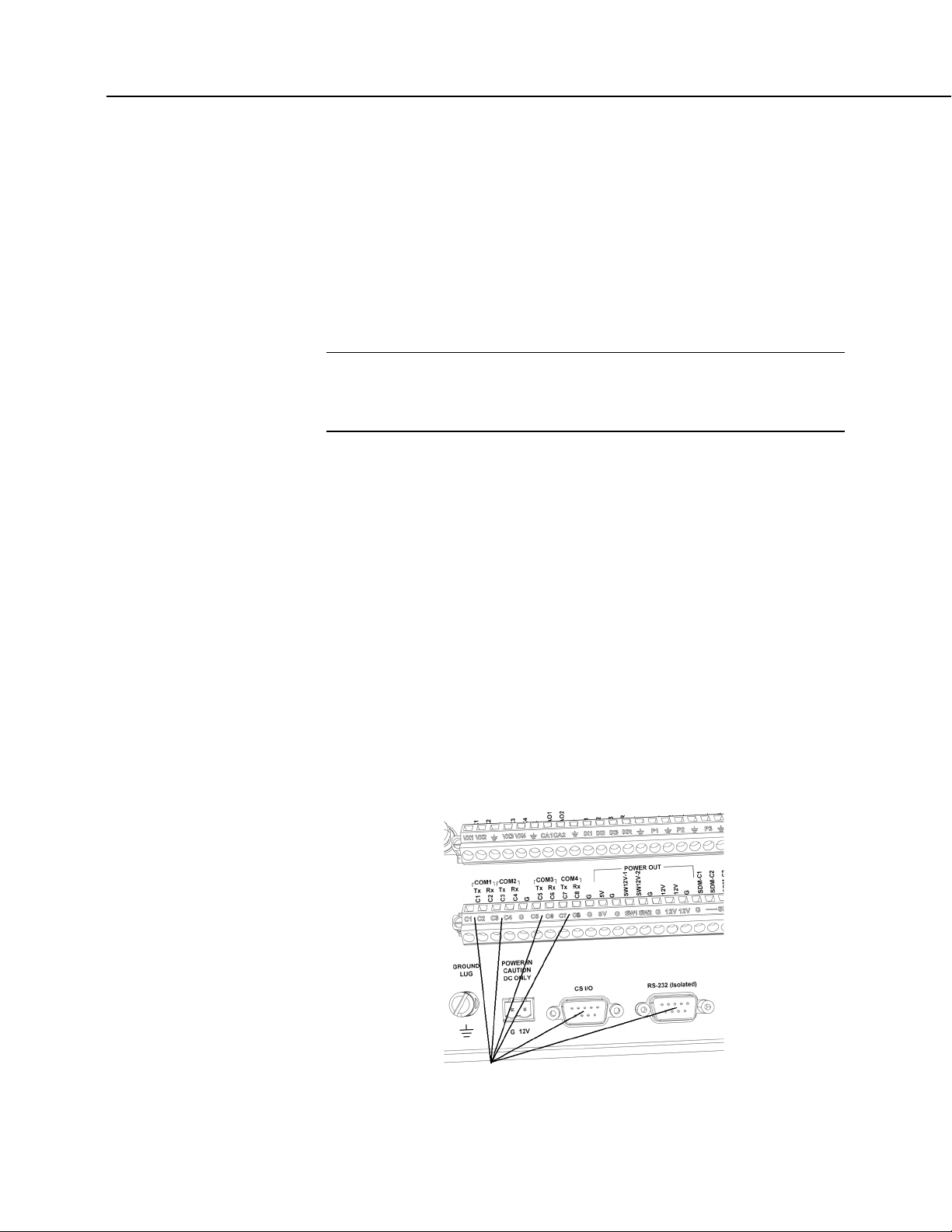

FIGURE 3: Connect Power and Comms (External-Power Supply) .............. 44

FIGURE 4: PC200W Main Window ............................................................. 45

FIGURE 5: Short Cut Temperature Sensor Folder ....................................... 47

Page 21

Table of Contents

21

FIGURE 6: Short Cut Outputs Tab ............................................................... 48

FIGURE 7: Short Cut Compile Con firmation Window and Results Tab ..... 49

FIGURE 8: PC200W Main Window............................................................. 50

FIGURE 9: PC200W Monitor Data Tab – Public Table ............................... 51

FIGURE 10: PC200W Monitor Data Tab — Public and OneMin Tables .... 52

FIGURE 11: PC200W Collect Data Tab ...................................................... 52

FIGURE 12: PC200W View Data Utility ..................................................... 53

FIGURE 13: PC200W View Data Table ...................................................... 54

FIGURE 14: PC200W View Line Graph ...................................................... 55

FIGURE 15: Data Acquisition System Components .................................... 56

FIGURE 16: Data Acquisition System — Overview .................................... 58

FIGURE 17: Wiring Panel ............................................................................ 60

FIGURE 18: Control and Monitoring with C te rminals ................................ 62

FIGURE 19: Analog Sensor Wired to Single-Ended Channel #1 ................. 69

FIGURE 20: Analog Sensor Wired to Differential Channel #1 .................... 69

FIGURE 21: Half-Bridge Wi ring Example — Wind Vane Potentiometer ... 73

FIGURE 22: Full-Bridge Wiring Example — Pressure Transducer ............. 73

FIGURE 23: Pulse Sensor Output Signal Types ........................................... 75

FIGURE 24: Pulse Input Wi ring Example — Anemometer ......................... 76

FIGURE 25: Terminals Configurable for RS-232 Input ............................... 78

FIGURE 26: Use of RS-232 and Digital I/O whe n R eading RS-232

Devices ................................................................................................... 79

FIGURE 27: Custom Menu Example ........................................................... 86

FIGURE 28: Enclosure ................................................................................. 98

FIGURE 29: Connecting to Vehicle Power Supply .................................... 101

FIGURE 30: Alkaline Battery Or ie ntation .................................................. 103

FIGURE 31: Sealed-Rechargeable Battery Wiring ..................................... 106

FIGURE 32: Schematic of Grounds ............................................................ 108

FIGURE 33: Lightning Protection Scheme ................................................. 109

FIGURE 34: Model of a Ground Loop with a Resistive Sensor ................. 112

FIGURE 35: Device Configura tion Utility (DevConfig) ............................ 114

FIGURE 36: Network Pla nner Setup .......................................................... 115

FIGURE 37: "Include" File Settings With DevConfig ............................... 120

FIGURE 38: "Include" File Settings With PakBusGraph ........................... 121

FIGURE 39: Summary of CR3000 Configuration ...................................... 129

FIGURE 40: Sequential-Mode Scan Priority Flow Diagrams .................... 167

FIGURE 41: CRBasic Editor Pr ogram Send File Control window ............ 181

FIGURE 42: Running-Average Frequency Response ................................. 200

FIGURE 43: Running-Average Signal Attenuation .................................... 200

FIGURE 44: Data from TrigVar Program .................................................. 203

FIGURE 45: Alarms Toggled in Bit Shift Example ................................... 205

FIGURE 46: Bool8 Data from B it Shift Example (Numeric Monitor) ....... 205

FIGURE 47: Bool8 Data from B it Shift Example (PC Data File) .............. 206

FIGURE 48: Input Sample Vectors ............................................................ 214

FIGURE 49: Mean Wind-Vector Graph ..................................................... 215

FIGURE 50: Standard Deviation of Direction ............................................ 216

FIGURE 51: Standard Deviation of Direction ............................................ 216

FIGURE 52: Custom Menu Example — Home Screen .............................. 224

FIGURE 53: Custom Menu Example — View Data Window .................... 224

FIGURE 54: Custom Menu Example — Make Notes Sub Menu ............... 224

FIGURE 55: Custom Menu Example — Predefined Notes Pick List ......... 225

FIGURE 56: Custom Menu Example — Free Entry Notes Window ..........

225

FIGURE 57: Custom Menu Example — Accept / Clear Notes Window .... 225

FIGURE 58: Custom Menu Example — Control Sub Menu ...................... 226

Page 22

Table of Contents

22

FIGURE 59: Custom Menu Example — Control LED Pick List ............... 226

FIGURE 60: Custom Menu Example — Control LED Boolean Pick List . 226

FIGURE 61: Quarter-Bridge Strain Gage with RC Resistor Shunt ............ 245

FIGURE 62: Strain Gage Shunt Calib r a tion Start ....................................... 246

FIGURE 63: Strain Gage Shunt Calib r a tion Finish .................................... 247

FIGURE 64: Zero Procedure Start .............................................................. 247

FIGURE 65: Zero Procedure Finish ............................................................ 247

FIGURE 66: Entering SDI-12 Transparent Mode ....................................... 256

FIGURE 67: PT100 BrHalf4W() Four-Wire Half-Bridge Schematic ......... 277

FIGURE 68: PT100 BrHalf3W() Three-Wire Half-Bridge Schematic ....... 281

FIGURE 69: PT100 BrFull() Four-Wire Full-Bridge Schematic ................ 285

FIGURE 70: PT100 Resistance() Basic-Circuit Schematic ........................ 291

FIGURE 71: PT100 Resistance() Basic-Circuit Series Sche matic .............. 295

FIGURE 72: PT100 Resistance() Four-Wire Full-Bridge Schematic ......... 296

FIGURE 73: HyperTerminal New Connection Description ....................... 317

FIGURE 74: HyperTerminal Connect-To Settings ..................................... 317

FIGURE 75: HyperTerminal COM Port Settings Tab: Click File |

Properties | Settings | ASCII Setup... and set as shown. ....................... 318

FIGURE 76: HyperTerminal ASCII Setup ................................................. 318

FIGURE 77: HyperTerminal Send-Text File Example ............................... 319

FIGURE 78: HyperTerminal Text-Capture File Example .......................... 319

FIGURE 79: Ac Power Noise Rejection Techniques .................................. 340

FIGURE 80: Input voltage rise and tr a nsient decay .................................... 343

FIGURE 81: Settling Time for Pressure Transducer ................................... 345

FIGURE 82: Example voltage measurement accuracy band, including

the effects of percent of reading and offset, for a differential

measurement with input reversal at a temperature between 0 to

40 °C. ................................................................................................... 354

FIGURE 83: Panel Temperature Error Summary ....................................... 358

FIGURE 84: Panel Temperature Gradients (low temperature to high) ....... 358

FIGURE 85: Panel Temperature Gradients (high temperature to low) ....... 359

FIGURE 86: Input Error Calculation .......................................................... 361

FIGURE 87: Diagram of a Thermocouple Junction Box ............................ 367

FIGURE 88: PGIA with Input Signal Decomposition ................................ 383

FIGURE 89: Simplified voltage measurement sequence. ........................... 383

FIGURE 90: Programmable Ga in Inp ut Amplifier (PGIA): H to V+, L to

V–, VH to V+, VL to V– correspond to text. ....................................... 384

FIGURE 91: Ac Power Noise Rejection Techniques .................................. 390

FIGURE 92: Input voltage rise and tr a nsient decay .................................... 392

FIGURE 93: Settling Time for Pressure Transducer ................................... 395

FIGURE 94: Example voltage measurement accuracy band, including

the effects of percent of reading and offset, for a differential

measurement with input r eversal at a temperature between 0 to

40 °C. ................................................................................................... 403

FIGURE 95: Pulse Sensor Output Signal Types ......................................... 405

FIGURE 96: Switch Closure Pulse Sensor ................................................. 405

FIGURE 97: Terminals Configurable for Pulse Input ................................. 406

FIGURE 98: Amplitude reduction of pulse count waveform (before and

after 1 µs µs time-co nstant filter ) ......................................................... 416

FIGURE 99: Vibrating Wire Sensor ........................................................... 417

FIGURE 100: Input Conditioning Circuit for Period Averaging ................ 419

FIGURE 101: Circuit to Limit C Terminal Input to 5 Vdc ......................... 420

FIGURE 102: Current-Limiting Resistor in a Rain Gage Circuit ............... 421

FIGURE 103: Current sourcing from C terminals configured for control .. 429

FIGURE 104: Relay Driver Circ uit with Relay .......................................... 431

Page 23

Table of Contents

23

FIGURE 105: Power Switching without Relay........................................... 431

FIGURE 106: Preconfigured HTML Home Page ....................................... 470

FIGURE 107: Home Page Created Using WebPageBegin() Instruction .... 471

FIGURE 108: Customized Numeric-Monitor Web Page ............................ 472

FIGURE 109: Keyboard and Display: Navigation ...................................... 484

FIGURE 110: Keyboard and Display: Displaying Data ............................. 485

FIGURE 111: CR1000KD Real-Time Tables and Graphs. ........................ 486

FIGURE 112: CR1000KD Real-Time Custom ........................................... 487

FIGURE 113: Keyboard and Display: Final Storage Data .......................... 488

FIGURE 114: Keyboard and Display: Run/Stop Program .......................... 489

FIGURE 115: Keyboard and Display: File Management ........................... 490

FIGURE 116: Keyboard and Display: File Edit.......................................... 491

FIGURE 117: Keyboard and Display: PCCard (Memory Card)

Management ......................................................................................... 492

FIGURE 118: Keyboard and Display: Port Status and Status Table ........... 493

FIGURE 119: Keyboard and Display: Settings........................................... 493

FIGURE 120: Keyboard and Display: Configure Display .......................... 494

FIGURE 121: Loosen Thumbscrews .......................................................... 498

FIGURE 122: Remove Back Cover Retainer Screw ................................... 499

FIGURE 123: Remove and Replace Battery ............................................... 500

FIGURE 124: Potentiometer R3 on PS100 and CH100 Charger /

Regulator .............................................................................................. 523

FIGURE 125: DevConfig Terminal Tab ..................................................... 525

FIGURE 126: Relationships of Accuracy, Precision, and Resolution ........ 564

List of Tables

PC200W EZSetup Wizard Prompt s ............................................ 45

CR3000 Wiring Panel Terminal Definitions, 1 ........................... 60

CR3000 Wiring Panel Terminal Definitions, 2 ........................... 61

Differential and Single-Ended Input Terminals .......................... 69

Pulse Input Terminals and Measurements ................................... 75

Alkaline Battery Temperatures and Service .............................. 103

CR3000 Base Sealed-Rechargeable Battery Specifications ...... 105

CR3000 Ac-Transformer Specifications ................................... 106

Info Tables and Settings Interfaces ........................................... 117

Common Configuration Actions and Tools............................. 123

Program Send Command Locations ........................................ 126

CRBasic Program Structure .................................................... 130

Data Types in Variable Memory ............................................. 137

Data Types in Final-Storage Memory ..................................... 138

Formats for Entering Nu mbers in CRB asic ............................. 149

Typical Data Table .................................................................. 152

TOA5 Environment Line ......................................................... 152

DataInterval() Lapse Parameter Options ................................. 156

Program T asks ......................................................................... 161

Program Timing Instructions ................................................... 163

Rules for Names ...................................................................... 169

Binary Conditions of TRUE and FALSE ................................ 174

Logical Expression Examples ................................................. 175

Data Process Abbreviations..................................................... 178

Program Send Options That Reset Memory1 .......................... 181

WindVector() OutputOpt Optio ns ........................................... 212

FieldCal() Codes ..................................................................... 231

Page 24

Table of Contents

24

Calibration Report for Relative Humidity Sensor ................... 233

Calibration Report for Salinity Sen sor .................................... 236

Calibration Report for Flow Meter .......................................... 238

Calibration Report for Water Co ntent Sensor ......................... 241

Maximum Measurement Speeds Using VoltSE() .................... 248

Voltage Measurement Instruction Parameters for Dwell

Burst ..................................................................................................... 252

SDI-12 Commands for Transparent Mode .............................. 257

SDI-12 Commands for Programmed (SDIRecorder()) Mode . 261

SDI-12 Sensor Configuration CRBasic Example — Results .. 270

Example Power Usage Profile for a Network of SDI-12

Probes ................................................................................................... 271

PRT Measurement Circuit Overview ...................................... 275

PT100 Temperature and ideal resistances (RS); α =

1

0.00385

............................................................................................... 276

Callandar-Van Dusen Coefficients for PT100, α = 0.00385 ... 276

Input Ranges (mV) .................................................................. 276

Input Limits (mV) ................................................................... 277

Excitation Ranges .................................................................... 277

BrHalf4W() Four-Wire Half-Bridge Equations ....................... 277

Bridge Resistor Values (mΩ) .................................................. 277

BrHalf3W() Three-Wire Half-Bridge Equations ..................... 281

Bridge Resistor Values (mΩ) .................................................. 282

Resistance() Basic Circuit Equa tion ........................................ 291

Number of PT100 .................................................................... 294

Four-Wire Half-Bridge Equations for PRT Example .............. 296