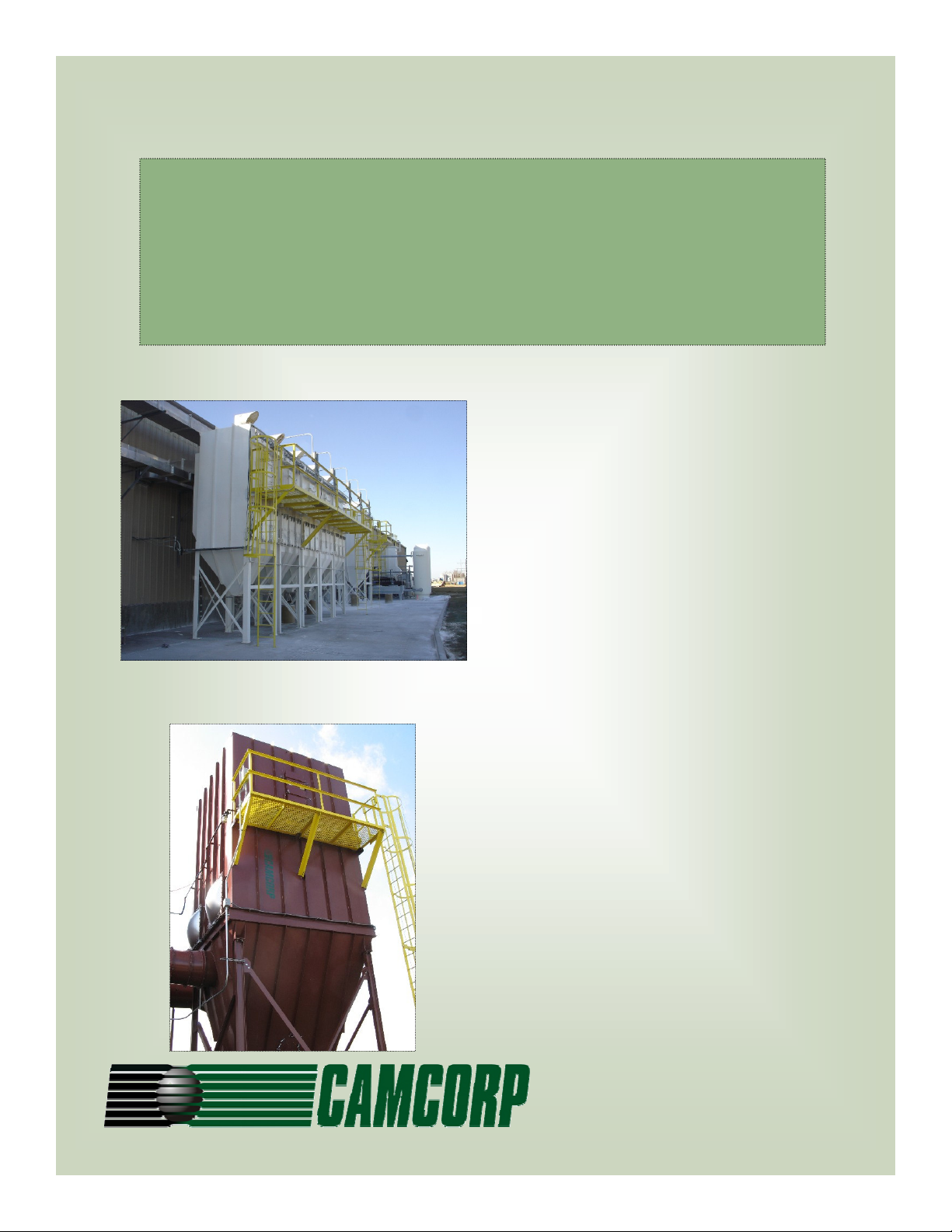

CAMCORP Baghouse Collector User Manual

Installation, Operation,

& Maintenance Manual

Unique Design & Engineering

Approaches for Industrial

Applications

TABLE OF CONTENTS

Section 1 - SAFETY

Safety Recommendations ............................................................................ 1-1

Section 2 - RECEIVING

Receiving & Inspection of the Unit............................................................. 2-1

Storage Recommendations .......................................................................... 2-2

Section 3 - INSTALLATION

Setting Up Your Unit................................................................................... 3-1

Bag & Cage Installation .............................................................................. 3-5

Electrical Wiring Diagram......................................................................... 3-11

Magnehelic Gauge Connections................................................................ 3-12

Explosion Vent Installation....................................................................... 3-13

Section 4 - OPERATION

Operating Principle...................................................................................... 4-1

Start-Up Check List.....................................................................................4-2

Start-Up Dust Control Systems ................................................................... 4-5

Shutdown Procedures .................................................................................. 4-6

Section 5 – COMPONENT INFORMATION

Main Component Listing............................................................................. 5-1

Magnehelic Gauge....................................................................................... 5-3

Timer............................................................................................................ 5-7

National Controls Corp – 120 VAC Standard Timer ............................ 5-7

National Controls Corp – 12-24 VDC (Optional) ................................. 5-9

Dwyer Smart Timer (Optional) ........................................................... 5-11

Diaphragm Valves..................................................................................... 5-19

Goyen #RCA20DD – ¾” Valve........................................................... 5-19

Goyen #RCA25DD – 1” Valve............................................................ 5-20

Goyen #RCA45DD – 1 ½” Valve........................................................ 5-21

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

www.camcorpinc.com

Section 6 - TROUBLESHOOTING

Dust Collector..............................................................................................6-1

Timer............................................................................................................ 6-5

Compressed Air System .............................................................................. 6-6

Section 7 - MAINTENANCE

Routine Maintenance................................................................................... 7-1

Section 8 – APPENDIX

Dust Collector Terms & Definitions ........................................................... 8-1

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

www.camcorpinc.com

Section 1 – Safety Recommendations

Because this unit may be under pressure or vacuum do not attempt to open any

device, doors or panels while fans or blowers are running. The unit has air hoses

and valves with a maximum recommended operating pressure of 100 psig. To

eliminate the danger of bursting care must be taken to insure maximum desired

pressure is not exceeded.

Before servicing any portion of the compressed air system the air supply must be

shut off and any pressure relieved.

If your unit is equipped with a discharge auger or an airlock assure that chain

guards are installed before start-up and servicing is attempted only after

electrical power is locked out.

While servicing the filter it is very important that there are no open flames,

welding or grinding sparks. Dust laden air could be highly explosive and extreme

care must be taken. Most filter bags will burn if exposed to sparks, welding or

open flames.

Before entering any dust collector:

• Run cleaning mechanism 20 minutes with the fan off to clean filter bags.

• Completely discharge dust solids from hopper, if applicable.

• Shut off compressed air supply and relieve pressure in the compressed air

manifold.

• Lock out all electrical power on all equipment especially rotating

equipment.

• On toxic operation, purge collector housing and install a blank in the inlet

duct.

• Install catwalks and safety cables as required.

• Secure access doors in an open position or remove doors.

• Use the buddy system.

• Wear a respirator or appropriate breathing equipment.

• Use common sense.

Follow all current OSHA regulations relative to Lockout / Tag-Out and Confined

Space Entry and any other applicable regulations when servicing your

equipment.

On the following page are examples of safety stickers you will find on Camcorp

equipment. These will help identify potential hazards on the equipment.

1-1

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

www.camcorpinc.com

Examples of Safety Stickers

------DANGER------

-----CAUTION------

-------OTHER-------

These stickers provide

instruction or helpful

information.

The DANGER &

CAUTION stickers

indicate serious potential

hazards which may result

in serious injury or

possible death. Extreme

care should be observed

when working in these

areas.

1-2

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

www.camcorpinc.com

Serial Number Plate

Important information

contained on these is

needed by Camcorp when

calling for parts or service.

Section 2 - Receiving

Receiving the Equipment

Prior to accepting the shipment(s) care must be taken to inspect all

equipment received both for proper count and for damage. Any and all

irregularities must be noted on the carrier’s copy of the shipping receipt to

assist in settling any claims for damage or shortages. All equipment is

shipped FOB point of origin whether on a prepaid or collect freight basis.

ANY CLAIM FOR DAMAGE IN TRANSIT OR SHORTAGES

MUST BE BROUGHT AGAINST THE CARRIER BY THE

PURCHASER.

Once your claim has been filed with the carrier, contact CAMCORP to

notify us of the problem(s). We will then advise the appropriate repair

procedure or recommend it be returned to our factory, depending on the

extent of the damage.

Inspection of the Equipment

Housing, Compressed Air Header and Timer Assembly: Particular

attention should be paid to the sheet metal housing of your collector. The

unit should be inspected for dents, cracks or rips. A dented housing may

seriously affect the structural integrity of the unit. The compressed air

header and timer assembly are very delicate pieces of the unit and must

be checked carefully for any signs of impact, warpage or loose fittings. If

any of these signs are present note them on the shipping receipt and

notify CAMCORP immediately. The entire unit should be checked against

the certified drawings for correctness. CAMCORP should be notified

immediately if there are any discrepancies. No corrections may be made

without the expressed written consent of CAMCORP.

Components: A count should be made of all pieces received and this

should be verified against the carrier’s manifest. Boxes should be

inspected for rough handling, which may have resulted in hidden damage.

2-1

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

www.camcorpinc.com

Storage Recommendations

Baghouse, Bin Vent, Filter Receiver, Dirty Air Hopper and Housing

• Housing can be stored outside.

• Equipment must be blocked up to keep the flanges out of the dirt.

• Most units are supplied with a plain unfinished interior. If storage of more

than two weeks is anticipated the interior should be prime coated before

storage.

• Covering the unit with a tarp is recommended to help keep the interior

from rusting or corroding as well as keeping the outer finish in new

condition, however a tarp is not absolutely necessary.

Baghouse, Bin Vent, Filter Receiver, and Clean Air Plenum

• Unit can be stored outside.

• Compressed air header, diaphragm and solenoid valves must be tarped

for weather protection.

• Position unit so water will not get in or remain inside the tube sheet area.

• Unit must be blocked up to keep the flanges, bag cups, venturis and air

header out of water and dirt.

• Ports on diaphragm and solenoid valves must be plugged and taped to

keep insects, dirt and moisture out.

• For extended storage (more than 4 weeks), it is recommended to remove

the timer panel and solenoid valve assembly (if mounted). These

components should be stored inside a cool dry area along with the copper

or black nylon tubing. The solenoids should have all ports capped and

taped to protect from insects, dirt and moisture.

• The unit should be tarped but is not absolutely necessary.

Filter Bags & Cages

• Filter bags must be stored inside a cool dry area protected from moisture,

rodents and insects.

• For extended storage the boxes for the bags should be wrapped with

plastic wrap or stretch wrap to protect from moisture.

• If the bags get wet for any reason, immediately lay them out with plenty of

ventilation to dry in order to prevent mold and mildew.

• It is recommended to store the cages inside a dry area if at all possible.

• If an inside location is not available the cages can be stored outside as

long as they are covered by a tarp.

• Cages are generally stored horizontally on pallets to keep them off the

ground.

2-2

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

www.camcorpinc.com

Storage Recommendations (continued)

• If cages can be stored horizontally do not stack over three boxes high.

• If the job site is in an area that may receive a significant snow load the

cages must be stored vertically in order to prevent being crushed by the

weight of the snow. Do not stack more than one box high.

Accessory Parts

• This includes all gauges, bag clamps, nylon or copper tubing, valves,

gaskets and other parts not specifically called out.

• These items should be stored inside a cool dry place protected from

moisture, insects, and rodents.

Fan and Fan Accessories

• Fans can be stored outside on a pallet or skid to keep them out of water

and dirt.

• Fan silencers, outlet dampers, and inlet boxes should also be tarped and

stored on a pallet or skid.

• Reference fan IOM manual for long-term storage.

Ducting

• Ducting can be stored outside on a pallet or skid to keep it off the ground.

It should be positioned so that water does not sit on or in the ducting.

• If ducting is unpainted carbon steel it should be at least primed coated

before storage.

• If ducting is already finish coated, it should be tarped to protect the finish,

but this is not absolutely necessary.

Knife Gate

• All limit switches, solenoids, and air cylinder ports must be capped and

taped to prevent any moisture or dirt from entering.

• Equipment can sit outside provided it is covered with a tarp and is on a

pallet or skid to keep it out of water and dirt.

• Reference knife gate IOM manual for long-term storage.

2-3

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

www.camcorpinc.com

Storage Recommendations (continued)

Isolation Dampers

• All limit switches, solenoids, and air cylinder ports must be capped and

taped to prevent any moisture or dirt from entering.

• Equipment can sit outside provided it is covered with a tarp and is on a

pallet or skid to keep it out of water and dirt.

Rotary Valve

• Rotor and interior of valve should be well oiled with vegetable oil to

prevent rust and to maintain compatibility with product.

• Unit can be stored outside provided it is covered with a tarp and is on a

pallet or skid to keep it out of water and dirt.

• Reference rotary valve IOM manual for long-term storage.

Butterfly (Wafer Valve)

• All limit switches, solenoids, and air cylinder ports must be capped and

taped to prevent any moisture or dirt from entering.

• Unit can be stored outside provided it is covered with a tarp and is on a

pallet or skid to keep it out of water, dirt and sunlight.

• Reference butterfly valve IOM manual for long-term storage.

Level Indicators

• Store these items inside a protected cool dry area.

AC Inverters

• Store these items and all other electrical controls inside a protected cool

dry area.

2-4

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

www.camcorpinc.com

Section 3 - Installation

Setting Up Your Unit

CAMCORP dust collectors are shipped either in one piece, fully assembled,

or in two or more sections depending on the unit size and weight. Before

attempting to move the dust collector or any of its sections review both the

certified general assembly drawing supplied from CAMCORP and the

rigging and lifting guidelines included in this manual. Become familiar with

the size and number of sections to be assembled, the orientation of inlet(s),

outlet(s), access door(s) and compressed air header(s), as well as the

number and location of lifting lugs.

Dust collectors of this type are manufactured from steel sheets or plate and

are quite flexible. Therefore, even though care has been taken to maintain

dimensional accuracy and squareness, some difficulty should be anticipated

and temporary bracing in the field may be required.

The following sequential procedure will help to minimize any assembly

difficulties:

STEP 1: Set up the supporting steel for the dust collector level and square.

Precision at this point will greatly help facilitate erection and bolt hole

alignment of the dust collector sections to follow.

STEP 2: Place the hopper with its girth channel on the supporting steel

work. Check for squareness, and for bolthole alignment between the hopper

flange and the girth channel. Apply the appropriate RTV silicone caulk

around the periphery of the hopper flange with one bead on each side of the

boltholes.

STEP 3: Lift the dirty air plenum, with the tube sheet, into place. DO NOT

LOWER THE PLENUM ONTO THE HOPPER FLANGE UNTIL

ALIGNMENT IS ACCOMPLISHED. The silicone caulk makes horizontal

movement very difficult once a load is applied. With the plenum suspended

over the hopper ½” to 1”, begin bolt hole alignment starting at the center of

the plenum and working toward the ends by using tapered drift pins. If the

wall(s) has flexed out of square it will be necessary to pry or pull it back into

alignment. Depending on the size of the unit and the degree of difficulty

hydraulic jacks and come-alongs may be required. When the mating holes

are properly aligned, finish lowering the plenum. Install the remaining bolts,

washers, and nuts and torque to the appropriate specifications.

3-1

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

www.camcorpinc.com

Setting Up Your Unit (continued)

Step 4: Check the top of the dirty air plenum for squareness and bolthole

alignment between the dirty air plenum and the tube sheet. Make sure that

the silicone caulk has been applied between the top flange of the dirty air

plenum and the underside of the tube sheet flange. Next, apply the caulk

around the periphery of the topside of the tube sheet flange one bead to

each side of the boltholes.

STEP 5: Lift the clean air plenum into place and assemble in the same

fashion as in STEP 3. Again, do not lower the clean air plenum completely

until preliminary alignment is accomplished. Start drift pin alignment at the

center of the plenum on the compressed air header side since the header

makes access to the flange more limited. When alignment is complete install

the remaining bolts, washers, and nuts and torque to the appropriate

specifications.

All CAMCORP dust collectors are provided with lifting lugs for ease in

handling of the units during field erection and installation. The number and

location of these lifting lugs will vary depending on the model, size, and

weight of the dust collector. Before attempting to rig and lift your dust

collector review the certified general assembly drawing supplied from

CAMCORP to verify the number and location of lifting lugs as well as visually

checking this information on the actual unit. Large units are frequently

shipped in several sections so check the lifting lugs provided on each

section. If these cannot be used or there is some question about lifting lug

location consult the engineering staff at CAMCORP for proper location since

proper care must be taken to prevent damage to housing or its components.

Rigging and Lifting Guidelines

Do not lift the dust collector by any attachments other than the lifting lugs

provided.

Use all of the lifting lugs provided on the dust collector or a section of the

dust collector when making a lift.

If the lifting lugs are located below the roofline of the dust collector or

below the top of the section of the dust collector a vertical pull must be

made to avoid crushing the top of the unit. Use spreader beams to

accomplish this vertical pull.

3-2

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

www.camcorpinc.com

Setting Up Your Unit (continued)

Attach tag lines at several locations to help in controlling the unit when

lifted and to prevent spinning or swinging.

The dust collector should be lifted and lowered at a slow, uniform rate

and not allowed to bounce or joggle since this can cause excessive

impact stresses at the lift points.

Compressed Air Manifold: Typically, CAMCORP ships the compressed

air manifold installed complete with diaphragm valves and solenoid

enclosure(s), except when units are over legal shipping width with them

in place.

Doors and Flanges: Hold-downs on doors should only be hand

tightened. Excessive pressure can distort the door panel itself resulting

in leakage. All bolts on flanges should be tight. All ports in the dust

collector not being used must be plugged prior to start-up.

Electrical: A 120 volt 60 Hertz circuit is required to operate the dust

collector’s pulse-jet cleaning system (unless a different voltage for

components was requested). This timer must be wired according to the

wiring diagrams and be provided with a circuit that is free from transient

currents. The timer has a feature called “Demand Pulse” that allows the

output terminals to be energized and de-energized by the high and low

set points of a differential pressure switch such as a Dwyer Photohelic

Series 3000. The “Demand Pulse” terminals are marked “Pressure

Switch”. Do not over fuse.

The NCC pulse timer boards have adjustable pulse duration and interval

(time between valves firing) settings. Before applying power to the timer

always check these settings according to the table below. Since there are

many variances in operations and conditions these are presented only as

initial start-up guidelines. If you experience problems in cleaning of the

filter bags, please contact CAMCORP.

TIMER BOARD ADJUSTMENTS

(Recommended at start-up)

VALVE SIZE PULSE DURATION INTERVAL

¾” .10 to .12 seconds 20 to 25 seconds

1” .10 to .12 seconds 20 to 25 seconds

1-½” .06 to .08 seconds 20 to 25 seconds

3-3

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

www.camcorpinc.com

Setting Up Your Unit (continued)

The firing sequence of the diaphragm valves on the dust collector should

be set so that no two adjacent rows of bags fire in succession to insure

maximum cleaning and life of the filter media. This can only be achieved

when wiring the pulse timer board to the solenoid valves. If you are

experiencing a high-pressure drop across the filter bags in your dust

collector the pulse interval should be reduced.

Apply electrical power to the timer and make sure that it is cycling

completely through all rows of the unit. In some cases the timer panel

may have more “positions” than required in which case the position

selector cable needs to be attached to the proper numerical value

corresponding to the number of diaphragm valves on the unit.

If your dust collector was shipped via common carrier rather than a

contract hauler there is a possibility that the solenoid enclosure was not

shipped installed on the unit. If this is the case, there is a mounting plate

welded on the housing or the air header with the bolt pattern of the

enclosure already drilled. Bolt the enclosure and install the nylon (or

copper) tubing with the fittings provided making sure that the solenoids

are connected to their corresponding diaphragm valve.

Valves and Piping: After the unit has been installed the diaphragm

valves should be checked to make sure that the port marked “IN” is

assembled to the compressed air manifold. The “IN” connection of the

solenoid valve is connected to the diaphragm valve by means of ¼” nylon

or ¼” copper refrigeration tubing. Each nut on the compression fittings

should be checked for tightness before the compressed air manifold is

pressurized. In most cases a slip fit fitting has been used. The integrity of

the nylon tubing inside each fitting should be checked by pulling gently on

each tube. If the tube pulls out, simply push it back into the fitting until it

will not go any further. The solenoids are shipped with a plastic plug in

the discharge side of the valve. These plugs must be removed for proper

operation.

Gauges: The differential pressure gauge, mounting bracket, fittings and

tubing are usually shipped loose in a box with the dust collector. When

installing these make sure that the high-pressure port of the gauge is

connected below the tube sheet and the low-pressure port is connected

above the tube sheet on the dust collector. There are pipe couplings

welded on the side of the dust collector for these connections. After the

differential pressure gauge is permanently mounted the gauge needs to

be zeroed prior to connecting the tubing to the gauge.

3-4

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

www.camcorpinc.com

Auxiliary Equipment: All auxiliary equipment must be installed

according to its manufacturer’s specifications and interlocked with the

entire system as needed. Direction of rotation of each item must be

checked prior to start-up of the entire system.

3-5

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

www.camcorpinc.com

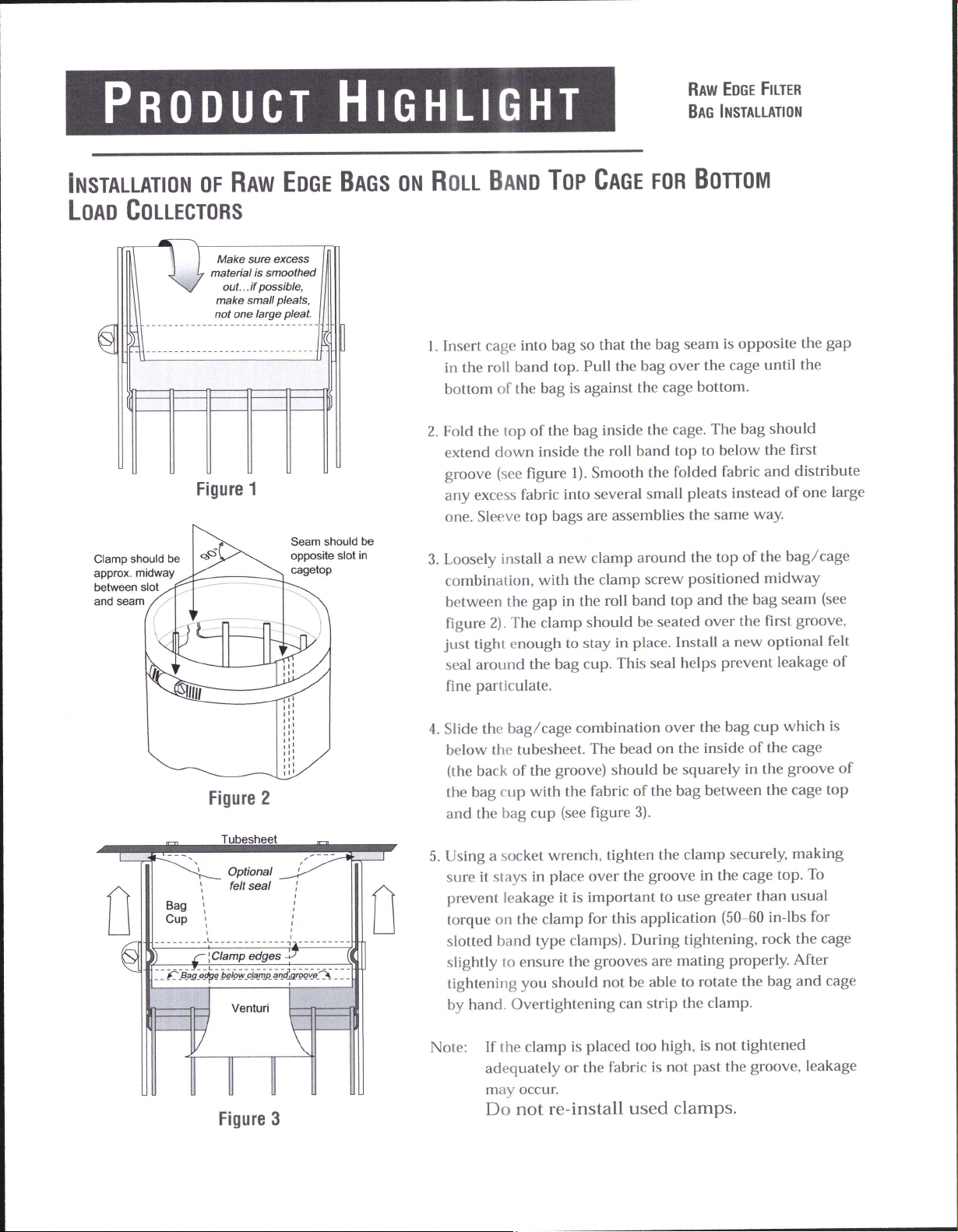

Bag and Cage Installation

Installation of Bag and Cage Assembly – Bottom Loader

Inspect the filter bag cages for any signs of damage, warping, bent wires

or missing welds. Inspect the filter bags for any signs of mold, mildew,

ripped seams or holes.

Be sure the wire cage has a bottom pan. Slip the filter bag over the cage,

centering the seam 1-½” or 2” on either side of the split at the top of the

cage roll band. Seam must be straight (not corkscrewed). Make sure that

the filter bag bottom is tight against the cage bottom pan.

Pull the bag up and over the full length of the cage and fold the entire

extra length over and down inside the top of the cage. Smooth out any

filter bag folds inside the top of the cage.

Slip the assembled filter bag and cage over the outside of the bag cup

(mounted on the tube sheet) making sure to mate the male groove of the

cage roll band top to the female groove of the bag cup.

If you try to move the assembly up and down you will be able to tell if the

grooves are properly aligned.

Install the worm gear bag clamp on the assembly and tighten around the

bag and cage at the point just above the groove on the cage. The clamp

head should be located in the best position for ease in tightening.

Tighten the clamp until secure. You should not be able to rotate the bagcage assembly by hand if it is tighten properly.

Close the access door and tighten accordingly. You are ready to begin

start-up procedures if all other preceding tasks and connections are

completed.

It is recommended to double check the tightness of the bag and cage

assembly approximately one month after the initial start-up.

3-6

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

www.camcorpinc.com

Bag and Cage Installation (continued)

Installation of Bag and Cage Assembly – Top Loader

Inspect the cages for any signs of damage, warping, bent wires or

missing welds. Inspect the filter bags for any signs of mold, mildew,

ripped seams or holes.

Remove the blowpipes inside the clean air plenum by loosening the

bulkhead fitting on the air header end of the blowpipe and then slide the

pipe out of the bulkhead fitting. Some CAMCORP dust collectors use a

retaining clip on the opposite end of the blowpipe and it must be removed

before removal of the blowpipe is possible.

Lower the closed end of the bag through the hole in the tube sheet and

carefully feed the bag in. Assure that the bag doesn’t scrap against the

sides of the tube sheet hole. Excessive scraping can damage filter bags

with special coatings or finishes.

With your hands, “kidney shape” the snap band bag top in order to fit and

align it within the tube sheet hole. Fit the groove of the snap band to the

I.D. of the tube sheet hole and allow it to expand and audibly snap into

place. If the band will not snap into place initially, do not push on the

“dimple” as doing this will permanently damage the snap band. Instead,

kidney shape the snap band from the opposite side of the dimple. Then

you can allow the band to expand and audibly snap into place.

Check the fit of the snap band in the tube sheet hole. It should be even in

height above the tube sheet around the entire circumference, which will

confirm to the installer that the filter bag is centered and well secured in

the tube sheet.

Lower the cage into the bag and press that cage top down into the bag’s

snap band I.D. When in position the rolled flange of the cage top will rest

on the tube sheet and the bag and cage assembly will be rigidly mated.

Replace the blowpipes in the opposite order stated above. Make sure

that the orifices in the blowpipes are properly oriented to blow straight

down the center of the bag and cage assembly before tightening the

bulkhead fitting.

Replace access doors and tighten accordingly. You are ready to begin

start-up procedures if all other preceding tasks and hook-ups are

completed.

3-9

CAMCORP, INC.

Phone: 913-831-0740 Fax: 913-831-9271

www.camcorpinc.com

Loading...

Loading...