Page 1

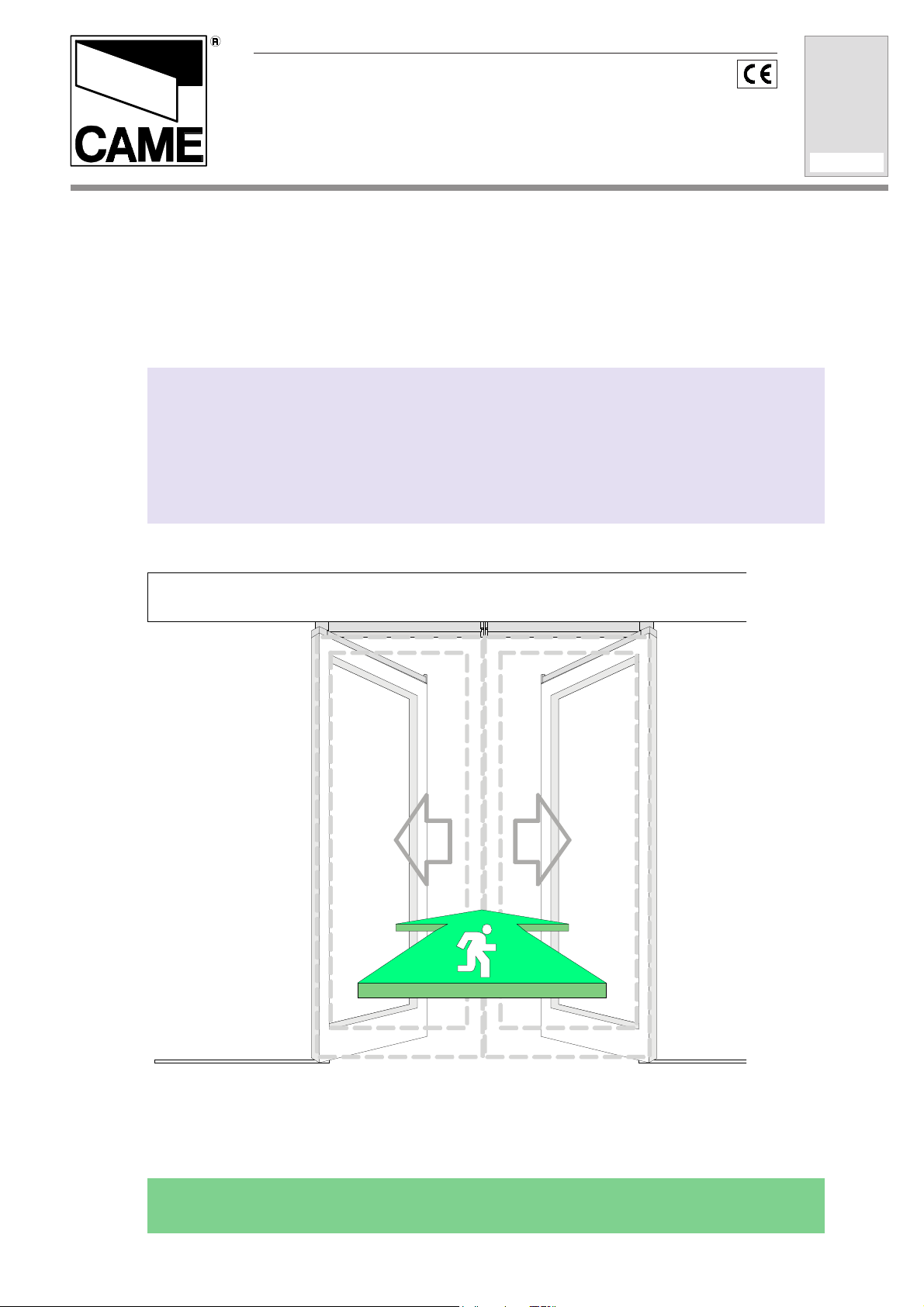

CANCELLI AUTOMATICI

AUTOMATIC DOORS

ANTIPANIC BREAKTHROUGH SYSTEM

ONLY FOR MOBILE DOORS

DEDE

ARMOIRESARMOIRES

ARMOIRES

ARMOIRESARMOIRES

SCHALTTAFEL

CUADROSCUADROS

CUADROS

CUADROSCUADROS

DE

DEDE

DEDE

DE

DEDE

COMMANDECOMMANDE

COMMANDE

COMMANDECOMMANDE

MANDOMANDO

MANDO

MANDOMANDO

CTRIC CONTROL PANELS

MI

10

20

MI6010 - 6110

MI6020 - 6120

COMPLETE MECHANICAL ENSEMBLE

to be applied on sliding opening frames.

In emergencies, it allows the OPENING of the ESCAPE EXIT

by BREAKING THROUGH THE DOORS.

Documentazione

Tecnica

M85

rev. 2.0

03/2003

©

CAME

CANCELLI

AUTOMATICI

119PM85-GB

Up to 120 kg per door

Page 2

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

pg. 3

pg. 4

pg. 5

pg. 8÷13

pg. 16÷19

pg. 20

pg. 21/22

pg. 23

- Operation and Use Limits

- Type of MI Antipanic System

- What the MI Package Contains

MI

FOR

COMMERCIAL

SERIES

- Section types and special instructions for door construction

MI

FOR CAME

S40

SERIES

- Section Types

- MI Antipanic Bar Machining

- Mounting of MI Antipanic System

- Spiral cable application and mobile door mounting

pg. 24

- Power connections

- pg. 2 -

Page 3

OPERATION and USE LIMITSOPERATION and USE LIMITS

OPERATION and USE LIMITS

OPERATION and USE LIMITSOPERATION and USE LIMITS

Sliding door INTERNAL MOUNTING solution:

Antipanic breakthroughs are successful only IF THE DOOR

IS FULLY CLOSED, not during movement.

The sliding door's operation can be restarted simply by moving

the door/doors to the side.

ESTERNO

locale da evacuare

INTERNO

locale da evacuare

Sliding door EXTERNAL MOUNTING solution:

Complete antipanic breakthrough can be achieved NO

MATTER WHAT POSITION THE SLIDING DOORS ARE

IN during movement;

This is the preferred solution to fully exploit the characteristics

of the antipanic breakthrough system.

Also in this case the sliding door's operation can be restarted

simply by moving the door/doors to the side.

ESTERNO

locale da evacuare

INTERNO

locale da evacuare

For MI6010 and MI6020 (door width of up to 1100 mm),

the maximum weight for each door indicated can be increased

by attaching a sliding wheel on the ground (part. P4173, pages

5 & 13).

WARNING: if the P4173 sliding wheel is added, the

adequate linearity of the plane on which it must turn must be

ensured.

EMPLOYMENT LIMITS

htdiW A

)mm(

ELGNIS

ROOD

htiW ASROC

citamotua

metsys

005 57 021

006 57 09

007 57 08

008 06 07

009 05 06

0001 54 05

0011 04 04

ehtfognitnuomehT 3714P sileehw

yrotadnamrevohtiw 0011 otpudna

0051 (mm 0216IM/0116IM .)

repdettimda

ROODELGNIS

htiW OEDOR

)gk(thgiew.xaM

citamotua

metsys

- pg. 3 -

Page 4

Types of MI Antipanic SystemsTypes of MI Antipanic Systems

Types of MI Antipanic Systems

Types of MI Antipanic SystemsTypes of MI Antipanic Systems

COMPLETE ANTIPANIC BREAKTHROUGH

SYSTEM

FOR

1 SLIDING DOOR

A

MOUNTING FROM

INSIDE THE

ROOM TO BE

EVACUATED

with A up to 1100 mm = MI6010

with A up to 1500 mm = MI6110

MOUNTING FROM

INSIDE THE

ROOM TO BE

EVACUATED

MOUNTING FROM

OUTSIDE THE

ROOM TO BE

EVACUATED

COMPLETE ANTIPANIC BREAKTHROUGH

SYSTEM

FOR

2 SLIDING DOORS

- pg. 4 -

MOUNTING FROM

OUTSIDE THE

ROOM TO BE

EVACUATED

A

A

with A up to 1100 mm = MI6020

with A up to 1500 mm = MI6120

Page 5

Antipanic breakthrough kit componentsAntipanic breakthrough kit components

Antipanic breakthrough kit components

Antipanic breakthrough kit componentsAntipanic breakthrough kit components

ANTIPANIC SYSTEM FOR MOBILE DOOR

HOOKING PLATES TO CARRIAGES

Art. P4116

FIXED UPPER SECTION

Art. PM339A

UPPER JOINT

Art. PM209

Art. PM208

Art. PM207

Art. PM205

FIXING SUPPORT

Art. PM576

SLIDING TUBE

Art. TB57

CONTACT CAPS

Art. P4117

OPENABLE LOWER SECTION

Art. PM338A

SPIRAL CABLE

Art. PM923

ANTIPANIC SPRING LATCH

Art. PM909

+PM910

+PM913

Art. PI405

RIP CORD 2X0,5

NYLON YARN

Art. FN930

COUPLING

SUPPORT

Art. PL564

Art. C7039

TERMINAL

LOWER HINGE FOR MOBILE DOOR

LOWER HINGE

MOBILE DOOR

Art. PM912

FLOOR GUIDE

Art. PM911A

MI6010/6110 represented; in

MI6020/6120 the components are

doubled.

SLIDING WHEEL

WARNING!It is a standard piece in all

set and it must be used in

applications in which the size of the

doors is not observed.

See pg. 3.

ANTE MOBILIANTE MOBILI

ANTE MOBILI

ANTE MOBILIANTE MOBILI

Art. P4173

GUIDE STOP

Art. PL593

- pg. 5 -

Page 6

This page left intentionally blank

- pg. 6 -

Page 7

MI System

applied to

commercial series

of sections for

automatic sliding doors

The sections, sizes, weather strip and everything else

mentioned in the following pages as

purely indicative and appear solely for the purpose of illustrating

the applicability of the MI system on sliding doors with frames

other than our series S40 type.

commercial series

are

- pg. 7 -

Page 8

istruzioni di montaggio per istruzioni di montaggio per

istruzioni di montaggio per

istruzioni di montaggio per istruzioni di montaggio per

SERIE COMMERCIALISERIE COMMERCIALI

SERIE COMMERCIALI

SERIE COMMERCIALISERIE COMMERCIALI

Our MI antipanic breakthrough series have been designed to be applied even on

sliding doors built with any type of adequately adapted commercial series.To this

purpose, the following pages contain the necessary measurements and/or notes

to plan and resize the doors.

Preliminary Notes:

- The preparation of the doorframes must allow the insertion of the hinge pins; it is

recommended that the faced and fixed cross members be mounted with U-bolts;

- Upper and lower hinging alignment must be axial.

- Pay attention to how the hinge elements are attached to the structure. They should be fixed

rigidly in order to avoid that with time vibrations and movement limit efficiency and make the

system unsafe for users;

- If the structure is not strong enough, the assembler must reinforce it.

- Upper and lower hinges must be aligned axially.

- Only in case of mobile doors, it is recommended that the glass be firmly set with silicone

sealant in addition to any other types of weather strip.

- Only stratified or tempered glass should be used.

MOBILE DOORS:

- Resize the length of the upright and cross sections according to the size of the sections

used- follow indications on pages 9÷13;

- Fasten the elements that make up the antipanic system for mobile doors.

- If necessary, insert the "wheel" device (art. P4173). See pg. 3.

ANTIPANIC BAR

- Cut sections PM339A and PM338A and chamfer and bore holes in section PM338A as

indicated on page 20.

- Apply the bar on the mobile door, mount the spiral cable and finish mounting the doors on the

Corsa or Rodeo beam, adapting the instructions for the S40 series on pages 21-23.

- Carry out the power connections and checks as indicated on page 24.

MAKE SURE THE BREAKTHROUGH SIDE IS THE CORRECT ONE AND THAT THE ANTIPANIC SYSTEM FOR

MOBILE DOORS IS COMPLETE BEFORE PERFORMING ANY MACHINING WORK!

- pg. 8 -

Page 9

Vertical section with COMMERCIAL SERIESVertical section with COMMERCIAL SERIES

Vertical section with COMMERCIAL SERIES

Vertical section with COMMERCIAL SERIESVertical section with COMMERCIAL SERIES

MOUNTING FROM INSIDE THE ROOM TO BE EVACUATED

127

29

151

169

LC00

13

±6

9

80

43

MOUNTING FROM OUTSIDE THE ROOM TO BE EVACUATED

135

29

151

195

LD00

13

±6

80

43

40

9

40

BREAKTHROUGH

DIRECTION

INSIDE THE ROOM TO BE EVACUATED

D

Y

H

C

M

BREAKTHROUGH

DIRECTION

INSIDE THE ROOM TO BE EVACUATED

Y

H

M

15

15

LEGEND

H = wall opening heigh

Y = Corsa/Rodeo beam fixing height:

with LC00 = H + 18*

with LD00 = H + 44*

M = sliding door height** = Y -108

C/D = Height under beam box = H

* these measurements allow net light continuity at the

passage between indoors and outdoors (H = C/D);

**Other specific dimensions are not provided for the

mobile door. Please refer to the door supplier's

documentation.

The use of LC00 or LD00 does not affect the choice of

mounting solution (inside or outside); even the Y fixing

height can be adapted to individual needs, as long as

the other formulas are also adapted.

- pg. 9 -

Page 10

Horizontal sections with the COMMERCIAL SERIESHorizontal sections with the COMMERCIAL SERIES

Horizontal sections with the COMMERCIAL SERIES

Horizontal sections with the COMMERCIAL SERIESHorizontal sections with the COMMERCIAL SERIES

MOUNTING FROM INSIDE THE ROOM TO BE EVACUATED

MI6010 / MI6110

LC00

LD00

Vsf

BREAKTHROUGH

DIRECTION

L

6

min

29 ±6

INDOOR ROOM TO BE AVACUATED

A

BREAKTHROUGH

DIRECTION

LC00

LD00

LEGEND

L = wall opening width

Vsf = Width of passage created with breakthrough

A* = Sliding door width

MI6020 / MI6120

L

Vsf

* Use MI6010 or MI6020 with A up to 1100;

use MI6110 or MI6120 with A up to 1500.

BREAKTHROUGH

DIRECTION

A

INDOOR ROOM TO BE EVACUATED

- pg. 10 -

Page 11

Horizontal sections with the COMMERCIAL SERIESHorizontal sections with the COMMERCIAL SERIES

Horizontal sections with the COMMERCIAL SERIES

Horizontal sections with the COMMERCIAL SERIESHorizontal sections with the COMMERCIAL SERIES

MOUNTING FROM OUTSIDE THE ROOM TO BE EVACUATED

MI6010 / MI6110

LD00

LC00

A

BREAKTHROUGH

DIRECTION

Vsf

L

29 ±6

INDOOR ROOM TO BE AVACUATED

LD00

LC00

BREAKTHROUGH

DIRECTION

LEGEND

L = wall opening witdth

Vsf = Width of passage created with breakthrough

A* = Sliding door width

MI6020 / MI6120

Vsf

L

* Use MI6010 or MI6020 with A up to 1100;

use MI6110 or MI6120 with A up to 1500.

A

BREAKTHROUGH

DIRECTION

INDOOR ROOM TO BE AVACUATED

- pg. 11 -

Page 12

COMMERCIAL SERIES mounting instructionsCOMMERCIAL SERIES mounting instructions

COMMERCIAL SERIES mounting instructions

COMMERCIAL SERIES mounting instructionsCOMMERCIAL SERIES mounting instructions

HINGING OF

MOBILE DOORS

Art. PM208

Art. PM207

Art. PM205

80 25 85 80

22

50

190

Art. PM339A

Art. PM338A

70 69 69 200 max

Thickening and reinforcing

the frame to be sized and

positioned are care of the

constructor.

Art. PM306

Art. PM911A Art. PL593

25 56

11

OUTSIDE MOUNTINGOUTSIDE MOUNTING

OUTSIDE MOUNTING

OUTSIDE MOUNTINGOUTSIDE MOUNTING

69

Art. MAM002*

- pg. 12 -

*MAM002 is simply a finishing accessory

that may be replaced with any other type of

finish the constructor chooses, even if it

requires a larger section of the door's

upright.

INSIDE MOUNTINGINSIDE MOUNTING

INSIDE MOUNTING

INSIDE MOUNTINGINSIDE MOUNTING

Page 13

COMMERCIAL SERIES mounting instructionsCOMMERCIAL SERIES mounting instructions

COMMERCIAL SERIES mounting instructions

COMMERCIAL SERIES mounting instructionsCOMMERCIAL SERIES mounting instructions

- MOBIL DOORS-

FRONTAL MATCH

Art. PM339A

Art. PM338A

200 max

Art. PM909

+PM910

Art. P4117

10

+PM913

200 max

When sizing sections PM339A and PM338A, pay attention to

the type of finish for the door in order to correctly align all

components.

SLIDING WHEEL - OPTIONAL

9

60

WARNING!!!

Art. P4173

Sliding surfaces presenting

irregularities or furrows affect the

proper operation of this element.

83

1 ÷ 3

Place the wheel at a sufficient distance so as to avoid contact with the

ground during the sliding door's opening, but not too far as this would hinder

easy rehooking.

143

5

- pg. 13 -

Page 14

This page left intentionally blank

- pg. 14 -

Page 15

MI System

Applied to our section series

for S40

automatic sliding doors

The following two pages have only some application examples

with our sections; for a complete series of the construction

types, heights and construction parts for the creation of these

doorframes, please refer to the technical documentation of

the S40 series.

- pg. 15 -

Page 16

S40 series - sectionsS40 series - sections

S40 series - sections

S40 series - sectionsS40 series - sections

MOUNTING FROM INSIDE THE ROOM TO BE EVACUATED

LC00

13

80

53

65

H

L

Vsf

M15

BREAKTHROUGH

DIRECTION

INDOOR ROOM TO BE AVACUATED

- pg. 16 -

BREAKTHROUGH

DIRECTION

LEGEND

H = wall opening height

L = wall opening width

Vsf = Width of passage created with breakthrough

M = sliding door height

INDOOR ROOM TO BE AVACUATED

A

A* = sliding door width

* Use MI6010 or MI6020 with A up to 1100;

use MI6110 or MI6120 with A up to 1500.

Page 17

S40 series - sectionsS40 series - sections

S40 series - sections

S40 series - sectionsS40 series - sections

MOUNTING FROM INSIDE THE ROOM TO BE EVACUATED

LD00

44

4

H

L

Vsf

80

M15

BREAKTHROUGH

DIRECTION

INDOOR ROOM TO BE EVACUATED

BREAKTHROUGH

DIRECTION

LEGEND

H = wall opening height

L = wall opening width

Vsf = Width of passage created with breakthrough

M = Mobile door height

BREAKTHROUGH

DIRECTION

A

INDOOR ROOM TO BE AVACUATED

A* = Sliding door width

* Use MI6010 or MI6020 with A up to 1100;

use MI6110 or MI6120 with A up to 1500.

- pg. 17 -

Page 18

S40 series - sectionsS40 series - sections

S40 series - sections

S40 series - sectionsS40 series - sections

MOUNTING FROM OUTSIDE THE ROOM TO BE EVACUATED

LC00

13

80

53

M15

BREAKTHROUGH

DIRECTION

INDOOR ROOM TO BE EVACUATED

A

H

- pg. 18 -

BREAKTHROUGH

DIRECTION

81

LEGEND

H = wall opening height

L = wall opening width

Vsf = Width of passage created with breakthrough

M = Mobile door height

L =Vsf

INDOOR ROOM TO BE EVACUATED

A* = Sliding door width

* Use MI6010 or MI6020 with A up to 1100;

use MI6110 or MI6120 with A up to 1500.

Page 19

S40 series - sectionsS40 series - sections

S40 series - sections

S40 series - sectionsS40 series - sections

MOUNTING FROM OUTSIDE THE ROOM TO BE EVACUATED

LD00

44

80

H

BREAKTHROUGH

DIRECTION

INDOOR ROOM TO BE EVACUATED

15 M

A

BREAKTHROUGH

DIRECTION

LEGEND

H = wall opening height

L = wall opening width

Vsf = Width of passage created with breakthrough

M = Mobile door height

BREAKTHROUGH

DIRECTION

L = Vsf

A* = Sliding door width

* Use MI6010 or MI6020 with A up to 1100;

use MI6110 or MI6120 with A up to 1500.

INDOOR ROOM TO BE EVACUATED

- pg. 19 -

Page 20

ANTIPANIC BAR machiningANTIPANIC BAR machining

ANTIPANIC BAR machining

ANTIPANIC BAR machiningANTIPANIC BAR machining

Wl + 50

1

2

2

45°

42

111

180

bore a ∅7 hole with a 200 max pitch

- Take out the PM339A (1)

and PM338A (2) upper and lower

hooking sections from the

package and remove the parts

inserted into them.

- Cut them to the proper

length using the indicated formula.

- Correctly evaluate the

breakthrough side of the doors and

work the lower section (2) as in

the illustration **. .

** The illustration shows the

work that must be performed on

the left door. The right door will

require mirror-image work.

- pg. 20 -

BREAKTHROUGH

DIRECTION

INDOOR ROOM TO BE EVACUATED

SX

DX

BREAKTHROUGH

DIRECTION

INDOOR ROOM TO BE EVACUATED

Page 21

S40 series - ANTIPANIC BAR application on MOBILE DOORSS40 series - ANTIPANIC BAR application on MOBILE DOORS

S40 series - ANTIPANIC BAR application on MOBILE DOORS

S40 series - ANTIPANIC BAR application on MOBILE DOORSS40 series - ANTIPANIC BAR application on MOBILE DOORS

PM205

1

4

MAL226 section for

outside application

PM912

PM207

A

UNI5931

M8x40

6

2

MAL227 section for

inside application

B

PM338A

C

D

MAMF002

A - Insert the PM205 upper pin and PM912 lower pin in the MAL226 back upright section and screw on with

screws provided in the holes indicated. Correctly align to the section before screwing on.

B - Assemble the joint parts to the jutting pin. Temporarily fasten M8X40 hooking screw.

C - Insert the PM338A lower section to the PM207 lower joint, making sure the breakthrough side is facing

the right way.

D - Match the two elements together (loosen M8X40 screw if necessary), align the door and bore a ∅ 4.5

hole matching the holes previously bored on the PM338A section and screw with ∅ 5.5 self-tapping

screws. The two edge screws will be screwed onto the MAMF002 edge elements (doorframe fixing

squares) to ensure more stability when fastening.

- pg. 21 -

Page 22

E

F

8

UNI5933

M12x25

S40 series - ANTIPANIC BAR application on MOBILE DOORSS40 series - ANTIPANIC BAR application on MOBILE DOORS

S40 series - ANTIPANIC BAR application on MOBILE DOORS

S40 series - ANTIPANIC BAR application on MOBILE DOORSS40 series - ANTIPANIC BAR application on MOBILE DOORS

4

PM208

P4117

P4116

1

PM339A

PM338A

PM339A

3

2

-

SPRING LATCH, MOVE IT TOWARD THE

MAM002

+

TO MODIFY THE ACTION OF THE

CENTRE OF THE SECTIONS

SPRING LATCH

G

E - Screw the M12X25 coupling screw and retighten the hooking screw (if necessary). Insert the PM339A

upper section on the PM208 upper joint and screw on the socket head screws provided.

Correctly align to the section before screwing.

F - Insert the two P4116 hooking plates (to attach to carriages) to the PM339A upper section and insert the

closing spring latch to the PM228A lower section, temporarily placing it at 5-8 cm from the edge.Prepare

the P4117 contact caps, making a bridge over the lower one and connecting the 2x0.50 bipolar cable to

the upper one (for connection to the "closed doors" control circuit). Close the two sections with the two

caps and thread the cable through the upper section until it reaches the other end (next to the joint).

G - For doors mounted from the outside, mount the MAM002 finish sector with the screws provided.

** In case of doors with irregular dimensions (see table on page 3), insert the P4117 sliding wheel as

indicated on page 13.

- pg. 22 -

Page 23

SPIRAL CABLE application and MOBILE DOOR mountingSPIRAL CABLE application and MOBILE DOOR mounting

SPIRAL CABLE application and MOBILE DOOR mounting

SPIRAL CABLE application and MOBILE DOOR mountingSPIRAL CABLE application and MOBILE DOOR mounting

- Apply the PL564 couplings to the beam (two at opposite edges if CORSA1 or RODEO1;

one at the centre and two at opposite edges if CORSA2 or RODEO2).

- Insert the coupling in FN930 nylon cable and fasten one end with the C7039 terminal. On

the other end, in sequence, attach:

a) a PM576 support with the TB57 sliding tube.

b) A PM923 spiral cable sized according to sliding length (extension

admitted is 20% as opposed to the coiled cable).

c) Thread through the central coupling and repeat a) and b)

sequences for the second door (only for CORSA2 and

RODEO2).

- Then insert the opposite coupling's nylon cable

and fasten with the terminal.

13

TB57

PM576

PM923

PL564

4

4

FN930

C7039

8

- Apply the door/doors' carriages as indicated in the CORSA or RODEO

technical sheets and insert the door/doors in the beam.

- Check the sliding movement and then align and fasten the PM576

connection supports to the appropriate carriages. Verify the correct

sizing of the spiral cable, close its ends with the clamps provided and

electrically connect the ends as shown in the electric diagram on the

next page.

- Similarly, size and connect the 2X0.50 bipolar connection cable to the

contact caps previously threaded through the door's structure.

- Lastly, set the PM911A guide to the ground as illustrated on page 12.

- pg. 23 -

Page 24

Power connectionsPower connections

Power connections

Power connectionsPower connections

Remove the 1-2 contact bridge

CONTROL BOARD

1

1,6 A

2345678

1

12345678910

1234

2

Spiral cables

3

3

Contact caps

Contact bridge

4

Contact bridge

4

CONNECTION SEQUENCE

The connection sequence creates a series of closed contacts with the doors in normal sliding

operating position. Breaking through either door will cause the opening of the series, immediately

arresting the sliding movement.

1 - remove the "total stop" bridge from terminals 1-2

2 - connect the terminals in the connection terminal board to the spiral cables.

3 - connect the spiral cables from the terminal board to the carriage terminals and from these to

the upper contact cap

4 - connect the contacts of the lower contact cap.

Checks

- Check that the caps' contacts are aligned in the reinforced door position.

- Check the conduction of the connection heads to terminals 1-2 with an ohm tester.

Note: If the antipanic system and an automatic (CORSA or RODEO) door are ordered together,

part of the connections described and the application of the spiral cables will have already been

done.The installer will only need to connect the magnetic contacts and the mobile doors.

The data contained in this booklet is indicative. Came Cancelli Automatici S.p.A. reserves the right to make changes according to the product's

technological evolution.

ASSISTENZA TECNICA

NUMERO VERDE

800 295830

W

www.came.it

E-MAIL

CANCELLI AUTOMATICI

CAME CANCELLI AUTOMATICI S.P.A.

(+39) 0422 4940 (+39) 0422 4941

info@came.it

DOSSON DI CASIER (TREVISO)

EB

SISTEMA QUALITÀ

CERTIFICATO

CAME LOMBARDIA S.R.L.______COLOGNO M. (MI)

(+39) 02 26708293 (+39) 02 25490288

CAME SUD S.R.L. ___________________NAPOLI

(+39) 081 7524455 (+39) 081 7529109

CAME (AMERICA) L.L.C.____________MIAMI ( FL)

(+1) 305 5938798 (+1) 305 5939823

CAME AUTOMATISMOS S.A__________MADRID

(+34) 091 5285009 (+34) 091 4685442

CAME BELGIUM__________________LESSINES

(+32) 068 333014 (+32) 068 338019

CAME FRANCE S.A.____NANTERRE CEDEX ( PARIS)

(+33) 01 46130505 (+33) 01 46130500

CAME GMBH________KORNTAL BEI ( STUTTGART)

(+49) 07 15037830 (+49) 07 150378383

CAME GMBH____________SEEFELD BEI ( BERLIN)

(+49) 03 33988390 (+49) 03 339885508

CAME PL SP.ZO.O______________WARSZAWA

(+48) 022 8365076 (+48) 022 8369920

CAME UNITED KINGDOM LTD___NOTTINGHAM

(+44) 01159 9210430 (+44) 01159 9210431

Loading...

Loading...