Page 1

M Series

Multi-Output Access Control

Power Supply Chargers

Installation Guide

Models Include:

•AL300ULM • AL400ULM

- 2.5 amp @ 12VDC or 24VDC. - 3 amp @ 12VDC

or 4 amp @ 24VDC.

• AL600ULM • AL1012ULM

- 6 amp @ 12VDC or 24VDC. - 10 amp @ 12VDC.

• AL1024ULM

- 10 amp @ 24VDC.

For a red enclosure, add an “R” suffix to the part # e.g. AL300ULMR

Rev. 111103

Page 2

Overview:

T

hese multi-output access control power supply/chargers are specifically designed for use with access control systems and

a

ccessories. These units convert a 115VA C / 60Hz input into five (5) individuall y protected 12VDC or 24VDC outputs (see

s

pecifications). Each output will route power to a variety of access control hardw are de vices including Mag Locks, Electric

Strikes, Magnetic Door Holders, etc. These outputs will operate in both Fail-Safe and Fail-Secure modes. Controlled

trigger input is achieved through normally open [NO] or normally closed [NC] supervised input or the polarity reversal

from an FACP (Fire Alarm Control Panel). A form “C” dr y output relay enables HVAC Shutdown, Elevator Recall or may

be used to trigger auxiliary devices.

M Series Power Supply Configuration Reference Chart:

Model Number

Altronix

Current (amp)

12VDC Total Output

24VDC Total Output

Current (amp)

Outputs

Power Limited

Class 2 Rated

115VAC 60Hz Input

AL300ULM 2.5 2.5 5 Yes 1.45

AL400ULM 4 3 5 Yes 1.9

AL600ULM 6 6 5 Yes 2.5

AL1024ULM - 10 5 Yes 4.4

AL1012ULM 10

- 5 Yes 1.9

(current draw/amp)

Input Fuse Rating

Power Supply Board

3.5 amp

250VAC

3.5 amp

250VAC

3.5 amp

250VAC

10 amp

250VAC

3.5 amp

250VAC

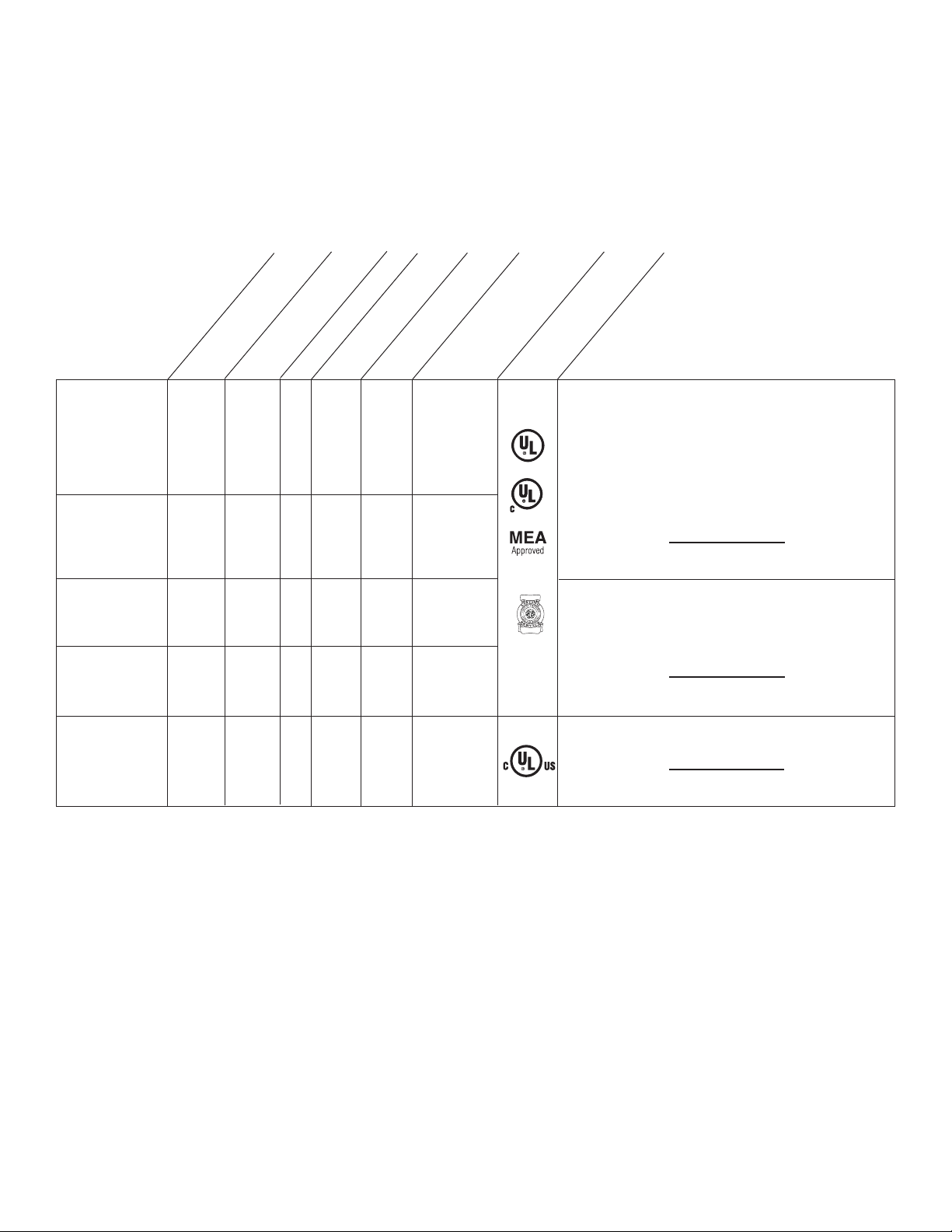

Agency Listings

NYC Dept.

of Buildings

California

State

Fire Marshal

File Numbers

UL Listings and

UL File # S4707

UL Listed for Power Supplies for

Fire Protective Signaling Systems

UL Listed Access Control System Unit.

UL Listed for Burglar Alarms Systems.

UL Listed Hospital Signaling and Nurse Call Equipment.

“Signal Equipment” Evaluated to CSA 22.2

UL Listed for Power Supplies for

Fire Protective Signaling Systems

UL Listed Access Control System Unit.

“Signal Equipment” Evaluated to CSA 22.2

UL Listed Access Control System Unit.

“Signal Equipment” Evaluated to CSA 22.2

UL 1481

UL 294

UL 603

UL 1069

N205-M1983

UL File # S4707

UL 1481

UL 294

N205-M1983

UL File # BP617

UL 294

N205-M1983

Specifications:

Input:

• Power input 115VAC 60Hz (see reference chart above).

• Fire Alarm Panel or Access Control System trigger

inputs. [NO] or [NC] supervised trigger input and

polarity reversal trigger input (4mA draw from FACP).

Output:

• Five (5) individual power limited class 2 outputs.

• Current limit is 2 amp @ 12VDC or 24VDC

per output (12VDC only for AL1012ULM and

24VDC only for AL1024ULM).

• Filtered and electronically regulated outputs.

• Thermal and short circuit protection with auto reset.

erload protection.

Ov

•

Output relay energizes when unit is triggered

•

m “C” contact rated 1 amp @ 28VDC).

(for

- 2 - Mseries

Battery Backup:

• Built-in charger for sealed lead acid or gel type batteries.

• Automatic switch over to stand-by battery when AC fails.

• AL300ULXB, AL400ULXB, AL600ULXB and

AL1012ULXB (P

rent .7 amp.

ge cur

char

AL1024ULXB (P

current 3.6 amp).

• Zero voltage drop when switching over to

battery backup.

• AL300ULM, AL400ULM and AL600ULM enclosures

accommodate up to two (2) 12VDC/7AH batteries.

• AL1012ULM should be fitted with

one (1) 12VDC/12AH batter

AL1024ULM enclosure accommodates

•

up to tw

o (2) 12VDC/12AH batteries.

ower Supply Board) maximum

er Suppl

w

o

y Board) maximum charge

.

y

Page 3

Specifications (cont’d):

Visual Indicators:

• DC output LED indicator.

• LEDs indicate condition of power outputs.

• Power & input trigger LED’s.

Supervision:

• AC fail supervision (form "C" contact).

• Low battery supervision (form "C" contact).

Supervision (cont’d):

• Battery presence supervision (form “C” contact).

• Power fail supervision relay (form “C” contact rated

1 amp @ 28VDC).

• Power supply is complete with enclosure, cam lock,

transformer and battery leads.

Installation Instructions:

Wiring methods shall be in accordance with the National Electrical Code/NFPA 70/NFPA 72/ANSI, and with all local

codes and authorities having jurisdiction. Product is intended for indoor use only.

1. Mount unit in desired location. Mark and predrill holes in the wall to line up with the top two keyholes in the

enclosure. Install two upper fasteners and screws in the wall with the screw heads protruding. Place the enclosure’s

upper keyholes over the two upper screws, level and secure. Mark the position of the lower two holes. Remove the

enclosure. Drill the lower holes and install the three fasteners. Place the enclosure’s upper keyholes over the two

upper screws. Install the two lower screws and make sure to tighten all screws

Secure enclosure to earth ground. It is recommended to first review the following tables for screw

terminals, switch selection and LED status indications. This will greatly facilitate installation hook-up.

Carefully review:

Output Voltage & Stand-by Specifications (pg. 4) Terminal Identification Table (pg. 10)

LED Diagnostics (pg. 9) Typical Application Diagrams (pgs. 11 & 12)

2. Set output v

AL300ULM, AL400ULM and AL600ULM set desired DC output voltage by setting switch SW1 to the appropriate

position on the power supply board (

is 24VDC only.

3. Secure green lead to earth g round. Connect AC power (115VAC 60Hz to terminals marked [L, G, N] on

power supply board

Use 18 AWG or lar

Use 22 AWG to 18 AWG for power limited circuits (AC Fail/Low Battery reporting).

4. Measure output voltage before connecting devices. This helps avoid potential damage.

Keep power limited wiring separate from non-power limited wiring (115VAC / 60Hz Input, Battery Wires).

Minim

5. Connect Fail-Secure type locking hardware (e.g. door strikes and electronic dead bolts) positive leads to terminals

ed [1 through 5 POS (+) DC OUTPUT (ALARM)] on MOM5 board and the negative leads to terminals marked

mark

[NEG 1 through NEG 5] on MOM5 board

6. Connect Fail-Safe type locking hardware (e.g. mag locks, door strikes and door holders) positive leads to terminals

marked [6 through 10 POS (+) DC OUTPUT (STAND-BY)] on MOM5 board and negative leads to terminals

marked [NEG 1 through NEG 5] on MOM5 board

7. To trigger the unit from a FACP connect signaling circuit of FACP to terminals marked [- INPUT +] on MOM5

board

ire alar

f

Note: A 2.2K EOL must be installed across terminals marked [TRIGGER] on MOM5 board or the unit will remain

in an alarm condition.

8. To trigger the unit using a supervised dr y contact connect the 2.2K resistor in series for a NC trigger input

and in parallel for [NO] trigger input (Fig. 5, pg. 11).

9. Connect auxiliary devices triggered by the unit to the terminals marked [DRY OUTPUT NO & C] on MOM5 board

for nor

output

Note: This relay will energize when the unit is triggered.

Access Control applications batteries are optional.

or

10.F

of output voltage. Batteries must be lead acid or gel type if used. Connect one (1) 12VDC battery to terminals

marked [+ BAT--] on power supply board for 12VDC operation

Fig. 4, pg. 8)

oltage:

Fig. 1B, pg. 5; Fig. 2B, pg. 6). AL1012ULM is 12VDC only and AL1024ULM

(Output Voltage and Stand-by Specification Charts below, pg. 4).

(Fig. 1, pg. 5; Fig. 2, pg. 6; Fig. 3, pg. 7; Fig. 4, pg. 8).

ger for all power connections (Batter

um .25” spacing m

ig. 1, pg. 5; Fig. 2, pg. 6; Fig. 3, pg. 7; Fig. 4, pg. 8).Polarity is shown in alarm condition. For latching

(F

m interf

mall

(Fig. 1, pg. 5; Fig. 2, pg. 6; Fig. 3, pg. 7; Fig. 4, pg. 8).

ace

(F

y open output or ter

. Use two (2) 12VDC batteries connected in series for 24VDC operation. (Battery leads included).

ust be provided.

igs. 8, 9, 10, pg

minals mark

(Fig. 1, pg. 5; Fig. 2, pg. 6; Fig. 3, pg. 7; Fig. 4, pg. 8).

. 12).

DR

ed [

y, DC output, AC input).

(Fig. 1, pg. 5; Fig. 2, pg. 6; Fig. 3, pg. 7; Fig. 4, pg. 8).

Y OUTPUT

When batteries are not used a loss of AC will result in the loss

NC & C] on MOM5 board for normally closed

(Fig. 1, pg. 5; Fig. 2, pg. 6; Fig. 3, pg. 7;

(Enclosure Dimensions, pg. 13,14).

Mseries - 3 -

Page 4

11.Connect supervisory trouble reporting devices to outputs marked [AC FAIL, LOW BAT] and [Power Fail]

s

upervisory relay outputs marked [NO, C, NC] on power supply board

F

ig. 4A, pg. 8).

N

ote:When used in fire alar m, burglar alar m or access control applications, “AC Fail” relay must be used to provide

a visual indication of AC power on.

12. Please insure that the cover is secured with the provided Key Lock.

U

se 22 AWG to 18 AWG for AC Fail & Low Battery reporting.

(

Fig. 1A, pg. 5; Fig. 2A, pg. 6; Fig. 3A, pg. 7;

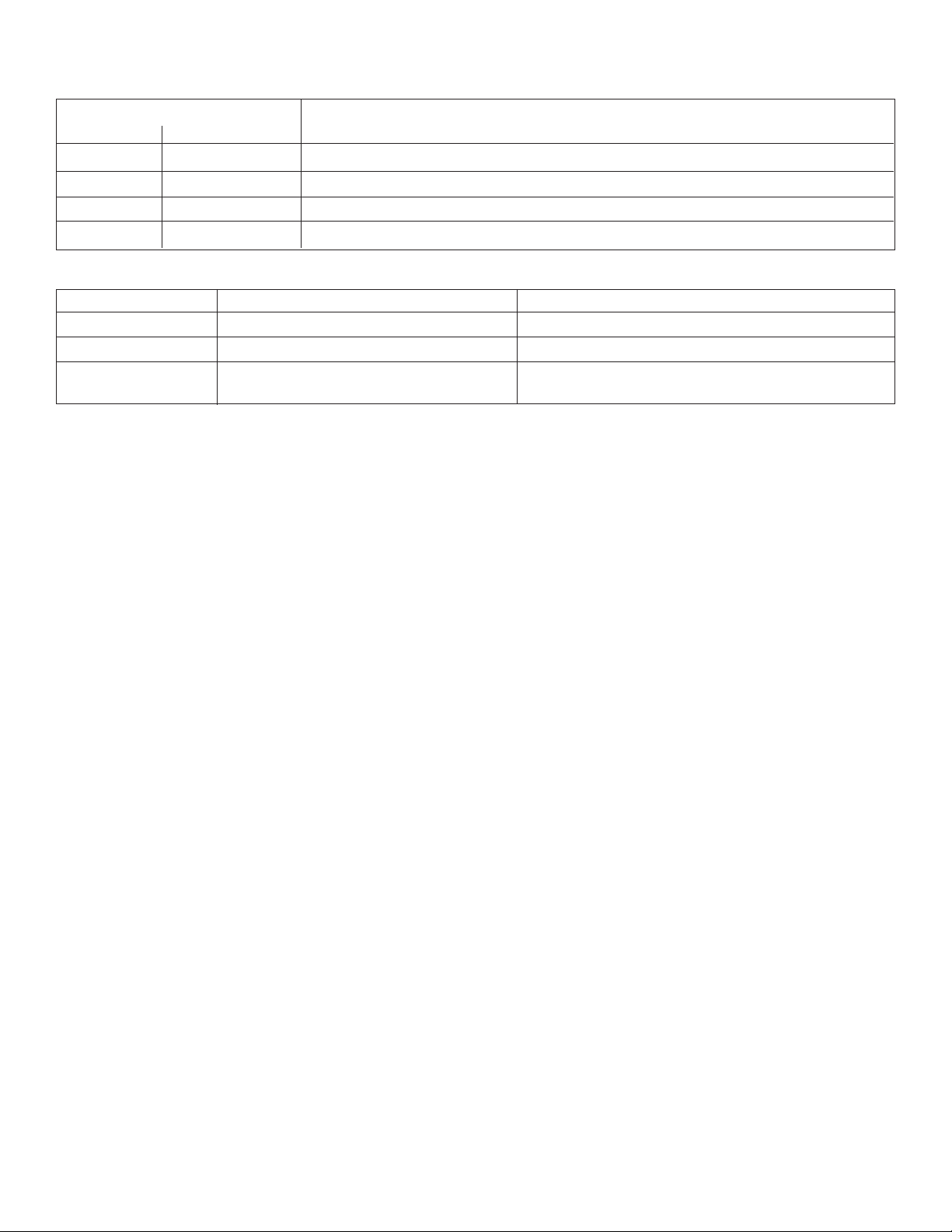

Output Voltage and Stand-by Specification Charts:

AL300ULM

Output Switch 4 hr. of Stand-by & 24 hr. of Stand-by & 60 hr. of Stand-by &

Position 5 Minutes of Alarm 5 Minutes of Alarm 5 Minutes of Alarm

12VDC / 40 AH Battery

24VDC / 12 AH Battery

24VDC / 40 AH Battery

Closed

Open

Open

Stand-by = 2.5 amp Stand-by = 1.0 amp Stand-by = 300mA

Alarm = 2.5 amp Alarm = 2.5 amp Alarm = 2.5 amp

Stand-by = 200mA

Alarm = 2.5 amp

Stand-by = 2.5 amp Stand-by = 1.0 amp Stand-by = 300mA

Alarm = 2.5 amp Alarm = 2.5 amp Alarm = 2.5 amp

AL400ULM

Output Switch 4 hr. of Stand-by & 24 hr. of Stand-by & 60 hr. of Stand-by &

Position 5 Minutes of Alarm 5 Minutes of Alarm 5 Minutes of Alarm

12VDC / 40 AH Battery

24VDC / 12

AH Battery

Closed

Open

Stand-by = 4.0 amp Stand-by = 1.0 amp Stand-by = 300mA

Alarm = 4.0 amp Alarm = 4.0 amp Alarm = 4.0 amp

Stand-b

y = 200mA

Alarm = 3.0 amp

24VDC / 40 AH Battery

Open

Stand-by = 3.0 amp Stand-by = 1.0 amp Stand-by = 300mA

Alarm = 3.0 amp

Alarm = 3.0 amp Alar

m = 3.0 amp

AL600ULM

Output Switch 4 hr. of Stand-by & 24 hr. of Stand-by & 60 hr. of Stand-by &

5 Minutes of Alarm 5 Minutes of Alarm 5 Minutes of Alarm

Stand-by = 6.0 amp Stand-by = 1.0 amp Stand-by = 300mA

m = 6.0 amp Alarm = 6.0 amp Alarm = 6.0 amp

Alar

Stand-by = 200mA

m = 6.0 amp

Alar

Stand-b

y = 6.0 amp

Alarm = 6.0 amp Alar m = 6.0 amp Alarm = 6.0 amp

Stand-b

y = 1.0 amp

Stand-by = 300mA

12VDC / 40 AH Battery

24VDC / 12 AH Battery

24VDC / 40

AH Batter

y

Position

Closed

Open

Open

AL1012ULM

Output

12VDC / 12 AH Battery

15 Minutes of Stand-b

y @ 10 amp

AL1024ULM

Output 15 mins. Stand-by / 4 hr. Stand-by / 24 hr. Stand-by / 60 hr. Stand-by /

5 mins. Alarm 5 mins. Alarm 5 mins. Alarm 5 mins. Alarm

24VDC / 12 AH Battery 7.7 amp / 9.7 amp 1 . 2 a mp / 9.7 a m p ------------------------- ------------------------24VDC / 65 AH Battery ------------------------- 7.7 amp / 9.7 amp 1.2 amp / 9.7 amp 200mA / 9.7 amp

- 4 - Mseries

Page 5

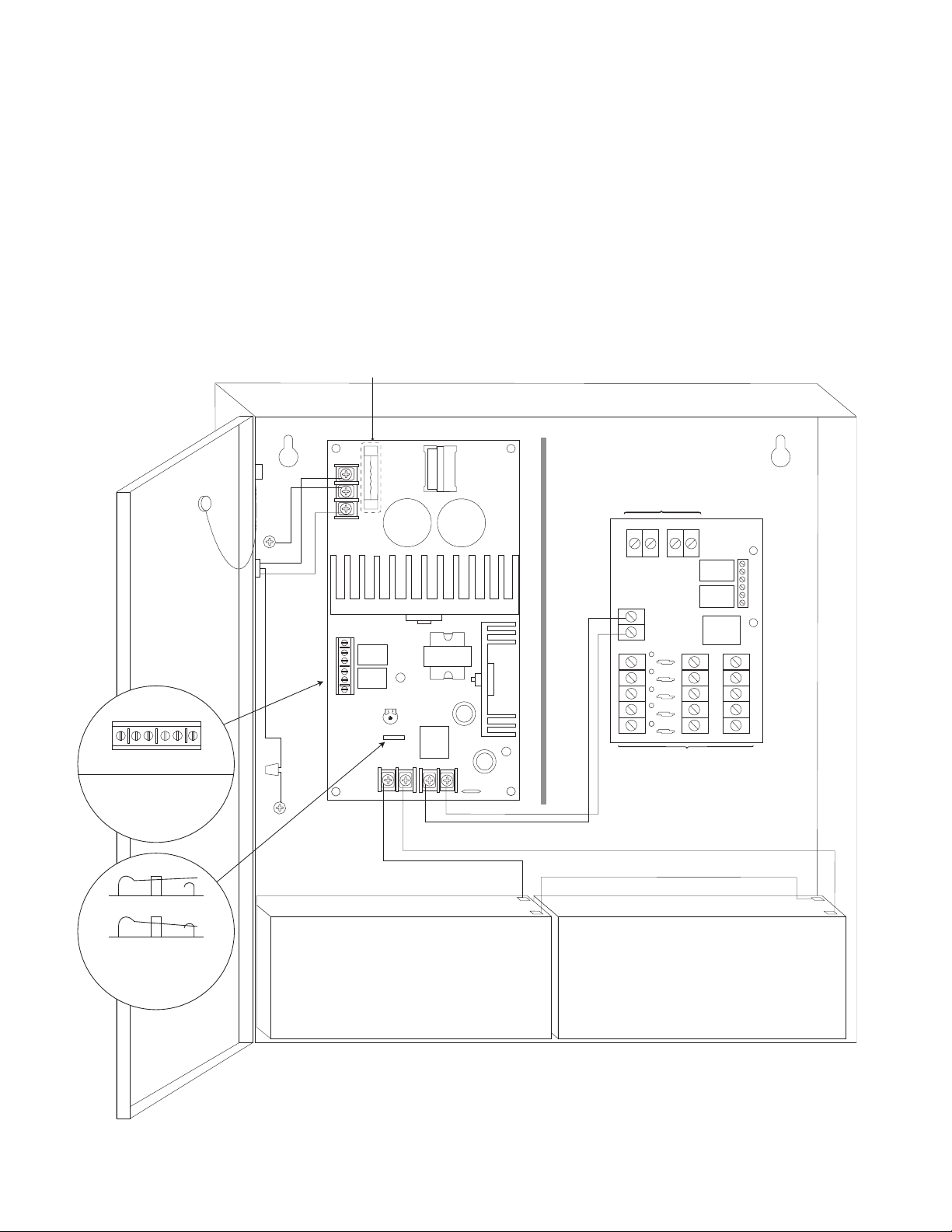

Maintenance:

Green

Lead

Battery connection (non power limited)

W

ire

S

trap

(

from

E

nclosure

to Door)

115VA C

power mains

non-power

limited

Class 1

Divider

NC C NO

DRY OUTPUT

TRIGGER

LED

6 7 8 9 10

POS (+) DC OUTPUT (STANDBY)

NC C NO

POWER FAIL

TRIGGER

1 2 3 4 5

POS (+) DC OUTPUT (ALARM)

NEG1 NEG2 NEG3 NEG4 NEG5

-- DC INPUT +

NEG (-) INPUT POS (+)

DC Outputs to devices

(power limited)

Fire Alarm

Interface

non-power limited

CAUTION: De-energize unit prior to servicing. For continued protection

against risk of electric shock and fire hazard replace fuses with the same type

and rating (see marking on the board). Replace fuse cover before energizing.

Do not expose to rain or moisture.

CAUTION: When power supply board is set for 12VDC use only one (1) 12VDC

stand-by battery.

Keep power limited wiring separate from non-power limited. Use minimum .25" spacing.

Power Limited

NC C NO NC C NO

A

C FAIL

BAT FAIL

Battery & AC

Supervision Circuit

(power limited)

Switch Detail

--- DC

+

L G N

PTC3

NC C NO NC C NO

+ BAT ---

DC

AC

24V - OPEN

12V - CLOSED

AC FAIL

RL2

BAT FAIL

RL1

RL3

SW1

OPEN SWITCH

CLOSED SWITCH

12VDC Rechargeable Battery

(optional)

12VDC Rechargeable Battery

(optional)

Green

Lead

Unit should be tested at least once a year for the proper operation as follows:

Output Voltage Test: Under normal load conditions, the DC output voltage should be checked for proper voltage level

(Output Voltage and Stand-by Specification Charts, pg. 4).

Battery Test: Under normal load conditions check that the batter y is fully charged, check specified voltage at

the battery terminals and at the board terminals marked [+ BAT-- ] to insure that there is no break in the batter y

connection wires.

Note: AL300ULXB, AL400ULXB, AL600ULXB and AL1012ULXB (Power Supply Board) maximum charge

current is .7 amp.

AL1024ULXB (Power Supply Board) maximum charge current is 3.6 amp.

Expected battery life is 5 years, however it is recommended to change batteries within 4 years or less if necessary.

Fig. 1

AL300ULM

AL400ULM

Fig. 1A

Fig. 1B

Mseries - 5 -

Page 6

Fig. 2

Green

Lead

Battery connection (non power limited)

Wire

Strap

(from

Enclosure

to Door)

1

15VAC

power mains

non-power

l

imited

Class 1

Divider

NC C NO

DRY OUTPUT

TRIGGER

LED

6 7 8 9 10

POS (+) DC OUTPUT (STANDBY)

NC C NO

POWER FAIL

T

RIGGER

1 2 3 4 5

POS (+) DC OUTPUT (ALARM)

NEG1 NEG2 NEG3 NEG4 NEG5

-- DC INPUT +

NEG (-) INPUT POS (+)

DC Outputs to devices

(power limited)

Fire Alarm

Interface

non-power limited

CAUTION: De-energize unit prior to servicing. For continued protection

against risk of electric shock and fire hazard replace fuses with the same type

and rating (see marking on the board). Replace fuse cover before energizing.

D

o not expose to rain or moisture.

Power Limited

NC C NO NC C NO

AC FAIL

BAT FAIL

Battery & AC

Supervision Circuit

(power limited)

+

DC ---

BAT FAIL

NC C NO NC C NO

+ BAT ---

DC

2

4V - OPEN

1

2V - CLOSED

SW1

AC FAIL

L G N

AC

A

C Delay

Switch Detail

OPEN SWITCH

CLOSED SWITCH

12VDC Rechargeable Battery

(optional)

12VDC Rechargeable Battery

(optional)

CAUTION: When power supply board is set for 12VDC use only one (1) 12VDC

stand-by battery.

Keep power limited wiring separate from non-power limited. Use minimum .25" spacing.

Green

Lead

A

L600ULM

F

ig. 2A

Fig. 2B

- 6 - Mseries

Page 7

Fig. 3

Green Lead

Battery connection (non power limited)

Door

Wire Strap

(from

Enclosure

to Door)

115VAC

p

ower mains

non-power limited

Divider

Battery and AC

S

upervision Circuit

(power limited).

Power

Limited

Class 1

DC Outputs

t

o devices

(power limited)

NC C NO NC C NO

CAUTION: De-energize unit prior to servicing. For continued protection

against risk of electric shock and fire hazard replace fuses with the same type

and rating (see marking on the board). Replace fuse cover before energizing.

Do not expose to rain or moisture.

12VDC Rechargeable Battery

(optional)

Keep power limited wiring separate from non-power limited. Use minimum .25" spacing.

Fuse

Cover

A

L1012ULM

Fig. 3A

Mseries - 7 -

Page 8

Fig. 4

Green Lead

Battery connection (non power limited)

Door

Wire Strap

(from

E

nclosure

to Door)

1

15VAC

p

ower mains

non-power limited

D

ivider

Battery and AC Supervision Circuit

(power limited).

Power

Limited

Class 1

D

C Outputs

to devices

(power limited)

NO C NC NO C NC

CAUTION: De-energize unit prior to servicing. For continued protection

against risk of electric shock and fire hazard replace fuses with the same type

and rating (see marking on the board). Replace fuse cover before energizing.

D

o not expose to rain or moisture.

12VDC Rechargeable Battery

(optional)

12VDC Rechargeable Battery

(optional)

Keep power limited wiring separate from non-power limited. Use minimum .25" spacing.

Fuse

Cover

A

L1024ULM

Fig. 4A

- 8 - Mseries

Page 9

LED Diagnostics:

Power Supply Board

L

ED

R

ed (DC) Green (AC) Power Supply Status

ON ON Normal operating condition.

ON OFF Loss of AC, Stand-by battery supplying power.

OFF ON No DC output. Short circuit or thermal overload condition.

OFF OFF No DC output. Loss of AC. Discharged battery.

MOM5 - Output Module

LED ON OFF

Power (Green) Normal operation. Power failure.

Trigger (Green) Input is triggered (alarm condition). No input trigger (non-alarm condition).

Outputs (Red) Output tripped due to a Normal operation.

short circuit or overload condition.

Mseries - 9 -

Page 10

Terminal Identification Tables:

Power Supply Board

T

erminal Function/Description

L

egend

L, G, N Connect 115VAC 60Hz to these terminals: L to hot, N to neutral, G to ground.

- DC + AL300ULM - 12VDC/24VDC @ 2.5 amp to MOM5 board (power limited).

AL400ULM - 12VDC @ 4 amp or 24VDC @ 3 amp to MOM5 board (power limited).

AL600ULM - 12VDC/24VDC @ 6 amp to MOM5 board (non-power limited).

AL1012ULM - 12VDC @ 10 amp to MOM5 board (non-power limited).

AL1024ULM - 24VDC @ 10 amp to MOM5 board (non-power limited).

AC FAIL Indicates loss of AC power, e.g. connect to audible device or alarm panel. Relay

NO, C, NC normally energized when AC power is present. Contact rating 1 amp @ 28VDC.

AC or brownout fail is reported within 1 minute of event. To delay reporting of up to

6 hrs., cut “AC delay” jumper and reset power to unit.

BAT FAIL Indicates low battery condition, e.g. connect to alarm panel. Relay normally

NO, C, NC energized when DC power is present. Contact rating 1 amp @ 28VDC.

A removed battery is reported within 5 minutes. Battery reconnection is reported

within 1 minute.

Low battery threshold:

12VDC output threshold set @ approximately 10.5VDC (N/A for AL1024ULM),

24VDC output threshold set @ approximately 21VDC.

+ BAT - Stand-by battery connections. AL300ULXB, AL400ULXB and AL600ULXB (Power Supply

Board) maximum charge current is .7 amp. AL1024ULXB (Power Supply Board)

maximum charge current is 3.6 amp.

MOM5 - Output Module

Ter minal Legend Function/Description

---DC INPUT + 12VDC or 24VDC from power supply.

TRIGGER Dr

y normally open [NO] or nor

input trigger. A shor t or open circuit will transfer power from terminals marked

[POS. (+) DC OUTPUT (ST

[POS (+) DC OUTPUT (ALARM)]

--- INPUT + Wet (5-30VDC) input trigger. Applying voltage to these terminals in the polarity shown

will transfer power from terminals marked [POS. (+) DC OUTPUT (STAND-BY)] to

terminals marked [POS (+) DC OUTPUT (ALARM)] (e.g. fire alar m control panel

indications circuit).

NEG 1 THRU NEG 5 Supplies constant negative (-) voltage.

POS (+) DC OUTPUT Supplies positive (+) voltage when dry trigger input or f ire

(ALARM) 1-5 alarm wet trigger input is applied.

e (+) voltage in normal condition.

POS (+) DC OUTPUT

Supplies positi

v

(STAND-BY) 6-10 Power is removed when dry trigger input or f ire alar m wet trigger input is applied.

NC, C, NO

When the MOM5 is triggered the terminals marked [C and NO] will open and the

DRY OUTPUT terminals marked [C and NC] will close. This output is used to trigger auxiliary devices.

(e.g. HVAC Shutdown, Elevator Recall etc.) Conta ct ratin g 1 am p @ 28 VDC.

m “C” contacts used for repor

or

NC, C, NO

F

POWER FAIL terminals. Under normal conditions, terminals marked [NO and C] are open, [NC and C]

are closed. A loss of power causes terminals marked [NO and C] to close and [NC and C]

to open. Contact rating 1 amp @ 28VDC.

mally closed [NC] supervised (2.2K EOL resistor)

AND-BY)]

to terminals marked

.

ting no v

oltage is present at [-- DC input +]

- 10 - Mseries

Page 11

TRIGGER

LED

TRIGGER

- DC INPUT+

NEG (-) INPUT POS (+)

POWER

ON LED

TRIGGER

LED

TRIGGER

- DC INPUT+

NEG (-) INPUT POS (+)

POWER

ON LED

EOL 2.2K

EOL 2.2K

MOM5_S

ALTRONIX CORP.

BROOKLYN, NY 11220

MADE IN USA

MOM5_S

ALTRONIX CORP.

BROOKLYN, NY 11220

MADE IN USA

N.O. INPUT FROM

FACP OR ACCESS

CONTROL DEVICE

DC VOLTAGE INPUT

FROM FACP

SIGNALING

OUTPUT OR ACCESS

CONTROL DEVICE

(+)

(--)

TO TRIGGER INPUT

OF NEXT MOM5

NC C NO

DRY OUTP UT

NC C NO

POWER FA IL

NC C NO

DRY OUTP UT

NC C NO

POWER FA IL

Typical Application Diagrams:

TRIGGER

NEG (-) INPUT POS (+)

E

OL 2.2K

(

+)

(

-

)

D

C VOLTAGE INPUT

F

ROM FACP

S

IGNALING

O

UTPUT OR ACCESS

C

ONTROL DEVICE

N

.C. INPUT FROM

F

ACP OR ACCESS

C

ONTROL DEVICE

TRIGGER

NEG (-) INPUT POS (+)

EOL 2.2K

(

+

)

(

-

)

D

C VOLTAGE INPUT

F

ROM FACP

S

IGNALING

O

UTPUT OR ACCESS

C

ONTROL DEVICE

N

.O. INPUT FROM

F

ACP OR ACCESS

C

ONTROL DEVICE

TRIGGER

LED

TRIGGER

- DC INPUT+

NEG (-) INPUT POS (+)

POWER

ON LED

T

RIGGER

LED

TRIGGER

- DC INPUT+

NEG (-) INPUT POS (+)

P

OWER

ON LED

EOL 2.2K

E

OL 2.2K

N.C. INPUT FROM

FACP OR ACCESS

CONTROL DEVICE

DC VOLTAGE INPUT

F

ROM FACP

S

IGNALING

O

UTPUT OR ACCESS

C

ONTROL DEVICE

(+)

(

--)

TO TRIGGER INPUT

OF NEXT MOM5

NC C NO

DRY OUTPUT

NC C NO

POWER F AIL

NC C NO

D

RY OUTPU T

NC C NO

P

OWER F AIL

Fig. 5

MOM5 module shown with wet and/or dry normally closed trigger inputs

MOM5 module shown with wet and/or dry nor mally open trigger

inputs (Non-Latching):

(Non-Latching):

Fig. 6- Two (2) or more MOM5 modules shown with wet and/or dry normally closed trigger inputs (Non-Latching):

F

. 7

ig

o (2) or more

w

- T

Mseries - 11 -

MOM5 modules shown with wet and/or dry normally open trigger inputs

(Non-Latching):

Page 12

TRIGGER

LED

TRIGGER

- DC INPUT+

NEG (-) INPUT POS (+)

POWER

O

N LED

TRIGGER

LED

TRIGGER

-

DC INPUT+

NEG (-) INPUT POS (+)

POWER

O

N LED

N.O. RESET

EOL 2.2K

EOL 2.2K

(+)

(-)

DC VOLTAGE INPUT

FROM FACP

S

IGNALING

OUTPUT OR ACCESS

CONTROL DEVICE

N.C. INPUT

FROM FACP

N

C C NO

DRY OUTPUT

NC C NO

POWER FAIL

NC C NO

D

RY OUTPU T

N

C C NO

POWER FAIL

TRIGGER

LED

TRIGGER

- DC INPUT+

NEG (-) INPUT POS (+)

POWER

ON LED

TRIGGER

LED

TRIGGER

- DC INPUT+

NEG (-) INPUT POS (+)

POWER

ON LED

EOL 2.2K

(+)

(-)

(+)

(-)

N.C. RESET

EOL 2.2K

DC VOLTAGE INPUT

FROM FACP

SIGNALING

OUTPUT OR ACCESS

CONTROL DEVICE

N.O. INPUT

FROM FACP

NC C NO

DRY OUTP UT

NC C NO

POWER FAIL

NC C NO

DRY OUTP UT

NC C NO

POWER FAIL

T

RIGGER

LED

TRIGGER

NEG (-) INPUT POS (+)

POWER

O

N LED

N

.C.

RESET

EOL 2.2K

(

+)

(

-

)

DC VOLTAGE INPUT

FROM FACP

SIGNALING OUTPUT

N.O. INPUT

FROM FACP

SIGNALING

OUTPUT

N

C C NO

D

RY OUTP UT

N

C C NO

POWER FA IL

TRIGGER

L

ED

TRIGGER

NEG (-) INPUT POS (+)

P

OWER

ON LED

N.O. RESET

E

OL 2.2K

(

+)

(

-

)

DC VOLTAGE INPUT

FROM FACP

SIGNALING OUTPUT

N

.C. INPUT

F

ROM FACP

S

IGNALING

O

UTPUT

N

C C NO

D

RY OUTPUT

NC C NO

P

OWER FA IL

Typical Application Diagrams (cont’d.):

F

ig. 8

OM5 module shown with with wet and/or dry

M

ormally open fire alar m trigger inputs (Latching

n

with Manual Reset)

:

OM5 module shown with with wet and/or dry

M

ormally closed fire alar m trigger inputs

n

(Latching with Manual Reset):

Fig. 9 - Two (2) MOM5 modules shown with wet and/or dry normally closed fire alar m trigger inputs

(Latching with Manual Reset):

Fig. 10 - Two (2) MOM5 modules shown with wet and/or dry normally open fire alar m trigger inputs

(Latching with Man

- 12 - Mseries

ual Reset)

:

Page 13

5

.10"

6.5625"

3.25"3.25"

5.10"

5

.10"

3.25"

1.00"10.50"1.00"

1.00"

1.00"

1.40"

1

.20"

1

.40"

1

.20"

0.75

"0.75" 11.00"

12.50"

3.25"

0.9375"

0.9375"

1

.40" 4.85" 4.85" 1.40"

1

.20"

Bottom

Top

RightLeft

• AL300ULM

•

AL400ULM

• AL600ULM

13.5”H x 13”W x 3.25”D

Enclosure Dimensions:

Mseries - 13 -

Page 14

1.285

1.285

• AL1012ULM

•

AL1024ULM

1

5.5”H x 12”W x 4.5”D

Enclosure Dimensions:

- 14 - Mseries

Page 15

Notes:

Mseries - 15 -

Page 16

Notes:

Altronix is not responsible for any typographical errors.

Altronix Corp.

140 58th Street, Brooklyn, New York 11220 USA, 718-567-8181, fax: 718-567-9056

web site: www.altronix.com, e-mail: info@altronix.com, Lifetime Warranty, Made in U.S.A.

IIMseries G11G

- 16 - Mseries

MEMBER

Loading...

Loading...