Page 1

r

w

CR200 Series Datalogge

Overvie

Revision: 3/07

Copyright © 2000-2006

Campbell Scientific, Inc.

Page 2

Page 3

CR200 Overview Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

CR200 Overview......................................................... OV-1

OV1. Physical Description ......................................................................OV-1

OV1.1 Measurement Inputs..............................................................OV-2

OV1.1.1 Analog Inputs ............................................................OV-2

OV1.1.2 Signal/Shield Grounds

OV1.1.3 Power Ground ............................................................OV-3

OV1.1.4 Ground Lug................................................................OV-3

OV1.1.5 Switched Voltage Excitation (VX)............................OV-3

OV1.1.6 Pulse Inputs................................................................OV-3

OV1.1.7 Control I/O.................................................................OV-3

OV1.1.8 Power In.....................................................................OV-3

OV1.1.9 Switched Battery........................................................OV-3

OV1.1.10 Power Supply and AC Adapter................................OV-3

OV1.2 Communication and Data Storage.........................................OV-4

OV1.2.1 RS-232........................................................................OV-4

OV1.2.2 Antenna......................................................................OV-5

OV2. Memory and Programming Concepts............................................OV-9

OV2.1 Memory.................................................................................OV-9

OV2.2 Measurements, Processing, Data Storage............................OV-10

OV2.3 Data Tables..........................................................................OV-10

OV2.4 PakBus Communication with the CR200............................OV-11

OV2.5 Serial ASCII Communication with the CR200...................OV-11

OV3. CR200 Setup using the Device Configurator Utility ...................OV-11

OV3.1 Power and Communication Connections to the CR200......OV-11

OV3.2 Using DevConfig to Set the PakBus Address.....................OV-12

OV3.3 CR206, CR211, and CR216 Radio Settings........................OV-14

OV3.3.1 Radio Hop Sequence................................................OV-14

OV3.3.2 Radio Address/Radio Net Address.......................... OV-14

OV3.3.3 Radio Power Mode..................................................OV-14

OV3.3.4 RF Protocol..............................................................OV-15

OV4. Quick Start Tutorial for Programming the CR200.......................OV-16

OV4.1 Software Products for the CR200 .......................................OV-16

OV4.1.1 Options for Creating CR200 Programs....................OV-16

OV4.2 Connections to the CR200 ..................................................OV-16

OV4.3 PC200W Software...............................................................OV-16

OV4.3.1 Creating a CR200 Program using Short Cut............OV-17

OV4.3.2 Configuring the Setup Tab.......................................OV-21

OV4.3.3 Synchronize the Clocks ...........................................OV-22

OV4.3.4 Send the Program.....................................................OV-22

OV4.3.5 Monitor Data Tables................................................OV-22

OV4.3.6 Collect Data.............................................................OV-22

OV4.3.7 View Data................................................................OV-23

OV4.5 Programming using the CRBasic Program Editor...............OV-24

OV5. Specifications...............................................................................OV-26

........................................OV-3

i

Page 4

CR200 Overview Table of Contents

Figures

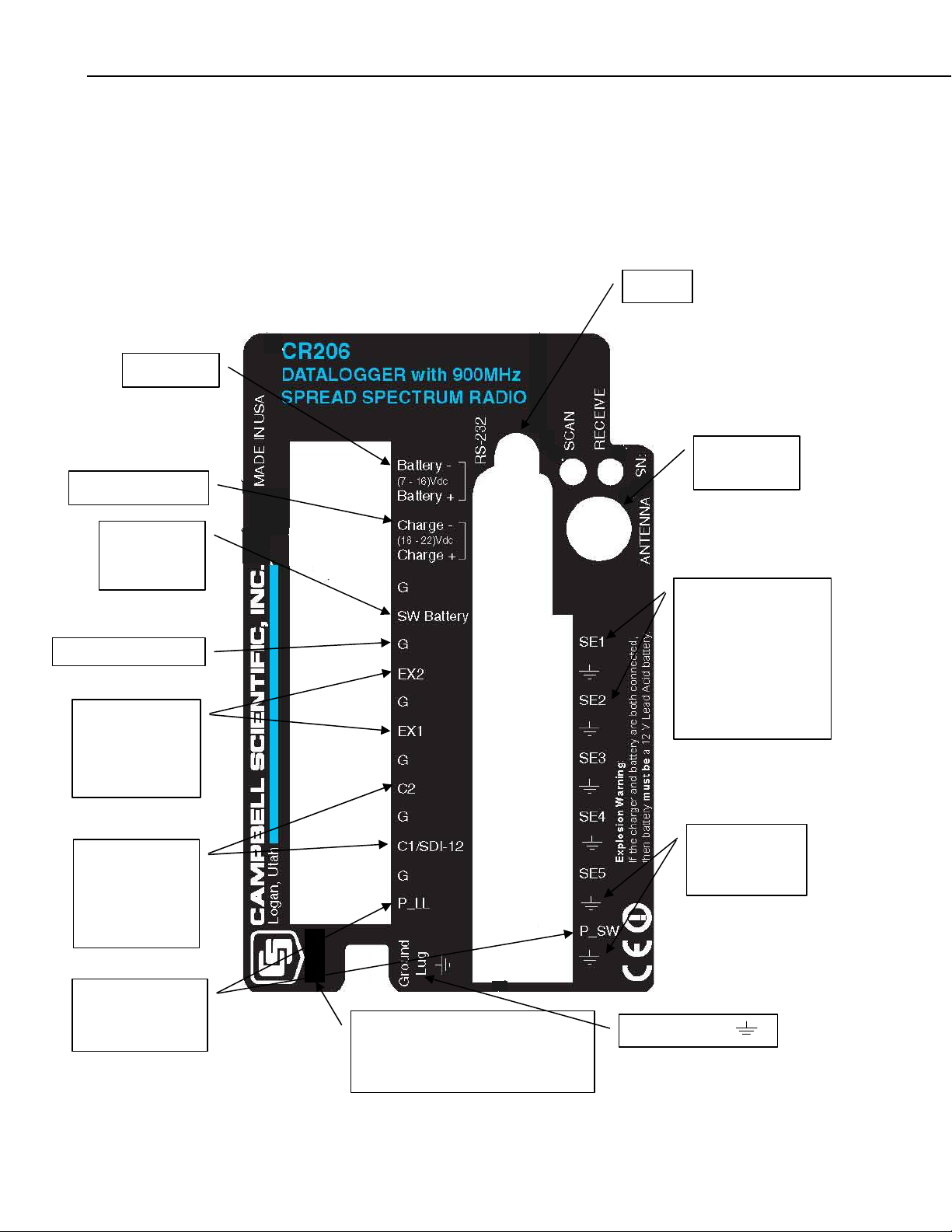

OV1-1 CR206 Datalogger with 900 MHz Spread Spectrum Radio....... OV-1

OV1-2 CR200 Panel and Associated Instructions.................................. OV-2

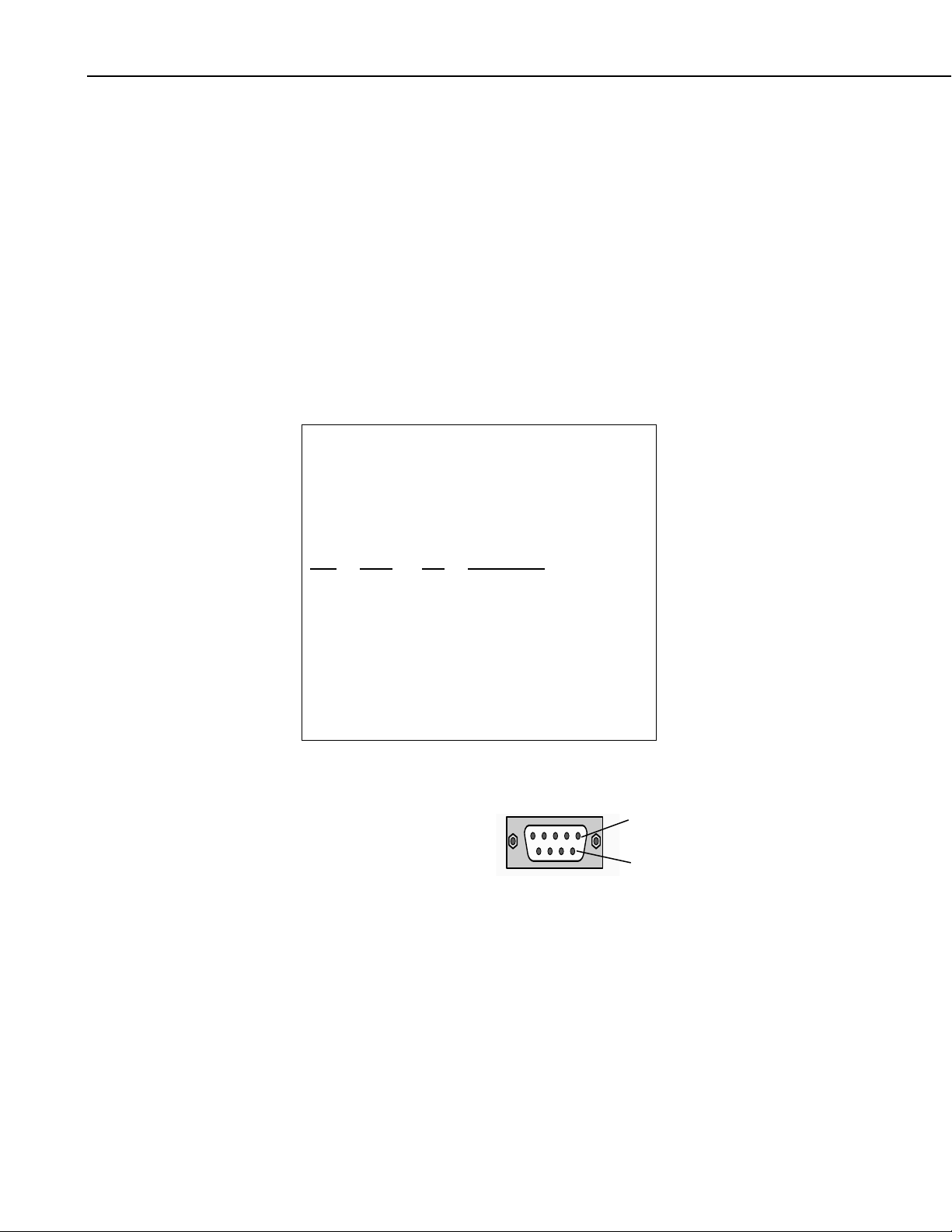

OV1-3. Serial Communication Interfaces............................................... OV-4

OV1-4. Some FCC Approved Antennas................................................. OV-8

OV1-5. Example COAX RPSMA-L Cable for Yagi or Omni Colinear.OV-9

OV1-6. Antenna Surge Protector............................................................OV-9

OV2-1. 512K on the datalogger label indicates the larger memory...... OV-10

OV3-1. Power and Communication Connections to the CR200........... OV-12

OV3-2. DevConfig Main Screen .......................................................... OV-13

OV3-3. Setting the PakBus Address..................................................... OV-13

Tables

OV1-1. Computer RS-232 Pin-Out......................................................... OV-4

OV2-1. Typical Data Table................................................................... OV-10

ii

Page 5

CR200 Overview

The CR200 datalogger provides versatile measurement capabilities in a low-cost, rugged,

battery-operated package. The CR200 includes CPU and analog and digital inputs and

outputs. The BASIC-like programming language includes data processing and analysis

routines.

The CR206, CR211, and CR216 combine the CR200 datalogger with a spread spectrum

radio for telemetering data. The different model numbers are for different spread spectrum

frequency ranges:

CR206 915 MHz U.S./Canada CR205 (Retired) 915 MHz U.S./Canada

CR211 922 MHz Australia/Israel CR210 (Retired) 922 MHz Australia/Israel

CR216 2.4 GHz Worldwide CR215 (Retired) 2.4 GHz Worldwide

The CR295 includes an additional 9-pin serial port and an instruction set that allows

communication with our TX312 HDR GOES satellite transmitter (see Appendix B).

Throughout this manual CR200 is used to refer to the datalogger that is the same

regardless of the model number.

FIGURE OV1-1. CR206 Datalogger with 900 MHz Spread Spectrum Radio

OV1. Physical Description

Figure OV1-2 shows the CR206 panel and the associated program instructions.

Unless otherwise noted, they are measurement instructions (Section 7).

OV-1

Page 6

CR200 Overview

y

OV1.1 Measurement Inputs

OV1.1.1 Analog Inputs

There are five single-ended inputs for measuring voltages from 0 to +2.5 V.

Resolution is 0.6 millivolts.

POWER IN

CHARGE INPUT

SWITCHED

BATTERY

SWBatt

POWER GROUNDS

SWITCHED

VOLTAGE

EXCITATION

ExDelSE

RS-232

ANTENNA

RadioPower

ANALOG INPUTS

VoltSE

ExDelSE (uses VX)

PeriodAvg

AnalogPortGet

AnalogPortSet

Other Measurements

Battery

CONTROL I/O

SDI12

PortGet

PortSet

SDI12Recorder

PULSE INPUTS

PulseCount

PulseCountReset

OV-2

512K

The 512K label indicates the larger

Serial Flash EEPROM. Dataloggers

without this label have a 128 kbyte

memor

FIGURE OV1-2. CR200 Panel and Associated Instructions.

instead of 512 kbytes.

GROUND LUG

SIGNAL AND

SHIELD

GROUNDS

Page 7

CR200 Overview

OV1.1.2 Signal/Shield Grounds

The terminals labeled

measurements and s

OV1.1.3 Power Gr

OV1.1.4 Ground L

OV1.1.5 Switched

OV1.1.6 Pulse Inp

ound (G)

The G terminals (Power Grounds) are used to carry return currents from other

devices powe

red by the SW Battery or battery and terminals.

ug

The earth ground lug is used to connect a heavy gage wire to earth ground. A

earth connection is necessary to fix the ground potential of the datalogger

good

o send to earth transients that come in on the terminals or are shunted to

and t

ground via the spark gaps protecting ot her inputs.

Voltage Excitation (VX)

Two switched excitation channels provide precision programmable voltag es

(+2.5 V + 5 V) for bridge measurem

to 20 mA at 2.5 V, 10 mA at 5 V.

uts

are used to connect the ground reference for

hield wires.

ents. Each analog output will provide up

OV1.1.7 Control I/

OV1.1.8 Power In

OV1.1.9 Switched

OV1.1.10 Power S

Two Pulse input channels can count pulses from high-level (5 V square wave),

h closure, or low-level A/C signals.

switc

O

There are two digital Input/Output channels (0 V low, 5 V high) for frequency

asurement, digital control, SDI-12 communication.

me

The Batt - and Batt + terminals are for connecting power from an external

battery to the CR200. The CR200 will operate on 7 to 16 VDC. These are the

only terminals that can be used to input battery power; the SW Battery terminal

is an output only. Power to charge a 12 V lead-acid battery (16-22 VDC) m

be connected to the Charge + and Charge – terminals.

ust

Battery

The SW Battery terminal provides an unregulated power from the battery that

can be switc

hed on and off under program control.

upply and AC Adapter

The CR200 does not have an internal power supply but d oe s have c o nnections

for an external battery and a buil

lead-acid battery from an externa

from a 16-22 VDC input such as a solar panel.

t-in charging regulator for charging a 12 V

l power source. Charging power can come

OV-3

Page 8

CR200 Overview

OV1.2 Commun

OV1.2.1 RS-232

ication and Data Storage

A computer can connect directly to the CR2

OV1-3). The CR200 RS-232 port is a DCE device. A limited version of the

RS-232 port is supported with no hardware fl ow contr ol . Tabl e OV 1- 1 gi v es a

brief description of each RS-232 pin.

The CR200 RS-232 port is not electrically isolated. Connection to an AC

powered computer may cause “ground loops” leading to measurement

problems.

Maximum input = ±25 V

Maximum Output = ±13 V

Typical Ou

TABLE OV1-1. Comp

ABR = Abbreviation for the function name

PIN

O

I = Signal Into the CR200 from a RS-23

PIN ABR I/O Description

tput = ±5.4 V

uter RS-232 Pin-Out

= Pin number

= Signal Out of the CR200 to a RS-232 device

00 through the RS-232 port (Figure

2 device

1 no connection

2 TX O asynchronous transmit

3 RX I asynchronous receive

4 no connection

5 GND ground

6 DSR O +5 V

7 no connection

8 CTS O V request to send +5

9 no connection

RS-232

Pin 1

FIGURE OV1-3. Serial Comm Interfaces unication

Pin 6

OV-4

Page 9

OV1.2.2 Antenna

CR200 Overview

Several antennas are offered to satisfy the needs for various base station and

remote station requirements. These antennas have been tested at an authorized

FCC open-field test site and are certified to be in compliance with FCC

emissions limits. All antennas (or antenna cables) have an SMA female

connector for connection to the CR200. The use of an unauthorized antenna

could cause transmitted field strengths in excess of FCC rules, interfere with

licensed services, and result in FCC sanctions against user. The CR205,

CR206, CR210, and CR211 use 900 MHz antennas, and the CR215 and CR216

use 2.4 GHz antennas.

NOTE

An FCC authorized antenna is a REQUIRED component. You

must pick one of the antennas listed below.

CSI Item Number Description

14310 0 dBd ANTENNA, 900 MHZ, OMNI ¼ WAVE WHIP,

RPSMA STRAIGHT, LINX, 3.2 inches long.

14204 0 dBd ANTENNA, 900 MHZ, OMNI ½ WAVE WHIP,

RPSMA RT ANGLE, ASTRON, 6.75 inches long.

14221 3 dBd ANTENNA, 900 MHZ, OMNI COLLINEAR,

ANTENEX FG9023, 24 inches tall, W/FM2 MOUNTS,

fits 1 in. to 2 in. O.D. mast (requires COAX RPSMA-L

or COAX NTN-L)

15970 1 dBd ANTENNA, 900 MHZ, INDOOR OMNI ½

WAVE DIPOLE, 10 ft. cable with SMA connector to fit

CR200 Series, window or wall mounted by sticky back,

4 inches wide.

14205 6 dBd ANTENNA, 900 MHZ, YAGI, LARSEN

YA6900 TYPE N-F, boom length 17.25 inches, longest

element 7.25 inches, W/MOUNTS, fits 1 in. to 2 in.

O.D. mast (requires COAX RPSMA-L or COAX NTNL)

14201 9 dBd ANTENNA, 900 MHZ, YAGI, MAXRAD

BMOY8905 TYPE N-F, boom length 21.4 inches,

longest element 6.4 inches, W/MOUNTS, fits 1 in. to 2

in. O.D. mast (requires COAX RPSMA-L or COAX

NTN-L)

16005 0 dBd ANTENNA, 2.4 GHz, OMNI ½ WAVE WHIP,

RPSMA RT ANGLE, LINX ANT-2.4-CW-RCT-RP,

4.5 inches long.

16755 13 dBd ANTENNA, 2.4 GHz, ENCLOSED YAGI,

allows vertical or horizontal polarization, MAXRAD

WISP24015PTNF, boom length 17 inches, diameter 3

inches, W/ END MOUNT to fit 1 to 2 in. O.D. mast

OV-5

Page 10

CR200 Overview

(requires either (1) COAX RPSMA-L for short runs or

(2) COAX NTN-L with Antenna Surge Protector Ki t )

COAX RPSMA-L LMR 195 ANTENNA CABLE, REVERSE POLARITY

SMA TO TYPE N MALE

COAX NTN-L RG8 ANTENNA CABLE, TYPE N MALE TO TYPE

N MALE CONNECTORS, REQUIRES 14462

14462 ANTENNA SURGE PROTECTOR KIT

FCC OET Bulletin No. 63 (October 1993)

Changing the antenna on a transmitter can significantly increase, or decrease,

the strength of the signal that is ultimately transmitted. Except for cable

locating equipment, the standards in Part 15 are not based solely on output

power but also take into account the antenna characteristics. Thus, a low

power transmitter that complies with the technical standards in Part 15 with a

particular antenna attached can exceed the Part 15 standards if a different

antenna is attached. Should this happen it could pose a serious interference

problem to authorized radio communications such as emergency, broadcast,

and air-traffic control communications.

CAUTION

In order to comply with the FCC RF exposure

requirements, the CR200 series may be used only with

approved antennas that have been tested with the onboard radio and a minimum separation distance of 20 cm

must be maintained from the antenna to any nearby

persons.

Read Appendix C of this manual for important FCC information.

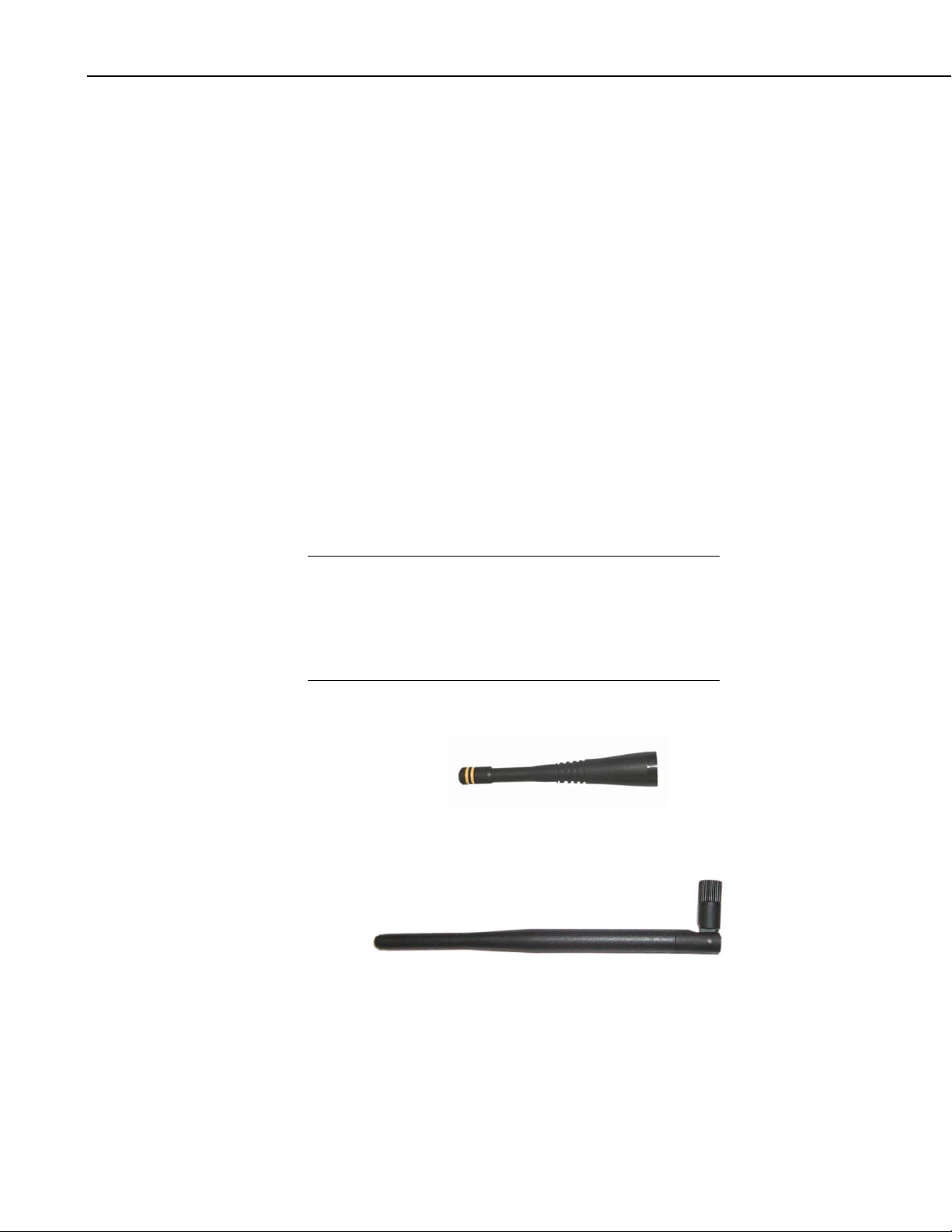

ITEM # 14310 900 MHZ OMNI ¼ WAVE WHIP 0 dBd

ITEM # 14204 900 MHZ OMNI ½ WAVE WHIP 0 dBd

OV-6

Page 11

CR200 Overview

ITEM # 14201 900 MHZ YAGI 9 dBd w/MOUNTS

ITEM #14205 900 MHz YAGI 6 dBd w/MOUNTS

ITEM # 14221 900 MHZ OMNI COLLINEAR 3 dBd w/MOU NTS

OV-7

Page 12

CR200 Overview

ITEM #15970 900 MHZ Indoor OMNI 1 dBd Window/Wall Mounted

ITEM #16005 2.4 GHz OMNI HALF WAVE WHIP 0 dBd

OV-8

ITEM #16755 2.4 GHz ENCLOSED YAGI, 13 dBd w/MOUNTS

FIGURE OV1-4. Some FCC Approved Antennas

Page 13

CR200 Overview

FIGURE OV1-5. Example COAX RPSMA-L Cable for Yagi or Omni

Colinear

FIGURE OV1-6. Antenna Surge Protector

OV2. Memory and Programming Concepts

OV2.1 Memory

The CR200 has 2K SRAM for communication buffers, calculations, and

variables, and 60K Flash EEPROM for the operating system and user program.

Dataloggers originally had a 128K Serial Flash EEPROM for data storage.

Campbell Scientific is increasing the data storage memory from 128 kbytes to

512 kbytes. Dataloggers with the increased memory have 512K on their label.

OV-9

Page 14

CR200 Overview

FIGURE OV2-1. 512K on the datalogger label indicates the larger memory.

OV2.2 Measurements, Processing, Data Storage

As a datalogger, the CR200 is programmed to measure the sensors and store

data in its EEPROM memory. Data are retrieved from the CR200 using a

computer and CSI software, e.g. LoggerNet.

A CR20X series datalogger with a spread spectrum radio (e.g. CR206) can also

function as a wireless interface between a sensor and a “master” PakBus

datalogger. In this configuration the CR200 measures the sensors and sends

the data to the master datalogger. Data are retrieved from the master, rather

than the CR20X.

OV2.3 Data Tables

The CR200 can store individual measurements or it may use its processing

capabilities to calculate averages, maxima, minima, etc., on periodic or

conditional intervals. Data are stored in tables such as listed in Table OV2-1.

The values to output are selected when running the program generator or when

writing a datalogger program directly.

TABLE OV2-1. Typical Data Table

TOA5 1 CR2XX v1.0 EXPLS4.CR2 45828 AvgTemp

TMSTAMP RECNBR SoilT_Avg(1) SoilT_Avg(2) SoilT_Avg(3) SoilT_Avg(4)

TS RN DegC DegC DegC DegC

Avg Avg Avg Avg

3/20/02 11:00 1 15.498 15.9926 18.516 19.5019

3/20/02 12:00 2 15.4996 15.9993 18.5069 19.502

3/20/02 13:00 3 15.4963 16.0042 18.4975 19.496

OV-10

Page 15

OV2.4 PakBus Communication with the CR200

The CR200 uses Pakbus to communicate with the computer and other Pakbus

devices. PakBus is a Campbell Scientific term for our packet-routing

communications protocol. Packets of information transmitted between PakBus

devices contain header information that is used to route the packets to their

final destination.

Every PakBus device needs a Pakbus address in order to receive, sen d, or route

packets. In a Pakbus network each device requires a unique address. The

CR200 is shipped with a default address of 1. The range of allowable addresses

is 1-3999.

A PakBus Networking Guide is available from the Campbell Scientific

website, which describes Pakbus and gives detailed examples for several

network configurations.

OV2.5 Serial ASCII Communication with the CR200

See Appendix A.

CR200 Overview

OV3. CR200 Setup using the Device Configurator

Utility

The Device Configurator Utility (DevConfig) ships with the LoggerNet, PC400

and PC200W software products, and is also available no-charge from the

Campbell Scientific website.

The Device Configuration Utility (DevConfig) sets up dataloggers and

peripherals before those devices are deployed in the field. Some key features

of DevConfig include:

• DevConfig only supports direct serial connections between the PC and

devices.

• DevConfig allows you to determine operating system types and versions.

• DevConfig provides a summary of the current configuration of a device

that can be shown on the screen and printed. This configuration can also

be saved to a file and used to restore the settings in the same or a

replacement device.

OV3.1 Power and Communication Connections to the CR200

To connect external power (7 – 16VDC) to the CR200, insert the positive lead

into the “Battery +”, followed by the negative lead into the “Battery-“

terminal, as shown in Figure OV3-1.

Connect the white serial cable (PN 10873, provided) be tween the port labeled

“RS232” on the CR200 and the serial port on the computer. For computers

that have only a USB port, a USB Serial Adaptor (PN 17394 or equivalent) is

required.

OV-11

Page 16

CR200 Overview

FIGURE OV3-1. Power and Communication Connections

to the CR200

OV3.2 Using DevConfig to Set the PakBus Address

The CR200 default PakBus address is 1. Unless the CR200 is used in a

network, there may be no need to change the Pakbus address, or any other

default setting. To change settings, the Device Configuration Utility

(DevConfig) is used, as described below.

To set the PakBus address, the CR200 must be powered up and connected to

the computer as described in Section OV 3.1.

Run the DevConfig Utility. The DevConfig window is divided into two main

sections: the device selection panel on the left, and tabs on the right. Select the

CR2XX device, and the COM port on the computer that will be used for

communications.

OV-12

Page 17

CR200 Overview

FIGURE OV3-2. DevConfig Main Screen

Click on the Connect button to establish communications. DevConfig

establishes communications with the CR200 and displays the scr e en shown in

Figure OV3-3.

FIGURE OV3-3. Setting the PakBus Address

OV-13

Page 18

CR200 Overview

OV3.3 CR206, CR211, and CR216 Radio Settings

To set the PakBus address, use the up and down arrows next to the “Pakbus

Address” box, or key in the desired number (e.g., 10) and click the Apply

button. Leave the PakBus address at 1 for use with the Quick Start Tutorial

(Section OV4). Click the Disconnect button to exit DevConfig.

The Spread Spectrum radios in the CR206, CR211, and CR216 and in the

RF400 have address, frequency, and power settings. These addresses are not

PakBus addresses but an address the radio encodes in its message. For two

radios to talk to each other the address and frequency settings must be the same

in both radios.

NOTE

In a PakBus network addresses and frequency settings in ALL

radios must be the same.

CR20X Radios are set up using the Deployment Tab as described in Section

OV3.3. The radio settings are described below.

OV3.3.1 Radio Hop Sequence

Spread Spectrum radios have a band of frequencies that they use. The radios

“hop” from one frequency to another within this band, allowing multiple sets

of radios to communicate at the same time without interfering with each other.

The “Radio Hop Sequence” determines the sequence in which the hops are

made. Radios must be set to the same “Radio Hop Sequence” in order to hear

each other (i.e., for the listening radio to synchronize with the transmitting

radio and hop to the same frequency at the same time). Set the same hop

sequence in all radios.

OV3.3.2 Radio Address/Radio Net Address

The “Radio Address” and “Radio Net Address” combined are sent as part of a

packet header with each message. Even if a radio is on the same hop sequence

and can hear another radio, it ignores the message unless that message has its

address in the header. Set the same “Radio Address” and “Radio Net

Address” in all radios.

OV-14

NOTE

RF400 Spread Spectrum Radios that communicate with the

CR206, CR211, or CR216 must also be set to the same Radio

Address and Radio Net Address. See the RF400 manual for

directions on setting these parameters in the RF400.

OV3.3.3 Radio Power Mode

The Radio Power Mode setting determines what portion of the time the radio is

powered up “listening” for incoming transmissions and how much power the

radio/datalogger consumes from its power supply.

RF_ON: Radio standby receive current <24 mA. The Radio Receiver is

always on. This provides the fastest response when the datalogger will be

interrogated but because of the current should only be used where an AC

backed power supply is available or the speed is absolutely necessary.

Page 19

CR200 Overview

RfpinEn: Radio standby receive current 0 mA.: For use as a wireless sensor

with a TD datalogger select RfpinEn for the Power Mode. This has the lowest

power requirement of all settings. The radio is controlled by the CR200

program. As a wireless sensor all transmissions are initiated by the CR200. The

radio is only powered for the transmission and a short time after while awaiting

the response from the master datalogger.

NOTE

In wireless sensor applications, the RF400 on the master

datalogger should be set to always on.

RF1_Sec: Radio standby receive current < 2 mA. The radio powers u p once

a second to listen for transmissions. The maximum response delay is 2 seconds.

RF8_Sec: Radio standby receive current < 0.4 mA. The radio powers up

every 8 seconds to listen for transmissions. The maximum response delay is 16

seconds.

RF1S_LH: Radio standby receive current < 2 mA. The radio powers up

once a second to listen for transmissions. When it initiates communication it

sends long header (>1 second) on messages. This is used only if the datalogger

will be initiating communications with SendGetData and other radios in the

system are using the 1 second standby mode. The long header insures other

radios in the network hear the message.

RF8S_LH: Radio standby receive current < 0.4 mA. The radio powers up

every 8 seconds to listen for transmissions. When it initiates communication it

sends long header (>8 seconds) on messages. This is used only if the

datalogger will be initiating communications with SendGetData and other

radios in the system are using the 8 second standby mode. The long header

insures other radios in the network hear the message.

After selecting the desired hop, address, and power mode settings, press “Save

Settings” to store the values to the radio.

OV3.3.4 RF Protocol

Identifies the radio protocol that will be used for the CR2xx. In order to be

compatible with other CR2xx and RF400 type devices, the default value of

transparent must be used. The following values are supported:

1. Transparent – This mode is compatible with older CR205, CR210, CR215,

2. PakBus – This mode can be used in networks invol vi n g

RF400, RF410, and RF415 operating systems.

RF401/RF411/RF416 ha rd ware or other, newer CR206/CR 21 1/ C R 216

devices and makes use of the retry capability inherent in the MaxStream

radios. This mode is not compatible with the older radios.

OV-15

Page 20

CR200 Overview

OV4. Quick Start Tutorial for Programming the

CR200

OV4.1 Software Products for the CR200

PC200W Starter Software supports a direct connection (RS232 cable or Spread

Spectrum radio) between the PC and the CR200, and includes Short Cut for

Windows (Short Cut) for creating CR200 programs. PC200W prov ides basic

tools for setting the datalogger’s clock, sending a program, monitoring sensors,

and manually collecting and viewing data. CR200 support was added to

PC200W in Version 3.0. PC200W is available at no charge from the Campbell

Scientific website.

PC400 Datalogger Support Software (mid-level software) supports a variety of

telecommunication options, manual data collection, and data display. PC400

includes Short Cut and the CRBasic Program Editor for creating CR200

programs. PC400 does not support combined communication options (e.g.,

phone-to-RF), PakBus® routing, or sche d ul ed dat a coll ect i o n.

LoggerNet Datalogger Support Software (full-featured software) supports

combined telecommunication options, data display, and scheduled data

collection. The software includes Short Cut and CRBasic for creating CR200

programs, and tools for configuring, trouble-shooting, and managing

datalogger networks.

OV4.1.1 Options for Creating CR200 Programs

1. Short Cut is a program generator that creates a datalogger program in four

easy steps, and a wiring diagram for the sensors. Short Cut supports the

majority of sensors sold by Campbell Scientific, and is recommended for

creating straightforward programs that measure the sensors and store data.

2. The CRBasic Editor is a program editor used to create more complex

CR200 programs. Short Cut generated programs can be imported into the

CRBasic Editor for adding instructions, or for functionality not supported

by Short Cut.

OV4.2 Connections to the CR200

Connect the CR200 to the 12V power supply and to the computer as described

in Section OV3.1.

OV4.3 PC200W Software

This Quick-Start tutorial prompts the user through the process of programming

the CR200, monitoring sensor measurements, collecting data, and viewing data

using the PC200W software. Before using PC200W, set the CR200 Pakbus

address to 1 as described in Section OV3.

When PC200W is first started, the EZSetup Wizard is launched. Click the

Next button and follow the prompts to select the CR200, the COM port on the

computer that will be used for communications, 9600 baud, and Pakbus

OV-16

Page 21

CR200 Overview

Address 1. When prompted with the option to Test Communications click

the Finish button.

To change a setting in the datalogger setup, select that datalogger from the

main window, and click the Edit button. If a datalogger was not added with

the Wizard, click the Add button to invoke the Wizard.

After exiting the EZSetup wizard, the Setup/Connect window appears, as

shown below. The Current Datalogger Profi l e, Datal o gg er C l ock, and

Datalogger Program features of PC200W are integrated into this window.

Tabs to the right are used to select the Monitor Values and Collect Data

windows. Buttons to the right of the tabs are used to run the Split, View, and

Short Cut applications.

Short Cut

OV4.3.1 Creating a CR200 Program using Short Cut

Objective: Every 10 seconds measure air temperature (°C) with a 109

Temperature Probe, and rainfall (mm) with a TE525WS rain gage. Every 1minute store average temperature, total rainfall, and minimum battery voltage.

Even if the 109 Temperature Probe and TE525WS Rain Gage sensors are not

available, the programming example can still be followed. Without a 109

probe connected the measurement result will be NAN; without a TE525WS

connected the measurement result will be 0.

Click on the Short Cut button to display the Home screen, as shown below.

OV-17

Page 22

CR200 Overview

Each of the four steps has a button with a ? for accessing Help. Use the Help

in conjunction with the steps outlined below:

Step 1: Create a New File

Step 1 is to open a new or existing file. From the Home page, click the New

button. Use the drop-down list box to select the CR200. Enter a 10 second

Scan Interval and click OK to complete Step 1.

Step 2: Select the Sensors

Step 2 is to select the sensors to be measured. From the Home page, click the

Sensors button. The Sensors worksheet is divided into two sections: the

Available sensors tree and the Selected sensors table, as shown below. The

sensors you want to measure are chosen from the Available sensors tree.

Double click on the Temperature application group to display the available

sensors. Double click on the 109 Temperature Probe sensor to add it the

selected sensors table. Click OK on the next screen to accept T109_C for the

measurement label, the DegC for the units.

Double click on the Meteorological application group. Double click on

Precipitation, and double click on the TE525 / TE525WS sensor to add it to

the selected sensors table. Click OK to accept Rain_mm for the measurement

label, and mm for the units.

OV-18

Page 23

CR200 Overview

Click on the Wiring Diagram tab to view the sensor wiring diagram, as shown

below. Wire the temperature probe and the TE525 rain gauge to the CR200 as

shown on the diagram. If you don’t have these sensors, a simple toggle switch

can be used to simulate the TE525. Without a 109 temperature probe

connected, the measurement result will be NAN (not a number).

Click the Sensors tab and the Home button to return to the Home page to

continue with Step 3.

OV-19

Page 24

CR200 Overview

Step 3: Output Processing

Step 3 is to define the output processing for the sensor measurements. From

the Home page, click the Output button.

The Output screen has a list of Selected Sensors on the left, and Output Tables

on the right. The default is for two Tables, Table1 and Table2. Both Tables

have a Store Every field and the drop-down list box that are used to set the

interval at which data will be stored.

The objective for this exercise calls for a one-minute output processing. To

remove Table2, Click on the Table2 tab to activate it, and click the Delete

Table button.

The Table Name field is the name that will be used for the Table in which the

output will be stored. Change the default Name of Table1 to OneMin, and

change the interval to 1 minute.

The Selected Sensors Table is provided on the left side of the screen. To add a

sensor measurement to the Output Table, highlight a measurement and click

one of the output buttons; e.g., Average.

Click the Default sensor (battery voltage) and double click the Minimum

button. Click the 109 temperature sensor and double click the Average button.

Click the TE525 rain gauge sensor and double click the Total button.

Click the Home button to continue with Step 4 to complete the program.

Step 4: Finish

OV-20

Step 4 is to finish the program. From the Home page, click the Finish button.

Type in CR200_QuickStart for the file name. Any errors the compiler may

have detected are displayed, along with the names of the files that were

created. The file C:\Campbellsci\SCWin\CR200_QuickStart.CR2 is the

program file that will be sent to the CR200, CR200_QuickStart.def is a

summary of the sensor wiring and measurement labels (click the Summary or

Page 25

CR200 Overview

Print buttons to view or print the file). Click the OK button and close Short

Cut.

OV4.3.2 Configuring the Setup Tab

From the Setup/Connect screen, click on the Connect button to establish

communications with the CR200. When communications have been

established, the text on the button will change to Disconnect.

Connect Button

OV-21

Page 26

CR200 Overview

OV4.3.3 Synchronize the Clocks

OV4.3.4 Send the Program

OV4.3.5 Monitor Data Tables

Click the Set Clock button to synchronize the datalogger’s clock with the

computer’s clock.

Click the Select and Send Program button. Navigate to the

C:\CampbellSci\SCWin folder and select the file CR200_QuickStart.CR2 and

click the Open button. A progress bar is displayed, followed by a message that

the program was successfully sent.

The Monitor Values window is used to display the current sensor measurement

values from the Public Table, and the most recent data from the OneMin Table.

Click on the Monitor Values tab. The Public Table is automatically selected

and displayed. To view the OneMin Table, click the Add button, select the

OneMin Table, and click the Paste button.

OV-22

OV4.3.6 Collect Data

Click on the Collect Data tab. From the Collect Data window you can choose

what data to collect, and where to store the retrieved data.

Click on the OneMin Table, with the Option New data from datalogger

selected. Click the Collect button and a dialog box appears, prompting for a

file name. Click the Save button to use the default file name

CR200_OneMin.dat. A progress bar, followed by the message Collection

Complete is displayed.

Page 27

CR200 Overview

OV4.3.7 View Data

To view the collected data, click on the View button (located in the upper right

hand corner of the main screen). Options are accessed by using the menus or

by selecting the toolbar icons. If you move and hold the mouse over a toolbar

icon for a few seconds, a brief description of that icon's function will appear.

To open a data file, click the Open file icon, and double click on the file

CR200_OneMin.dat in the PC200W folder. Click the Expand Tabs icon to

display the data in columns with column headings. To graph thermocouple

temperature, click on the data column with the heading Temp_C, then click the

Show Graph, 1 Y axis icon on the toolbar.

Open File Expand Tabs Show Graph

OV-23

Page 28

CR200 Overview

Close the graph and view screens, and close PC200W.

OV4.5 Programming using the CRBasic Program Editor

Users who are not familiar with the CRBasic programming language may find

Short Cut to be an excellent way to learn CRBasic. First create a program

using Short Cut, then open the file with CRBasic to see how Short Cut created

the program. The program file listed below is the Short Cut file

200_QuickStart.CR1 from the tutorial after being imported into the CRBasic

editor.

See Section 4 for information on the CRBasic programming.

'CR200 Series

'Created by SCWIN (2.2)

'Declare Variables and Units

Public Batt_Volt

Public T109_C

Public Rain_mm

Units Batt_Volt=Volts

Units T109_C=Deg C

Units Rain_mm=mm

'Define Data Tables

DataTable(OneMin,True,-1)

DataInterval(0,1,Min)

Minimum(1,Batt_Volt,False,False)

Average(1,T109_C,False)

Totalize(1,Rain_mm,False)

EndTable

OV-24

Page 29

'Main Program

BeginProg

Scan(10,Sec)

'Default Datalogger Battery Voltage measurement Batt_Volt:

Battery(Batt_Volt)

'109 Temperature Probe measurement T109_C:

Therm109(T109_C,1,1,1,1.0,0.0)

'TE525/TE525WS Rain Gauge measurement Rain_mm:

PulseCount(Rain_mm,P_SW,2,0,0.254,0)

'Call Data Tables and Store Data

CallTable(OneMin)

NextScan

EndProg

CR200 Overview

OV-25

Page 30

CR200 Overview

OV5. Specifications

ANALOG INPUTS; DIGITAL I/O

Channels SE1 to SE5 can be individually configured

for single-ended measurement or digital I/O.

SINGLE-ENDED MEASUREMENT (SE1 TO SE5):

Analog Input Range: 0 ≤ V < 2.5 Vdc

Measurement Resolution: 0.6 mV

Measurement Accuracy

Typical: ±(0.25% of reading + 1.2 mV offset)

over -40° to +50°C

Worst-case: ±(1% of reading + 2.4 mV offset)

over -40° to 50°C

DIGITAL I/O (SE1 TO SE5):

Input/Output High State: 2.1 to 3.3 Vdc

Input/Output Low State: <0.9 Vdc

Output High State: 3.3 V (no load)

Drive Current: 220 µA @ 2.7 Vdc

Maximum Input Volt

HALF BRIDGE MEASUREMENTS:

Accuracy: Relative to the excitation.

Using +2.5 Vdc excitation, is

±(0.06% of reading + 2.4 mV)

PERIOD AVERAGING (SE1 TO SE4):

Maximum Input Voltage: 4 Vdc

Frequency Range: 0 to 150 kHz

Voltage Threshold: counts cycles on transition

from <0.9 Vdc to >2.1 Vdc

EXCITATION CHANNELS (EX1 AND EX2):

Range: Programmable 0, 2.5, 5 Vdc, or

off (floating)

Accuracy: ±25 mV on +2.5 Vdc range, ±125 mV

on +5.0 Vdc range

Maximum Current: 25 mA on +2.5 Vdc range,

10 mA on +5.0 Vdc range

age: 4 Vdc

CONTROL PORTS (C1 AND C2)

DIGITAL I/O:

Voltage Level When Configured as Input:

<0.9 Vdc (low state) to >2.7 Vdc (high state)

Voltage Level When Configured as Output:

0 V (low state), 5 Vdc (high state) (no load)

Logic Level: TTL

Drive Current: 1.5 mA @ 4.5 V

SDI-12: SDI-12 sensors connect to C1

PULSE COUNTERS

SWITCH CLOSURE (P_SW):

Maximum Count Rate: 100 Hz

Minimum Switch Open Time: 5 ms

Minimum Switch Closed Time: 5 ms

Maximum Bounce Time: 4 ms

PULSE COUNT (P_SW, C1, AND C2):

Voltage Threshold: count on transition from

<0.9 V to >2.7 Vdc

Maximum Input Frequency: 1 kHz

Max Input Voltage: C1 & C2 (6.5 V), P_SW (4 Vdc)

LOW LEVEL AC (P_LL):

Voltage Threshold: <0.5 to >2 V

Minimum Input: 20 mV RMS

Maximum Frequency: 1 kHz

Maximum Input: ±20 V

Note: P_LL, C1, & C2 can be used for switch

closure using the battery voltage and a

20 kOhm pull-up resistor. If the dc offset is

>0.5 V, then AC coupling is required.

COMMUNICATIONS

SERIAL INTERFACE: Female RS-232 9-pin interface

for logger-to-PC communications

ON-BOARD SPREAD SPECTRUM RADIO:

Frequency: 915 MHz (CR206), 922 MHz (CR211),

or 2.4 GHz (CR216)

Transmission Range: 1 mile with 0 dBd ¼ wave

antenna (line-of-sight) and 900 MHz radios;

0.6 miles (1 km) with 0 dBd ½ wave antenna

(line-of-sight) and 2.4 GHz radio;

up to 10 miles with higher gain antenna

(line-of-sight)

RF4XX used as a base station radio

AVAILABLE RADIO TRANSMISSION MODES:

Always on, program controlled

Cycle Time: 1 or 8 s cycles; on for 100 ms every

period; checks for incoming communication

Scheduled Transmission Time: off until transmis-

sion time

P

®

AKBUS

packet switching network protocol

CLOCK ACCURACY

8.2 minutes/month @ -40° to +50°C; 1 minute/month

@ +25°C

CPU AND STORAGE

FINAL STORAGE: 512 kbyte Flash, data format

is 4 bytes per data point (table-based)

PROGRAM STORAGE: 6.5 kbyte Flash

FASTEST SCAN RATE: once per second

SWITCHED BATTERY (SW BATTERY)

Switched under program control; 300 mA minimum

current available

POWER

BATTERY VOLTAGE RANGE: 7 to 16 Vdc (can program

datalogger to measure internal battery voltage)

BATTERY: 12 Vdc sealed rechargeable with on-board

charging circuit. Alkaline cells, lithium, or other

non-rechargeable battery types may be connected

if the charging circuit is not used (i.e. nothing

connected to charging terminals).

CHARGER INPUT VOLTAGE: 16 to 22 Vdc

SHELF LIFE OF CLOCK’S BACKUP BATTERY:

5 years

CURRENT DRAIN (@12 V)

QUIESCENT CURRENT DRAIN:

No Radio or Radio Powered Off: ~0.2 mA

ACTIVE CURRENT DRAIN:

No radio ~3 mA

Radio receive ~20 mA (CR206, CR211),

~36 mA (CR216)

Radio transmit ~75 mA (CR206, CR211, CR216)

AVERAGE CONTINUOUS CURRENT DRAIN:

Radio always on ~20 mA (CR206, CR211),

~36 mA (CR216)

Radio in 1 s duty cycle ~2.2 mA (CR206,

CR211), ~4 mA (CR216)

Radio in 8 s duty cycle ~0.45 mA (CR206,

CR211), ~0.8 mA (CR216)

CE COMPLIANCE (as of 03/02)

CE COMPLIANT DATALOGGERS: CR200, CR206,

CR211, CR216

STANDARD(S) TO WHICH CONFORMITY IS

DECLARED: IEC61326:2002

EMI AND ESD PROTECTION

IMMUNITY: Meets or exceeds following standards:

ESD: per IEC 1000-4-2; ±8 kV air, ±4 kV contact

discharge

RF: per IEC 1000-4-3; 3 V/m, 80-1000 MHz

EFT: per IEC 1000-4-4; 1 kV power, 500 V I/O

Surge: per IEC 1000-4-5; 1 kV power and I/O

Conducted: per IEC 1000-4-6; 3 V 150 kHz-80 MHz

Emissions and immunity performance criteria available

on request.

PHYSICAL

CASE DESCRIPTION: Aluminum with spring-loaded

terminals

DIMENSIONS (including terminals): 5.5” x 3” x 2”

(14.0 x 17.6 x 5.1 cm)

WEIGHT:

CR200 or CR295: 8.5 oz (242 g)

CR206, CR211, or CR216: 9.5 oz (271 g)

CUSTOM CASE: available for OEM applications;

contact Campbell Scientific

WARRANTY

One year covering parts and labor.

OV-26

Page 31

This is a blank page.

Page 32

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com

info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za

cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au

info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br

suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca

dataloggers@campbellsci.ca

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk

sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr

campbell.scientific@wanadoo.fr

Campbell Scientific Spain, S. L.

Psg. Font 14, local 8

08013 Barcelona

SPAIN

www.campbellsci.es

info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...