Page 1

Gateline

OPERATOR

FOR SWING GATES

Installation manual

FA40230-FA40230CB

English

N

Gateline

119DW02EN

Page 2

p.

2

2 - M anual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

Index

General safety instructions 3

Legend 4

Description 4

Packing list 4

Intended use 4

Operational limits 4

Technical data 4

Dimensions 5

Main component parts 5

System feasibility 6

Preliminary checks 6

Tools and equipment 6

Types and thickness of cables 6

Standard installation 7

Application examples 7

Installation 8

Laying the corrugated tubing and fastening the brackets 8

Installing the gearmotor and transmission arms 10

Mounting the mechanical endstops (if no mechanical strike plates are included) 11

Adjusting the limit switches 13

Manual release override and blocking of the gearmotor 15

Command and control electronics 16

Description 16

Main component parts 16

LED signal light 17

Electrical connections 18

Power supplies 18

Warning devices 18

Command devices 19

Gearmotor with encoder 20

Photocells 22

Sensitive safety edges 22

Electrical connection for operating the photocell's safety test 23

Settings and adjustments 23

Programming 24

Memorising data 24

Description of programming commands 24

Menu map 25

Motor test and calibrarion menu 26

Features menu 27

Users menu 32

Info menu 32

Adding user with associated command 33

Cancelling one user 33

Motor test 34

Calibrating travel 35

Error messages 36

Safety instructions 36

Maintenance 37

Periodic maintenance 37

Extraordinary maintenance 37

Dismantling and disposal 38

CE Dec

laration 39

Page 3

p.

3

3 - M anual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

General safety instructions

WARNING!

important safety instructions:

READ THIS PART CAREFULLY!

Introduction

• This product is only intended to be used for the purpose it was designed. Any

other use is therefore improper and dangerous. La CAME Cancelli Automatici

S.p.A. is not liable for any damage due to improper, erroneous and unreaso-

nable use • Keep these warnings together with the installation and users'

manual for the automation system.

Before installing

(check what's there: if the outcome is negative, refrain from continuing until

you are compliant with safety standard)

Check that the part being automated is in proper working order, that it is ba-

lanced and aligned, and that it opens smoothly. Make sure you have suitable

mechanical stops. If the operator will be installed less than 2.5 m from the

fl oor or from any other access level, check whether you need additional pro-

tections and/ or warnings. With pedestrian doors framed into the doors that

will be automated, a system must be in place to block their opening during

movement. Make sure the opening of the automated door leaf does not cause

any trapping situations involving any surrounding fi xed parts. Do not install the

operator upside down or on any elements that may bend. If necessary, add

suitable reinforcements at the fastening points. Do not fi t onto door leafs that

are installed on a slope, only on level ground. Check that any watering devices

cannot wet the gearmotor from the bottom upwards.

Installation

Properly demarcate the entire site to prevent any unwanted access by unau-

thorised personnel to the working area, especially children and minors. Be

careful when handling operators that weigh more than 20 kg (see installation

manual). If needed, use specifi c safety moving equipment. All opening com-

mands (buttons, key switches, magnetic card readers, etc.) must be installed

at least 1.85 M from the gate's area of movement, or so that they are unrea-

chable from the outside. Also, the direct commands (button or touch) must be

installed at least 1.5 m high and not reachable by the public. All "maintained

action" commands must be placed where the moving door leaves and transit

areas are completely visible. If missing, a x a permanent tag showing the

position of the release device. Before delivering to the end user, check that the

operator complies with Standard EN 12456 (impact testing), making sure the

operator is properly set and adjusted and that all safety and protection devices

and manual release work properly. A x the Warning Signs in places that are

clearly visible, where necessary (such as the gate tag).

Instructions and special recommendations for users

Keep gate-operating are free of any obstacles. Keep the photocells' range of

operation free of vegetation. Do not allow children to play with the fi xed com-

mand devices, or in the area of operation of the gate. Keep the remote control

devices (transmitters) away from children. Check the system frequently, for

any anomalies and signs of wear and tear or damage to the mobile structures,

the component parts of the operator, all fastening points and devices, the cable

and any accessible connections. Keep any jointed parts like hinges lubricated

and clean of debris and the guide-sleds free of any friction. Perform functional

checks to the photocells and sensitive edges every six months. Ensure proper

cleaning of the glass on the photocells (use a slightly damp cloth); do not use

solvents or other chemical products). If repairs or changes to the system set-

tings become necessary, release the operator do not use it until all safety con-

ditions are restored. Cut the main power supply before releasing the operator

to perform manual openings. Check the instructions. It is FORBIDDEN for users

to perform ANY OPERATIONS THAT ARE NOT EXPRESSLY REQUESTED OF SAID

USERS in the manuals. For repairs, changes to the settings and extra-ordinary

maintenance, CALL FOR TECHNICAL ASSISTANCE. Enter any interventions in

the periodic maintenance log.

Special instructions and recommendations for everyone

Keep away from the hinges and any moving mechanical parts. Stay out of the

operating range of the operator while it is moving. Do not oppose the move-

ment of the operator as this may result in danger. Always be careful around

the dangerous parts, which must be properly indicated with warning signs and

black and yellow stripes. When using a selector switch or a maintained-action

mode command, keep checking that no persons come within the operating

range of the moving parts, until the command is released. The gate may move

at any moment without warning. Always cut o the main electric power supply

before performing any cleaning or maintenance.

Page 4

#

#

p.

4

4 - M anual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

Legend

Technical data

Description

Intended use

Operational limits

Packing list

The complete range:

001

FA40230 - Self-locking gearmotor with articulated transmission arm for leaves up to 2.3 m;

001FA40230CB - Self-locking gate-operator with built-in control panel complete with articulated transmission arm for gate leaves of up to 2.3 m.

Optional accessories:

001FA001 - LED card;

001LOCK81 - Single cylinder release electro-lock;

001LOCK82 - Double cylinder release electro-lock;

001STYLO-BD - Straight transmission arm with slide guide;

001H3000 - Safety casing complete with release toggle and command button for the L = 5 m. pull-cord release.

Important! Make sure that the command and safety equipment and accessories are CAME originals; this will ensure easy installation and maintenance

of your system.

This operator is engineered and built by Came Cancelli Automatici S.p.A. in compliance with current safety regulations, to automate residential and aparment building siwng-gates.

Any installation or use other than that indicated in this manual is forbidden.

Model FA40230 - FA40230CB

Maximum leaf length 2.3 m 2 m 1.5 m 1 m

Maximum leaf weight 200 kg 215 kg 250 kg 300 kg

This symbol means parts must be read carefully.

This symbol means the parts describe safety issues.

This symbol tells you what to notify to the user.

Gearmotor

ate bracket

T

ransmission

arms

Mechanical

end stops

FA40230CB FA40230

Power supply 230 V AC 50/60 Hz

Mot

or power supply 230 V AC 50/60 Hz 230 V AC 50/60 Hz

Maximum draw. A 1.4 A 1.4

Power rating 160 W 160 W

Maximum Torque. 180 Nm 180 Nm

Opening time at 90° 18 S 18 S

Duty cycle 30% 30%

Protection rating IP54 IP54

Motor heat protection 150°C 150°C

Weight 12,700 kg 10,860 kg

Insulation class I I

x2 UNI 5931 M8x80 bolt

x2 UNI 7474 M8 nut

x1 Ø10 plug

x1 Slow shaft washer

x1 UNI 5739 M10x14 bolt

x2 Arm pin

x2 UNI 6593 Ø6 washer

x2 UNI 5739 M6x10 bolt

x1 UNI 6592 Ø12 washer

x2 UNI 5933 M8x20 bolt

Page 5

4

9

19

14

11

5

12

13

17

8

10

15

16

7

6

14

15

16

18

3

2

20

21

24

22

1

23

200

235

230

173

100

81,5

40

120

60

18

p.

5

5 - M anual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

Main component parts

1. Cover

2. FA40230 gearmotor

3. FA40230CB gearmotor

4. ZF4 electronic board

5. Post-fastening bracket

6. Transmission arm

7. Drive arm

8. Gate-fastening bracket

9. Release hatch

10. Mechanical endstops.

11. UNI5931 M8x80 gearmotor fastening bolts

12. UNI7474 M8 nuts

13. limit-switch adjusting grub screws

14. Arm pin

15. UNI6593 Ø6 washer

16. UNI5739 M6x10 bolt

17. UNI6592 ø12 washer

18. Rubber shim

19. Ø10 plug

20. Slow shaft washer

21. UNI5739 M10x14 bolt

22. FA001 LED card

23. Transmission arm pin

24. Straight arm with 001STYLO-BD slide guide (optional

accessory)

Gearmotor

F

astening bracket

Dimensions

Page 6

p.

6

6 - M anual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

Types and thickness of cables

N.B.: If cables are of a different length than that shown in the table, determine the cable section based on the actual draw and the number of connected

devices and according the what is set forth in the CEI EN 60204-1 code of regulations.

For connections featuring several loads on the same line (i.e. sequential ones), the dimensions shown on the table must be reconsidered according to

the total draw and actual distances. When connecting products not featured in this manual, only refer to the literature accompanying such products.

Connection for Type of cable

Cable length

1 < 10 m

Cable length

10 < 20 m

Cable length

20 < 30 m

230 V power supply to control panel

FROR CEI

20-22

CEI EN

50267-2-1

3G x 1.5 mm

2

3G x 2.5 mm

2

3G x 4 mm

2

Motor powered by 230 V AC 4G x 1 mm

2

4G x 1.5 mm

2

4G x 2.5 mm

2

Flashing light 2 x 0.5 mm

2

2 x 1 mm

2

2 x 1.5 mm

2

Photocell transmitters 2 x 0.5 mm

2

2 x 0.5 mm

2

2 x 0.5 mm

2

Photocell receivers 4 x 0.5 mm

2

4 x 0.5 mm

2

4 x 0.5 mm

2

Safety and command devices 2 x 0.5 mm

2

2 x 0.5 mm

2

2 x 0.5 mm

2

Antenna RG58 max. 10 m

Encoder TWISTED max. 30 m

Before beginning to install, do the following:

S

et up pr

oper omnipolar cut-off device, with more than 3mm of distance between contacts, with sectioned power source;

• Set up proper conduits and electric cable raceways, making sure these are protected from any mechanical damage;

• Set up a drainage tube to prevent stagnation of moisture that can lead to oxydation;

•

Check that any connections inside the container (made for continuity purposes of the protective circuit) be fitted with extra insulation compared

to other internal conductive parts;

• Make sure the gate structure is sturdy enough, that the hinges are efficient and that there is no friction among the fixed and moving parts.

Make sure there are mechanical opening and closing strike plates.

Installation must be carried by skilled, qualified technicians in accordance with current regulations.

Tools and equipment

Make sure you have all the tools and materials needed to carry out the installation in total safety and in accordance with current regulations. The figure

shows some examples of the tools needed by installers.

System feasibility

Preliminary checks

Page 7

6

1

4

2

6

6

6

9

3

5

8

7

7

8

8

p.

7

7 - M anual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

1. FA40230CB Gate Operator

2. FA40230 gearmotor

3. Flashing light

4. Antenna

5. Key switch

6. Photocells

7. Small post for photocells

8. End strike

9. Junction pit-box

Standard installation

Application examples

Page 8

A

E

120 min.

C

47,5

310 max.

200 min.

173

81,5

40

120

100

60

18

p. 88 - Manual code: 119 DW 02119 DW0 2 ver. 2 .02. 0 06/2012 © CAME Cancelli Automatici S.p. A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

Installation

Opening

angle

ACE

90°

140 0÷200 420

160÷180 200 380

110° 200 ÷22 0 0÷ 50 400

Note: the drawings are for installing the left-side gearmotor. Installing the right-side gearmotor is symmetrical.

Determine the most suitable point to fasten the gate bracket while respecting the distances (mm) shown in the drawing on the table below.

The following illustrations are just examples, in that the space for securing the operator and accessories depends on the installation zone. It

is up to the installer to choose the most suited solution.

Set up the necessary corrugated tubing (Ø 25 mm) for connections coming

from the junction pit.

N.B.: the number of tubes depends on the type of accessories featured.

You need to set up two corrugate tubes where the FA40230CB operator will

be installed.

Laying the corrugated tubing and fastening the brackets

Page 9

3

4

7

5

6

5

1

2

p.

9

9 - M anual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

Mark the fastening points for fastening the bracket to the post and for the fastening bracket to the gate. The centre distances of the bracket holes are

shown in the paragraph about dimensions. Drill the fastening hole points, insert the plugs or use suitable inserts to hold the brackets.

Note: the illustrations are indicative. It is up to the installer to decide on the best solution depending on the thickness of the gate wing.

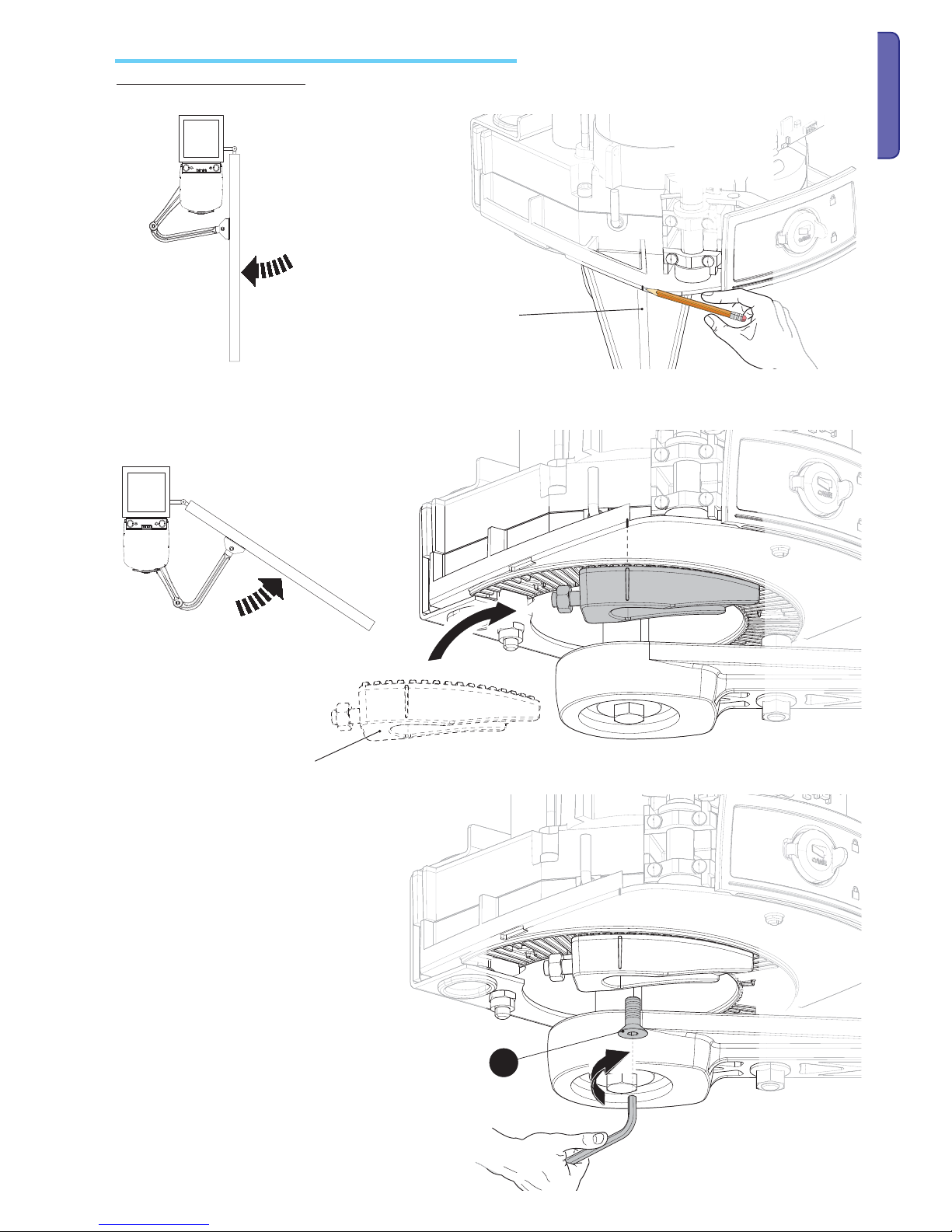

Before installing the operator, remove the gearmotor cover. Remove the cap protecting the release override hatch lock, fi t the key into the lock and turn it

(Π().

Open the ha

tch and turn the screw that fastens the cover to the gearmotor (Ž ().

Lift the cover slightly from the sides ().

Remove the gearmotor fastening bracket ().

F

asten the brackets with suitable screws. Insert the rubber shim into the post fastening bracket.

Page 10

d

e

a

b

f

g

h

f

g

i

h

c

p.

10

10 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

Fit plug into the gearmotor shaft hole. Fasten the transmission arm to the shaft with slow-shaft washer and the bolt .

Fasten the drive arm to the transmission arm with the pin, bolt and washer ().

Release the gearmotor (see paragraph manual release override and block of the gearmotor), fasten the drive arm to the gate bracket as shown in the

drawing().

Set up the required electrical cables threading them through the cable glands and blocking them to the gate post fastening U bracket. Insert the

gearmotor into the bracket and fasten it with nuts and bolts ( ).

Installing the gearmotor and transmission arms

Page 11

j

p.

11

11 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

Mounting the mechanical endstops (if no mechanical strike plates are included)

Manually close the leaf. Insert the mechanical stop as shown. The mark on the case must match the groove on the stop.

Fasten the stop using the bolt .

Mechanical endstop

Centre of the arm

For the opening mechanical endstops .

With the gearmotor released, completely open the leaf, manually. Mark the case near the centre of the arm.

Page 12

j

p.

12

12 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

Manually open leaf. Insert the mechanical stop as shown. The mark on the case must match the groove on the stop.

Fasten the stop using the bolt .

Mechanical endstop

Centre of the arm

For the closing mechanical endstops .

With the gearmotor released, completely open the leaf, manually. Mark the case near the centre of the arm.

Page 13

-

+

-

+

-

+

-

+

p.

13

13 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

Adjusting the limit switches

In the same way, adjust the opening limit-switch by turning the grub screw of the other stop (see drawing).

Adjusting the closing and opening endstop points of left-side gearmotors (internal view).

With the gearmotor released and the gate leaf closed, adjust the closing limit-switch grub screw by turning it either clockwise or anti clockwise. Fasten

the grub screw using the nut (see drawing).

Page 14

-

+

-

+

-

+

-

+

p.

14

14 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

In the same way, adjust the opening limit-switch by turning the grub screw of the other stop (see drawing).

Adjusting the opening and closing endstop points of the right-side gearmotor (internal view).

With the gearmotor released and the gate leaf closed, adjust the closing limit-switch grub screw by turning it either clockwise or anti clockwise. Fasten

the grub screw using the nut (see drawing).

Page 15

1

2

3

5

6

4

3

2

1

5

4

p.

15

15 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

RELEASE - Remove the protective cap from the lock Œ . Insert the trilobe key and turn it anticlockwise . Open the hatch and activate the release override lever Ž .

Manual release override and blocking of the gearmotor

BLOCK - Close the release override hatch . Insert the trilobe key and turn it clockwise . Insert the

protective cap

.

After making the electrical connections and necessary programming, fi

t the cover onto the gearmotor and fasten it . Close the hatch Ž, block the

gearmotor using the key and fi t the protective ca

p .

Note: when fi

tting the cover, be careful with the cable connecting the FA001 card to the electronic card.

Page 16

1

22

2

5

10

12

11

4

13

16

17

18

21

20

19

15

14

6

6

9

3

3

7

8

23

25

24

p.

16

16 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

Description

Main component parts

Command and control electronics

The control panel should be powered by 230 V AC, at 50/60 Hz frequency.

the command devices and accessories are powered by 24 V. The accessories must not exceed 50 W overall.

All connections are protected by quick fuses, see table.

The functions on the entry and exit contacts, the time settings and user management, are all set and viewable on the display which is managed by the

software.

Warning! Before acting on the control panel, cut off

the power supply.

1 Transformer

2 V power supply terminals

3 Transformer terminals

4 Gearmotor terminals

5 Command and safety device terminals

6) Encoder terminals

7 Terminals for transponder-based devices

8 Keypad selector terminals

9 Antenna terminals

10 Electro-lock fuse

11 -Accessories fuse

12 Board fuse

13 Line fuse

14 power on voltage present LED warning light

15 Programming indicator LED

16 Display

17 Programming buttons

18 FA001 board connector

19 Memory roll card connector

20 700 R800 or R800 card connector

21 AF card connector

22 FA001 board

23 4 Connector for connecting to the ZF4 card

24 001 Terminals for connecting the second FA001 card

25 25 LED to signal gate status

FUSE TABLE

Line fuse

5 A-F

Accessories fuse

1.6 A-F

Control unit fuse 630 mA-F

Electro-lock fuse 3.15 A-F

Page 17

p.

17

17 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

LED signal light

- QUICK switching-on

of th

e blue LEDs UPWARDS, signals the

leaves are opening.

- SLOW switching-on of

blue LEDs - UPWARDS,

signals that the leaves

are in opening slow

down.

- Red flashing LEDs 1

and 2, signal encoder

malfunction, call for

assistance.

- Red flashing LEDs 1, 2,

3 and 4, signal that the

normally closed (N.C.)

contacts are open (e.g.

photocells, stop button).

- QUICK switching-on

of the blue LEDs DOWNWARDS, signals

that the leaves are

closing.

- SLOW switchingon of blue LEDs DOWNWARDS, signals

that the leaves are in

closing slow down.

- The CAME logo stays lit

always.

Page 18

24V 12V 0

U V W X Y E

L1T L2T CT

L N

10 11 ES

24V 12V 0

10 11 ES TS 1 2 3 3P 4 5 7 CX CY

U V W X Y E

L2T L1T

1 2 3 4

0 12 24

p.

18

18 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

Electrical connections

Power supplies

Terminals for powering the

24V A

C accessories

Overall allowed power: 50 W

Power supply at 230

V AC, Frequency 50 /

60 Hz

12 V - 15 W max. Electro-lock

FA001 board. Signals the gate movement

and slow down phases, see signal LED light

paragraph.

Gate open warning light (Contact rated for: 24 V - 3 W

Max.). Signals gate status, see feature F 10.

Movement Flasher (contact rated for: 230 V - 25

W Max.). Flashes while

gate opens and closes.

Warning devices

Cycle or courtesy lamp (contact rated for: 230 V - 25 W Max).

Aux

iliary connection to freely position outdoor lamp, to enhance lighting when parking or driving off.

Cycle: it stays lit from the moment the lead starts opening until it is completely closed

(including the automatic closing time).

Courtesy: stays lit for a set time of 180 seconds.

Tra nsfor mer

Black

Red

White

Orange

Purple

Blue

Page 19

CANCELLI AUTOMATICI

R700

CANCELLI AUTOMATICI

R800

10 11 ES TS 1 2 3 3P 4 5 7 CX CY

+ENC1-

+ENC2-

S1 GND

A B

AF

CAME

ACCESS CONTROL

p.

19

19 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

Command devices

Stop button (N.C. contact.). Gate stop button that excludes the automatic

closing cycle, to resume movement press the command button or use

another command device.

N.B.: if contact is unused, select 0 (Deactivated) from the F 1

function.

Opening device (N.O. contact)

Command device (N.O. contact). Commands for opening

and closing the gate, see feature F 7.

Device for partial or pedestrian opening (N.O. contact).

Command for opening a leaf for pedestrian passages.

Closing device (N.O. contact)

N.B.: plug in the (R700) coding card

for the (TSP00) sensor or the (LT001)

card reader to be recognised.

Antenna with RG58 cable for

remote controls.

N.B.: insert the R800

decoding board to have

the S6000/S7000 keypad

selector recognised.

AF remote control card.

Red

Black

White

Blue

(N.O.) contact. for command device

(Transponder or card reader with

R700 board).

(N.O.) contact. for command

device (keypad selector with

R800 board).

Page 20

U V W X Y E

+ ENC1 - + ENC2 -

FA40230FA40230CB

U V W X Y E

+ ENC1 - + ENC2 -

FA40230FA40230CB

FA40230CBFA40230

FA40230CBFA40230

U V W X Y E

+ ENC1 - + ENC2 -

U V W X Y E

+ ENC1 - + ENC2 -

FA40230CB

p.

20

20 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

Gearmotor with encoder

Encoder wire colours:

+ = Wh

ite

ENC = Brown

- = green

Encoder wire colours:

+ = White

ENC = Brown

- = green

Default setting for electrical connections:

operator installed on the left and gearmotor

installed on the right (internal vie

w) with operator

closing delay.

Electrical connections:

gearmotor installed on the left and operator

installed on the right (internal view) with operator

closing delay.

Default setting for electrical connections:

operator installed on left side (internal view)

Electrical connections:

operator installed on right side (internal view)

Page 21

10 11 ES TS 1 2 3 3P 4 5 7 CX CY

S 1 2 3 3P 4 5 7 CX CY

DF

10 11 ES TS 1 2 3 3P 4 5 7 CX CY

10 11 ES TS 1 2 3 3P 4 5 7 CX CY

RX TX

./ # .#

RX TX

p.

21

21 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

DF with control card for DFI

connections

Confi gure contact CX or CY (N.C.), input for sensitivesafety-edge type devices, that are EN 12978 standards

compliant. See CX input functions (Function F2) or CY

(Function 3) in:

- C7 reopening when closing, while the gate is closing,

opening the contact will invert movement until it is

completely opened;

-C8 reclosing when opening, while the gate is opening,

opening the contact will invert movement until it is

completely closed.

N.B.: if contacts CX and CY are unused, they should

be deactivated when programming.

Photocells

Confi gure contact CX or CY (N.C.), input for

safety devices such as photocells, compliant with EN 12978

standards.

See CX input functions (Function F2) or CY (Function 3) in:

- C1 reopening when closing, while the gate is closing, opening

the contact will invert movement until it is completely opened;

- C2 reclosing when opening, when leaves are opening,

opening the contact will trigger inversion of movement until

completely closed;

- C3 partial stop, leaves stop if moving with consequent

triggering of automatic closing (if automatic closing feature

is inserted);

- , obstacle stand-by , stops the leaves if they are moving and

resumes movement after obstacle is removed.

N.B.: if contacts CX and CY are unused, they should be deactivated when programming.

Photocells

DIR

Photocells

DELTA-S

Photocells

DELTA

Sensitive safety edges

Page 22

10 11 ES TS 1 2 3 3P 4 5 7 CX CY

10 11 ES TS 1 2 3 3P 4 5 7 CX CY

./

.#

#

&53)"),%M!

48

48

48

#

.#

DELTA

DIR / DELTA S

24V 12V 0

U V W X Y E

L1T L2T CT

L N

10 11

L2T L1T

1 2 3 4

0 12 24

p.

22

22 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

With each opening and closing command, the card checks the e ciency of the safety devices (i.e. photocells). Any anomalies in the working of the

photocells is fl agged on the electrical card, and this cancels any commands from the radio transmitters or buttons.

Electrical connection to work the photocells safety test:

- the transmitter and receiver, must connected as shown in the diagram:

- select from the F5 feature which inputs the test should be activated on.

Electrical connection for operating the photocell's safety test

Settings and adjustments

To vary the motor torque, move the faston shown to

one of the four positions; 1 min ÷ 4 max.

Page 23

CANCELLI AUTOMATICI

R700

ACCESS CONTROL

TOP

TSP00LT001

CAME

TAM

ATOMO

TWIN

TOUCH

CANCELLI AUTOMATICI

R800

S7000

24V 12V 0

U V W X Y E

L1T L2T CT

L N

10 11 ES TS 1 2 3 3P 4 5 7 CX CY

+ENC1-

+ENC2-

S1 GND

A B

AF

S6000

ESC < > ENTER

F I

p.

23

23 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

Programming

Memorising data

Description of programming commands

To register, edit or remove users or command the operator via radio transmitter, plug in the AF43S card.

If using either the transponder of card reader, fit the R700 board or, alternatively, the R800 keypad selector board.

Fit the memory roll to save and load registered users onto another board.

{

{

The ENTER button is for:

- accessing the menus;

- confirm and memorise the set value.

The ESC button is for:

- exiting menus;

- cancelling any changes.

The <> keys are for:

moving from one menu item to another;

- increasing or decreasing values.

Display

Memory roll

AF card

R700 card

R800 board

{

Page 24

p.

24

24 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

Menu map

F 1 Total stop feature (1-2)

F 2 Function associated to CX input

F 3 Function associated to CY input

F 5 Safety test function

F 6 Maintained action function

F 7 Command mode on 2-7

F 8 Command mode on 2-3

F 9 Obstacle detection when motor is idle function

F 10 Indicator light function

F - 11 Excluding encoder

F 14 Sensor-type selection feature

F 16 Recoil function

F 18 Supplementary light feature

F 19 Automatic closing time

F 20 Automatic closing time after partial opening;

F 21 Pre-flashing time

F 22 Working time

F 23 Delay time when closing

F 24 Delay time when closing

F 30 Adjusting motor slow down speed

F 34 Sensitivity during movement

F 35 Sensitivity during deceleration

F 36 Adjusting open-partially

F 37 Adjusting the motor's starting point of slow down when opening

F 38 Adjusting the motor's starting point of slow down when closing

F 39 Adjusting the motor's end-strike starting point when opening

F 40 Adjusting the motor's end-strike starting point when closing

F 46 Setting the number of motors

F 50 Saving date in the memory roll

F 51 Reading memory roll data

F 59 Enabling CAME logo feature

U 1 Registering new users with associated command

U 2 Cancelling one user

U 3 Completely cancel users

A 2 Motor test

A 3 Calibrating travel

A 4 Reset parameters

H 1 Software version

Page 25

F

i

A2

0

i

ENTER

>

>

ENTER

>...>

F

i

A4

0

ENTER

>

>

ENTER

>...>

i

F

i

A3

0

i

ENTER

>

>

ENTER

>...>

p.

25

25 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

A 2 (Motor test): test activation to check for proper rotation direction of the gearmotor (see the paragraph about motor test).

0 = deactivated; 1 = activated.

Confirm with the ENTER button after choosing the value for each feature.

Motor test and calibrarion menu

Important! We suggest starting the programming by first doing the following:

1 Motor test;

2 Calibration of travel.

A 4 (Reset parameters): data restoring procedure (for default settings) and travel calibration cancellation.

0 = deact

ivated; 1 = activated.

A 3 (travel calibration): automatic gate-travel calibration operation (see the paragraph about calibrating travel).

0 = deact

ivated; 1 = activated.

Warning! If needed, you can restore the factory settings with the following feature:

Page 26

F

i

0

i

ENTER

ENTER >

>

F

i

0

F

2

8

F

i

0

F

5

F

i

0

3

F

3

2

4

4

i

i

i

2

2

3

3

ENTER >

>

>

>

>

>

>

>

ENTER > > >

>

>

>

>

ENTER

>

>

>

>

ENTER

ENTER

ENTER

8

7

7

>...>

>...>

F

i

0

F

6

i

ENTER > > ENTER

>...>

p.

26

26 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

Features menu

F 1 (Total Stop 1-2) - N.C. input: gate stop with consequent exclusion of possible automatic closing cycle; to restore movement act on the command

devic

e. Insert safety device on [1-C2]; if unused, select function "0.

= 0 = Deactivated (default); 1 = activated

F 2 (2-CX input): NC safety contact with possibility to associate the following functions: C1 (reopen when closing), (reclose when opening), C3 (par

tial

stop;), C4 (obstacle stand-by), C7 (reopen when closing, for sensitive safety edges), (reclose when opening, for sensitive safety edges) or deactivated,

see safety devices in electrical connections.

= 0 = Deactivated (default); 1 = C1; 2 = C2; 3 = C3; 4 = C4; 7 = C7; 8 = C8.

F 3 (2-CY input): NC safety contact with possibility to associate the following functions: C1 (reopen when closing), (reclose when opening), C3 (par

tial

stop;), C4 (obstacle stand-by), C7 (reopen when closing, for sensitive safety edges), (reclose when opening, for sensitive safety edges) or deactivated,

see safety devices in electrical connections.

= 0 = Deactivated (default); 1 = C1; 2 = C2; 3 = C3; 4 = C4; 7 = C7; 8 = C8.

F 5 (Safety test): allows the card to check the efficiency of safety devices (i.e. photocells) after every opening or closing command.

= 0 = Deac

tivated (default); 1 = CX; 2 = CY; 3 = CX+CY

F 6 (Maintained action): the gate works by keeping the button pressed (a 2-3 button for opening, a 2-4 button for closing). This excludes all of the

other c

ommand devices including the radio command.

0 = Deactivated (default); 1 = activated.

Page 27

F

i

0

F

7

i

ENTER > > ENTER

>...>

F

i

0

F

8

F

i

0

F

9

i

i

ENTER >

>

ENTER

ENTER > > ENTER

>...>

>...>

F

i

0

F0 i

i

ENTER > > ENTER

>...>

F i i

F

i

0

i

ENTER

>...>

> > ENTER

F

i

0

i

ENTER > > ENTER

F4 i

>...>

F

i

0

i

ENTER > > ENTER

F6 i

>...>

p.

27

27 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

F 7 (Command 2-7): setting the 2-7 contact to either the step (open-close) or sequential (open-stop-close-stop) modes.

0 = step-step (default); 1 = sequential.

F 8 (Command 2-3P): setting contact on 2-3P to pedestrian opening (total opening of the second leaf) or partial (partial opening of the second leaf

depending on p

ercentage setting between 10 and 80 of the travel, feature F 36).

0 = pedestrian opening (default); 1 = Partial opening.

F 9 (Obstacle detection): with motor idle (gate closed, open or after a total stop command), it prevents any movement if the safety devices (e.g.

photo

cells) detect an obstacle.

0 = Deactivated (default); 1 = activated.

1 = - 1 = - gate is opening, it flashes intermittently each half-second;

- gate closing, it flashes intermittently each second;

- gate open, stays lit;

- gate closed, stays off.

F 11 (Encoder exclusion): excludes management of the slow downs, obstacle detection and sensitivity.

0 = E

ncoder activated. (default); 1 = Encoder deactivated.

F 10 (Open signal-light): Light bulb connected to 10-5, signals gate status.

F 14 (Sensor type): setting the sensor-type for the operator command via TSP00 transponder or LT001 magnetic card reader with the R700 coding

board or S70

00 keypad with R800 coding board.

0TAG; 1 = S7000 (default).

F 16 (Ramming): before each opening and closing manoeuvre, the leaves press against the strike-plate for a few seconds to facilitate the electro-lo

ck

release (to adjust the time, see feature F26).

0 = deactivated (default); 1 = activated.

0 = gate open or moving, stays lit (default)

Page 28

F

i

ENTER

> >

ENTER

> >

>...>

0

0 I

i

F i2

F

i

ENTER

> >

ENTER

> >

>...>

i

F02 I08

2

F

i

ENTER

>

>

ENTER

>

>

>...>

F9 i

0

i

I08

F

i

ENTER

> >

ENTER

> >

>...>

F22

I02

5

6

F

i

ENTER

> >

ENTER

> >

>...>

F32

0

0 I

i

F

i

0

F8 i

i

2

ENTER > > ENTER

>

>...>

p.

28

28 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

F 19 (Automatic closing time): The automatic closing timer activates at the closing endpoint. The pre-set time is adjustable, and is anyhow conditio-

ned by a possible intervention by the safety devices and is deactivated after a total emergency stop or when the power is cut.

The waiting time can be deactivated or adjusted from 1" to 180".

= 0 = Deactivated (default); 1 = 1 second; 2 = 2=seconds; .................. 180 = 180=seconds.

F 20 (Automatic closing time after partial or pedestrian opening): leaf automatic closing time after a partial or pedestrian opening command.

The d

oor closes automatically once this time-frame has elapsed and is anyway subject to the trigger of any safety devices and it deactivates after a

«total emergency stop" or due to power outages . The waiting time can be adjusted from 1" to 180”

Note: the automatic closing time (see F 19) should not be deactivated.

1 = 1 second; 2 = 2=seconds; .................. 5 = 5=seconds (default); .................. 180 = 180=seconds.

F 21 (Pre-flashing time): after an opening or closing command, the flashing light connected on (10-E), flashes for an adjustable time interval before

the mano

euvre begins.

the pre-flashing time can be deactivated or adjusted from 1" to 10".

= 0 = Deactivated (default); 1 = 1 second; 2 = 2=seconds; .................. 10 = 10=seconds.

F 22 (Working time): motor operation time in when opening or closing.

the wo

rking time can be adjusted to between 5" and 120"

5 = 5=(seconds; .................. 120 = 120=(seconds (default).

F 23- (Opening delay time): after an opening command, the leaf of gearmotor (M1) starts moving after that of gearmotor (M2) and the time is adju-

stabl

e.

the delay time can be deactivated or adjusted from 1" to 10".

= 0 = Deactivated (default); 1 = 1 second; 2 = 2=(seconds .................. 10 = 10=seconds.

F 18 (Light W-E): output on contact W-E for the light with the following feature:

- movement war

ning flashing light, flashes while gate is opening and closing.

- outdoor freely placeable light, to enhace lighting in the parking area, set as courtesy light which stays lit for a set time of 180 seconds or as a cycle

light that stays on from the moment the leaf starts opening until it is completely closed (including automatic closing time) .

0 = Flashing light (by default); 1 = Cycle; 2 = Courtesy.

Page 29

F

i

ENTER

> >

ENTER

> >

>...>

0

i

F42

52

F

i

F03

ENTER

> >

ENTER

>

>

>...>

F

i

I00

0 I

I I

ENTER

> >

ENTER

>

>

>...>

F43

F

i

I00

0 I

I I

ENTER

> >

ENTER

>

>

>...>

F53

F

i

0 I

I I

ENTER

> >

ENTER

>

>

>...>

F63

08

F

i

0 I

I I

ENTER

> >

ENTER

>

>

>...>

F73

06

0

i

3

2

p.

29

29 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

F 24 (Closing delay time): after a closing command or after automatic closing, the M2 gearmotor lead delays its start compared to gearmotor

M1; the time is adjustable.

the delay time can be deactivated or adjusted from 1" to 25".

= 0 = Deactivated (default); 1 = 1 second; 2 = 2=(seconds .................. 25 = 25=seconds.

F 30 (Slow down speed): setting the time during motor slow downs.

= 0 = Deac

tivated; 1 = maximum speed; 2 = intermediate speed 3 = minimum speed.

F 34 (travel sensitivity): adjusts the obstacle-detection sensitivity during travel.

10 = maximum sensitivity; .................. 100 = minimum sensitivity (default).

F 35 (Deceleration sensitivity): adjusts the obstacle detection sensitivity when decelerating.

10 =

maximum sensitivity; .................. 100 = minimum sensitivity (default).

F 36 (Adjusting partial opening): adjusts the leaf opening of the second motor M2 as a percentage of the total travel

10 = 10% of the travel (default); .................. 80 = 80% of the run-cycle.

F 37 (Opening slow down point): adjusts the motor's beginning slow down point before the opening endstop.

T

he b

eginning slow down point is calculated as a percentage of the leaf's complete travel (see par. about illustrating the slow down and end-strike

areas and points)

10 = 10% of the travel; .................. 25 = 25% of the run-cycle (default); .................. 60 = 60% of the run-cycle.

Page 30

F

i

F93

0 I

i

2

F

i

0 I

I I

ENTER

> >

ENTER

>

>

>...>

F83

06

ENTER

> >

ENTER

>

>

>...>

F

i

F04

0 I

i

2

ENTER

> >

ENTER

>

>

>...>

F

i

0

F64

i

ENTER > > ENTER

>...>

F

i

0

F05

i

ENTER > > ENTER

>...>

F

i

0

F i5

i

ENTER > > ENTER

>...>

p.

3 0

3 0 - M anual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

F 38 (Closing slow down point): adjusts the motor's beginning slow down point before the closing endstop.

the beginning deceleration point is calculated as a percentage of the leaf's complete travel (see par. illustration of slow down and end strike areas and

points )

10 = 10% of the travel; .................. 25 = 25% of the run-cycle (default); .................. 60 = 60% of the run-cycle.

F 39 (Opening end-strike point): adjusts the starting point of the motor's end-strike before the opening endstop.

the b

eginning end-strike point is calculated as a percentage of the leaf's complete travel. (see par. illustration of slow down and end strike areas and

points )

1 = 1% of the travel; .................. 5 = 5% of the run-cycle (default); ..................10 = 10% of the run-cycle.

F 40 (Closing end-strike point): adjusts the starting point of the motor's end-strike before the closing endstop.

the b

eginning end-strike point is calculated as a percentage of the leaf's complete travel (see par. illustration of slow down and end strike areas and

points )

1 = 1% of the travel; .................. 5 = 5% of the run-cycle (default); .................. 10 = 10% of the run-cycle.

F 46 (Number of motors): setting the number of motors connected to the control panel.

0 = Ena

bling both motors (M1+M2) (default); 1 = 2 = Enabling just one motor (M2)

F 50 (Save data): saves users and all settings in the memory roll.

Not

e: this feature appears only if the memory roll is plugged into the mother board.

= 0 = Deactivated; 1 = activated

F 51 (Data reading): loads memory roll data onto the mother board.

Not

e: this feature appears only if the memory roll is plugged into the mother board.

= 0 = Deactivated; 1 = activated.

Page 31

5

F

i

3

i

2

4

ENTER > > ENTER

>...>

u i

>

> >

F

i

>...>

ENTER

ENTER

> >

>

>

52

i

2

u2

F

i

0

u3

i

ENTER > > ENTER

>...>

F

i

H I

0i.

ENTER

ENTER

>...>

0 I

F

i

0

F95

i

ENTER > > ENTER

>...>

>

> >

I08

p.

31

31 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

U 1 (Adding user with associated command): registering users (max 25 users) associated to a command, via transmitter (see paragraph about

registering users with associated command).

1 = 1 = step-step command (open-close); 2 = 2 = 2 = sequential command (open-stop-close-stop); 3 = open only command; 4 = 8 = partial/pede-

strian command (see feature F8); 5 = B1-B2 output.

U 2 (Cancelling users): cancelling one user (see paragraph on cancelling one user)

U 3 (Cancelling users): cancelling all users on memory. Press Enter button to confirm cancellation

0 = Deac

tivated; 1 = 1 = Cancelling all users

H 1 (Version): view software version.

Users menu

Info menu

F 59 (Enabling the CAME logo ): enables switching on or off of the CAME logo of after the gate is completely closed, it stays on for a time that can be

adjust

ed to between10” and 180”.

= 0 = Deactivated; 1 = Activated (default); 10 = 10 seconds................. 11 = 11=(seconds .................. 180 = 180=seconds..

Page 32

ESC < > ENTER

I

U

ESC < > ENTER

2

<

<

> EN

>

>

ESC < > ENTER

8

ESC < > ENTER

2

2

ESC < > ENTER

2

U

<

<

> ENTE

EN >

>

ESC < > ENTER

C

L

p.

32

32 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

Select U 1.

Press ENTER to confirm.

Important! Before entering users, remove the memory roll card if present.

... an available number between 1 and 25 will

fla

sh for a few seconds, this number will be

assigned to the user after the code is sent via

transmitter or other such command device).

User Associated com-

mand

12 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 -

Adding user with associated command

Select U 2.

Pre

ss ENTER to confirm.

2) Use the arrow buttons to select the user number you wish to cancel.

Press ENTER to confirm...

... CLr will be displayed to confirm cancellation.

Cancelling one user

Select a command to associate to the user.

The commands are:

- step-step (open-close) = 1

- sequential (open-stop-close-stop) = 2;

- open = 3;

- partial opening/pedestrian = 4.

Press ENTER to confirm...

N.B.: during registering / cancelling new users operations, the fl ashing numbers viewed, are available and usable for any user needing to be r

egistered (

maximum 25 users).

Page 33

ESC < > ENTER

I

ESC < > ENTER

2

a

>

>

ESC < > ENTER

---

M2M1

ESC < > ENTER

oP2

M2M1

ESC < > ENTER

oP I

p.

33

33 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

Select A 2.

Press ENTER to confirm.

1) Select 1 to activate the test.

Press ENTER to confirm...

... 3) ..."---" will appear on the screen, waiting for

a command...

Keep the > button pressed and check that the

leaf of the second gearmotor M2 opens completely .

Note: if the leaf closes, invert the motor phases.

Do the same procedure with the < arrow button

to check the leaf of the first gearmotor M1.

Note: if the leaf closes, invert the motor phases.

Motor test

Page 34

ESC < > ENTER

a3

ESC < > ENTER

i

<

<

> EN

>

>

ESC < > ENTER

cl i

ESC < > ENTER

cl2

ESC < > ENTER

op2

ESC < > ENTER

op I

M2

M1

M2

M1

M2

M1

M2

M1

p.

34

34 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

Select A 3.

Press ENTER to confirm.

1) Select 1 and press ENTER to confirm the

automatic-calibration-of-travel mode...

The leaf of the first motor will perform a closing

manoeuvre until it reaches the strike plate.

...consequently, the leaf of the second motor will

perform the same manoeuvre...

...then the second motor's leaf, will open completely until the end-strike...

... the leaf of the first motor will perform the same

manoeuvre.

N.B.: before calibrating the travel, check that the manoeuvring area is free of any obstacles and check for the presence of any mechanical

opening and closing strik

e-plates.

Important! While calibrating, all safety devices will be deactivated until calibration is complete, except for the TOTAL STOP.

Calibrating travel

Page 35

p.

3 5

35 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

This product is only intended to be used for the purpose it was designed. Any other use is therefore

improper and dangerous. The manufacturer is not liable for any damage caused by improper, wrongful

or unreasonable use.

Stay away from working mechanical parts. Stay out of the working range of the moving operator.

Do not oppose the movement of the operator as this may result in danger.

Do not allow children to play to loiter within the working range of the operator. Keep transmitters and any other command devices away from children,

to prevent the operator from being activated by mistake.

Immediately stop using the operator if any anomaly is manifested.

Danger high voltage Transit forbidden during opera-

tion

Important general safety instructions

Safety instructions

Error messages

Er1: calibration of motor M1 interrupted; check proper connection and operation of motor M1.

Er2: calibration of motor M2 interrupted; check proper connection and operation of motor M2.

Er3: encoder out-of-order; call for assistance.

Er4: services test error: check proper connections and functioning state of the safety devices.

Er5: insu cient working time; check the set time, it could be insu cient to complete a full cycle.

Er6: maximum number of detected obstacles

C0: contact 1-2 (stop) unused and not deactivated

C1/2/3/4/7/8: unused and not deactivated CX and/or CY contacts

RED fl ashing LED: command board still not calibrated to the travel.

Periodic servicing performed by end-user includes: cleaning the photocells' glass, checking the proper working state of the safety devices and making sure the operator is free of any impediments.

We also recommend to periodically check the lubrication the tightness of the bolts and screws on the operator.

To check that the safety devices are working properly, wave an object in front of the photocells during closing; if the operator inverts its direction of

travel or blocks movement, then the photocells are working properly. This is the only maintenance job that should be done with the power source on.

Before doing any maintenance or repair job, cut off the main power, to prevent any dangerous situations.

To wipe clean the photocell glass, use a slightly damp cloth, and do not use any solvents or other chemical products that may ruin the device.

Check that there is not vegetation within range of the photocells, and that no objects interfere with the operation of the automated device.

Maintenance

Periodic maintenance

Danger of hand crushing

Page 36

p.

3 6

3 6 - M anual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A . to notify said changes.

ENGLISH

Periodic maintenance log to be done twice yearly by the end-users

Date Notes Signature

The following table is used to log extraordinary maintenance, repair and improvement jobs done by the specialised external firms.

N.B.:. All extraordinary maintenance jobs must be carried out by skilled technicians.

Extraordinary maintenance log

Installer's stamp Product name

Date of job

Technician's signature

Customer's signature

Job carried out

_________________________________________________________________________________________________

_____________________________________________________________________________________________________________

__________________________________________________________________________

Extraordinary maintenance

COn its premises, Cancelli Automatici S.p.A. implements a certified Environmental Management System in compliance with the UNI EN ISO

14001 standard to ensure environmental protection.

Please help us to safeguard the environment. At CAME we believe this to be one of the fundamentals of our market operations and development strategies. Just follow these short disposal instructions:

DISPOSING OF THE PACKAGING

The components of the packaging (i.e. cardboard, plastic, etc.) are solid urban waste and may be disposed of without much trouble, simply by separating

them for recycling.

Before proceeding it is always a good idea to check your local legislation on the matter.

DO NOT DISPOSE OF IN NATURE!

PRODUCT DISPOSAL

Our products are made up of various materials. The majority of these (aluminium, plastic, iron, electrical wires) is solid urban waste. These can be

disposed of at local solid waste management dumps or recycling plants.

Other components (i.e. electronic cards, transmitter batteries, etc. ) may contain hazardous substances.

These must therefore be handed over the specially authorised disposal firms.

Before proceeding it is always a good idea to check your local legislation on the matter.

DO NOT DISPOSE OF IN NATURE!

Dismantling and disposal

Installer's stamp Product name

Date of job

Technician's signature

Customer's signature

Job carried out

_________________________________________________________________________________________________

_____________________________________________________________________________________________________________

__________________________________________________________________________

Page 37

p.

37

37 - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2.0 06/2012

© CAME Cancelli Automatici S.p.A . - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.A. to notify said changes.

ENGLISH

CE Declaration

Page 38

CA ME

CA ME

Fra nce

France

S.a.

S.a. FRANCE

7, Rue Des Haras

Z.i. Des Hautes Patures

92737

Nante rre Cedex

Nanterre Cedex

(+33) 0 825 825 874

(+33) 1 46 13 05 00

GERMANY

CA ME Gmbh See feld

CAME Gmbh Seefeld

Akazienstrasse, 9

16356

Seefe ld

Seefeld Bei Berlin

(+49) 33 3988390

(+49) 33 39883985

CA ME Au tomatismes S. a.

CA ME Automatismes S.a. FRANCE

3, Rue Odette Jasse

13015

Marseille

Marseille

(+33) 0 825 825 874

(+33) 4 91 60 69 05

U.A.E.

CA ME Gulf Fze

CAME Gulf F ze

O ce No: S10122a2o210

P.O. Box 262853

Jebel Ali Free Zone -

Dubai

Dubai

(+971) 4 8860046

(+971) 4 8860048

CA ME Au tomatismos S. a.

CA ME Automatismos S.a. SPAIN

C/juan De Mariana, N. 17-local

28045

Madrid

Madrid

(+34) 91 52 85 009

(+34) 91 46 85 442

RUSSIA

CAME Rus

CAME Rus

Umc Rus L lc

Umc Rus Llc

Ul. Otradnaya D. 2b, Str. 2, o ce 219

127273,

Moscow

Moscow

(+7) 495 739 00 69

(+7) 495 739 00 69 (ext. 226)

CA ME Unit ed K ingdom Ltd.

CA ME United Kingdom Ltd. GREAT BRITAIN

Unit 3 Orchard Business Park

Town Street, Sandiacre

Nottingha m

Nottingham - Ng10 5bp

(+44) 115 9210430

(+44) 115 9210431

PORTUGAL

CA ME Po rtugal

CAME Portugal

Ucj Por tuga l Unipessoal Ld a

Ucj Portugal Unipessoal Lda

Rua Liebig, nº 23

2830-141

Barreir o

Barreiro

(+351) 21 207 39 67

(+351) 21 207 39 65

CA ME Grou p Benelux S.a.

CA ME Group Benelux S.a. BELGIUM

Zoning Ouest 7

7860

Le ssin es

Lessines

(+32) 68 333014

(+32) 68 338019

INDIA

CA ME India

CAME India

Aut omation Solutions P vt. Ltd

Automation Solutions Pvt. Ltd

A - 10, Green Park

110016 -

New Delhi

New Delhi

(+91) 11 64640255/256

(+91) 2678 3510

CA ME Am eric as A utomati on L lc

CA ME Americas Automation Llc U.S.A

11345 NW 122nd St.

Medley

Medley, FL 33178

(+1) 305 433 3307

(+1) 305 396 3331

ASIA

CA ME As ia Pacifi c

CAME A sia Pacific

60 Alexandra Terrace #09-09

Block C, The ComTech

118 502

Singapore

Singapore

(+65) 6275 0249

(+65) 6274 8426

CA ME Gmbh

CA ME Gmbh GERMANY

Kornwestheimer Str. 37

70825

Korntal

Korntal Munchingen Bei Stuttgart

(+49) 71 5037830

(+49) 71 50378383

CA ME Ca ncelli A uto matici S.p. a.

CA ME Cancelli Automatici S.p.a. ITALY

Via Martiri Della Libertà, 15

31030

Dosson Di Casier

Dosson Di Casier (Tv)

(+39) 0422 4940

(+39) 0422 4941

Informazioni Commerciali 800 848095

ITALY

CA ME Sud s.r.l.

CA ME Sud s.r.l.

Via F. Imparato, 198

Centro Mercato 2, Lotto A/7

80146

Napoli

Napoli

(+39) 081 7524455

(+39) 081 7529190

CA ME Service Italia S.r.l.

CA ME Service Italia S.r.l. ITALY

Via Della Pace, 28

31030

Dosson Di Casier

Dosson Di Casier (Tv)

(+39) 0422 383532

(+39) 0422 490044

Assiste nza Tecnica 800 295 830

Assistenza Tecnica 800 295830

ITALY

CA ME Glob al U tilities s.r.l .

CA ME Global Utilities s.r.l.

Via E. Fermi, 31

20060

Gessate

Gessate (Mi)

(+39) 02 95380366

(+39) 02 95380224

09_2011

www.came.com www.came.it

Eng li sh

Eng li sh - Manual code:

119 DW 02

119 DW0 2 ver.

2. 0

2. 0 06/2012 © CAME Cancelli Automatici S.p. A.

The data and information in this manual may be changed at any time and without obligation on the part of CAME Cancelli Automatici S .p.A. to notify said changes.

Loading...

Loading...