CAMBRIDGE qt 300, qt 600 Installation & Operation Manual

csmqt.com 800.219.8199

Qt™ 300/600

Installation & Operations Guide

page 2

1

2

3

Qt™ 300/600 Quick Installation Guide

page 3

4

5

6

For more information visit csmqt.com

or call 800.219.8199

page 4

Contents

Qt 300/600 Introduction

Hardware Installation

Installing the Control Module

Wall Mount

Rack Mount

Installing Qt Emitters

Emitter Installation Order

Installing Paging or Music to the Audio Inputs

Installing Contact Closures

Custom Cabling Guidelines

Battery Replacement

System Conguration (Front Panel and Monitor Control Software)

System Congurable Feature List (Front Panel / MCS)

Conguring the Control Module for the Network

IP Address DHCP

NETBIOS Support

Other Recommended Connections

Suggestions for Managing Multiple Control Modules

Front Panel Control

System Information

Setting Sound Masking Levels

Setting Audio Input Levels

Lock/Unlock the Front Panel

Congure Network Name and IP Address

Real-Time Clock or Network Clock

Reset System to Default Settings

System Control Using Monitor Control Software (MCS)

Connecting to the Qt 300/600 over Ethernet

MCS: Operation Section

6

8

8

8

9

10

10

12

12

13

14

15

15

16

16

16

16

16

17

17

18

20

20

21

21

21

22

22

23

page 5

Changing Masking Level Using MCS

Auto Ramping

Changing Input A and B Level

Time of Day Masking

Errors

MCS: Administration Section

Service

Zone Names

Networking and Security

Notication of Errors

Date and Time – Time Zone

Setting Equalizers and Emitter Fault Detection

MCS: Help

Links to Help Topics

Software Update

Documentation

MCS: Printout

Error Codes and Message

Post Installation Handoff

Warranty

Warranty

Settings Record

Homerun Zone Destination Record

24

24

25

26

27

27

28

28

28

28

29

30/31

33

33

33

34

34

34

36

37

38

39

40

page 6

Qt 300/600 Introduction

This manual discusses the installation of a sound masking system

using either the Qt 300 or the Qt 600. The Qt 300 and Qt 600

controllers have identical functionality, but different number of

zones supported - the Qt 300 supports 3 zones whereas the Qt 600

supports 6 zones. As you use this guide, remember the number of

zones and total area of coverage is the only real functional difference

between the systems. Collectively, the systems are referred to as

‘QtPro’ throughout this guide.

The Qt 600 supports six zones of sound masking, each with 1 to 120

emitters covering 100 to 12,000 square feet (9.3 m2 - 1,115 m2) per

zone. The Qt 300 supports three zones of sound masking, each with

1 to 120 emitters, covering up to 12,000 square feet per zone (1,115

m2). Each systems comes with two audio inputs which can be used

for paging and/or music. Additional controls for each zone include

time-of-day masking, auto ramping, self-monitoring fault detection

and notication, and independent equalizers for masking and audio

inputs. The system may be operated from its control module front

panel OR by a computer directly-connected to the module OR by

a computer connected through a local area network. See system

conguration on page 15.

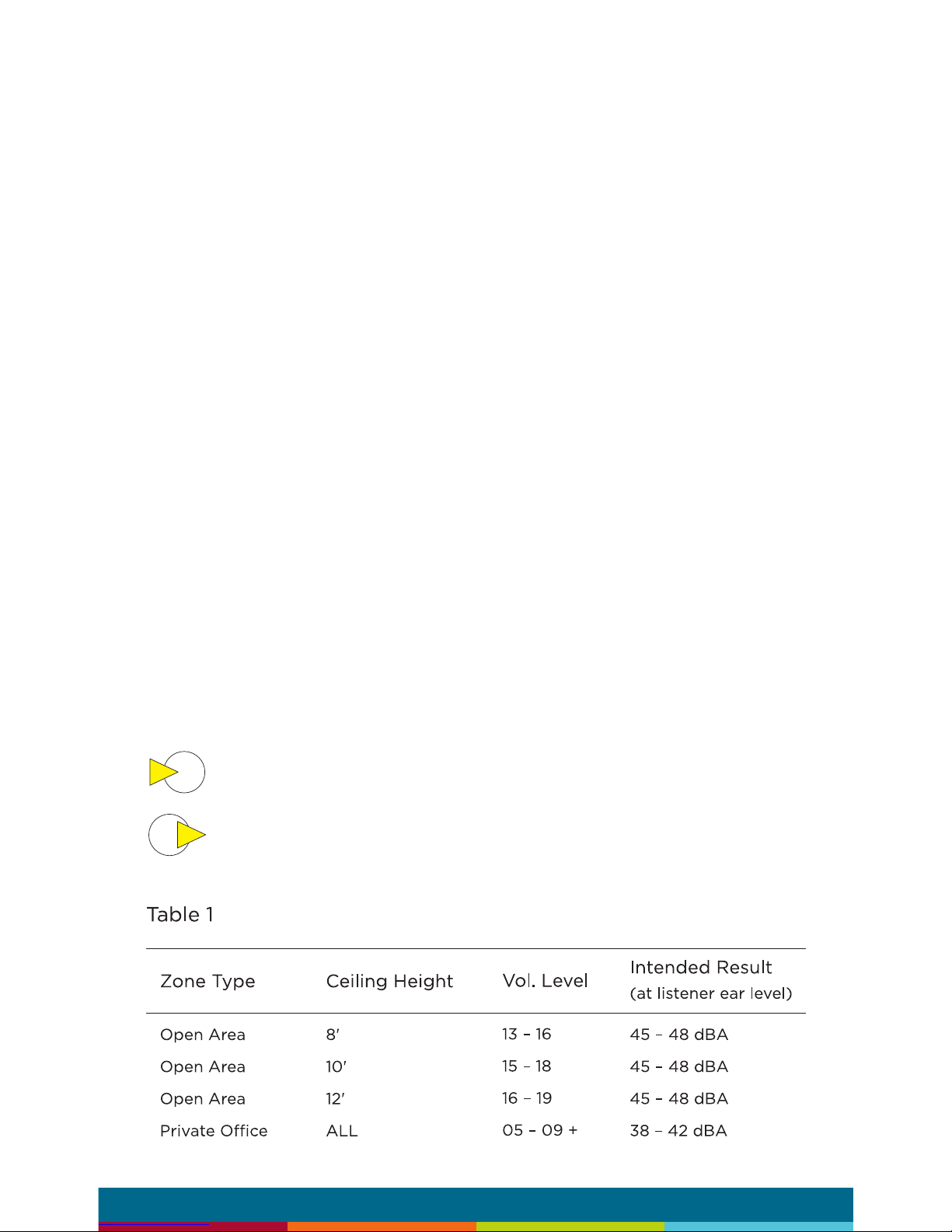

It is important that the control module’s masking volumes be set

correctly for each zone to obtain the full effectiveness of the system.

If volumes are set too low, speech privacy will be reduced and work

place distractions will be much more apparent. If volumes are set too

high, the masking sound itself could become a source of distraction.

The higher the setting that can be used comfortably, the better the

acoustic privacy. For a given open ofce design, including ceiling

height, ceiling material and workstation panel height, we can dene

the masking volume required to achieve “normal acoustic privacy,”

i.e., when it is relatively easy to ignore surrounding conversations.

For a very large range of open ofce designs, the target level is

in the 45–48 dBA range, measured 3 ft. (0.9 m) above oor level.

Similarly, for private ofces, based on wall panel design and ceiling

construction, we can dene masking volumes required to achieve

“condential privacy,” i.e., conversations in adjacent ofces cannot

be understood. Most private ofces have a target level in the 38–42

dBA range, averaged spatially within the ofce.

page 7

Setting the masking volumes can be approached in one of two ways:

BEST: If a sound level meter is available, it is recommended that

the control module’s masking volumes be adjusted up or down to

achieve the following readings on the meter:

Private Ofce Zones

38-42 dBA, averaged spatially within the ofce

Open Area Zones

45-48 dBA, measured 3 ft. (0.9 m) above oor level

OTHERWISE: If a sound level meter is not available, the above levels

are likely to be achieved in most environments by setting the control

module’s masking volumes as follows:

Private Ofce Zones

05-09, for all ceiling heights

Open Area Zones

13-16, for 8 ft. (2.4 m) ceilings

15-18, for 10 ft. (3 m) ceilings

17-20, for 12 ft. (3.7 m) ceilings

Masking volumes must be set sufciently high to improve speech

privacy and reduce distraction but not so high that the masking

sound becomes objectionable. Settings within the above ranges

should accommodate both objectives. As a general rule, use the high

end of the range. Base nal settings on site conditions and customer

preferences. If people object to the sound level, set masking volumes

toward the bottom of the range or refer to the ‘Ramping’ section of

this guide, found on page 24 for more information on introducing

masking into the space gradually. Remember that the effectiveness

of the system relies on sufcient masking sound level and that initial

objections are often overcome as people become accustomed to the

sound.

Different day and a night volumes may be set. The control module

ramps linearly between these two settings beginning at the time

specied and over the period of time specied. As the control

module ramps between settings, the current volume is displayed

under “Current.”

NOTE: This document uses the QtPro software version 6.0.0 for

feature conguration.

page 8

Qt 300/600 Introduction

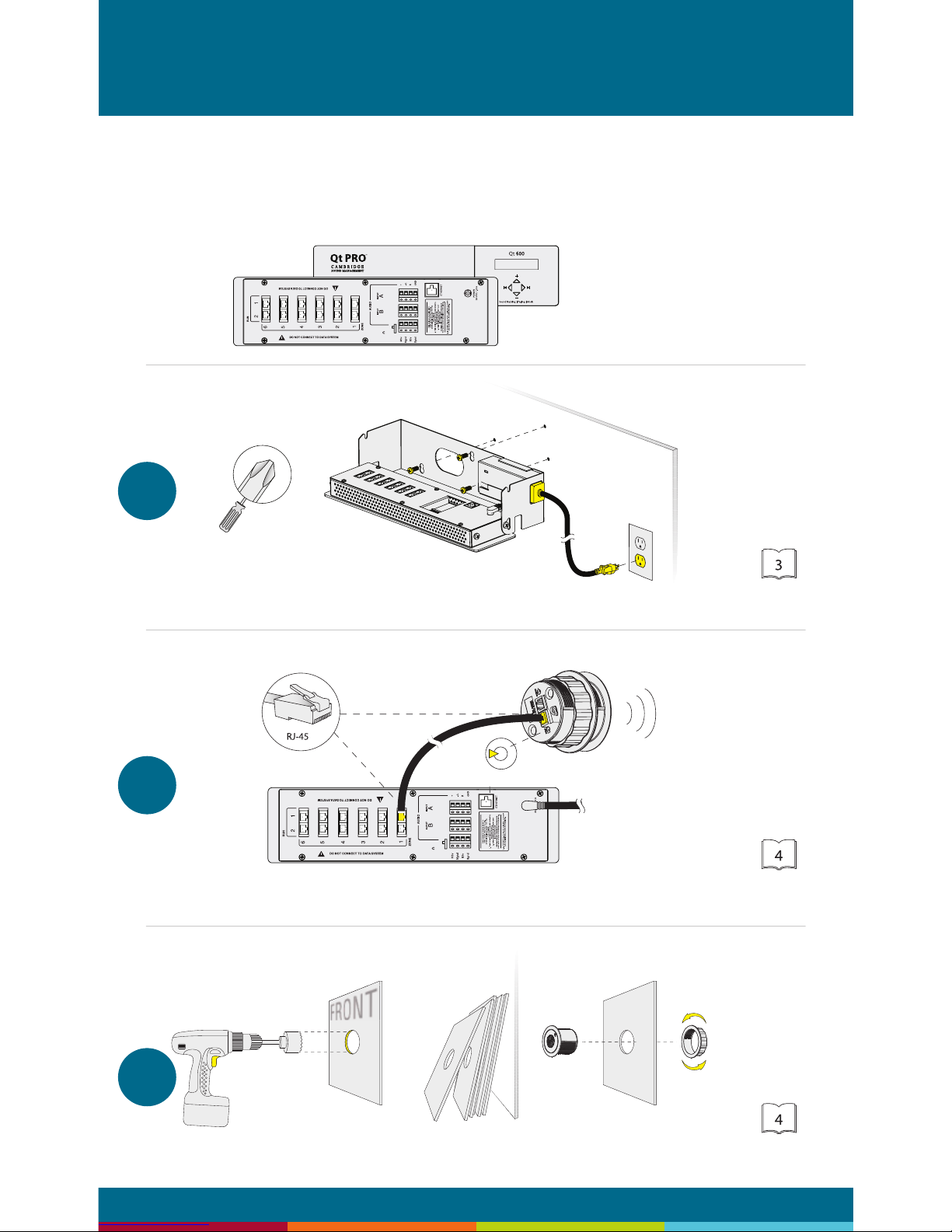

Installing the Control Module

NOTE: Always plug/unplug power supply at wall outlet

NOTE: The Qt 600 is shown in the gures, but the Qt 300 installs in

the same manner.

Wall Mount

Mount the bracket using the three screws and plastic anchors

(mollies) provided. Use a ¼ inch drill bit for the anchor hole. See

Figure 1.

Plastic anchors are #10-12 x 1¼ in. with #10 x 1½ screws.

NOTE: The control module hinges forward for wall mounting and

cable installation. To hinge forward, loosen screws A and B (see

Figure 1) used to secure the module during shipping.

Check to see that the panel lock switch is in the

UN-LOCKED position.

A

B

Figure 1

B3v

Bgnd

M3v

Mgnd

AUDI

O

+

-/LRGND

A

B

page 9

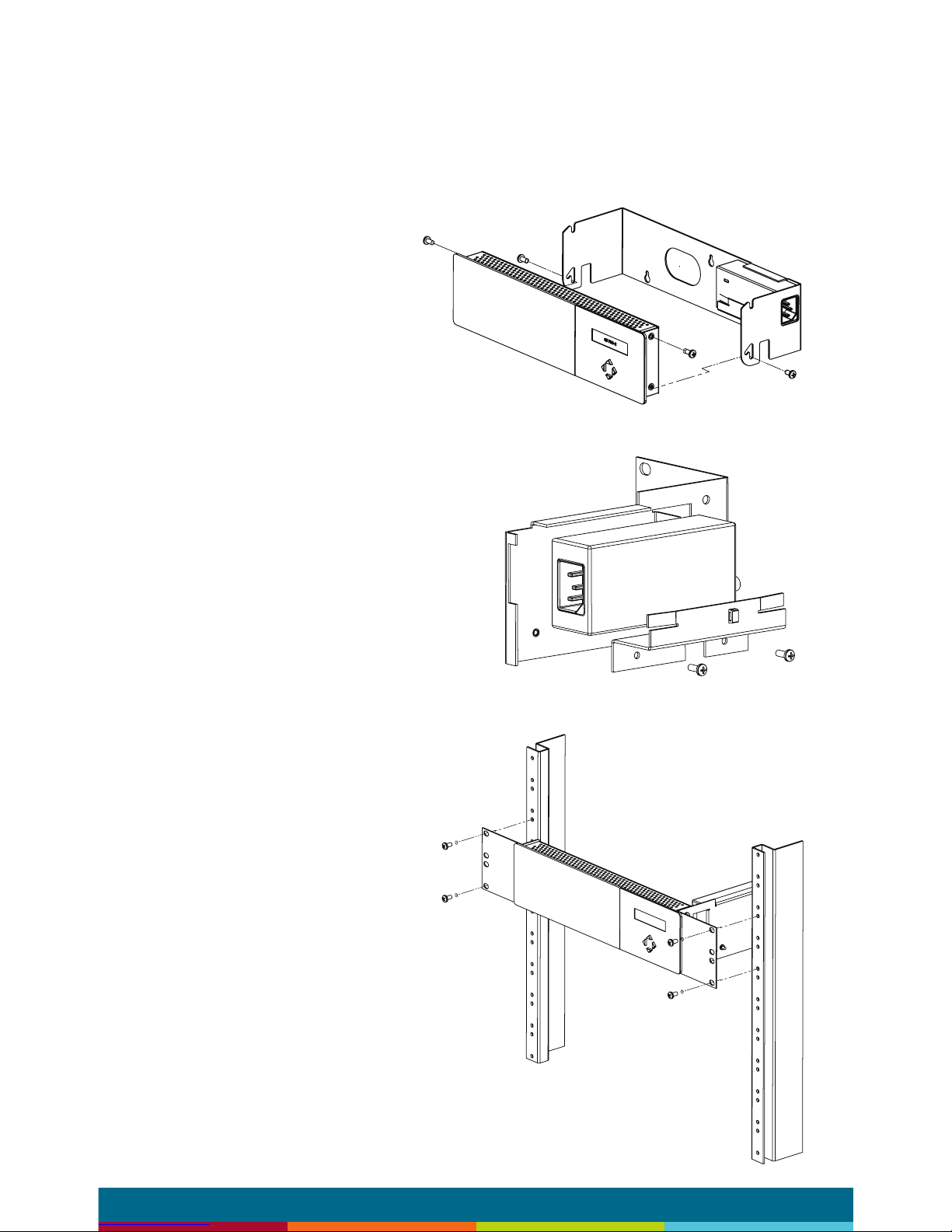

Rack Mount

Attach optional rack mount brackets to each end of the control

module.

NOTE: When rack mounted, the control module does not hinge

forward.

Step 1

Remove the QtPro and

power supply bracket from

wall mount bracket.

Step 2

Reassemble power supply

to right rack mount bracket

using 6:32 black screws

(included with bracket).

Step 3

Fasten left and right rack

mount brackets to QtPro

using the screws removed in

Step 1.

Step 4

Mount QtPro to 19” cabinet

rail using 10:32 screws

as shown (included with

bracket).

A

B

B

page 10

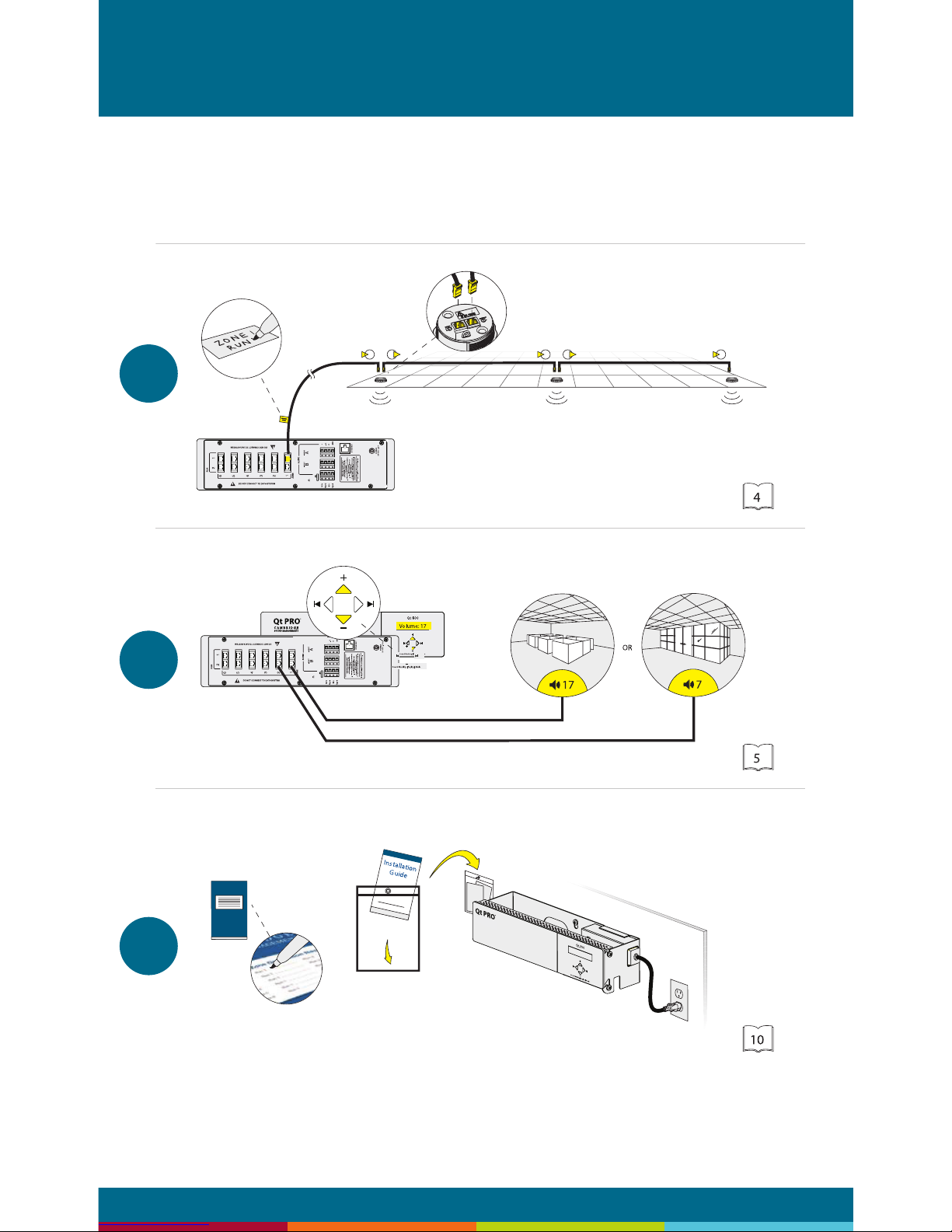

Installing the Qt Emitters

Important Considerations:

▪ Each run has a maximum of 60 emitters

▪ Each run should have a maximum length of 1000 ft. (305 m).

▪ Each home run cable attached to the control module should

be labeled by zone # and run #. Adding a logical name (e.g.

Marketing, Private Ofces) is suggested. In addition, ll out

“Home Run Zone Destination Record” at the end of this Guide.

▪ Each zone has two identical outputs, run 1 and run 2. All

emitters on run 1 and run 2 are controlled equally for each zone.

▪ Each job-made cable should be manufactured according to

ANSI/ TIA/EIA Standard 568-B. See custom cabling guidelines

on page 13.

▪ Job-made cables should be tested with a LAN tester before

installation. Adjustable emitters should be set for lower sound

levels, within a zone, when sound level measurements show an

acoustically loud subsection.

Emitter Installation Order

1. Set the masking output level of all zones to level 20.

2. Refer to the emitter layout and wiring diagram provided by the

dealer for cable run connections by zone.

3. Run home run cables from control module to the location of the

rst emitter for all runs in all zones.

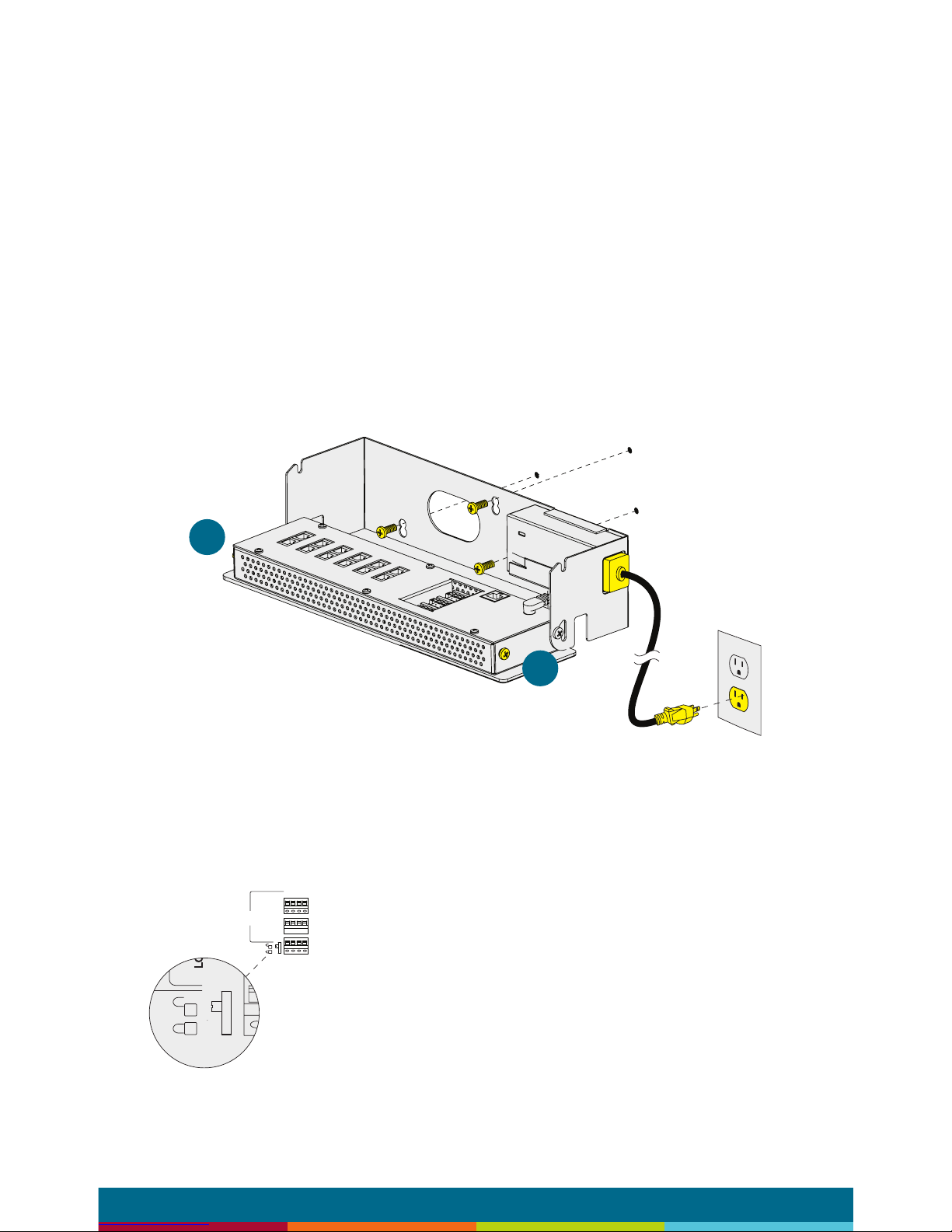

4. Gather all ceiling tiles (per layout drawing) that are to receive

emitters. Use the supplied hole saw to cut holes in designated

tiles. Cut all tiles from the front. (Different types of emitter

housings are available to attach in areas where there are no

suspended ceiling tiles.)

5. Push the emitter through the front of the hole in tile and secure

it by pushing down and twisting the locking ring at the back of

the emitter.

6. Connect a run cable from the specied zone OUTPUT jack on

the module to the INPUT jack of the rst emitter. Listen to each

emitter as it is connected. If you cannot hear its “whooshing”

sound:

a. Try a different emitter.

b. Test all four previous cables for continuity and shorts.

Repair any faulty cables.

c. If there is a short, masking volume will shut off. The

short should clear itself in approximately ve minutes.

If it does not, power cycle (unplug and re-plug) the

control module.

page 11

NOTE: The “tombstone” hook on the back of each emitter is next to

the INPUT jack. This can help you nd the INPUT jack by touch.

NOTE: To adjust for unexpected obstacles such as sprinkler heads,

each emitter may be moved up to two feet (one tile) in any direction,

if necessary.

7. Connect the next OUTPUT cable to the emitter OUTPUT jack.

8. Run the cable to next designated tile specied on emitter layout

and wiring diagram. Tie cables up to structure or suspend from

deck as required by local building code.

9. On the next emitter, connect this cable to the INPUT jack.

10. Repeat Steps 4 through 9 for the remaining emitters on the

home run.

11. Set sound masking volume levels for each zone, using either the

front panel controls or the software interface. Set sound levels

according to Table 1.

12. If a small area within a zone exhibits a perceived volume louder

than the rest of the zone, use the adjustable emitter toggle

switches to turn the volume down for the emitters in that area.

Emitters can decrease volume by 3,6 or 9 dB. See emitter spec

sheet for more details.

Be sure to x any problems and hear the “whooshing” sound before

installing the next emitter. If necessary see the Errors section of this

guide, found on page 27.

Note:

The input jack of each emitter bears this symbol

and is located near the safety tie off

The output jack of each emitter bears this symbol

page 12

Installing Paging or Music to the Audio Inputs

1. Be sure power is OFF by unplugging power cord from wall

outlet.

2. Balanced Audio Input: (most often, but not always characteristic

of paging systems.) Connect signal wires to + and - at input A or

B. Connect the shield to GND at the audio source.

3. Unbalanced Audio Input: (typical of music systems.)

a. Mono Signals: Connect signal wire to both L and R at

input A or B. Connect the ground wire to GND.

b. Stereo Signals: Connect signal wires to L and R at

input A or B. Connect the ground wire to GND.

4. If a music source is to be connected, using Input B allows

emergency music shut-off. See Contact Closures below.

Installing Contact Closures

The QtPro provides an instant shut-off capability for masking and/ or

audio Input B if connected to a contact closure interface. The contact

closure utilizes the same style connector as audio Inputs A and B (4pin).

To leverage this feature for masking, connect a two-conductor cable

to the two connectors, labeled M3V and MGND. To leverage this

feature for Audio Input B, connect a two-conductor cable to the two

connectors, labeled B3V and BGND.

The other end of these conductors (treated as pairs/circuits) can be

terminated on closure mechanisms of choice.

1. To shut off masking, form a connection between the two “M”

conductors.

2. To resume masking, break the connection (Don’t break the

connectors as you may want to reuse them).

The contact closure for audio Input B follows the same logic.

Loading...

Loading...