CAMBRIDGE M-SERIES Technical Manual

M-SERIES

DRAW THRU

DIRECT GAS-FIRED

MAKE-UP AIR HEATERS

TECHNICAL MANUAL

mWARNING:

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death. Read the installation, operating, and maintenance instructions thoroughly

before installing or servicing this equipment.

FOR YOUR SAFETY

The use and storage of gasoline or other flammable vapors and liquids in open containers in

the vicinity of this appliance is hazardous.

ASHRAE

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

Made in the USA

ASHRAE

90.1

COMPLIANT

COMPLIANT

®

®

M-TM1-0915

M110-M115 (3HP) REV. G

M115 (5HP) REV. H

M118-M136 REV. C

M140 REV. A

LIMITED WARRANTY

Cambridge Engineering, Inc. (“Manufacturer”) warrants its products (“the Products”) to be free from

defects in material and workmanship. Manufacturer’s M-Series Products shall be warranted for a period of

twenty-four (24) months from the date of shipment, except that burner assemblies are warranted for

five (5) years from date of shipment.

Buyer’s sole and exclusive remedy for any nonconformity with this warranty shall be, at Manufacturer’s

option, repair or replacement of nonconforming parts, provided that Buyer shall return to Manufacturer, shipping

prepaid, said nonconforming part(s) bearing a durable tag indicating the Serial Number of the Product

from which the part was taken. In addition, Manufacturer may opt not to repair or replace nonconforming

Product or part(s), but instead may refund to Buyer the price thereof, in lieu of repair or replacement. In no

event shall Manufacturer be liable for more than a refund of the purchase price or replacement value of the

Product or part(s), whichever is less. This Warranty does not apply to field labor charges.

This Warranty does not apply and shall be void as to any Products that are misused or misapplied, that are

installed, operated or maintained not in conformity with Manufacturer’s design, specifications, instructions, or Technical Manual, or are installed, operated or maintained in violation of any applicable national

or local codes or industry standards.

Manufacturer does not warrant Products if they are abused, improperly operated or maintained, subjected

to abnormal wear and tear, damaged due to improper gas or electric service, damaged in transit, or that

have been repaired or modified by others without Manufacturer’s written authorization.

Buyer shall have no right to enforce this Warranty unless it has complied with all of its obligations under

the contract for purchase/lease of the Products, including without limitation being current on all payment

terms.

THIS LIMITED WARRANTY IS MANUFACTURER’S ONLY WARRANTY WITH RESPECT

TO THE PRODUCTS, AND IT IS IN LIEU OF AND SUPERSEDES ANY AND ALL OTHER

WARRANTIES OF ANY KIND WHATSOEVER, WHETHER WRITTEN, ORAL OR IMPLIED,

INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. THE REMEDIES AFFORDED BUYER BY THIS WARRANTY

ARE THE ONLY REMEDIES AFFORDED BUYER FOR ANY NONCONFORMITY WITH THIS

WARRANTY OR FOR ANY DEFECT IN PRODUCTS, SERVICES, OR REPRESENTATIONS

PROVIDED BY MANUFACTURER IN CONNECTION WITH SUCH PRODUCTS. IN NO EVENT

SHALL MANUFACTURER BEAR ANY LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES OF ANY KIND WHATSOEVER, INCLUDING WITHOUT LIMITATION PERSONAL

INJURY (INCLUDING DEATH), PROPERTY DAMAGE, LOST PROFITS OR OTHER ECONOMIC

LOSS.

Buyer acknowledges that the foregoing warranty, limitations, and exclusions are a reasonable allocation

of commercial risks by and among sophisticated business entities and are not subject to dispute as to their

commercial reasonableness, fairness or ability to satisfy the essential purposes of the parties’ transaction.

M-SERIES

TECHNICAL MANUAL

Contents

Hazard Summary .............................................................................................................. 2

Typical System Overview

Accessory Identication .................................................................................................. 4

Heater / Accessory Weights ............................................................................................5

Heater Operation ............................................................................................................. 6

Heater Conguration

Installation Instructions

Uncrating Instructions

Mounting Location

Horizontal Mount - Mounting Curb ................................................................................ 8

Horizontal Mount - Roof Top Conguration .................................................................. 9

Horizontal Mount - Outdoor Pad Mount Conguration ...............................................13

Horizontal Mount - Thru Wall Conguration ...............................................................16

Vertical Mount - Outdoor Conguration ....................................................................... 19

Vertical Mount - Indoor Conguration .........................................................................23

Gas Piping ..................................................................................................................... 26

Electrical .......................................................................................................................27

Start-Up Instructions ....................................................................................................... 28

Operating Instructions ..................................................................................................... 35

Operating Sequence ......................................................................................................35

Electronic Thermostat ................................................................................................... 36

TSS Controller ..............................................................................................................38

Maintenance Instructions ................................................................................................ 47

Reference ........................................................................................................................ 48

Heater Roof and Wall Openings ...................................................................................48

Heater Discharge Dimensions .......................................................................................48

Gas Train Drawings ......................................................................................................49

Electrical Control Enclosure Isometric Drawing ......................................................... 55

Electrical Wiring Diagrams ........................................................................................... 58

Connection Diagram ..................................................................................................... 64

Gas Control Systems ..................................................................................................... 65

Remote Control Station Components ........................................................................... 65

Individual Heater Component Descriptions .................................................................. 66

Damper Motor Replacement & Adjustment ................................................................. 70

Troubleshooting Guide..................................................................................................73

ANSI/ASHRAE/IESNA Standard 90.1 ..........................................................................79

Maintenance Log ............................................................................................................ 80

................................................................................................. 3

....................................................................................................... 6

..................................................................................................... 7

..........................................................................................................7

Copyright 2015

Cambridge Engineering, Inc.

All Rights Reserved

Cambridge Engineering, Inc.

760 Long Road Crossing Dr.

Chesterfield, MO. 63005

Phone: (636) 532-2233, Fax: (636) 530-6133

www.cambridge-eng.com

HAZARD SUMMARY

Hazard Identification

Warnings and Cautions appear at appropriate sections throughout this manual. Read these carefully.

mWARNING: Indicates a potentially hazardous situation which could result in

death or serious injury.

mCAUTION: Indicates a potentially hazardous situation which may result in

minor or moderate injury. It may also be used to alert against

unsafe practices.

CAUTION: Indicates a situation that may result in accidents with equipment or

property damage only.

The following safety precautions apply to the installation, operation, and maintenance of the equipment

described by this technical manual.

mWARNING:

Any unauthorized modification of this equipment

shall void the warranty.

mWARNING:

Only qualified personnel should attempt installation, service, and repair of this equipment. Use

extreme caution and observe safety regulations at

all times.

mWARNING:

Recirculation of room air is not permitted.

Adequate building relief shall be provided so as to not

over-pressurize the building when the make-up air heating system is operating at its rated capacity. It should be

noted that this can be accomplished by taking into

account, through standard engineering methods, the

structure’s designed infiltration rate, by providing properly sized relief openings, by interlocking a powered

exhaust system, or by a combination of these methods.

when the heater is providing the make-up air to a boiler

room), the heater is to be interlocked to open inlet air

dampers or other such devices.

If the heater is installed such that an inlet duct is utilized, the duct system must be purged with at least four

air changes prior to an ignition attempt.

IMPORTANT

Installation in Aircraft Hangars

Refer to the Standard for Aircraft Hangars, ANSI/

NFPA 409, for specific information on the installation

requirements for these heaters in airplane hangars.

IMPORTANT

Installation in Parking Garages

Refer to the Standard for Parking Structures, ANSI/

NFPA 88A, or the Standard for Repair Garages, ANSI/

NFPA 88B, for specific information on the installation

requirements for these heaters in public garages.

If in doubt regarding installation or application,

contact Cambridge Engineering Customer Service

Group at 800-473-4569 during the hours of 8:00 a.m.

to 5:00 p.m. Central Time, Monday through Friday.

If the failure or malfunction of this heater creates a hazard to other fuel burning equipment in the building (e.g.

Cambridge Engineering, Inc. 2 M-Series Technical Manual

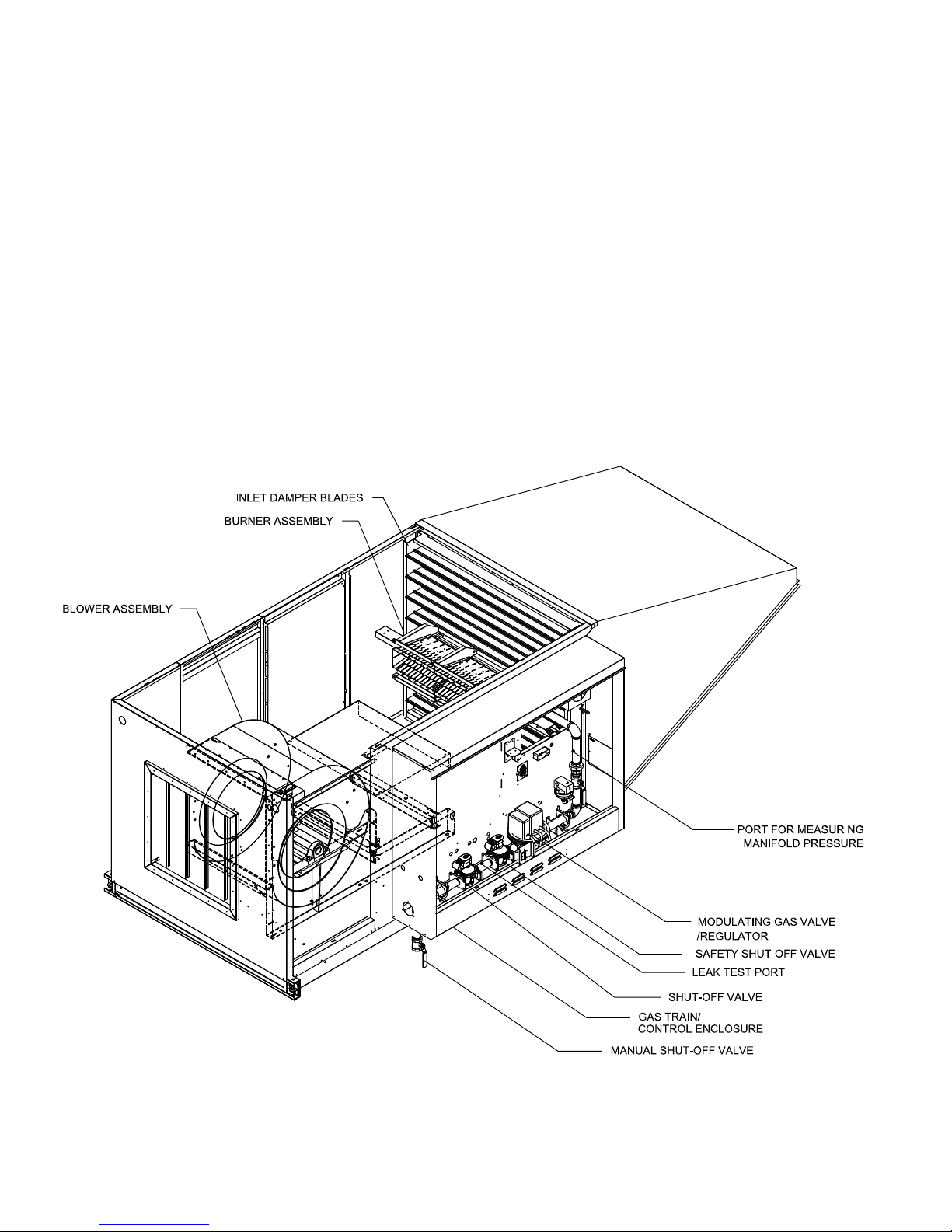

TYPICAL SYSTEM OVERVIEW

CONTROL SYSTEMS:

MAXITROL SERIES 14

The Maxitrol Series 14 electronic discharge temperature

control system maintains a constant discharge temperature. The standard control permits manual adjustment

of discharge temperature (55° to 90°F) from inside the

heater control enclosure. As an option, a Remote Heat

Adjust control with override capability to 130°F can be

provided to allow manual adjustment of discharge temperature (55° to 130°F) from either inside the heater con-

trol enclosure or in the Remote Control Station.

MAXITROL SERIES 14 WITH SPACE

THERMOSTAT

The Maxitrol Series 14 modulation controls function as

described above using the optional Remote Heat Adjust

control in conjunction with an electronic space thermostat switch contact to increase discharge temperature.

The discharge temperature will increase to a preset rise

(0°F to 40°F) above the set point on the Remote Heat

Adjust control face based on the setting of the override

temperature dial, which is visible from the top of the

control.

MAXITROL SERIES 44

The Maxitrol Series 44 modulation controls maintain

a constant space temperature by increasing or decreasing the discharge temperature. The Space Temperature

Selector is set to maintain the space temperature of the

heated space by controlling the heater output between

the MIN and MAX setting on the amplifier. The MIN

dial setting determines the minimum discharge temperature the heater will deliver (40°F to 80°F). The MAX dial

setting determines the maximum discharge temperature

the heater will deliver (80°F to 140°F).

MAXITROL SERIES 44 / TAMPER PROOF

The Maxitrol Series 44 / Tamper Proof temperature

control system is similar to the Maxitrol Series 44 controls above except the adjustable Space Temperature

Selector control is replaced by two other controls. The

adjustable portion of the temperature selector is typically

mounted in the Remote Control Station to prevent unwanted

tampering of the temperature setting and the non-adjustable

space sensor is mounted in the space being heated.

M-Series Technical Manual 3 Cambridge Engineering, Inc.

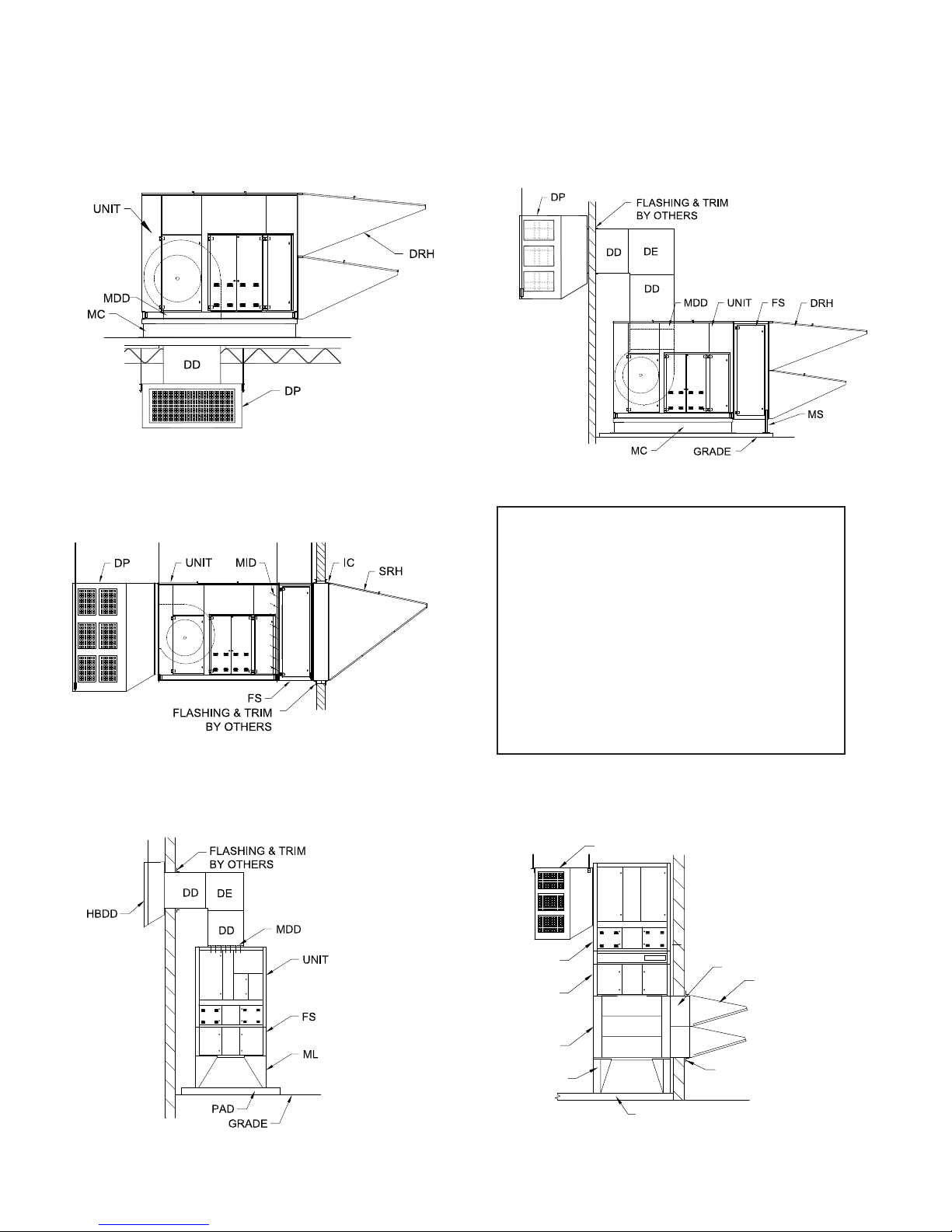

TYPICAL SYSTEM OVERVIEW

FLOOR

ACCESSORY IDENTIFICATION

Horizontal Mount

Roof Top Configuration

Horizontal Mount

Thru Wall Configuration

(Not applicable to M140)

Horizontal Mount

Outdoor Pad Mount Configuration

Component Identification

DD Discharge Duct

DE Discharge Elbow

DP Discharge Plenum

DRH Dual Rainhood w/ Inlet Screen & Filter Rack

FS Filter Section V-Bank

FSID V-Bank Filter Section/Inlet Damper Combo

HBDD Horizontal Blast Discharge Diffuser

IC Inlet Collar

IE Inlet Elbow

MC Mounting Curb

MDD Motorized Discharge Damper

MID Motorized Inlet Damper

ML Mounting Legs

SRH Single Rainhood w/ Inlet Screen

Vertical Mount

Outdoor Configuration

Cambridge Engineering, Inc. 4 M-Series Technical Manual

UNIT

FSID

Vertical Mount

Indoor Configuration

DP

IE

ML

IC

DRH

FLASHING & TRIM

BY OTHERS

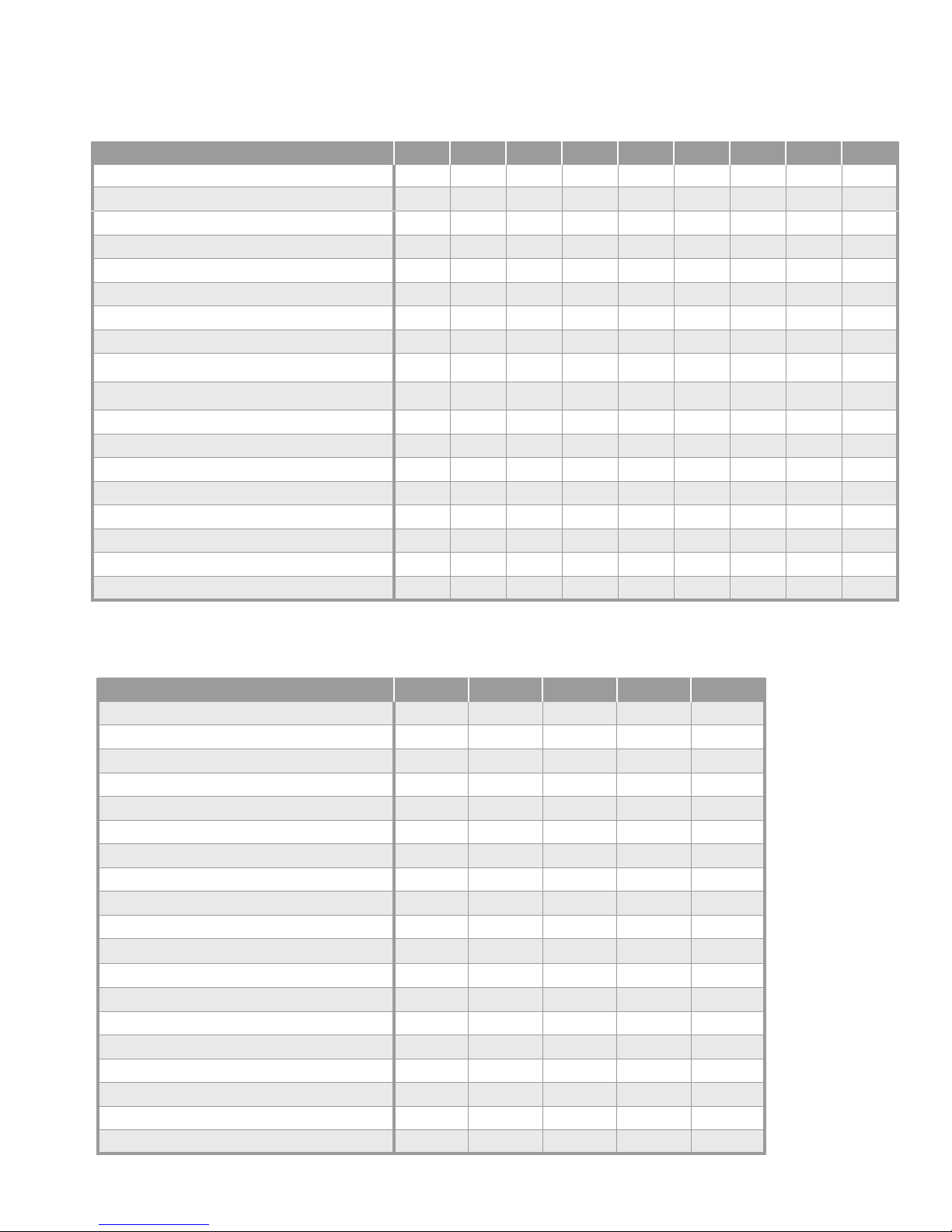

HEATER / ACCESSORY WEIGHTS

Horizontal Mount (Weights Shown In Pounds)

Model M110 M112 M115

Base Heater

Rain Hood - Single

Rain Hood - Dual, Upper

Rain Hood - Dual, Lower

Filters for Rain Hood

Inlet Screen

Inlet Collar

Inlet Damper (internal)

V-Bank Filter Section

Discharge Duct - 20"

425 440 550 1125 1395 2045 2475 2845 5345*

45 45 70 135 175 275 325 375 N/A

N/A N/A N/A 95 145 240 270 325 480

N/A N/A N/A 75 105 170 205 280 410

10 10 15 20 30 45 60 80 90

5 5 10 10 15 25 35 40 45

40 40 50 85 110 170 200 230 335

25 25 35 55 65 125 155 210 290

70 70 100 215 235 285 400 500

M118 M120 M125 M130 M136 M140

**

Discharge Duct - 50"

Discharge Duct - 72"

Discharge Damper (internal)

Discharge Plenum 4-way

Discharge Plenum 3-way

Discharge Splash Pan

Curb 14"

Curb 24"

60 70 80 90 120 140 160 180 200

70 85 95 125 150 180 220 250 280

N/A N/A N/A 30 30 35 45 55 75

100 150 200 250 300 400 470 930 1480

80 130 175 220 260 360 430 500 795

40 40 40 60 60 60 80 80 80

60 70 80 100 120 180 210 230 270

100 120 140 170 200 270 310 340 445

*Due to shipping constraints the M140 consists of a of blower module (3625 lbs.) and burner module (1720 lbs.)

**Consult Factory

Vertical Mount (Weights Shown In Pounds)

Model

Base Heater

Rain Hood - Single

Rain Hood - Dual, Upper

Rain Hood - Dual, Lower

Filters for Rain Hood

Inlet Collar

Inlet Elbow

Inlet Damper

V-Bank Filter Section

Filter Section/Inlet Damper Combo

Discharge Duct - 20"

Discharge Duct - 50"

Discharge Duct - 72"

Discharge Damper (internal)

Discharge Elbow

Discharge Plenum 3-way w/enclosure

Discharge Diffuser

Mounting Legs 3-foot, set of 4

Mounting Legs 5-foot, set of 4

M118 M120 M125 M130 M136

1800 2300 2900 3200 3600

105 165 285 395 485

80 120 210 290 345

55 90 150 210 275

20 30 45 60 80

80 110 170 200 230

450 500 780 1040 1175

305 345 400 475 490

280 380 420 555 715

470 600 670 860 920

90 120 140 160 180

125 150 180 220 250

35 35 40 60 75

95 120 170 230 340

280 320 420 510 580

210 230 280 310 350

250 250 250 250 250

400 400 400 400 400

M-Series Technical Manual 5 Cambridge Engineering, Inc.

TYPICAL SYSTEM OVERVIEW

HEATER OPERATION

Cambridge M-Series Draw-Thru heaters provide

fresh air ventilation to a facility, provide tempered air

to replace the air that is mechanically exhausted, or

address cold drafts from natural infiltration. Heater

operation is typically electrically interlocked with

mechanical exhaust fans, manually operated switches,

HEATER CONFIGURATION

programmable timers, or other process control systems. The discharge temperature of heaters with fixed

discharge temperature controls is typically set 10°F to

20°F above the desired space temperature. The entering air thermostat acts as an economizer by deactivating burner operation during mild weather.

Cambridge Engineering, Inc. 6 M-Series Technical Manual

INSTALLATION INSTRUCTIONS

UNCRATING INSTRUCTIONS

1. Verify the number of items on the Bill of Lading

versus the number of items received.

IMPORTANT

Field constructed intake accessories should be designed to minimize the entry of snow

and rain.

2. Check for shipping damage. If damage is found,

immediately file a claim with carrier before

proceeding further.

3. Check items received to make sure they agree with

ordering information including verification of data

on the make-up air heater nameplate.

IMPORTANT

Do not discard any components or accessories.

MOUNTING LOCATION

Verify feasibility of the installation location selected

with respect to accessibility to the heater for service

and maintenance functions. Ensure the positioning of

the heater does not inhibit fork truck operation, storage rack access, or other operations within the facility.

Ensure the heater inlet and outlet are not blocked or

severely restricted, such that it would affect the rated

airflow through the heater or affect the desired air distribution pattern of the heater. If upon review of the

proposed installation, a problem is discovered which

may be considered detrimental to the performance of

the heater, or restricts its serviceability, or deviates from

the instructions or drawings which may be provided, it

is the responsibility of the installer to communicate that

information to the person or persons responsible for providing the installation instructions or drawings prior to

proceeding with the installation.

IMPORTANT

Minimum clearance from the face of the electrical control enclosure to surrounding grounded surfaces for

service activities is 42". Adequate clearance for burner

removal is also required, which is based on 42" or

the length of the burner + 12", whichever is greater.

Access for service functions is also required on the opposite side of the make-up air heater from the control

enclosure for a distance of 24".

mWARNING:

Where the mounting height of the heater is

required to be above 15 feet, work platforms or

service lifts should be provided for accessibility to the equipment for service and maintenance

activities.

M-Series Technical Manual 7 Cambridge Engineering, Inc.

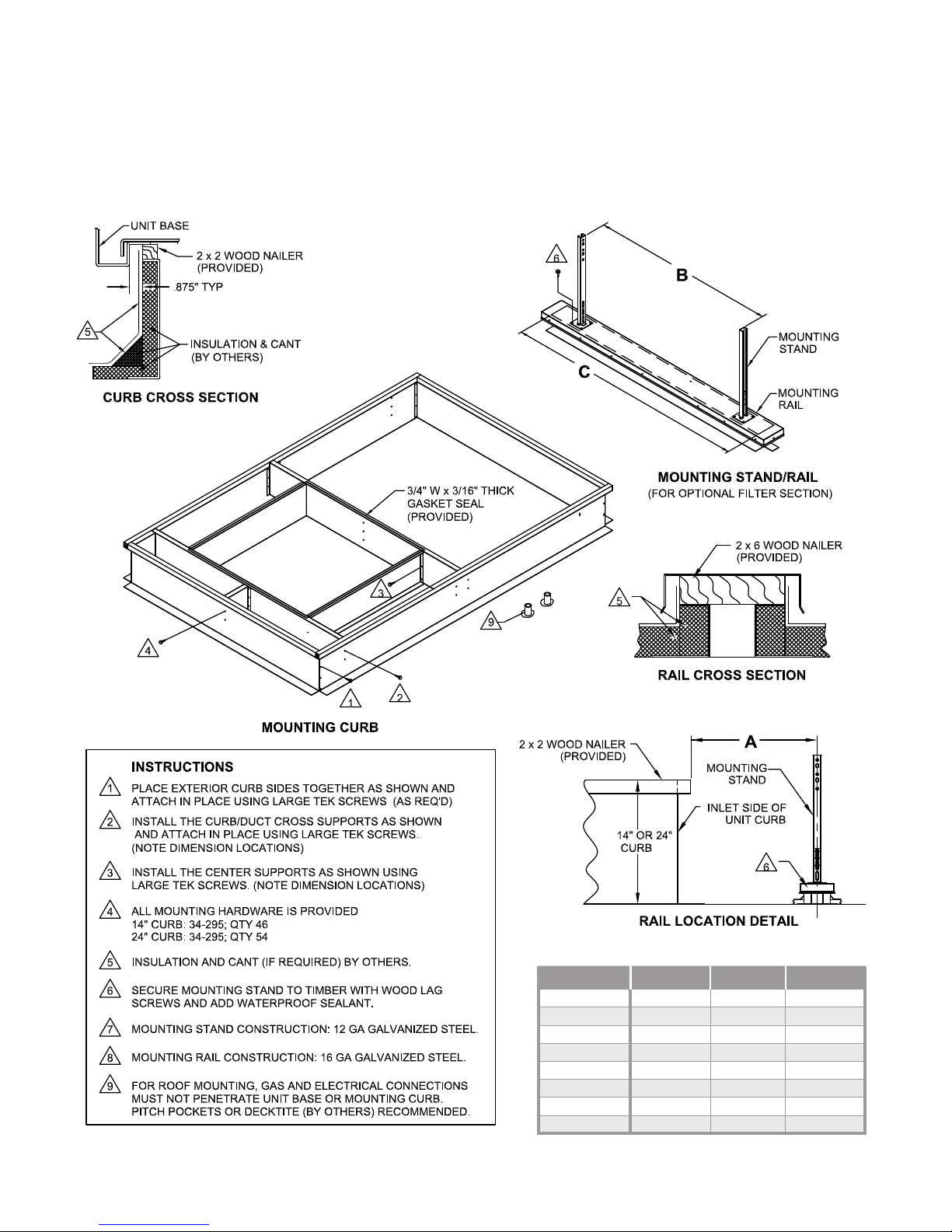

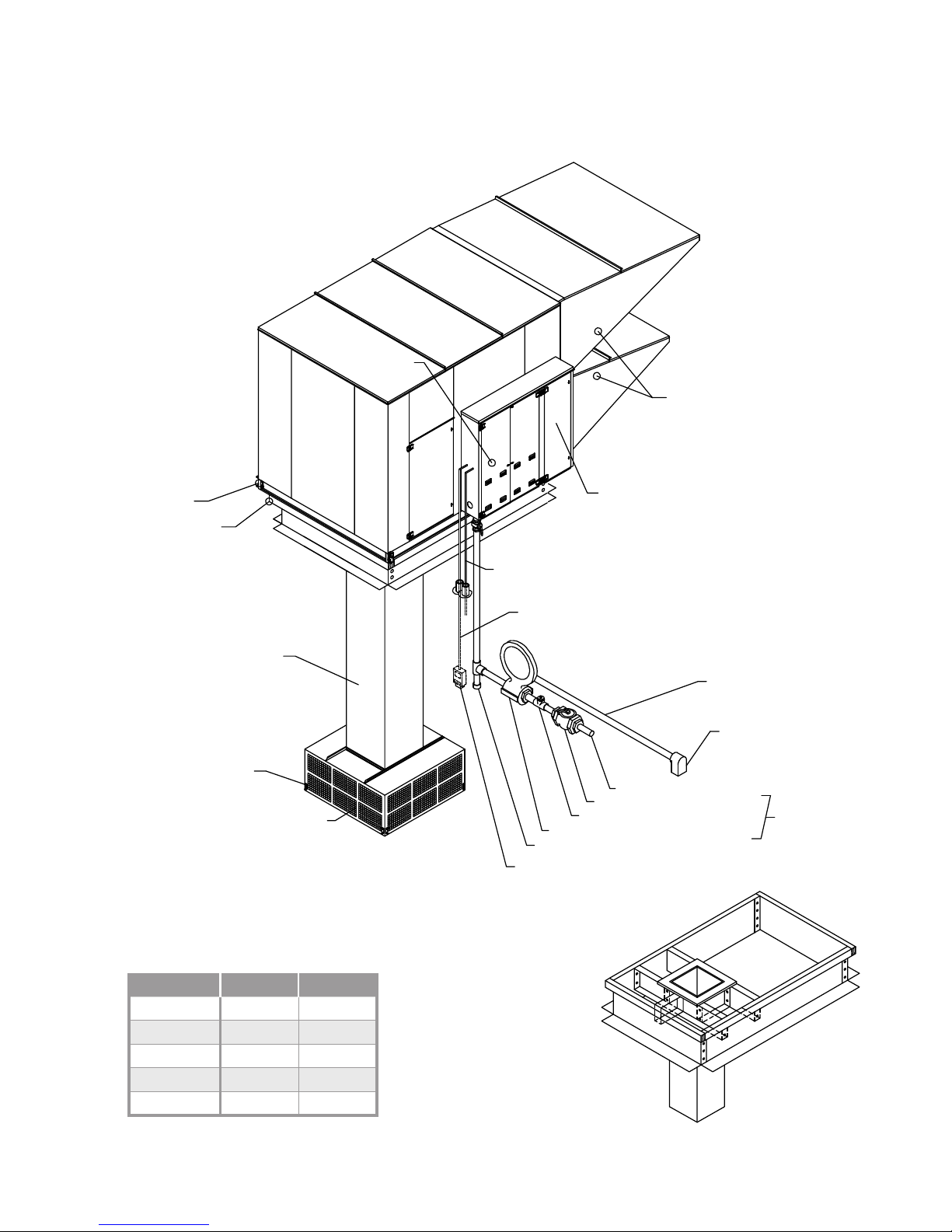

INSTALLATION INSTRUCTIONS

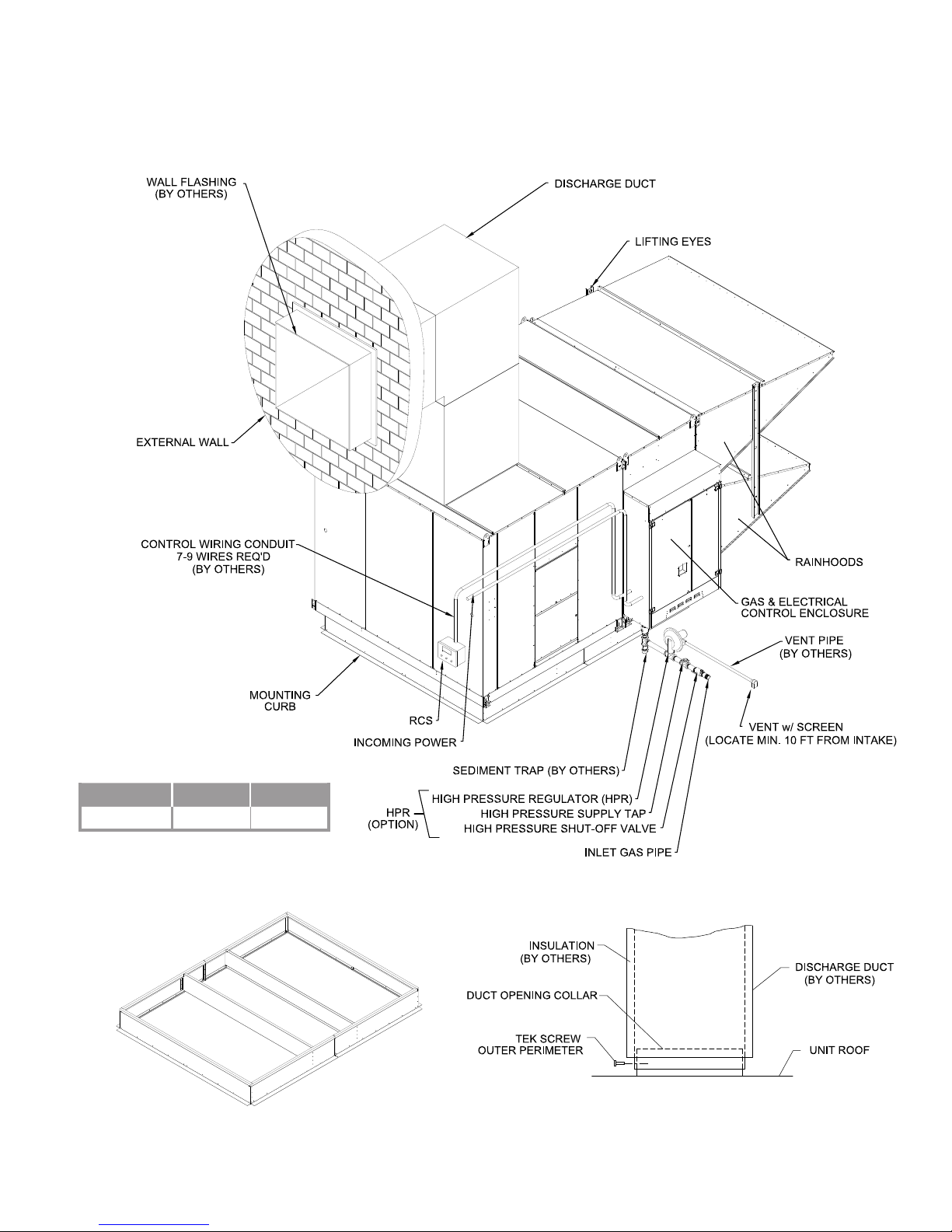

HORIZONTAL MOUNT - MOUNTING CURB

M110 - M136

(Shown for Roof Top Configuration - Downblast Application)

Cambridge Engineering, Inc. 8 M-Series Technical Manual

Model A B C

M110

M112

M115

M118

M120

M125

M130

M136

32.38" 27.12" 48"

32.38" 27.12" 48"

32.38" 40.31" 60"

32.38" 44.10" 60"

32.38" 50.26" 72"

37.88" 63.12" 84"

37.63" 84.81" 96"

37.88" 84.81" 96"

INSTALLATION INSTRUCTIONS

HORIZONTAL MOUNT - ROOF TOP CONFIGURATION

mWARNING:

Due to the size and weight of this equipment, it is

recommended that the heater support structure be

reviewed and approved by a qualified structural engineer and the roof manufacturer before installing this

equipment.

IMPORTANT

Before proceeding with the installation, verify the feasibility of the location selected with respect to accessibility to the equipment for service and maintenance

functions.

IMPORTANT

To minimize snow and rain ingestion, position the heater inlet opposite the prevailing wind.

mCAUTION:

To prevent contaminated air from being drawn into

the heater, install the heater’s inlet at least 10 feet

from any building exhaust, process exhaust, sewer

stacks, or other sources that would allow contaminants to be drawn into the heater. Consult local

codes for applicable building code provisions for

ventilation air.

IMPORTANT

For model M140 heaters, refer to the “Field Assembly

Instructions” worksheets included with this manual for

detailed heater assembly directions.

IMPORTANT

The roof curb or support structure should be installed such that the heater will sit level. Cambridge

Engineering recommends mounting the heater 24" off

the roof surface in areas where snow accumulation

could impact heater operation.

3. Lower the discharge duct through the roof opening.

4. Install the roof curb gasket.

5. Use a crane or comparable lifting device to raise

and position the equipment. Block the heater where

necessary. Use a spreader bar to prevent damage and

connect slings to the lifting eyes.

6. Caulk all joints of the heater’s accessories installed

in the field. Use a clear or gray latex based polyurethane caulking to prevent water leaks.

7. Seal all roof penetrations to prevent roof leaks.

8. Install the discharge plenum, where used, by screwing the plenum to the discharge duct. Install 4 hanging rods from the ceiling supports to the plenum’s

support brackets.

1. Prepare the roof for installation. (See pages 10-12

for roof opening dimensions for your specific

heater.) The gas and electrical connections must not

penetrate the unit base or mounting curb. Cambridge

Engineering recommends using pitch pockets or

decktite to seal the penetrations.

IMPORTANT

Accurate measurements are critical and will affect installation process.

2. Assemble and secure the roof curb to the support

structure per the recommendations of the structural

engineer and roof manufacturer.

M-Series Technical Manual 9 Cambridge Engineering, Inc.

TYPICAL INSTALLATION

HORIZONTAL MOUNT - ROOF TOP CONFIGURATION

M110 - M115

Roof Opening

Model W L

M110

M112

M115

19.25" 19.25"

20.75" 20.75"

23.5" 23.75"

Cambridge Engineering, Inc. 10 M-Series Technical Manual

Typical Curb and

Discharge Duct

Typical Curb and

Discharge Duct

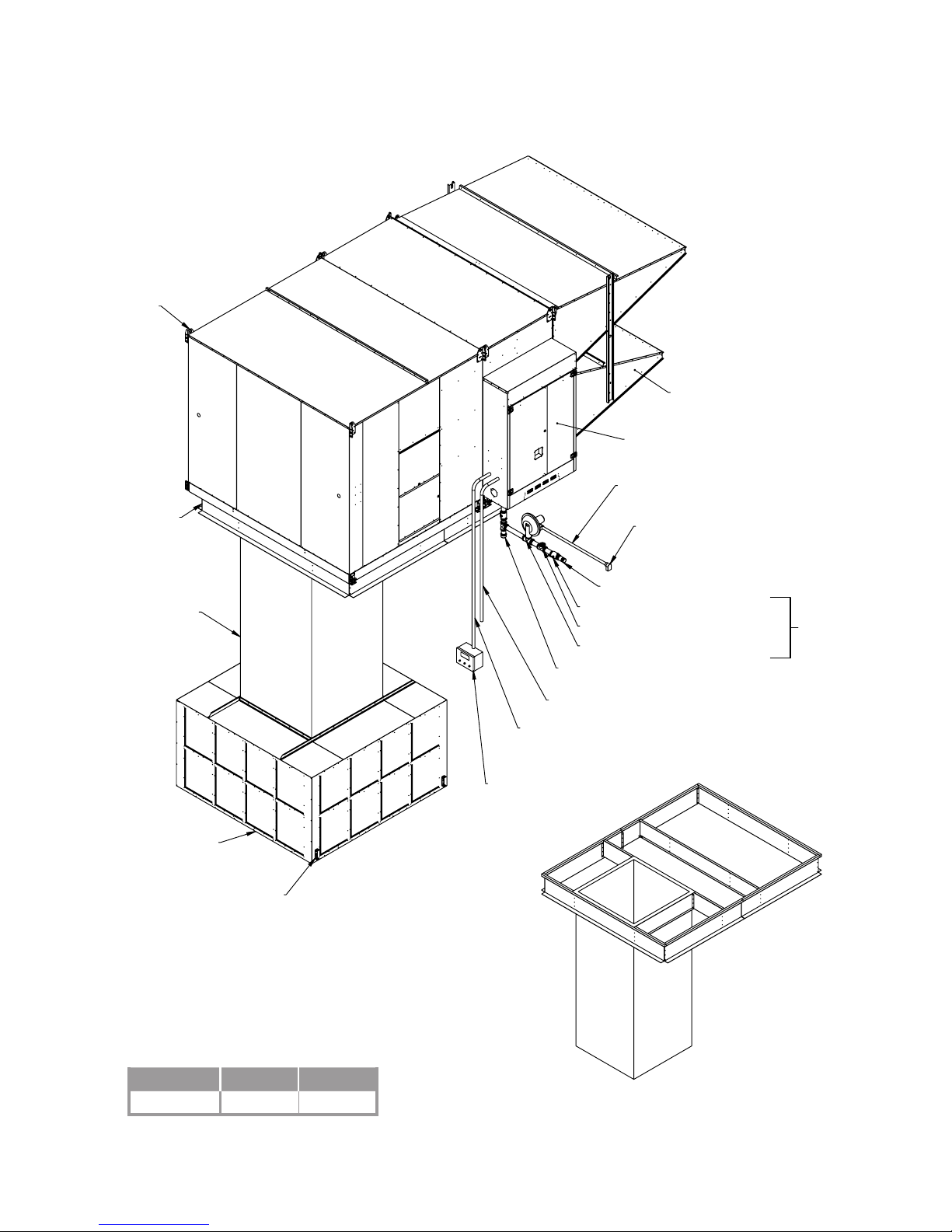

TYPICAL INSTALLATION

HORIZONTAL MOUNT - ROOF TOP CONFIGURATION

M118 - M136

GAS CONTROL

ENCLOSURE

RAINHOOD

LIFTING EYES

MOUNTING

CURB

DISCHARGE

HANGING

BRACKET

DUCT

DISCHARGE

PLENUM

INCOMING POWER

CONTROL WIRING CONDUIT

7-9 WIRES REQ'D

(BY OTHERS)

HIGH PRESSURE SUPPLY TAP

HIGH PRESSURE REGULATOR (HPR)

SEDIMENT TRAP (BY OTHERS)

RCS

ELECTRICAL CONTROL ENCLOSURE

VENT PIPE

(BY OTHERS)

VENT w/ SCREEN

(LOCATE MIN. 10 FT FROM INTAKE)

INLET GAS PIPE

HIGH PRESSURE SHUT-OFF VALVE

HPR

(OPTION)

Roof Opening

Model W L

M118

M120

M125

M130

M136

26.5" 26.5"

30.5" 30.5"

36" 36"

42" 42"

48" 48"

M-Series Technical Manual 11 Cambridge Engineering, Inc.

Typical Curb and

Discharge Duct

TYPICAL ROOF TOP INSTALLATION

TYPICAL INSTALLATION

HORIZONTAL MOUNT - ROOF TOP CONFIGURATION

M140

Lift Eyes

Rainhoods

Gas Control Enclosure

Vent Pipe (By Others)

Mounting Curb

Discharge Duct

Discharge Plenum

Hanger Bracket

Incoming Power

Control Wiring Conduit

7-9 Wires Req'd

(By Others)

RCS

Typical Curb and

Typical Curb and

Discharge Duct

Discharge Duct

Vent w/ Screen

(Locate Min 10 Ft from Intake)

Inlet Gas Pipe

High Pressure Shut-off Valve

High Pressure Supply Tap

High Pressure Regulator (HPR)

Sediment Trap (By Others)

HPR

(Option )

Roof Opening

Model W L

M140

55" 55"

Cambridge Engineering, Inc. 12 M-Series Technical Manual

INSTALLATION INSTRUCTIONS

HORIZONTAL MOUNT - OUTDOOR PAD MOUNT CONFIGURATION

IMPORTANT

mWARNING:

Due to the size and weight of this equipment, it

is recommended the heater support structure be

reviewed and approved by a qualified structural engineer before installing this equipment.

IMPORTANT

Before proceeding with the installation, verify the feasibility of the location selected for accessibility to the

equipment for service and maintenance functions.

IMPORTANT

To minimize snow and rain ingestion, position the

heater inlet opposite the prevailing wind.

mCAUTION:

To prevent contaminated air from being drawn into

the heater, install the heater’s inlet at least 10 feet

from any building exhaust, process exhaust, sewer

stacks, or other sources that would allow contaminants to be drawn into the heater. Consult local

codes for applicable building code provisions for

ventilation air.

Cambridge Engineering recommends mounting the

heater a minimum of 24" off the mounting surface in

areas where snow accumulation could impact heater

operation.

4. Caulk all joints of the heater’s accessories installed

in the field. Use a clear or gray latex based polyurethane caulking to prevent water leaks.

5. Install the discharge duct through the wall opening.

6. Install fiberglass insulation in the gaps between the

wall opening and discharge duct. Apply enough

insulation material to accommodate the full thickness of the wall.

7. Install finish trim pieces (by others) to the top, sides

and bottom of the discharge duct on both the inside

and outside wall surfaces.

8. Apply a bead of latex based polyurethane caulk that

best matches the color of the exterior wall surface

of the facility and/or the color of the heater accessories

at the joint between the top discharge duct and outside

wall surface. Make certain this is a continuous bead and

that it runs the entire width of the duct. Caulk all other

exposed joints.

IMPORTANT

For model M140 heaters, refer to the “Field Assembly

Instructions” worksheets included with this manual for

detailed heater assembly directions.

1. Prepare the wall for installation. (See pages 14-15

for wall opening dimensions for your specific

heater.)

IMPORTANT

Accurate measurements are critical and will affect installation process.

2. Assemble and secure the support structure per the

structural engineer’s recommendations.

IMPORTANT

The support structure should be installed such that the

heater will sit level.

3. Use a crane or comparable lifting device to raise and

position the equipment. Block the heater where

necessary. Use a spreader bar to prevent damage and

connect slings to the lifting brackets.

9. Install the discharge plenum, where used, by screwing the plenum to the discharge duct. Install hanging

rods from the ceiling supports to the plenum’s support brackets.

M-Series Technical Manual 13 Cambridge Engineering, Inc.

TYPICAL INSTALLATION

HORIZONTAL MOUNT - OUTDOOR PAD MOUNT CONFIGURATION

M118 - M136

Wall Opening

Model W L

M118

M120

M125

M130

M136

25.5" 25.5"

29.5" 29.5"

35" 35"

41" 41"

47" 47"

Typical Curb

Typical Duct Interface

Cambridge Engineering, Inc. 14 M-Series Technical Manual

TYPICAL INSTALLATION

HORIZONTAL MOUNT - OUTDOOR PAD MOUNT CONFIGURATION

M140

Wall Opening

Model W L

M140

54" 54"

TYPICAL CURB

M-Series Technical Manual 15 Cambridge Engineering, Inc.

Typical Duct Interface

INSTALLATION INSTRUCTIONS

HORIZONTAL MOUNT - THRU WALL CONFIGURATION

mWARNING:

Due to the size and weight of this equipment, it is

recommended that the heater support structure be

reviewed and approved by a qualified structural engineer before installing this equipment.

IMPORTANT

Before proceeding with the installation, verify the feasibility of the location selected with respect to accessibility to the equipment for service and maintenance

functions.

IMPORTANT

To minimize snow and rain ingestion, position the heater inlet opposite the prevailing wind.

mCAUTION:

To prevent contaminated air from being drawn into

the heater, install the heater’s inlet at least 10 feet

from any building exhaust, process exhaust, sewer

stacks, or other sources that would allow contaminants to be drawn into the heater. Consult local

codes for applicable building code provisions for

ventilation air.

4. Apply washers and double lock nuts to secure equipment on hanging rods. Note: The discharge end of

the heater should be raised slightly (1/8

to allow ingested moisture to drain from the heater.

5. Apply shims at the bottom of the rainhood to take up

slack in the opening, leaving a small joint between

the top of the heater and the wall.

6. Install fiberglass insulation in the gaps between the

wall opening and the inlet collar. Apply enough

material to accommodate the full thickness of the

wall.

7. Install finish trim pieces (by others) to the top, sides

and bottom of the inlet collar on both the inside and

the outside wall surfaces.

8. Apply a bead of latex based polyurethane caulk that

best matches the color of the exterior wall surface

of the facility and/or the color of the heater accessories

at the joint between the top inlet collar and outside wall

surface. Make certain this is a continuous bead and

that it runs the entire width of the collar. Caulk all other

exposed joints.

" above level)

1. Prepare the wall for installation. (See pages 17-18 for

wall opening dimensions for your specific heater.)

IMPORTANT

Accurate measurements are critical and will affect the

installation process.

2. Install heater support rods per the structural engineer’s recommendations.

3. Use a crane or comparable lifting device to raise and

position equipment. Block the heater where necessary. Use a spreader bar to prevent damage and connect slings to the lifting brackets.

IMPORTANT

Cambridge Engineering recommends mounting the

heater’s rainhood a minimum of 24" off the ground or

other surfaces.

9. Install the discharge plenum, where used, by screwing the plenum to the heater or to the discharge duct,

as applicable. Install hanging rods from the ceiling

supports to the plenum’s support brackets.

Cambridge Engineering, Inc. 16 M-Series Technical Manual

TYPICAL INSTALLATION

HORIZONTAL MOUNT - THRU WALL CONFIGURATION

M110 - M115

M-Series Technical Manual 17 Cambridge Engineering, Inc.

Wall Opening

Model W H

M110

M112

M115

32" 35.25"

32" 35.25"

46" 35.25"

TYPICAL INSTALLATION

HORIZONTAL MOUNT - THRU WALL CONFIGURATION

M118 - M136

Cambridge Engineering, Inc. 18 M-Series Technical Manual

Wall Opening

Model W H

M118

M120

M125

M130

M136

50" 55"

56" 55"

68" 71.75"

89.75" 71.75"

89.75 96.75"

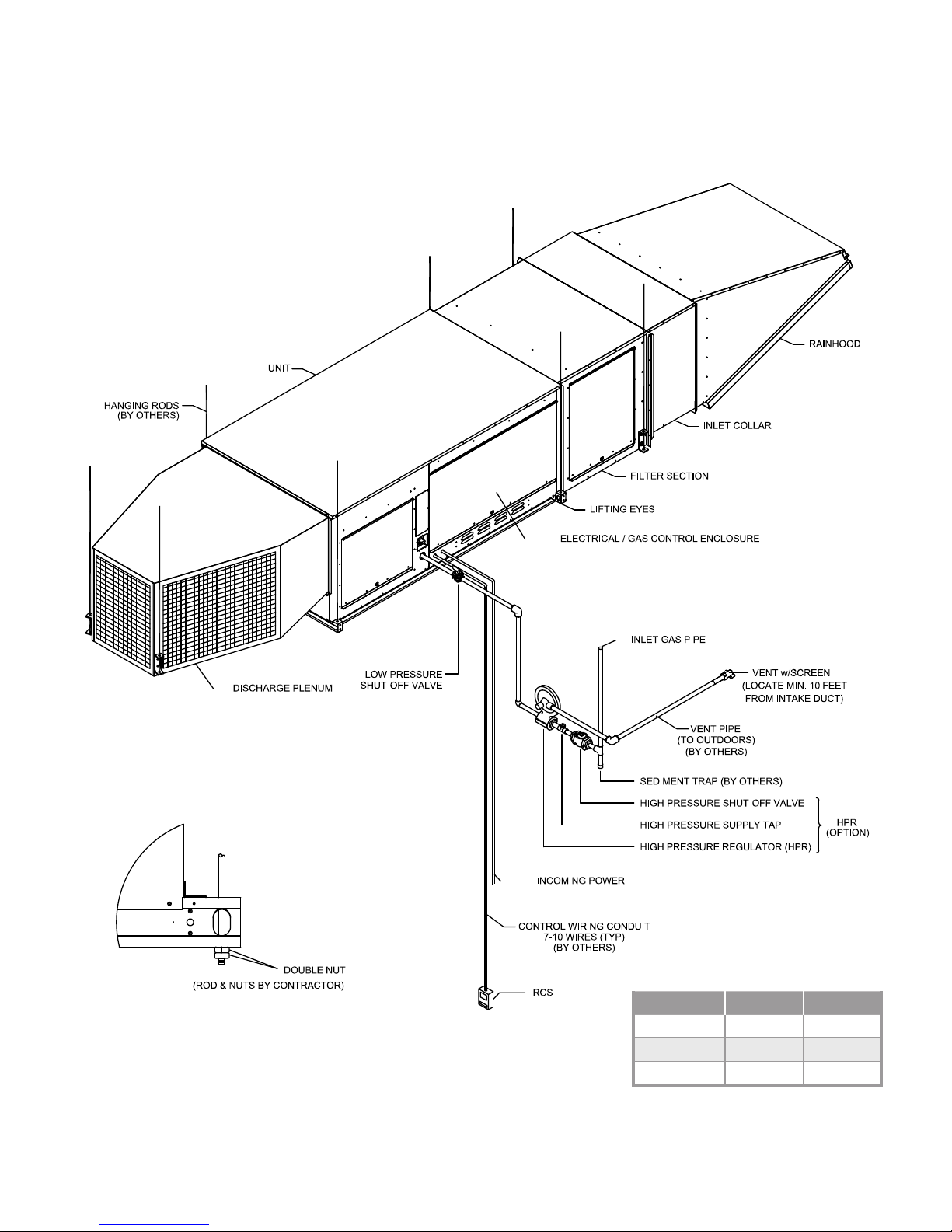

INSTALLATION INSTRUCTIONS

VERTICAL MOUNT - OUTDOOR CONFIGURATION

IMPORTANT

Before proceeding with the installation, verify the feasibility of the location selected with respect to accessibility to the equipment for service and maintenance

functions.

IMPORTANT

To prevent contaminated air from being drawn into the

heater, install the heater’s inlet at least 10 feet from

any building exhaust, process exhaust, sewer stacks,

or other sources that would allow contaminants to be

drawn into the heater. Consult local codes for applicable building code provisions for ventilation air.

IMPORTANT

This heater should be mounted on a concrete pad with

a minimum thickness of 4" and with length and width

dimensions that exceed the dimensions of the heater by

at least 5 feet (30" on each side). The pad should be

poured at least two weeks before installation begins to

permit proper curing. The pad should slope slightly

away from the building (approximately 1/4" per foot) to

avoid water collecting under the heater.

1. Prepare the wall for installation. (See pages 21-22

for opening dimensions for your specific heater.)

Accessory Identification drawings (see page 4) to

identify the locations of these sections.

IMPORTANT

Cambridge Engineering recommends mounting the

heater a minimum of 60" off the mounting surface

in areas where snow accumulation could impact the

heater operation.

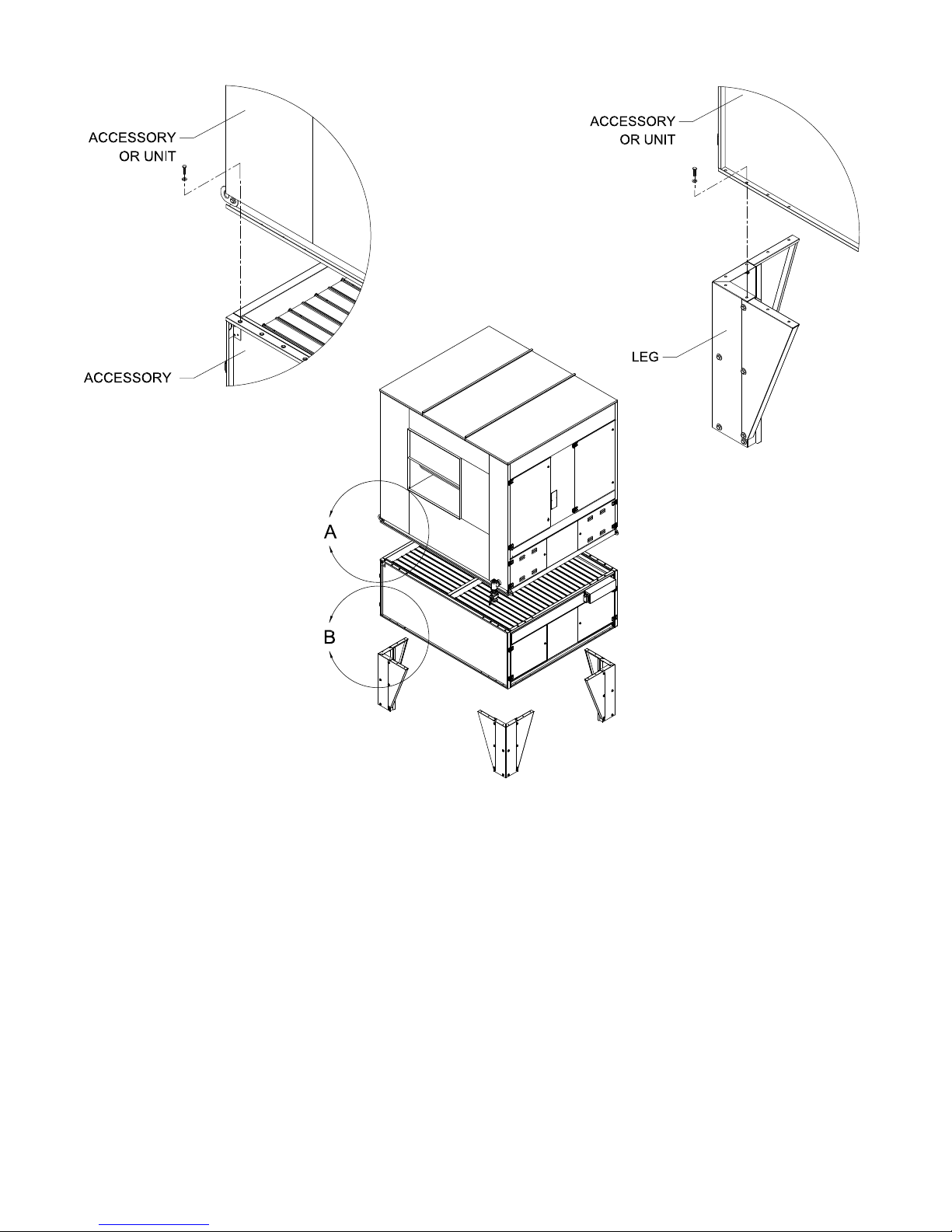

4. Attach each mounting leg to the inlet accessory (filter section, inlet damper, or filter section/inlet damper combo, as specified) using the 1/2"-13 x 1-1/2"

bolts. The bolts install downward through a clearance hole in the accessory into a threaded insert in

the mounting leg. Install all four legs on the accessory, then set this assembly in its intended position.

If no inlet accessory is specified, install the legs

directly to the heater. Level the assembly by placing

shims under the appropriate legs.

5. Position the heater on the inlet accessory. Secure

the heater using the 1/2"-13 x 1-1/2" bolts. The

bolts install downward through a clearance

hole in the heater into a threaded insert in the inlet

accessory.

6. Attach discharge duct to heater.

IMPORTANT

Accurate measurements are critical and will affect the

installation process.

2. Install the discharge duct through the wall opening.

3. Use a crane or comparable lifting device to raise and

position the equipment. Block the heater where necessary. Use a spreader bar to prevent damage and

connect slings to the lifting eyes.

The Vertical Mount heaters may be shipped in

sections due to shipping constraints. Review the

M-Series Technical Manual 19 Cambridge Engineering, Inc.

7. Caulk all joints of the heater’s accessories installed

in the field. Use a clear or gray latex based polyurethane caulking to prevent water leaks.

8. Install fiberglass insulation in the gaps around the

wall opening and discharge duct. Apply enough

insulation material to accommodate the full thickness

of the wall.

9. Install finish trim pieces (by others) to the top, sides

and bottom of the discharge duct on both the inside

and outside wall surfaces.

DETAIL A

DETAIL B

10. Apply a bead of latex based polyurethane caulk that

best matches the color of the exterior wall surface

of the facility and/or the color of the heater accessories at the joint between the top discharge duct and

outside wall surface. Make certain this is a continuous bead and that it runs the entire width of the duct.

Caulk all other exposed joints.

Cambridge Engineering, Inc. 20 M-Series Technical Manual

11. Install the discharge plenum by screwing the plenum

to the discharge duct. Install hanging rods from ceiling supports to the plenum’s support brackets.

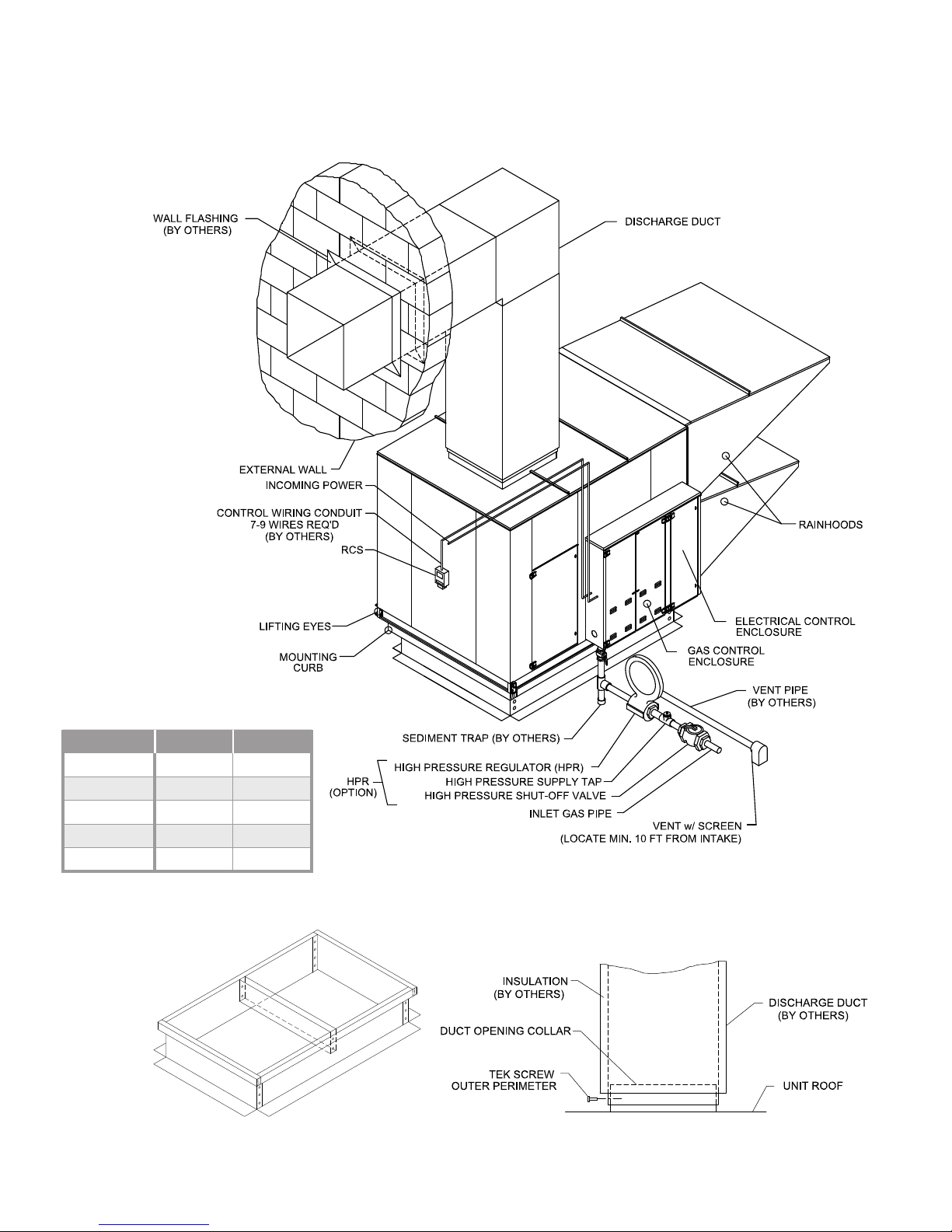

TYPICAL INSTALLATION

HIGH PRESSURE REGULATOR (HPR)

VERTICAL MOUNT - OUTDOOR CONFIGURATION

HORIZONTAL BLAST

M118 - M136

LIFTING

BRACKETS

EXTERNAL WALL

WALL FLASHING

(BY OTHERS)

CONTROL WIRING CONDUIT

7-9 WIRES REQ'D

(BY OTHERS)

Wall Opening

Model W H

M118

M120

M125

M130

M136

RCS

INCOMING

POWER

25.5" 25.5"

29.5" 29.5"

35" 35"

41" 41"

47" 47"

SEDIMENT TRAP

(BY OTHERS)

VENT PIPE

(BY OTHERS)

INLET GAS PIPE

HIGH PRESSURE SHUT-OFF VALVE

HIGH PRESSURE SUPPLY TAP

VENT w/ SCREEN

(LOCATE MIN.

10 FT FROM INTAKE)

HPR

(OPTION)

M-Series Technical Manual 21 Cambridge Engineering, Inc.

TYPICAL INSTALLATION

(OPTION)

VERTICAL MOUNT - OUTDOOR CONFIGURATION

UP BLAST

M118 - M136

DISCHARGE DUCT

DISCHARGE ELBOW

W/ TURNING VANES

DISCHARGE DUCT

Model W H

M118

M120

M125

M130

M136

Wall Opening

25.5" 25.5"

29.5" 29.5"

35" 35"

41" 41"

47" 47"

WALL FLASHING

(BY OTHERS)

EXTERNAL WALL

RCS

CONTROL WIRING CONDUIT

7-9 WIRES REQ'D

(BY OTHERS)

INSULATION

DUCT OPENING COLLAR

TEK SCREW

OUTER PERIMETER

INCOMING

POWER

SEDIMENT TRAP

(BY OTHERS)

DISCHARGE DUCT

UNIT ROOF

LIFTING BRACKETS

VENT PIPE

(BY OTHERS)

VENT w/ SCREEN

(LOCATE MIN. 10 FT

FROM INTAKE)

INLET GAS PIPE

HIGH PRESSURE SHUT-OFF VALVE

HIGH PRESSURE SUPPLY TAP

HIGH PRESSURE REGULATOR (HPR)

HPR

Cambridge Engineering, Inc. 22 M-Series Technical Manual

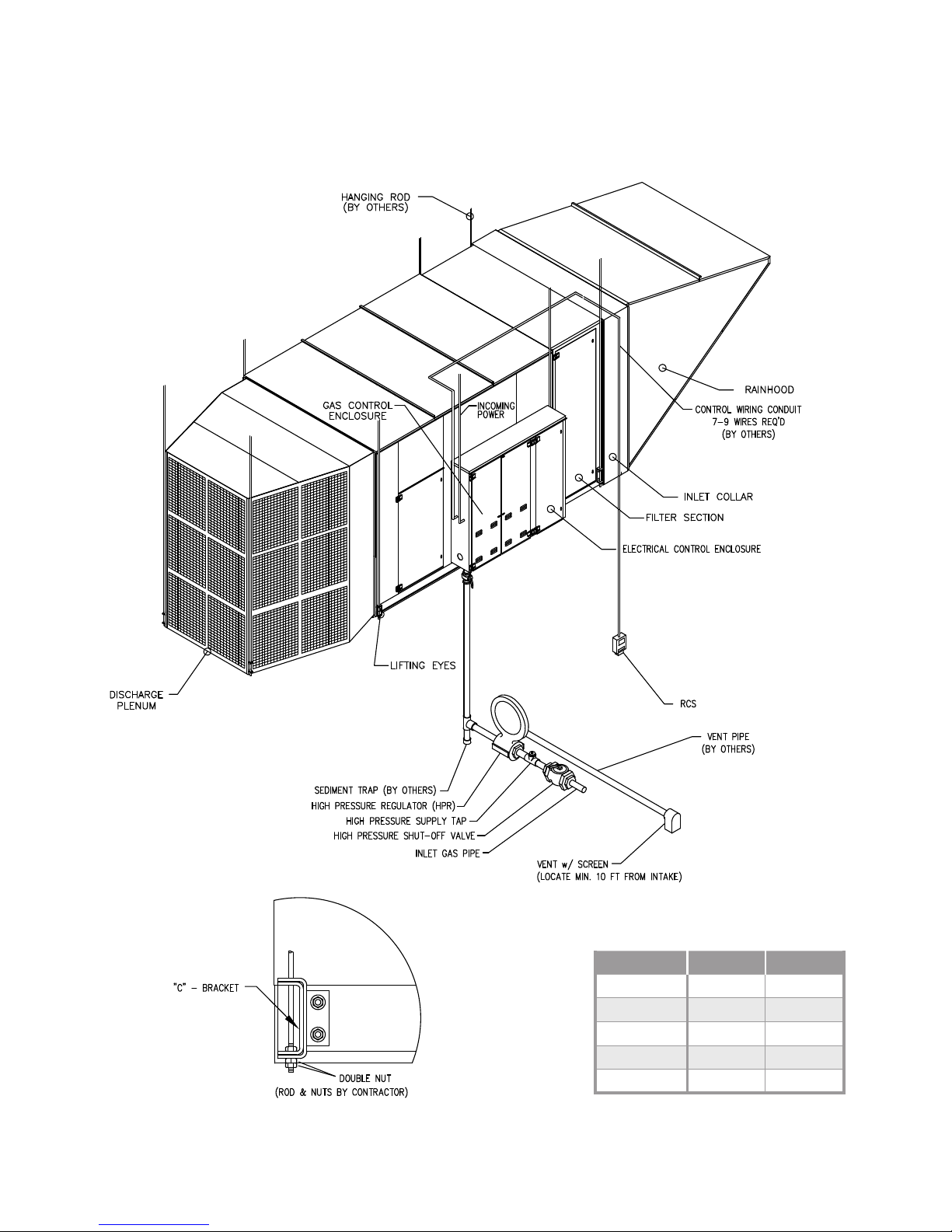

INSTALLATION INSTRUCTIONS

VERTICAL MOUNT - INDOOR CONFIGURATION

IMPORTANT

Before proceeding with installation, verify the feasibility of the location selected with respect to accessibility

to the equipment for service and maintenance functions.

IMPORTANT

To prevent contaminated air from being drawn into the

heater, install the heater’s inlet at least 10 feet from

any building exhaust, process exhaust, sewer stacks,

or other sources that would allow contaminants to be

drawn into the heater. Consult local codes for applicable building code provisions for ventilation air.

1. Prepare the wall for installation. (See page 25 for

opening dimensions for your specific heater.)

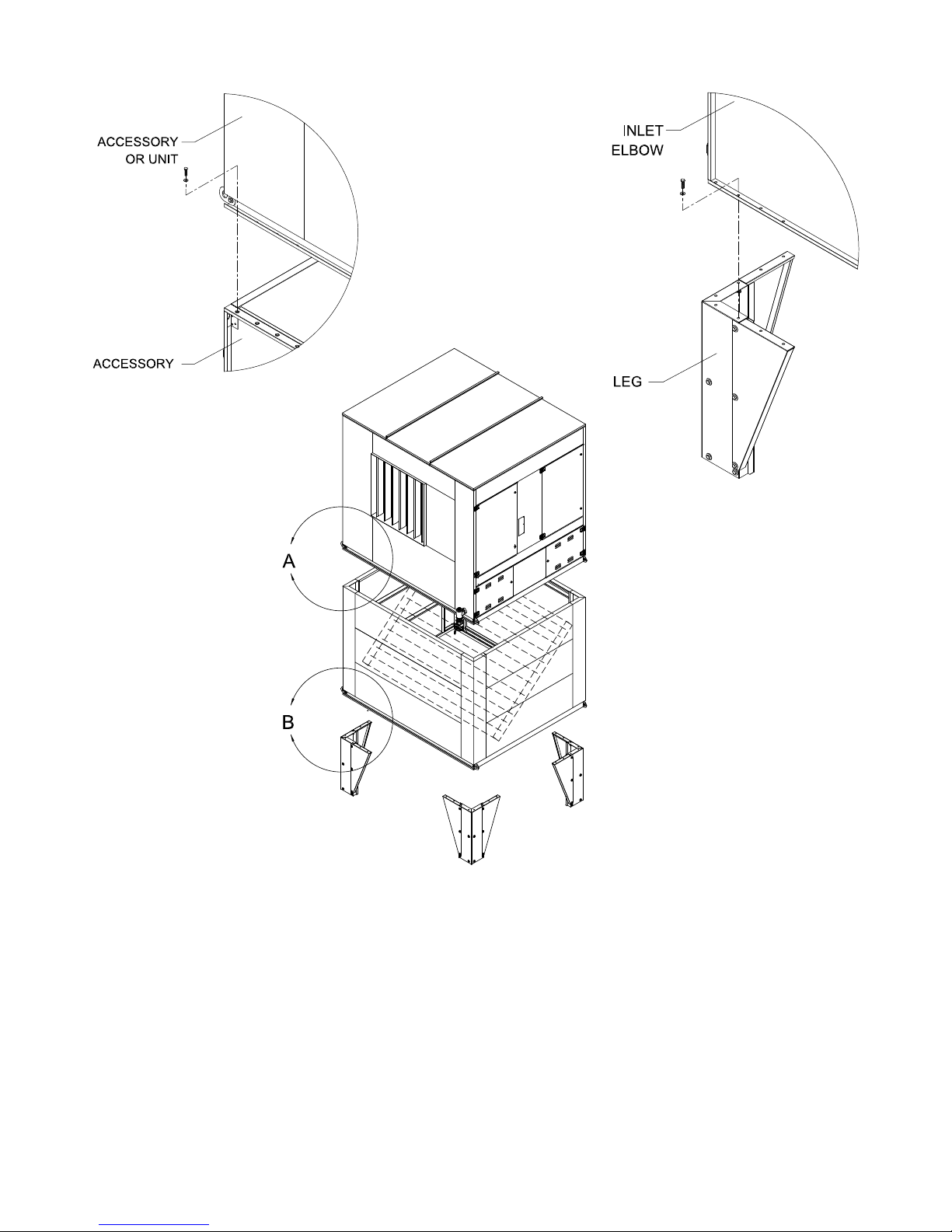

4. Attach each Mounting Leg to the inlet elbow using

the 1/2"-13 x 1-1/2" bolts. The bolts install downward through a clearance hole in the accessory into

a threaded insert in the Mounting Leg. Install all

four legs on the accessory, and then attach the inlet

collar to the inlet elbow using the 5/16"-18 x 1/2"

bolts. Position this assembly with the inlet collar

situated through the wall. Level the assembly by

placing shims under the appropriate legs.

5. Position the next inlet accessory, if specified, on

the inlet elbow, and then secure them to each other

using the 1/2"-13 x 1-1/2" bolts. The bolts install

downward through a clearance hole in the upper

accessory into a threaded insert in the inlet elbow.

IMPORTANT

Accurate measurements are critical and will affect the

installation process.

2. Install heater support rods per the structural engineer’s recommendations.

3. Use a crane or comparable lifting device to raise and

position the equipment. Block the heater where necessary. Use a spreader bar to prevent damage and

connect slings to the lifting eyes.

The Vertical Mount heaters may be shipped in

sections due to shipping constraints. Review the

Accessory Identification drawings (see page 4) to

identify the locations of these sections.

IMPORTANT

Cambridge Engineering recommends mounting the

heater’s rain hood a minimum of 60" off the ground or

other surfaces in areas where snow accumulation could

impact operation.

6. Position the heater on the last inlet accessory.

Secure the heater using the 1/2"-13 x 1-1/2" bolts.

The bolts install downward through a clearance hole

in the heater into a threaded insert in the inlet accessory.

7. Attach the rain hoods to the inlet collar using the

5/16"-18 x 1/2" bolts.

8. Install fiberglass insulation in the gaps around the

wall opening and inlet collar. Apply enough insulation material to accommodate the full thickness of

the wall.

9. Install finish trim pieces (by others) to the top, sides

and bottom of the inlet collar on both the inside and

outside wall surfaces.

M-Series Technical Manual 23 Cambridge Engineering, Inc.

DETAIL A

DETAIL B

10. Apply a bead of latex based polyurethane caulk that

best matches the color of the exterior wall surface of

the facility and/or the color of the heater accessories

at the joint between the top inlet collar and outside

wall surface. Make certain this is a continuous bead

and that it runs the entire width of the collar. Caulk

all other exposed joints.

Cambridge Engineering, Inc. 24 M-Series Technical Manual

11. Install the discharge plenum by screwing the plenum

to the heater. Install hanging rods from the ceiling

supports to the plenum’s support brackets.

Loading...

Loading...