Page 1

CAME UNITED KINGDOM LTD

ORCHARD PARK INDUSTRIAL ESTATE

TOWN STREET, SANDIACRE,

NOTTINGHAM, NG10 5BP

TECHNICAL

TEL: 0115 921 0430

FAX: 0115 921 0431

INTERNET - www.cameuk.com

E-MAIL - enquiries@cameuk.com

HELPLINE

0115 921 0430

ATI KIT

Installation Instructions

for a “Pair” of gates...

THE ATI-P KIT CONSISTS OF:

2 X ATI MOTORS

1 X CONTROL PANEL

1 X RADIO FREQUENCY CARD

1 X TUNED ANTENNA

2 X REMOTE CONTROL TRANSMITTERS

1 X PAIR SAFETY BEAMS

Page 2

INTRODUCTION

THESE INSTRUCTIONS WILL SHOW YOU HOW TO INSTALL

AN ATI GATE KIT TO A PAIR OF GATES.

PLEASE READ THESE INSTRUCTIONS AND DIAGRAMS

CAREFULLY BEFORE STARTING ANY WORK.

UNDER NO CIRCUMSTANCES SHOULD THIS EQUIPMENT BE OPERATED UNLESS FITTED TO A GATE.

FAILURE TO COMPLY WILL INVALIDATE THE GUARANTEE.

1

Page 3

INSTALLATION INSTRUCTIONS

CONTENTS

1) Stage 1:- Civil & Mechanical Section Page

1.1 BASIC HINGE GEOMETRY 3

1.2 BASIC CABLE LAYOUT 4

1.3 LOW VOLTAGE CABLE LAYOUT 5

1.4 ATTACHING BRACKETS 5

1.5 ATTACHING THE REAR BRACKET 6

1.6 ATTACHING THE FRONT BRACKET 7

2) Stage 2:- Wiring & Electrical

2.1 FITTING THE CONTROL PANEL IN THE CASING 9

2.2 GAINING ACCESS TO MOTORS 10

2.3 INSTALLING THE MOTORS 11

2.4 ADJUSTING OPEN/STOP LIMIT SWITCH 11

2.5 WIRING THE MOTORS 13

2.6 WIRING THE SAFETY PHOTOCELLS 14

2.7 INSERTING THE FREQUENCY CARD 14

2.8 WIRING IN THE TUNED ANTENNA 15

2.9 CODING THE REMOTE CONTROLS 15

2.10 POWERING UP THE CONTROL PANEL 15

3) Stage 3:- Commissioning the Control Panel

3.1 INITIAL WIRING & CONTROL PANEL SETUP 17

3.2 OPENING & CLOSING THE GATES 18

3.3 CONTROL PANEL ADJUSTMENTS 19

3.4 AUTOMATIC CLOSE & SAFETY PHOTOCELLS 20

3.5 PROGRAMMING THE REMOTE CONTROLS TO THE

CONTROL PANEL 21

4) Troubleshooting Guide 23

5) Technical Information

5.1 TECHNICAL SPECIFICATIONS 25

5.2 MOTOR TORQUE SETTINGS 26

5.3 ZA4 CONTROL PANEL DESCRIPTION 27

5.4 ZA4 WIRING DIAGRAM 29

5.5 CONTROL PANEL ADJUSTMENTS 30

5.6 ELECTRICAL CONNECTIONS 31

7) Contact Information

“TIME MARCHES ON BUT CAME AUTOMATION EQUIPMENT STANDS THE TEST OF TIME...”

Page 4

STAGE 1

CIVIL & MECHANICAL SECTION

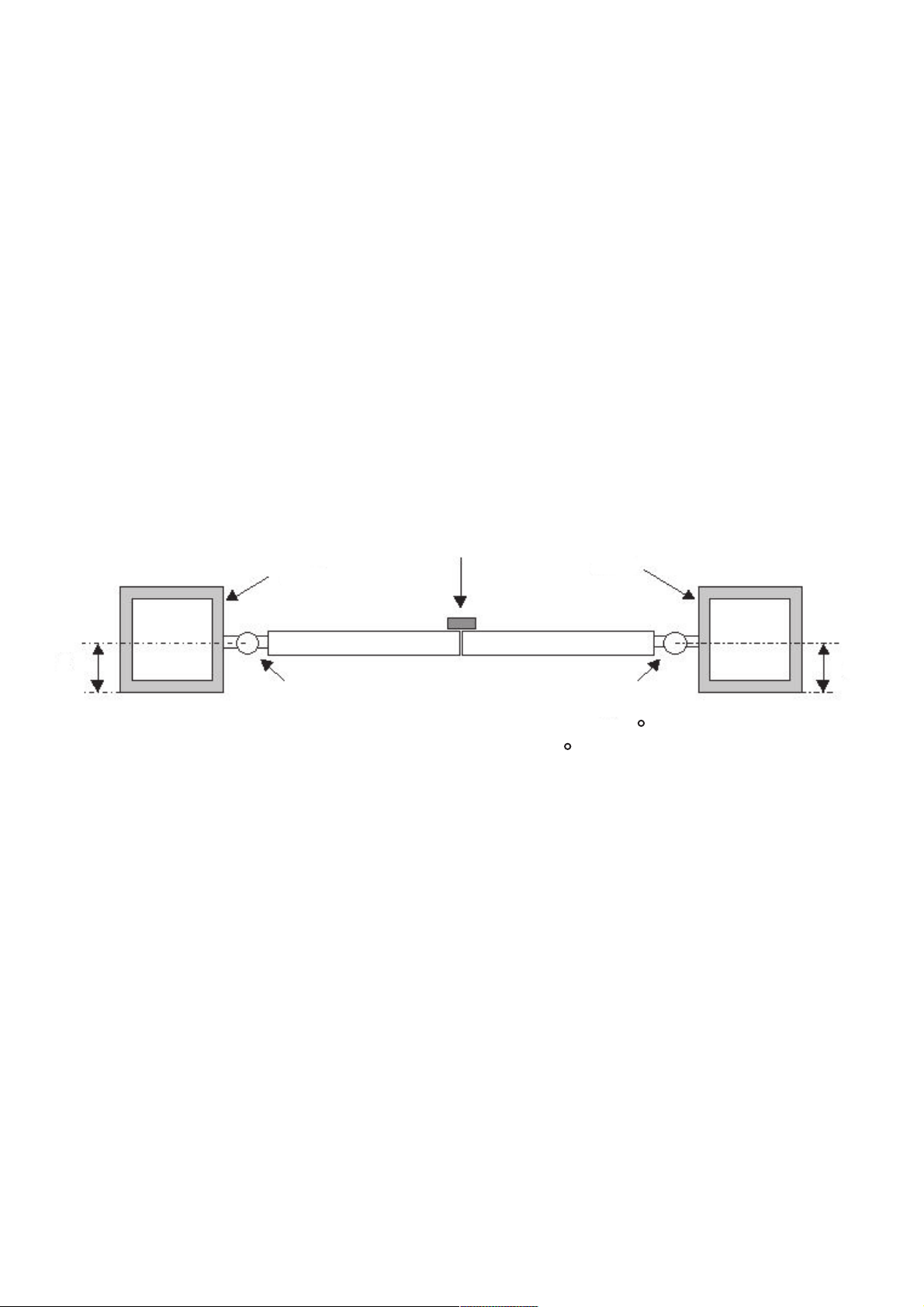

1.1- Basic Hinge Geometry

BEFORE BEGINNING YOUR INSTALLATION OF YOUR ATI SYSTEM, CHECK THE

FOLLOWING:

* YOUR GATE PIERS OR POSTS ARE SUFFICIENTLY STRONG ENOUGH

TO SUPPORT THE GATES AND OPERATORS AND THE GATES SWING

FREELY AND THERE IS NO FRICTION BETWEEN THE MOVING PARTS.

* MEASUREMENT C MUST NOT BE GREATER THAN THE VALUE SHOWN

BELOW. IF THIS IS THE CASE, IT IS NECESSARY TO MODIFY THE

PILLAR SO THAT THIS MEASUREMENT CORRESPONDS.

Fig 1

CENTRE STOP

PILLAR

PILLAR

C

HINGE HINGE

Dimension C must be no greater than 120mm for 90 opening and

no greater than 70mm for a 130 opening.

* ENSURE THAT A GATE CENTRE STOP IS SECURELY CONCRETED INTO THE

GROUND AND AS A GUIDE, THE CENTRE STOP SHOULD NOT PROTRUDE OUT

OF THE GROUND NO MORE THAN 65mm, IF IT IS MUCH HIGHER IT MAY

CATCH ON THE UNDER-SIDE OF A CAR.

C

3

Page 5

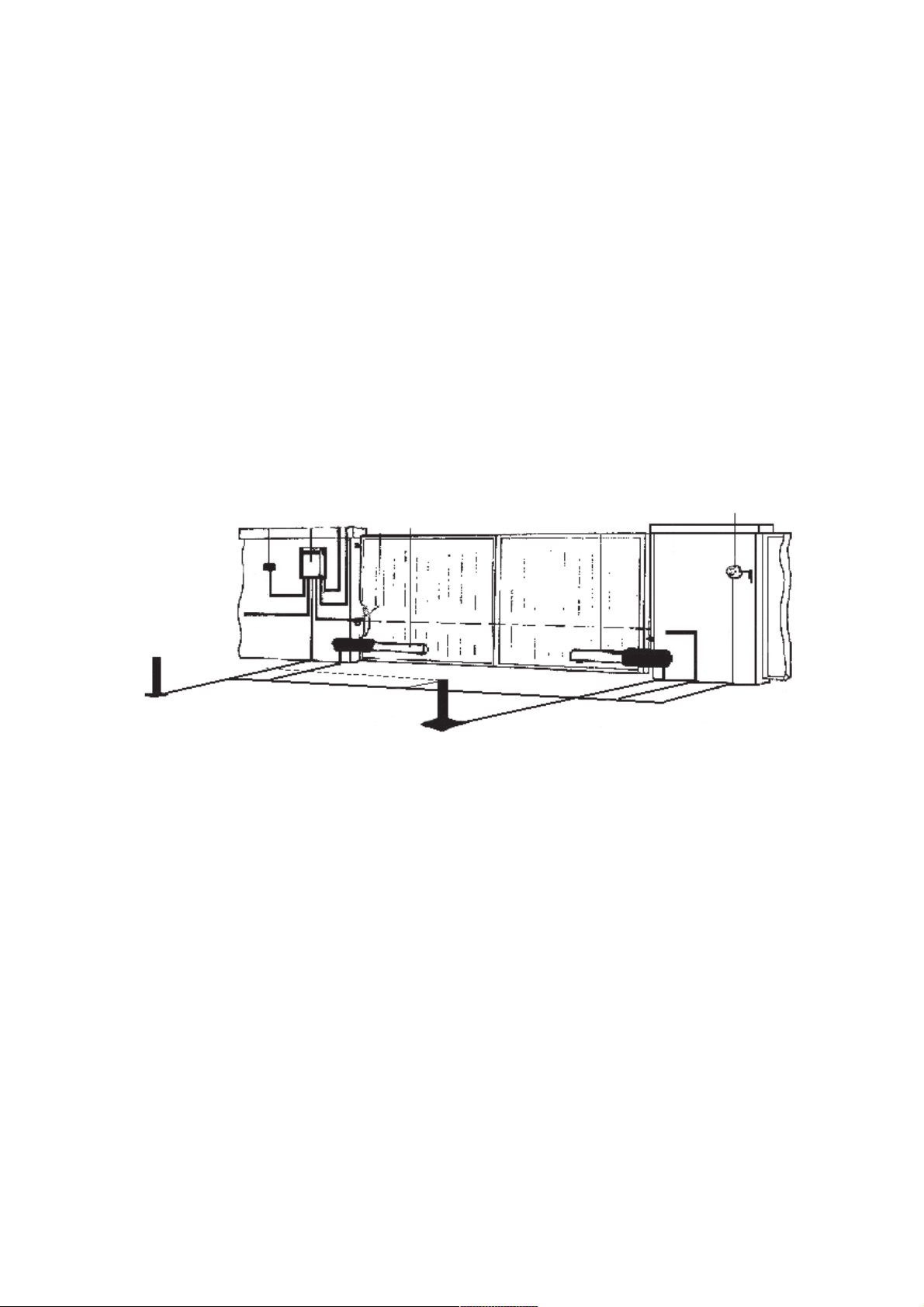

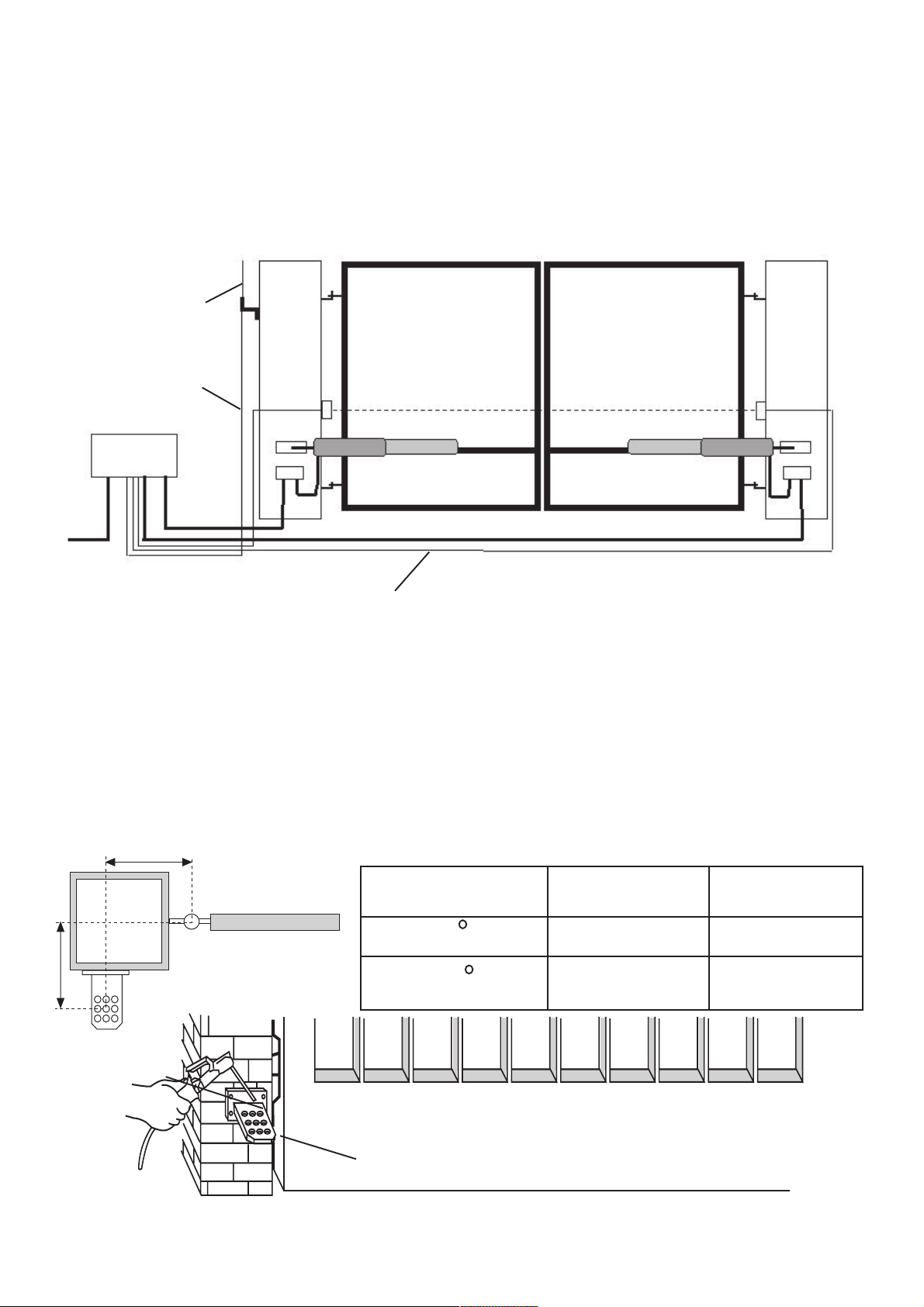

1.2 - Basic Cable Layout

THIS DIAGRAM DETAILS THE BASIC CABLE LAYOUT FOR

A PAIR OF MOTORS.

THE POWER SUPPLY TO THE CONTROL PANEL SHOULD BE LIVE AND

PROTECTED IN ACCORDANCE WITH THE 16TH EDITION ELECTRICAL

REGULATIONS. THE SUPPLY SHOULD BE RATED AT A MINIMUM OF 6 AMPS.

WHEN INSTALLING WIRES OUTDOORS THE CABLE APPROACH TO ALL

DEVICES MUST BE FROM BELOW TO CREATE A “DRIP-LOOP” AND THEREBY

AVOID UNNECCESSARY WATER INGRESS.

Fig 2

CONTROL PANEL

HOUSING

240V A.C

3 CORE

1.5mm SWA

4 CORE

1.5mm FLEX

JOINT BOX

WHEN INSTALLING LOW VOLTAGE CABLE AROUND THE GATEWAY IT IS

ADVISED TO PUT ALL LOW VOLTAGE CABLE IN EITHER DUCTING OR

ALKATHENE PIPING. ALL CABLE JOINTING SHOULD BE CARRIED OUT

ABOVE GROUND.

4

Page 6

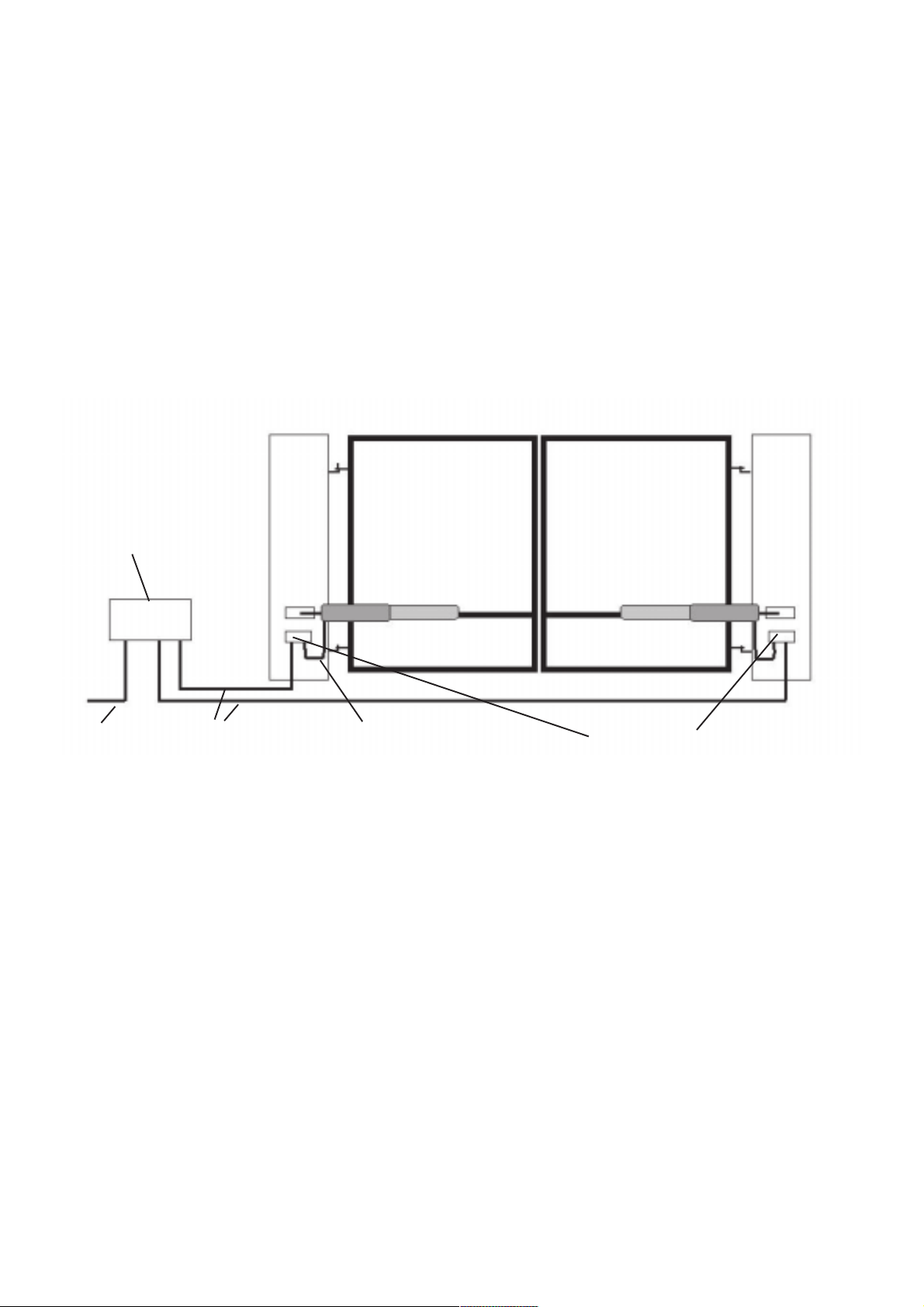

1.3 - Low Voltage Cable Layout

ALL CAME ACCESSORIES CAN BE WIRED 0.2m STRANDED CABLE (BUGLAR

ALARM TYPE). THE TUNED ANTENNA SHOULD BE WIRED WITH COAXIAL

CABLE (RG59).

Fig 3

TUNED

ANTENNA

COAXIAL

CABLE

8 CORE 0.2mm STRANDED

CABLE TO ALL SAFETY BEAMS

DOC E SAFETY

BEAMS

1.4 - Attaching Brackets

WELD THE 9 HOLE BRACKET TO THE FIXING PLATE THEN SECURLEY

ATTACH THE FIXING BRACKET TO THE PIER OR POST, OBSERVE

MEASUREMENT A AND B BETWEEN THE HINGE PIN AND THE CENTRAL

HOLE IN THE BRACKET.

Fig 4

A

B

FIXING PLATE

Opening

90

130

REAR BRACKET

5

A

mm mm

200

200

B

200

140

Page 7

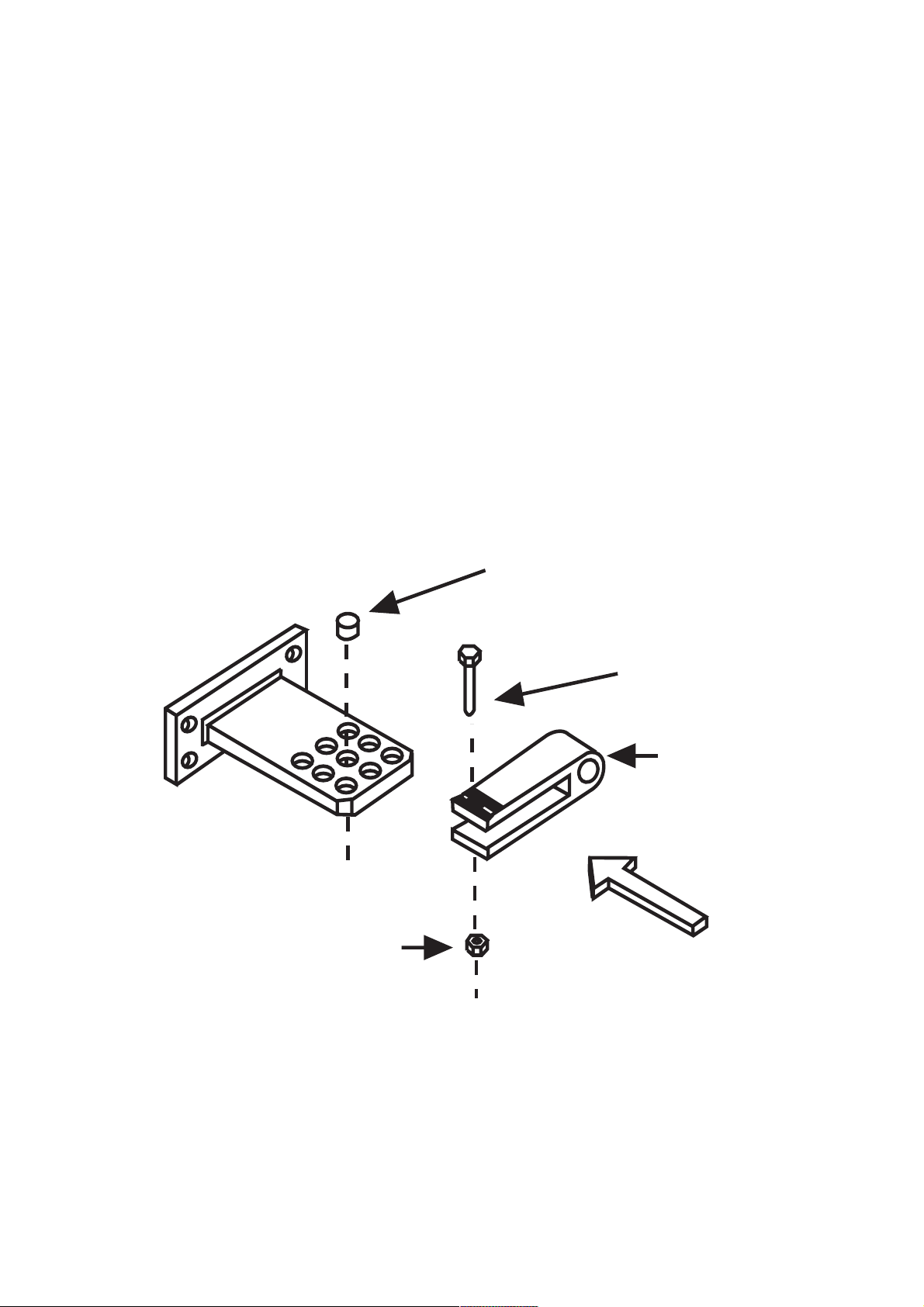

1.5 - Attaching the Rear Bracket

THE REAR BRACKET IS EQUIPPED WITH ADDITIONAL HOLES TO MAKE

INSTALLATION OF THE GATE MOTOR EASIER, OR TO CHANGE THE

OPENING ANGLE OF THE GATE. THE REAR BRACKET CAN BE LENGHENED

OR SHORTENED TO SUIT THE INDIVIDUAL INSTALLATION SITE AND THE

POSITION OF THE GATES (WITH RESPECT TO THE PILLARS).

N.B IF MEASUREMENT B IS INCREASED, THE ANGLE OF APETURE IS

REDUCED. THIS THEREFORE REDUCES THE PERIPHERAL SPEED

AND INCREASES THE THRUST EXERTED BY THE MOTOR ON THE

GATE. IF MEASUREMENT A IS INCREASED, THE ANGLE OF

APERTURE IS INCREASED. THIS THEREFORE INCREASES THE

PERIPHERAL SPEED AND REDUCES THE THRUST EXERTED BY THE

MOTOR ON THE GATE.

WHEN THE REAR BRACKET IS SECURELY ATTACHED TO THE PIER OR POST,

INSERT THE BUSH INTO THE DESIRED HOLE AND ATTACH THE REAR JOINT

ARM, LUBRICATING WITH A NEUTRAL GREASE.

MB

Fig 5

BUSHING

M8 X 38

REAR JOINT

6

Page 8

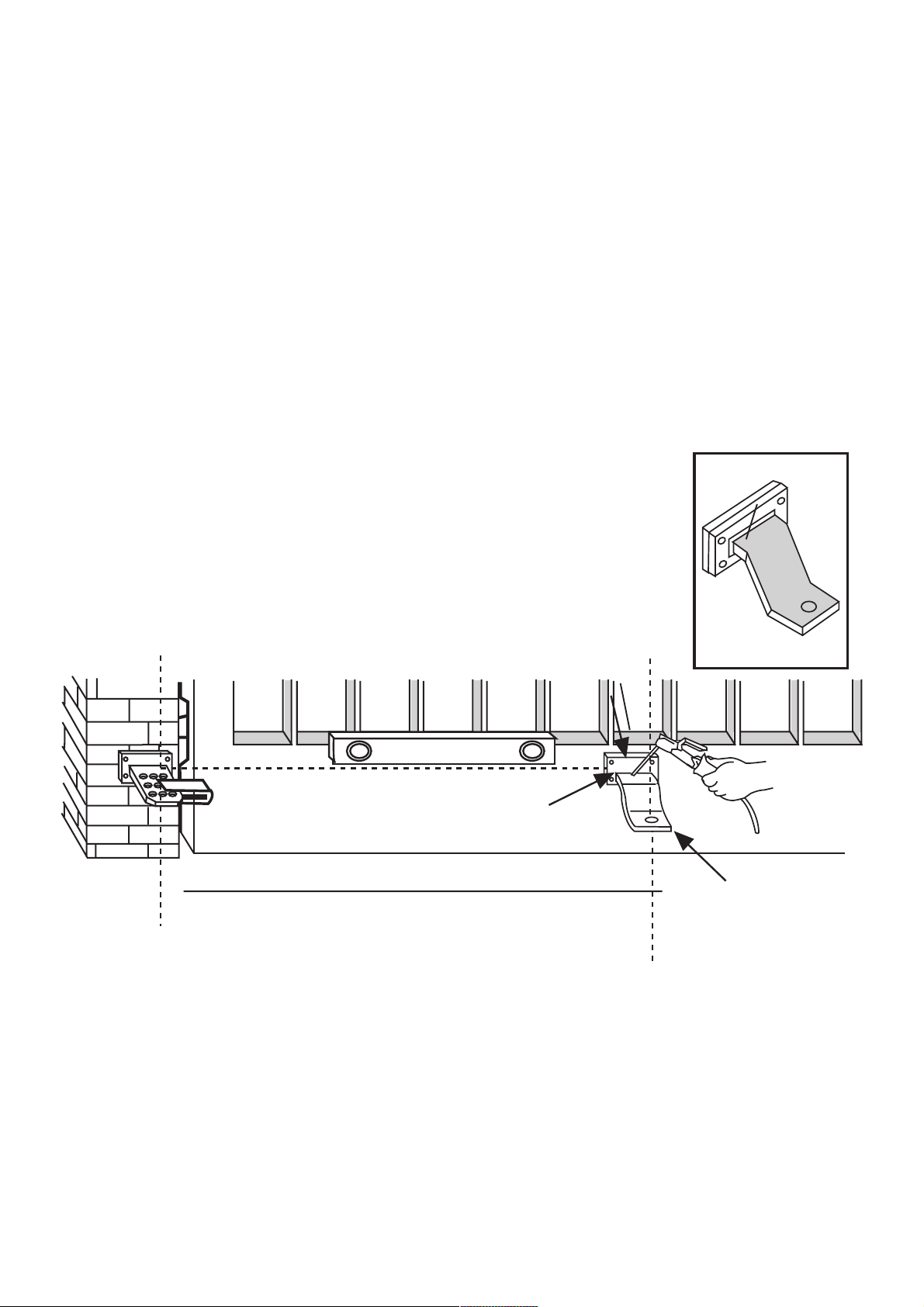

1.6 - Attaching the Front Bracket

WITH THE GATE IN THE FULLY CLOSED POSITION WELD THE FRONT

BRACKET TO THE FIXING PLATE THEN ATTACH IT TO THE GATE. THE

ANCHOR PLATE MUST BE HORIZONTALLY ALIGNED WITH THE REAR

BRACKET MOUNTED ON THE PEIR OR POST ENSURING DIMENSION IS

OBSERVED.

N.B WHEN INSTALLING THE UNIT ON SPECIAL FRAMES, IT MAY BE

NECCESSARY TO FIT ADDITIONAL SPACERS WITH A MINIMUM

THICKNESS OF 10mm IN ORDER TO PREVENT CONTACT BETWEEN

THE OPERATOR AND THE GATE WING.

Fig 6

THICKNESS

MIN 10mm

LEVEL THE BRACKET

E=880 mm

FIXING

PLATE

FRONT

BRACKET

7

Page 9

END OF INSTALLATION

STAGE 1

BEFORE STARTING STAGE 2 - Wiring & Electrical

PLEASE CHECK THAT YOU HAVE CORRECTLY:

Ref

Page

1. PREPARED THE CABLING CORRECTLY 1.2 4

2. CORRECTLY ATTACHED THE BRACKETS 1.4 5

NOW STAGE 1 IS FULLY COMPLETED YOU ARE READY TO

BEGIN STAGE 2 OF YOUR ATI AUTOMATION KIT

INSTALLATION

8

Page 10

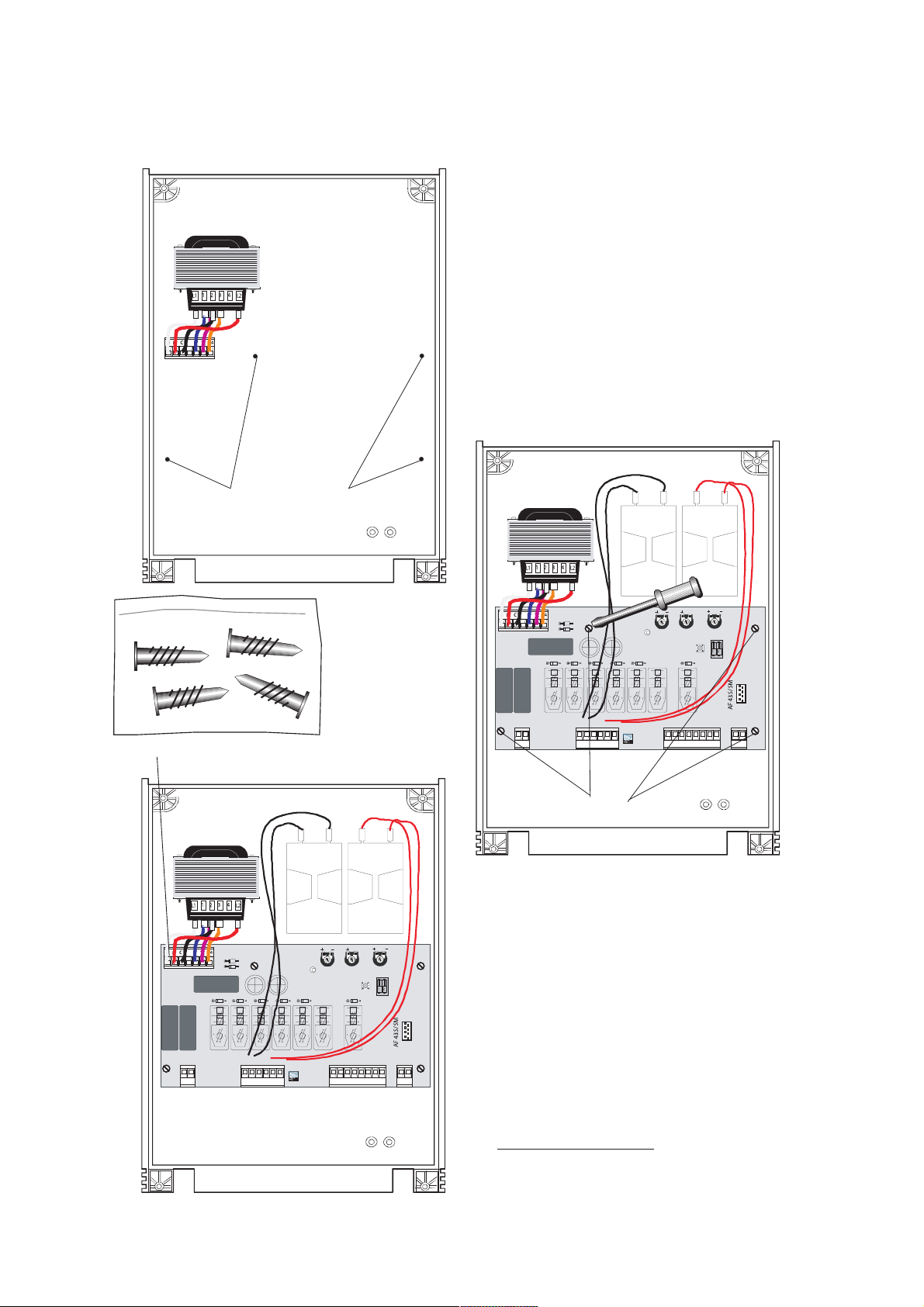

STAGE 2 - WIRING & ELECTRICAL

2.1 - Fitting the Control Panel in the Casing

Securely fasten the control panel PCB to the

casing with the screws supplied.

Screw positioning holes

Fastening screws

Green connector point

Screws

Plug the green connector from the transformer to

the PCB ensuring that it connects the correct way .

NB FROG Series Motors:

connect the black wires

coming out of the board to one capacitor and the

red wires to the other.

9

Page 11

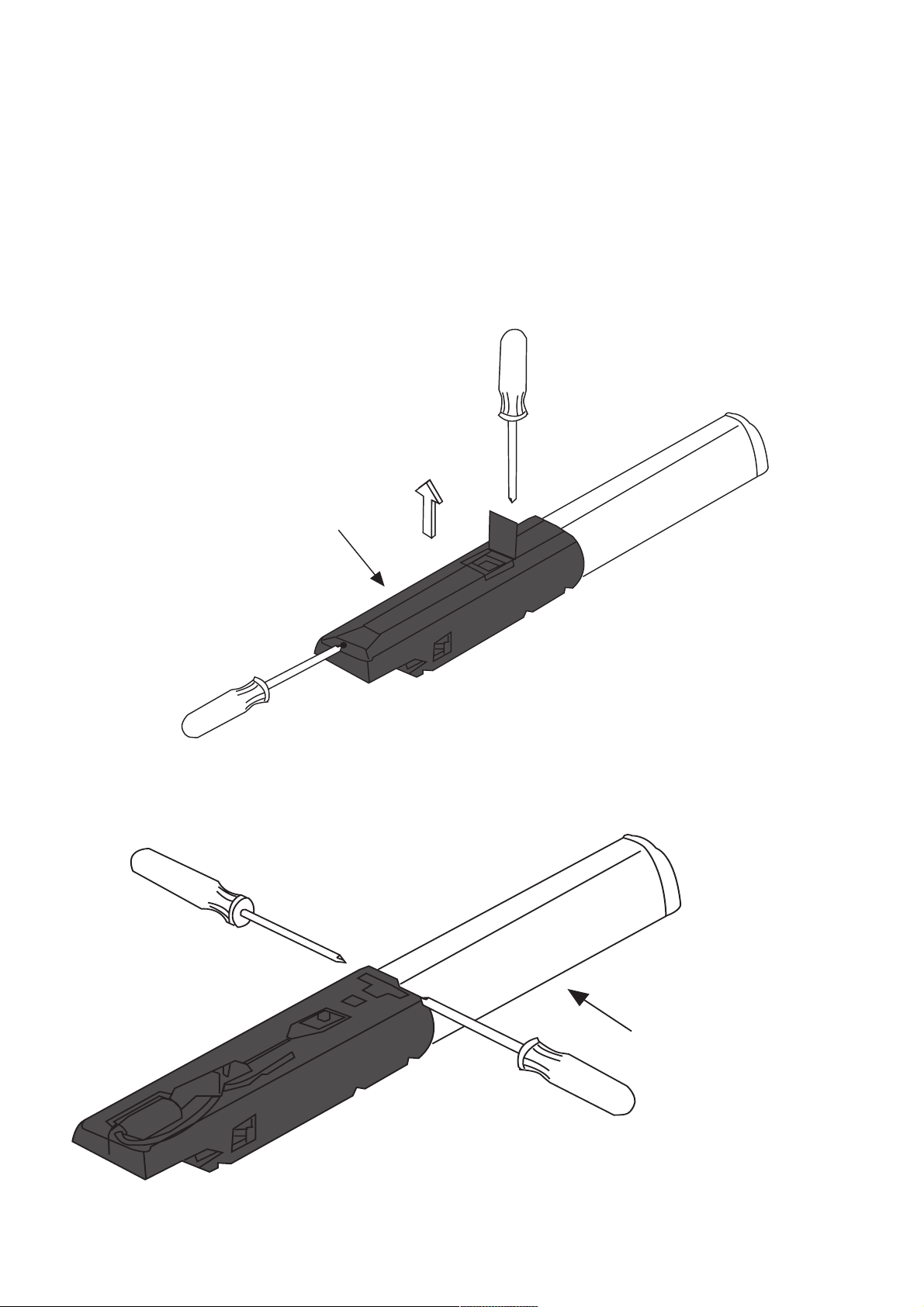

2.2 - Gaining Access to the Motors

TO GAIN ACCESS TO THE MOTOR TERMINALS AND WORM DRIVE FIRST

REMOVE THE COVERS. FIRST REMOVE THE SCREWS FROM THE TOP

COVER. THEN REMOVE THE TWO SCREWS THAT SECURE THE WORM

DRIVE COVER.

Fig 7

CASING

Fig 8

COVER

10

Page 12

2.3 - Installing the Motors

WITH THE COVERS REMOVED INSTALL THE MOTOR ON THE TWO

BRACKETS AND SECURE THE MOTOR WITH THE NUTS AND BOLTS

PROVIDED.

Fig 9

M8 LOCKNUT

WORM-GEAR

M8 X 50

M8 X 10

2.4 - Adjusting the Open Stop Microswitch

MANUALLY RELEASE THE REDUCTION GEAR BY INSERTING THE RELEASE

KEY AND TURNING IT 180.

Fig 10

180°

11

Page 13

MOVE THE GATE TO THE DESIRED OPEN POSITION. LOOSEN THE SCREWS

WHICH HOLD THE MICROSWITCH IN POSITION. SLIDE THE MICROSWITCH

ON THE SUPPORT PLATE UNTIL THE MICROSWITCH IS TRIPPED. THEN

TIGHTEN THE SCREWS TO ANCHOR THE MICROSWITCH IN POSITION.

Fig 11

MICROSWITCH

SUPPORT PLATE

MICROSWITCH

WORMGEAR

SCREWNUT

FIXING SCREW

12

Page 14

2.5 - Wiring the Motors

ENSURE BOTH MOTORS ARE ADEQUATELY EARTHED.

Fig 12

MOTOR 1 MOTOR 2

U V W W X Y

MOTOR

EARTH

MOTOR

EARTH

U V W X Y E E3

13

Page 15

2.6 - Wiring in the Safety Photocells

SAFETY BEAMS SHOULD BE FITTED APPROXIMATELY

15 INCHES FROM GROUND LEVEL

CONTROL PANEL

Fig 13

10 11 2 C1

NC

C

C

TX

10

11

NC

RX

10

11

SAFETY

BEAM

TRANSMITTER

SAFETY

BEAM

RECEIVER

IF FITTING A SECOND ARC LINE SET OF SAFETY BEAMS THEN C & NC MUST BE WIRED IN “SERIES”

2.7 - Inserting the Radio Frequency Card

Fig 14

INSERT THE RADIO FREQUENCY

CARD INTO THE SMALL SOCKET

ON THE CONTROL PANEL

(ENSURE THAT THE POWER IS

TURNED OFF TO THE CONTROL

PANEL BEFORE INSERTING THE

FREQUENCY CARD)

ZA4

ANTENNA

WIRING

POINT

14

Page 16

2.8 - Wiring in the Tuned Antenna

Bat

8 9 10

Bt

Batt

1

Fig 15

ANTENNA

WIRING

POINT

2.9 - Coding the Remote Controls

1. REMOVE THE BATTERY COVER & CASING OF THE REMOTE CONTROL

HANDSET TO REVEAL THE DIAGRAM BELOW

2. SET THE BANK OF

DIPSWITCHES ON

ALL REMOTES TO

EXACTLY THE SAME

CODE OF YOUR

CHOICE.

Fig 16

ON OFF

ON

1 2 3 4 5 6 7 8 9 10

Battery 12V

3. UNLESS PROGRAMMING FOR GATES AND

GARAGE DOORS TO OPEN BY REMOTE

CONTROL FROM THE SAME HANDSET ENSURE

THAT THE JUMPER STRAPS SHOWN HERE ARE

IN THE SAME POSITIONS ON ALL REMOTES

2.10 - Powering up the Control Panel

CONNECT PROTECTED MAINS POWER TO TERMINALS L1 + L2 IN THE

CONTROL PANEL (L2 BEING LIVE!). ENSURE THAT THE CONTROL PANEL

IS ADEQUATELY EARTHED.

15

Page 17

END OF INSTALLATION

STAGE 2

BEFORE STARTING STAGE 3 -

Commissioning the Control Panel

PLEASE CHECK THAT YOU HAVE CORRECTLY:

Ref Page

1. GAINED ACCESS TO MOTORS 2.1 9

2. INSTALLED MOTORS 2.2 10

3. ADJUSTED OPEN/STOP LIMIT SWITCH 2.3 10

4. WIRED THE MOTORS 2.4 12

5. WIRED THE SAFETY PHOTOCELLS 2.5 13

6. INSERTING THE FREQUENCY CARD 2.6 13

7. WIRED THE TUNED ANTENNA 2.7 14

8. CODED THE REMOTE CONTROLS 2.8 14

9. POWERED UP THE CONTROL PANEL 2.9 14

NOW STAGE 2 IS FULLY COMPLETED YOU ARE READY TO

BEGIN STAGE 3 OF YOUR ATI AUTOMATION KIT

INSTALLATION

16

Page 18

STAGE 3

COMMISSIONING THE CONTROL PANEL

3.1 - Initial Wiring & Control Panel Setup

Fig 17

1. CONNECT POWER TERMINALS L1 - L2

AND A SUITABLE EARTH (L2 BEING LIVE!)

2. SELECT THE MOTOR POWER SETTING ON

THE TRANSFORMER TO LEVEL 1 FOR

COMMISSIONING

1 2 3 4 5 6 7 8 9 10

ON

3. SELECT DIPSWITCHES 1 & 2 OFF FOR

COMMISSIONING

OFF

Fig 18

4. ENSURE HARD WIRE LINK IS FITTED

BETWEEN TERMINALS 1 & 2 AND

2 & C1

10 11 S 1 2 3 3P 4 5 7 2 C1 CX B1 B2

Fig 19

17

Page 19

3.2 - Opening & Closing the Gates

L1 L2 U V W X Y E1 10 11 1 2 3 5 7 C1

Fig 20

L1 L2 U V W X Y E1 10 11 1 2 3 5 7 C1

Fig 21

1. MOMENTARILY PULSE TERMINALS

2 & 3 WITH A PIECE OF WIRE

TRAILING FROM TERMINAL 2 AND

MOMENTARILY TOUCHING

TERMINAL 3.

THE GATES SHOULD START TO

OPEN. IF THEY START TO CLOSE

TURN THE POWER OFF TO THE

CONTROL PANEL AND CHANGE

AROUND EITHER U-V (MOTOR 1)

OR X-Y (MOTOR 2) TO CHANGE

THE MOTOR DIRECTION.

2. ONCE YOU HAVE PROVED THE

MOTOR DIRECTION USE

TERMINALS 2 & 7 TO OPEN AND

CLOSE THE GATES WITH A

TRAILING WIRE ONCE AGAIN INTO

TERMINAL 2, MOMENTARILY

TOUCHING TERMINAL 7.

18

Page 20

3.3 - Control Panel Adjustments

1. TO DELAY ONE GATE LEAF, ADJUST POTENIOMETER TR2M TO DELAY

THE CLOSING OF GATE NO. 2 IN THE CLOSING CYCLE

Fig 22

TRIMMER TR2M

TO SET THE TOTAL RUNNING TIME OF THE MOTORS, ADJUST

2.

POTENIOMETER TL TO ALLOW THE MOTORS TO RUN FOR A FURTHER

5-7 SECONDS AFTER THE MOVEMENT CYCLE HAS BEEN COMPLETED

(I.E FULLY OPEN OR FULLY CLOSED)

Fig 23

TRIMMER TL

3. CHECK THE SENSITIVITY OF THE GATES

BY TRYING TO PHYSICALLY STOP THE

GATE AND ADJUST THE POWER

SETTINGS ON THE TRANSFORMER

ACCORDINGLY. IF MORE POWER IS

NEEDED FOR HEAVIER GATES THEN

SWITCH OFF POWER AND MOVE

TRANSFORMER WIRE UP TO SETTING 2.

FOR RECHECKING SENSITIVITY, REPEAT

PROCESS UP TO 3 OR 4 IF EVEN MORE

POWER IS NEEDED.

Fig 24

19

Page 21

3.4 - Automatic Close & Activating Safety Photocells

Fig 25

ON

1

1

1. TO SELECT AUTOMATIC CLOSING,

SELECT DIPSWITCH 2 ON.

OFF

SET THE AUTOMATIC CLOSING TIME BY ADJUSTING POTENTIOMETER TCA

TRIMMER

TCA

Fig 26

6 O’CLOCK

FULLY ANTI-CLOCKWISE WILL APPROX. AUTOMATICALLY CLOSE THE GATES

AFTER 10 SECONDS AND FULLY CLOCKWISE WILL APPROX. CLOSE THE

GATES AFTER 80 SECONDS. A SENSIBLE SETTING IS ABOUT HALFWAY

(I.E 6 O’CLOCK POSITION) WHICH WILL AUTOMATICALLY CLOSE THE

GATES AFTER APPROX. 30 SECONDS.

10 11 1 2 3 5 7 C1

10 11 C NC

Fig 27

2. FOR RE-OPENING DURING CLOSING.

REMOVE HARD WIRE LINK BETWEEN

2 & C1 AND INSERT SAFETY BEAM

WIRES AS SHOWN.

20

Page 22

3.5 - Programming the Remote Controls

to the Control Panel

To use the remote control system, proceed as follows:

A) Turn power OFF and insert AF radio frequency board then turn

power back on

B) Code the transmitter. See the relevant instruction sheet

(See Fig 11)

C) To store the code on the circuit board Proceed as follows:

Press and hold down the programming button on the radio receiver

card (the signal LED will start to flash)

At the same time transmit on the top button of your remote

control; keep both the top button and the yellow receiver button

pressed until the LED stops flashing and remains on constant. It

will then go out to indicate that the code has been successfully

stored.

N.B. If you wish to change the code on your transmitter in the future,

simply repeat the procedure above with all the remotes on the

installation.

WARNING: Disconnect the power supply from the control board before

inserting OR removing the AF radio-frquency card from the

socket.

21

Page 23

END OF INSTALLATION

STAGE 3

PLEASE CHECK THAT YOU HAVE CORRECTLY:

Ref Page

1. SET POWER SETTING, SET DIPSWITCHES FOR

COMMISSIONING, ENSURE WIRE LINK

IS FITTED BETWEEN TERMINALS 1 & 2

AND 2 & C1 3.1 16

2. SET THE OPENING AND CLOSING TIMES

FOR GATES 3.2 17

3. ADJUSTED THE CONTROL PANEL 3.3 18

4. IF REQUIRED, ACTIVATED AUTOMATIC

CLOSING AND SAFETY PHOTOCELLS 3.4 19

5. PROGRAMMED THE REMOTE TO THE

CONTROL PANEL 3.5 20

22

Page 24

4. TROUBLESHOOTING GUIDE

A MULTIMETER WILL BE NEEDED

PROBLEM SOLUTION

GATE WILL NOT RESPOND

WHEN GIVEN A COMMAND

GATES ARE OPEN BUT WILL

NOT CLOSE AND GREEN LED

IS FLASHING

1. CHECK POWER SUPPLY TO THE

CONTROL PANEL.

2. CHECK CONTROL PANEL FUSES.

3. CHECK HARD WIRE LINK FITTED

BETWEEN TERMINALS 1 & 2.

1. CHECK SAFETY BEAMS ARE WIRED

CORRECTLY. (IF MORE THAN ONE

SET OF BEAMS ARE FITTED THEY

MUST BE WIRED IN SERIES.)

2. CHECK THAT THERE IS POWER

GOING TO THE BEAMS, IF NOT

RESTORE POWER.

WHEN COMMISSIONING

GATE AUTOMATICALLY

OPENS BUT DOES NOT

AUTOMATICALLY CLOSE

3. IF SAFETY BEAMS ARE NOT FITTED

ENSURE THAT A HARD WIRE LINK IS

FITTED BETWEEN TERMINALS 2 & C1

4. REMOVE SAFETY BEAM WIRES 2 &

C1 FROM CONTROL PANEL AND

CHECK IF YOU HAVE A NORMALLY

CLOSED CIRCUIT COMING FROM

THE BEAMS.

1. MOTOR WIRES ARE WRONG WAY

ROUND. CHECK AND PROVE MOTOR

DIRECTION BY MOMENTORIALLY

PULSING TERMINALS 2 & 3. THE

GATE SHOULD OPEN UP. TURN

OFF

AUTOMATIC CLOSING

SWITCH 2) UNTIL MOTOR

DIRECTION HAS BEEN PROVED.

(DIP

CONTINUED ON NEXT PAGE

23

Page 25

PROBLEM

SOLUTION

GATES WILL NOT RESPOND

TO REMOTE CONTROL

COMMAND

1. AF FREQUENCY CARD NOT FITTED TO

CONTROL PANEL.

2. REMOTE CONTROL HAS NOT BEEN

PROGRAMMED INTO THE CONTROL

PANEL.

3. REMOTE CONTROL HAS THE WRONG

CODE SETTING.

4. “OPERATOR PRESENT” HAS NOT BEEN

SELECTED TO DEACTIVATE RADIO

REMOTE CONTROLS (DIPSWITCH 1).

5. WRONG FREQUENCY CARD FITTED

FOR THE REMOTE CONTROL.

IF THE PROBLEM IS STILL APPARENT CONTACT THE

CAME TECHNICAL HELPLINE:

CAME

0800 970 6655

THIS INSTALLATION WAS COMPLETED BY:

..............................................................................

NAME.............................................................................

ADDRESS............................................................

..............................................................................

............................................................................

...........................................................................

TEL........................ MOBILE................................

DATE OF INSTALLATION

.......................................

24

Page 26

5. TECHNICAL INFORMATION

5.1 - Technical Specification

88mm

PILLAR

C

B

126mm

A

HINGE

933mm

880mm

Travel

500mm

GATE WING

CLOSED

CENTRE

STOP

E

TYPE

OPENING

90 DEGREES

A mm B mm

200

200

C Max

mm

120

E mm

880

A5000

130 DEGREES

200 140

70

880

WIDTH OF GATE WING (M) WEIGHT OF GATE WING (KG)

2.00

2.50

3.00

4.00

5.00

1000

800

600

500

400

For particularly heavy gates, two motors per leaf can be fitted. In this case the

weight indicated for the gate can be doubled.

GEAR

A5000

VERSION

1.2

WEIGHT

11Kg

POWER

230V

POWERNOMINAL

1.2A 150W

25

DUTY

50%

1/36400

PUSHREDUCTION

400/

3000*N

CAPACITOR

10uF

Page 27

5.2 - Motor Torque Settings

SEE ALSO PAGE 14

To vary the motor torque, move the indicated spade connector to one of the

four position : 1=min, 4=max.

N.B. It is always best to start from position one and increase the torque

setting as required.

Fig 28

26

Page 28

5.3 - ZA4 Control Panel Description

Description of Control Panel:

Micro-processor controlled electrical cabinet powered by 230V (a/c) at

50-60Hz, single phase. Designed for control of CAME (ATI/FERNI/FROG), for

hinged gates, hinged industrial doors. Designed and built entirely by CAME to

meet UNI8612 safety standards at an IP 54 level of protection. Housing made of

ABS is equipped with vents to provide internal air circulation. Guaranteed for 3

years, unless tampered with. This control panel is powered 230V a.c across

terminals L1 and L2, and is protected by a 5A fuse on the main power line.

Control systems are powered by low voltage and protected by a 2A fuse. The

accessories total wattage (24V) must not exceed 20W.

The Control Panel and Motors should be suitably Earthed

Safety:

SAFETY BEAMS CAN BE CONNECTED TO OBTAIN:

Re-Opening

Total Stop

: During closing (2-C1), if the beam is broken while the gate is

closing, they will reverse the direction of movement until the gate is

completely open and will stay open until the obstacle is removed.

: (1-2) Creates immediate stop of gate movement without automatic

closing: (a pushbutton or radio remote control must be

actuated to resume movement).

N.B IF A NORMALLY CLOSED SAFETY CIRCUIT

(2-C1, 1-2) IS OPENED, THE L.E.D WILL

FLASH TO INDICATE THE FACT THAT THE BEAM IS

BROKEN.

Accessories that can be Connected to this Unit:

“Gate in Motion” Lamp

: The lamp that lights the manoeuvering zone: it remains

lit from the the moment the gate begins to open until

they are completely closed (including the time required

for the automatic closure). When automatic closure is

not enabled, the lamp remains lit only during

movement (E-E3).

27

Page 29

Other functions available:

Automatic closing

: The automatic closing timer is automatically activated at the

“Operator present”

Fig 29

end of the opening cycle. The pre-set, adjustable automatic

closing time is automatically interrupted by the activation of

any safety system, and is deactivated after a STOP

command or in case of power failure.

function:

Gate operates only when the pushbutton is held down (the

radio control system is deactivated)

2 ATI MOTORS

1 CONTROL PANEL

1 FREQUENCY CARD

1 PAIR SAFETY

BEAMS

2 REMOTE CONTROL

TRANSMITTERS

TUNED ANTENNA

28

Page 30

230V A/C

M1

Single-Phase motor

5.4 - ZA4 Wiring Diagram

Terminals 1 and 2, 2 and C1 are normally closed circuits and if

they are not used they must be linked

L1 L2 U V W X Y E1 10 11 1 2 3 5 7 C1

Co-axial cable

M2

Single-Phase motor with leaf delay

on closing cycle

11 TX

10

Safety beams which are connected to obtain Re-opening

During the closing cycle

RX

11

10

C

NC

29

Page 31

5.5 - Control Panel Adjustments

Trimmer T.L. - Adjustment of operating time from a minimum of 0 seconds to a

maximum of 120 seconds N.B. it is advised to let the motors run on for between 6 and 8

seconds after the last gate has fully close.

Trimmer T.C.A - Adjustment of automatic closing time from a minimum of 1 to a

maximum of 120 seconds.

Trimmer T.R.2.M - Partial opening time adjustment and delay in closing of the second

motor leaf delay from a minimum of 0 seconds to a maximum of 20 seconds.

Fig 25

ZA4

T.L T.C.A T.R.2.M

TRIMMERS

ADJUSTMENT

30

Page 32

L1

L2

U

W

V

5.6 - Electrical Connections

L1 L2 U V W X Y E1 10 11 1 2 3 5 7 C1

Power supply for control panel

Connection for motor one (delay in opening)

X

W

Y

W

E1

10

5

10

11

1

2

2

Connection for motor two (delay on closing)

230V (A.C) 25W max output in motion (e.g. flashing light)

“Gate Open” signal light (24V 3W max)

24V (A.C) Output power supply to accessories (max 20W)

Stop button (N.C)

Open only button (N.O)

3

2

7

2

C1

Contact for radio and or pushbutton control for open-close

(N.O)

Contact (N.C) for re-opening during closing

Antenna connection

31

Page 33

Notes

Page 34

Notes

Page 35

Notes

Page 36

6. CONTACT INFORMATION

CAME UNITED KINGDOM LTD

UNIT 3

ORCHARD PARK INDUSTRIAL ESTATE

TOWN STREET, SANDIACRE, NOTTINGHAM NG10 5BP

TEL: 0115 921 0430

FAX: 0115 921 0431

INTERNET : www.cameuk.com

E-MAIL: enquiries@cameuk.com

THIS INSTALLATION WAS COMPLETED BY:

..............................................................................

NAME.............................................................................

ADDRESS............................................................

..............................................................................

............................................................................

...........................................................................

TEL........................ MOBILE................................

DATE OF INSTALLATION

.......................................

Loading...

Loading...