Page 1

CX-ED2079-1

‘ANSI’ Electric Strike

Installation Instructions

This Package Includes:

1- 4 PIN power connector

1- ESP1B faceplate

4- Wire nuts

5- M5 x 12mm screws

2- #10 x 1 1/4” wood

screws

2- #10-32 x 1/2” screws

2- Mounting brackets

2- Spacers

1- Varistor

1- Trim Plate

1. Description

Camden CX-ED2079-1 low prole grade 2 ANSI strike for

cylindrical locksets offers the very best strike quality and

performance, with three stainless steel faceplates provided.

The ‘ANSI’ strike design delivers unparalleled application

exibility, with eld selectable voltage, fail safe/fail secure

operation and mechanical adjustment of the strike body.

2. Specifications

Voltage

Current Draw

12/24V AC/DC

300mA@12V DC

150mA@24V DC

3. Dimensions

5/8”

(16mm)

1 1/4”

(32mm)

UL 1034

UL 294

Static Strength

Dynamic Strength

Endurance

Mode

Mech. Adjustment

Operation

Duty

Dimensions (Body)

1,000 Lbs.

50 Ft-Lbs.

700,000 Cycles (Factory Tested)

250,000 Cycles (UL Verified)

Field Selectable

Fail Safe/Fail Secure

Strike Body/Faceplate

AC-Buzz

DC-Silent

Continuous

3 3/8” H x 1 7/8” W x 1 7/32” D

(86mm x 47mm x 31mm)

Page 1 of 3

(104mm)

4 7/8”

(123mm)

3 3/8”

(86mm)

4 1/8”

1 7/32”

(31mm)

1 7/32”

(31mm)

1/8”

(3mm)

1 7/8”

(47mm)

1 5/8”

(42mm)

3/4”

(19mm)

1 1/4”

(32mm)

1 7/32”

(31mm)

1/2”

(12mm)

Page 2

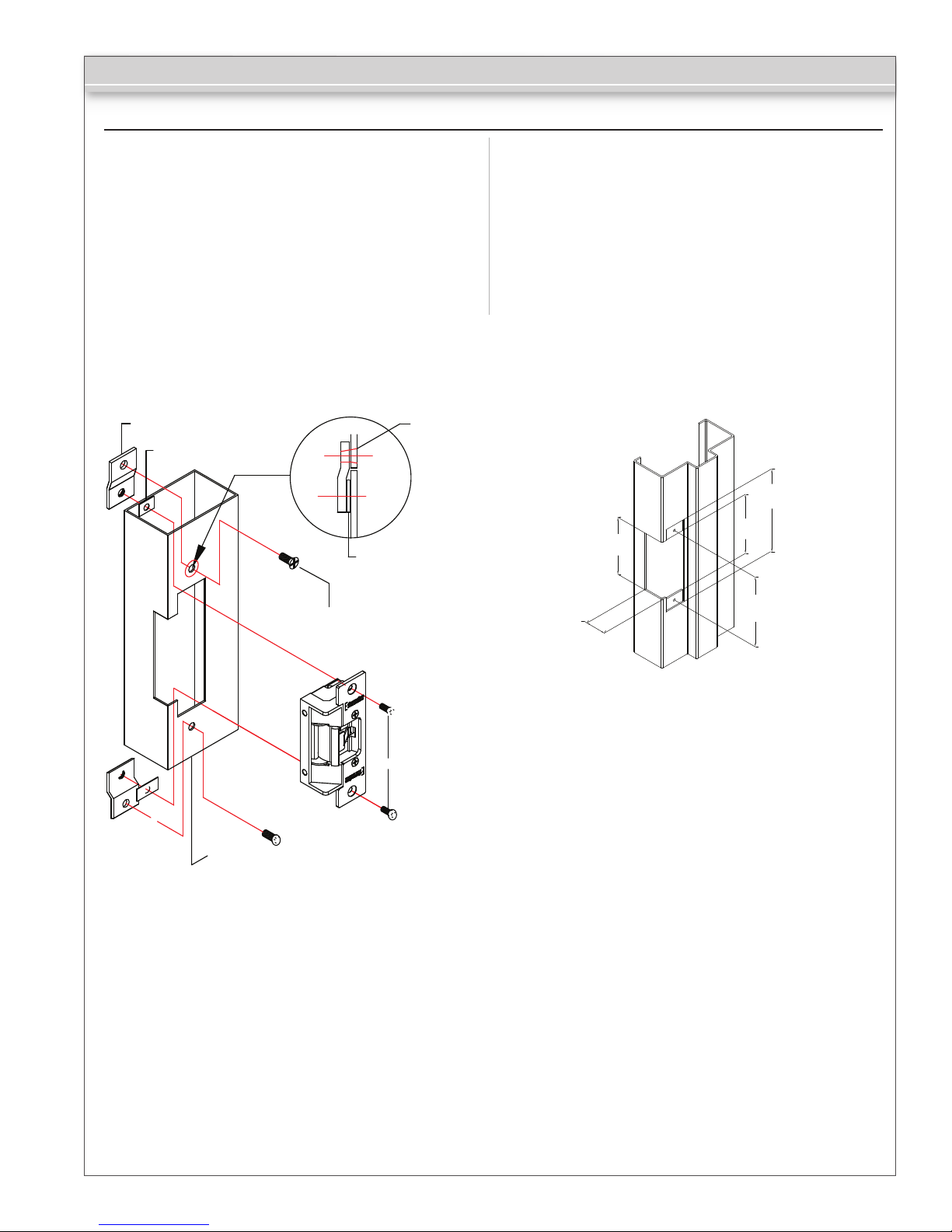

4. Installation

Jamp

CX-ED2079-1 ‘ANSI’ Electric Strike

1. Prepare the door jamb as per the appropriate drawing.

2. Install mounting brackets to jamb using M5x12 screws

and pressed metal nuts. Do not tighten.

3. Spacers are used to assure ush nal assembly of

faceplate into jamb. Add one of more spacers between

jamb and mounting bracket when face plate extends

beyond the jamb. When the faceplate sits inside the

jamb, spacers must be added between the mounting

Mounting Bracket

Spacer

Spacer (Option)

M5x12 Flat-Head Screw (2pcs)

Spacer

bracket & the lip bracket. Make sure clearance hole in

spacer aligns with hole in mounting bracket.

4. Connect wires coming from the low voltage side of the

transformer to wires (black) from strike.

5. Install electric strike jamb by attaching with # 10-32

screws and lockwashers.

6. Secure M5x12 screws holding mounting brackets to jamb.

4 7/8”

(124mm)

3 1/2”

(89mm)

4 1/8”

(105mm)

1 7/32”

(31mm)

3 3/8”

(86mm)

ESP1B + ESP2B

M5x12 Screw

Vertical Centerline

Note: The products are intended to be installed in accordance with the installation wiring diagram,

mechanical assembly drawings provided with each product, the local authority having jurisdiction

(AHJ) and the National Electric Code, NFPA 70. When installed in fail secure mode, the local authority

shall be consulted with regard to the use of possible panic hardware to allow emergency exit from the

secure area.

The electric door strike shall be installed in such a way and in such a location so as to not impair the

operation of an emergency exit device or panic hardware mounted on the door.

Page 2 of 3

Page 3

CX-ED2079-1 ‘ANSI’ Electric Strike

5. Connections

POWER

12VDC

Red/Black: +12V

Blue/Green: Ground

A varistor is provided to protect/prevent strike from spikes.

Connect varistor between input wires.

Note: The door strikes are to be powered via a class 2 power

limit output from a control panel or power supply that is UL

listed to UL Burglar Alarm/Access control standards.

24VDC

Red: +24V

Black/Blue: Green: Ground

Power

12V

(+12V)

Varistor

( - )

(+24V)

Varistor

( - )

24V

Red

Black

Blue

Green

Red

Black

Blue

Green

6. Operation

How to modify fail-safe to fail-secure or vice versa.

(1). Loosen the screw as per the product diagram below.

(2). Rotate the set plate 180° and slide the plate until it is

properly seated.

(3). Tighten the screw.

Fail Safe

Changing

7. Faceplates

INCLUDED IN PACKAGE

⁄”

(16mm)

4 ⁄”

(104mm)

4 ⁄”

(123mm)

ESP1B - ANSI Square

1 ¼”

(32mm)

3 ⁄”

(85mm)

¾”

(19mm)

Black

Red

Blue

Green

Power

Fail Secure

ADDITIONAL FACEPLATE

⁄”

(16mm)

6 ⁄”

(154mm)

6 ⁄”

(173mm)

ESP3B - Hollow Metal Door ESP4B - Wood Door ESP2B - Ansi Round

1 ¼”

(32mm)

3 ⁄”

(85mm)

1 ¾”

(44mm)

(16mm)

7 ⁄”

(200mm)

⁄”

7 ½”

(189mm)

1 ⁄”

(36mm)

3 ⁄”

(85mm)

2 ¼”

(57mm)

4 ⁄”

(123mm)

⁄”

(16mm)

4 ⁄”

(104mm)

1 ¼”

(32mm)

3 ⁄”

(85mm)

¾”

(19mm)

Push Buttons Keypads Strikes Magnetic Locks Key Switches Relays & Timers Access Control

5502 Timberlea Blvd.,

Mississauga, ON Canada

L4W 2T7

www.camdencontrols.com

Toll Free: 1.877.226.3369

Page 3 of 3

File: CX-ED2079-1 ‘ANSI’Designer

Installation Instructions.indd R2

Revision: 31/05/2018

Part No.: 40-82B221

Loading...

Loading...