Page 1

IN-GROUND OPERATOR FOR SWING GATES

FROG SERIES

INSTALLATION MANUAL

FROG-A 24V

Page 2

“IMPORTANT INSTALLATION, SAFETY INSTRUCTIONS”

“CAUTION: IMPROPER INSTALLATION MAY CAUSE SERIOUS DAMAGE, FOLLOW ALL INSTALLATION INSTRUCTIONS CAREFULLY”

“THIS MANUAL IS ONLY FOR PROFESSIONAL OR QUALIFIED INSTALLERS”

1 Legend of symbols

This symbol tells you to read the section with particular care.

This symbol tells you that the sections concern safety issues.

This symbol tells you what to say to the end-users.

ENGLISH

2 Condition of use

2.1 Intended use

The FROG operator was engineered to power residential and condominium swing gates.

The use of this product for purposes other than those described above and installation executed in a manner other than

as instructed in this technical manual are prohibited.

2.2 Limits to use

For intensive use and condominiums: max weight of the gate 400kg with max length of 3.5m.

3 Reference Standards

For its quality processes management CAME cancelli automatici is ISO 9001:2000 certified, and for its environmental management it is ISO 14001 certified. CAME engineers and manufactures all of its products in Italy.

This product complies with the following standards: see declaration of conformity.

4 Description

4.1 Operator

This product is engineered and manufactured by CAME CANCELLI AUTOMATICI S.p.A. and complies with current safety regulations.

Guaranteed 24 months if not tampered with.

The operator is made up of a foundation box, a release assembly, a gearmotor and a transmission arm.

The foundation casing is made of 1.5 mm thick ABS plastic on the sides and of 4mm galvanised steel on the bottom plate. On the

inside is the release assembly with a customised, manual-release key and the gearmotor – made of a cast aluminium shell, inside

of which operates an irreversible, gear-ratio and, endless screw plus helical crown system. A transmission arm is connected to

the gearmotor.

4.2 Technical features

FROG

Motor power supply: 24V D.C.

Max draw.: 15 A

Power: 180W

Max Torque.: 320N

Opening time (90°): fron 16 to 45 s

Gear ratio: 1/1396,5

Duty cycle: Intensive use

Protection rating: IP67

Weight: 12 kg

Insulation rating:

#

The data and information shown in this dialogue may be changed by Came Cancelli Automatici S.p.A. at any time without prior warning.

2

#

Page 3

4.3 Dimensions

67

60

160

405 330

5 Installation

Installation must be carried out by expert qualified personnel and in full compliance with current regulations.

5.1 Preliminary checks

ENGLISH

Before installing, do the following:

• Make sure you have a suitable omnipolar cut-off device with contacts more than 3 mm apart, and independent (sectioned off)

power supply;

• Make sure you have suitable tubing and conduits for the electrical cables to pass through and be protected against mechanical

damage;

• Fit tubing to drain away any water leaks which may cause oxidation;

• Make sure that any connections inside the case (that provide continuance to the protective circuit) be fitted with extra

insulation as compared to the other conductive parts inside;

• Make sure the structure of the gate is sturdy, the hinges work and that there is no friction between moving and non-moving

parts;

• Make sure there is a mechanical stop for opening and closing.

5.2 Tools and materials

Make sure you have all the tools and materials you will need for the installation at hand to work in total safety and compliance with the current standards and regulations. The following figure illustrates the minimum equipment needed by the

installer.

The data and information shown in this dialogue may be changed by Came Cancelli Automatici S.p.A. at any time without prior warning.

3

Page 4

5.3 Cable list and minimum thickness

Connections Type of cable Length of cable 1 < 10 m Leng. cable 10 < 20 m Leng. cable 20 < 30 m

Control panel power supply 230V

3G 1,5 mm

Motor power supply 24V 3 x 1 mm

Flashing light 2 x 0,5 mm

Photocell transmitters 2 x 0,5 mm

Photocell receivers 4 x 0,5 mm

Accessories power supply 2 x 0,5 mm

ENGLISH

FROR CEI

20-22

CEI EN

50267-2-1

2

2

2

2

2

2

3G 2,5 mm

3 x 1,5 mm

2 x 1 mm

2 x 0.5 mm

4 x 0,5 mm

2 x 0,5 mm

2

2

2

2

2

2

3G 4 mm

3 x 2,5 mm

2 x 1,5 mm

2 x 0,5 mm

4 x 0,5 mm

2 x 1 mm

2

2

2

2

2

2

Control and safety devices 2 x 0,5 mm

2

2 x 0,5 mm

2

2 x 0,5 mm

2

Antenna connection RG58 max. 10 m

N.B.: If the cable length differs from that specified in the table, then you must determine the proper cable diameter in the basis

of the actual power draw by the connected devices and depending on the standards specified in CEI EN 60204-1.

For connections that require several, sequential loads, the sizes given on the table must be re-evaluated based on actual power

draw and distances. When connecting products that are not described in this manual, please refer to the instructions that come

with said products.

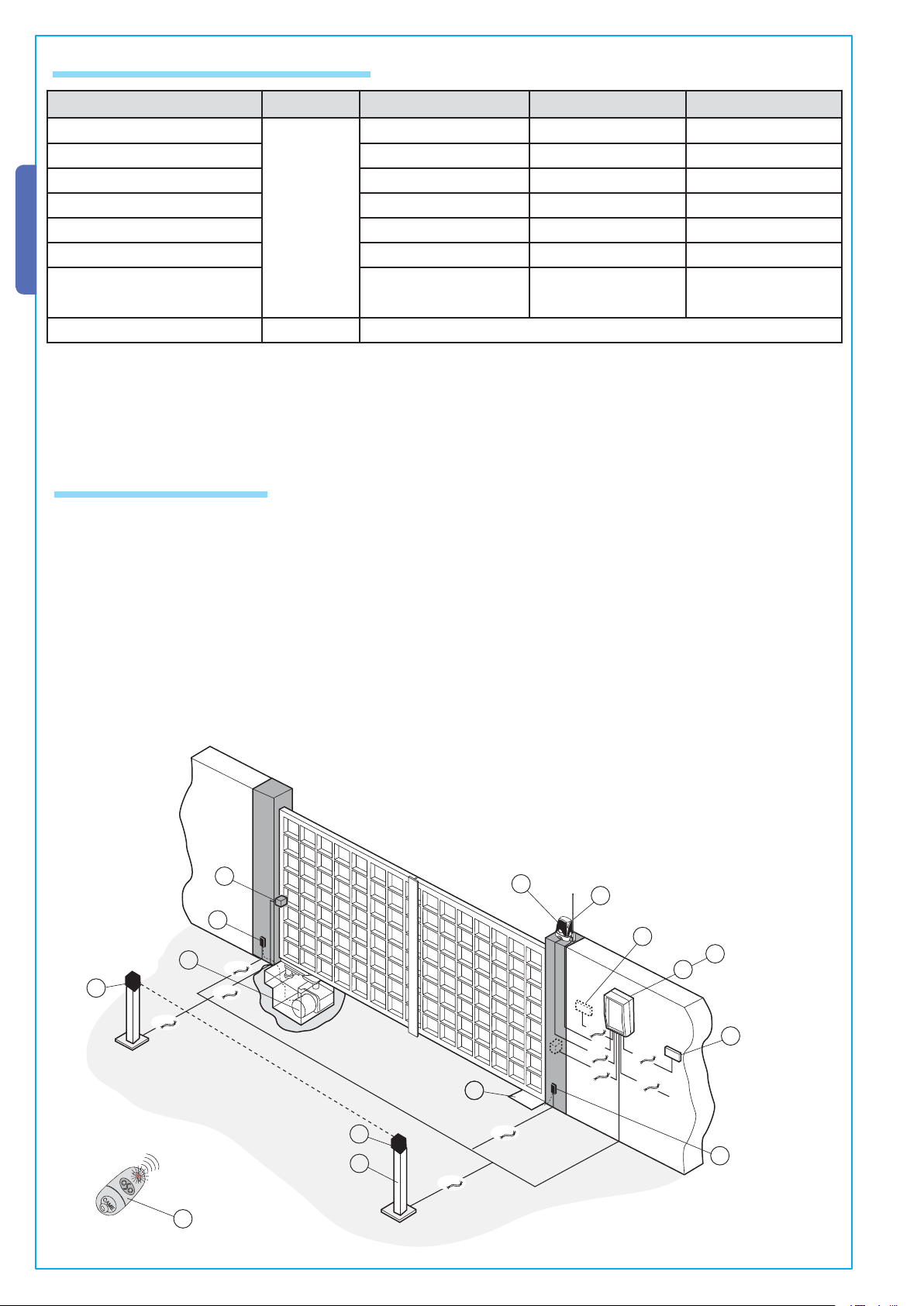

5.4 Standard installation

1) FROG unit

2) Control panel

3) Safety photocells

4) Radio receiver

5) Key-switch selector

6) Antenna

7) Command push-buthon panel

8) Flashing light

9) Photocell column

10) Shunt box

11) Transmitter

3

TX

10

1

RX

9

4x1

11

4x1,5

2x1

3

9

TX

2x1

8

1

4x1,5

6

5

4

2

3x1

RG58

2x1,5

RX

5x1

4x1

3x1,5

230V

7

10

The data and information shown in this dialogue may be changed by Came Cancelli Automatici S.p.A. at any time without prior warning.

4

Page 5

5.5 Assembly diagram

Fig.2

67

3

160

100 60

67

5.6 Installing the unit

- Check the effi ciency of both moving and non-moving parts on the structure that will be supporting the operator;

- Determine, depending on the type of supporting structure and desired opening, the exact position of the motor assembly by

following the standard applications shown;

- Set up a closing end stop and an opening end stop (fi g. 4, p. 5).

- Dig, depending on the size of the assembly, a foundation pit in the chosen spot (Fig. 3);

- Prepare a drainage system in the foundation, to drain away any water leaks which may cause oxidation (fi g 3 – part.1);

- The foundation box makes for quick and easy setting up of the assembly. Place it inside the pit with the pin aligned to the upper

hinge (Fig. 3 – part. 2), sink it into the cement (Fig. 3 – part. 3) making sure it is perfectly levelled and that the upper edge is

3mm above ground level (Fig. 3 part. 4);

- Plan for the route of the electrical cables according to the command and safety instructions using the apposite hole on the box

(Fig. 3 – part. 5);

- Grease the rotation pins of the foundation box and the gate attachment lever; the hinge and pin lever must be aligned;

- Position the gate leaf between the upper hinge and the pin lever; the hinge and pin lever must be aligned;

- Secure the pin lever to the gate leaf, by welding spots 3 to 4 cm apart along the contact surface. Avoid any welding near the

threaded screws (Fig. 3 – Part. 6).

ENGLISH

Fig.3

Fig.4

The data and information shown in this dialogue may be changed by Came Cancelli Automatici S.p.A. at any time without prior warning.

Fig.4-1

- Screw the M10 x 100 (A) and the M10 (B) bolt onto the gearmotor

arm as shown in fi g. 4-1 (RIGHT HAND installation) and fi g. 4-2

N(LEFT HA D installation);

- Affi x the gearmotor to the foundation box using the threaded pins

and securing it using the provided bolts and washers;

- Insert the (C ) transmission lever between the motor arm and

the box lever and electronically shut the gate against the closing

end stop.

Adjust screw (A) until it touches the (C) transmission lever.

- When testing, adjust the screw so as to allow proper closing

pressure of the gate leaf and allow its re-hooking during the

mechanism’s release procedure.

- Once adjustment is complete, secure the (B) nut.

C

SX

A

B

C

Fig.4-2

DX

A

B

SX

DX

5

Page 6

5.7 Manual release

- In emergencies (i.e. power outages) the release mechanisms allow the gate to hook back up when closing.

- You may choose among three different release models: model A4366 with customised key (Fig. 5-A), model A4365 with tri-lobed

key and model A4364 with lever key (Fig. 5-B). We suggest greasing the release’s hook-up key (Fig. 5-B – part. 3); Consult the

documentation pertinent to the relative items for the release procedure.

N. B.: release operations are to be carried out during emergency procedures and with the power disconnected.

ENGLISH

Fig. 5

Fig. 5-A

Fig. 5-B

A4366

A4365

A4364

3

6 Connecting to the control panel

- We suggest making the gearmotor cable connections in shunt boxes;

For further information concerning the functions, see the technical documentation for the ZL19 N – ZL 170 N control panels.

brown

R1-Ra1

Motor 1

blue

brown

Control panel terminals

brown

blue

Motor 2

Motor 1 opening brake microswitch.

R1-Rc1

Motor 1 closing brake microswitch.

R2-Ra2

Motor 2 opening brake microswitch.

brown

R2-Rc2

Motor 2 closing brake microswitch.

Control panel terminals

6

The data and information shown in this dialogue may be changed by Came Cancelli Automatici S.p.A. at any time without prior warning.

Page 7

6.1 Adjusting the brake microswitches

– Using the motor, make so that the gate leaf is max 500mm from being fully opened.

At this point do a fi rst adjustment of the (endstop) microswitches, positioning them close to the magnet. Consider that this type of

endstop reads the magnetic fi eld. You may have to repeat the procedure to increase the precision of the adjustment (fi g. 6/7);

Microswitch

Magnet

Endstop

holding plate

ENGLISH

Fig. 6

Fig. 7

Microswitch

6.2 Adjusting the limit stop’s stopping zone

... Take the template supplied with the panel and hold it against one of the limit stops as shown in fi g. 8 (make the adjustment on

either the opening or closing limit stop).Operate the gate – using either a command button or the remote control – and rotate

the OP TIME trimmer counter-clockwise until the gate leaf inverts its direction the moment it touches the obstacle/template.

Then turn the template onto its shorter side (fi g. 9) and turn the OP TIME trimmer clockwise until the gate leaf halts touching

the obstacle/template.

Fig. 8

The data and information shown in this dialogue may be changed by Came Cancelli Automatici S.p.A. at any time without prior warning.

Fig. 9

A =Effective range of the motion-inverter amperometric sensor.

B =Run zone at normal speed.

C =Run zone at slow speed.

D =Effective range of the motion-stop amperometric sensor

E =

Opening/Closing position mechanical gate stops

7

Page 8

7 Safety instructions

Important safety instructions

This product must only be employed for its originally intended use. Any other use is wrong and potentially dangerous. The

manufacturer cannot be held liable for any damages resulting from wrongful, erroneous or negligent uses.

Avoid working close to the hinges or other moving mechanical parts. Stay out of the opening/closing arc when operator is in

motion. Do not exercise force against the motion of the operator as this could result in potentially dangerous situations.

ENGLISH

Do not allow children to play or loiter within the opening/closing arc of the operator.

Keep remote controls and any other command device out the reach of children, to prevent operator from being activated by

accident.In the event of anomalous behaviour, stop using the operator immediately.

Danger of crushing hands

Danger of crushing feet

Danger! High voltage

No transit during operation

The data and information shown in this dialogue may be changed by Came Cancelli Automatici S.p.A. at any time without prior warning.

8

Page 9

8 Maintenance

8.1 Periodic maintenance

Periodic maintenance to be carried out by the end-user is as follows: wipe clean the glass surface of the photocells; check that the safety devices work properly; remove any obstructions.

We suggest checking the state of lubrication and tightness of the anchoring screws on the operator.

To check the efficiency of the safety devices, move an object in front of the photocells when gate is closing. If the operator

inverts the motion or stops, the photocells are working properly.

This is the only maintenance procedure to be carried out with the power source connected.

Before performing any maintenance procedures, cut off the main power, to prevent possible accidents due to gate movement.

To clean the photocells use a water dampened cloth. Do not use solvents or other chemical products which may ruin the

devices.

In the event of any strange vibrations or squeaking, lubricate the joints with grease, as shown in the diagram.

ENGLISH

Make sure there are no plants within the photocell’s beam, and that the gate motion is free of any obstacles.

8.2 Trouble shooting

MALFUNCTIONS POSSIBLE CAUSES CHECK AND REMEDIES

The data and information shown in this dialogue may be changed by Came Cancelli Automatici S.p.A. at any time without prior warning.

The gate will not open

nor close

The gate opens but will

not close

The flasher does not

work

• There is no power

• The gearmotor is released

• The remote control’s batteries are run down

• The transmitter is broken

• The stop button is either stuck or broken

• The opening/closing button or the key selector are stuck

• The photocells are engaged • Check that photocells are clean

• The bulb is burnt • Call assistance

• Check that the power is up

• Call assistance

• Replace batteries

• Call assistance

• Call assistance

• Call assistance

and in good working order

• Call assistance

9

Page 10

Periodic maintenance log (for end-user) (every 6 moths)

Date Notes Segnature

ENGLISH

8.3 Extra-ordinary maintenance

The following table serves to note down any extraordinary maintenance, repairs or improvements performed by specialised firms.

N.B.: Any extraordinary maintenance must be performed by specialised technicians.

Extra-ordinary maintenance log

Installer’s stamp Operator name

Date of job

Tec hnician’s segnature

Requester’s segnature

Job performed_____________________________________________________________________________________

________________________________________________________________________________________________

Installer’s stamp Operator name

Date of job

Tec hnician’s segnature

Requester’s segnature

Job performed_____________________________________________________________________________________

________________________________________________________________________________________________

The data and information shown in this dialogue may be changed by Came Cancelli Automatici S.p.A. at any time without prior warning.

Installer’s stamp Operator name

Date of job

Tec hnician’s segnature

Requester’s segnature

Job performed_____________________________________________________________________________________

________________________________________________________________________________________________

10

Page 11

Installer’s stamp Operator name

Date of job

Tec hnician’s segnature

Requester’s segnature

Job performed_____________________________________________________________________________________

________________________________________________________________________________________________

ENGLISH

Installer’s stamp Operator name

Date of job

Tec hnician’s segnature

Requester’s segnature

Job performed_____________________________________________________________________________________

________________________________________________________________________________________________

9 Demolition and disposal

In its premises, CAME cancelli automatici s.p.a. implements an Environmental Management System certified in compliance with the UNI EN ISO 14001 standard to ensure environmental protection.

Please continue our efforts to protect the environment—which CAME considers one of the cardinal elements in the developmentof its operational and market strategies—simply by observing brief recommendations as regards disposal:

DISPOSAL OF PACKAGING

The packaging components (cardboard, plastic, etc.) are all classifiable as solid urban waste products and may be disposed of

easily, keeping in mind recycling possibilities.

Prior to disposal, it is always advisable to check specific regulations in force in the place of installation.

PLEASE DISPOSE OF PROPERLY!

PRODUCT DISPOSAL

Our products are made up of various types of materials. Most of them (aluminium, plastics, iron, electrical wires, etc.) may

be disposed of in normal garbage collection bins and can be recycled by disposing of in specific recyclable material collection

bins and disposal in authorized centres.

Other components (electrical boards, remote control batteries, etc.), however, may contain polluting substances.

They should therefore be removed and given to qualified service companies for proper disposal.

Prior to disposal, it is always advisable to check specific regulations in force in the place of disposal.

PLEASE DISPOSE OF PROPERLY!

10 Maker’s statement

MANUFACTURER’S DECLARATION OF CONFORMITY

CAME Cancelli Automatici S.p.A.

via Martiri della Libertà, 15

31030 Dosson di Casier - Treviso - ITALY

tel (+39) 0422 4940 - fax (+39) 0422 4941

The data and information shown in this dialogue may be changed by Came Cancelli Automatici S.p.A. at any time without prior warning.

internet: www.came.it - e-mail: info@came.it

Declares under its own responsibility that the equipments for automatic garage doors and

gates listed below:

FROG-A

… comply with the National Law related to the following European Directives and to the

applicable parts of the following Standards.

98/37/CE - 98/79/CE M

98/336/CEE - 92/31/CEE ELECTROMAGNETIC COMPATIBILITY DIRECTIVE

73/23/CEE - 93/68/CE LOW VOLTAGE DIRECTIVE

89/106/CEE CONSTRUCTION PRODUCTS DIRECTIVE

EN 13241-1 EN 12635 EN 61000-6-2

EN 12453 EN 12978 EN 61000-6-3

EN 12445 EN 60335-1 EN 60204-1

ACHINERY DIRECTIVE

Pursuant to annex II B of the Machinery Directive 98/37/EC

Do not use the equipment specifi ed here above, before completing the full installation

In full compliance with the Machinery Directive 98/37/EC

IMPORTANT WARNING!

AMMINISTRATORE DELEGATO

Sig. Andrea Menuzzo

Reference code to request a true copy of the original: DDF B EN A001D

11

Page 12

CAME UNITED KINGDOM LTD

UNIT 3, ORCHARD BUSINESS PARK TOWN

STREET, SANDIACRE

NOTTINGHAM - NG10 5BP - U.K.

Tel 0044 115 9210430

Fax 0044 115 9210431

Cod. 119AU35 ver. 0.1 01/07 © CAME cancelli automatici s.p.a.

Loading...

Loading...