REVERSE AIR - MODEL SWF

DUST COLLECTOR BAGHOUSE

(Fan Mounted Outside Unit)

INSTRUCTION, OPERATIONS &

MAINTENANCE MANUAL

Phone:

CAMCORP, INC.

913-831-0740 Fax: 913-831-9271

TABLE OF CONTENTS

OPERATING PRINCIPLE & SECTION/PARTS DETAIL........................................... 1-1

RECEIVING & INSPECTION OF UNIT.......................................................................2-1

ON SITE STORAGE RECOMMENDATIONS.............................................................3-1

SETTING UP YOUR UNIT............................................................................................4-1

BAG & CAGE INSTALLATION................................................................................... 5-1

START-UP CHECK LIST .............................................................................................. 6-1

START-UP DUST CONTROL SYSTEMS.................................................................... 7-1

SHUTDOWN PROCEDURES........................................................................................ 8-1

TROUBLE SHOOTING THE DUST COLLECTOR.....................................................9-1

TOUBLESHOOTING THE CLEANING MECHANISM............................................ 10-1

SAFETY RECOMMENDATIONS...............................................................................11-1

ROUTINE MAINTENANCE........................................................................................ 12-1

COMPONENT IOM MANUALS.................................................................................13-1

Phone: 91

CAMCORP, INC.

3-831-0740 Fax: 913-831-9271

OPERATION PRINCIPLE

A. Solids laden air or gases enter the unit at the hopper or housing inlet.

B. Air passes through the filter media.

C. Solids are retained on the filter media surface.

D. Cleaning consists of a rotating sweep arm with nozzles positioned over the bags

that continuously blows a reverse flow of air into the bags.

1. This momentarily takes a row of bags off stream through pressure reversal.

2. Flexing filter bags.

3. Solids are released to fall towards hopper and through rotary valve or other

discharge equipment.

Phone:

1-1

CAMCORP, INC.

913-831-0740 Fax: 913-831-9271

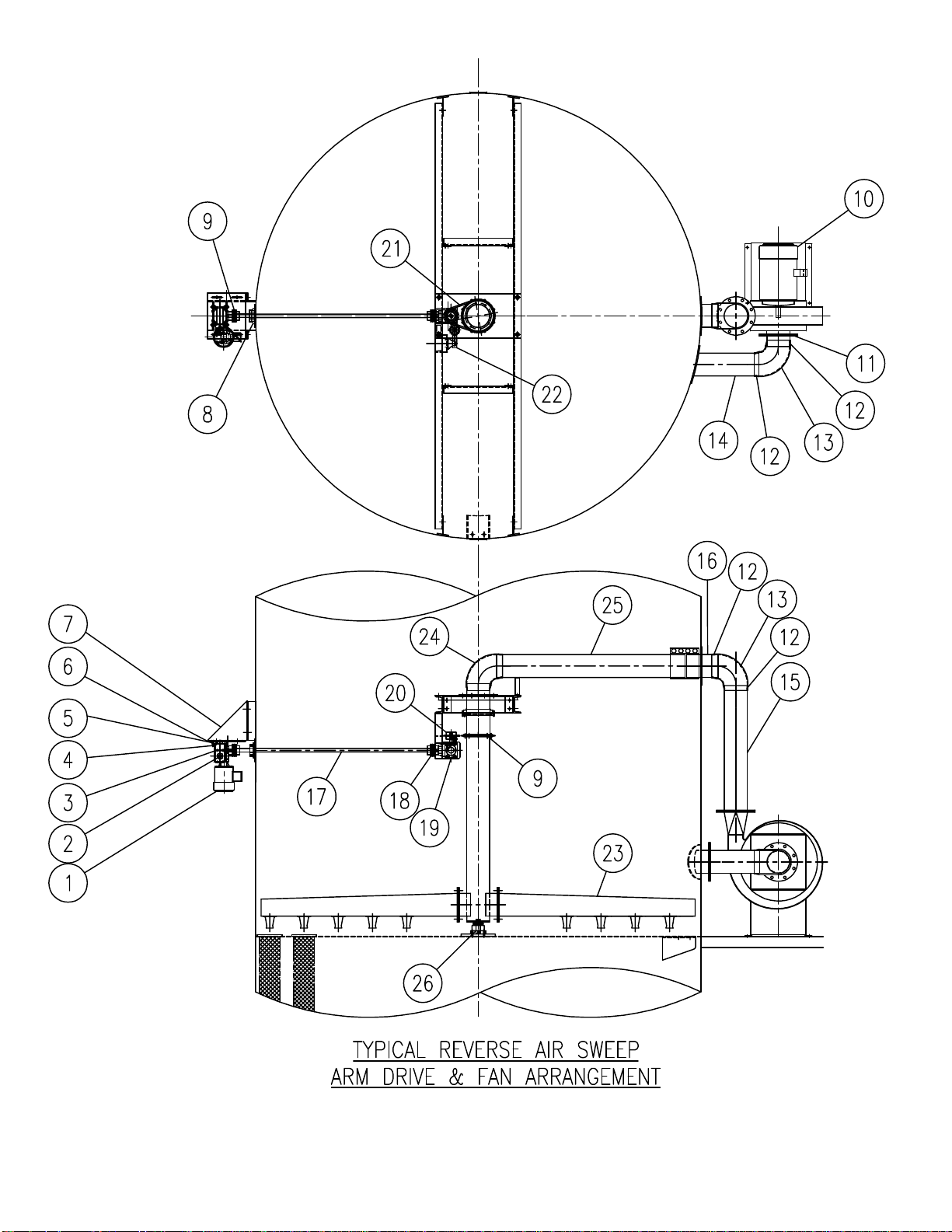

Camcorp Reverse Air Field Assembled Components

Item Quantity Description

1 1 Motor, ½ HP or 1 HP - 1,800 RPM, 56C, 208-230/460/3/60

2 1 Primary Gear Reducer, 133Q56R20, 20:1 Ratio

3 1 Adapter Kit

4 1 Secondary Gear Reducer, 206Q56L40, 40:1 Ratio

5 1 Bracket Kit, 206S-BK (Secondary Reducer)

6 1 Motor Mounting Plate

7 2 Drive Mount Table Wall Brackets

8 1 Ball Bearing, 4-Bolt Flange, 1 ¼”

9 1 Chain Coupling

10 1 Reverse Air Fan (Size Determined by Unit Size)

11 1 Fan Inlet Stub Adapter

12 4 Hose Clamps

13 2 8” Rubber Elbow

14 1 Air Inlet Pipe

15 1 Fan Exhaust Pipe

16 1 Fan Exhaust Air Stub

Camcorp Reverse Air Shop Assembled Components

17 1 Drive Shaft

18 1 Chain Coupling

19 1 Bevel Box Gear Reducer

20 1 Torque Limiter Clutch

21 1 Drive Chain

22 1 Chain Tensioner

23 1 or 2 Sweep Arm (Size Determined by Unit Size)

24 1 8” Rubber Elbow

25 1 Baghouse Air Inlet Pipe

26 1 Thrust Bearing, 4-Bolt

27 1 Rotary Bearing Assembly

Visit our Website at: www.camcorpinc.com

CAMCORP, INC.

Phone 913-831-0

740 iFax 913-831-9271

RECEIVING YOUR UNIT

Prior to accepting shipment, care must be taken to inspect all equipment received both for

proper count and for damage. Any and all irregularities must be noted on the carriers’

copy of the shipping receipt to assist in settling any claims for damage or shortages. All

equipment is shipped FOB point of origin whether on a prepaid or collect freight basis.

ANY CLAIM FOR DAMAGE IN TRANSIT OR SHORTAGES MUST BE

BROUGHT AGAINST THE CARRIER BY THE PURCHASER.

Once your claim has been filed with the carrier contact CAMCORP to notify us of the

problem(s), and then we will advise the appropriate repair procedure or recommend it to

be returned to the factory depending on the extent of damage.

INSPECTION OF UNIT

Housing: Particular attention should be paid to the sheet metal housing of your collector.

The unit should be inspected for dents, cracks, or rips. A dented housing may seriously

affect the structural integrity of the unit. If any of these signs are present, note them on

the shipping receipt and notify CAMCORP immediately. The entire unit should be

checked against the certified drawings for correctness and the manufacturer notified

immediately if there are any discrepancies. No corrections may be made without the

expressed written consent of the manufacturer.

Components: A count should be made of all pieces received and this should be verified

against the carrier’s manifest. Boxes should be inspected for rough handling, which may

have resulted in hidden damage.

2-1

CAMCORP,

Phone: 913-831-0740 Fax: 913-831-9271

INC.

ON SITE STORAGE RECOMMENDATIONS

I. Baghouse and Housing

1. Housing can be stored outside.

2. Equipment must be blacked up to keep the flanges out of the dirt.

3. Many units are supplied with a plain finish bare steel interior. If storage of

more than two week is anticipated, the interior should be prime coated before

storage.

4. Covering the unit with a tarp is recommended to keep the interior from rusting

or corroding as well as keeping the finish in new condition. However, the tarp

is not absolutely necessary.

II. Bags & Cages

1. Bags must be stored inside a cool dry area protected from rodents and insects.

2. For extended storage the boxes for the bags should be wrapped with plastic

wrap or stretch wrap to protect from moisture.

3. If the bags get wet for any reason, immediately lay them out with adequate

ventilation to dry in order to prevent mold and mildew.

4. It is recommended to store the cages inside a dry area if at all possible.

5. If an inside location is not available, cages can be stored outside as long as they

are covered by a tarp.

6. Cages are generally stored horizontally on pallets to keep off the ground.

7. If cages can be stored horizontally, do not stack over three boxes high.

8. If the job site is in an area that may receive a significant snow load, the cages

must be stored vertically in order to prevent being crushed by the weight of the

snow. Do not stack more than one box high.

III. Accessory Parts

1. This includes all gauges, bag clamps, nylon or copper tubing, gaskets, and other

ports not specifically called out.

2. These items should be stored inside a cool dry place protected from insects and

rodents.

3-1

CAMCORP, INC.

Phone:

913-831-0740 Fax: 913-831-9271

ON SITE STORAGE RECOMMENDATIONS (continued)

IV. Fan and Fan Accessories

1. Fans can be stored outside on a pallet or skid to keep out of water and dirt.

2. Equipment should be covered with a tarp to protect from the bags.

3. Fan silencers, outlet dampers, and inlet boxes should also be tarped and stored

on a pallet or skid.

V. Ducting

1. Ducting can be stored outside on a pallet or skid to keep it off the ground. It

should be positioned so that water does not sit in the equipment.

2. If ducting is unpainted steel, it should be at least primed coated before storage.

3. If ducting is already finish coated, it should be tarped to protect the finish but is

not absolutely necessary.

VI. Knife Gate

1. All limit switches, solenoids, and air cylinder ports must be capped and taped to

prevent any moisture or dirt from entering.

2. Equipment can sit outside provided it is covered with a tarp and is on a pallet or

skid to keep it out of the water and dirt.

VII. Isolation Dampers

1. All limit switches, solenoids, and air cylinder ports must be capped and taped to

prevent any moisture or dirt from entering.

2. Equipment can sit outside provided it is covered with a tarp and is on a pallet or

skid to keep it out of the water and dirt.

VIII. Rotary Valve

1. Rotor and interior of valve should be well oiled with vegetable

oil to prevent

rust and to maintain compatibility with product.

2. Unit can be stored outside provided it is covered with a tarp and is on a pallet or

skid to keep it out of the water and dirt.

3-2

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

ON SITE STORAGE RECOMMENDATIONS (continued)

IX. Butterfly (Wafer Valve)

1. All limit switches, solenoids, and air cylinder ports must be capped and taped to

prevent any moisture or dirt from entering.

2. Unit can be stored outside provided it is covered with a tarp and is on a pallet or

skid to keep it out of the water and dirt and sunlight.

X. Level Indicators

Store these items inside a cool dry area protected from rodents

XI. AC Inverters

Store these items and all other electrical controls inside a cool dry area protected

from rodents.

Phone: 913-8

3-3

CAMCORP, INC.

31-0740 Fax: 913-831-9271

SETTING UP YOUR UNIT

CAMCORP dust collectors are shipped in various states of assembly depending on the

size and configuration of the unit. Before attempting to move the dust collector or any of

its sections, review both the certified general assembly drawing supplied with your unit

and the rigging and lifting guidelines included in this manual. Become familiar with the

size and number of sections to be assembled, the orientation of inlet(s), outlet(s), access

door(s), and fan as well as the number and location of lifting lugs.

Dust collectors of this type are manufactured from steel sheets and are quite flexible.

Therefore, even though care has been taken to maintain dimensional accuracy and

squareness, some difficulty should be anticipated, and temporary bracing in the field may

be required.

Rigging and Lifting Guidelines

1. Do not lift the dust collector by any attachments other than the lifting lugs

provided.

2. Use all of the lifting lugs provided on the dust collector, or a section of the

dust collector, when making a lift.

3. If the lifting lugs are located below the roof line of the dust collector or

below the top of the section of the dust collector, a vertical pull must be made

to avoid crushing the top of the unit. Use spreader beams to accomplish this

vertical pull.

4. Attach tag lines at several locations to be able to control the unit when lifted

and to prevent spinning or swinging.

5. The dust collector should be lifted and lowered at a slow, uniform rate and

not allowed to bounce or joggle since this can cause excessive impact

stresses at the lift points.

Doors and Flanges: Hold-downs on doors should only be hand tightened. Excessive

pressure can distort the door panel itself resulting in leakage. All bolts on flanges should

be tight. All holes in the dust collector must be plugged prior to start-up if not being

connected.

4-1

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

Platform Installation: The platform, ladder, handrail, and bracing are to be installed as

shown on the general arrangement drawing. Fan platforms are mounted onto bolt-on

mounting gussets that attach to the sidewall.

Explosion Vents (where applicable):

1. Figure 6 – The explosion vents are attached with a minimum of standard

steel fasteners for shipment. THESE MUST BE REMOVED and the

PVC Bolts installed that are included in the shipment. Extreme care should

be exercised when installing the PVC Bolts as they are very fragile. A

gasket is factory installed that will provide a seal between the vent panel

and the frame. DO NOT use silicone sealer or any other sealer or adhesive

at this joint as this will prevent the vent from operating properly.

2. The area around the vents should be clear of any personnel or obstructions

to prevent injury or damage.

Electrical: A 230/460 volt 3 phase 60 Hertz circuit is required to operate the dust

collector’s ½ HP or 1 HP sweep arm drive motor as well as the reverse air fan. Please

refer to the general arrangement drawing for the exact type and HP of motor used on the

reverse air fan.

Gauges: Check the pressure differential gauge to make sure that the high-pressure tap is

connected below the tube sheet and the low-pressure tap is connected above the tube

sheet. Verify that the gauge have been zeroed prior to connection when it is in its

permanent mounting position.

Reverse Air Fan & Drive Motor Assembly: Refer to the figures on the following pages

to assemble the components for the reverse air fan and drive. Fan – Locate the pieces and

assemble as shown. Drive Assembly - Slide the motor assembly up or down to align the

gear reducer shaft with the drive shaft. Assure that the bolts in the horizontal slide base

are tight when doing this or the chain coupling will bind when these are tightened. Use

the horizontal motor slide base to assist in the assembly of the chain coupling. Assure that

the chain coupling is not binding and is fully engaged on each shaft. Test for proper

operation of the sweep arm with the fan off.

Auxiliary Equipment: All auxiliary equipment must be installed according to its

manufacturer’s specifications and interlocked with the entire system as needed. Direction

of rotation of each item must be checked prior to start-up of the entire system.

Phone: 913-8

4-2

CAMCORP, INC.

31-0740 Fax: 913-831-9271

TOP LOAD BAG AND CAGE INSTALLATION

1. Inspect the cage for any signs of damage, warping, bent wires, or missing

welds.

2. Inspect the filter bag for any signs of mold, mildew, ripped seams, or holes.

3. Lower the closed end of the bag through the hole in the tube sheet.

4. With your hands, “kidney shape” the snap band bag top in order to fit and

align it within the tube sheet hole.

5. Fit the groove of the snap band to the I.D. of the tube sheet hole and allow it

to expand and audibly snap into place. If the band will not snap into place

initially, do not push on the “dimple” as doing this will permanently damage

the snap band. Instead, kidney shape the snap band from the opposite side of

the band. Then you can allow the band to expand and audibly snap into

place.

6. Check the fit of the snap band to the tube sheet. It should be even in height

above the tube sheet around the entire circumference, which will confirm to

the installer that the tube sheet is centered and well secured into the middle

groove of the snap band.

7. Lower the cage into the bag and press that cage top down into the bag’s snap

band I.D. When in position, the rolled flange of the cage top will rest on the

tube sheet and the bag and cage assembly will be rigidly mated. The O.D. of

the cage top provides a compression fit to the I.D. of the snap band.

8. Disconnect the drive chain to allow the sweep arm to rotate freely to access

the holes under the sweep arm if necessary.

9. Replace access doors and tighten accordingly. You are ready to begin startup procedures if all other preceding tasks and hook-ups are completed.

Phone: 913-8

5-1

CAMCORP, INC.

31-0740 Fax: 913-831-9271

PRODUCT HIGHLIGHT

BEADED SNAPBAND FILTER BAG DESIGN FOR FLAT TUBESHEET HOLE

The snapband was developed to improve sealing efficiency. This design eliminates multiple parts, minimizing labor

expenses. Camcorp provides a uniform double beaded gasket in the cuff assembly. This assures a leakproof seal for flat

plate tubesheet holes. When installing the bags, follow instructions provided.

PROPERINSTALLATIONOFTHECUFF

1. Form the snapband into the shape of a kidney.

The vertical seam in the cuff should be on the

outer radius of the kidney shape.

2. Seat the seam of the cuff into the hole first with

the tubesheet fitting between the beads, with

one above and one below it .

3. Release the band and it will spring securely into

place. Use caution, and ensure all fingers are

out of the tubesheet opening when the snapband is released. Make sure the snapband fits

squarely in the hole and there are no kinks in

the metal band.

NOTE:If you are converting to a snapband bag from some other type of sealing method, the tubesheet holes must

be inspected carefully to ensure that proper sealing will result. The surface finish on the inside diameter must be

relatively smooth. Any deep grooves or protrusions will cause leakage. Ahole that was flame cut, but not ground

smooth is one example. The tubesheet holes must be consistent in circumference from one hole to another.

If the circumference difference is determined by measuring, the holes should be checked to the nearest 0.001 in.

Slight out-of-roundness is acceptable. Take three measurements for each hole and record the average of these three

measurements. Compare all the hole averages. The difference between the largest average and smallest average hole

size should not exceed 0.020 in. Try sample cuff in largest and smallest hole to confirm proper fit.

When checking the sample snapband in the hole for fit, push on the edge of the snapband slightly with your thumb

to try and move it inward. If a gap occurs easily between the snapband and the edge of the tubesheet hole, leakage

may result. If the inside surface of the hole is smooth, check the cuff fit by trying to spin the cuff in the hole. If it

spins easily, it may leak.

Flat Plate Tubesheet Hole

Snapband

Top View

Seam

START-UP CHECKLIST

1. Installation

Make sure the unit is secured to grade. The ladder(s) and platform(s) must be

tightened and set up according to OSHA requirements. Ducting and piping must

be secured and routed out of the way of traffic whenever possible to avoid injury.

Ducting must also be free of all debris including moisture.

2. Interior of the dirty air plenum

A. Make sure that the filter bag assemblies hang straight and the bottoms do not

touch each other or any part of the collector interior. If this occurs, the bags

will have holes worn in them wherever they contact and will require

replacement.

B. High-level alarms should be connected sufficiently below the air inlet(s) to

avoid a plugged up inlet or blinded off filter bags.

3. Clean air plenum

A. All bolts on the flanges must be in place and properly tighten.

B. Verify that the reverse air fan and sweep arm drive are properly installed.

4. Exterior of dust collector

A. Access doors, inspection ports, and relief vents should seat effectively to

prevent leakage.

B. All bolts must be properly tightened.

C. Operate any equipment connected to the dust discharge of the dust collector.

Check the rotation of any motor driven equipment such as rotary airlocks,

horizontal unloading valves, live bottom bin activators, and screw conveyors.

Check slide gates and butterfly valves for binding.

5. Explosion relief panels – shear bolt style (where applicable)

A. Inspect for broken or missing bolts.

Phone: 913-8

6-1

CAMCORP, INC.

31-0740 Fax: 913-831-9271

START-UP DUST CONTROL SYSTEMS

1. Fan or blower system

A. Start the fan or blower and check rotation.

B. Check dust pickup points for proper suction; balance airflow in individual

ducts.

C. Check for air leakage at all flanged connections.

2. Equipment start-up sequence

A. Start the sweep arm drive motor (direction of rotation is not critical).

B. Start the reverse air fan motor and check rotation.

C. Dust take away equipment such as rotary airlocks, screw conveyors,

horizontal unloading valves, live bottom bin activators, and pneumatic

conveying systems can now be started in their correct sequence.

D. Check that all access doors, hatches, ports, and other openings are closed and

latched or bolted.

E. The main exhaust fan can now be started and brought up to speed.

F. Start the dust laden air through the collector. The collector should be started

under partial load to allow the bags to become slowly and evenly coated with

dust particles.

On pneumatic conveying systems, watch the differential pressure gauge

closely for the first hour or so. If unstable, the collector discharge system

may be too small for the volume it is seeing. A quick fix is to reduce the

material feed until the discharge rate can be increased.

G. Observe the manometer or magnahelic differential pressure gauge reading.

As the new filter bags become coated with dust, the efficiency of the filtering

action increases, and the differential pressure across the filter bags will also

increase. Slowly bring the collector to full load and note the final pressure

drop across the filter bags. Never allow the pressure drop across the filter

bags to exceed 17” w.g. maximum or filter bags may collapse.

H. Check the main airflow with a pitot tube, or equivalent measuring device, to

establish initial conditions. If the main airflow must be adjusted up or down

to suit the process, repeat step 2-H above.

7-1

CAMCORP,

Phone: 913-831-0740 Fax: 913-831-9271

INC.

SHUT-DOWN PROCEDURES

1. Dust control systems

Reverse start-up procedure, shut down fan, then after 5 or 10 minute delay, shut

down the reverse air fan and sweep arm drive motor.

2. Pneumatic systems

Reverse start-up procedure, shut down fan, then after 5 or 10 minute delay, shut

down the reverse air fan and sweep arm drive motor.

Phone:

8-1

CAMCORP, INC.

913-831-0740 Fax: 913-831-9271

TROUBLESHOOTING THE DUST COLLECTOR

I. Excessive pressure drop across filter bags

The differential pressure gauge or manometer on your dust collector should read

6” w.g. or less. Higher readings and/or steadily increasing readings are an

indication that the main airflow through the dust collector may be restricted, and

a potential process problem such as poor suction at duct pickup points may

exist. In extreme cases (over 17” w.g.) filter bags will be damaged. Check the

following:

A. Pressure Gauge

Check the differential pressure gauge or manometer and the tubing leading

to the dust collector for proper operation. Disconnect the lines at the gauge

or manometer and clear with compressed air. Look for loose fittings,

cracked, broken, or pinched tubing. Make sure the gauge is zeroed or that

the manometer is level, zeroed and contains the correct fluid.

B. Bags Loaded with Dust

If the cleaning system is not operating properly refer to the section titled

“Troubleshooting the Cleaning System”.

A condition known as blinding. If the dust is dry, see paragraph

1-4; if the dust is wet, see paragraphs 5 and 6.

1. Dust Not Discharging from the Hopper

Check hopper for over-loading or bridging across the dust discharge.

Correct by repairing dust discharge equipment, replacing with higher

capacity equipment, or installing hopper vibrators, etc. as required to

keep the hopper clear.

2. Air Flow too High

If the main airflow is too high to allow dust to drop off of the filter bags,

an excessive pressure drop across the dust collector will result and dust

will build up in the system. In many cases this high pressure drop in

turn leads to a reduction in the main air flow so that it is necessary to

remove the dust accumulation from the filter bags (and the rest of the

system) before measuring the main air flow volume.

Phone: 913-8

9-1

CAMCORP, INC.

31-0740 Fax: 913-831-9271

TROUBLESHOOTING THE DUST COLLECTOR (continued)

Visually inspect the bags for heavy caking; if caking is evident, see the

note below and take the necessary action to clean the bags. Next,

measure the main airflow with a pitot tube or equivalent devise and

compare with the original volume for which the unit was designed. If

the flow is too high, cut back the main fan to prevent a recurrence of the

problem.

3. Particle Size and Dust Load

If possible, compare the dust particle size and loading with the original

design specifications. Finer dust may cause a higher pressure drop. Do

not hesitate to call the factory; we have experience with many kinds of

dust.

4. Bags Too Tight

Bags that have shrunk on their cages may not flex sufficiently during the

compressed air pulse to loosen caked dust. If the bags were cleaned or

laundered, pull a bag tight around its cage; you should be able to

“gather” a small fold of material between your fingers.

5. Water Leaks

Inspect the dust collector housing and ductwork for holes, cracks, or

loose gasketing where water could enter the collector.

6. Condensation

If moisture has been condensing inside the collector, check the dew

point temperature of the incoming air stream. If may be necessary to

insulate the collector and/or the ductwork leading to the collector to keep

surface temperatures above the dew point and prevent condensation of

the filter bags.

NOTE: Collectors that have had blinded or caked bags can possible be

put into service by running the pulsing air system for 15 to 30 minutes

with a 10 second timer “off time” and without the main fan or blower. If

the pressure drop is not lower when the main fan is started again, take

the bags out of the collector and remove the caked dust by special drycleaning. Make sure the timer “off time” has been reset to specifications

prior to re-start. Information pertaining to filter bag cleaning may be

obtained by calling your CAMCORP sales representative.

9-2

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

TROUBLESHOOTING THE DUST COLLECTOR (continued)

II. Extremely Low Pressure Drop

A. Pressure Gauge

Check the differential pressure gauge or manometer and the tubing leading

to the dust collector as in I-A of this section.

B. Holes in Filter Bags or Bags Incorrectly Installed.

Inspect the filter bags for holes, rips, tears, or excessive wear. Make sure

that the filter bags were installed correctly according to the “Bag & Cage

Installation” section.

C. Ductwork and Dampers

Inspect the ductwork to and from the dust collector for air leaks or blockage.

Make sure that any dampers in the system are correctly positioned to allow

air to flow through the dust collector.

D. Leaks in the Housing

Check the tube sheets (flat steel sheets from which the filter bags are

suspended) and the dust collector housing for holes, cracks or loose

gasketing that would permit air to bypass the dust collector or filter bags.

III. Continuous Flow of Dust in the Clean Air Exhaust (Primary Dusting)

A. Holes in the Filter Bags or Bags Incorrectly Installed

Inspect the filter bags as in II-B this section.

B. Holes in the Tube Sheets

Check the tube sheets for holes, cracks, or loose bolts that would permit

dusty air to bypass the filter bags.

IV. Puff of dust in the clean air exhaust after each pulse (secondary dusting)

A. Worn filter bags

Inspect the filter bags for wear. Thin bags may not stop fine dust when

flexed by a compressed air pulse.

9-3

Phone:

CAMCORP, INC.

913-831-0740 Fax: 913-831-9271

TROUBLESHOOTING THE DUST COLLECTOR (continued)

B. Residual Dust

If dust has gotten into the clean air plenum because of a dropped or torn bag,

hole in tube sheet, etc., the reverse air may stir up the dust and allow it to

escape into the clean air exhaust. Residual dust may also be driven down

inside the filter bags by the reverse air; if the filter bags are filled with

several inches of dust, clean both the clean air plenum and the filter bags to

avoid further problems.

V. Short Filter Bag Life

This is often a complicated problem to diagnose and we recommend calling the

factory for advice. The following list may be helpful in performing some

preliminary check:

A. Temperature

Operating Temperature above the recommended limit of the filter bag

material (220 degrees F max.)

B. Chemical Attack

Bag material degrades due to attack from certain chemicals in the dust or

gasses in the air stream.

C. High Moisture

High moisture content in the collector may cause certain filter bag material

to shrink or degrade (more rapidly at elevated temperatures).

D. Localized abrasion

Abrasion of the bags at the dusty air inlet; a dust impingement baffle may be

required.

E. Internal Bag Supports Gone Bad

Corroded, rusted or broken filter cages can cause excessive bag wear.

Stainless steel or coated cages are available.

Phone: 913-8

9-4

CAMCORP, INC.

31-0740 Fax: 913-831-9271

TROUBLESHOOTING THE CLEANING MECHANISM

1. Fan - If the fan is not operating properly please refer to the New York Blower

manual located in this IOM manual.

2. Sweep Arm Drive – Motor not rotating.

A. Remove the motor from the gear drive and check for proper operation. If

the motor does not rotate, repair or replace.

B. If the motor does rotate properly check for binding or roughness in the

gear drive. Repair or replace one or both gear boxes as necessary.

3. Sweep Arm Drive – Motor rotating and sweep arm not rotating or rotating

intermittently.

A. Enter the clean air plenum and check for obstructions in the path of the

rotating sweep arm. Remove any obstructions

B. Verify that the sweep arm is rotating parallel to the tubesheet and that the

nozzles do not strike the cage tops and cause the sweep arm to stop.

C. Verify that the torque limiting clutch on the small sprocket is slipping.

D. Verify that the chain is not binding. If it is then check the sprocket

alignment.

E. Disconnect the drive chain. The sweep arm should rotate freely and with

no binding or roughness. If binding is experienced grease the rotary union.

If the binding or roughness continues inspect the bearing and replace if

necessary.

Phone:

10-1

CAMCORP, INC.

913-831-0740 Fax: 913-831-9271

SAFETY RECOMMENDATIONS

Because this unit may be under pressure, do not attempt to open any device doors or

panels while fans or blowers are running.

If your unit is equipped with a discharge auger or an airlock, be sure chain guards are

installed before start-up and servicing is attempted only after electrical power is locked

out.

While servicing the filter, it is very important that there are no open flames, welding or

grinding sparks. Dust laden air could be highly explosive and extreme care must be

taken.

Before entering any dust collector:

1. Run cleaning mechanism 20 minutes with the fan off to clean filter bags.

2. Discharge solids from hopper.

3. Lock out electrical power on all rotating equipment.

4. On toxic operation, purge collector housing and install a blank in the inlet

duct.

5. Install catwalks and safety cables.

6. Secure access doors in an open position or remove doors.

7. Use buddy system.

8. Wear a respirator.

9. Use common sense.

11

-1

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

ROUTINE MAINTENANCE

A. Inspection

Frequency will vary as widely as there are operating conditions. In general

proceed as follows:

1. Daily – Check unit differential pressure.

2. Weekly – Verify that the sweep arm drive and reverse air fan are operating

properly.

3. Monthly – Lubricate fan, rotary valve and screw conveyor. Check seals on

latter two for dust loss.

4. Quarterly – On Top Access Units, check for dust accumulation in clean air

plenum.

B. Repairs

1. Filter bags – Generally replacement, although some applications can be

laundered.

2. Rotary Valves – Usually a matter of periodic seal and blade replacement.

More detailed information is supplied with the valve.

3. Screw Conveyors – Periodic replacement of “V” belts and shaft seals.

Inspect hanger bearings during filter bag change. Failure will be detected by

the squeal.

4. Fans – “V” belt tension and replacement of bearings if running rough.

Make sure rotor balance is maintained.

12

-1

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

COMPONENT IOM MANUALS

MORSE RAIDER WORM GEAR SPEED REDUCER (Maintenance).........................1-8

BROWNING BEVEL BOX ……………………………………………………………. 9

MARTIN TORQUE LIMITER CLUTCH .................................................................10-12

NEW YORK BLOWER PRESSURE BLOWER (IOM)............................................ 13-18

®

MAINTENANCE INSTRUCTIONS

FOR WORM GEAR

SPEED REDUCERS

Emerson Power Transmission

P O Box 687

MAYSVILLE, KY 41056

Phone: 800-626-2093

www.emerson-ept.com

F O R M

8721

March 2003

Center Distances

1.33, 1.54, 1.75, 2.06, 2.37, 2.62, 3.00, 3.25

3.75, 4.50, 5.16 and 6.00

™

wercspaC

eziS

euqroT

)sbL.tF(

02-4/152.6

81-61/531

61-8/302

41-61/753

31-2/105

11-8/509

INTRODUCTION

The following instructions apply to RAIDER® Worm Gear Speed Reducers. When ordering parts or requesting information

be sure to provide all the data stamped on the reducer nameplate.

EQUIPMENT REQUIRED

In addition to standard Mechanic's tools, the following equipment is required: arbor press, wheel puller, torque wrench,

dial indicator, seal driver, bluing, adhesive sealant, snap ring pliers for internal and external rings.

GENERAL INSTRUCTIONS

Housings - Clean external surfaces of reducer before removing seal cages and end covers to

prevent dirt from falling into the unit. Record mounting dimensions of accessories for reference

when reassembling. If it is necessary to remove the reducer from its operating area, disconnect

CAPSCREW

TIGHTENING

TORQUES

all connected equipment and lift reducer from its foundation.

Seals - Replacement of all seals is recommended when a unit is disassembled. However, if seals

are not to be replaced, protect seal lips by wrapping shaft with plastic tape coated with oil or

grease before removing or replacing seal cage assembly. Clean the shaft but do not use any

abrasive material on the shaft surface polished by the seal.

CAUTION

If the reducer is painted, extreme care should be taken to mask the shaft

extensions and rubber surface of the seals. Paint on the shaft adjacent to the

Table 1

seal or on the seal lip will cause oil leakage.

TO CHANGE OUTPUT SHAFT DIRECTION

To change the hand of a unit from left hand to right hand, or vice versa, the following instructions apply:

1. Remove drain plug and drain oil from unit.

2. Remove end cover and seal cage capscrews; then while supporting output shaft remove end cover and shims from

the unit. (The shims may be between the seal cage/end cover and housing, or between the bearing outer race and

seal cage/end cover - do not remove the bearing race unless it is to be replaced).

3. Remove output shaft and seal cage together from extension side.

NOTE: Keep all shims with their respective seal cage and end cover.

4. Reassemble unit per instructions later in this manual.

UNIT DISASSEMBLY

1. Remove drain plug and drain oil from unit.

2. Low speed shaft (gear shaft) removal:

A. Remove end cover and seal cage capscrews.

B. With a firm hold on the output extension remove end cover and shims (The shims may be between the seal cage/

end cover and housing, or between the bearing outer race and seal cage/end cover - do not remove the bearing

race unless it is to be replaced).

C. Carefully slide output shaft assembly and seal cage out extension side.

D. Slide seal cage off low speed shaft using caution to prevent damage to seal lips.

E. Wire or tie the shims to their mating end cover and seal cages. (This only applied if the shims are between the

seal cage/end cover and housing). They will be available for reference when assembling the unit. Some units

are factory assembled with internal shims so this note may not apply.

!

WARNING

High voltage and rotating parts may cause

serious or fatal injury.

Turn off power to install or service.

Operate with guards in place.

Read and follow all instructions in this manual.

2

Disconnect all before adjusting units

© Emerson Power Transmission Manufacturing, L.P. or affiliates 2003. All Rights Reserved.

3. High speed shaft (worm shaft) removal:

C-Flange units

1.33 C.D. through 3.25 C.D.:

Use a small chisel to make a groove in the stamped steel cover opposite the motor flange. Pry off the cover. Remove

internal snap ring from housing bore. Remove motor flange. Using a plastic hammer, gently tap on the motor end of the

shaft to feed worm shaft assembly through housing and out.

3.75 C.D. through 6.00 C.D.:

Remove motor flange. Remove seal cage opposite motor face. Keep shims with seal cage for reassembly. Remove bearing

nut and washers from end opposite motor. Using a plastic hammer, gently tap the shaft on the motor end. Push shaft

assembly through housing until rear bearing outer race is free. Slide bearing inner-races off the shaft and remove worm

through front of housing. If a press is available, pressing the shaft out is preferable.

Basic units

1.33 C.D. through 3.25 C.D.:

Use a small chisel to make a groove in the stamped steel cover opposite the motor flange. Pry off the cover. Remove

internal snap ring from housing bore. Remove motor flange. Using a plastic hammer, gently tap on the extension end of

the shaft, to feed worm shaft assembly through housing and out. On units with C.D. of 1.33, 1.54, 2.63, and 3.00, front

bearing will remain in housing bore. Use soft tool and plastic hammer to tap bearing out extension end of housing from

rear. Be sure to tap on outer-race of bearing. If a press is available, pressing this bearing out is preferable.

3.75 C.D. through 6.00 C.D.:

Remove front and rear seal cages. Keep shims with seal cages for reassembly. Remove bearing nut and washers from

end opposite extension. Using a plastic hammer, gently tap the shaft on extension end. Push shaft assembly through

housing until rear bearing outer-race is free. Slide bearing inner-races off shaft. Reverse direction and push shaft through

extension end of housing and out. If a press is available, pressing the shaft out is preferable.

PARTS SERVICE

1. Housing – Clean inside of housing with kerosene or solvent and then dry.

2. Seal cages and end cover – Remove dirt from joint faces, wipe clean and dry.

3. Air vent – Wash in kerosene, blow clean and dry.

4. Seals – To replace seals without dismantling reducer refer to steps C through F below. To replace seals when the

entire reducer is dismantled and coupling hubs, sprockets, pulleys, pinions, keys, etc. have been removed the

following instructions apply:

Note: Replacement of all seals is recommended when a unit is disassembled. New seals will leak if the seal lips

are damaged or if seal’s rubbing surface on the shaft has been altered. Protect seal lips at all times. Clean the shaft

but do not use any abrasive material on the shaft surface polished by the seal.

A. Block up seal cages and press or drive out seal.

B. Remove old sealing compound from seal seat in cage if it is present. If a seal with rubber coating on the outside

diameter is used, no sealant is necessary. If no rubber coating is on seal outside diameter, coat seal cage bore

with adhesive sealant immediately before assembly.

To prevent possible damage to seal lips, do not reassemble seals until high speed and low speed shafts have

been reassembled to the housing. Then see steps E and F below.

C. See Figures 1 through 4 – To replace seals without dismantling reducer, proceed as follows:

Do not damage shaft; new seals will leak if seal contacting surface is marred. Use punch and place two or more

holes in steel casing of seal, Figure 1. (The steel casing may be rubber coated) Insert sheet metal screws, leaving

the heads sufficiently exposed so they can be pried up or grasped with pliers, Figure 2. Do not drill holes because

chips may get into the unit.

Sheet Metal Screws

Disconnect all power before adjusting units

© Emerson Power Transmission Manufacturing, L.P. or affiliates 2003. All Rights Reserved.

Figure 3 Figure 4Figure 1 Figure 2

3

D. Work seal loose. Be careful to keep all metal or dirt particles from entering unit. Remove old sealing compound

from seal seat if it is present. Also remove burrs and sharp edges from shaft. Clean with rag moistened with solvent.

Do not use abrasive material on shaft seal contacting surface.

E. Protect seal lips when handling; seal leakage will result if these are damaged. If a seal with rubber coating

on the outside diameter (O.D.) is used, no sealant is necessary. If no rubber coating is on seal O.D., coat

seal cage bore with adhesive sealant. Coat seal lips with oil and carefully work seal into position. Before

sliding seal into position, protect seal lips from shaft keyway edges by wrapping shaft with plastic tape coated

with oil. Position garter spring toward the inside of the unit. Place a square faced pipe or tube against the seal

O.D. and drive or press seal until fully seated as shown in Figure 3. Do not strike seal directly.

F. For best performance, seat the seal square with shaft within .005" at 180°. Check with dial indicator as shown

in Figure 4, Page 3, or with a straight edge and feelers, or square and feelers. To straighten a cocked seal, place

tubing over the seal and tap the tube lightly at a point diametrically opposite the low point on the seal. Do Not

strike seal directly.

5. Bearings –

A. Wash all bearings per bearing manufacturers recommendations and then dry.

B. Inspect bearings carefully and replace those that are worn or questionable.

Note: Replacement of all bearings is recommended.

C. Use a wheel puller or press to remove worm shaft bearings. Apply force to inner race only – not to cage or outer

race.

D. Use a wheel puller or press to remove taper bearing inner races.

E. To replace tapered bearing inner races and all ball bearings, heat bearings in an oil bath or oven to maximum

of 290° F (143° C). Slide high speed shaft bearings onto the oiled shaft until seated against the shoulder or snap

ring of the shaft. Slide low speed shaft bearing onto the oiled shaft against the gear spacer.

F. Thoroughly coat all bearings with lubrication oil.

6. Worm, gear and shafts

A. Worm and high speed shaft – since all worms are integral with the high speed shaft, any wear or damage to the

worm will necessitate replacing both.

B. Press shaft out of bronze worm gear. To reassemble gear and low speed shaft, freeze shaft or heat gear. Do

not exceed 200° F (93° C). Insert key into the shaft keyway and press shaft into oiled gear bore.

Note: It is advisable to replace both the worm and worm gear should either of the assemblies require

replacement.

UNIT REASSEMBLY

1. Preliminary

A. Check to see that all worn parts have been replaced, gear and bearings coated with oil and all parts cleaned.

Remove all foreign matter from unit feet. The feet must be flat and square with each other.

B. Before starting to reassemble reducer, clean old shims or replace with new shims of equal thickness.

2. High Speed Shaft (Worm Shaft) Assembly

C-Flange units

1.33 C.D. through 3.25 C.D.:

Lubricate Bearing Bores of Housing. Press bearing onto end of worm shaft flush to shoulder (or snap ring). Lock bearing

onto shaft with external snap ring. Insert shaft assembly from opposite motor end into housing until seated against shoulder

in bore. Lock shaft assembly into housing bore with internal snap ring. Coat outside diameter of stamped steel end cover

with adhesive sealant (except, if end cover is rubber coated DO NOT use sealant) and press into input bore opposite motor

flange until flush with housing.

C-Flange units

3.75 C.D. through 6.00 C.D.:

Apply adhesive sealant to both housing input faces. Sub-assemble the two bearing inner-races onto rear of worm shaft

and secure with lock nut and washers. Insert shaft assembly into rear bore of housing along with the first bearing outerrace. With plastic hammer gently tap end of shaft until bearing outer-race is seated against shoulder in housing bore. If

a press is available, pressing the assemble in is preferable. Press the final bearing outer race in and install the rear seal

cage. Adjust end play per instructions below (Item 3C). Install motor flange.

Basic units

1.75 , 2.06, 2.37 and 3.25 C.D.:

Disconnect all power before adjusting units

© Emerson Power Transmission Manufacturing, L.P. or affiliates 2003. All Rights Reserved.

4

Lubricate Bearing Bores of Housing. Sub-assemble the rear bearing onto worm shaft. Lock rear bearing onto shaft with

external snap ring. Insert shaft assembly from opposite extension end into housing until bearing is seated against shoulder

in bore. Lock shaft assembly in housing bore with internal snap ring. Coat outside diameter of stamped steel endcover with

adhesive sealant (except, if end cover is rubber coated DO NOT use sealant) and press into input bore opposite extension,

until flush with housing.

1.33 , 1.54, 2.62 and 3.00 C.D.:

Lubricate Bearing Bores of Housing. Sub-assemble the rear bearing onto worm shaft. Lock rear bearing onto shaft with

external snap ring. Insert shaft assembly from opposite extension end into housing until bearing is seated against shoulder

in bore. Lock shaft assembly in housing bore with internal snap ring. Press front bearing into extension side of housing

until seated against shoulder or snap ring on the worm shaft. Coat outside diameter of stamped steel endcover with

adhesive sealant (except, if end cover is rubber coated DO NOT use sealant) and press into input bore opposite extension,

until flush with housing.

3.75 through 6.00 C.D.:

Apply adhesive sealant to both housing input faces. Press extension side bearing inner-race onto worm shaft. Insert worm

shaft into extension side bore of housing. Hold worm shaft in place and slip bearing inner-race onto shaft until seated

against shoulder. Press rear bearing outer-race into housing bore opposite extension until seal cage can be installed. Install

seal cage. Adjust end play per instructions below (Item 3C).

3. Low Speed Shaft (Gear Shaft) Assembly

A. Determine output shaft direction.

B. Assemble low speed shaft assembly, seal cage, and end cover with shims on both seal cage and end cover.

Torque capscrews to torques listed in Table 1. Rotate the input shaft to seat output bearings.

C. Moving the shaft back and forth by hand, check axial float with dial indicator as shown in Figure 5. Axial float must

be .0005 - .003" with .0005 being the absolute minimum. Do not preload bearings. If the axial float is not as

specified, add or subtract required shims under end cover or behind bearing outer race, inside the cover,

depending on the unit.

D. Remove output shaft with seal cage and apply bluing to several teeth on the gear. Worm thread and gear teeth

must be clean of oil. Reassemble output shaft and seal cage with output key facing up.

E. Use a rag to apply hand pressure to the output shaft and rotate the high speed shaft both directions until the gear

teeth with bluing have gone through gear mesh several times. Return output shaft to original position. Remove

output shaft and seal cage to inspect contact. Compare with Figure 6. If contact is not correct, move assembly

in the direction shown in Figure 6 by adjusting the shims. Maintain the same total shim thickness so the bearing

end play is not affected. Repeat Steps D a E until contact pattern is acceptable.

F. Recheck axial float with dial indicator.

G. When contact pattern is correct, tighten seal cage and end cover capscrews to torques listed in Table 1.

Fig. 5

Disconnect all power before adjusting units

© Emerson Power Transmission Manufacturing, L.P. or affiliates 2003. All Rights Reserved.

5

4. Seals - To reassemble seals to unit, see Parts Service Steps on

Page 3.

5. Motorized Coupling Adapter

Reassemble using the original dimensions determined under "General

Instructions" on Page 2.

6. Final Inspection

A. Turn the gear train by hand as a final check.

B. Re-install reducer and accessories.

C. Fill reducer with the recommended oil to the appropriate level.

See the installation instructions supplied with the

reducer.

D. Spin test for three minutes and check for noise, leakage or rapid

temperature rise.

1/3

1/3

IDEAL

1/3

RUNS FROM

CENTER TOWARDS

LEAVING EDGE

Fig. 6a: Entering and Leaving Sides

1/6 OF FACEWIDTH

CLEAR ON

ENTERING SIDE

Fig. 6b: ACCEPTABLE

DOES NOT ENTER

CENTER THIRD

MOVE GEAR

MOVE GEAR

RUNS TO

ENTERING EDGE

Fig. 6c: UNACCEPTABLE

PREVENTATIVE MAINTENANCE

1. After first week, check all external capscrews and plugs for tightness.

2. Periodically, check oil level when gears are at rest. Add oil if needed. Do not fill above the recommended level because

leakage and overheating may result.

Printed in U.S.A.

6

Emerson Power Transmission

P.O. Box 687

Maysville, Kentucky 41056

TEL: 800-626-2093

© Emerson Power Transmission Manufacturing, L.P. or affiliates 2003. All Rights Reserved.

Emerson Power Transmission

P O Box 687

MAYSVILLE, KY 41056

Phone: 800-626-2093

www.emerson-ept.com

F O R M

7893-E

Revised

May, 2002

RIGHT ANGLE BEVEL GEAR

BOXES

INSTALLATION &

LUBRICATION INSTRUCTIONS

High voltage and rotating parts may cause

serious or fatal injury.

Turn off power to install or service.

Operate with guards in place.

Read and follow all instructions in this manual.

INSTALLATION - Install the drive in the desired mounting position by bolting securely to a solid foundation. (If the pinion shaft extends vertically upward, or

output shaft vertical, provisions must be made at the factory to grease lubricate the upper bearings.) Accurately align all couplings. Install all sheaves and

sprockets as close as practical to the oil seals. Do not hammer on shafts.

LUBRICATION - Remove the breather and fill the housing to the proper oil level with one of the recommended oils from Table 1 below. The proper oil level

is established and maintained at the oil level plug half way up the side of the housing. The approximate oil capacity is shown in Table 2.

RELUBRICATION - After approximately one week or 100 hours operation, drain the reducer, preferably while warm. Thoroughly flush the housing with a light

flushing oil and replace with fresh lubricant. Under favorable conditions, change oil every 2500 operating hours or every 6 months, whichever comes first. For

less favorable conditions such as rapid temperature changes, dirty, dusty or damp atmospheres, more frequent intervals are desired.

Reducer shipped without oil. Fill to proper level before

operating to avoid equipment damage and/or personal injury.

Read and follow all instructions on this sheet.

!

WARNING

!

WARNING

Table No. 1

.oNAMGA2.oNAMGA4.oNAMGA

ocomA

oconoC

.oCnoxxE

yollAbuloM

.oCliOnuS

.cnIocaxeT

Table No. 2

3

6

9

21

51

81

RECOMMENDED OILS

F°001@ytisocsiVUSS743-482USS567-626

.pmeTtneibmAF°06-51F°521-05

rerutcafunaMemaNedarT

13.oNliO.dnI.remA

513-SoruD

86enibruTCOnorvehC

03-TrekamecaPOGTIC

O&R33lotceD

86cisserreT

02.oNCLHefiLraeG

33ynomraH

muideMyvaeHliOETD

3.oNliO.dyH

513liOsungaM

86enibruTCOnorvehC

86enibruTCOnorvehC

)O&R(CPlageR

86-WAXANU

.proCliOfluG

.proCliOliboM

.oClioznneP

.oCliOnoinU

dleifhciR-citnaltA

.oCliOnorvehC

.oCliOecivreSseitiC

ynapmoCliOllehS

)YK(.oCliOdradnatS

eziSrecudeRyticapaCliOetamixorppA

.cnIstnacirbuLsuomaF

.oCgnitacirbuLenotsyeK

.oCmuelortePspillihP

.laCfo.oCliOdradnatS

)oihO(.oCliOdradnatS

A4-CLK

306A-M

85sulleT

25sirotcaF

159sivnuS

.zo4

.zo11

.zo41

.zo62

.zo68

.zo67

57.oNliO.dnI.remA

007-SoruD

051enibruTCOnorvehC

08-TrekamecaPOGTIC

O&R67lotceD

051OTUN

04.oNCLHefiLraeG

57ynomraH

3-CLK

yvaeHartxEliOETD

906A-M

5.oNliO.dyH

007liOsungaM

051sulleT

051enibruTCOnorvehC

051enibruTCOnorvehC

66nortsudnI

999sivnuS

)O&R(FlageR

051-WAXANU

The Emerson logo is a trademark and a service mark of Emerson Electric Co.

© Emerson Power Transmission Manufacturing, L.P. or affiliates 2002.

All Rights Reserved.

Printed in U.S.A.

Martin

SPROCKET & GEAR, INC.

BULLETIN TL-1

TORQUE LIMITER CLUTCH

DRIVE OVERLOAD PROTECTION

Now in Stock at All

MartinFacilities

Also Stock Plate Sprockets Bored to

Size and Face Ground for Torque Limiters

MartinTORQUE-LIMITER

clutch offers thrifty overload protection

that’ s easy to adjust.

Here is low cost protection for your machinery . . . a torque

limiting clutch that is easy to install.

Torque-Limiter clutches feature an exclusive “Easy-Set

Adjustment.” With “Easy-Set,” torque adjustment is accomplished quickly! The need for hammer and block, brute

strength and spanner wrenches is eliminated.

These simple steps and the job is done:

1. Snug up the adjusting nut, finger tight, locate set screw

over nearest spline notch and tighten. See table at right.

2. Tighten three cap screws until heads bottom — with a

small wrench; this gives maximum torque.

3. For less torque — back off the cap screws, loosen the set

screw, back off adjusting nut to one of the six spline

notches as required, and retighten set screw and cap

screws.

“Easy-Set Adjustment” not only simplifies installation, it provides solid support for pressure plates by compression at

their peripheries.

The Torque-Limiter clutch gives machinery permanent prote c tion against overloads during starting, reversing or driving —

by slipping at any desired load. It resumes driving without

resetting when the overload is relieved. It is simple in

design, compact, efficient and built for long life. It provides

low cost torque limiting service for a wide variety of applications. No lubrication . . . minimum maintenance.

Starting shock from electric motors is a major cause of

maintenance of moving parts. Torque-Limiter clutches provide a cushion by slipping until the torque drops to a pre-set

level. They can be set to reduce shock loads on motors and

driven equipment during reversing or inching. They provide

mechanical protection against breakage due to sudden

overload — by slipping when the pre-set torque limit is

reached.

2

T orque-Limiter

Clutches

Torque-Limiter clutches may be used with a sprocket, gear,

sheave, flange or other driven member. It is recommended

that the rubbing sides of the driven member be ground to

provide a smooth rubbing surface of 65 to 125 micro-inches.

See torque rating table on following page.

The driven member is mounted on an oil-impregnated bushing and clamped between two, high quality friction discs by

spring pressure. Each Torque-Limiter unit, completely

assembled, contains one spring. Higher torque ratings can

be obtained by the use of a second spring nested within the

original spring. See rating table on following page.

When an overload occurs, the driven member slips between

long-life, clutch-type friction discs. After slipping has started,

it will continue at approximately 90% of the torque setting,

due to the lower coefficient of friction when slipping, until the

overload condition has been corrected.

TORQUE (lb.-ins.)

70-2

70-1

50-2

50-1

35-2

35-1

25-2

25-1

01234567

SPLINES

Note:

Graph indicates approximate rated torque vs number of

splines adjusting nut is backed off from finger tight.

TORQUE-LIMITER CLUTCH CALIBRATION

#25 300 700 400 1200

#35 600 1700 900 2500

#50 950 2650 2350 5700

#70 2000 8000 3100 11500

Torque Rating

One Spring Two Springs

Size Min. Max. Min. Max.

12000

11000

10000

9000

8000

7000

6000

5000

4000

3000

2000

1000

0

3

T orque-Limiter

Clutches

Stock Plate Sprockets with Ground

Face and Bored to Fit the Martin

T orque Limiter

Sprocket Size

35TTA25-25

35TTA26-25

40TTA20-25

40TTA22-25

40TTA24-25

40TTA28-25

40TTA30-25

50TTA17-25

50TTA21-25

50TTA22-25

Sprocket Size

35TTA35-35

35TTA40-35

40TTA28-35

40TTA30-35

40TTA32-35

50TTA22-35

50TTA24-35

50TTA25-35

50TTA26-35

60TTA18-35

60TTA20-35

TT25 1 300 700 400 1200 21⁄2 13⁄41⁄811⁄3229⁄6419⁄6419⁄64 21⁄2 11⁄2 1.368 1.631/1.628

TT35 2.5 600 1700 900 2500 3

1

⁄2 27⁄161⁄85⁄845⁄6423⁄6435⁄64 33⁄16 115⁄16 1.675 2.006/2.003

TT50 6 950 2650 2350 5700 5 2

7⁄81⁄85⁄853

⁄6429⁄6421⁄32 45⁄16 213⁄16 2.625 3.008/3.005

TT70 18 2100 8000 3100 11500 7 3

7⁄81

⁄4 11⁄455⁄6431⁄6429⁄32 6 4 3.811 4.197/4.194

Torque Rating ▲ CKL

(Pound-Inches) +.000 +.003

With One With Two –.002 –.000

Size Avg. Spring Springs** G Spline Spkt.

No. Wt.

Min. Max. Min. Max

A B Min. Max. D E

♦ H J O. D. Bore

T orque-Limiter Clutch Ratings

TT25

1

⁄2

7

⁄8 1

TT35

3

⁄4 13⁄16 11⁄4

TT50 1 13⁄4 2

TT70 13⁄8 23⁄4 3

Size Stock

Max. Bore

No. Bore Std. KW* Shallow KW*

1

⁄2-9⁄16

1

⁄8 ×1⁄16 17⁄16-13⁄4

3

⁄8 × 3⁄16

5

⁄8-7⁄8

3

⁄16 ×3⁄32 113⁄16-21⁄4

1

⁄2 ×1⁄4

15

⁄16-11⁄4

1

⁄4 ×1⁄8 25⁄16-23⁄4

5

⁄8 ×5⁄16

15⁄16-13⁄8

5

⁄16 ×5⁄32 313⁄16-3

3

⁄4 ×3⁄8

Torque- TorqueLimiter Limiter

Bore Keyway Bore Keyway

TT25 1⁄25⁄83⁄47⁄8

TT35

3⁄47

⁄8 1

TT50 1 11⁄8 13⁄16 11⁄4 13⁄8 17⁄16 11⁄2 15⁄8

TT70 17⁄16 11⁄2 13⁄4 115⁄16 2 27⁄16

Size

No. Finished Bores

STK. 25 19 19 16 .. .. .. .. .. ..

TT25 Min. Teeth MTO 25 19 19 16 .. .. .. .. .. ..

Bush. Lght. Req’d.

1

⁄8

1⁄81

⁄4

1

⁄4 .. .. .. .. .. ..

STK. 35 25 26 21 18 15 .. .. .. ..

TT35 Min. Teeth MTO 33 25 26 21 18 15 .. .. .. ..

Bush. Lght. Req’d.

1

⁄8

1⁄81

⁄4

1⁄43

⁄83⁄8 .. .. .. ..

STK. 48 35 35 29 25 19 .. .. .. ..

TT50 Min. Teeth MTO 46 35 35 29 25 19 .. .. .. ..

Bush. Lght. Req’d.

1

⁄8

1⁄81

⁄4

1⁄43

⁄83⁄8 .. .. .. ..

STK. .. .. 48 38 33 26 21 18 16 14

TT70 Min. Teeth MTO .. .. 48 38 33 26 21 18 16 14

Bush. Lght. Req’d. .. .. 1⁄4

1⁄43

⁄83⁄81⁄27⁄87⁄8 1

Unit

Min. Allowable Sprocket Teeth and Length of Bushing Req’d for Chain Number

Size Sprocket Pitch 35 41 40 50 60 80 100 120 140 160

★ Min. number of teeth on sprocket stocked by factory which can be used w/Torque-Limiter clutch.

Min. number of teeth on made-to-order sprocket which will permit chain to clear friction disc.

* Use one

3

⁄8″ long bushing and one 1⁄2″ long.

♦ Use two 1⁄2″ long bushings.

† KW Same as Std. Listed in Tables Above. Additional S.S. See List Price

Bored to Size T orque Limiters w/Std. KW & I-SS

†

† Additional SS See List Price Alterations

* KW To Be Cut Central w/Threaded Spline

Standard Keyways

Stock Bores — T orque Limiters (No KW I-SS

†

)

▲ Using a center member with rubbing sides ground

parallel — 65 to 125 micro-inches. Center member

must be clean and free from oil, rust, etc.

** Second spring may be nested in one originally fur-

nished. Order if required.

♦ Nominal for maximum torque setting. For minimum

torque setting, add

3

⁄64 for No. 25; 5⁄64 for No. 35; 3⁄32 for

Nos. 50 and 70. When two springs are used this

dimension is increased approximately

1

⁄16″ on Nos.

25, 35 and 50 —

3

⁄32″ on No. 70.

TORQUE-LIMITER CLUTCHES

Each assembled unit contains one

spring. Higher ratings can be obtained

by ordering a second spring to nest in

the original one. Bushings need to be

ordered separately if required.

The rubbing sides of the center

member should be ground parallel —

65 to 125 micro-inches.

Sprocket Size

40TTA35-50

50TTA30-50

50TTA32-50

60TTA25-50

60TTA26-50

60TTA28-50

60TTA30-50

80TTA20-50

80TTA22-50

80TTA24-50

Sprocket Size

60TTA36-70

80TTA26-70

80TTA28-70

80TTA30-70

80TTA36-70

100TTA22-70

100TTA24-70

PRESSURE PLATE 2

FRICTION DISC 2

ADJ. NUT ASSY. & S.S. 1

ADJ. TENSION NUT 3

HUB 1

TT25 TT50

TT35 TT70 QTY. REG.*

SPARE PARTS

UNIT TT25 UNIT TT35

UNIT TT50 UNIT TT70

* PER UNIT

B

GE

C

ED

JLK

A

7

Coupling

Safety

WARNING & SAFETY

REMINDER

Safety must be considered a basic factor in machinery operation at all times. Most accidents

are the result of carelessness or negligence. All rotating power transmission products are potentially dangerous and must be guarded by the contractor, installer, purchaser, owner, and user as

required by applicable laws, regulations, standards, and good safety practice. Additional specific information must be obtained from other sources including the latest editions of American

Society of Mechanical Engineers; Standard A.N.S.I. B15.1. A copy of this standard may be

obtained from the American Society of Mechanical Engineers at 345 East 47th Street, New

York, NY 10017 (212-705-7722).

It is the responsibility of the contractor, installer, purchaser, owner, and user to install, maintain, and operate the parts or components manufactured and supplied by Sprocket &

Gear, Inc., in such a manner as to comply with the Williams-Steiger Occupational Safety Act

and with all state and local laws, ordinances, regulations, and the American National Standard

Institute Safety Code.

Guards, access doors, and covers must be securely fastened before operating any equip-

ment.

If parts are to be inspected, cleaned, observed, or general maintenance performed,

the

motor driving the part or components is to be locked out electrically in such a manner

that it cannot be started by anyone,

however remote from the area. Failure to follow these

instructions may result in personal injury or property damage.

CAUTION

NOTE: CA TALOG DIMENSIONS

Every effort is made to keep all catalog dimensions and styles current in the catalog, however

from time to time, it is necessary because of manufacturing changes to alter stock products

dimensionally .

If any stock product dimension or style shown in this catalog is critical to your application

please consult factory for certification.

WARNING

A WORD ABOUT SAFETY

The above WARNING decal appears on all nyb fans. Air moving

equipment involves electrical wiring, moving parts, sound, and

air velocity or pressure which can create safety hazards if the

equipment is not properly installed, operated and maintained.

To minimize this danger, follow these instructions as well as the

additional instructions and warnings on the equipment itself.

All installers, operators and maintenance personnel should

study AMCAPublication 410, "Recommended Safety Practices

for Air Moving Devices", which is included as part of every shipment. Additional copies can be obtained by writing to New York

Blower Company, 7660 Quincy St., Willowbrook, IL60521.

ELECTRICAL DISCONNECTS

Every motor driven fan should have an independent disconnect

switch to isolate the unit from the electrical supply. It should be

near the fan and must be capable of being locked by maintenance personnel while servicing the unit, in accordance with

OSHA procedures.

MOVING PARTS

All moving parts must have guards to protect personnel. Safety

requirements vary , so the number and type of guards needed to

meet company, local and OSHA standards must be determined

and specified by the user. Never start a fan without having all

safety guards installed. Check regularly for damaged or missing

guards and do not operate any fan with guards removed. Fans

can also become dangerous because of potential “windmilling”,

even though all electrical power is disconnected. Always block

the rotating assembly before working on any moving parts.

SOUND

Some fans can generate sound that could be hazardous to

exposed personnel. It is the responsibility of the system

designer and user to determine sound levels of the system, the

degree of personnel exposure, and to comply with applicable

safety requirements to protect personnel from excessive noise.

Consult nyb for fan sound power level ratings.

AIR PRESSURE AND SUCTION

In addition to the normal dangers of rotating machinery, fans

present another hazard from the suction created at the fan inlet.

This suction can draw materials into the fan where they become

high velocity projectiles at the outlet. It can also be extremely

dangerous to persons in close proximity to the inlet, as the

forces involved can overcome the strength of most individuals.

Inlets and outlets that are not ducted should be screened to

prevent entry and discharge of solid objects.

ACCESS DOORS

The above DANGER decal is placed on all nyb cleanout doors.

These doors, as well as access doors to the duct system,

should never be opened while the fan is in operation. Serious

injury could result from the effects of air pressure or suction.

Bolted doors must have the door nuts or fasteners securely

tightened to prevent accidental or unauthorized opening.

RECEIVING AND INSPECTION

The fan and accessories should be inspected on receipt for any

shipping damage. Turn the wheel by hand to see that it rotates

freely and does not bind. If dampers or shutters are provided,

check these accessories for free operation of all moving parts.

F.O.B. factory shipping terms require that the receiver be

responsible for inspecting the equipment upon arrival. Note

damage or shortages on the Bill of Lading and file any claims

for damage or loss in transit. nyb will assist the customer as

much as possible; however, claims must be originated at the

point of delivery.

INSTALLATION

MAINTENANCE,

OPERATING

INSTRUCTIONS

PRESSURE BLOWERS

TYPE HP PRESSURE BLOWERS

IM-140

12345

THIS FAN HAS MOVING PARTS THAT CAN CAUSE

SERIOUS BODILY INJURY. BEFORE OPERATING

OR STARTING MAINTENANCE READ THE

INSTALLATION AND MAINTENANCE

INSTRUCTIONS AND THE AMCA SAFETY

PRACTICES MANUAL PROVIDED WITH THIS FAN.

DURING OPERATION

1. KEEP BODY, HANDS, AND FOREIGH OBJECTS

AWAY FROM THE INLET,THE OUTLET, AND THE

OTHER MOVING PARTS OF THE FAN SUCH AS

SHAFTS, BELTS, AND PULLEYS.

2. DO NOT OPERATE AT EXCESSIVE SPEEDS OR

TEMPERATURES.

BEFORE STARTING MAINTENANCE WORK:

LOCK POWER SUPPLY IN OFF POSITION AND

IMMOBILIZE FAN WHEEL.

98-0250

DO NOT OPEN UNTIL THE POWER

SUPPLY HAS BEEN LOCKED OFF

AND THE SHAFT HAS STOPPED

ROTATING.

FAILURE T O DO THIS CAN RESUL T

IN SERIOUS BODILY INJURY.

98-0249

HANDLING AND STORAGE

Fans should be lifted by the base, mounting supports, or lifting

eyes only. Never lift a fan by the wheel, shaft, motor, motor

bracket, housing inlet, outlet, or any fan part not designed for

lifting. Aspreader should always be used to avoid damage.

On a direct drive Arrangement 8 fan, lifting holes are provided

in the motor base to assist in handling the fan assembly. These

lifting holes should be used in conjunction with the lifting eyes

when lifting and positioning the fan onto its foundation. A heavy

round steel bar or appropriate fixture can be passed through the

lifting holes to simplify attachment of the lifting device. Be sure

to follow all local safety codes when moving heavy equipment.

Whenever possible, fans and accessories should be stored in a

clean, dry location to prevent rust and corrosion of steel components. If outdoor storage is necessary, protection should be

provided. Cover the inlet and outlet to prevent the accumulation

of dirt and moisture in the housing. Cover motors with waterproof material. Refer to the bearing section for further storage

instructions.

Check shutters for free operation and lubricate moving parts

prior to storage. Inspect the stored unit periodically. Rotate the

wheel by hand every two weeks to redistribute grease on

internal bearing parts.

FAN INSTALLATION

nyb wheels are dynamically balanced when fabricated.

Complete assembled fans are test run at operating speeds to

check the entire assembly for conformance to nyb vibration limits. Nevertheless, all units must be adequately supported for

smooth operation. Ductwork or stacks should be indepen-

dently supported as excess weight may distort the fan

housing and cause contact between moving parts. Where

vibration isolators are used, consult the nyb certified drawing

for proper location and adjustment.

Slab-Mounted Units

Acorrectly designed and level concrete foundation provides the

best means of installing floor-mounted fans. The mass of the

base must maintain the fan/driver alignment, absorb normal

vibration, and resist lateral loads. The overall dimensions of the

concrete base should extend at least six inches beyond the

base of the fan. The weight of the slab should be two to three

times the weight of the rotating assembly, including the motor.

The foundation requires firmly anchored fasteners such as the

anchor bolts shown in Figure 1.

Move the fan to the mounting location and lower it over the

anchor bolts, leveling the fan with shims around the bolts.

Fasten the fan securely. When grout is used, shim the fan at

least 3/4-inch from the concrete base. (See Figure 1.) When

isolation is used, check the nyb certified drawing for installation

instructions.

Elevated Units

When an elevated or suspended structural steel platform is

used, it must have sufficient bracing to support the unit load and

prevent side sway. The platform should be of welded construction to maintain permanent alignment of all members.

Figure 1

V-BELT DRIVE

Installation

1. Remove all foreign material from the fan and motor shafts.

Coat shafts with machine oil for easier mounting. Mount

the belt guard backplate at this time if partial installation is

required prior to sheave mounting.

2. Mount sheaves on shafts after checking sheave bores and

bushings for nicks or burrs. Avoid using force. If resistance

is encountered, lightly polish the shaft with emery cloth

until the sheave slides on freely. Tighten tapered bushing

bolts sequentially so that equal torque is applied to each.

3. Adjust the motor on its base to a position closest to the fan

shaft. Install belts by working each one over the sheave

grooves until all are in position. Never pry the belts into

place. On nyb packaged fans, sufficient motor adjustment

is provided for easy installation of the proper size belts.

4. Adjust sheaves and the motor shaft angle so that the

sheave faces are in the same plane. Check this by placing

a straightedge across the face of the sheaves. Any gap

between the edge and sheave faces indicates misalignment. Important: This method is only valid when the width

of the surface between the belt edge and the sheave face

is the same for both sheaves. When they are not equal, or

when using adjustable-pitch sheaves, adjust so that all

belts have approximately equal tension. Both shafts should

be at the right angles to the center belt.

Belt Tensioning

1. Check belt tension with a tensioning gage and adjust using

the motor slide base. Excess tension shortens bearing life

while insufficient tension shortens belt life, can reduce fan

performance and may cause vibration. The lowest allowable tension is that which prevents slippage under full load.

Belts may slip during start-up, but slipping should stop as

soon as the fan reaches full speed. For more precise tensioning methods, consult the drive manufacturer’s literature.

2. Recheck setscrews, rotate the drive by hand and check for

rubbing, then complete the installation of the belt guard.

Page 2

3. Belts tend to stretch somewhat after installation. Recheck

tension after several days of operation. Check sheave

alignment as well as setscrew and/or bushing bolt tightness.

COUPLING

Coupling alignment should be checked after installation and

prior to start up. Alignment is set at the factory, but shipping,

handling, and installation can cause misalignment. Also check

for proper coupling lubrication. For details on lubrication and

for alignment tolerances on the particular coupling supplied,

see the manufacturer's installation and maintenance supplement

in the shipping envelope.

Installation

Most nyb fans are shipped with the coupling installed. In cases

where the drive is assembled after shipping, install the coupling

as follows:

1. Remove all foreign material from fan and motor shafts and

coat with machine oil for easy mounting of coupling halves.

2. Mount the coupling halves on each shaft, setting the gap

between the faces specified by the manufacturer. Avoid

using force. If mounting difficulty is encountered, lightly

polish the shaft with emery cloth until the halves slide on

freely.

Alignment

1. Align the coupling to within the manufacturer's limits for

parallel and angular misalignment (see Figure 2). A dial

indicator or laser can also be used for alignment where

greater precision is desired. Adjustments should be made

by moving the motor to change shaft angle, and by the use

of foot shims to change motor shaft height. Do not move

the fan shaft or bearing.

2. When correctly aligned, install the flexible element and

tighten all fasteners in the coupling and motor base.

Lubricate the coupling if necessary.