Page 1

BlackGlobe Temperature

Sensor for Heat Stress

Revision: 9/13

Campbell Scientific, Inc.

Copyright © 2013

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell’s obligation under this warranty is

limited to repairing or replacing (at Campbell’s option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction.................................................................1

2. Cautionary Statements............................................... 1

3. Initial Inspection .........................................................1

3.1 Ships With List.....................................................................................1

4. Overview......................................................................2

5. Specifications .............................................................2

5.1 Accuracy ..............................................................................................2

6. Installation...................................................................4

6.1 Siting ....................................................................................................4

6.2 Assembly and Mounting ......................................................................4

6.2.1 Mounting the BlackGlobe on the Mounting Arm .........................4

6.2.2 Mounting the BlackGlobe Assembly on a Horizontal

Crossarm....................................................................................6

7. Operation.....................................................................7

7.1 Wiring ..................................................................................................7

7.2 Calculations..........................................................................................8

7.2.1 Wet-Bulb Globe Thermometer Index (WBGT)............................8

7.2.2 Dewpoint.......................................................................................8

7.2.3 Vapor Pressure ..............................................................................9

7.2.4 Saturated Vapor Pressure ..............................................................9

7.2.5 Wet-Bulb.......................................................................................9

7.2.6 Mean Site Barometric Pressure Calculation (SP_kPa)................10

7.3 Programming......................................................................................10

7.3.1 Example CR1000 Program .........................................................10

7.4 Long Lead Lengths ............................................................................12

8. Maintenance ..............................................................12

9. References ................................................................12

i

Page 6

Table of Contents

Appendices

The Theory of BlackGlobe Temperature and

A.

Heat Stress ............................................................A-1

B. Edlog Programming Examples ..............................B-1

B.1 Example CR10X Program............................................................... B-1

B.2 Edlog Programming for Long Lead Lengths................................... B-9

Figures

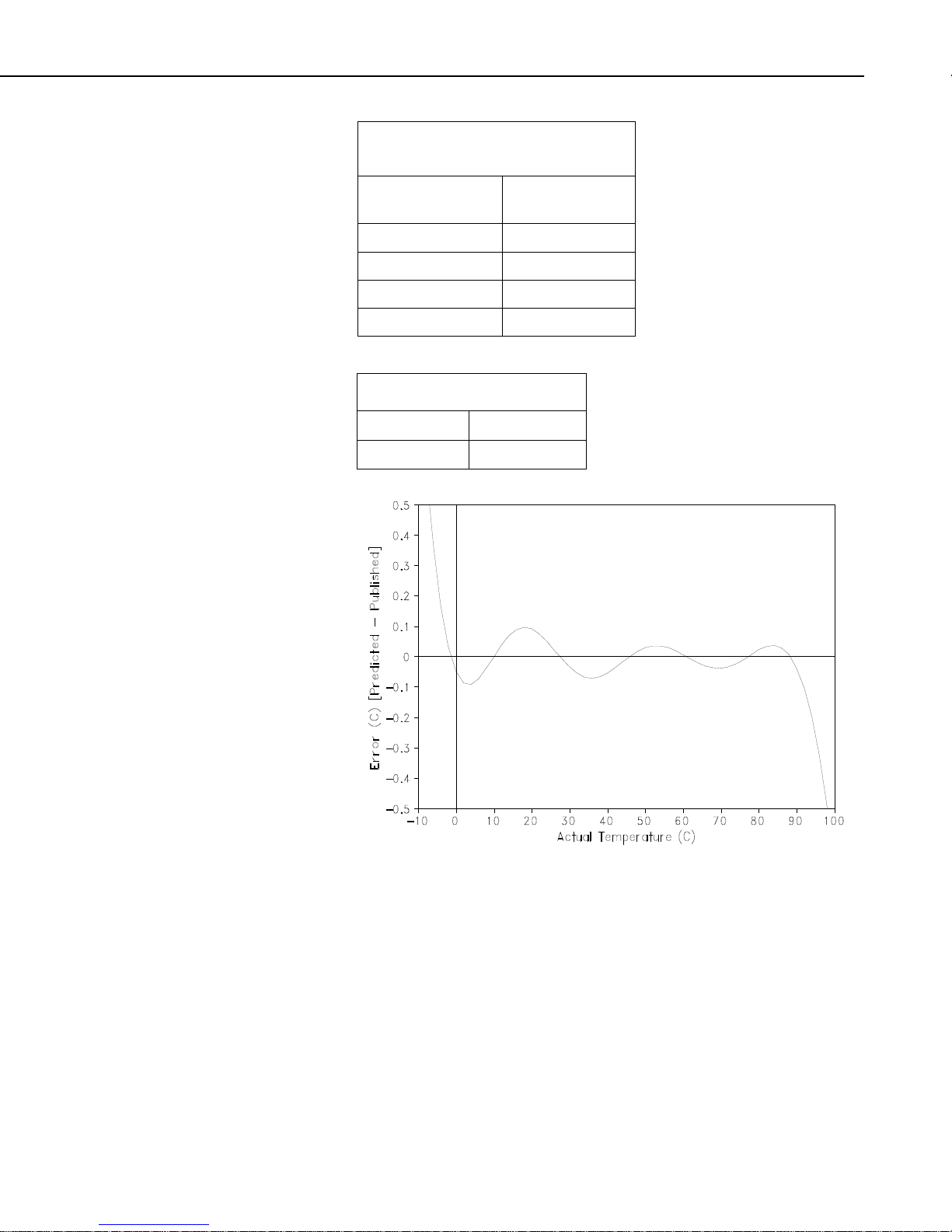

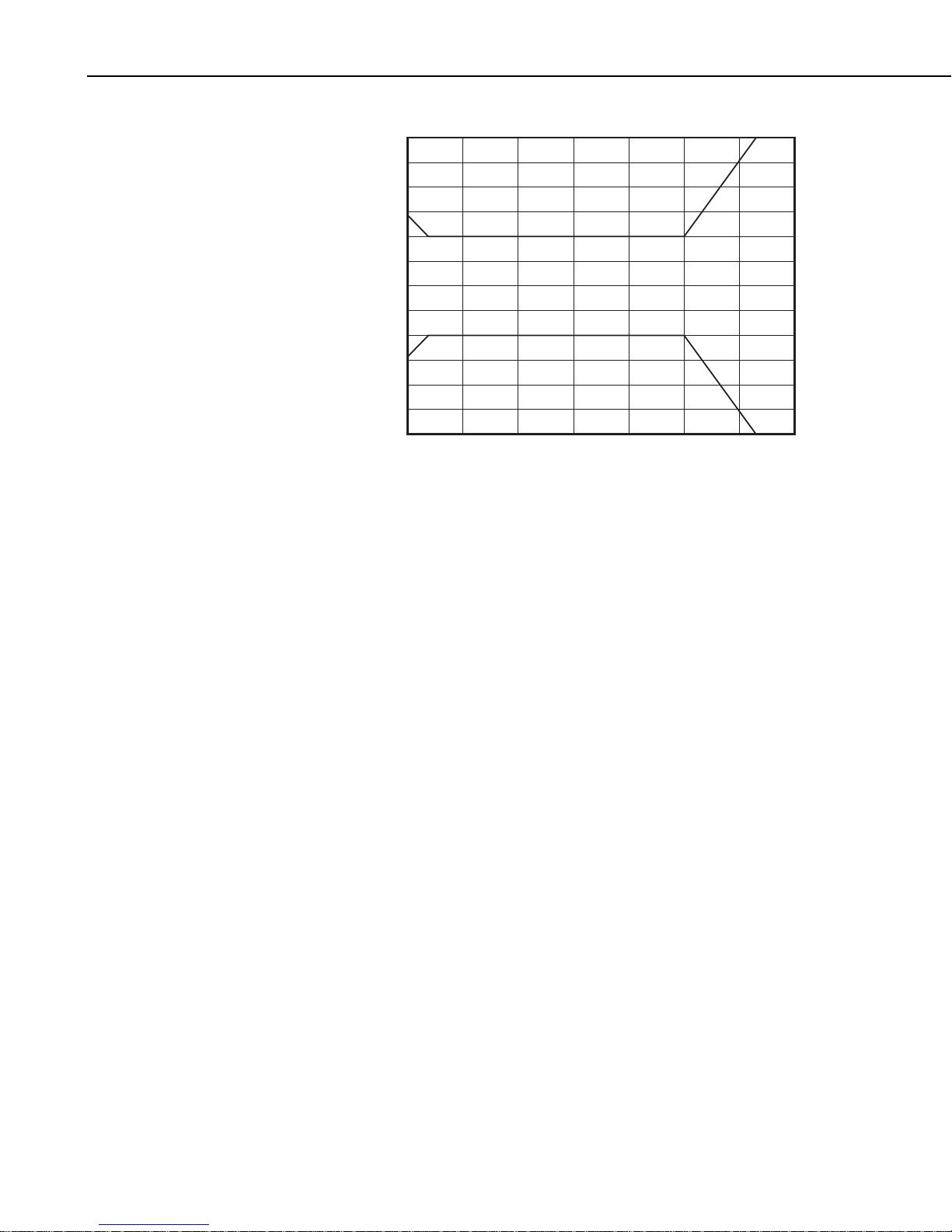

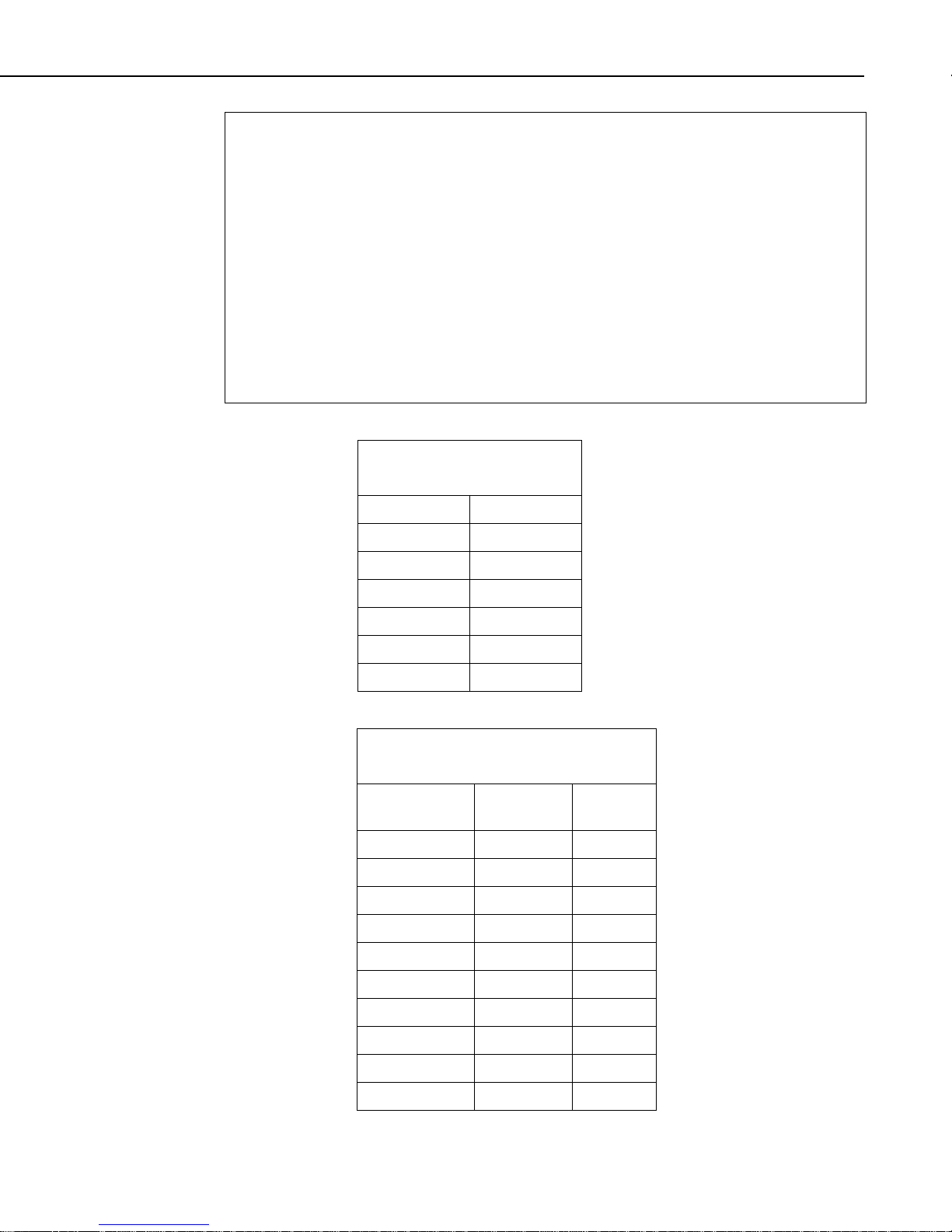

5-1. Polynomial error curve (Edlog dataloggers only)................................ 3

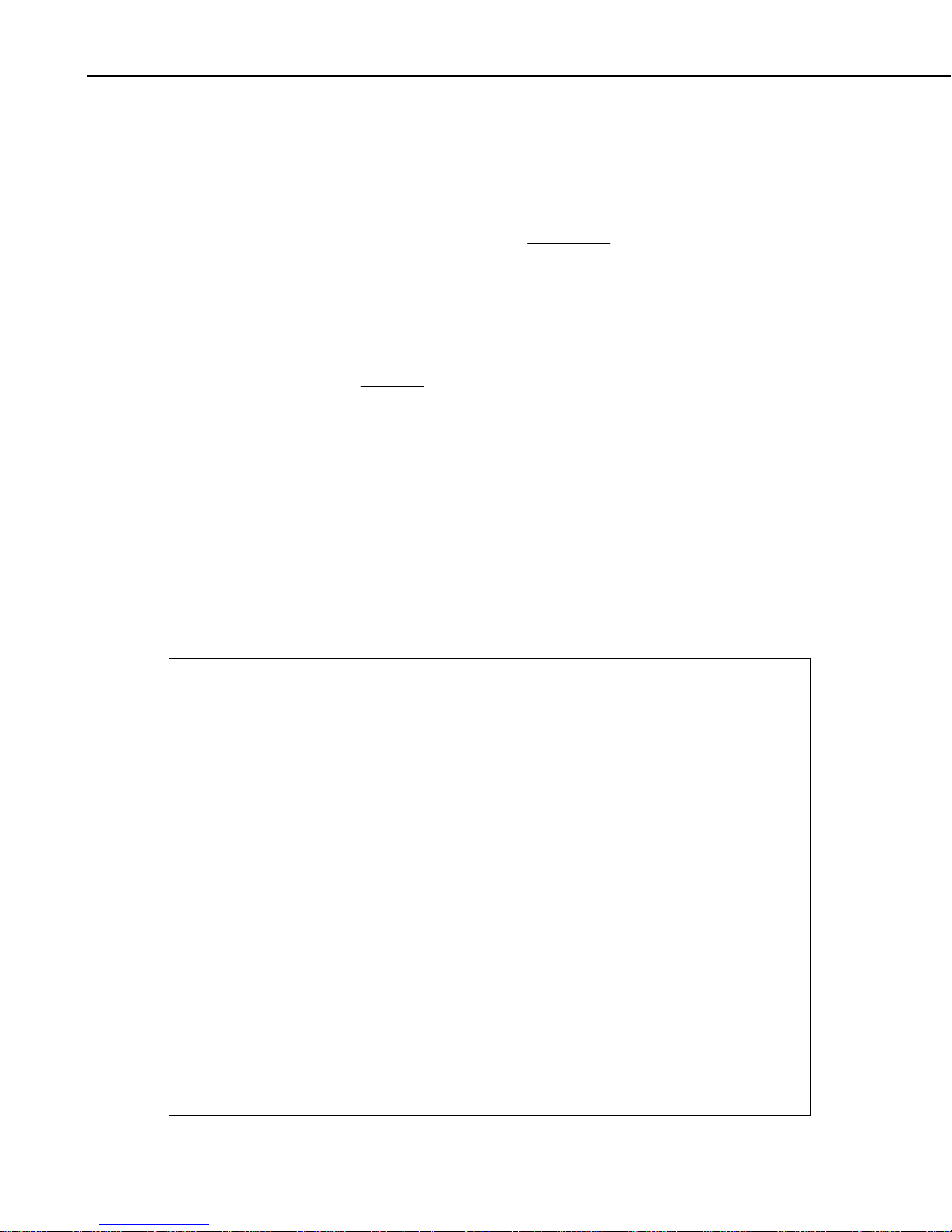

5-2. Thermistor interchangeability limits ................................................... 4

6-1. Mounting kit components.................................................................... 5

6-2. Nuts and lock washers on mounting bolt............................................. 5

6-3. BlackGlobe fitting and cable alignment .............................................. 6

6-4. BlackGlobe mounted to a crossarm (front view)................................. 7

6-5. BlackGlobe mounted to a crossarm (back view)................................. 7

Tables

5-1. Thermistor Interchangeability Specification ....................................... 3

5-2. Polynomial Error ................................................................................. 3

7-1. Wiring Diagram for Campbell Scientific Dataloggers ........................ 8

A-1. Sample use of WBGT Index............................................................ A-1

B-1. Polynomial Coefficients .................................................................. B-7

B-2. Actual Temperature, Sensor Resistance, and Computed

Temperature................................................................................. B-7

ii

Page 7

BlackGlobe Temperature Sensor for

Heat Stress

1. Introduction

The BlackGlobe Temperature Sensor for Heat Stress (BlackGlobe) measure

radiant temperature. This measurement, along with the measurement of

ambient air and wet-bulb temperatures, is used to calculate the wet-bulb globe

temperature (WBGT). The WBGT index combines the effects of temperature,

humidity, radiant heat, and wind into one single index employed to express

environmental heat stress. The measurement of heat stress is important

because loss of physical and mental efficiency occurs under definable degrees

of heat stress. Severe heat stress can lead to fatigue, exhaustion and possibly

even disability or death.

Before installing the BlackGlobe, please study

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

2. Cautionary Statements

• The BlackGlobe is a precision instrument. Please handle it with care.

• The black outer jacket of the cable is Santoprene® rubber. This

compound was chosen for its resistance to temperature extremes, moisture,

and UV degradation. However, this jacket will support combustion in air.

It is rated as slow burning when tested according to U.L. 94 H.B. and will

pass FMVSS302. Local fire codes may preclude its use inside buildings.

• Do not use the BlackGlobe with long lead lengths in an electrically noisy

environment.

3. Initial Inspection

• Upon receipt of the BlackGlobe, inspect the packaging and contents for

damage. File damage claims with the shipping company. Immediately

check package contents against the shipping documentation (see Section

3.1, Ships With List). Contact Campbell Scientific about any

discrepancies.

• The model number and cable length are printed on a label at the

connection end of the cable. Check this information against the shipping

documents to ensure the expected product and cable length are received.

3.1 Ships With List

• (4) 7362 8 inch Wire Ties

• (1) 29956 BlackGlobe Mounting Kit

• ResourceDVD

1

Page 8

BlackGlobe Temperature Sensor for Heat Stress

4. Overview

The BlackGlobe uses a thermistor inside a 15.24 cm (6 in) hollow copper

sphere, painted black to measure radiant temperature. This measurement along

with the measurement of ambient air and wet-bulb temperatures may be used to

calculate the WBGT index, which is sometimes referred to as the Humidex.

Sensor cable length is specified at the time of order. Do not exceed 1000 feet

of cable.

To calculate the wet-bulb globe thermometer index (WBGT), the measurement

of the BlackGlobe (radiant heat), wet-bulb (evaporative heat), and ambient air

(dry-bulb) temperatures are required. The wet-bulb temperature can be

calculated using air temperature and relative humidity if a wet-bulb

thermometer is not available. See Section 7.2, Calculations.

5. Specifications

Temperature Measurement Range: –5° to +95°C

Temperature Survival Range: –50° to +100°C

NOTE

5.1 Accuracy

Thermistor Interchangeability Error: Typically < ±0.2°C over 0°C to 70°C

and ±0.3 at 95°C

Polynomial Linearization Error: < ±0.5°C over –7°C to +90°C

Near Normal Emittance: 0.957

Maximum Cable Length: 305 m (1000 ft)

The black outer jacket of the cable is Santoprene

compound was chosen for its resistance to temperature extremes,

moisture, and UV degradation. However, this jacket will support

combustion in air. It is rated as slow burning when tested

according to V.L. 94 H.B. and will pass FMVSS302. Local fire

codes may preclude its use inside buildings.

The overall probe accuracy is a combination of the thermistor’s

interchangeability specification, the precision of the bridge resistors, and the

Steinhart-Hart equation error (CRBasic dataloggers) or the polynomial error

(Edlog dataloggers). In a worst case, all errors add to an accuracy of ±0.3°C

over the range of –3° to 90°C and ±0.7°C over the range of –5° to 95°C. The

major error component is the interchangeability specification of the thermistor,

tabulated in TABLE 5-1 and plotted in FIGURE 5-2. For the range of 0° to

50°C, the interchangeability error is predominantly offset and can be

determined with a single point calibration. Compensation can then be done

with an offset entered in the measurement instruction. The bridge resistors are

0.1% tolerance with a 10 ppm temperature coefficient. Polynomial errors are

tabulated in TABLE 5-2 and plotted in FIGURE 5-1.

@

rubber. This

2

Page 9

BlackGlobe Temperature Sensor for Heat Stress

TABLE 5-1. Thermistor

Interchangeability Specification

Temperature (°C)

−5

Temperature

Tolerance (±°C)

0.14

0 to +70 0.10

+85 0.25

+95 0.35

TABLE 5-2. Polynomial Error

–5° to +95° < ±0.5°C

–3° to +90° < ±0.1°C

FIGURE 5-1. Polynomial error curve (Edlog dataloggers only)

3

Page 10

BlackGlobe Temperature Sensor for Heat Stress

6. Installation

Thermistor Interchangeability Limits

0.3

0.25

0.2

0.15

0.1

T

error

T

error

_therm_pos

_therm_neg

0.05

0

-0.05

-0.1

-0.15

-0.2

-0.25

-0.3

-5 10 25 40 55 70 85 100

T

FIGURE 5-2. Thermistor interchangeability limits

6.1 Siting

The BlackGlobe must be mounted in a location that will not be shadowed and

is representative of the environmental conditions to be measured.

6.2 Assembly and Mounting

Tools required for installing on a tripod or tower:

• Adjustable end wrench or 7/16 in. and 1/2 in. open end wrench

• Small screwdriver provided with the datalogger

• Small pair of diagonal-cutting pliers

• UV resistant cable ties provided with the BlackGlobe

6.2.1 Mounting the BlackGlobe on the Mounting Arm

The BlackGlobe and mounting kit (pn 29956) requires some assembly before

installation. The mounting kit comes with (see Figure 6.1):

• Mounting arm

• Mounting bolt

• Two lock washers

• Two nuts

• Two pipe clamps (not used when mounted to a horizontal pipe cross

arm)

• U-bolt with associated nuts and washers

4

Page 11

BlackGlobe Temperature Sensor for Heat Stress

m

N

t

Mounting Ar

Pipe Clamps

Pipe Clamp Slot

uts

Lock Washers

U-bolt

Mounting Bol

FIGURE 6-1. Mounting kit components

1. Place the mounting bolt through the hole in the mounting arm as shown in

FIGURE 6-2.

2. Slide one of the lock washers against the mounting arm.

3. Thread both nuts about half way down the bolt and then slide on the last

lock washer. The hardware should be arranged as shown in FIGURE 6-2.

FIGURE 6-2. Nuts and lock washers on mounting bolt

5

Page 12

BlackGlobe Temperature Sensor for Heat Stress

4. Tighten down the nut closest to the mounting arm so the bolt is held firmly

in place.

5. Thread the BlackGlobe fitting onto the bolt. Thread it as far down as it

will go, but you may have to back it off a bit. The cable gland and cable

should align with the mounting arm as shown in FIGURE 6-3.

6. Tighten down the nut closest to the BlackGlobe fitting. The BlackGlobe

and mounting bolt should not move when the all the hardware is tightened

down.

Cable Gland

FIGURE 6-3. BlackGlobe fitting and cable alignment

6.2.2 Mounting the BlackGlobe Assembly on a Horizontal Crossarm

The BlackGlobe assembly must be mounted on a horizontal crossarm.

1. Position the sensor so that the cable gland is facing down (FIGURE 6-3).

2. Use the mounting hardware supplied to hold the sensor on the horizontal

crossarm. FIGURE 6-4 and FIGURE 6-5 show a BlackGlobe mounted on

a crossarm by using the U-bolts.

3. Use the wire ties provided with the unit to secure the cabling to the

crossarm.

4. Leave a small loop of cable at the cable entry into the sensor to act as a

drip line for any condensed moisture or rain (FIGURE 6-4).

6

Page 13

BlackGlobe Temperature Sensor for Heat Stress

FIGURE 6-4. BlackGlobe mounted to a crossarm (front view)

7. Operation

7.1 Wiring

FIGURE 6-5. BlackGlobe mounted to a crossarm (back view)

The wiring diagram for the BlackGlobe to a Campbell Scientific datalogger is

given in TABLE 7-1. Temperature is measured with one single-ended input

channel and a voltage excitation channel. Multiple probes can be connected to

the same excitation channel (the number of probes per excitation channel is

physically limited by the number lead wires that can be inserted into a single

voltage excitation terminal, approximately six).

7

Page 14

BlackGlobe Temperature Sensor for Heat Stress

TABLE 7-1. Wiring Diagram for Campbell Scientific Dataloggers

Color

Black Voltage

Description

Excitation

CR800

CR850

CR5000

CR3000

CR1000

CR9000(X)

Switched

Voltage

Excitation

Red Temperature

Signal

Purple Signal Ground

Clear Shield

Single-Ended

Input

7.2 Calculations

7.2.1 Wet-Bulb Globe Thermometer Index (WBGT)

To calculate the WBGT index, a measurement of the BlackGlobe (radiant

heat), wet-bulb (evaporative heat), and ambient air (dry-bulb) temperatures are

required (Equation 1). In the approach discussed here, air temperature and

relative humidity measurements are used to calculate the actual vapor pressure,

and a dewpoint temperature is used to calculate the wet-bulb temperature.

CR510

CR500

CR10(X)

Switched

Excitation

Single-Ended

Input

AG

G

21X

CR7

CR23X

Switched

Excitation

Single-Ended

Input

7.2.2 Dewpoint

Air temperature and relative humidity (%) measurements required for this

calculation can be made by a variety of sensors. In the examples shown in

Section 7.3, Programming, the HC2S3 is used.

Ultimately,

WBGT = (0.2 × BlackGlobe Temp) + (0.7 × Wet-Bulb Temp) + (0.1 × DryBulb Temp) (1)

Dewpoint and Wet-Bulb temperature units include: °C, °F, °K

Equation 2 is used to calculate dewpoint.

T

= (241.88*ln(P/0.61078))/(17.558-ln(P/0.61078)) (2)

d

where

T

= dewpoint (°C)

d

P = vapor pressure (kPa)

8

Page 15

The equation is an inverse of a version of Teten’s equation (Tetens, 1930),

optimized for dewpoints in the range –35° to 50°C, and is accurate to within

plus or minus 0.1°C within that range.

7.2.3 Vapor Pressure

Vapor pressure is calculated by the datalogger using Equation 3.

BlackGlobe Temperature Sensor for Heat Stress

P = RH*P

/100 (3)

sw

where

RH = relative humidity (%)

P

= saturation vapor pressure (kPa) over water

sw

7.2.4 Saturated Vapor Pressure

Saturation vapor pressure over water is calculated by the datalogger using

Equation 4.

(kPa) = 0.1*(6.107799961 + T(4.436518521 × 10–1 + T(1.428945805 ×

P

sw

–2

+ T(2.650648471 × 10–4 + T(3.031240396 × 10-6 + T(2.034080948 × 10–8

10

+ 6.136820929 × 10

where

T = air temperature (dry-bulb temperature) (°C)

7.2.5 Wet-Bulb

Wet-bulb is derived using an iterative process. The wet-bulb temperature lies

somewhere between the dry-bulb temperature (air temperature) and the

dewpoint temperature. The datalogger uses Equation 5 to calculate vapor

pressure using the dry-bulb temperature and a wet-bulb temperature estimate:

–11

× T)))))) (4)

–(0.000660*(1+0.00115*Tw)*(T–Tw)*SP) (5)

P = P

w

where

P

= saturation vapor pressure (kPa) at the wet-bulb temperature (°C)

w

T

= wet-bulb temperature (°C)

w

T = air temperature (dry-bulb temperature) (°C)

SP = standard air pressure (kPa) at the user entered elevation

The resulting vapor pressure is compared to the true vapor pressure (see above)

and the difference determines the next wet-bulb temperature estimate. The

process repeats until the difference between the current wet-bulb temperature

estimate and the previous wet-bulb temperature estimate is only plus or minus

0.01°C. The datalogger thus derives the wet-bulb temperature.

9

Page 16

BlackGlobe Temperature Sensor for Heat Stress

(

7.2.6 Mean Site Barometric Pressure Calculation (SP_kPa)

The wet-bulb instruction needs mean barometric pressure which is closely

related to elevation of the site. U.S. Standard Atmosphere and dry air were

assumed when Equation 6 was derived (Wallace & Hobbes, 1977).

SP

kPa

25328.5

⎧

⎛

⎪

11325.101325.101

−−−=

⎜

⎨

⎝

⎪

⎩

E

69231.44307

⎫

⎞

⎪

⎟

⎠

(6)

⎬

⎪

⎭

The value of SP

is in kilopascals and the site elevation, E, is in meters.

kPa

Use Equation 7 to convert feet to meters.

)

()

mE

The value for SP

ftE

=

281.3

(7)

ft/m

must be put into the datalogger program.

kPa

7.3 Programming

7.3.1 Example CR1000 Program

The example includes measurements of the BlackGlobe temperature, and the

calculation of wet-bulb temperature and wet-bulb globe temperature.

Measurements of air temperature and relative humidity are supplied by an

HC2S3 in this example. Calculations for dewpoint, wet-bulb, and wet-bulb

globe temperature are also included.

'CR1000 Series Datalogger

'Program: BlackGlobe.CR1

'Declare constants

'Mean site barometric pressure at 1357.58 meters.

'CHANGE THIS VALUE TO MATCH YOUR ELEVATION.

Const SP_kPa = 86.04377

'Declare Public Variables

'Datalogger variables.

Public PnlTempC 'Datalogger panel temperature

Units PnlTempC=Deg C

Public Batt_Volt 'Datalogger battery voltage

Units Batt_Volt=VDC

'BlackGlobe variables.

Public BGTemp_C 'BlackGlobe temperature

Units BGTemp_C=Deg C

'Rotronic HC2S3 variables.

Public AirTempC 'Air temperature

Units AirTempC=Deg C

Public AirRH 'Humidity

Units AirRH=%

'Calculated variables.

Public DewPnt_C 'Dewpoint temperature

Public WetBlb_C 'Wet-bulb temperature

Public WBGT_C 'Wet-bulb globe (HUMIDEX) temperature

Dim SVP_kPa

Dim VP_kPa

10

Page 17

BlackGlobe Temperature Sensor for Heat Stress

Dim UpperTmp

Dim LowerTmp

Dim old_wbT, new_wbT

Dim WB_VP_kPa, Diff_VP_kPa

Dim Diff_wbT

'Define Data Tables

'Hourly data table.

DataTable (Hourly,1,-1)

DataInterval (0,1,Hr,10)

Average (1,AirTempC,FP2,False)

Sample (1,AirRH,FP2)

Average (1,DewPnt_C,FP2,False)

Average (1,WetBlb_C,FP2,False)

Average (1,WBGT_C,FP2,False)

EndTable

'Daily datalogger status table.

DataTable (Daily,True,-1)

DataInterval (0,1,Day,10)

Maximum (1,Batt_Volt,FP2,False,False)

Minimum (1,Batt_Volt,FP2,False,False)

Maximum (1,PnlTempC,FP2,False,False)

Minimum (1,PnlTempC,FP2,False,False)

EndTable

'Main Program

BeginProg

Scan (5,Sec,3,0)

PanelTemp (PnlTempC,250)

Battery (Batt_Volt)

'Rotronic HC2S3 powered up all the time.

VoltSe (AirTempC,1,mV2500,1,0,0,_60Hz,0.1,-40)

VoltSe (AirRH,1,mV2500,2,0,0,_60Hz,0.1,0)

If (AirRH >= 100) AND (AirRH <= 108) Then AirRH = 100

SatVP (SVP_kPa,AirTempC)

VP_kPa = SVP_kPa * AirRH/100

DewPoint (DewPnt_C,AirTempC,AirRH)

If (DewPnt_C > AirTempC) Or (DewPnt_C = NAN) Then DewPnt_C = AirTempC

UpperTmp = AirTempC

LowerTmp = DewPnt_C

'BlackGlobe wired to SE channel 3 and excitation channel VX1.

Therm108 (BGTemp_C,1,3,Vx1,0,_60Hz,1.0,0)

'Loop to find wet-bulb temperature.

Do

old_wbT = new_wbT

new_wbT = ((UpperTmp - LowerTmp)/2) + LowerTmp

WetDryBulb (WB_VP_kPa,AirTempC,new_wbT,SP_kPa)

Diff_VP_kPa = WB_VP_kPa - VP_kPa

Diff_wbT = ABS (old_wbT - new_wbT)

If Diff_VP_kPa > 0 Then

UpperTmp = new_wbT

Else

LowerTmp = new_wbT

EndIf

If Diff_wbT < 0.01 Then ExitDo

Loop

'Wet-bulb temperature.

WetBlb_C = new_wbT

'Calculate Wet-Bulb Globe (HUMIDEX) temperature.

WBGT_C = (0.1 * AirTempC) + (0.2 * BGTemp_C) + (0.7 * WetBlb_C)

'Call data storage tables.

CallTable Hourly

CallTable Daily

NextScan

EndProg

11

Page 18

BlackGlobe Temperature Sensor for Heat Stress

7.4 Long Lead Lengths

If the BlackGlobe has lead lengths greater than 300 feet, a longer settling time

before the measurement is made is required. For CRBasic loggers, the 60 and

50 Hz integration options include a 3 ms settling time; longer settling times

also can be entered into the Settling Time parameter. In Edlog, use the DC

Half Bridge Instruction (Instruction 4) with a 2 ms delay to measure the

temperature.

CAUTION

Do not use the BlackGlobe with long lead lengths in an

electrically noisy environment.

8. Maintenance

The BlackGlobe requires minimal maintenance. Check monthly to ensure the

sphere is free from dirt and debris. Clean with water and soft cloth if

necessary. Do not use solvents as they may dissolve the paint.

9. References

Lowe, P.R. 1977. J. Appl. Meteor., 16:100-103

Tetens, O. 1930. Z. Geophys., 6:297

Wallace, J.M. and P.V. Hobbes, 1977: Atmospheric Science: An Introductory

Survey, Academic Press, pp. 59 – 61

12

Page 19

Appendix A. The Theory of BlackGlobe

Temperature and Heat Stress

The Wet-Bulb Globe Temperature Index (WBGT) combines the effects of

temperature, humidity, radiant heat, and wind into one single index employed

to express environmental heat stress. Loss of physical and mental efficiency

occurs under definable degrees of heat stress. Severe heat stress can lead to

fatigue, exhaustion and possibly even disability or death. Personnel can

increase their resistance to heat stress by acclimatizing gradually to hot

environments and by maintaining a good water and salt balance.

Heat stress can be reduced by decreasing the lengths of exposure and

decreasing the workload of individuals under heat stress. Situational factors

such as the type of clothing worn, the type of work performed, the

psychological effects of stress, and the availability of fluids can also affect the

assessment of heat stress. These factors are not easily quantified, and so the

individual in a given situation must estimate their significance. Environmental

factors such as temperature, humidity, and wind are more easily measured to

assess heat stress. TABLE A-1 provides some guidelines for using the WBGT

index.

TABLE A-1. Sample use of WBGT Index

Readings Guidelines

WBGT Index

Reading 26 – 27.5

WBGT Index

Reading 27.5 – 29

WBGT Index

Reading 29 – 31

WBGT Index

Reading 31 – 32

WBGT Index

Reading >32

Precautions should be taken. Water intake should be a

minimum of 0.5 liters/hr. The work/rest cycle for an

acclimatized person should be 50/10 min/hr.

Increased water intake should be emphasized. Water

intake should be 0.5 to 1 liters/hr. The work/rest cycle

for an acclimatized person should be 50/10 min/hr.

Increased supervision of personnel performing physical

activity is required. Water intake should be 1 to 1.5

liters /hr. The work/rest cycle for an acclimatized person

should be 45/15 min/hr.

Physical activity should be limited to a maximum of 6

hours per day for fully acclimatized personnel. Water

intake should be 1.5 to 2 liters/hr. The work/rest cycle

for an acclimatized person should be 30/30 min/hr.

All strenuous activity should be suspended. Water

intake should be a minimum of 2 liters/hr. The

work/rest cycle for an acclimatized person (nonstrenuous activity) should be 20/40 min/hr.

A-1

Page 20

Appendix A. The Theory of BlackGlobe Temperature and Heat Stress

A-2

Page 21

Appendix B. Edlog Programming

Examples

B.1 Example CR10X Program

Instruction 5 (AC Half Bridge) is used to measure the thermistor probe inside

the sphere. Instruction 55 (Polynomial) is used to calculate the temperature

in degrees Celsius. The polynomial coefficients are shown in TABLE B-1.

Thermistor resistance and computed temperature over a –10 to +84°C range is

shown in TABLE B-2. The example includes instructions for measuring an

HC2S3 to supply air temperature and relative humidity values. Calculations

for dewpoint, wet-bulb, and wet-bulb globe temperature are also included.

;{CR10X}

;Program: BLACKGLOBE.CSI

;Date: June 2013

*Table 1 Program

01: 5.0000 Execution Interval (seconds)

1: Batt Voltage (P10)

1: 1 Loc [ BattVolt ]

2: Internal Temperature (P17)

1: 2 Loc [ CR10XTmpC ]

;Rotronic HC2S3 temperature and relative humidity.

;Sensor powered on all the time.

3: Volt (SE) (P1)

1: 1 Reps

2: 5 2500 mV Slow Range

3: 1 SE Channel

4: 4 Loc [ AirTempC ]

5: 0.1 Multiplier

6: -40 Offset

4: Volt (SE) (P1)

1: 1 Reps

2: 5 2500 mV Slow Range

3: 2 SE Channel

4: 5 Loc [ AirRH ]

5: 0.1 Multiplier

6: 0 Offset

5: If (X<=>F) (P89)

1: 5 X Loc [ AirRH ]

2: 3 >=

3: 100 F

4: 30 Then Do

B-1

Page 22

Appendix B. Edlog Programming Examples

6: If (X<=>F) (P89)

1: 5 X Loc [ AirRH ]

2: 4 <

3: 108 F

4: 30 Then Do

7: Z=F x 10^n (P30)

1: 100 F

2: 0 n, Exponent of 10

3: 5 Z Loc [ AirRH ]

8: End (P95)

9: End (P95)

;BlackGlobe temperature - °C

10: AC Half Bridge (P5)

1: 1 Reps

2: 23 25 mV 60 Hz Rejection Range

3: 3 SE Channel

4: 1 Excite all reps w/Exchan 1

5: 1000 mV Excitation

6: 3 Loc [ BGTemp_C ]

7: 200 Multiplier

8: 0 Offset

11: Polynomial (P55)

1: 1 Reps

2: 3 X Loc [ BGTemp_C ]

3: 3 F(X) Loc [ BGTemp_C ]

4: -26.97 C0

5: 69.635 C1

6: -40.66 C2

7: 16.573 C3

8: -3.455 C4

9: 0.301 C5

;Calculate saturated vapor pressure.

12: Saturation Vapor Pressure (P56)

1: 4 Temperature Loc [ AirTempC ]

2: 9 Loc [ SVP_kPa ]

;Calculate vapor pressure.

13: Z=X*Y (P36)

1: 9 X Loc [ SVP_kPa ]

2: 5 Y Loc [ AirRH ]

3: 10 Z Loc [ VP_kPa ]

14: Z=X*F (P37)

1: 10 X Loc [ VP_kPa ]

2: 0.01 F

3: 10 Z Loc [ VP_kPa ]

B-2

Page 23

;Dewpoint calculation.

15: Z=X*F (P37)

1: 10 X Loc [ VP_kPa ]

2: 1.63725 F

3: 20 Z Loc [ scratch1 ]

16: Z=LN(X) (P40)

1: 20 X Loc [ scratch1 ]

2: 20 Z Loc [ scratch1 ]

17: Z=X*F (P37)

1: 20 X Loc [ scratch1 ]

2: 241.88 F

3: 21 Z Loc [ scratch2 ]

18: Z=F x 10^n (P30)

1: 17.558 F

2: 0 n, Exponent of 10

3: 22 Z Loc [ scratch3 ]

19: Z=X-Y (P35)

1: 22 X Loc [ scratch3 ]

2: 20 Y Loc [ scratch1 ]

3: 22 Z Loc [ scratch3 ]

20: Z=X/Y (P38)

1: 21 X Loc [ scratch2 ]

2: 22 Y Loc [ scratch3 ]

3: 7 Z Loc [ DewPnt_C ]

21: If (X<=>Y) (P88)

1: 7 X Loc [ DewPnt_C ]

2: 3 >=

3: 4 Y Loc [ AirTempC ]

4: 30 Then Do

22: Z=X (P31)

1: 4 X Loc [ AirTempC ]

2: 7 Z Loc [ DewPnt_C ]

23: End (P95)

;Mean site pressure at elevation of 1357.58 meters.

24: Z=F x 10^n (P30)

1: 86.0437 F

2: 00 n, Exponent of 10

3: 17 Z Loc [ SP_kPa ]

;Wet-bulb calculation

25: Z=X (P31)

1: 4 X Loc [ AirTempC ]

2: 14 Z Loc [ UpperTmp ]

Appendix B. Edlog Programming Examples

B-3

Page 24

Appendix B. Edlog Programming Examples

26: Z=X (P31)

1: 7 X Loc [ DewPnt_C ]

2: 15 Z Loc [ LowerTmp ]

;Iterative loop to figure out wet-bulb temperature.

27: Beginning of Loop (P87)

1: 0 Delay

2: 25 Loop Count

28: Z=X (P31)

1: 12 X Loc [ new_wbT ]

2: 11 Z Loc [ old_wbT ]

29: Z=X-Y (P35)

1: 14 X Loc [ UpperTmp ]

2: 15 Y Loc [ LowerTmp ]

3: 12 Z Loc [ new_wbT ]

30: Z=X*F (P37)

1: 12 X Loc [ new_wbT ]

2: 0.5 F

3: 12 Z Loc [ new_wbT ]

31: Z=X+Y (P33)

1: 12 X Loc [ new_wbT ]

2: 15 Y Loc [ LowerTmp ]

3: 12 Z Loc [ new_wbT ]

32: Wet/Dry-Bulb Temp to VP (P57)

1: 9 Pressure Loc [ SVP_kPa ]

2: 4 Dry-bulb Loc [ AirTempC ]

3: 12 Wet-bulb Loc [ new_wbT ]

4: 18 Loc [ WB_VP_kPa ]

33: Z=X-Y (P35)

1: 11 X Loc [ old_wbT ]

2: 12 Y Loc [ new_wbT ]

3: 16 Z Loc [ Diff_wbT ]

34: Z=ABS(X) (P43)

1: 16 X Loc [ Diff_wbT ]

2: 16 Z Loc [ Diff_wbT ]

35: Z=X-Y (P35)

1: 18 X Loc [ WB_VP_kPa ]

2: 10 Y Loc [ VP_kPa ]

3: 13 Z Loc [ DiffVPkPa ]

36: If (X<=>F) (P89)

1: 13 X Loc [ DiffVPkPa ]

2: 3 >=

3: 0 F

4: 30 Then Do

B-4

Page 25

Appendix B. Edlog Programming Examples

37: Z=X (P31)

1: 12 X Loc [ new_wbT ]

2: 14 Z Loc [ UpperTmp ]

38: Else (P94)

39: Z=X (P31)

1: 12 X Loc [ new_wbT ]

2: 15 Z Loc [ LowerTmp ]

40: End (P95)

41: If (X<=>F) (P89)

1: 16 X Loc [ Diff_wbT ]

2: 4 <

3: 0.01 F

4: 31 Exit Loop if True

42: End (P95)

;Wet-bulb temperature.

43: Z=X (P31)

1: 12 X Loc [ new_wbT ]

2: 8 Z Loc [ WetBlb_C ]

;Calculate Wet-Bulb Globe (HUMIDEX) temperature.

44: Z=X*F (P37)

1: 4 X Loc [ AirTempC ]

2: 0.1 F

3: 20 Z Loc [ scratch1 ]

45: Z=X*F (P37)

1: 3 X Loc [ BGTemp_C ]

2: 0.2 F

3: 21 Z Loc [ scratch2 ]

46: Z=X*F (P37)

1: 7 X Loc [ DewPnt_C ]

2: 0.7 F

3: 6 Z Loc [ WBGT_C ]

47: Z=X+Y (P33)

1: 20 X Loc [ scratch1 ]

2: 6 Y Loc [ WBGT_C ]

3: 6 Z Loc [ WBGT_C ]

48: Z=X+Y (P33)

1: 21 X Loc [ scratch2 ]

2: 6 Y Loc [ WBGT_C ]

3: 6 Z Loc [ WBGT_C ]

;Store hourly data.

B-5

Page 26

Appendix B. Edlog Programming Examples

49: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

50: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 101 Array ID

51: Real Time (P77)

1: 1220 Year,Day,Hour/Minute (midnight = 2400)

52: Average (P71)

1: 1 Reps

2: 4 Loc [ AirTempC ]

53: Average (P71)

1: 1 Reps

2: 7 Loc [ DewPnt_C ]

54: Average (P71)

1: 1 Reps

2: 8 Loc [ WetBlb_C ]

55: Average (P71)

1: 1 Reps

2: 6 Loc [ WBGT_C ]

56: Sample (P70)

1: 17 Reps

2: 3 Loc [ BGTemp_C ]

;Daily station status data.

57: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 1440 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

58: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 102 Array ID

59: Real Time (P77)

1: 1220 Year,Day,Hour/Minute (midnight = 2400)

60: Maximum (P73)

1: 1 Reps

2: 0 Value Only

3: 1 Loc [ BattVolt ]

61: Minimum (P74)

1: 1 Reps

2: 0 Value Only

3: 1 Loc [ BattVolt ]

B-6

Page 27

62: Maximum (P73)

1: 1 Reps

2: 0 Value Only

3: 2 Loc [ CR10XTmpC ]

63: Minimum (P74)

1: 1 Reps

2: 0 Value Only

3: 2 Loc [ CR10XTmpC ]

*Table 2 Program

01: 0 Execution Interval (seconds)

*Table 3 Subroutines

End Program

TABLE B-1. Polynomial

Coefficients

Coefficient Value

Appendix B. Edlog Programming Examples

C0 –26.97

C1 69.635

C2 –40.66

C3 16.573

C4 –3.455

C5 0.301

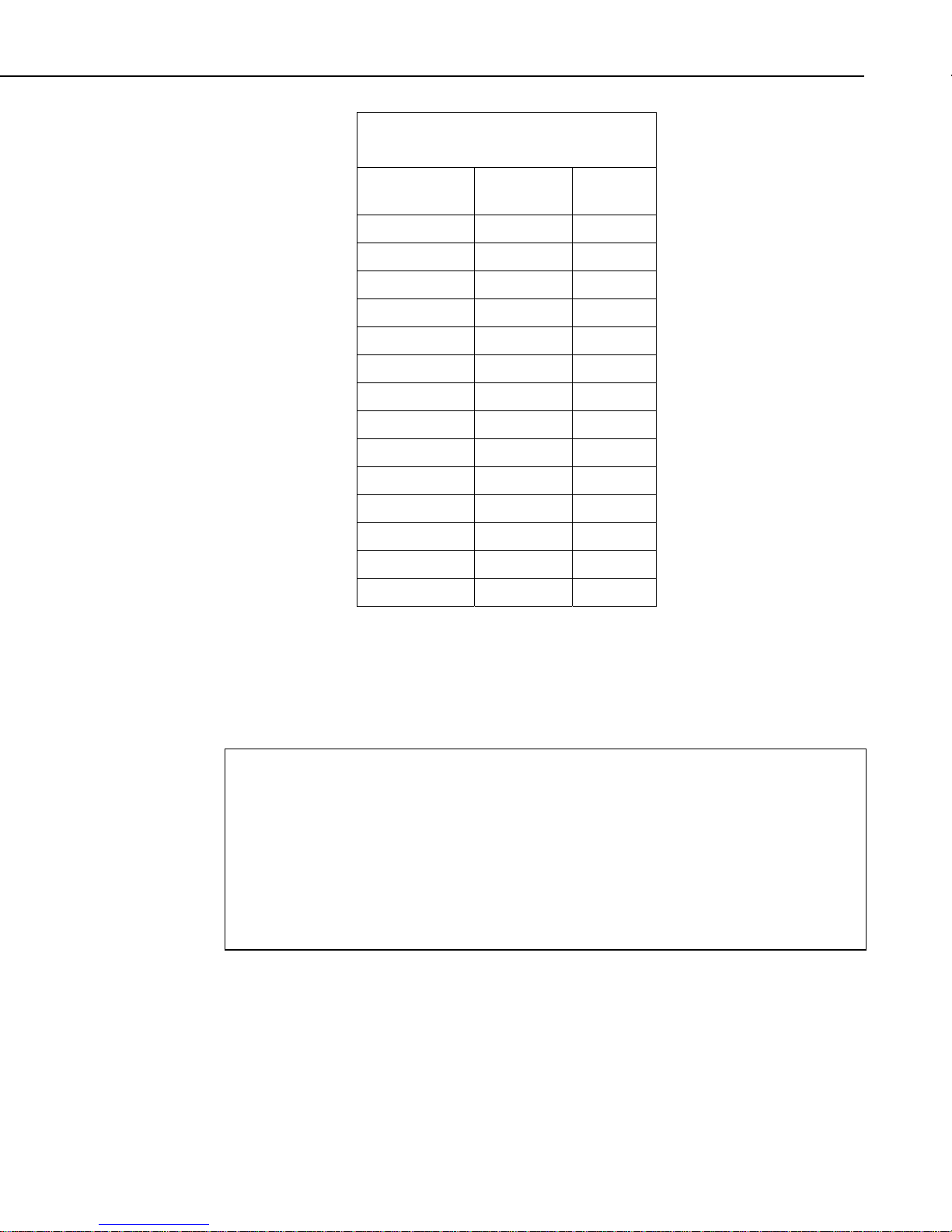

TABLE B-2. Actual Temperature, Sensor

Resistance, and Computed Temperature

Temperature

°C

Resistance

OHMS

Output

°C

–10.00 612366 –9.02

–8.00 546376 –7.36

–6.00 488178 –5.63

–4.00 436773 –3.83

–2.00 391294 –1.97

0.00 351017 –0.05

2.00 315288 1.91

4.00 283558 3.91

6.00 255337 5.93

8.00 230210 7.96

B-7

Page 28

Appendix B. Edlog Programming Examples

TABLE B-2. Actual Temperature, Sensor

Resistance, and Computed Temperature

Temperature

°C

Resistance

OHMS

Output

°C

10.00 207807 10.00

12.00 187803 12.04

14.00 169924 14.07

16.00 153923 16.09

18.00 139588 18.10

20.00 126729 20.09

22.00 115179 22.07

24.00 104796 24.05

26.00 95449 26.02

28.00 87026 27.99

30.00 79428 29.97

32.00 72567 31.94

34.00 66365 33.93

36.00 60752 35.93

38.00 55668 37.93

40.00 51058 39.94

42.00 46873 41.96

44.00 43071 43.98

46.00 39613 46.00

48.00 36465 48.02

50.00 33598 50.03

52.00 30983 52.03

54.00 28595 54.03

56.00 26413 56.03

58.00 24419 58.02

60.00 22593 60.01

62.00 20921 61.99

64.00 19388 63.98

66.00 17981 65.97

68.00 16689 67.96

70.00 15502 69.96

72.00 14410 71.97

B-8

Page 29

Appendix B. Edlog Programming Examples

TABLE B-2. Actual Temperature, Sensor

Resistance, and Computed Temperature

Temperature

°C

74.00 13405 73.98

76.00 12479 75.99

78.00 11625 78.01

80.00 10837 80.02

82.00 10110 82.03

84.00 9438.1 84.04

86.00 8816.9 86.03

88.00 8241.9 88.00

90.00 7709.7 89.96

92.00 7216.3 91.89

94.00 6758.9 93.80

96.00 6334.5 95.67

98.00 5940.5 97.51

100.00 5574.3 99.31

Resistance

OHMS

Output

°C

B.2 Edlog Programming for Long Lead Lengths

The following is a portion of an example CR10X program that uses the ExciteDelay (SE) (P4) instead of the AC Half Bridge (P5).

01: Excite, Delay,Volt(SE) (P4)

1: 1 Rep

2: 3 ±25 mV slow range ;On the 21X and CR7 use the 50 mV input range.

3: 1 IN Chan ;Entry depends on the datalogger SE channel used

4: 1 Excite all reps w/EXchan 3 ;Entry depends on the excitation channel used

5: 2 Delay (units .01sec)

6: 1000 mV Excitatio ;On the 21X and CR7 use the 2000 mV excitation

7 1 Loc [BGTemp_C ]

8: .2 Mult ;Use a multiplier of 0.1 with a 21X or CR7

9: 0 Offset

B-9

Page 30

Appendix B. Edlog Programming Examples

02: Polynomial (P55)

1: 1 Reps

2: 1 X Loc [BGTemp_C ] ;

3: 1 F(X) Loc [BGTemp_C ]

4: -26.97 C0

5: 69.635 C1

6: -40.66 C2

7: 16.573 C3

8: -3.455 C4

9: .301 C5

B-10

Page 31

Page 32

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (CSL France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Ltd. (CSL Germany)

Fahrenheitstraße 13

28359 Bremen

GERMANY

www.campbellsci.de • info@campbellsci.de

Campbell Scientific Spain, S. L. (CSL Spain)

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Loading...

Loading...