Page 1

Tripod Installation Manual

Models CM110, CM115, CM120

Revision: 5/10

Copyright © 2005-2010

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The CM110, CM115, AND CM120 are warranted by CAMPBELL

SCIENTIFIC, INC. to be free from defects in materials and workmanship

under normal use and service for twelve (12) months from date of shipment

unless specified otherwise. Batteries have no warranty. CAMPBELL

SCIENTIFIC, INC.'s obligation under this warranty is limited to repairing or

replacing (at CAMPBELL SCIENTIFIC, INC.'s option) defective products.

The customer shall assume all costs of removing, reinstalling, and shipping

defective products to CAMPBELL SCIENTIFIC, INC. CAMPBELL

SCIENTIFIC, INC. will return such products by surface carrier prepaid. This

warranty shall not apply to any CAMPBELL SCIENTIFIC, INC. products

which have been subjected to modification, misuse, neglect, accidents of

nature, or shipping damage. This warranty is in lieu of all other warranties,

expressed or implied, including warranties of merchantability or fitness for a

particular purpose. CAMPBELL SCIENTIFIC, INC. is not liable for special,

indirect, incidental, or consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company

serves your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container.

CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Declaration of Hazardous Material

and Decontamination” form and comply with the requirements specified in it.

The form is available from our website at

completed form must be either emailed to repair@campbellsci.com

435-750-9579. Campbell Scientific will not process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

www.campbellsci.com/repair

. A

or faxed to

Page 3

Tripod Installation Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. General .........................................................................1

2. Specifications ..............................................................2

3. Tools List (for tripod, mast and crossarm) ...............3

4. Tripod Components.....................................................3

5. Tripod Installation........................................................4

5.1 Tripod Base...............................................................................................4

5.2 Mast..........................................................................................................5

5.3 Installing the Guy Kit ...............................................................................9

5.3.1 Guy Duckbill Anchor Kits............................................................11

5.3.2 Lowering Mast after Attaching Guy Wires...................................13

5.4 Staking the Tripod Feet ..........................................................................14

5.5 Tripod Grounding...................................................................................15

5.6 Crossarm Attachment .............................................................................17

5.7 Enclosure Attachment.............................................................................17

5.7.1 Enclosure Mounting to Tripod Mast.............................................17

5.7.2 Enclosure Mounting to Tripod Leg...............................................18

6. Mounting Brackets ....................................................20

6.1 CM210 Crossarm Mounting Kit.............................................................20

6.2 CM216 Mast Mounting Kit....................................................................21

6.3 CM220 Right Angle Mounting Kit.........................................................22

6.4 CM225 Pyranometer Mounting Stand....................................................23

6.5 CM230 Adjustable Angle Mounting Kit................................................24

6.6 CM235 Magnetic Mounting Stand.........................................................25

6.7 RM Young Gill Radiation Shields..........................................................26

Appendix

A. Tripod Tote Bag....................................................... A-1

Figures

1-1. CM110 Tripod with Optional Guy Kit....................................................1

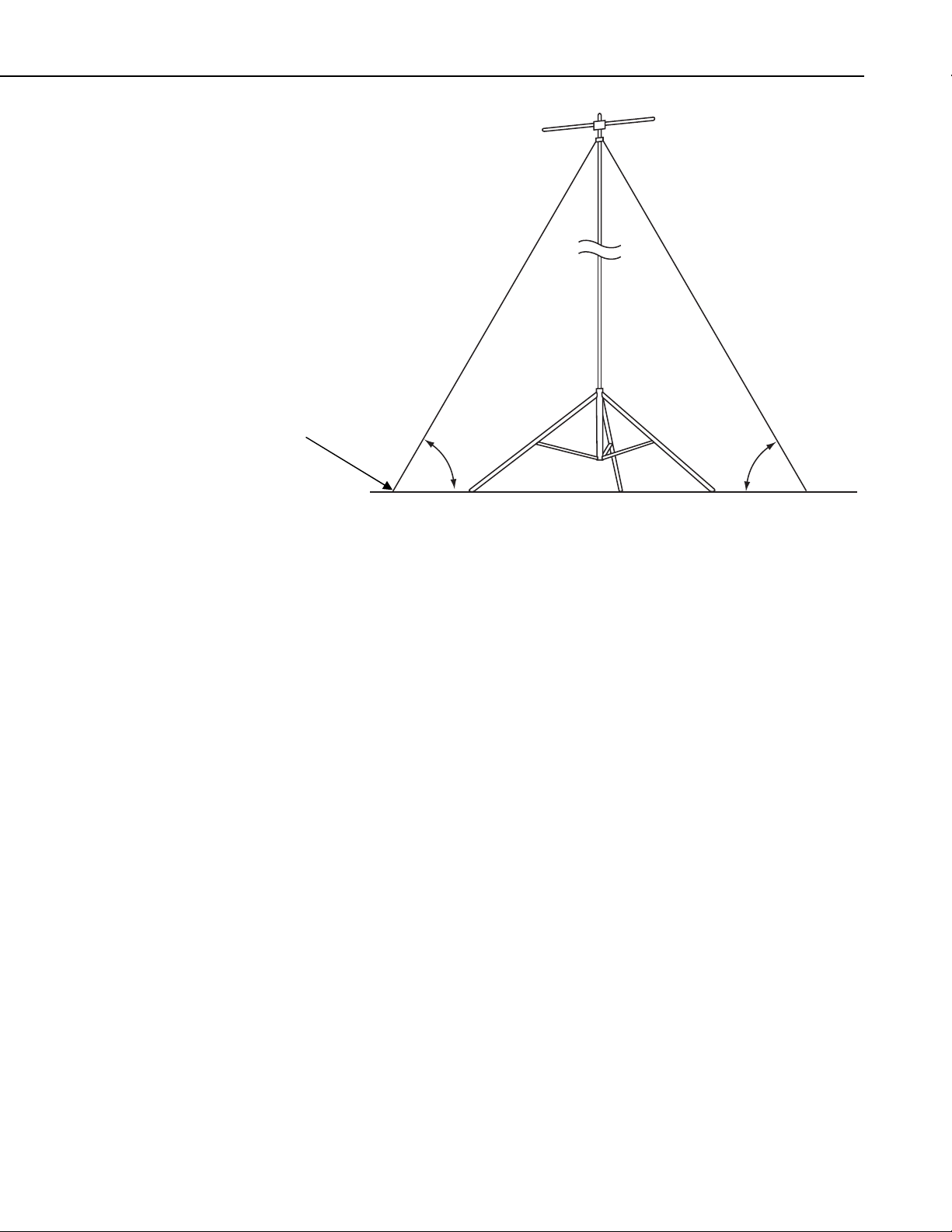

2-1. 60-Degree Guy Angle .............................................................................3

4-1. Tripod Components.................................................................................4

5-1. Tripod Leg, Slide Collar Components.....................................................5

i

Page 4

Tripod Installation Table of Contents

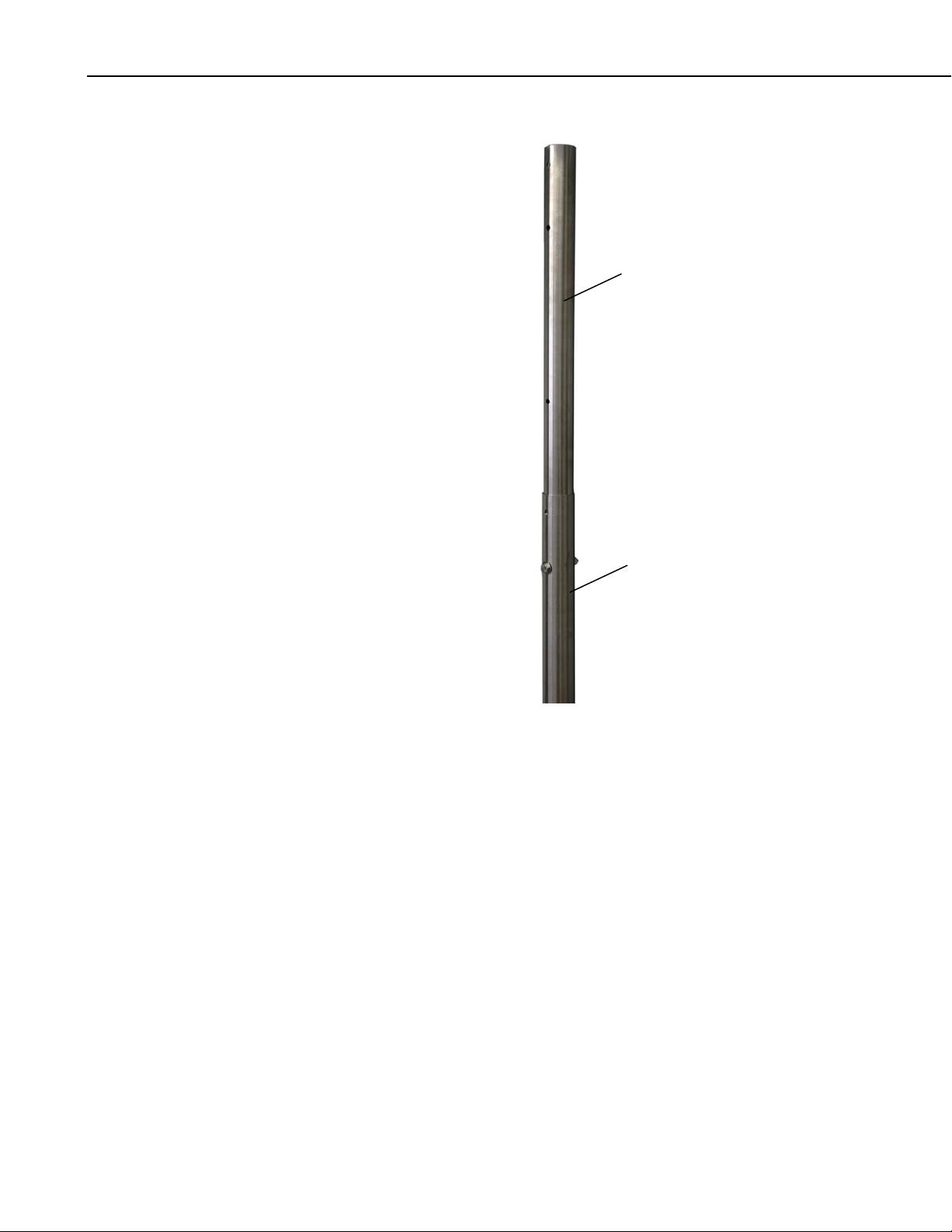

5-2. Tripod Mast and Insert ........................................................................... 6

5-3. Mast Attachment to Tripod Base............................................................ 7

5-4. Mast Lock Bracket.................................................................................. 8

5-5. Guy Collar .............................................................................................. 9

5-6. Guy Cinch and Lever Arm ................................................................... 10

5-7. Mechanical Drawing of Guy Hook and Case....................................... 11

5-8. Duckbill Guy Anchor ........................................................................... 12

5-9. Top View and Guy Anchor Layout...................................................... 13

5-10. Staking the Tripod Feet ...................................................................... 14

5-11. Ground Rod and Clamp......................................................................15

5-12. Lightning Rod and Tripod Grounding Lug ........................................ 16

5-13. CM204 Crossarm................................................................................ 17

5-14. Enclosure with the –MM Bracket ....................................................... 18

5-15. Enclosure with the –LM Bracket........................................................ 19

6-1. CM210 Crossarm Mounting Kit...........................................................20

6-2. CM216 Mast Mounting Kit.................................................................. 21

6-3. CM220 Right Angle Mounting Kit....................................................... 22

6-4. CM225 Pyranometer Mounting Stand.................................................. 23

6-5. CM230 Adjustable Angle Mounting Kit.............................................. 24

6-6. CM235 Magnetic Mounting Stand....................................................... 25

6-7. RM Young Gill Radiation Shield......................................................... 26

ii

Page 5

Tripod Installation Manual Models CM110, CM115, CM120

1. General

The CM110 (10 feet), CM115 (15 feet), and CM120 (20 feet) tripods are

corrosion-resistant stainless steel instrument mounts that support the

attachment of sensors, solar panels, and environmental enclosures. A guy kit is

included with the CM115 and CM120 models, and is an option for the CM110.

A durable Tripod Tote Bag is available as an option.

FIGURE 1-1. CM110 Tripod with Optional Guy Kit

1

Page 6

Tripod Installation Manual Models CM110, CM115, CM120

2. Specifications

Height w/mast insert: 10’ (3 m) 15.5’ (4.7 m) 21.0’ (6.4 m)

Weight: 34 lbs (15 kg) 40 lbs (18 kg) 46 lbs (21 kg)

Base diameter w/legs extended: 7 ft (2 m) 7 ft (2 m) 7 ft (2 m)

Dimensions of collapsed tripo d: 6” x 6” x 57”

Vertical load limit: 100 lb (45 kg) 100 lb (45 kg) 100 lb (45 kg)

Mast description

Number of sections: 1 2 3

Length: 4.6’ (1.4m) 9.3’ (2.8 m) 14.0’ (4.3 m)

Length w/insert: 8.6’ (2.6 m) 13.3’ (4.1 m) 18.0’ (5.5 m)

OD: 1.9” (4.8 cm) 1.9” (4.8 cm) 1.9” (4.8 cm)

Insert OD: 1.75” (4.45 cm) 1.75” (4.45 cm) 1.75” (4.45 cm)

Mounting hole in tripod foot: 0.75” diameter hole

Wind load recommendations

Sustained wind (mph): *75 (unguyed)

CM110

(15 x 15 x 145 cm)

for user-supplied

0.5” J-bolts

80 (guyed at feet)

CM115 (see note 3)

6” x 6” x 57”

(15 x 15 x 145 cm)

0.75” diameter hole

for user-supplied

0.5” J-bolts

*56.25 (guyed at feet)

75 (guyed at 60°)

CM120 (see note 3)

6” x 6: x 57”

(15 x 15 x 145 cm)

0.75” diameter hole

for user-supplied

0.5” J-bolts

*42.25 (guyed at feet)

65 (guyed at 60°)

Gust tolerance (mph): 95 (unguyed)

100 (guyed at feet)

Tote bag dimensions: 8” (20 cm) diameter,

60” (152 cm) length

71.25 (guyed at feet)

95 (guyed at 60°)

8” (20 cm) diameter,

60” (152 cm) length

55.25 (guyed at feet)

85 (guyed at 60°)

8” (20 cm) diameter,

60” (152 cm) length

2

Page 7

*Anchors must hold at least

400 lbf in both x, y axis

Tripod Installation Manual Models CM110, CM115, CM120

60º

60º

FIGURE 2-1. 60-Degree Guy Angle

3. Tools List (for tripod, mast and crossarm)

1/2” and 7/16” open end wrenches

adjustable wrench

socket wrench with 1/2”and 7/16” deep sockets (optional)

Phillips head screw driver (medium)

Straight bit screwdriver (large)

12” torpedo level

side-cut pliers

pencil

tape measure

compass and site declination angle

shovel

sledge hammer (for driving ground rod and stakes)

step ladder

4. Tripod Components

Figure 4-1 shows the tripod components packaged for shipment. The tripod

base is packaged with the mast, ground rod, lightning rod and (6 ) stakes. The

ground rod clamp, lightning rod, and grounding wires are enclosed in a bag.

The guy kit (optional for the CM110), and tripod tote bag (optional) are

packaged separately. The CM115 and CM120 tripods include additiona l mast

sections. A diagram showing how to stow the components inside the tote bag

is shown in Appendix A.

3

Page 8

Tripod Installation Manual Models CM110, CM115, CM120

FIGURE 4-1. Tripod Components

5. Tripod Installation

5.1 Tripod Base

WARNING

Tripod installation near power lines is dangerous. The

minimum safe recommended distance from overhead

power lines is 2 times the height of the tripod and mast

combined. Call Blue Stakes to locate buried utilities

prior to installation.

All three models of tripods use the same tripod base. Each leg is adjustable,

which allows the tripod to be adjusted for non-level terrain.

Prepare the area where the tripod will be installed. The tripod requires an area

approximately 7 feet in diameter. Natural vegetation and the ground surface

should be disturbed as little as possible, but brush and tall weeds should be

removed.

Stand the tripod base up on end, and rotate the feet perpendicular to the legs.

Each leg has a slide collar and T-knob with a spring loaded pin that locks into

holes located on the underside of the leg as shown in Figure 5-1.

Extend each leg until the pin engages in a hole (depress the tab to disengage

the pin from a hole). With the legs extended, orient the tripod so that the open

channel of the tripod base faces North. The tripod is typically plumbed after

the mast has been installed, as described in Section 5.2.

4

Page 9

Tripod Installation Manual Models CM110, CM115, CM120

Holes for Pins

Slide Collar

5.2 Mast

Spring-Loaded Pin

T-Knob

FIGURE 5-1. Tripod Leg, Slide Collar Components

The CM110, CM115 and CM120 tripods have one, two or three mast sections

respectively. The top mast section has a 48” long insert with a series of holes

that can be extended to lengthen the mast. Remove the bolt that secures the

insert to the inside of the mast, and slide the insert out from the mast to see the

different hole locations. Slide the insert back into the mast, aligning the

appropriate holes of the insert with holes in the mast, and replace the bolt.

Additional 56” mast section(s) included with the CM115 and CM120 tripods

have a 16” long insert that is used to connect the mast sections together.

Remove the bolt that secures the insert to the inside of the mast and extend the

insert 8”. Align the holes and replace the bolt. Attach additional mast sections

by sliding the bottom of the next mast section over the insert of a lower section,

aligning the holes and installing the bolt. Typically the bottom mast section is

attached to the tripod and tilted down to a horizontal position, and the

additional mast sections bolted to the bottom section.

5

Page 10

Tripod Installation Manual Models CM110, CM115, CM120

Insert

Mast

FIGURE 5-2. Tripod Mast and Insert

The tripod base has two sets of right-angled holes for attaching the mast;

typically the lower set is used (Figure 5-3A). The mast is attached to the base

with a pin, and secured in the upright position with a locking bracket. Both the

pin and the locking bracket are secured with a lanyard.

To attach the lower mast section, hold the mast upright and align the hole in the

bottom of the mast with the holes in the tripod base. Insert the pin through the

holes, and rotate the wire retainer over the end of the pin as shown in Figure

5-3B. The pin should be seated in the bottom of the hole when the mast is

upright. Lift the mast up so that the pin is in the upper end of the hole to allow

the mast to be tilted down to a horizontal position.

6

Page 11

Tripod Installation Manual Models CM110, CM115, CM120

Pin

Right-Angled Hole

Wire

Retainer

FIGURE 5-3. Mast Attachment to Tripod Base

Secure the mast in the upright position by installing the locking bracket (Figure

5-4A). Insert the top of the bracket into the notches in the tripod base, and

using both thumbs, press the bracket into the body of the base until the lower

tabs lock into position. Install the pin as shown in Figure 5-4C. To remove the

bracket, remove the pin and squeeze the lower part of the bracket to disengage

the tabs, then rotate the bracket out and up.

Plumb the tripod by adjusting the northeast and south facing legs. With a level

on the East side of the mast, adjust the Northeast leg for plumb. With the level

on the South side of the mast, adjust the South leg for plumb.

7

Page 12

Tripod Installation Manual Models CM110, CM115, CM120

t

Locking Bracke

Lower Tabs

8

Pin

FIGURE 5-4. Mast Lock Bracket

Page 13

Tripod Installation Manual Models CM110, CM115, CM120

5.3 Installing the Guy Kit

The CM115 and CM120 tripods include a guy kit; the guy kit is an option for

the CM110. With the mast tilted down in the horizontal position, install the

guy collar over the mast insert, and attach the guy wires as shown in Figure

5-5. Return the mast to the upright position and install the locking bracket.

Guy Collar

Guy Wire

FIGURE 5-5. Guy Collar

On the end of each guy line is a case consisting of a hook, clamp, and lever

arm. Rotate the lever arm to the “open” position, and attach the hook to the

tripod leg as shown in Figure 5-6. Loosen the Phillips screw, and remove the

slack in the guy line by feeding the load end of the guy wire through the wedge

while pulling up on the dead end (Figure 5-7).

After the slack has been removed from the guy lines, tighten the Phillips

screws and rotate the lever arms to “closed” position to tension the guy lines.

9

Page 14

Tripod Installation Manual Models CM110, CM115, CM120

Phillips Screw

Lever Arm “Open”

Hook

Lever Arm “Closed”

FIGURE 5-6. Guy Cinch and Lever Arm

10

Page 15

Tripod Installation Manual Models CM110, CM115, CM120

load end

dead end

Phillips screw

lever

hook

FIGURE 5-7. Mechanical Drawing of Guy Hook and Case

5.3.1 Guy Duckbill Anchor Kits

Duckbill anchors are recommended for areas subjected to higher winds. They

allow the guy wires to be anchored at points beyond the feet, thereby

increasing the rating of the tripod for higher winds.

Two duckbill anchor kits are offered for these lightweight tripods. The 19282

Guy Duckbill Standard Anchor Kit is for standard soils, and the 25699 Guy

Duckbill Heavy Duty Kit is for aggressive soils. Aggressive soils have:

• Resistivity of less than 3000 ohm-cm

• pH of less than 5

• Chloride of greater than 1000 ppm

• Sulfate of greater than 500 ppm

• Poor aeration

The 19282 and 25699 have their own drive bar. The 19282 also has thr ee

duckbill anchors with a cable attached to each of them. At the end of the cable

is a loop for connecting the guy wires. The 25699 has a threaded rod attached

to each of the three duckbill anchors instead of the cable. At the end of the

threaded rod is a metal ring for connecting the guy wires.

The duckbill anchors are driven to the ground at a 60-degree guy angle as

shown in Figure 5-8. Locate the anchors on a 7.5’ radius for the CM115, or a

10’ radius for the CM120 as shown in Figure 5-9. Specifications for sustained

wind speed and gust tolerance are given based on guy angle, and the ability of

the anchors to hold at least 400 lbf.

NOTE

Dukbill anchors are not suitable for rocky or sandy soils; the

UTEYE anchors should be considered for these types of soils.

11

Page 16

Tripod Installation Manual Models CM110, CM115, CM120

r

r

It is important that the anchors be driven at the same angle as the guy wires.

Insert the drive bar into the anchor body and drive the anchor into the ground

using a sledgehammer until only the top half of the loop or metal ring remains

above the ground. Place a bar or highlift jack through the loop or metal ring

and jack the anchor up about four inches to rotate the an chor into the load-lock

position.

WARNING

Failure to install and lock the anchor at the correct

angle will result in the anchor cable cutting through

the soil until the angles equalize, causing slack

Drive Ba

Duckbill Ancho

o

60

FIGURE 5-8. Duckbill Guy Anchor

12

Page 17

Tripod Installation Manual Models CM110, CM115, CM120

RADIUS

Distance between anchors

120

CENTER POINT

TILT DIRECTION

(NORTH)

ANCHOR LOCATIONS

(3) PLCS

Radius Distance Between Anchors

CM115 7.5’ 13’

CM120 10’ 17.3’

FIGURE 5-9. Top View and Guy Anchor Layout

5.3.2 Lowering Mast after Attaching Guy Wires

Once the guy lines have been adjusted the lever arms can be “opened” and the

guy hooks removed to allow the mast to be lowered to the horizontal position.

13

Page 18

Tripod Installation Manual Models CM110, CM115, CM120

5.4 Staking the Tripod Feet

Six stakes are provided for securing the tripod feet to the ground. Drive two

stakes through holes in each foot at an angle as shown in Figure 5-10.

Stakes may not be adequate depending on soil structure, maximum wind

speeds experienced at the site, mast height, or wind load from the

instrumentation. For questionable situations, additional stakes (PN 17049) or

even concrete footings for the tripod feet and guy anchors should be

considered.

FIGURE 5-10. Staking the Tripod Feet

14

Page 19

5.5 Tripod Grounding

Place the clamp over the ground rod and drive the rod (close to the center of

the tripod) using a sledge hammer or fence post driver. Strip 1/2” inch of

insulation from both ends of the black 4 AWG ground wire. Insert one end of

the ground wire between the clamp and ground rod and tighten the bolt on the

clamp. Attach the other end of the ground wire to the lug on the tripod base as

shown in Figure 5-12.

Tripod Installation Manual Models CM110, CM115, CM120

FIGURE 5-11. Ground Rod and Clamp

Strip 1/2” of insulation from the ends of the green 12 AWG wire. Attach one

end of the wire to the tripod ground lug, and the other end to the enclosu re

ground lug as shown in Figure 5-12.

Mount the lightning rod and clamp to the tripod mast as shown in Figure 5-12.

15

Page 20

Tripod Installation Manual Models CM110, CM115, CM120

Lightning Rod

Clamp

Ground Lug

Ground Wire

Enclosure Ground Lug

16

Enclosure Ground Wire

Ground Lug

FIGURE 5-12. Lightning Rod and Tripod Grounding Lug

Page 21

Tripod Installation Manual Models CM110, CM115, CM120

5.6 Crossarm Attachment

Attach the CM202 (2 ft, 0.6m), CM204 (4 ft, 1.2m), or CM206 (6 ft, 1.8m)

crossarm to the tripod mast as shown in Figure 5-13. For wind sensors, the

crossarm should be approximately 103 inches above the ground for a 3m

mounting height, or 64 inches for a 2m mounting height. Typically the

crossarm is oriented East/West for wind sensors, North/South for

pyranometers.

FIGURE 5-13. CM204 Crossarm

5.7 Enclosure Attachment

The ENC 10/12, ENC 12/14, ENC 14/16, and ENC 16/18 enclosures can be

ordered with mounting brackets for the CM100 series tripods. All enclosure

models can be mounted to the tripod mast (above the legs) with the –MM Mast

Mount bracket option. All enclosure models except the ENC 16/18 can be

mounted to the tripod base and leg with the –LM Leg Mount bracket option.

Two enclosures with the –LM brackets can be mounted in a “back to back”

configuration.

5.7.1 Enclosure Mounting to Tripod Mast

An enclosure ordered with the –MM bracket has a three-piece top and bottom

brackets with a U-bolt for each bracket.

Attach an enclosure with the –MM mounting bracket to the tripod mast as

follows:

CM200 Series

Crossarm

Tripod Mast

Remove the U-bolts washers and nuts from the brackets.

Position the enclosure against the tripod’s mast (North side recommended).

17

Page 22

Tripod Installation Manual Models CM110, CM115, CM120

–

Install the U-bolts, flat washers, lock washers, and nuts. Tighten the nuts until

the lock washers are compressed.

Route the 14 AWG wire from the grounding lug on the bottom side of the

enclosure to the grounding lug on the base of the tripod (Figure 5-14). Strip

1/2” of insulation from each end of the wire. Insert wire ends into the

grounding lugs and tighten.

U-Bolt

MM Bracket

18

FIGURE 5-14. Enclosure with the –MM Bracket

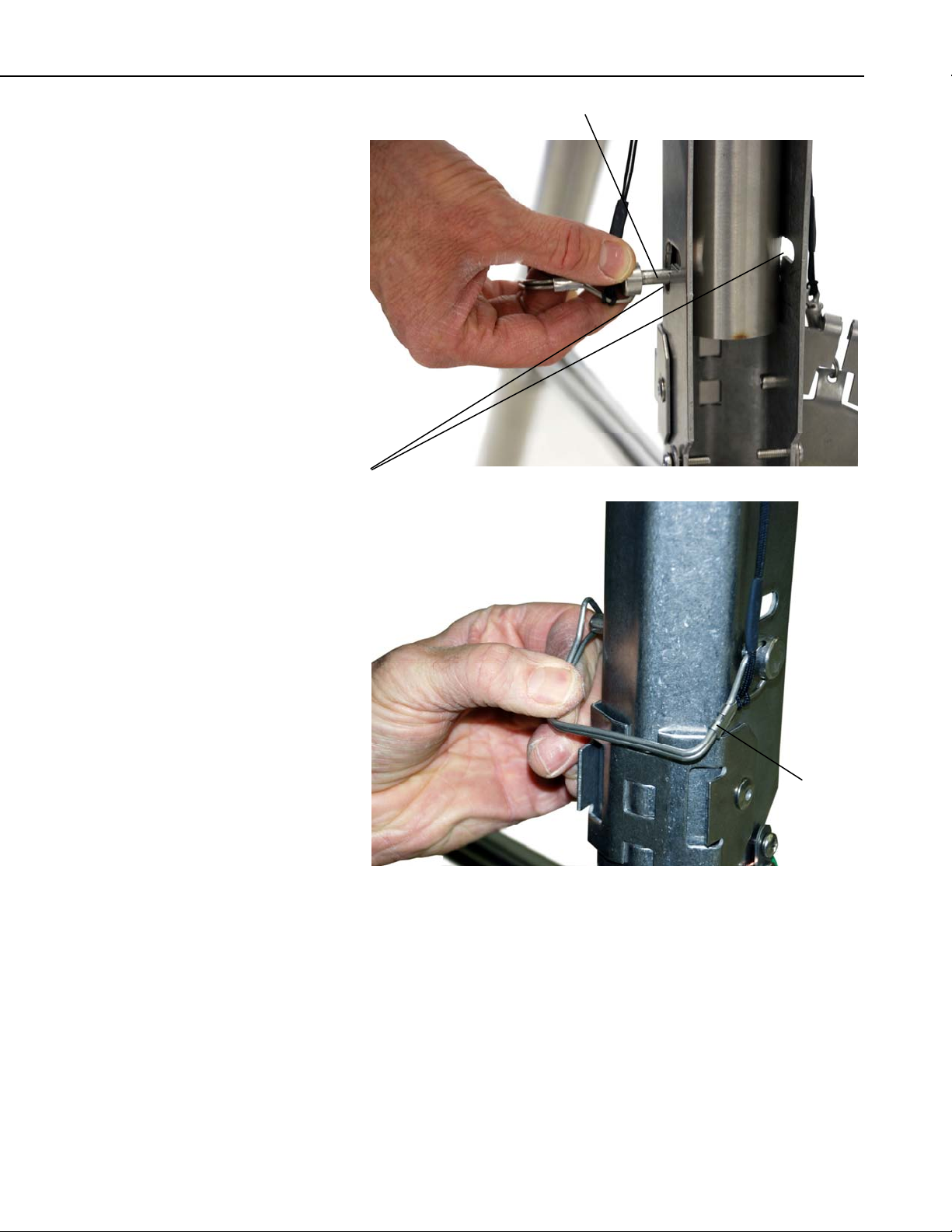

5.7.2 Enclosure Mounting to Tripod Leg

An enclosure ordered with the –LM bracket has a bracket on each side of the

enclosure, and a U-bolt bracket for securing the enclosure to a tripod leg.

Attach an enclosure with the –LM mounting bracket to the tripod base as

follows:

Slide the keyhole notches in the upper and lower corners of the –LM bracket

over the two extended Phillips head screws located on the tripod base as shown

in Figure 5-15B.

Remove the washers, nuts and U-bolt from the U-bolt bracket. Install the

bracket as shown in Figure 5-15C. Tighten the nuts on the U-bolt until the lock

washers are compressed.

Page 23

Tripod Installation Manual Models CM110, CM115, CM120

t

Route the 14 AWG wire from the grounding lug on the bottom side of the

enclosure to the grounding lug on the base of the tripod (Figure 5-15). Strip

1/2” of insulation from each end of the wire. Insert wire ends into the

grounding lugs and tighten.

–LM Bracket

Keyhole Notch

Phillips Head Screw

U-Bolt Bracke

FIGURE 5-15. Enclosure with the –LM Bracket

19

Page 24

Tripod Installation Manual Models CM110, CM115, CM120

6. Mounting Brackets

Mounting brackets covered in this section have U-bolts that attach to vertical

and/or horizontal pipes with the following ranges of outside diameters:

inches mm Nominal Pipe Size (inches)

1.5” U-bolt 1.0 – 1.5 25.4 – 38.1 ¾ – 1

2” U-bolt 1.3 – 2.1 33.0 – 53.3 1 – 1 ½

2” U-bolt

with plastic V-block

Some of the brackets (e.g. the CM210) include 1.5” and 2” U-bolts to extend

the range of pipe diameters that the bracket can accommodate. Brackets with

holes for a 1.5” U-bolt will accept a user-supplied 1.75” U-bolt.

1.0 – 2.1 25.4 – 53.3 ¾ – 1 ½

6.1 CM210 Crossarm Mounting Kit

CM200 series crossarms include a CM210 bracket as shown in Figure 6-1.

The CM210 can be ordered separately to attach a user-supplied pipe (1.0 –

1.5” OD) to a mast or tower leg (1.0 – 2.1” OD), or to attach a crossarm to two

tower legs.

CM210

20

FIGURE 6-1. CM210 Crossarm Mounting Kit

(shown with user-supplied pipe)

Page 25

Tripod Installation Manual Models CM110, CM115, CM120

6.2 CM216 Mast Mounting Kit

The CM216 attaches to the top of the mast, and provides a 3/4” or 1” mounting

pipe (1.05” or 1.32” OD) that extends 4” above the mast, as shown in Figure

6-2.

CM216

FIGURE 6-2. CM216 Mast Mounting Kit

21

Page 26

Tripod Installation Manual Models CM110, CM115, CM120

6.3 CM220 Right Angle Mounting Kit

The CM220 attaches a vertical pipe (1.0 – 1.5” OD) to the CM200 series

crossarms or horizontal pipe (1.0 – 1.5” OD ) as show n in Fi gu re 6- 3.

CM220

CM220

22

FIGURE 6-3. CM220 Right Angle Mounting Kit

Page 27

Tripod Installation Manual Models CM110, CM115, CM120

6.4 CM225 and 18098 Pyranometer Mounting Stand

The CM225 is used to attach a pyranometer or quantum sensor to a horizontal

pipe (1.0 to 2.1” OD) or vertical pole (1.0 to 2.1” OD).

The LI200X pyranometer and LI190SB quantum sensor mount to the CM225

via the LI200S leveling base (see Figure 6-4). The CS300 pyranometer mounts

to the CM225 via the 18356 leveling base. The CMP3 and LP02 pyranometers

include their own bubble level and leveling screws allowing them to mount

directly to the CM225.

The 18098 provides a larger surface for mounting a user-supplied Eppley

pyranometer.

LI2003S

CM225

LI200X Pyranometer

CM225

FIGURE 6-4. CM225 Pyranometer Mounting Stand

23

Page 28

Tripod Installation Manual Models CM110, CM115, CM120

6.5 CM230 Adjustable Angle Mounting Kit

The CM230 mounts an antenna (1.0 – 1.5” OD) to a mast or vertical pipe

(1.3 – 2.1” OD) as shown in Figure 6-5. The bracket allows the antenna to be

adjusted for different angles.

CM230

FIGURE 6-5. CM230 Adjustable Angle Mounting Kit

24

Page 29

Tripod Installation Manual Models CM110, CM115, CM120

6.6 CM235 Magnetic Mounting Stand

The CM235 provides a 3.5” (8.8 cm) square platform for mounting magnetic

base antennas. The CM235 attaches to horizontal or vertical pi pes (1. 0 –

2.1” OD) as shown in Figure 6-6.

FIGURE 6-6. CM235 Magnetic Mounting Stand

25

Page 30

Tripod Installation Manual Models CM110, CM115, CM120

6.7 RM Young Gill Radiation Shields

RM Young Gill Radiation Shields are used to house and attach temperature and

relative humidity sensors to the tripod mast (1.0 – 2.1” OD) or crossarm as

shown in Figure 6-7. Radiation shields ship with the U-bolt configured for

attachment to a vertical pipe. To attach the radiation shield to a horizontal

pipe, the U-bolt and plastic V-block must be moved to the other set of holes.

26

FIGURE 6-7. RM Young Gill Radiation Shield

Page 31

Appendix A. Tripod Tote Bag

The Tripod Tote Bag is an option for the CM110 series tripods. The bag is

constructed of nylon, with a main compartment for the tripod base, and pocke ts

for stowing the other components as shown below:

Guy Kit

Mast(s)

Ground Rod

Lightning Rod

Tripod Base

(6) Stakes

Ground Wires

A-1

Page 32

Page 33

Page 34

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br • suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...