Page 1

Electrified Locks, Relays and Timers

WC11PS Series Restroom Control

INSTALLATION INSTRUCTIONS

1. GENERAL DESCRIPTION

The CX-WC11PS Restroom Control Kit allows access in and out of

a restroom with the ability to secure the door once inside. The Kit

also provides annunciation by including an Occupied light. The

designation of “PS” in the part number reects that this kit now

comes pre-wired in a metal enclosure with a power supply which

is ready to accept all eld wiring.

The CX-WC11PS Restroom Control Kit is controlled by Camden’s

advanced relay logic controller part numbered as the CX-33.

The CX-WC11PS has two modes. One is Mode 7 for a normally

unlocked restroom and the other is Mode 8 for a normally locked

restroom. In Mode 7 when the exterior PUSH to OPEN button

is pressed it will trigger the door operator to open the door. In

Mode 8 when the exterior PUSH to OPEN button is pressed it will

unlock the strike and trigger the door operator to open the door.

Once in the restroom and the PUSH to LOCK button is pressed it

will keep the door locked in either mode and disable the exterior

PUSH to OPEN button, as well as, providing annunciation with an

Occupied light. When exiting the restroom, you can either press

the inside PUSH to OPEN button to unlock the door and open the

door or you can push the crash bar, paddle or turn the knobset

to break the door contact circuit which will also unlock the door

and reset the system. The Occupied light will turn off signaling

the restroom is available.

2. INSTALLATION

Operation at a Glance

When the exterior PUSH TO OPEN button is pressed it will send

a momentary closure to the outside PUSH TO OPEN terminal

on the CX-WC11PS allowing the door to swing open. When

the interior PUSH TO LOCK button is pressed it will send a

momentary closure to the to inside PUSH TO LOCK terminal

on the CX-WC11PS causing it to lock the restroom and turn on

the Occupied light. When the inside PUSH TO OPEN button is

pressed it will send a momentary closure to the inside PUSH TO

OPEN terminal on the CX-WC11PS causing it to unlock the door

and open it. The Occupied light will now turn off signalling the

restroom is now vacant. The restroom can also be unlocked by

opening the door from the inside which will break the door contact

circuit causing the CX-WC11PS to reset and unlock the door.

Mounting

IMPORTANT: Do not apply power to the unit until you have fully

read the instructions and have made the required adjustments.

The CX-WC11PS cabinet should be mounted in a clean dry

location out of direct contact with the elements.

Wiring the CX-WC11PS Series Restroom

Control Kit is as follows:

The CX-WC11PS comes from Camden with the CX-33 pre-wired

to a labeled set of two terminal strips. This will make the wiring

of the push buttons easier since the wiring manual will no

longer need to be directly referenced for termination points. A

complete wiring diagram is adhered to the inside of the door

to provide a layout of the wiring as a reference when wiring the

eld devices to the kit.

There are two terminal strips that mirror the locations on the

CX-33. The left strip is used for power to the CX-33, the PUSH

TO OPEN and PUSH TO LOCK buttons, the door position switch,

and the Wet trigger. The right strip is for the outputs to drive the

strike (Relay 1), door operator (Relay 2), Occupied light (Relay3),

and to provide VDC power for the door strike.

Once all eld devices are wired to the CX-WC11PS then AC

power can be wired in.

IMPORTANT: Conrm the electrical panels breaker you are

going to be using is currently off. Do not wire the primary

terminals of the transformer until the secondary terminals

are connected rst.

The supplied CX-TRX-5024 transformer will have its secondary

terminals wired to the terminals on the top of the left terminal

strip marked as “AC”. Next, wire the primary terminals to the AC

feed to be used. Conrm your connections and apply power by

turning on the electrical panels breaker.

Selecting a Mode

The CX-WC11PS has two restroom applications built in (Mode

7 & 8). The default mode for the CX-WC11PS is Mode 7

(normally unlocked).

Determining which mode is correct for you will be based on

whether the restroom will be normally unlocked (Mode 7) or

normally locked (Mode 8).

Page 1 of 9

Page 2

WC11PS SERIES RESTROOM CONTROL

INSTALLATION INSTRUCTIONS

There are three LED displays that will allow you to see what mode

you have selected when advancing through the modes. To change

the mode of the CX-WC11PS simply press the MENU button once

and use the UP button to advance to the desired mode.

Editing the Settings for a Mode

Camden builds in typical times for lock release and door

operator activation and is ready to use without changing any

parameters. If you need to change the timing or delay for an

output, it can be done by pressing the “MENU” button within

the mode you selected. Once the option is selected you can

use the “UP or DOWN” buttons to select the timing needed.

The rst option (H & 1 ashing) will be how long relay 1 will be

activated for (0-50 seconds). The second option (d & 1 ashing)

will be how long to wait before activating relay 2 (0-15 seconds).

The third option (H & 2 ashing) will be how long relay 2 will be

activated for (0-50 seconds). The fourth option (d & 2 ashing)

will be how long to wait before activating relay 3 (0-15 seconds).

The fth option (H & 3 ashing) will be how long relay 3 will be

activated for (0-50 seconds). See chart below.

Factory Reset (Defaulting the CX-33)

To return the CX-33 back to its factory default settings you will

need to remove power, then hold down the “MENU” button

while powering up the CX-33. Once started you will see the

rmware version listed then a number “1” will be displayed.

Reconnect your power and press the “MENU” button once then

use the “UP” or “DOWN” button to advance to the desired mode.

Fully test the operation of the CX-WC11PS for proper functionality.

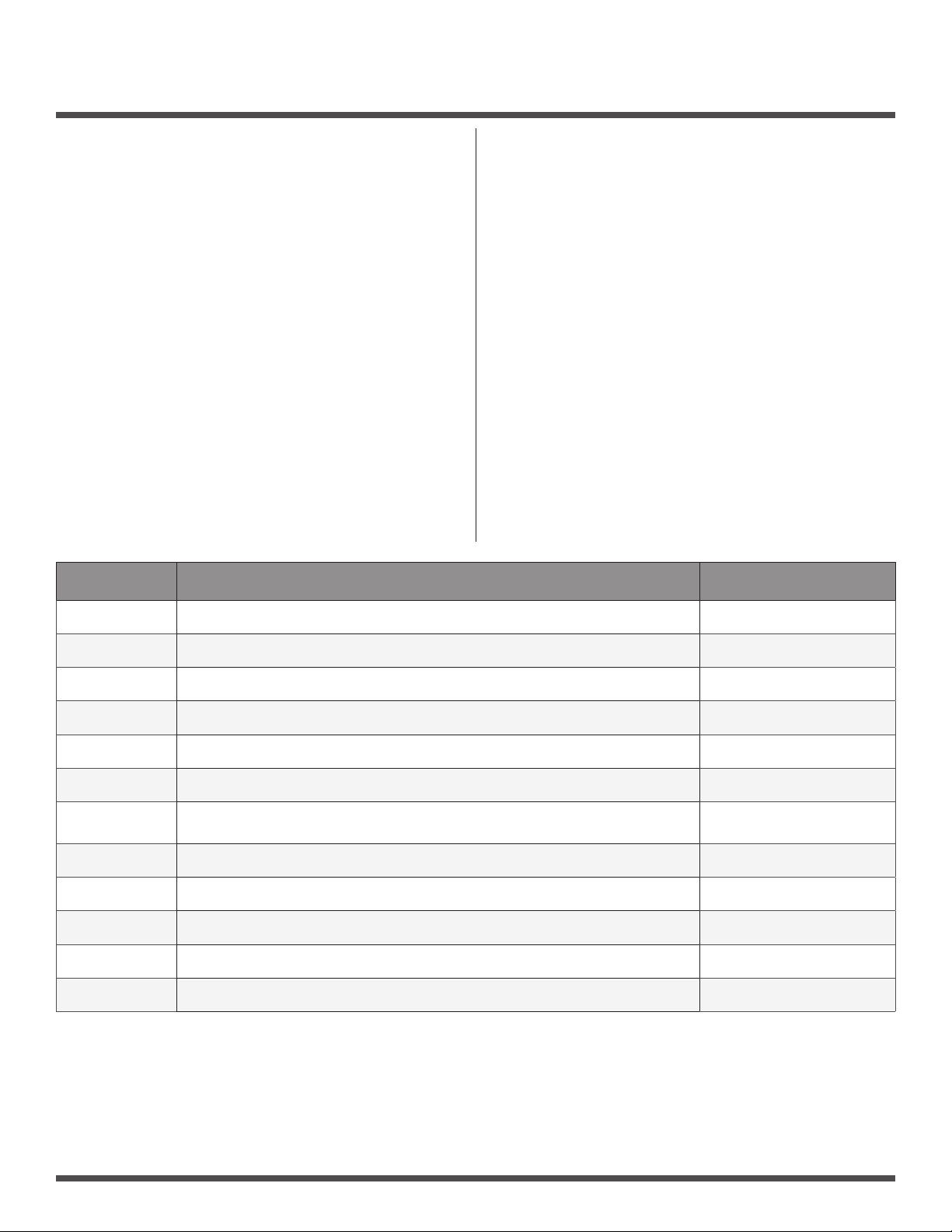

Display (M) Description ( Mode you are in) Parameters (1-15 )

H, then 1

d, then 1

H, then 1

d, then 1

H, then 1

d

A

1

2

3

4

5

Relay 1 Hold Time 0.0 to 50 seconds

Relay 2 Delay Time 0.0 to 15 seconds

Relay 2 Hold Time 0.0 to 50 seconds

Relay 3 Delay Time Depends on Mode

Relay 3 Hold Time 0.0 to 50 seconds

Sets the display ON or OFF during operating mode ON or OFF

Input delay on Activate. If other than 0.0 is selected, the input must

be held in for the time period chosen before the CX-33 will activate.

Set Dry Input 1 to activate on normally open or normally closed contact. N/O OR N/C

Set Dry Input 2 to activate on normally open or normally closed contact. N/O OR N/C

Set Dry Input 3 to activate on normally open or normally closed contact. N/O OR N/C

Set Dry Input 4 to activate on normally open or normally closed contact. N/O OR N/C

Set Dry Input 5 to activate on normally open or normally closed contact. N/O OR N/C

0.0 to 10 seconds

Page 2 of 9

Page 3

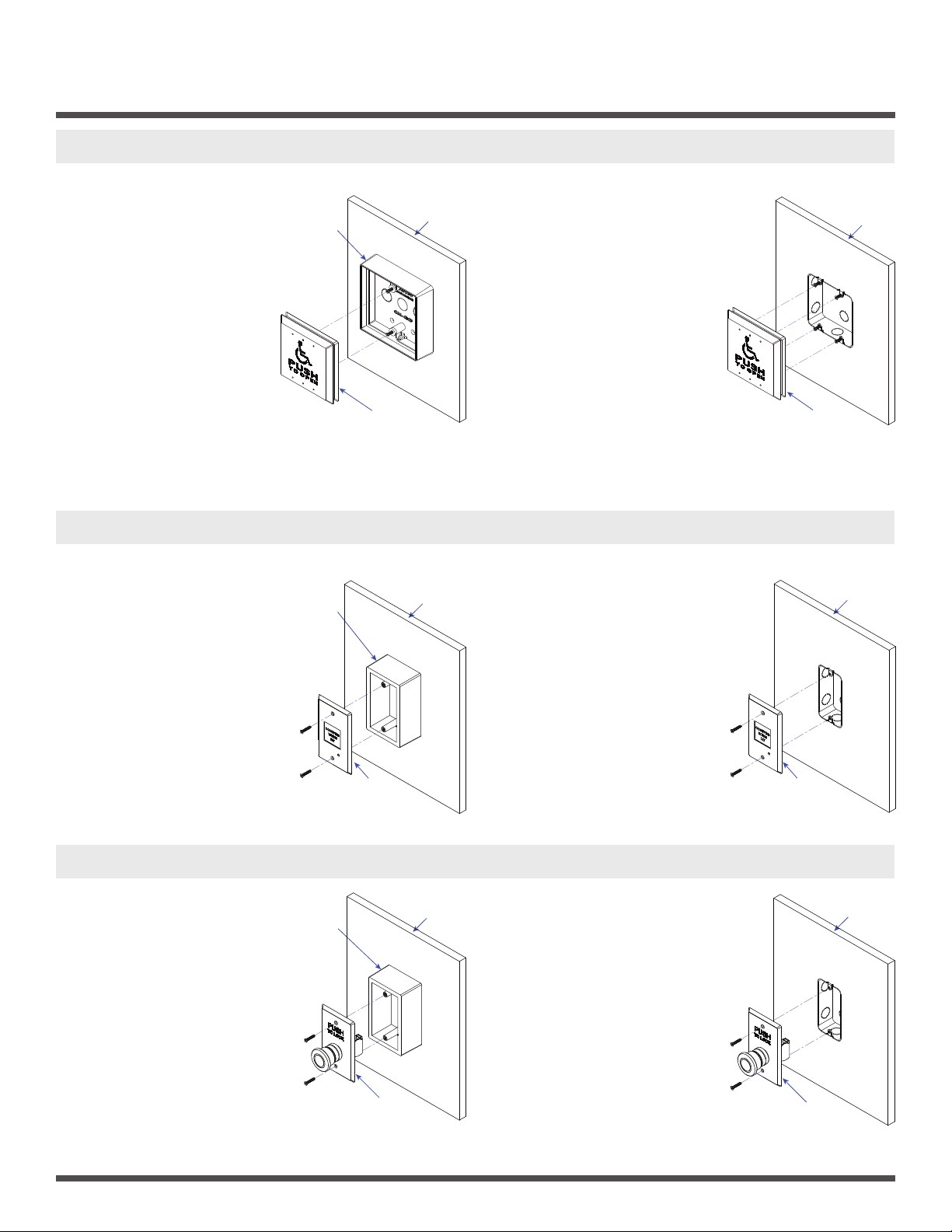

WC11PS SERIES RESTROOM CONTROL

Wall

Surface

Mount

Enclosure

CM-45/4 Active Switch

Wall

Surface

Mount

CM-AF500

LED Annunciator

CM-400/8 Switch

Wall

Surface

Mount

INSTALLATION INSTRUCTIONS

CM-45 MOUNT INSTALLATION

Surface Mount Installation

1. Position the back box (CM-43CBL)

on the wall in the desired location

and use the supplied #10 x 1 pan

head screws with the green PVC

Surface

Mount

Enclosure

Wall

anchors to mount the back box

to the wall.

Note: the back box will need the

screw holes drilled out prior to

mounting it to the wall.

2. Screw in the supplied #6-32

screws only a few threads deep

into the back box and t in the

assembled CM-45/4 by locating

the holes on the back plate and

CM-45/4 Active Switch

sliding it down in place on the back box.

3. Fit the HEX key through the hole on the faceplate and completely

tighten the #6-32 screws in place.

CM-AF500 MOUNT INSTALLATION

Surface Mount Installation

1. Position the back box (CM-34BL)

on the wall in the desired location

and use the supplied #10 x 1 pan

head screws with the green PVC

anchors to mount the back box

to the wall.

Note: the back box will need the

screw holes drilled out prior to

mounting it to the wall.

2. Position the CM-AF500 so that

the holes on the faceplate line-up

with the screw holes on the back

box and tighten the supplied

#6-32 screws securely in place.

Surface

Mount

Enclosure

CM-AF500

LED Annunciator

Wall

Flush Mount Installation

1. With the back box already roughed-in,

screw in the supplied 6-32 screws

only a few threads deep into the

back box and t in the assembled

CM-45/4 by locating the holes on

the back plate and sliding it down

in place on the back box.

2. Fit the HEX key through the hole

on the faceplate and completely

tighten the #6-32 screws in place.

Flush Mount Installation

1. With the back box already roughed-in,

position the CM-AF500 so that

the holes on the faceplate line-up

with the screw holes on the back

box and tighten the supplied

#6-32 screws securely in place

and completely tighten the

#6-32 screws in place.

Wall

CM-45/4 Active Switch

Wall

CM-AF500

LED Annunciator

CM-400/8 MOUNT INSTALLATION

Surface Mount Installation

1. Position the back box (CM-34BL)

on the wall in the desired location

and use the supplied #10 x 1 pan

head screws with the green PVC

anchors to mount the back box

to the wall.

Note: the back box will need the

screw holes drilled out prior to

mounting it to the wall.

2. Position the CM-400/8 so that the

holes on the faceplate line-up with

the screw holes on the back box and

tighten the supplied #6-32 screws

securely in place.

Page 3 of 9

Surface

Mount

Enclosure

CM-400/8 Switch

Wall

Flush Mount Installation

1. With the back box already roughed-in,

position the CM-400/8 so that

the holes on the faceplate line-up

with the screw holes on the back

box and tighten the supplied

#6-32 screws securely in place.

Wall

CM-400/8 Switch

Page 4

WC11PS SERIES RESTROOM CONTROL

CX-ED2079 ‘Universal’ Electric Strike

1. Prepare the door jamb as per the appropriate drawing.

4. Installation

INSTALLATION INSTRUCTIONS

CX-ED2079 'UNIVERSAL' ELECTRIC STRIKE INSTALLATION

2. Install mounting brackets to jamb using M5x12 screws

and pressed metal nuts. Do not tighten.

faceplate into jamb. Add one of more spacers between

jamb and mounting bracket when face plate extends

beyond the jamb. When the faceplate sits inside the

jamb, spacers must be added between the mounting

bracket & the lip bracket. Make sure clearance hole in

spacer aligns with hole in mounting bracket.

Mounting Bracket

Spacer

Spacer (Option)

Spacer

4. Connect wires coming from the low voltage side of the

transformer to wires (black) from strike.

5. Install electric strike jamb by attaching with # 10-32

screws and lockwashers.

6. Secure M5x12 screws holding mounting brackets to jamb.

4-7/8”

(124mm)

3-1/2”

(89mm)

4-1/8”

(105mm)

ESP1B + ESP2B

1-7/32”

(31mm)

3-3/8”

(86mm)

M5x12 Flat-Head Screw (2pcs)

M5x12 Screw

Jamp

Vertical Centerline

ote: The products are intended to be installed in accordance

th the installation wiring diagram, mechanical assembly

rawings provided with each product, the local authority having

risdiction (AHJ) and the National Electric Code, NFPA 70.

hen installed in fail secure mode, the local authority shall be

sulted with regard to the use of possible panic hardware to

llow emergency exit from the secure area.

he electric door strike shall be installed in such a way and

such a location so as to not impair the operation of an

rgency exit device or panic hardware mounted on the door.

1-7/32”

(31mm)

1-7/32”

(31mm)

3-3/8”

(86mm)

3-3/8”

(86mm)

1-3/8”

(36mm)

5-11/16”

(144mm)

6-1/8”

(155mm)

(200mm)

6-3/8”

(168mm)

7-3/8”

(187mm)

6-7/8”

(173mm)

ESP3B

7-7/8”

ESP4B

Page 4 of 9

Page 5

WC11PS SERIES RESTROOM CONTROL

POWER

How to modify fail-safe to fail-secure or vice versa.

INSTALLATION INSTRUCTIONS

CONNECTIONS OPERATIONS

12VDC

Red/Black: +12V

Blue/Green: Ground

24VDC

Red: +24V

Black/Blue: Green: Ground

A varistor is provided to protect/prevent strike from spikes.

Connect varistor between input wires.

Note: For UL 294 / UL 1034 compliance the door strikes are to be

powered via a UL 294/ UL 603 class 2 power limited output from a

control panel and or power supply. Furthermore, when powered

by AC/DC the units shall use a UL regulated UL 294/UL 603 power

limited class 2 output rated 12/24V with AC on indicator.

Power

12V

(+12V)

Varistor

( - )

24V

(+24V)

Varistor

( - )

Red

Black

Blue

Green

Red

Black

Blue

Green

1. Loosen the screw as per the product diagram below.

2. Rotate the set plate 180

° and slide the plate until

it is properly seated.

3. Tighten the screw.

Fail Safe

Fail Secure

Changing

Black

Red

Blue

Green

Power

ORDERING INFORMATION FOR REPLACEMENT PARTS

Item Part Number Description

1 60-31A037

2

3

4

5

6

7

60-42C012 Square Aura Insert

60-40E033 Advanced Logic Control Relay and 2 Amp Power Supply in pre-wired metal cabinet

CX-MDA Magnetic Door Contact

60-42C019

60-42C010

60-81C021 English Self-Adhesive Vinyl Sign ‘’WAIT FOR DOOR TO CLOSE’’

Mounting Box, Flush Aura Enclosure. Flame/Impact Resistant Black Polymer (ABS)

Mounting Box, Surface Aura Enclosure. Flame/Impact Resistant Black Polymer (ABS)

Red/Green Aura PC Board

6-1/2"W X 6-1/2"H X 2"D

5-1/4"W X 5-1/4"H X 2"D

Page 5 of 9

Page 6

Notes :

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

WC11PS SERIES RESTROOM CONTROL

INSTALLATION INSTRUCTIONS

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

Questions? Call us toll-free at 1-877-226-3369 or technical support 905-366-3377 (ext. 505)

Opening New Doors to

Innovation, Quality and Support!

Call: 1.877.226.3369 / 905.366.3377

Visit: www.camdencontrols.com

File: WC11PS Restroom Controls

Manual.indd

Rev.: March 10, 2020

Part No: 40-82B240

Page 6 of 9

Page 7

Page 7 of 9

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

CAMDEN DOOR CONTROLS. ANY

REPRODUCTION IN PART OR AS A

WHOLE WITHOUT THE WRITTEN

PERMISSION OF CAMDEN DOOR

CONTROLS IS PROHIBITED.

INSIDE THE

RESTROOM

WAIT FOR DOOR TO CLOSE

TO LOCK THIS DOOR

40-81C021

to unlock door and exit.

Light ring on switch will turn red when door is locked.

Place sign

inside the

on the door

restroom at

eye level

AC

SW1

SW2

ACAC

24V

OPEN

CLSD

OPEN

OPEN

12V

-

6V

CLSD

OPEN

POWER SUPPLY

6, 12, 24 VDC

SW1

SW2

SMP3

BAT+

-

DC+

DC

TO

PUSH

LOCK

CX-33PS

(if applicable)

the ceiling tiles

the wall or above

to be mounted on

Power Supply Cabinet

WC11PS SERIES RESTROOM CONTROL

INSTALLATION INSTRUCTIONS

RESTROOM SIGNAGE

TO OPEN

PUSH

Page 8

WC11PS SERIES RESTROOM CONTROL

CX-WC11AXFM-PS Wiring Diagram with CX-WEC10-K2 Integration

FILENAME:

DRAWING No:

SCALE: NONE DRAWN BY: REV: DATE:

CAMDEN DOOR CONTROLS

5502 Timberlea Blvd

Mississauga, Ontario

L4W 2T7

JML

Jan 20, 2020

1

CX-WC11AXFM/SM-PS & CX-WEC10K2 Wiring Diagram

Notes

1. CX-33 can be set to Mode 7 (Normally Unlocked)

or Mode 8 (Normally Locked).

2. Mode 7 = Set Set Strike to Fail Safe.

3. Mode 8 = Set Strike to Fail Secure.

Door Position Switch

Transformer

CX-TRX-5024

24 VAC, 50 VA

CM-45/4

Outside

Push to Open

CM-45/4

Inside

Push to Open

CM-400/8

Push to Lock

CX-WEC10-K2

Emergency Call System Wiring

Electric Strike

CX-ED2079

Wire MOV

directly to

strike or

magnet

Connect directly to DPS if no Emergency Call System is installed

120 VAC

N.C.

1

2

3

4

CM-AF540SO

CM-AF141SO

GRY

BLK

N/O

N/C

BLK

GRY

Model: 60-40E033

AC

AC

Outside

Push To Open

Inside

Push To Open

Push To

Lock

DPS NC

DPS COMM

+ WET

- INPUT

+ Lock

+ Strike

- Strike

*

Door

Operator

*

Occupied +

Light -

*

+ VDC

- VDC

PUSH

TO OPEN

PUSH

TO OPEN

PUSH TO

LOCK

OCCUPIED

WHEN

LIT

CM-AF500

Occupied

When

Lit

MOV

Door Operator

INSTALLATION INSTRUCTIONS

Page 8 of 9

Page 9

9-5/8”

L

(243.9 mm)

L

C

11-1/16”

(281.4 mm)

Page 9 of 9

WC11PS SERIES RESTROOM CONTROL

INSTALLATION INSTRUCTIONS

CABINET BASE & MOUNTING TEMPLATE

7-7/8” (200.2 mm)

6” (152.7 mm)

6” (152.7 mm)

C

Loading...

Loading...