Page 1

h

AXO SERIES

AUTOMATION FOR SWING GATES

INSTALLATION MANUAL

AX3024 / AX5024

Englis

Page 2

EN

ENGLISH

WARNING!

Important instructions for the safety of people:

READ CAREFULLY!

Foreword

• Use of the products must be restricted to its intended use

(i.e. that for which it was expressly built for). Any other use is

to be considered dangerous. Came Cancelli Automatici S.p.A.

is not liable for any damage resulting from improper, wrongful

ENGLISH

or unreasonable use • Keep these warnings with the installation and use manuals issued with the automated system.

Before installing

(preliminary check: in case of a negative

outcome, do not proceed before having

complied with the safety obligations)

• Make sure that the parts you intend to automate are in

good working order, and that they are properly balanced

and aligned. Also, make sure that proper mechanical stops

are already in place • If the operator will be installed at a

height of less than 2.5 m from the ground or other access

level, check whether you will need any protections and/or

warnings • Any gate leaves, fi tted with pedestrian entrances,

onto which you will install an operator, must have a blocking

mechanism when the gate is in motion • Make sure that the

opening of the automated gate is not an entrapment hazard

as regards any surrounding fi xed parts • Do not mount the

operator upside down or onto any elements that may fold

under its weight. If needed, add suitable reinforcements at

the points where it is secured • Do not install onto gates on

either an upward or downward slope (i.e. that are not on fl at,

level ground) • Check that any lawn watering devices will not

wet the gearmotor from the bottom up.

are working properly • Where necessary and in plain sight,

apply the Warning Sings (e.g. gate plate).

Special instructions and

advice for users

• Keep the gate’s area of operation clean and clear of any

obstacles. Trim any vegetation that may interfere with the

photocells • Do not allow children to play with the fi xed command devices, or in the gate’s area of operation. Keep any

remote control devices (i.e. transmitters) away from the children as well • Frequently check the system, to see whether

any anomalies or signs of wear and tear appear on the moving

parts, on the component parts, on the securing points, on the

cables and any accessible connections. Keep any joints (i.e.

hinges) lubricated and clean, and do the same where friction may occur (i.e. slide rails) • Perform functional tests on

photocells and sensitive edges, every six months. Keep glass

panels constantly clean (use a slightly water-moistened cloth;

do not use solvents or any other chemical products) • If the

system requires repairs or modifi cations, release the operator

and do not use it until safety conditions have been restored

• Cut off the power supply before releasing the operator for

manual openings. See instructions • Users are FORBIDDEN

to carry out ANY ACTIONS THAT THEY HAVE NOT BEEN

EXPRESSLY ASKED TO DO OR SO INDICATED in the manuals. Any repairs, modifi cations to the settings and extraordinary maintenance MUST BE DONE BY THE TECHNICAL

ASSISTANCE STAFF • On the periodic maintenance log, note

down the checks you have done.

Installation

• Carefully section off the entire site to prevent unauthorised

access, especially by minors and children • Be careful when

handling operators that weigh more than 20 Kg (see installation manual). In such cases, employ proper weight handling

safety equipment • All opening commands (e.g. buttons, key

selectors, magnetic detectors, etc.) must be installed at least

1.85 m from the gate’s area of operation perimeter - or where

they cannot be reached from the outside of the gate. Also,

the direct commands (e.g. push button, or proximity devices,

etc.) must be installed at a height of at least 1.5 m and must

not be accessible to the public • All ‘maintained action’ commands, must be placed where the moving gate leaves, transit

areas and driveways are completely visible • If missing, apply a permanent label that shows the position of the release

mechanism • Before delivering to the client, verify that the

system is EN 12453 (impact test) standard compliant. Make

sure that the operator has been properly adjusted and that the

safety and protection devices, as well as the manual release

Special instructions and

advice for all

• Avoid working near the hinges or moving mechanical parts

• Stay clear of the gate’s area of operation when in motion •

Do not resist the direction of movement of the gate; this may

present a safety hazard • At all times be extremely careful

about dangerous points that must be indicated by proper

pictograms and/or black and yellow stripes • When using

a selector or command in ‘maintained action’ mode, keep

checking that there are no people in the area of operation of

the moving parts. Do this until you release the command •

The gate may move at any time without warning • Always cut

the power when cleaning performing maintenance.

CAME cancelli automatici s.p.a.

Via Martiri della Libertà, 15

31030 Dosson di Casier

TREVISO - ITALY

www.came.it - info@came.it

Page 3

General conditions of sale

1. GENERAL POINTS

These general conditions shall apply to all purchase agreements for Came Cancelli Automatici SpA materials, hereinafter called “the

company”.

2. OFFERS AND QUOTATIONS

The company’s quotations are valid for a 30-day period at the most starting from the date they are sent.

3. ORDERS

The sale agreement is executed once the written order is confirmed by Came Cancelli Automatici Spa or when the order is fulfilled by

the company. Orders that are addressed, and signed by clients, to Came Cancelli Automatici SpA are deemed to be firm and irrevocable

for 30 days starting from the date they are received by the company. Any change or addition to the single provisions of these general

conditions or single provisions of the order which was originally addressed by the client, shall have no validity unless otherwise approved

in writing by the company. For any changes to the order, the company reserves the right to cancel both the changes an the original order.

The delivery date for the goods appearing on the orders is always and in any case exclusively indicative, and any delays of such term may

never justify claims for compensation or cancellation of contract.

Particularly, the company reserves the right to extend the delivery terms or cancellation of order in the event of: force majeure or events

that are beyond the control of the company; change of the Client’s legal status; difficulty in sourcing raw materials and component parts.

4. DELI VERY AN D FORWARDING

The place of production or registered office of the company shall be the place of fulfilment for delivery. The cost and risk of the travelling

goods is borne by the buyer ex works, pursuant to the 2000 incoterms. Unless otherwise agreed, the company establishes, for and on

behalf of the client, the type of shipping, the travel route and type of carrier. The company reserves the right to carry out partial deliveries

and fulfilment of orders, thereby issuing a separate invoice each time: in this case all partial deliveries shall be autonomously invoiced and

the terms of payment shall begin as of the date on each invoice; the client may not, therefore, defer payment of partial orders, until the last

deliver y is made as concerns the original order.

5. PRICES AND PRICE LISTS

The prices are intended for goods delivered free to the company’s registered office, not including VAT, with normal packaging, and not

including forwarding expenses. Any reference to list prices shall refer to the latest price list published by the company, which theretofore

cancels any previous price lists.

6. PAYMENTS

Non-payment within the established terms, shall result in the application of interest pursuant to Lgs. Decr. 09/10/2002 n. 231 and

subsequent amendments and upgrades, with any possible greater damage unprejudiced. Any delay in payment, shall mean that the client

shall owe the company, any losses due to exchange rates. The client may not advance any demands nor raise any exceptions as concerns

the company, unless after having paid the goods it purchased. The company reserves the right to block all shipping and supply orders

underway in the face of any irregularities in the payments, without need of prior notice nor compensatory damages of any kind.

7. RETURNS AND CLAIMS

All claims must be filed in writing within 8 days of receiving the goods, whether such claims refer to the quantity or quality of the delivered

goods. Returned goods shall be accepted by company only following a written agreement, and only for new and packaged goods. Any

returned goods must be complete of their relative transport documents, showing the company’s written authorisation to accept the

returned goods including the quality and quantity of the returned goods.

The returned goods shall not be accepted by the company unless carried out in the above mentioned manner and, especially, returned

goods shall not be accepted if received at any of the company’s premises.

8. GUARANTEE

The company guarantees the proper functioning of the products that it provides, as per the technical characteristics that are expressly

shown on its products’ technical sheets. The guarantee shall not apply in the case of any environmental interferences of any nature, which

could cause disturbances in the functioning of any existing or future installations (radio frequencies – proximity of electric power lines…).

The guarantee does not cover the normal wear and tear of the equipment, or mistakes made during the mounting phase or due to

maintenance flaws, and in any case it does not cover any cases in which flaws in the functioning can be traced back to factors stemming

from anything other than manufacturing.

The deadlines for filing a claim for any flaws or for the statute of limitations for actions to which the buyer is entitled are those foreseen by

Italian law. The company at its own leisure, may decide to withdraw any goods supplied which it has ascertained as faulty, or decide to

repair said ascertained flaws. The client may not request to be compensated for any indirect damages, missed gains, production losses,

and in any case may not expect as compensation any sums greater than the value of the supplied components or products.

9. REPAIRS

Repairs to purchased items request by the client shall be carried out by the company following an agreement on the price of said repairs.

In any case the expenses for labour and shipping (roundtrip) shall be borne by the client.

10. RESE RVATION OF TITLE

It is expressly agreed that, any delivered goods remain owned by the company until the client pays the entire balance, regardless of who

is in possession of said goods. Transport expenses and any other expenses needed to retrieve the equipment, therein including any

extraordinar y expenses as well as any repeatable ones, shall be borne by the client.

11. APPLICCABLE L AW – SET TLEMENT OF ANY DIS PUTES Any arising dispute resulting from the sale agreement, shall be settled

according to the Italian law, thereby excluding any other law and in supplement to the Vienna Convention on the international sale of

goods. All disputes shall be subject to Italian jurisdiction and come under the exclusive competence of the Tribunal of Treviso, Italy.

12. PROVISION S ON THE SAFEGUARDING OF PERSONAL DATA.

Pursuant to current legislation for the safeguarding of personal data, clients are aware that their personal data is inputted into the

company’s databank, which is necessary for the proper carrying out of the contractual relationship and for compliance with certain

provisions of law, as well as for purposes of statistics, promotion, marketing, commercial, credit protection, management and transfer of

the same .

The personal data of the buying party are processed through automated and paper-based tools by authorised persons, by using safety

procedures designed to guarantee confidentiality. The personal data of the client may by shared with Public Bodies, companies of the

group, credit recovery firms, or consortiums or associations with business scopes, market research scopes, or marketing scopes. The

data processor shall be the company, and the client may address said company to uphold their own rights as per law. To this end the

buying party is aware that at any time it may access its personal data, ask that it be updated, corrected and /or prohibit it from being used.

ENGLISH

Page 4

2

119DU8 5

0.1

“IMPORTANT INSTALLATION, SAFETY INSTRUCTIONS”

“CAUTION: IMPROPER INSTALLATION MAY CAUSE SERIOUS DAMAGE, FOLLOW ALL INSTALLATION INSTRUCTIONS CAREFULLY”

“THIS MANUAL IS ONLY FOR PROFESSIONAL OR QUALIFIED INSTALLERS”

1 Legend of symbols

This symbol tells you to read the section with particular care.

This symbol tells you that the sections concern safety issues.

This symbol tells you what to say to the end-users.

ENGLISH

2 Intended use and application

2.1 Intended use

The AXO operator is designed to automate swing gates used in residential or condominium settings..

The use of this product for purposes other than those described above and installation executed in a manner other than as

instructed in this technical manual are prohibited.

2.2 Application

Type AX302304 - AX402306 - AX412306 AX402306 - AX412306

Length of gate leaf (m) 22.53 4*

Weight of gate leaf (kg) 800 600 500 300

Type AX71230

Length of gate leaf (m) 22.53 4*5*6**7**

Weight of gate leaf (kg) 1000 800 700 500 400 350 300

* The electrolock must be installed onto the door-leaf.

** If it is larger than 5 meters, panels must not be fitted.

Attention must be paid when there is strong wind with the reversible versions if the gate is open as it could slam shut.

3 Reference Standards

The company CAME cancelli automatici is ISO 9001:2000 quality certified; it has also obtained the ISO 14001 environmental

safeguarding certification. CAME engineers and manufactures all of its products in Italy.

This product complies with the following legislation: see declaration of compliance.

4 Description

4.1 Gate Operator

This product is engineered and manufactured by CAME cancelli automatici s.p.a. and complies with current safety regulations.

Guaranteed 24 months if not tampered with.

The gearmotor is made up of two aluminium alloy half shells housing the Encoder gearmotor – which features an electric blocking

mechanism – and an epicyclical reduction system with endless screw.

230V A.C. surface gearmotors:

001AX302304 - irreversible gearmotor with encoder for gate leaves of up to 3 m.

001AX402306 - irreversible gearmotor with encoder for gate leaves of up to 4 m.

001AX412306 - reversible gearmotor with encoder for gate leaves of up to 4 m.

001AX71230 - reversible gearmotor with encoder for gate leaves of up to 7 m.

Control panel:

002ZM3E - Multifunction control panel with signalling display, self-diagnosis of safety devices and built-in radio decoding

Accessories:

001LOCK81 - Blocking electro-lock - single cylinder

001LOCK82 - Blocking electro-lock - double cylinder

0.1 01/2009 © CAME cancelli automatici s.p.a. - The data and information repor ted in this installation manual are susceptible to change at any time and without obligation on C AME cancelli automatici s.p.a. to notif y users.

119DU85 ver.

2 - Manual code:

Pag.

Page 5

3

119DU8 5

0.1

4.2 Technical features

GEARMOTOR AX302304

Control board power supply: 230V A.C.

50/60Hz

Motor power supply: 230V A.C. 50/60Hz

Max draw.: 1,5A

Power: 175W

Adjustable thrust: 500÷4500N

Opening time(90°): 20s

Duty cycle: 50%

Protection rating: IP44

Motor’s thermal protection: 150 C°

#

#

GEARMOTOR AX402306 / AX412306

Control board power supply: 230V A.C.

50/60Hz

Motor power supply: 230V A.C. 50/60Hz

Max draw.: 1,5A

Power: 175W

Adjustable thrust: 500÷4500N

Opening time(90°): 28s

Duty cycle: 30%

Protection rating: IP44

Motor’s thermal protection: 150 C°

#

4.3 Description of parts

1) Operator

2) Pilaster bracket

3) Gate bracket

4) M8x35 UNI5737 screw for securing pillar bracket

5) Bushing

6) M8 UNI5588 nut for securing pillar bracket

7) Sheath holder

#

GEARMOTOR AX71230

Control board power supply: 230V A.C.

50/60Hz

Motor power supply: 230V A.C. 50/60Hz

Max draw.: 1,5A

Power: 175W

Adjustable thrust: 500÷4500N

Opening time(90°): 40s

Duty cycle: 30%

Protection rating: IP44

Motor’s thermal protection: 150 C°

#

#

8) Mechanical stop

9) M6X20 UNI5739 screws for mechanical stop

10) Endless screw pin

11) Ø8x24 UNI6593 washer

12) Gate bracket screw for securing to M8x10 UNI5739 pin

13) Securing bracket

14) Small release door

ENGLISH

13

4.4 Dimensions

AX302304

AX402306

AX412306

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

4

AX302306 - AX402306 - AX412306AX71230

4

13

2

5

6

1

7

5

2

6

7

1

14

10

8

8

13

3

9

9

11

12

123

325

800

100

880

AX71230

01/2009 © CAM E cancelli automatici s.p.a. -

0.1

ver.

119DU85

:

Manual code

3 -

Pag.

1100

1180

625

100

123

(mm)

Page 6

4

119DU8 5

0.1

5 Installation

Installation must be carried out by expert qualified personnel and in full compliance with current regulations.

5.1 Preliminary checks

Before installing, do the following:

• Make sure you have suitable tubing and conduits for the electrical cables to pass through and be protected against mechanical

damage;

• Fit tubing to drain away any water leaks which may cause oxidation;

ENGLISH

Make sure that any connections inside the case (that provide continuance to the protective circuit) be fitted with extra insulation

•

as compared to the other conductive parts inside;

• Make sure the structure of the gate is sturdy, the hinges work and that the is no friction between moving and non-moving parts;

• Make sure there is a mechanical stop for opening and closing.

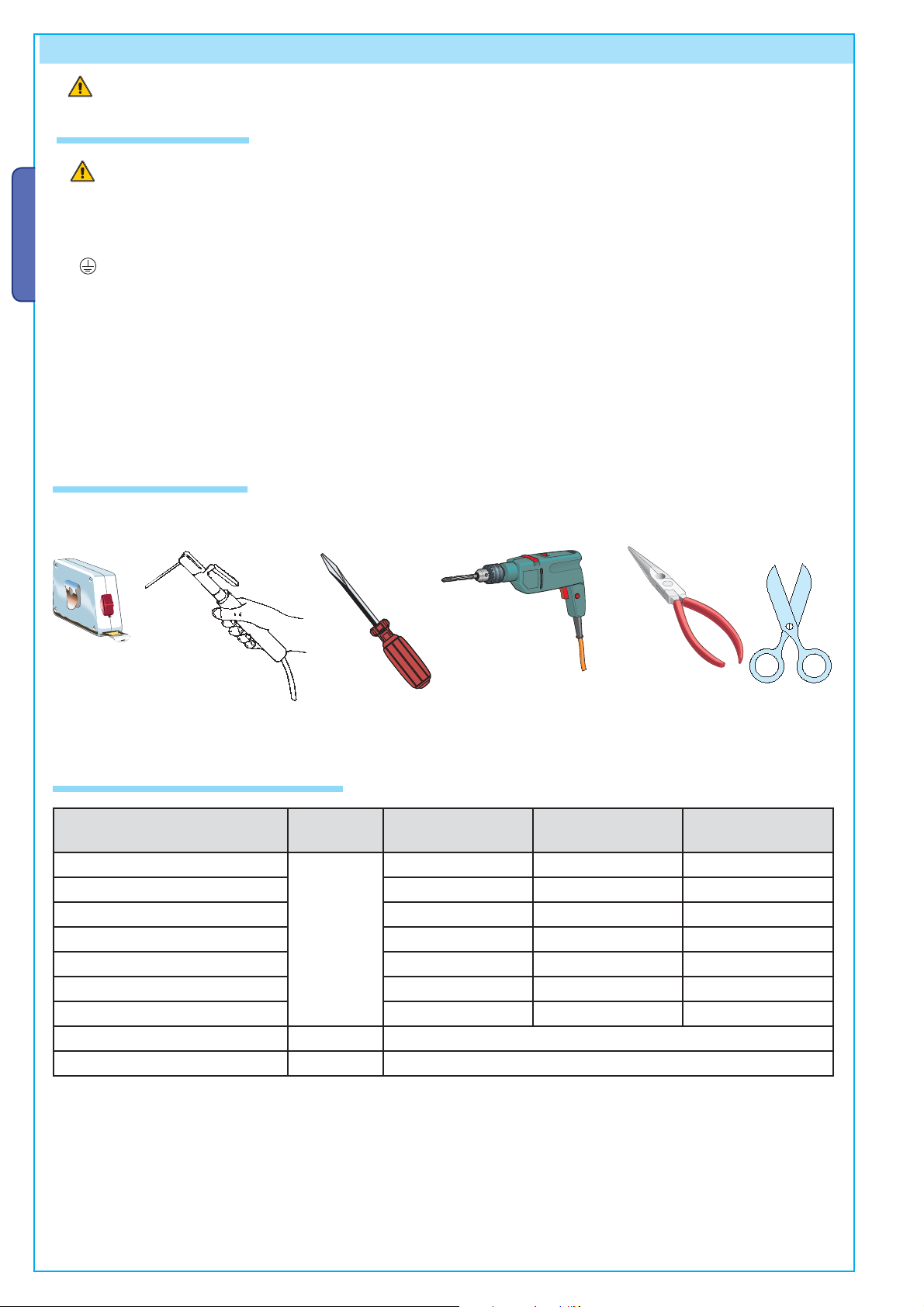

5.2 Tools and materials

Make sure you have all the tools and materials you will need for the installation at hand to work in total safety and compliance with the

current standards and regulations. The following figure illustrates the minimum equipment needed by the installer.

5.3 Cable list and minimum thickness

Connections Type of cable Type of cable

Control panel power supply 230V

3G x 1,5 mm

Motor power supply 230V 4G x 1 mm

Flashing light 2 x 0,5 mm

Photocell transmitters 2 x 0,5 mm

Photocell receivers 4 x 0,5 mm

FROR CEI

20-22

CEI EN

50267-2-1

Accessories power supply 2 x 0,5 mm

Control and safety devices 2 x 0,5 mm

2

2

2

2

2

2

2

Length of cable

10 < 20 m

3G x 2,5 mm

4G x 1,5 mm

2 x 1 mm

2 x 0.5 mm

4 x 0,5 mm

2 x 0,5 mm

2 x 0,5 mm

Encoder connection TWISTATO 3 x 05 mm

Antenna RG58 max. 10 m

2

2

2

2

2

2

2

2

Length of cable

20 < 30 m

3G x 4 mm

4G x 2,5 mm

2 x 1,5 mm

2 x 0,5 mm

4 x 0,5 mm

2 x 1 mm

2 x 0,5 mm

2

2

2

2

2

2

2

N.B.: If the cable length differs from that specified in the table, then you must determine the proper cable diameter in the basis of the

actual power draw by the connected devices and depending on the standards specified in CEI EN 60204-1.

For connections that require several, sequential loads, the sizes given on the table must be re-evaluated based on actual power draw

and distances.

When connecting products that are not specified in this manual, please follow the documentation provided with said products.

0.1 01/2009 © CAME cancelli automatici s.p.a. - The data and information repor ted in this installation manual are susceptible to change at any time and without obligation on C AME cancelli automatici s.p.a. to notif y users.

119DU85 ver.

4 - Manual code:

Pag.

Page 7

5

119DU8 5

0.1

5.4 Standard installation

1) AXO operator

2) Control panel

3) Reception antenna

4) Flashing light

5) Selector switch

6) Photocells

7) Electric cable junction box

8) Mechanical gate stops

9) Photocell column

6

6

ENGLISH

6

4

3

1

8

5

2

1

9

6

8

9

7

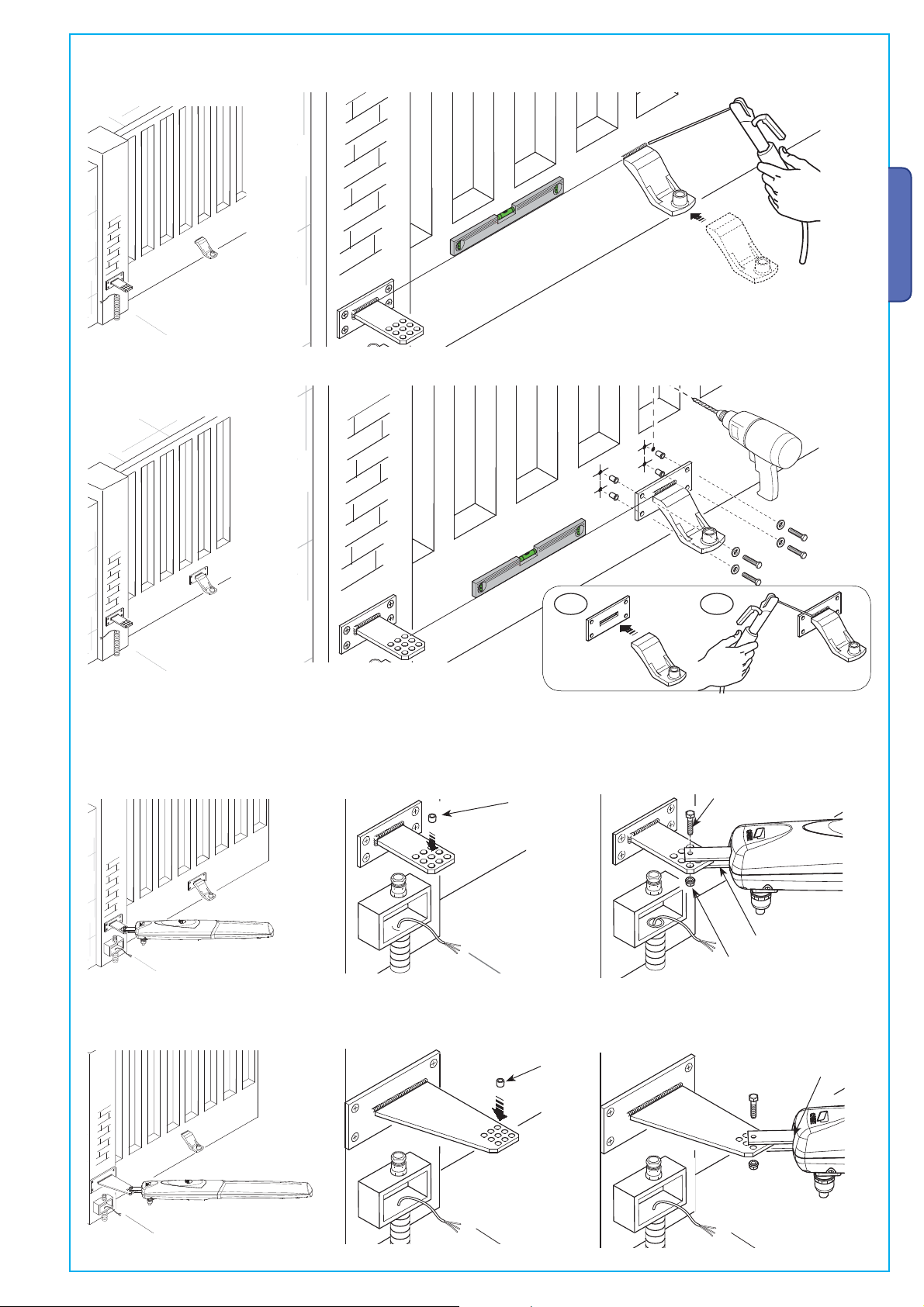

5.5 Installing the operator

The following illustrations are only examples, given that the space available for anchoring the operator and accessories may vary

from gate to gate. It is up to the installer, thus, to choose the most suitable solution.

Lay the corrugated tubing needed for the connections deriving from the junction box.

N.B. the number of tubes depends on the type of system and accessories employed.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

01/2009 © CAM E cancelli automatici s.p.a. -

0.1

ver.

119DU85

:

Manual code

5 -

Pag.

Electric cable junction box

Page 8

6

119DU8 5

0.1

Warning: after establishing the best point to which you will secure the gate bracket, secure the bracket to the pillar and make sure the

quotas shown in the table below are met.

Note: by increasing measure B, the opening angle and gate speed are reduced, while the gearmotor thrust is increased. By increasing

the measure A, the opening angle and gate speed are increases, while the gearmotor thrust is decreased.

ENGLISH

Pillar bracket

Gate bracket

E

E

AX302304 - AX402306 - AX412306

AX71230

Gate leaves of up to 4m

Opening

angle

A

mmB mm

C max mmE

mm

Opening

90° 130 130 70 800

120° 150 80 0 800

120 ° 14 0 100 50 800

Assemble and weld the two parts of the pillar bracket. Secure the bracket to the point you have chosen with proper plugs and screws

or - if the pillar is made of metal - weld it on.

Gate leaves of up to 7 m

A

angle

mm

90° 200 220 150 1100

120° 220 220 100 1100

B mmC max mmE

mm

1

2

AX302304

AX402306 - AX412306

AX71230

1

0.1 01/2009 © CAME cancelli automatici s.p.a. - The data and information repor ted in this installation manual are susceptible to change at any time and without obligation on C AME cancelli automatici s.p.a. to notif y users.

2

119DU85 ver.

6 - Manual code:

Pag.

Page 9

7

119DU8 5

0.1

Weld the gate bracket to the gate leaf making sure the quotas shown in the table are met.

Note: for AX5024 gearmotors, require an additional 10 mm shim between the gate and the bracket.

Note: on non-metal gate leaves assemble and weld the two parts of the bracket and secure them with proper screws.

Secure the tail joint to the bracket.

ENGLISH

1

2

Insert the bushing (lubricated) into the pillar bracket’s hole. The bracket has holes that allow the opening angle to be changed. Secure

the tail joint to the bracket.

Bushing

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Screw M8 x 35

Tail joint

AX302304

Nut UNI 7474 M8

AX402306 - AX412306

Bushing

01/2009 © CAM E cancelli automatici s.p.a. -

0.1

ver.

119DU85

:

Manual code

7 -

Pag.

AX71230

Tail joint

Page 10

8

119DU8 5

0.1

Open the gate leaf and insert the pin into the gate bracket and secure it using a washer and nut.

ENGLISH

Gate bracket

UNI6593 Ø8 washer

Screw UNI5739 M8x10

Release the gearmotor (see paragraph on manual release), completely open the gate leaf, loosen the nuts of the opening mechanical

stop and position it up against the attachment pin, then secure it.

Opening

Attachment pin

mechanical stop

Close the gate leaf, loosen the nuts on the closing mechanical stop, place it up against the attachment pin, then secure it.

Attachment pin

Closing mechanical stop

0.1 01/2009 © CAME cancelli automatici s.p.a. - The data and information repor ted in this installation manual are susceptible to change at any time and without obligation on C AME cancelli automatici s.p.a. to notif y users.

119DU85 ver.

8 - Manual code:

Pag.

Page 11

9

119DU8 5

0.1

5.6 Manual release of the gearmotor

Slide open the small door that protects the release, insert the tri-lobed key and turn it.

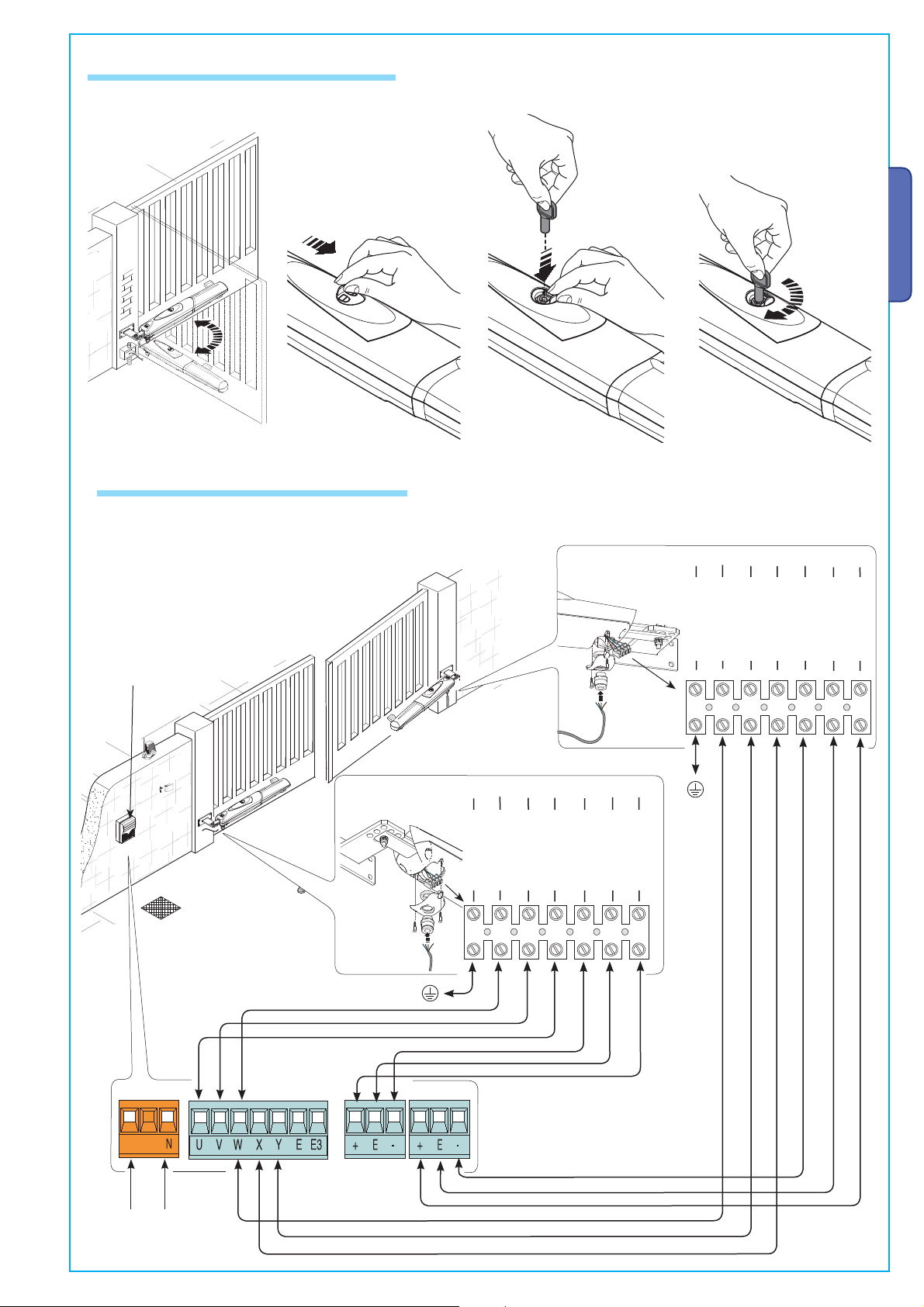

5.7 Connecting to the control panel

ENGLISH

For the electrical connection procedures, use the junction box and branching boxes.

ZM3E Control panel

Connecting the 230V a.c. delayed opening gearmotor

blue

yellow/green

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Connecting the 230V a.c. delayed closing gearmotor

blue

black

brown

yellow/green

black

green

brown

white

brown

green

white

brown

01/2009 © CAM E cancelli automatici s.p.a. -

0.1

ver.

,

119DU85

:

Manual code

9 -

Pag.

Power

230V a.c. - 50/60 Hz

Encoder B

Encoder A

Page 12

10

119DU8 5

0.1

5.8 Outward opening installation

ENGLISH

E

E

(non-issued)

A

A

Supplementary bracket

TABLE 1 TABLE 2

Opening

A

(mm)

B

(mm)

90° 130 130 800

E

(mm)

Opening

A

(mm)

90° 200 220 1100

B

(mm)

E

(mm)

Weld pillar bracket to the non-issued supplementary bracket, while gate is open, then secure the brackets to the pillar, making sure the

“A” and “B” quotas shown in table 1 are met. Weld, or secure with proper screws, the gate bracket, making sure the “E” quota is met,

as shown in table 1. Finally, secure the gearmotor to the brackets with the issued screws and washers.

1

2

Gate bracket

Pillar bracket

Extra bracket

For AX5024 gearmotors, directly secure the standard issue bracket to the pillar without using the supplementary bracket, while taking

into account the measurements shown in table 2.

Finally, secure the gearmotor to the brackets with the issued screws and washers.

Gate bracket

0.1 01/2009 © CAME cancelli automatici s.p.a. - The data and information repor ted in this installation manual are susceptible to change at any time and without obligation on C AME cancelli automatici s.p.a. to notif y users.

119DU85 ver.

Pillar bracket

10 - Manual code:

Pag.

Page 13

11

119DU8 5

0.1

Fully close the gate-leaf, place the mechanical stop against it with the pin attachment and fi x it in place.

Opening

Attachment pin

mechanical stop

Fully open the gate-leaf, place the mechanical stop against it with the pin attachment and fi x it in place.

ENGLISH

Attachment pin

Connect the gearmotors to the panel as shown in the diagram.

,

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

Power

230V a.c.

50/60 Hz

Closing mechanical stop

white

brown

green

brown

black

blue

yellow/green

Delayed

closing

action

01/2009 © CAM E cancelli automatici s.p.a. -

0.1

ver.

119DU85

:

white

brown

green

brown

black

blue

Delayed

opening

action

yellow/green

Manual code

11 -

Pag.

Page 14

12

119DU8 5

0.1

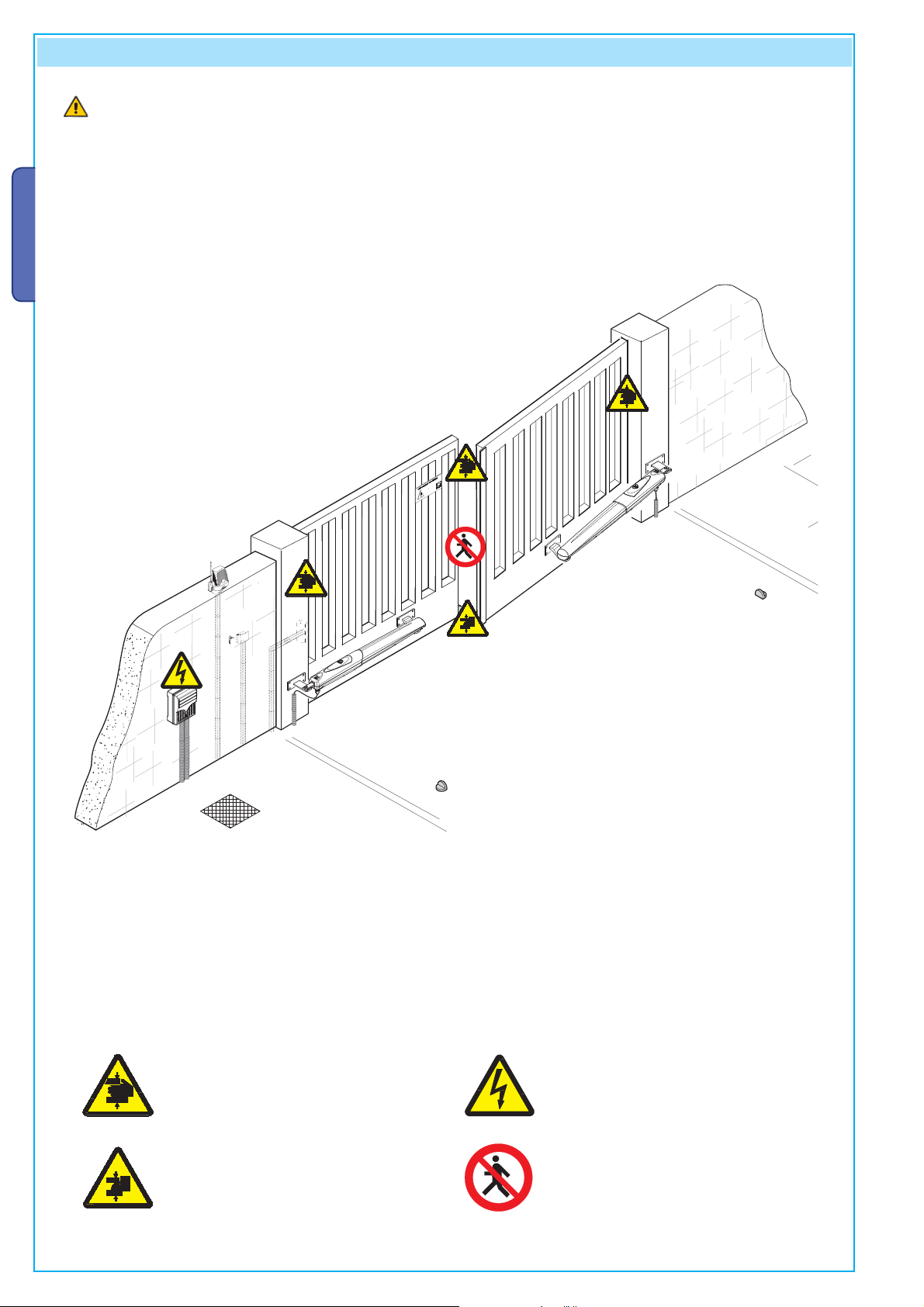

6 Safety instructions

Important safety instructions

This product must only be employed for its originally intended use. The automation installation using these gearmotors requires

adequate safety systems on the gate leaves to detect any obstacles (e.g. sensitive edges), in compliance with EN12445 and EN12453

Technical Standards relative to the impact force generated by the moving gate. Any other use is wrong and potentially dangerous. The

manufacturer cannot be held liable for any damages resulting from wrongful, erroneous or negligent uses.

Avoid working close to the hinges or other moving mechanical parts. Stay out of the opening/closing arc when operator is in motion.

Do not exercise force against the motion of the operator as this could result in potentially dangerous situations.

ENGLISH

Do not allow children to play or loiter within the opening/closing arc of the operator.

Keep remote controls and any other command device out the reach of children, to prevent operator from being activated by accident.

In the event of anomalous behaviour, stop using the operator immediately.

Danger of crushing hands

Danger of crushing feet

Danger! High voltage

No transit during operation

0.1 01/2009 © CAME cancelli automatici s.p.a. - The data and information repor ted in this installation manual are susceptible to change at any time and without obligation on C AME cancelli automatici s.p.a. to notif y users.

119DU85 ver.

12 - Manual code:

Pag.

Page 15

13

119DU8 5

0.1

7 Maintenance

7.1 Periodic maintenance

Periodic maintenance to be carried out by the end-user is as follows: wipe clean the glass surface of the photocells; check that

the safety devices work properly; remove any obstructions.

We suggest checking the state of lubrication and tightness of the anchoring screws on the operator.

To check the efficiency of the safety devices, move an object in front of the photocells when gate is closing. If the operator inverts the

motion or stops, the photocells are working properly.

This is the only maintenance procedure to be carried out with the power source connected.

Before performing any maintenance procedures, cut off the main power, to prevent possible accidents due to gate movement.

To clean the photocells use a water dampened cloth. Do not use solvents or other chemical products which may ruin the devices.

In the event of any strange vibrations or squeaking, lubricate the joints with grease, as shown in the diagram.

Lubricate the endless screw via the hole located under the die-casting of the motor (fig. A)

Fig.A

ENGLISH

Make sure there are no plants within the photocell’s beam, and that the gate motion is free of any obstacles.

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

7.2 Trouble shooting

MALFUNCTIONS POSSIBLE CAUSES CHECK AND REMEDIES

The gate will not open

nor close

01/2009 © CAM E cancelli automatici s.p.a. -

0.1

ver.

The gate opens but

119DU85

will not close

:

The Flashing light

Manual code

does not work

13 -

Pag.

• There is no power

• The gearmotor is released

• The transmitter’s batteries are run down

• The transmitter is broken

• The stop button is either stuck or broken

• The opening/closing button or the selector switch are stuck

• Check that the power is up

• Call assistance

• Replace batteries

• Call assistance

• Call assistance

• Call assistance

• The photocells are engaged • Check that photocells are clean

and in good working order

• Call assistance

• The bulb is burnt • Call assistance

Page 16

14

119DU8 5

0.1

Periodic maintenance log for end-user (every 6 moths).

ENGLISH

Date Notes

Signature

7.3 Extra-ordinary maintenance

The following table serves to note down any extraordinary maintenance, repairs or improvements performed by specialised firms.

N.B.: Any extraordinary maintenance must be performed by specialised technicians.

Extra-ordinary maintenance log

Installer’s stamp Operator name

Date of job

Technician’s signature

Requester’s signature

Job performed _______________________________________________________________________________________

__________________________________________________________________________________________________

____________________________________________________________________________________________

Installer’s stamp Operator name

Date of job

Technician’s signature

Requester’s signature

Job performed _______________________________________________________________________________________

__________________________________________________________________________________________________

____________________________________________________________________________________________

Installer’s stamp Operator name

0.1 01/2009 © CAME cancelli automatici s.p.a. - The data and information repor ted in this installation manual are susceptible to change at any time and without obligation on C AME cancelli automatici s.p.a. to notif y users.

Date of job

Technician’s signature

119DU85 ver.

Requester’s signature

Job performed _______________________________________________________________________________________

__________________________________________________________________________________________________

____________________________________________________________________________________________

14 - Manual code:

Pag.

Page 17

15

119DU8 5

0.1

Installer’s stamp Operator name

Date of job

Technician’s signature

Requester’s signature

Job performed _______________________________________________________________________________________

__________________________________________________________________________________________________

____________________________________________________________________________________________

Installer’s stamp Operator name

Date of job

Technician’s signature

Requester’s signature

Job performed _______________________________________________________________________________________

__________________________________________________________________________________________________

____________________________________________________________________________________________

8 Phasing out and disposal

CAME cancelli automatici s.p.a. employs a UNI EN ISO 14001 certified and compliant environmental protection system at its

plants, to ensure that environmental safeguarding.

We ask you to keep protecting the environment, as CAME deems it to be one of the fundamental points of its market operations

strategies, by simply following these brief guidelines when disposing.

DISPOSING THE PACKING MATERIALS

The packing components (cardboard, plastic, etc.) are solid urban waste and may be disposed of without any particular difficulty, by

simply separating them so that they can be recycled.

Before actions it is always advisable to check the pertinent legislation where installation will take place.

DO NOT DISPOSE OF IN NATURE!

DISPOSING OF THE PRODUCT

Our products are made using different types of materials

The majority of them (aluminium, plastic, iron, electric cables) can be considered to be solid urban waste

They may be recycled at authorised firms

Other components (electrical circuit board, remote control batteries etc.) may contain hazardous waste.

They must, thus, be removed and turned in to licensed firms for their disposal.

Before acting always check the local laws on the matter.

DO NOT DISPOSE OF IN NATURE!

ENGLISH

9 Conformity declaration

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

MANUFACTURER’S DECLARATION OF CONFORMITY

CAME Cancelli Automatici S.p.A.

via Martiri della Libertà, 15

31030 Dosson di Casier - Treviso - ITALY

tel (+39) 0422 4940 - fax (+39) 0422 4941

internet: www.came.it - e-mail: info@came.it

Declares under its own responsibility that the equipments for automatic garage doors and gates listed below:

AX302304 / AX402306 / AX412306 / AX71230

… comply with the National Law related to the following European Directives and to the applicable parts of the

01/2009 © CAM E cancelli automatici s.p.a. -

following Standards.

0.1

IRECTIVES ---

--- D

98/37/CE - 98/79/CE M

ver.

98/336/CEE - 92/31/CEE ELECTROMAGNETIC COMPATIBILITY DIRECTIVE

73/23/CEE - 93/68/CE LOW VOLTAGE DIRECTIVE

89/106/CEE CONSTRUCTION PRODUCTS DIRECTIVE

119DU85

:

Manual code

Reference code to request a true copy of the original: DDF B IT A001i

15 -

Pag.

ACHINERY DIRECTIVE

Pursuant to annex II B of the Machinery Directive 98/37/EC

--- STANDARDS --EN 13241-1 EN 12635 EN 61000-6-2

EN 12453 EN 12978 EN 61000-6-3

EN 12445 EN 60335-1

Do not use the equipment specifi ed here above, before

In full compliance with the Machinery Directive 98/37/EC

IMPORTANT WARNING!

completing the full installation

MANAGING DIRECTOR

Mr. Gianni Michielan

Page 18

CAME F rance S.a.

CAME France S.a.

Nanter re Ce dex -

CAME G mbh S eefel d

Seefel d

CAME A utoma tisme s S.a .

Marsei lle -

CAME G mbh

Korn tal

CAME A utoma tismo s S.a .

Madri d -

CAME A meric as Au tomat ion L lc

Sunris e

CAME A utoma tismo s Cat aluny a S.a .

Sant Vicen c Del Hort s -

CAME M iddle East Fzco

Dubai -

Paf - CAME

Rio D e Mou ro -

CAME P olska Sp.Z o.o

Warsza wa -

CAME U nited King dom L td.

Nottin gham

S.c. C AME R omani a S.r .l.

Bucare st -

CAME B elgiu m Spr l

Lessi nes -

CAME R ussia

Moskva

CAME C ancel li Au tomat ici S .p.a.

Dosso n Di Casie r

CAME N ord s .r.l.

Colog no Mo nzese

CAME S ervic e Ita lia S .r.l.

Dosso n Di Casie r

Assist enza Tecni ca 80 0 295 830

CAME S ud s. r.l.

Napol i

En glish

... .. .. .. ..

...

7, Rue Des Haras

Z.i. Des Hautes Patures

92737

Nanterre Cedex - FRANCE

(+33) 1 46 13 05 05

(+33) 1 46 13 05 00

CAME Gmbh Seefeld

Akazienstrasse, 9

16356

Seefeld

Bei Berlin - DEUTSCHLAND

(+49) 33 3988390

(+49) 33 39883985

CAME Automatismes S.a.

3, Rue Odette Jasse

13015

Marseille - FRANCE

(+33) 4 95 06 33 70

(+33) 4 91 60 69 05

CAME Automatismos S.a.

C/juan De Mariana, N. 17-local

28045

Madrid - SPAIN

(+34) 91 52 85 009

(+34) 91 46 85 442

CAME Automatismos Catalunya S.a.

P.i. Moli Dels Frares N. 23 C/a

08620

Sant Vicenc Del Horts - SPAIN

(+34) 93 65 67 694

(+34) 93 67 24 505

Paf - CAME

Estrada Nacional 249-4 Ao Km 4,35

Cabra Figa - Trajouce

2635-047

Rio De Mouro - PORTUGAL

(+351) 219 257 471

(+35) 219 257 485

Kornwestheimer Str. 37

Munchingen Bei Stuttgart - DEUTSCHLAND

(+49) 71 5037830

(+49) 71 50378383

CAME Americas Automation Llc

1560 Sawgrass Corporate Pkwy, 4th Floor

Sunrise, FL 33323 - U.S.A

(+1) 305 433 3307

(+1) 305 396 3331

CAME Middle East Fzco

Po Box 17131 Warehouse N. Be02

South Zone - Jebel Ali Free Zone -

(+971) 4 8860046

(+971) 4 8860048

CAME Polska Sp.Zo.o

01-237

Warszawa - POLAND

(+48) 22 8365076

(+48) 22 8363296

CAME Gmbh

70825

Korntal

Dubai - U.A.E.

Ul. Ordona 1

CAME United Kingdom Ltd.

Unit 3 Orchard Business Park

Town Street, Sandiacre

Nottingham - Ng10 5du - UNITED KINGDOM

Buftea, Judet Ilfov

(+44) 115 9210430

... ../.... © CAME cancelli automatici s.p.a.

........... ver.

(+44) 115 9210431

CAME Belgium Sprl

Zoning Ouest 7

7860

Lessines - BELGIUM

(+32) 68 333014

(+32) 68 338019

S.c. CAME Romania S.r.l.

B-dul Mihai Eminescu, Nr. 2, Bloc R2

Scara A, Parter, Ap. 3

Bucarest - ROMANIA

(+40) 21 3007344

(+40) 21 3007344

CAME Russia

Leningradskij Prospekt, Dom 80

Pod’ezd 3, offi ce 608

125190,

Moskva - RUSSIA

(+7) 495 937 33 07

(+7) 495 937 33 08

The data and information reported in this installation manual are susceptible to change at any time and without obligation on CAME cancelli automatici s.p.a. to notify users.

English - Manual code:

CAME Cancelli Automatici S.p.a.

Via Martiri Della Libertà, 15

31030

Dosson Di Casier (Tv)

(+39) 0422 4940

(+39) 0422 4941

20093

CAME Nord s.r.l.

Piazza Castello, 16

Cologno Monzese (MI)

(+39) 02 26708293

(+39) 02 25490288

Informazioni Commerciali 800 848095

www.came.it

CAME Service Italia S.r.l.

Via Della Pace, 28

31030

Dosson Di Casier (Tv)

(+39) 0422 383532

(+39) 0422 490044

Assistenza Tecnica 800 295830

CAME Sud s.r.l.

Via F. Imparato, 198

Cm2 Lotto A/7

80146

Napoli

(+39) 081 7524455

(+39) 081 7529109

Loading...

Loading...