Page 1

012 WEATHER STATION

OPERATOR'S MANUAL

COPYRIGHT (c) 1989, 1991 CAMPBELL SCIENTIFIC, INC.

REVISION: 9/91

Page 2

This is a blank page.

Page 3

WARRANTY AND ASSISTANCE

The 012 WEATHER STATION is warranted by CAMPBELL SCIENTIFIC, INC. to be free from defects in

materials and workmanship under normal use and service for twelve (12) months from date of shipment

unless specified otherwise. Batteries have no warranty. CAMPBELL SCIENTIFIC, INC.'s obligation under

this warranty is limited to repairing or replacing (at CAMPBELL SCIENTIFIC, INC.'s option) defective

products. The customer shall assume all costs of removing, reinstalling, and shipping defective products

to CAMPBELL SCIENTIFIC, INC. CAMPBELL SCIENTIFIC, INC. will return such products by surface

carrier prepaid. This warranty shall not apply to any CAMPBELL SCIENTIFIC, INC. products which have

been subjected to modification, misuse, neglect, accidents of nature, or shipping damage. This warranty

is in lieu of all other warranties, expressed or implied, including warranties of merchantability or fitness for

a particular purpose. CAMPBELL SCIENTIFIC, INC. is not liable for special, indirect, incidental, or

consequential damages.

Products may not be returned without prior authorization. To obtain a Returned Materials Authorization

(RMA), contact CAMPBELL SCIENTIFIC, INC., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please write this number clearly on

the outside of the shipping container. CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

CAMPBELL SCIENTIFIC, INC. does not accept collect calls.

Non-warranty products returned for repair should be accompanied by a purchase order to cover the repair.

815 W. 1800 N.

Logan, UT 84321-1784

USA

Phone (435) 753-2342

FAX (435) 750-9540

www.campbellsci.com

Campbell Scientific Canada Corp.

11564 -149th Street

Edmonton, Alberta T5M 1W7

CANADA

Phone (780) 454-2505

FAX (780) 454-2655

Campbell Scientific Ltd.

Campbell Park

80 Hathern Road

Shepshed, Loughborough

LE12 9GX, U.K.

Phone +44 (0) 1509 601141

FAX +44 (0) 1509 601091

Page 4

This is a blank page.

Page 5

SPECIAL OPERATING NOTES

1. Check the shipping list in the front of the

manual and make sure that all the parts

checked off the list are with the weather station.

If any parts are missing please contact

Campbell Scientific, Inc. 435-753-2342.

2. When connecting the battery avoid shorting

the battery to the weather station base (Section

2.5.1).

3. Damage to the electronics will occur if

moisture builds up inside the weather station. A

moisture detection sensor is used to detect

excessive humidity levels. This reading must

be monitored and corrective action taken if

moisture is detected (Section 4).

4. The hex bolts sealing the squeeze plates at

each end of the canister must be tightened

every spring and fall to maintain seal integrity

(Section 4).

Page 6

This is a blank page.

Page 7

012 WEATHER STATION

TABLE OF CONTENTS

PAGE

SECTION 1. WEATHER STATION DESCRIPTION

1.1 Standard Sensors ...................................................................................................................1-1

1.2 Data Retrieval Options ............................................................................................................1-1

1.3 Power Supply Options.............................................................................................................1-1

SECTION 2. WEATHER STATION INSTALLATION

2.1 Site Selection ..........................................................................................................................2-1

2.2 Tools and Supplies..................................................................................................................2-1

2.3 Foundation Construction .........................................................................................................2-2

2.4 Weather Station Assembly......................................................................................................2-4

2.5 Power Supply Installation ........................................................................................................2-6

2.6 Data Retrieval Option Installation............................................................................................2-9

2.7 Sensor Verification Using the CR10KD Keyboard Display....................................................2-14

2.8 Setting the Clock with the CR10KD Keyboard Display .........................................................2-14

2.9 Setting Flag 1 to Enable Soil Temperature Measurements ..................................................2-16

SECTION 3. PROGRAMMING

3.1 Programming Sensor Measurements .....................................................................................3-1

3.2 PC208 Datalogger Support Software......................................................................................3-5

SECTION 4. MAINTENANCE

4.1 Moisture in Canister ................................................................................................................4-1

4.2 Rain Gage ...............................................................................................................................4-1

4.3 Solar Radiation........................................................................................................................4-1

4.4 Wind Speed and Direction ......................................................................................................4-1

4.5 Temperature and Relative Humidity Probe.............................................................................4-2

4.6 Battery Voltage........................................................................................................................4-2

SECTION 5. TROUBLESHOOTING

5.1 Sensor Troubleshooting ..........................................................................................................5-1

5.2 Datalogger Troubleshooting ....................................................................................................5-1

APPENDICES

Apdx A. Program Listing ...................................................................................................................... A-1

Apdx B. Sensor Specifications and Schematics .................................................................................. B-1

TABLES

2.2-1 Tool Requirements..................................................................................................................2-1

2.2-2 Materials Requirements for Constructing Foundation.............................................................2-1

2.6 Rad Modem Connections......................................................................................................2-10

2.7-1 Sensor Verification ................................................................................................................2-16

2.8 Sequence of Time Parameters in *5 Mode ...........................................................................2-16

3.0 012 Standard Program Outputs ..............................................................................................3-1

3.1 Parameters for Sensor Measurement Instruction ...................................................................3-2

I

Page 8

012 TABLE OF CONTENTS

FIGURES

2.1 Effect of Structure on Wind Flow ........................................................................................... 2-1

2.3-1 012 Foundation Construction ................................................................................................. 2-2

2.3-2 012 Weather Station with Solar Panel ................................................................................... 2-3

2.3-3 Template and Anchor Bolt Assembly ..................................................................................... 2-3

2.4-1 012 Weather Station Assembly.............................................................................................. 2-4

2.4-2 Wind Set Alignment................................................................................................................ 2-5

2.5-1 Battery/Solar Panel Connections ........................................................................................... 2-7

2.5-2 Battery/AC Charging Connections ......................................................................................... 2-8

2.6-1 RAD Modem Connections.................................................................................................... 2-10

2.6-2 Phone Modem Connections................................................................................................. 2-11

2.6-3 012 Weather Station with Radio Antenna ............................................................................ 2-12

2.6-4 012 Weather Station with Storage Module........................................................................... 2-13

2.8 Day of Year Calendar........................................................................................................... 2-15

5.2 CR10 Serial I/O Connector ....................................................................................................5-2

B.1 Sensor Channel Assignments and Connections .................................................................... B-1

B.2 Sensor Wind Direction ........................................................................................................... B-2

B.3 Sensor Rain Gage.................................................................................................................. B-3

B.4 Sensor Pyranometer ..............................................................................................................B-4

B.5 Sensor Temperature and RH ................................................................................................. B-5

B.6 Sensor Air Temperature......................................................................................................... B-6

B.7 Sensor Soil Temperature ....................................................................................................... B-7

B.8 Sensor Wind Speed ...............................................................................................................B-8

II

Page 9

SECTION 1. WEATHER STATION DESCRIPTION

The 012 Weather Station is designed to reduce the cost and logistics of routine climatological

monitoring. Installation is simplified through a modular design and prewired sensors. This manual

covers installation, sensor options, power supply options, programming, maintenance, and trouble

shooting.

1.1 STANDARD SENSORS

Sensors with preassigned channels include:

• wind speed

• wind direction

• temperature

• relative humidity

• solar radiation

• rainfall

• soil temperature

• moisture detection

Section 3 explains the channel assignments

and how to program the weather station.

1.2 DATA RETRIEVAL OPTIONS

Telecommunication options include phone,

short haul, and radio. Different options require

different wiring connections in the base of the

weather station. Section 2 covers various

modem options.

When telecommunications are not required,

storage modules (SM192, SM716) may be used

for on-site data retrieval.

1.3 POWER SUPPLY OPTIONS

The base of the weather station is designed to

fit a user supplied 12 VDC deep cycle marine

battery. Power cables supplied with the station

fit 3/8" diameter battery posts. The battery may

be periodically replaced with a freshly charged

one, or it may be charged in place with either

the PS12 charging regulator and 110 VAC to 16

VAC transformer, or the MSX10R solar panel.

CSI offers a 7 Amp-hour rechargeable battery

which should be continuously charged due to its

small capacity.

1-1

Page 10

This is a blank page.

Page 11

SECTION 2. WEATHER STATION INSTALLATION

FIGURE 2.1. Effect of Structure on Wind Flow

2.1 SITE SELECTION

The site, including its climate and topography,

should represent the general area being

measured. Also avoid man-made or natural

obstructions such as buildings, asphalt parking

lots, and trees. General sensor placement

guidelines are:

WIND SENSORS

Trees, buildings, or other structures can greatly

influence wind speed and direction

observations. As a rule of thumb, a structure

will disturb the air flow an upwind distance of

about twice the height of the structure; a

downwind distance of about six times the height

of the structure and a vertical distance of up to

twice the height of the structure. (Figure 2.1).

TEMPERATURE AND RELATIVE

HUMIDITY PROBE

The radiation shield provides protection from

direct sunlight and rain. The shield does not

protect against irrigation water which may be

sprayed up into the plates. If the RH chip goes

through wetting and drying cycles, the active

sensing material separates from the substrate,

damaging the sensor.

RAIN GAGE

Do not place the rain gage where it may catch

irrigation water. When possible, there should

be no obstructions in a 45

of the gage.

o

line rising off the lip

SOLAR RADIATION

The pyranometer should be located so it is not

shadowed by surrounding objects.

TABLE 2.2-1. Tool Requirements

• sledgehammer • compass

• open end wrench 3/4" • rag

• trowel (for cement) • shovel

• tape measure • flat metal file

• dozen 16 penny nails • wheelbarrow

• wire strippers • level

• screw driver, regular head • hammer

• screw driver, phillips head • wood saw

• screw driver, regular head thin blade

2.2 TOOLS AND SUPPLIES

An itemized list of weather station components

included in the shipment is found in the front of

the manual. Tables 2.2-1 and 2.2-2 list the

tools and supplies, respectively, required to

install the weather station.

TABLE 2.2-2. Materials Requirements for

Constructing Foundation

5 80 lb. sacks of sakrete

1 8' x 2" x 4" lumber

* 11" x 11" metal template

* 4 1/2" x 12" stainless steel anchor bolts

* 1" conduit elbow

1 1/4" diameter x 3 1/2' long pipe (solar

panel systems only)

*CSI supplied

2-1

Page 12

SECTION 2. WEATHER STATION INSTALLATION

2.3 FOUNDATION CONSTRUCTION

The 012 Weather Station mounts on a cement

foundation as shown in Figures 2.3-1 and 2.3-2.

CSI provides a (1) metal template for locating

the anchor bolts and conduit in the base, (2)

four anchor bolts with two nuts each for leveling

the station, and (3) a conduit for

communication wire entry/exit at the base.

Step 1 - Dig an 18" square hole that is 12-13"

deep. These estimates are for heavy soils only;

light, shifting, or sandy soils require a deeper

base (and more cement). Excavate a slot for

the conduit elbow at about 9" below the surface

on the side where the communication cables

will enter. The slot should be oversized, making

it easier to install the conduit (Step 3).

Step 2 - Construct a wood form for the above

ground portion of the foundation. If the surface

area of the hole is 18", cut two 18" and two

21.5" boards from the 8' 2x4. Nail the boards

together to make an 18" (inside dimension)

square form. Center the form over the hole.

Step 3 - Three cubic feet of cement are

required to fill a 18" x 18" x 16" deep hole. This

amounts to approximately five (5) eighty pound

(80 lb.) sacks of sakrete. Mix the cement. Stuff

a rag into one end of the conduit elbow to

prevent cement from clogging the conduit.

While holding the conduit in place pour the

cement. Examine the template to judge where

to position the top of conduit. About 1.5 inches

of conduit should be exposed above the cement

surface.

Step 4 - While the cement is setting, assemble

the template and anchor bolts as shown in

Figure 2.3-3. Set the anchor bolts and template

in the cement so the conduit is coming through

the conduit hole in the template. The threaded

end of the anchor bolts should extend a

minimum of 1.75" above the top of the concrete.

This will allow the template to rest on the lower

set of nuts about 1" above the surface of the

concrete (Figure 2.3-1). Adjustment of the

lower set of nuts will allow you to level the

template and later the 012 weather station. Do

not remove the template. It is used as the

bottom for the pedestal base when the weather

station is assembled.

Step 5 - Weather stations using a solar panel

for charging the battery need to insert a user

supplied 1 1/4" pipe into the cement pad (Figure

2.3-2).

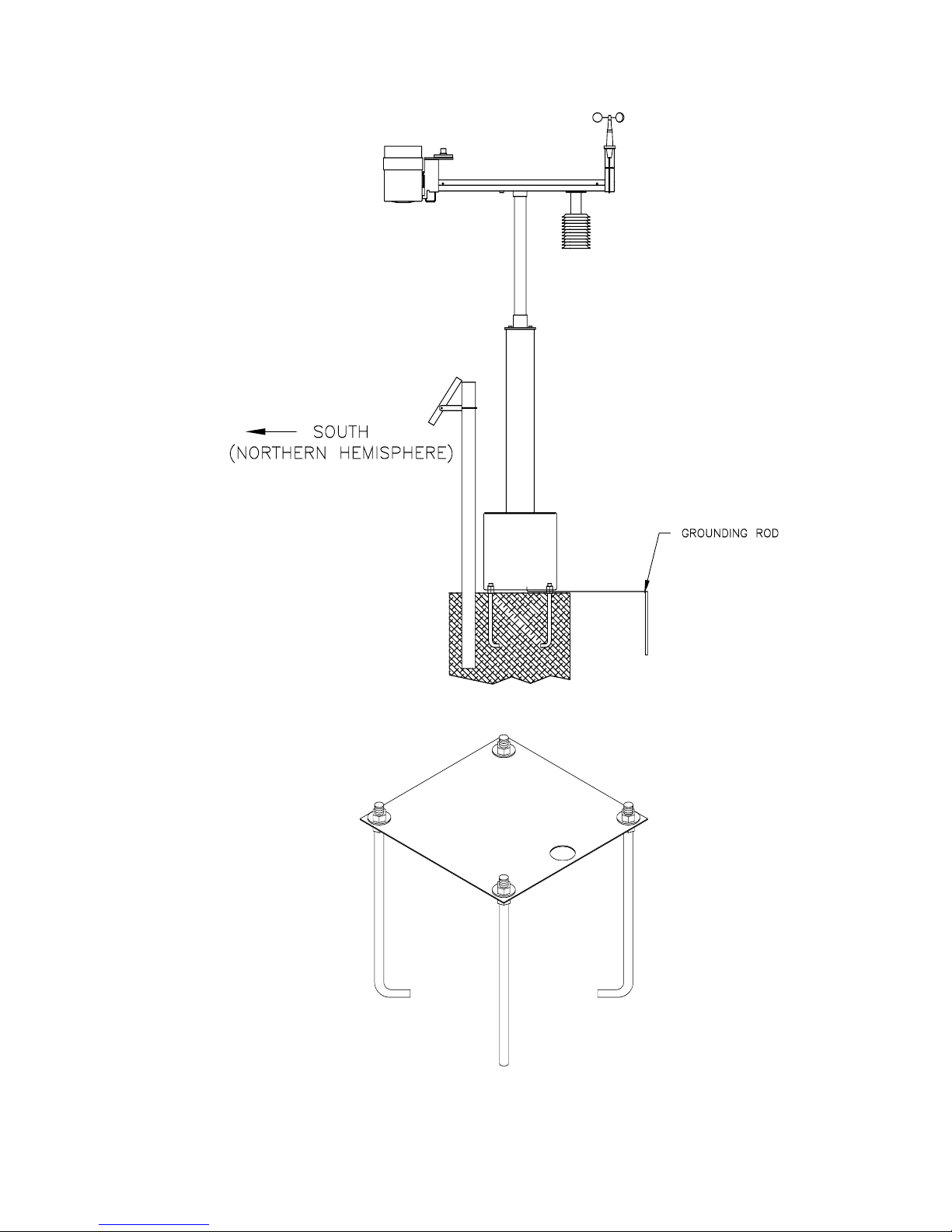

FIGURE 2.3-1. 012 Foundation Construction

2-2

Page 13

SECTION 2. WEATHER STATION INSTALLATION

FIGURE 2.3-2. 012 Weather Station with Solar Panel

FIGURE 2.3-3. Template and Anchor Bolt Assembly

2-3

Page 14

SECTION 2. WEATHER STATION INSTALLATION

FIGURE 2.4-1. 012 Weather Station Assembly

2.4 WEATHER STATION ASSEMBLY

The following instructions describe the

installation of the 012 weather station. All steps

except those marked with an asterisk (*) are

shown in Figure 2.4-1.

Before assembling the threaded ends of the

mast, apply the teflon pipe dope provided with

the weather station to prevent the aluminum

from galling.

2-4

Step 1 Thread the cables from the canister

through the mast and hand tighten the mast to

the canister. Do not twist the cables.

Step 2. Remove the crossarm cover.

Thread the cables through the center hole of

the crossarm and screw the crossarm to the

mast.

Page 15

SECTION 2. WEATHER STATION INSTALLATION

CAUTION: Over-tightening the mast will

cause excessive torque.

Step 3 Mount the weather station on the

cement pad aligning the conduit with the conduit

notch in the bottom of the pedestal. Vertically

plumb the weather station by adjusting the

upper and lower nuts that secure the pedestal

base to the anchor bolts.

*

Step 4 (Figure 2.4-2) Tighten the crossarm

and mast as much as possible while aligning

the crossarm north-south. The crossarm end,

with the 1 5/8" hole on the underside, must be

pointed north. Use of a compass is

recommended as the crossarm orientation

affects the accuracy of the wind direction

measurement.

Step 5 Mount the wind sensors on the north

end of the crossarm using the brackets

provided. The windset crossarm should be

oriented east-west, with the wind direction

sensor oriented to the east (Figure 2.4-2).

For stations which measure wind speed only,

the wind speed sensor may be mounted on

either end of the windset crossarm. A small

square metal piece is provided to fill in the area

left vacant for the wind direction sensor.

Step 6 Mount the solar radiation and rain

gage sensors on the south end of the crossarm.

NOTE: Insert the sensor cables through

the grommeted slot before attaching

sensors to the crossarm.

Level the radiation sensor using the 3

adjustment screws and the fixtures bubble level.

NOTE: Accurate radiation measurements

require accurate leveling.

Remove the top of the rain gage and make sure

that the magnet is not holding the bucket at a

dead center position. Manually tip the bucket,

checking that it tips freely to both sides.

Replace and level the the lid.

Step 7 Mount the radiation shield into the 1

5/8" diameter hole on the underside of the

crossarm. Put the Temperature and Relative

Humidity sensor into the radiation shield. Make

sure that the temperature and RH sensor is

properly seated into the radiation shield.

NOTE: For weather stations with a

temperature sensor only, the temperature

sensor is mounted in the radiation shield.

FIGURE 2.4-2. Wind Set Alignment

2-5

Page 16

SECTION 2. WEATHER STATION INSTALLATION

Step 8 Attach the lightning rod to the 1 1/4"

sleeve on the underneath side of the crossarm.

*

Step 9 The serial (I/O) cable is mounted on

the underside of the crossarm, near the mast.

Remove the screws, insert the 9 pin D shaped

connector, and then replace the screws.

NOTE: The cover lid is held in place by a

long bolt. Make sure that the cover plate is

in place before tightening the screws.

Step 10 Route the windset cables through

the bottom of the crossarm. Make sure the

cables pass through the grommeted slot.

*

Step 11 Observe the labeling on the sensor

leads and connect the sensor cables to the

appropriate canister cables. Arrange the

connectors so they don't interfere with the

crossarm cover. Tie down all sensor leads with

the nylon ties provided in the ends of the crossarm.

Replace the crossarm cover using the six screws.

*

Step 12 Double check the weather station to

make sure that the solar radiation and rain gage

sensors are level. Also, check to see that the

wind direction sensor is mounted on the east

side of the crossarm.

Step 13 Proper grounding of the station is

required to minimize damage from transients

caused by lightning strikes or other voltage

surges. Drive the copper plated ground rod into

the earth adjacent to the weather station and

attach the ground rod clamp. A 12 AWG green

grounding wire is connected to a ground lug on

the base. Connect the free end of the green

wire to the ground rod clamp. This important

step grounds the communications modem, the

weather station, and the CR10 datalogger.

*

Step 14 The soil temperature probe is an

optional sensor. Connections are made in the

base for ease of installation into the soil.

2.5 POWER SUPPLY INSTALLATION

2.5.1 BATTERY INSTALLATION

NOTE: The 012 Weather Station base is at

power ground. When installing the battery

on the template inside the base, take care

not to short the positive post of the battery

to the base.

The battery may be continuously charged or

periodically exchanged with a fresh one.

Following the procedure below, batteries may

be replaced without losing power to the station.

To install a battery, locate the terminal block

inside the pedestal base where power supply

connections are made (Figures 2.5-1 and 2.5-

2). Connect the battery to the terminal labeled

"Batt 12V". The power Sonic battery supplied

by CSI is prewired with red lead positive and

black lead negative. The Power Sonic should

be continuously changed due to its smaller

capacity, 6Ahr.

Connect a user supplied battery with one of the

two power cables provided. Connect the cable

to the "BATT 12V" red positive, black negative

terminal block first then connect to the battery.

Do not connect a battery to the AUX BATT 12V

Terminal when using the PS12 charging

regulator as explained below.

Battery Replacement The battery should be

replaced when discharged below 11 volts

(Sections 2.7, 4.6). The second set of battery

cables are provided for exchanging batteries

without interrupting power to the CR10

Datalogger. Leave the old battery connected

until the new battery is connected. Connect the

cable to the "AUX BATT 12V" terminals first,

then the circular lugs of the battery. Disconnect

and remove the old battery. Store the cable

until needed for the next battery change. Never

leave a battery cable connected to the power

strip with the circular lugs dangling.

WARNING: If the 12V power is

disconnected from the weather station the

data in the datalogger is lost.

2.5.2 CHARGING OPTIONS

CSI offers the PS12 12V Charger with 110

VAC to 16 VAC transformer or the MSX10R

Solar Panel for continuously charging the

battery power supply. The charging source

must be connected to the terminals labeled

"INPUT EXTERNAL CHARGING SOURCE". If

ordered with the weather station, the PS12 is

pre-mounted in the base. The MSX10R Solar

Panel is used when AC power is not available.

NOTE: The "EXTERNAL CHARGING

SOURCE" connects only to the "BATT 12V"

terminals. The "AUX BATT 12V" terminals

are not included in the charging circuit.

2-6

Page 17

SECTION 2. WEATHER STATION INSTALLATION

PS12

For safety reasons, DO NOT mount the 110

VAC supply directly to the weather station.

Mount the transformer external to the stations

and run 16 VAC to the station (Figure 2.5-2).

The maximum distance for the 16 VAC using an

18 awg cable is 2000 ft. The electrical

connections should be done in accordance with

the National, State, and Local electrical codes.

Solar Panel

The solar panel is mounted (Figure 2.3-2) on

the south side of the weather station (northern

hemisphere only) and connects to the terminals

labeled "INPUT EXTERNAL CHARGING

SOURCE" (Figure 2.5-1).

FIGURE 2.5-1. Battery/Solar Panel Connections

2-7

Page 18

SECTION 2. WEATHER STATION INSTALLATION

FIGURE 2.5-2. Battery/AC Charging Connections

2-8

Page 19

SECTION 2. WEATHER STATION INSTALLATION

2.6 DATA RETRIEVAL OPTION

INSTALLATION

The four options available for data collection are

the Rad Modem, DC112 Phone Modem, RF95

Radio Frequency modem, and storage modules.

Any modem ordered with the station is premounted in the canister. Refer to the specific

manuals of each device for technical information

on the modems and storage modules.

2.6.1 RAD MODEMS

Figure 2.6-1 shows the RAD modem terminal

block located inside the pedestal base. The

communication cable is connected between the

modem at the PC and the weather station

according to the labels shown in Table 2.6. The

communications cable connecting the station to

the computer must be two twisted pairs (4

conductors) and suitable for burial. Examples

are *Anixter part number F-02P22BPN (Rodent

Proof) or *Belden part number 1048A.

TABLE 2.6. Rad Modem Connections

SRM-6A at PC Base of Weather Station

+XMT +XMT

-XMT -XMT

+RCV +RCV

-RCV -RCV

*Anixter *Belden

4711 601 FRD P.O. Box 1980

Skokie, IL 60076 Richmond, IN 47375

708-677-2600 1-800-BELDEN1

2.6.2 DC112 PHONE MODEM

Figure 2.6-2 shows the phone modem terminal block

located inside the pedestal base. A copper shielded,

burial phone cable should enter the weather station

pedestal via the conduit. Strip 1 7/8 inches of the

insulation off the cable without cutting the copper

shield. Strip the shield 1 1/2", insert the cable into

the ground lug mounted on the center terminal, and

tighten it onto the copper shield.

CAUTION: Do not over tighten ground lug

or damage to the phone line will occur.

Connect the RING signal (orange or blue wires)

to the terminal labeled RING and the TIP signal

(white/orange or white/blue wires) to the

terminal labeled TIP.

2.6.3 RF MODEM

Mount the antenna to the mast of the weather

station as shown in Figure 2.6-3. Fish the

connecting COAX cable through the grommeted

hole in the bottom of the cross arm adjacent at

the mast. Connect the cable to the antenna.

Take care not to kink the COAX cable or

damage will occur.

The RF95 Modem must be removed from the

canister to set the station ID number if the

switches have not been preset. Directions for

setting the ID switches are described in the

Radiotelemetry Network Applications Manual.

2.6.4 STORAGE MODULE SM192/SM716

The CR10 is programmed to automatically

transfer data when it detects that a storage

module is connected. The storage module is

brought to the site and connected to the CR10

as shown in Figure 2.6-4. Data transfer begins

within 5 seconds after making connections, and

ends a maximum of 55 seconds later. If an

SC90 Line Monitor is used, an LED turns on

and off when data transfer starts and stops,

respectively. Disconnect the storage module

and proceed to the office for data playback.

Never leave the storage module connected

to the weather station.

2-9

Page 20

SECTION 2. WEATHER STATION INSTALLATION

FIGURE 2.6-1. RAD Modem Connections

2-10

Page 21

SECTION 2. WEATHER STATION INSTALLATION

FIGURE 2.6-2. Phone Modem Connections

2-11

Page 22

SECTION 2. WEATHER STATION INSTALLATION

FIGURE 2.6-3. 012 Weather Station with Radio Antenna

2-12

Page 23

SECTION 2. WEATHER STATION INSTALLATION

FIGURE 2.6-4. 012 Weather Station with Storage Module

2-13

Page 24

SECTION 2. WEATHER STATION INSTALLATION

TABLE 2.7-1. Sensor Verification; Accessing CR10 Input Locations

Description Units

Battery Voltage

CR10 Temperature

Canister Moisture

Ambient Temperature

Ambient Temperature

*

**

Volts 1

o

0-1000 3

o

o

Relative Humidity %RH 6

Solar Radiation

1

kW/m

Wind Speed mph 8

Wind Direction

2

degree 9

Precipitation inches 10

Soil Temperature

*** o

Input Keyboard

Location Entry

*

6A

C2*62A

*

63A

C4*64A

F5*65A

*

2

7

66A

*

67A

*

68A

*

69A

*

610A

F11*611A

2.7 SENSOR VERIFICATION USING

THE CR10KD KEYBOARD DISPLAY

The following steps allow verification of the

sensor measurements performed every 10

seconds.

Connect the CR10KD Keyboard Display to the

serial I/O connector in the crossarm (refer to

Figure 2.6-4) using the Model SC12 cable.

Upon connection, the display activates, showing

meaningless numbers. Enter

should show LOG1. The sensor measurements

are stored in the CR10's Input Locations,

*

accessed through the

6 Mode; refer to the

keyboard entry column in Table 2.7-1. If you

get lost or make a mistake, start over by

*

entering

6. Once you are in *6 the A key may

be used to advance through the locations and

the B key may be used to backup through the

locations.

*

NOTE: Due to reverse polarity protection

diodes in the circuit, the battery voltage

measurement is approximately .7 volts

lower than the actual battery voltage.

Minimum operating voltage for the CR10 is

9.6 V.

**

WARNING: Readings above 200 indicate

high humidity inside the canister. The

canister must be opened and dried, and the

desiccant reactivated by heating at 250o for

12 hours.

*

0 and the display

1. Typical values should be between 300

(overcast) and 1000 (bright sunshine).

2. To check the wind vane, point it to the east

o

and compare new reading to 90

***

NOTE: Soil temperature readings are

.

made only if the CR10 User Flag #1 is set

high. Refer to Section 2.9 for details.

2.8 SETTING THE CLOCK WITH THE

CR10KD KEYBOARD DISPLAY

To set the year, day of year, and time, enter *5

and advance the display to the appropriate

window (refer to Table 2.8). Key in the desired

value and enter it by pressing the A key. When

a new value for hours and minutes is entered,

the seconds are set to zero and current time is

again displayed. Figure 2.8 shows a day of year

calendar.

TABLE 2.8. Sequence of Time Parameters in

*5 Mode

Key Display

*5 :HH:MM:SS Display current time

A 05:XX Display/enter year

A 05:XXXX Display/enter day of

Description

in hours, minutes,

and seconds

year

2-14

A 05:HH:MM

Display/enter

hours:minutes in

military time

Page 25

SECTION 2. WEATHER STATION INSTALLATION

During leap year add 1 to day 60 (March 1st) through day 365.

FIGURE 2.8. Day of Year Calendar

An example of entering year 89, day 100, and

time 1437 is shown below:

Key Display

*5 Current if time has not been set,

Description

CR10 time time since power up

is shown

A 05:XX display year

89 05:89 key in correct year

A 05:XXXX enter correct year and

display day of year

100 05:100 key in correct day of year

A 05:HH:MM enter correct day of year

and display hours and

minutes

1437 05:14:37 key in correct time

A :14:37:00 enter correct time and

display time

Verify that the year, day and time are entered

correctly by entering the

*5 mode and advancing

to each location:

Key Display

Description

*5 :14:37:15 display hour, minutes,

and seconds

A 05:89 display year

A 05:100 display day of year

A 05:14:37 display hour and minutes

A :14:37:20 return to the original

display of hours,

minutes, and seconds

Leave the clock mode (

*5) and return to the Log

Mode by keying *0.

2-15

Page 26

SECTION 2. WEATHER STATION INSTALLATION

2.9 SETTING FLAG 1 TO ENABLE SOIL

TEMPERATURE MEASUREMENTS

The optional soil temperature probe is read only

if Flag 1 is set high.

To set Flag 1, enter * 6 11 A. The display reads

11:XXXXX, where XXXXX represents the

contents of Input Location 11. Press the D key

and the display reads 00:000000. The zeros,

from left to right, show that Flags 1 through 8

are not set. To set Flag 1 press 1. The display

reads 10:000000. Return to Input Location 11

by pressing the A key. A soil temperature

reading appears in 10 seconds or less.

If the soil temperature measurement is

performed when no probe is connected, the

value -53.46 is recorded. Follow the same

procedure as outlined above to reset Flag 1 and

disable the measurement.

2-16

Page 27

SECTION 3. PROGRAMMING

The CR10 Measurement and Control Module begins executing the program stored in its PROM when

power is connected to the weather station. This "program-on-power-up" function is not found in standard

CR10s where users enter their own programs. Users desiring additional sensors or outputs different

from this "standard" program may create their own program and overwrite the existing one.

The resident program listed in Appendix A measures wind speed, wind direction, air temperature,

relative humidity, solar radiation, and rain every 10 seconds. Soil temperature is measured only if

enabled by the user; Flag 1 = 1 (Section 2.9).

The program stores hourly, daily and conditional data as shown below.

TABLE 3-1. 012 Standard Program Outputs

Hourly Output 24 Hour Output

01: Array ID 129 01: Array ID 139

02: Day 02: Day

03: Hour, Minute 03: Hour, Minute

04: Avg. Temperature (F) 04: Avg. Temperature (F)

05: Instantaneous RH (%) 05: Maximum Air Temperature (F)

06: Avg. Solar Radiation (kW/m

07: Avg. Wind Speed (mph) 07: Maximum Relative Humidity

08: Wind Speed Weighted Avg. Dir. 08: Minimum Relative Humidity

09: Standard Deviation of Wind Dir. 09: Avg. Solar Radiation (kW/m

optional (Flag 1 set high) 10: Maximum Wind Speed (mph)

10: Soil Temperature (F) 11: Avg. Wind Speed (mph)

Conditional Output

1 Minute Rain Fall Intensity 15: Maximum CR10 Temperature (C)

01: Array ID 124 16: Minimum CR10 Temperature (C)

02: Hour, Minute optional (Flag 1 set high

03: Rain Fall (inches) 17: Maximum Soil Temperature (F)

2

) 06: Minimum Air Temperature (F)

12: Total Rain Fall (inches)

13: Maximum Internal Moisture Index

14: Sample Battery Voltage

18: Minimum Soil Temperature (F)

2

)

Appendix A is a listing of the resident program.

3.1 PROGRAMMING SENSOR

MEASUREMENTS

The instructions used to measure and convert

sensor signals to the values displayed in Input

Memory (*6 Mode) are discussed in the

following pages. The standard sensors are

assigned fixed CR10 Input Channels and

Excitation Ports. These and other

measurement parameters used in the program

are summarized in Table 3-2.

3-1

Page 28

SECTION 3. PROGRAMMING

TABLE 3-2. Parameters for Sensor Measurement Instruction

Instr. Input Input Range Excit

Sensor Measurement

No. Ch. Code mV Ch mV

Temperature AC Half Bridge 11 1S N/A N/A 1 2000

Relative Humidity DC Half Bridge 4 4S 5 2500 2 0000

Solar Radiation Diff. Voltage 2 3D 2 7.5 N/A N/A

Wind Speed Frequency 3 1 N/A N/A N/A N/A

(AC Magnetic)

Wind Direction Half Bridge 4 3S 5 2500 2 2500

Rain Contact Closure 3 2 N/A N/A N/A N/A

Moisture Index AC Half Bridge 5 12S 13 25 3 2500

S = Single Ended Analog Channel

D = Differential Analog Channel

3.1.1. TEMPERATURE AND RELATIVE

HUMIDITY

The thermistor is read using Instruction 11.

The RH sensor is read using Instructions 20

and 4. Instruction 20 switches 12 V to the RH

sensor; Instruction 4 delays 80 ms then makes

the measurement. Instruction 20 is used again

to switch the 12 V off. Instructions 37 and 34

convert the temperature to degrees F and put it

into location 5.

03: P11 Temp 107 Probe

01: 1 Rep

02: 1 IN Chan

03: 1 Excite all reps w/EXchan 1

04: 4 Loc [:temp C ]

05: 1 Mult

06: 0 Offset

04: P37 Z=X*F

01: 4 X Loc temp C

02: 1.8 F

03: 5 Z Loc [:temp F ]

05: 80 Delay (units .01sec)

06: 0000 mV Excitation

07: 6 Loc [:RH ]

08: .1 Mult

09: 0 Offset

08: P20 Set Port(s)

01: 0000 C8..C5=low/low/low/low

02: 0000 C4..C1=low/low/low/low

3.1.2 WIND SPEED

The wind speed sensor is read by pulse count

Instruction 3, programmed for low level AC and

to measure frequency. The relationship

between wind speed, ws, and frequency, f, for

the R.M. Young Wind Sentry is:

ws = 1.677f + 0.4

where ws has units of mph and f is in Hz. The

result is placed in location 8. If the result equals

the anemometer offset (0.4 mph), the wind

speed value is set to 0; i.e., when there is no

wind speed the offset is not used in the wind

vector calculations.

05: P34 Z=X+F

01: 5 X Loc temp F

02: 32 F

03: 5 Z Loc [:temp F ]

06: P20 Set Port(s)

01: 0000 C8..C5=low/low/low/low

02: 1000 C4..C1=high/low/low/low

07: P4 Excite,Delay,Volt(SE)

01: 1 Rep

02: 5 2500 mV slow Range

03: 7 IN Chan

04: 2 Excite all reps w/EXchan 2

3-2

10: P3 Pulse

01: 1 Rep

02: 1 Pulse Input Chan

03: 21 Low level AC; Output Hz.

04: 8 Loc [:WS mph ]

05: 1.677 Mult

06: .4 Offset

11: P89 If X<=>F

01: 8 X Loc WS mph

02: 1 =

03: . 4 F

04: 30 Then Do

Page 29

SECTION 3. PROGRAMMING

12: P30 Z=F

01: 0 F

02: 0 Exponent of 10

03: 8 Z Loc [:WS mph ]

13: P95 End

3.1.3 WIND DIRECTION

The wind direction potentiometer is read using

Instruction 4 and the result placed in Location 9.

The measurement is delayed 20 ms longer than

normal after applying the excitation. The

potentiometer has a 5° deadband between 355

and 360°; measurements in this region are

acceptable because they are close to 0. The

multiplier is 355/2500 = 0.142°/mV. The offset

is zero.

The wind direction sensor is mounted such that

a 0° reading occurs for an east direction; 90° is

added to each measurement and 360°

subtracted if the result exceeds 360°.

14: P4 Excite,Delay,Volt(SE)

01: 1 Rep

02: 5 500 mV slow Range

03: 3 IN Chan

04: 2 Excite all reps w/EXchan 2

05: 2 Delay (units .01sec)

06: 2500 mV Excitation

07: 9 Loc [:Wind Dir ]

08: .142 Mult

09: 0 Offset

15: P34 Z=X+F

01: 9 X Loc Wind Dir

02: 90 F

03: 9 Z Loc [:Wind Dir ]

16: P89 If X<=>F

01: 9 X Loc Wind Dir

02: 3 >=

03: 360 F

04: 30 Then Do

17: P34 Z=X+F

01: 9 X Loc Wind Dir

02: - 360 F

03: 9 Z Loc [:Wind Dir ]

18: P95 End

3.1.4 RAIN GAGE

Instruction 3 is used to read the switch closure

from the tipping bucket rain gage; 1/100 of an

inch of rain per tip.

19: P3 Pulse

01: 1 Rep

02: 2 Pulse Input Chan

03: 2 Switch closure

04: 10 Loc [:Rain Fall]

05: .01 Mult

06: 0 Offset

3.1.5 SOLAR RADIATION

Instruction 2 is used to obtain a differential

voltage measurement and place the result in

-2

Location 7 in units of kWm

. The solar sensor

output is trimmed with a potentiometer to

provide a constant multiplier of 0.2 kWm

for all units.

09: P2 Volt (DIFF)

01: 1 Rep

02: 2 7.5 mV slow Range

03: 3 IN Chan

04: 7 Loc [:kW/m2 ]

05: . 2 Mult

06: 0 Offset

3.1.6 INTERNAL MOISTURE DETECTION

SENSOR

The moisture sensor is used to detect

humidities above 33% inside the canister

(electronics). The value stored in Location 3

ranges from 0 to 1000 for dry to wet when

programmed as shown below.

23: P5 AC Half Bridge

01: 1 Rep

02: 13 25 mV fast Range

03: 12 IN Chan

04: 3 Excite all reps w/EXchan 3

05: 2500 mV Excitation

06: 3 Loc [:moisture ]

07: 201 Mult

08: 0 Offset

24: P37 Z=X*F

01: 3 X Loc moisture

02: 1000 F

03: 3 Z Loc [:moisture ]

-2

/mV

25: P45 Z=INT(X)

01: 3 X Loc moisture

02: 3 Z Loc [:moisture ]

3-3

Page 30

SECTION 3. PROGRAMMING

3.2 PC208 DATALOGGER SUPPORT

SOFTWARE

The PC208 Datalogger Support Software is

used for interactive telecommunication between

the weather station and the computer. The

PC208 software has five software programs:

TELCOM, GraphTerm, EDLOG, SPLIT, and

SMCOM. Detailed information on each of these

programs is found in the PC208 instruction

manual.

TELCOM

TELCOM automates data retrieval from the

weather station over a communication link. The

creation of a station file to specify the

communication link, data file name and format,

and the calling schedule is menu driven.

GraphTerm

GraphTerm is a terminal emulator program for

remote monitoring and displaying of data,

downloading and uploading datalogger

programs, and remote keyboard entry.

Datalogger type, interface option and baud rate

are specified and saved in a station file similar

to that created in Telcom.

EDLOG

EDLOG is used to develop and document

datalogger programs. Once this program is

saved TERM can download it to the weather

station.

SPLIT

SPLIT is a general purpose data reduction

program that operates on data produced by the

weather station. SPLIT can select data from

one or more files, process and/or combine the

data and generate a titled report with labeled

data columns.

SMCOM

SMCOM (Storage Module Communications

Software) establishes communication with the

SM192 and SM716 Storage Modules for

retrieving and storing data on disk, as well as

for storing and retrieving datalogger programs.

SMCOM provides prompts requesting

information from the user.

3-4

Page 31

SECTION 4. MAINTENANCE

4.1 MOISTURE IN CANISTER

The hex bolts used to seal the top and bottom

of the canister should be tightened every spring

and fall to maintain seal integrity. As a

guideline, the bolts should be tightened to about

160 inch pounds.

The readings from a moisture detection sensor

housed in the canister are displayed in Location

3 and accessed by keying *63A (Section 2.7).

The sensor detects humidity above 33% with 0

dry and readings in the 100s being wet. The

readings should be monitored regularly and if

they are above 200, the weather station must

be dried out.

WARNING: Damage to the CR10, modem,

and wiring panel will occur if high moisture

levels are not corrected. The weather

station should be dried out and the

desiccant reactivated when the moisture

reading is 200 or greater.

When opening the canister, loosen each hex

bolt one half turn until each bolt has been

loosened two full turns.

CAUTION: DO NOT REMOVE THE

BOLTS FROM THE CANISTER.

Desiccant can be reactivated by placing it

in an oven at 250 oF for 16 hours.

filled to within 2.5 inches of the top may be

used for a rough field calibration).

4. If it takes less than 45 minutes for this

water to run out, the hole in the can is too

large.

5. One hundred tips plus or minus three tips

should occur.

6. Adjusting screws are located on the bottom

adjacent to the large center drain hole.

Adjust both screws the same number of

turns. Rotation clockwise increases the

number of tips per 16 oz. of water; counter

clockwise rotation decreases the number of

tips per 16 oz. of water. One half turn of

both screws causes a 2% to 3% change.

7. Check and re-level the rain gage lid.

4.3 SOLAR RADIATION

Inspect and clean the pyranometer every two to

three months. Dusty environments may require

more frequent cleaning. Be careful not to

scratch the surface of the sensor. A blast of

clean, dry air or a soft bristle, camel hair brush

are best used for cleaning the diffuser surface.

Recalibration of the radiation sensor is

recommended every two (2) years.

4.4 WIND SPEED AND DIRECTION

4.2 RAIN GAGE

Inspect and clean the rain gage as needed to

remove leaves, debris, etc. The rain gage

calibration is 0.01 in. per tip. The following

check is advised every 6 to 12 months.

Rain Gage Calibration:

1. Secure a metal can that will hold at least

one quart of water.

2. Punch a very, very small hole in the bottom

of the can.

3. Place the can in the top funnel of the rain

gage and pour 16 fluid ounces (1 pint) of

water into the can (A 16oz. soft drink bottle

Inspect the operation of the anemometer and

windvane bearings at least once a year. They

should move freely and react to a windspeed of

2-3 mph. Check the windvane by manually

positioning it and verifying the reading.

Components requiring replacement due to

normal wear are the precision ball bearings and

the azimuth potentiometer. The bearings have

a life expectancy of twenty million revolutions (3

to 5 years in normal use). This time may be

reduced to 1 year or less in high wind areas.

The anemometer bearings should be replaced if

they become noisy or if the starting threshold

increases above an acceptable level.

CAUTION: DO NOT use WD-40 or other

lubricants on the bearings.

4-1

Page 32

SECTION 4. MAINTENANCE

4.5 TEMPERATURE AND RELATIVE

HUMIDITY PROBE

The HMP35C Probe requires minimal

maintenance. Monthly, check to make sure the

radiation shield is free from debris. The screen

on the sensor should also be checked as often.

Annually, check the calibration of the probe. (It

should be sent to CSI if recalibration is needed

and facilities to do so are unavailable.)

4.6 BATTERY VOLTAGE

The battery voltage is recorded daily. The

battery should be recharged when the voltage

is below 11 volts. Incorrect battery voltage

readings occur when the battery is low.

Weather stations charging with AC power

should check the charging source, transformer,

or regulating circuit if the voltage readings are

12 volts or less. A normal charging voltage is

around 13.5 volts.

4-2

Page 33

SECTION 5. TROUBLE SHOOTING

The weather station is divided into sensors and the CR10 datalogger for trouble shooting purposes.

Appendix B contains sensor specifications and schematics.

5.1 SENSOR TROUBLE SHOOTING

The *6 Mode is used to display current sensor

readings (Section 2.7). If an individual sensor

reading is incorrect, the sensor circuit should be

checked with a VOM (Volt/OHM meter).

Appendix B provides wiring schematics of each

sensor. All sensors, except for the rain gage,

have a measurable resistance. Infinite

resistance indicates an open circuit.

NOTE: DO NOT connect an Ohm meter to

the temperature and relative humidity

probe.

Wind Speed

The resistance of the coil measured between

pins 1 and 2 should be between 1100 - 1400

ohms. Infinite resistance indicates the coil is

broken; zero resistance indicates a short. Open

the sensor and check for moisture or pinched

wires.

Wind Direction

Solar Radiation

The solar radiation sensor should measure

between 60 and 100 ohms when the sensor is

dark. Check for an open circuit.

Temperature and Relative Humidity (RH)

If you are experiencing problems with the

temperature and relative humidity probe,

consider the following:

1. Are both the temperature AND the relative

humidity readings bad? If so, make sure

the radiation shield and sensor endcap are

free from debris.

2. Is just the temperature reading bad?

Again, make sure the radiation shield and

sensor endcap are free from debris.

3. Is just the relative humidity reading bad? In

this case, the probe needs to be

recalibrated. (Contact CSI if facilities to

recalibrate are unavailable.)

The resistance between pins 1 and 2 of the

windvane varies from 1 - 11 kohms for a 0-355o

direction. A 5o open or "dead" band exists at

355o. The wiper in the potentiometer is most

likely damaged if infinite resistance is

measured.

The resistance between pins 1 and 3 should

always be 10K ohms. Infinite resistance

indicates the potentiometer is open and should

be replaced.

Rain Gage

The rain gage has a reed switch that closes as

the bucket tips. Connect the ohm meter to pins

1 and 2 and tip the bucket very slowly. The

meter display will flutter momentarily as the

switch contacts close then reopen. Lack of

contact indicates the reed switch should be

replaced.

4. If 1,2 and 3 prove to be ineffective, contact

CSI.

5.2 DATALOGGER TROUBLE

SHOOTING

The CR10 (1) measures the sensors, (2)

converts the measurements to engineering

units, (3) processes the values over a time

interval and (4) stores the processed result. If

stored data is incorrect, evaluate the current

measurements directly using the CR10KD

Keyboard Display (Section 2.7).

False battery readings of 9 to 10 volts can be

observed in the *6 Mode (*6A, Section 2.7) if

the battery voltage falls to 8 volts. If the sensor

readings are unreasonable, yet the sensors

check out according to Section 5.1, measure

the battery voltage independently (Figures 2.5-1

and 2.5-2). Check the charging system if the

system has one.

5-1

Page 34

SECTION 5. TROUBLE SHOOTING

The CR10 has a regulated 5 volts which can be

measured at the serial I/O connector (Figure

2.6-2) using the VOM. Figure 5.2 represents

the connector. The 5 volts, ñ1 millivolt, is

measured between sockets 1 (+5V) and 2

(ground). Insert a bent paper clip or similar

object into each socket to provide solid

connections to the VOM.

High internal moisture will short connections to

the datalogger, resulting in erroneous

measurements. Refer to Section 4 for action to

be taken.

.G.MRK370.PLT;2.5";1.67";HPGL

FIGURE 5.2. CR10 Serial I/O Connector

5-2

Loading...

Loading...