Page 1

Model 024A Met One

Wind Direction Sensor

Revision: 6/10

Copyright © 1989-2010

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The 024A MET-ONE WIND DIRECTION SENSOR is warranted by

Campbell Scientific, Inc. to be free from defects in materials and workmanship

under normal use and service for twelve (12) months from date of shipment

unless specified otherwise. Batteries have no warranty. Campbell Scientific,

Inc.'s obligation under this warranty is limited to repairing or replacing (at

Campbell Scientific, Inc.'s option) defective products. The customer shall

assume all costs of removing, reinstalling, and shipping defective products to

Campbell Scientific, Inc. Campbell Scientific, Inc. will return such products

by surface carrier prepaid. This warranty shall not apply to any Campbell

Scientific, Inc. products which have been subjected to modification, misuse,

neglect, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied, including warranties of merchantability

or fitness for a particular purpose. Campbell Scientific, Inc. is not liable for

special, indirect, incidental, or consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company

serves your country.

To obtain a Returned Materials Authorization (RMA), contact Campbell

Scientific, Inc., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Declaration of Hazardous Material

and Decontamination” form and comply with the requirements specified in it.

The form is available from our website at

completed form must be either emailed to repair@campbellsci.com

435-750-9579. Campbell Scientific will not process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

www.campbellsci.com/repair

. A

or faxed to

Page 3

024A Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. Function........................................................................1

2. Specifications ..............................................................1

3. Installation....................................................................2

3.1 Siting.........................................................................................................2

3.2 Assembly and Mounting...........................................................................2

4. Wiring............................................................................3

5. Programming ...............................................................3

5.1 Datalogger Instruction..............................................................................3

5.2 Calibration and Orientation ......................................................................4

5.3 Example Programs....................................................................................5

6. General Maintenance Schedule..................................8

6.1 6 to 12 Month Periodic Service *.............................................................8

6.2 24 to 36 Month Service * .........................................................................8

7. References .................................................................11

Appendix

A. Wind Direction Sensor Orientation........................A-1

A.1 Determining True North and Sensor Orientation................................ A-1

Figures

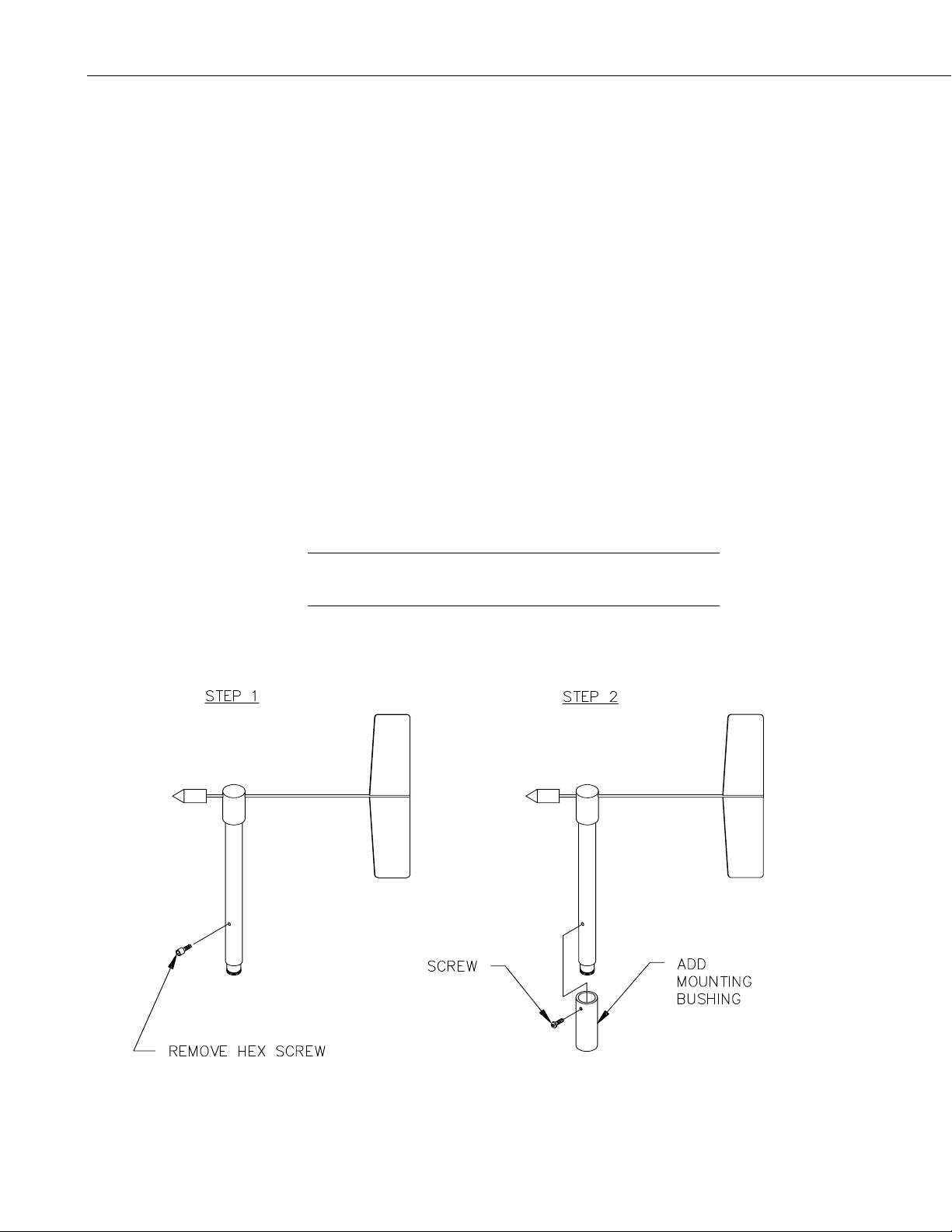

3-1. Bushing Installation on 024A Sensor......................................................2

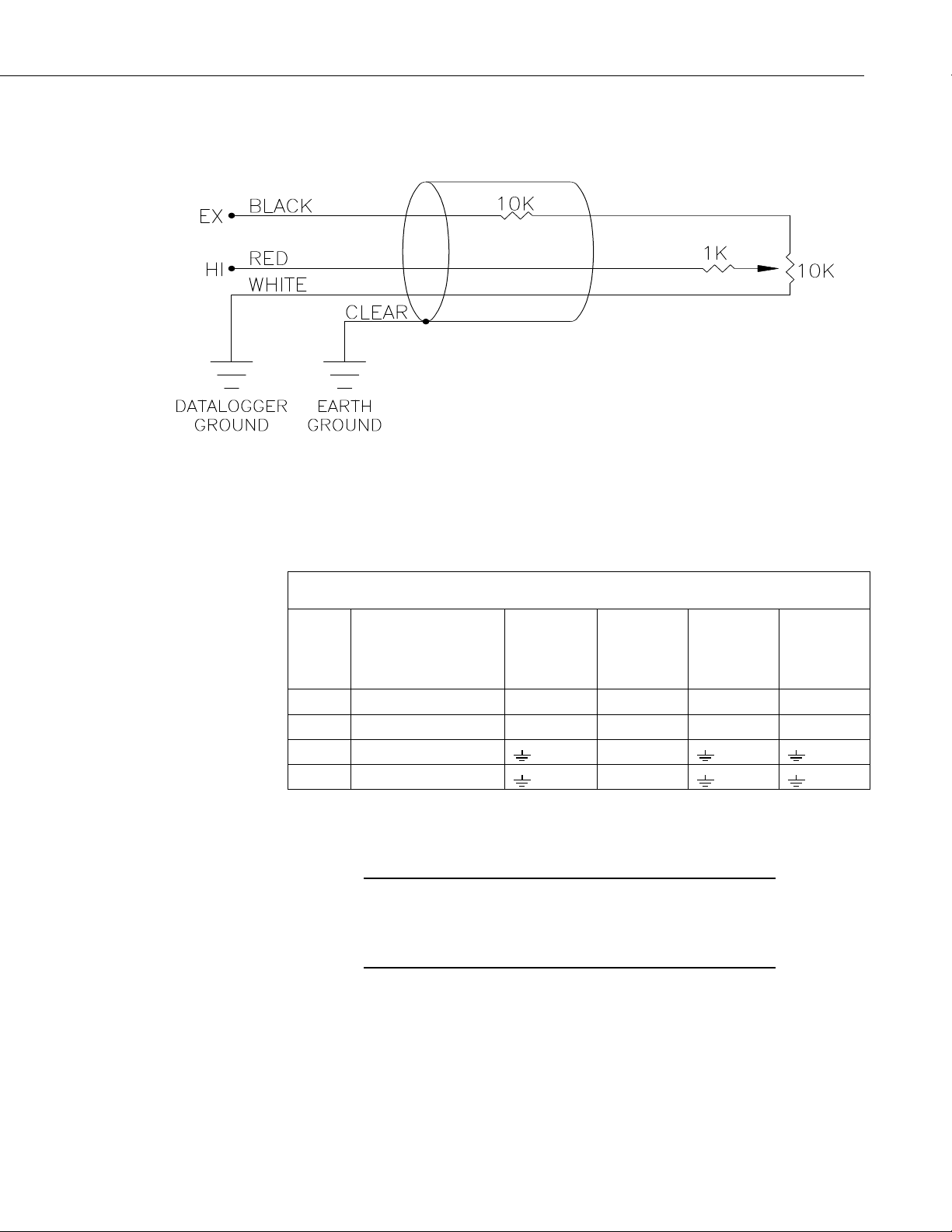

3-2. Schematic of 024A Wind Direction Sensor ............................................3

6-1. Cable Diagram.........................................................................................8

6-2. Parts Diagram..........................................................................................9

A-1. Magnetic Declination for the Contiguous United States................... A-2

A-2. Declination Angles East of True North Are Subtracted From 0

to Get True North ........................................................................ A-2

A-3. Declination Angles West of True North Are Added to 0

to Get True North ........................................................................ A-3

i

Page 4

024A Table of Contents

Tables

1-1. Recommended Lead Lengths ................................................................. 1

4-1. Connections to Campbell Scientific Dataloggers................................... 3

5-1. Parameters for Wind Direction............................................................... 4

6-1. Met-One Parts List Reproduced by Campbell Scientific, Inc............... 10

ii

Page 5

024A Met-One Wind Direction Sensor

1. Function

The Met-One 024A Wind Vane measures wind direction from 0 to 360 degrees

with a 5 degree accuracy specification. The 024A utilizes a potentiometer to

vary the sensor resistance in relation to wind direction.

Lead length for the 024A is specified when the sensor is ordered. Table 1-1

gives the recommended lead length for mounting the sensor at the top of a

tripod/tower via a CM202 or 019ALU crossarm.

TABLE 1-1. Recommended Lead Lengths

CM6 CM10 CM110 CM115 CM120 UT10 UT20 UT30

11’ 14’ 14’ 19’ 24’ 14’ 24’ 37’

2. Specifications

Range 0 to 360 degrees

Threshold 0.447 m/s (1.0 mph)

Accuracy ±5 degrees

Temperature Range -50°C to +70°C

Delay Distance Less than 1.5 m (5 ft.)

Damping Ratio

Standard 0.25

Optional 0.4

Potentiometer Specifications

Sand, Dust, and Fungus MIL-E-5272

Salt Spray MIL-E-12934

Resistance 0-10,000 Ohms

Weight 450 g (1 lb.)

Dimensions

Overall height 13.3” (33.8 cm)

Overall length 17.6” (44.7 cm)

Tail height 12” (30.5 cm)

Tail Width 3” (7.6 cm)

1

Page 6

024A Met-One Wind Direction Sensor

3. Installation

3.1 Siting

Locate wind sensors away from obstructions (e.g. trees and building). As a

general rule of thumb there should be a horizontal distance of at least ten times

the height of the obstruction between the windset and the obstruction. If it is

necessary to mount the sensors on the roof of a building, the height of the

sensors, above the roof, should be at least 1.5 times the height of the building.

See Section 7 for a list of references that discuss siting wind direction sensors.

3.2 Assembly and Mounting

Remove the Allen hex screw in the lower part of the sensor housing and insert

the 024A in the mounting bushing (see Figure 3-1). Tighten the screw in the

bushing onto the sensor housing.

Mount the crossarm to the tripod or tower. Orient the crossarm North-South,

with the CM220 mount or 17953 1” x 1” NU-RAIL fitting on the North end.

Insert the sensor in the CM220 or NU-RAIL fitting. Align the sensor so that

the counter weight points to true South and tighten the u-bolts on the CM220

or tighten the set screws on the NU-RAIL fitting.

NOTE

Appendix A contains detailed information on determining and

using a compass and the magnetic declination for the site.

Connect the cable assembly to the sensor receptacle.

2

FIGURE 3-1. Bushing Installation on 024A Sensor

Page 7

4. Wiring

024A Met-One Wind Direction Sensor

FIGURE 4-1. Schematic of 024A Wind Direction Sensor

Figure 4-1, Figure 6-1, and Table 4-1 shows wiring. When Short Cut for

Windows software is used to create the datalogger program, the sensor should

be wired to the channels shown on the wiring diagram created by Short Cut.

Color

Description

Red Wind Dir. Signal SE Analog SE Analog SE Analog SE Analog

Black Wind Dir. Excitation Excitation Excitation Excitation Excitation

White Wind Dir. Reference

Clear Wind Dir. Shield

5. Programming

NOTE

5.1 Datalogger Instruction

TABLE 4-1. Connections to Campbell Scientific Dataloggers

CR800

CR5000

CR3000

CR1000

CR510

CR500

CR10(X)

AG

G

21X

CR7

CR23X

This section is for users who write their own programs. A

datalogger program to measure this sensor can be created using

Campbell Scientifics’ Short Cut Program Builder software. You

do not need to read this section to use Short Cut.

CR200(X)

The datalogger instruction that measures the 024A is datalogger dependent.

The BRHalf measurement instruction is used for our CR800, CR850, CR1000,

CR3000, and CR5000 dataloggers. Our CR200(X)-series dataloggers use the

EX-DEL_SE. Our Edlog dataloggers (e.g., CR510, CR10(X), CR23X) use

3

Page 8

024A Met-One Wind Direction Sensor

Instruction 4 – Excite, Delay, Measure. Excitation voltages, range codes, and

delays for CSI dataloggers are listed in Table 5-1. The process for determining

the correct multiplier is provided in Section 5.2.

TABLE 5-1. Parameters for Wind Direction

Measurement

Range

Excitation

Voltage

Delay or Settling

Time

Multiplier See Section

Offset 0 0 0 0 0

CR200(X)

2500 mV 250 mV, fast 500 mV, fast 2500 mV,

2500 mV 500 mV 1000 mV 2500 mV 5000 mV

2 ms 2 ms 2 ms 2 ms 2 ms

5.2

CR10(X),

CR510

See Section 5.2 See Section

CR7, 21X,

CR23X

5.2

CR800, CR850,

CR1000

250 microsecond

integration,

reverse excitation

See Section 5.2 See Section 5.2

CR5000,

CR3000

5000 mV,

250 microsecond

integration, reverse

excitation

5.2 Calibration and Orientation

Conversion of the voltage output into wind direction is done by entering the

proper multiplier. The proper multiplier is calculated by dividing 360 by the

full scale input voltage (i.e., 360/FSIV). The full scale input voltage (FSIV) is

the maximum voltage output from the wind vane. This is found by creating a

datalogger program with a multiplier of 1, the default excitation, and a fast

scan interval. With a multiplier of 1, the value stored in the variable or input

location is simply the voltage output. Slowly turn the wind vane; the shoulder

screw must first be removed. The maximum value observed is the full scale

input voltage (FSIV).

4

NOTE

If the reading is -99999, exceeds 500 on the 21X or CR7, or

exceeds 250 on the CR10, then reduce the millivolts of

excitation by 5 mV.

Multiplier 360/FSIV*

Offset 0.0

*FSIV = Full scale input voltage

Enter the calculated multiplier in the program.

Orientation of the 024A Wind Direction Sensor should be complete if the

024A counter weight was aligned due south.

Page 9

5.3 Example Programs

024A Met-One Wind Direction Sensor

NOTE

'CR200(X) Series

'Created by Short Cut (2.5)

'Declare Variables and Units

Public Batt_Volt

Public WindDir

Public NewMult

Units Batt_Volt=Volts

Units WindDir=degrees

'Define Data Tables

DataTable(Table2,True,-1)

DataInterval(0,1440,Min)

Minimum(1,Batt_Volt,False,False)

EndTable

'Main Program

BeginProg

Scan(10,Sec)

'Default Datalogger Battery Voltage measurement Batt_Volt:

Battery(Batt_Volt)

'024A Wind Direction Sensor measurement WindDir:

ExDelSE(WindDir,1,1,1,2500,2000,1.0,0)

NewMult=360/WindDir

'Call Data Tables and Store Data

CallTable(Table2)

NextScan

EndProg

For these examples, the multiplier is listed as 1. The multiplier

is unique to individual devices. Follow the procedure provided

in Section 5.2 to acquire the correct multiplier for your sensor.

5

Page 10

024A Met-One Wind Direction Sensor

'CR1000

'Created by Short Cut (2.5 Beta)

'Declare Variables and Units

Public Batt_Volt

Public WindDir

Public NewMult

Units Batt_Volt=Volts

Units WindDir=degrees

'Define Data Tables

DataTable(Table1,True,-1)

DataInterval(0,60,Min,10)

Sample(1,WindDir,FP2)

EndTable

DataTable(Table2,True,-1)

DataInterval(0,1440,Min,10)

Minimum(1,Batt_Volt,FP2,False,False)

EndTable

'Main Program

BeginProg

Scan(5,Sec,1,0)

'Default Datalogger Battery Voltage measurement Batt_Volt:

Battery(Batt_Volt)

'024A Wind Direction Sensor measurement WindDir:

BrHalf(WindDir,1,mV2500,1,1,1,2500,True,2000,250,1.0,0)

NewMult=360/WindDir

'Call Data Tables and Store Data

CallTable(Table1)

CallTable(Table2)

NextScan

EndProg

6

'CR3000

'Created by Short Cut (2.5)

'Declare Variables and Units

Public Batt_Volt

Public WindDir

Public NewMult

Units Batt_Volt=Volts

Units WindDir=degrees

'Define Data Tables

DataTable(Table1,True,-1)

DataInterval(0,60,Min,10)

Sample(1,WindDir,FP2)

EndTable

Page 11

024A Met-One Wind Direction Sensor

DataTable(Table2,True,-1)

DataInterval(0,1440,Min,10)

Minimum(1,Batt_Volt,FP2,False,False)

EndTable

'Main Program

BeginProg

Scan(5,Sec,1,0)

'Default Datalogger Battery Voltage measurement Batt_Volt:

Battery(Batt_Volt)

'024A Wind Direction Sensor measurement WindDir:

BrHalf(WindDir,1,mV5000,1,1,1,5000,True,2000,250,1.0,0)

NewMult=360/WindDir

'Call Data Tables and Store Data

CallTable(Table1)

CallTable(Table2)

NextScan

EndProg

;{CR10X}

;

*Table 1 Program

01: 10 Execution Interval (seconds)

;Measure sensor. Multiplier is unique to individual devices.

1: Excite-Delay (SE) (P4)

1: 1 Reps

2: 14 250 mV Fast Range

3: 1 SE Channel

4: 1 Excite all reps w/Exchan 1

5: 2 Delay (0.01 sec units)

6: 500 mV Excitation

7: 1 Loc [ wind_dir ]

8: 1.0 Multiplier

9: 0.0 Offset

;Store measurements in final storage

2: If time is (P92)

1: 0000 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

3: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 101 Array ID

4: Real Time (P77)

1: 1220 Year,Day,Hour/Minute (midnight = 2400)

5: Sample (P70)

1: 1 Reps

2: 1 Loc [ wind_dir ]

7

Page 12

024A Met-One Wind Direction Sensor

6. General Maintenance Schedule

6.1 6 to 12 Month Periodic Service *

Inspect sensor for physical damage and verify that the vane assembly rotates

freely. To verify parts and locations, refer to the parts diagram (Figure 6-2)

and the parts list (Table 6-1).

6.2 24 to 36 Month Service *

A complete factory overhaul of the sensor, including the replacement of the

potentiometer, is recommended. Contact Campbell Scientific and get a Return

Materials number (RMA) before sending it to Campbell Scientific.

* Schedule is based on average to adverse environments.

8

FIGURE 6-1. Cable Diagram

Page 13

024A Met-One Wind Direction Sensor

FIGURE 6-2. Parts Diagram

9

Page 14

024A Met-One Wind Direction Sensor

Item Part No. Description. Qty./Assy

1 102105 Vane Assembly 1

2 101685-1 Wind Dir. Support 1

3 101049-2 Label, Wind Dir. 1

4 101789 Label, Caution 1

5 860015 Screw, Shoulder 1

6 601100 Screw, Pan Hd Ph, 2-56x3/16 3

7 601680 Scrw, Set A/H, 8-32x3/8 2

8 101687 Label, Met-One 1

9 102017 Assy, Potentiometer 1

10 980495 Wire, 22Ga, Yel 1

11 980450 Wire, 22Ga, Blu 1

TABLE 6-1. Met-One Parts List Reproduced by

Campbell Scientific, Inc.

12 980475 Wire, 22Ga, Orn 1

13 995425 Loctite 222 A/R

14 500280 Connector, 6 Pin 1

15 995100 Adhesive, Epoxy A/R

16 995060 Adhesive, Silicone 5ml

17 510020 Cap 1

18

19

20

21 101806 Assembly, Cable Ref

22 101699 Assy Instructions Ref

23 101706 014 & 024 Installation Ref

24 101697 Wir. Diagram Ref

25

26 601850 Scrw, Cap A/H SS 10-32x5/8 1

10

Page 15

7. References

024A Met-One Wind Direction Sensor

The following references give detailed information on siting wind speed and

wind direction sensors.

EPA, 1989: Quality Assurance Handbook for Air Pollution Measurements

System, Office of Research and Development, Research Triangle Park, NC,

27711.

EPA, 1987: On-Site Meteorological Program Guidance for Regulatory

Modeling Applications, EPA-450/4-87-013, Office of Air Quality Planning

and Standards, Research Triangle Park, NC 27711.

The State Climatologist, 1985: Publication of the American Association of

State Climatologists: Height and Exposure Standards, for Sensors on

Automated Weather Stations, vol. 9, No. 4.

WMO, 1983: Guide to Meteorological Instruments and Methods of

Observation, World Meteorological Organization, No. 8, 5th edition, Geneva,

Switzerland.

11

Page 16

024A Met-One Wind Direction Sensor

12

Page 17

Appendix A. Wind Direction Sensor Orientation

A.1 Determining True North and Sensor Orientation

Orientation of the wind direction sensor is done after the datalogger has been

programmed, and the location of True North has been determined. True North is

usually found by reading a magnetic compass and applying the correction for

magnetic declination; where magnetic declination is the number of degrees

between True North and Magnetic North. Magnetic declination for a specific site

can be obtained from a USGS map, local airport, or through a computer service

offered by the USGS at www.ngdc.noaa.gov/geomag. A general map showing

magnetic declination for the contiguous United States is shown in Figure A-1.

Declination angles east of True North are considered negative, and are subtracted

from 0 degrees to get True North as shown Figure A-2. Declination angles west

of True North are considered positive, and are added to 0 degrees to g et Tru e

North as shown in Figure A-3. For example, the declination for Logan, Utah is

14° East. True North is 360° - 14°, or 346° as read on a compass.

Orientation is most easily done with two people, one to aim and adjust the

sensor, while the other observes the wind direction displayed by the

datalogger.

1. Establish a reference point on the horizon for True North.

2. Sighting down the instrument center line, aim the nose cone, or

counterweight at True North. Display the input location or variable for wind

direction using a hand-held keyboard display, PC, or palm.

3. Loosen the u-bolt on the CM220 or the set screws on the Nu-Rail that secure

the base of the sensor to the crossarm. While holding the vane position,

slowly rotate the sensor base until the datalogger indicates 0 degrees.

Tighten the set screws.

A-1

Page 18

Appendix A. Wind Direction Sensor Orientation

Subtract declination from 360° Add declination to 0°

22 E

20 E

18 E

16 E

14 E

12 E

10 E

8 E

6 E

4 E

2 E

2 W

0

20 W

18 W

16 W

14 W

12 W

10 W

8 W

6 W

4 W

FIGURE A-1. Magnetic Declination for the Contiguous United States

A-2

FIGURE A-2. Declination Angles East of True North Are Subtracted

From 0 to Get True North

Page 19

Appendix A. Wind Direction Sensor Orientation

FIGURE A-3. Declination Angles West of True North Are Added to 0 to

Get True North

A-3

Page 20

Appendix A. Wind Direction Sensor Orientation

This is a blank page.

A-4

Page 21

Page 22

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br • suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...