CAMBRIDGE DL-CSW-10AT-LFT Installation, Setup And Operation

2

TABLE OF CONTENTS

Specifications-------------------------------------------------------3

Owner’s Information-----------------------------------------------4

Parts Description----------------------------------------------------5

Unpacking your Scale----------------------------------------------5

Equipment Needed for Installation-------------------------------6

Installation: Scale Section-----------------------------------------6-7

Installation: CSW-10AT-LFT Meter & Bracket---------------------8-9

Meter Connections-------------------------------------------------10

Operation------------------------------------------------------------11

1.0 Scale Procedure------------------------------------------------12

1.1 Software Navigation Flowchart-------------------------12-13

1.2 Navigation Keys-------------------------------------------13

1.3 Scale Menu Definitions-----------------------------------14-15

1.4 Numeric Entries---------------------------------------------------16

1.5 Set Up Parameters------------------------------------------------16

2.0 Calibration Procedures------------------------------------------------17

2.1 Calibration Menu Definitions-----------------------------------17

2.2 Calibration---------------------------------------------------------18

2.3 Linearity Calibration---------------------------------------------18

3.0 Communications Setup------------------------------------------------19

3.1 Communications Menu Definitions----------------------------19-20

4.0 Testing Procedure------------------------------------------------------21

4.1 Testing Menu Definitions----------------------------------------21

5.0 Warranty----------------------------------------------------------------22

6.0 Assistance--------------------------------------------------------------22

3

SPECIFICATIONS

Model CSW-10AT-LFT Electronic Lift Truck Scale:

Accuracy: .01% of applied load.

Operating Temperature: 14 to 140 deg. F (-10 to 60 deg. C)

Overload: 500% of Rated Capacity.

Capacity: 5,000 Pounds.

Meter: CSW-10AT-LFT with:

- .56 inch led display

- RS-232 Port for peripheral Device

- Mounting Hardware

- Operator Friendly

Warranty: Twelve (12) month Warranty against defect in

workmanship and/or materials

4

topNew Text

OWNERS INFORMATION

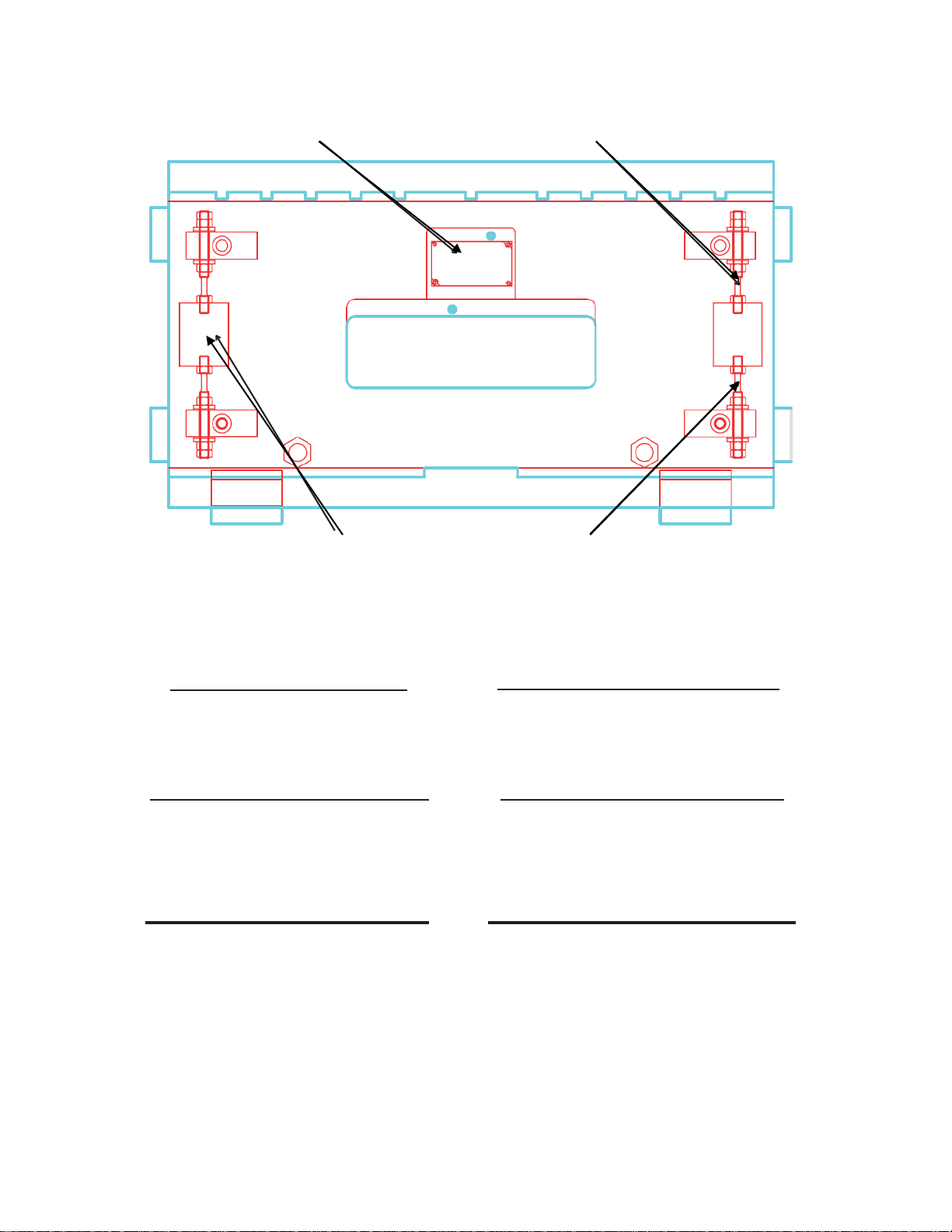

Junction Box Top Flexure Rod

Load Cell Bottom Flexure Rod

Meter Serial Number: Scale Section Serial Number:

#1 Load Cell Serial Number: #2 Load Cell Serial Number:

Scale Capacity and Graduation

Capacity: X Graduation: lbs

5

PARTS DESCRIPTION

SCALE SECTION

The scale section attaches to the lift truck carriage and you will install your

existing forks to the front of it. The scale section detects the weight of the load.

The weight of the load is then sent to the CSW-10AT-LFT Meter through the signal

cable.

CSW-10AT-LFT METER

The CSW-10AT-LFT Meter converts the weight from the scale section into

an accurate digital weight and displays it. Additionally, the CSW-10AT-LFT

sends data/information to peripheral devices. Mounting hardware is also

provided for the CSW-10AT-LFT so that it may be mounted to your fork truck

in either the dash mount or overhead mount.

UNPACKING YOUR SCALE

Your CAMBRIDGE Lift Truck Scale is shipped on a pallet. A Lift Truck Scale

system includes the following components:

1) One Scale Section to attach to the forklift carriage with bottom cleats.

2) One Signal Cable (coil).

3) One Power Cable.

4) One Electronic Meter (CSW-10AT-LFT) with mounting hardware.

5) One Cable Protection Guard - attached to the scale section.

6) Ten 5 1/2 inch wire ties.

7) Ten 21 inch wire ties.

Upon receipt of your scale system, please inspect to make sure the above parts

are present in your shipment.

6

EQUIPMENT NEEDED FOR INSTALLATION

Prior to installing your lift truck scale, gather all equipment (listed below)

needed to complete the installation;

- 1/2-inch hex allen wrench for removing and reinstalling the bottom cleats

- 1-1/2 inch open end wrench for adjusting the carriage adjustment bolts and

tightening the nuts of the carriage adjustment bolts

- Cutting pliers for cutting the wire ties

- Adjustable wrench (10-inch) for installing the cable protection guard

- 5/16-inch hex allen wrench for removing and installing fork stops

- 4-inch grinder

INSTALLATION: SCALE SECTION

NOTE: The Scale Section is shipped with the carriage adjustment bolts backed

out. You must adjust the carriage adjustment bolts. Improper installation

of the scale section causes most weighing problems. When installing the

the scale section keep the following in mind.

1) Scale section must touch the carriage at four points.

2) Scale section must be as parallel as possible to the carriage.

3) Scale section must not rock, swing, or slide in any direction.

INSTALLATION:

1) Remove forks from your existing truck. Remove backrest if required

2) Make sure the carriage face is not too rough; if it is, use the grinder

over any uneven areas.

3) Remove the bottom cleats from the scale section using the 1/2 inch

hex allen wrench.

4) Remove the cable protection guard and bolt. Install the lifting eye provided.

This allows you to lift the complete scale for installation.

7

INSTALLATION: SCALE SECTION-Continued

5) Attach the scale section to the existing carriage. The top cleats of the scale

will hold it to the carriage.

6) Make sure the top cleats are seated solid on the top of the carriage. The

center stop pin should also be seated solid in the center notch of the carriage.

7) Raise the carriage and adjust the carriage adjustment bolts so that both

bolts touch the plate of the carriage and daylight can be seen between

the scale section and the carriage face. (lock down the bolts with locking

nuts, 1 1/2-inch). Make sure the bolts are tight.

8) Install the bottom cleats provided with your system. Make sure they are

tight. There must be daylight showing on the back and bottom of the

cleats. No part of the cleat should touch the bottom of the carriage. If

this happens, repeatability will be affected. Corrective action would be

to install washers between the cleat and scale back plate to provide a

clearance gap.

9) Remove the fork stops and attach the forks to the front of the scale.

10) Reinstall the fork stops.

11) Remove the lifting eye and reinstall the cable protection guard and bolt.

The scale section installation is now complete.

Loading...

Loading...