Cambridge BLOW-THRU, DIRECT GAS-FIRED INDUSTRIAL BLOW-THRU User Manual

S-SERIES

®

DIRECT GAS-FIRED

INDUSTRIAL BLOW-THRU® SPACE HEATER

TECHNICAL MANUAL

mWARNING:

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating, and maintenance instructions

thoroughly before installing or servicing this equipment.

FOR YOUR SAFETY

The use and storage of gasoline or other flammable vapors and liquids in open containers

in the vicinity of this appliance is hazardous.

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

Made in the USA

ASHRAE

ASHRAE

90.1

COMPLIANT

COMPLIANT

®

S-TM8-0120

S-SERIES

BLOW-THRU

®

SPACE HE ATER

TECHNICAL MANUAL

LIMITED WARRANTY

Cambridge Air Solutions' Limited Warranty is included within the Terms and Conditions that are sent

with every Order Acknowledgement. For questions regarding Limited Warranty, contact Cambridge Air

Solutions' Customer Service Group at 1-800-473-4569.

Copyright © 2020

Cambridge Air Solutions

All Rights Reserved

Cambridge Air Solutions

760 Long Road Crossing Dr.

Chesterfield, MO. 63005

Phone: (636) 532-2233, (800) 899-1989

Fax: (636) 530-6133

www.cambridgeair.com

CONTENTS

Hazard Summary ................................................2

Typical System Overview ................................... 3

AccessoryIdentication .............................3

Heater Operation ........................................ 5

HeaterConguration .................................. 5

Installation Instructions ....................................... 6

Uncrating Instructions ................................ 6

Mounting Location .....................................6

Roof Top Mounting -

Curb / Stand / Rail......................................7

Roof Top / Thru Wall Mounting -

Stand / Rail ................................................. 8

Under Roof Mounting - Curb ....................8

Roof Top Mounting ....................................9

Thru Wall Mounting .................................11

Roof Top / Thru Wall Mounting ..............13

Under Roof Mounting .............................. 15

Vertical Indoor Mounting ......................... 17

Vertical Outdoor Mounting ...................... 19

Vertical S-Series

Structural Inlet Elbow .............................. 21

Vertical S-Series Structural

Non-Adjustable Elbow .............................25

Vertical S-Series Adjustable Stand ...........27

Vertical S-Series 3', 4', &5'

Duct Extensions .......................................30

Vertical S-Series Adjustable Elbow .........32

Vertical S-Series Structural

Filter Section ............................................ 34

S-Series 24", 38", & 50"

Wall Sleeves ............................................. 37

S-Series Downturn With Lugs ................ 39

S-Series Upturn ....................................... 41

Horizontal S-Series 4’

Mounting Stand .......................................43

Vertical Inlet Skirt ................................... 46

Rain Hood Inlet Skirt .............................. 47

Unit Inlet Skirt .........................................48

Gas Piping ................................................ 49

Electrical Wiring .....................................50

Remote Control Station and Temperature

Sensor Locations ...................................... 51

Thermistor Sensor .................................... 53

Start-Up Instructions ......................................... 54

Calibration Procedures ..................................... 60

Operating Instructions ....................................... 63

Operating Sequence .................................63

Electronic Thermostat .............................. 64

TSS Controller ........................................66

Bacnet Controller ..................................... 75

Maintenance Instructions .................................. 79

Troubleshooting Instructions ............................83

Troubleshooting Guide ............................83

Damper Motor Replacement

& Adjustment ........................................... 89

Reference ..........................................................91

Electrical Control Enclosure

Isometric Drawing ...................................91

Electrical Wiring Diagrams .....................92

Remote Control Station Electrical

Connection Diagram ...............................97

Building Automation System ................... 98

Gas Train Drawings .................................99

Individual Component

Descriptions ...........................................103

ANSI/ASHRAE/IESNA

Standard 90.1 .........................................109

Maintenance Log ............................................ 110

QR Code.......................................................... 113

HAZARD SUMMARY

Hazard Identification

Warnings and Cautions appear at appropriate sections throughout this manual. Read these carefully.

mWARNING: Indicates a potentially hazardous situation which could result in

death or serious injury.

CAUTION: Indicates a situation that may result in accidents with equipment or

mCAUTION: Indicates a potentially hazardous situation which may result in

minor or moderate injury. It may also be used to alert against

unsafe practices.

property damage only.

The following safety precautions apply to the

installation, operation, and maintenance of the

equipment described by this technical manual.

mWARNING:

Any unauthorized modification of this equipment

shall void the warranty.

mWARNING:

Only qualified personnel should attempt

installation, service, and repair of this equipment.

Use extreme caution and observe safety

regulations at all times.

mWARNING:

Recirculation of room air is not permitted.

Adequate building relief must be provided so as to not

over pressurize the building when the heating system

is operating at its rated capacity. It should be noted

that this can be accomplished by taking into account,

through standard engineering methods, the structure’s

designed infiltration rate, by providing properly sized

relief openings, or by interlocking a powered exhaust

system, or by a combination of these methods.

If the failure or malfunction of this heater creates

a hazard to other fuel burning equipment in the

building, (e.g. when the heater is providing the makeup air to a boiler room), the unit is to be interlocked to

open inlet air dampers or other such devices.

If the heater is installed such that an inlet duct is

utilized, the duct system must be purged with at least

four air changes prior to an ignition attempt.

Installation in Aircraft Hangars

Refer to the Standard for Aircraft Hangars,

ANSI/NFPA 409, for specific information on

the installation requirements for these heaters in

aircraft hangars.

Installation in Parking Garages

Refer to the Standard for Parking Structures,

ANSI/NFPA 88A, or the Standard for Repair

Garages, ANSI/NFPA 88B, for specific

information on the installation requirements for

these heaters in public

Installation in Car Wash Facilities

A non-recirculating, S-Series Space Heater used in

a Car Wash tunnel application may be designated

as a T-Series Heater on the nameplate.

This S-Series Technical Manual also applies to all

T-Series Heaters.

If in doubt regarding installation application, contact

Cambridge Customer Service Group at 1-800-4734569 during the hours of 8:00 a.m. to 5:00 p.m.

Central Time, Monday through Friday.

garages.

IMPORTANT

Cambridge Air Solutions 2 S-Series Technical Manual

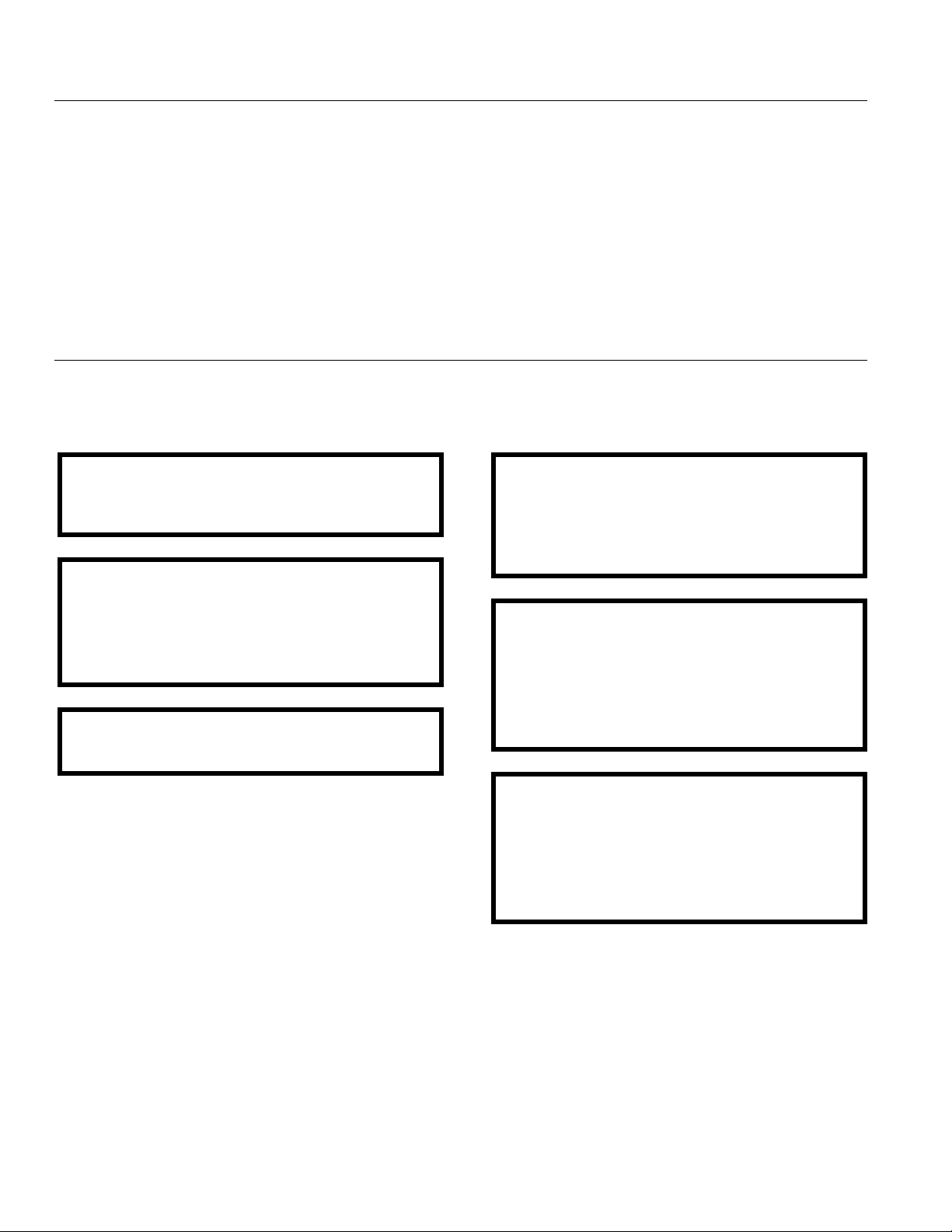

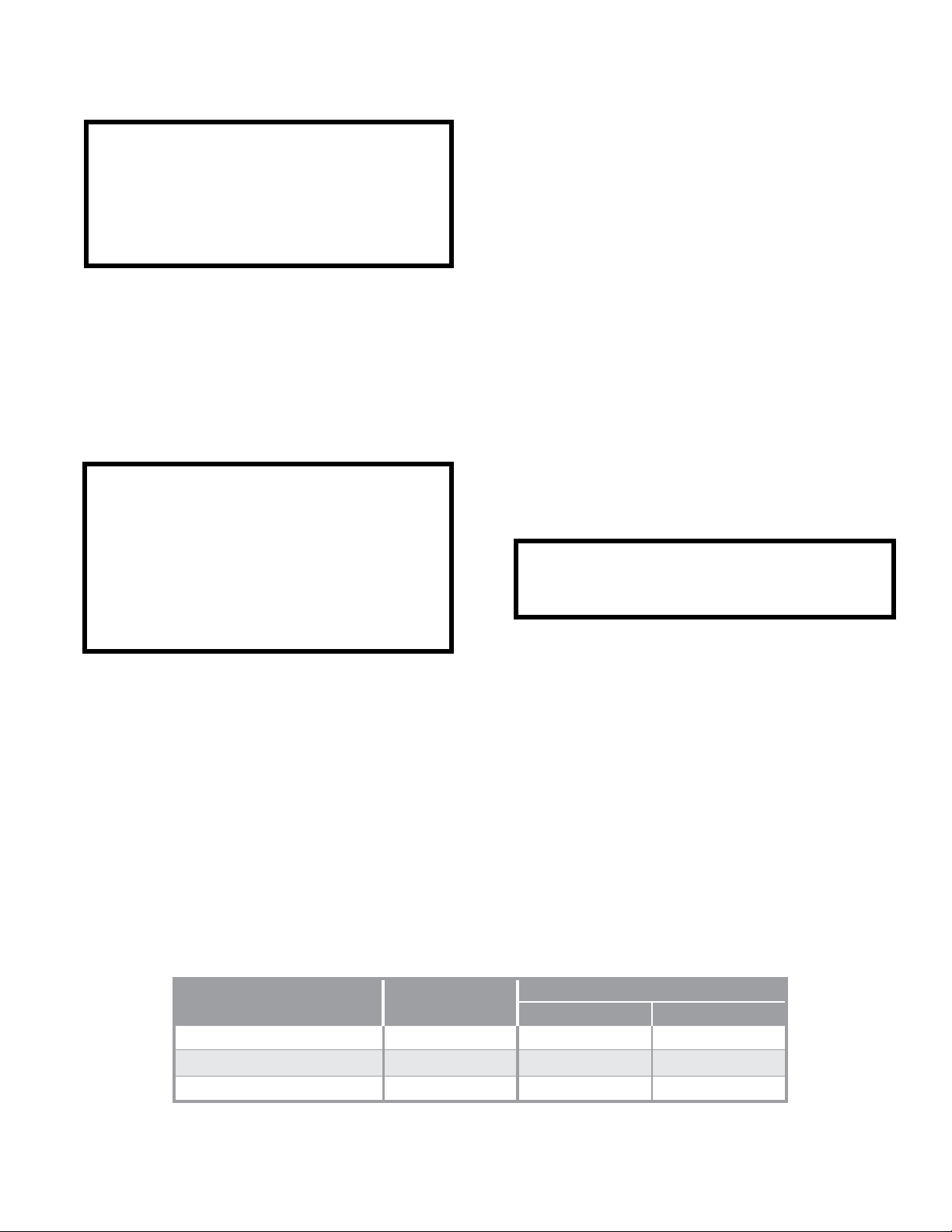

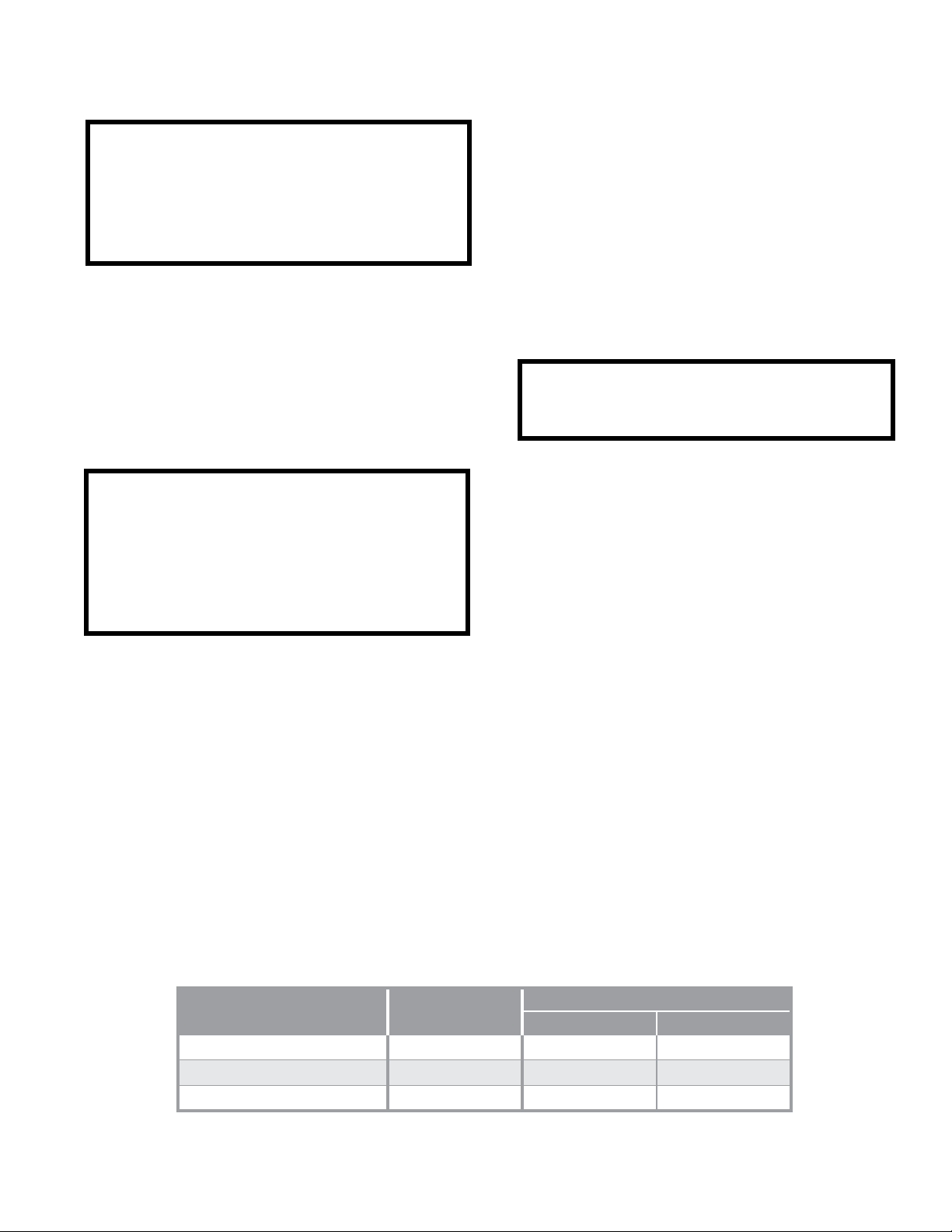

TYPICAL SYSTEM OVERVIEW

RH-RT

MDD

DT

UNIT

C

DE

DE

IP

ISU

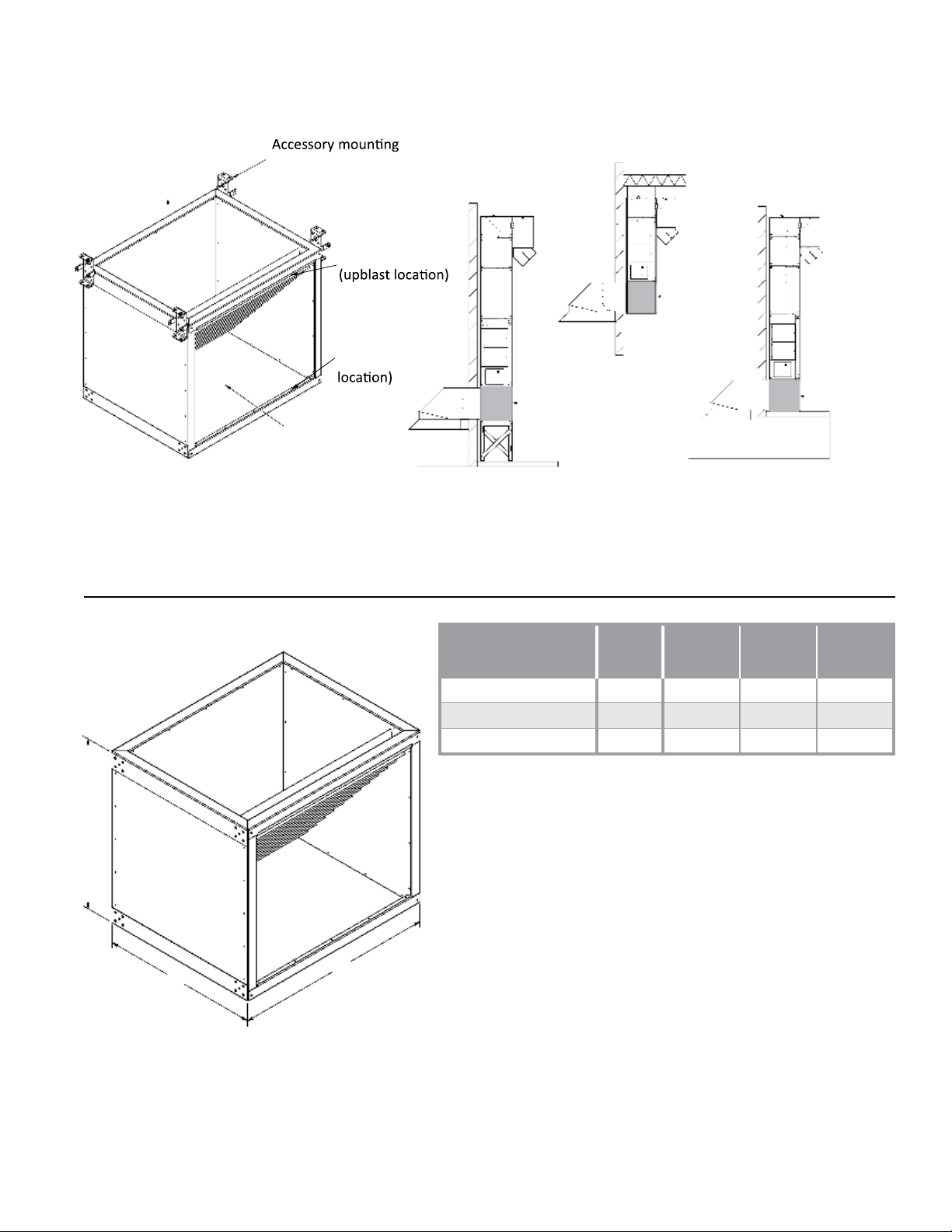

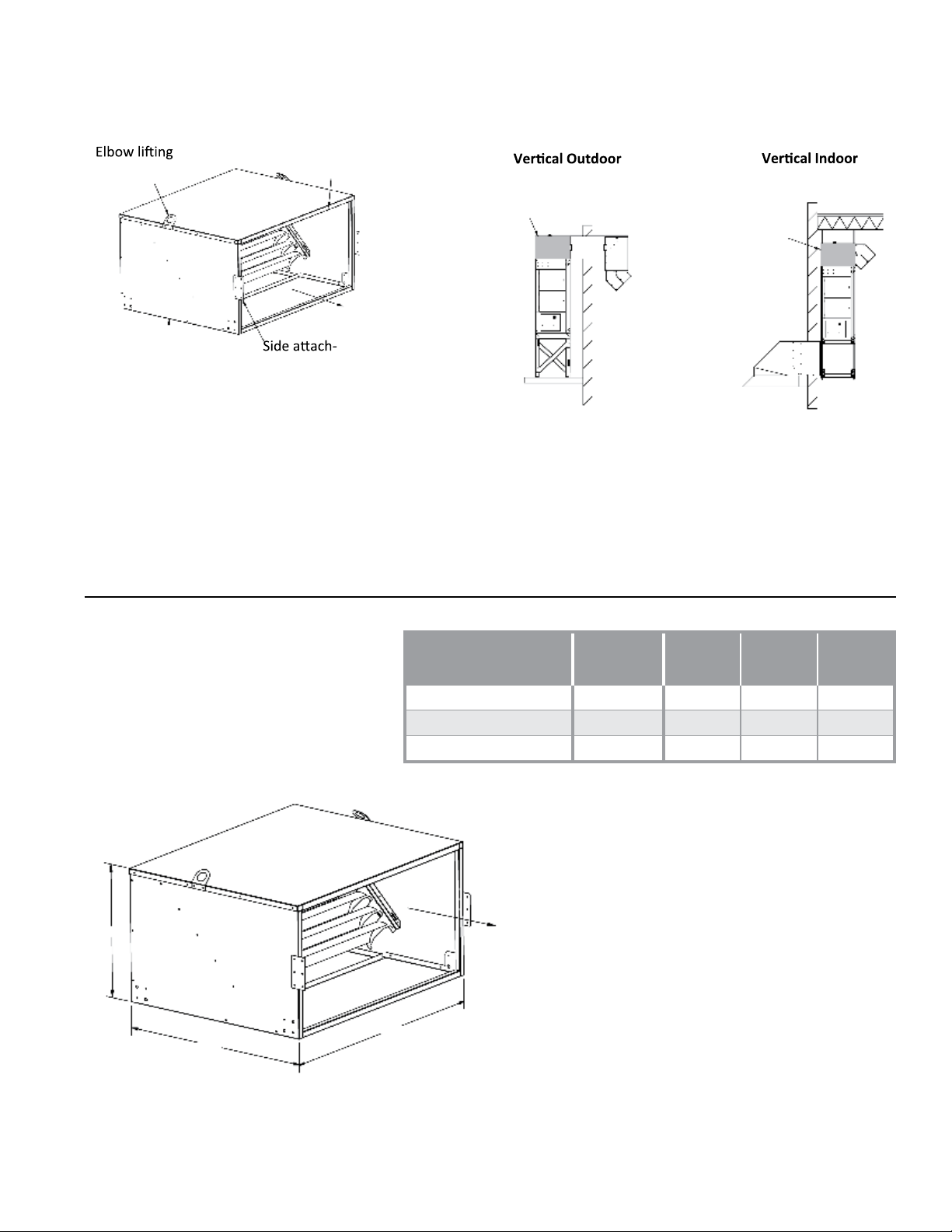

ACCESSORY IDENTIFICATION

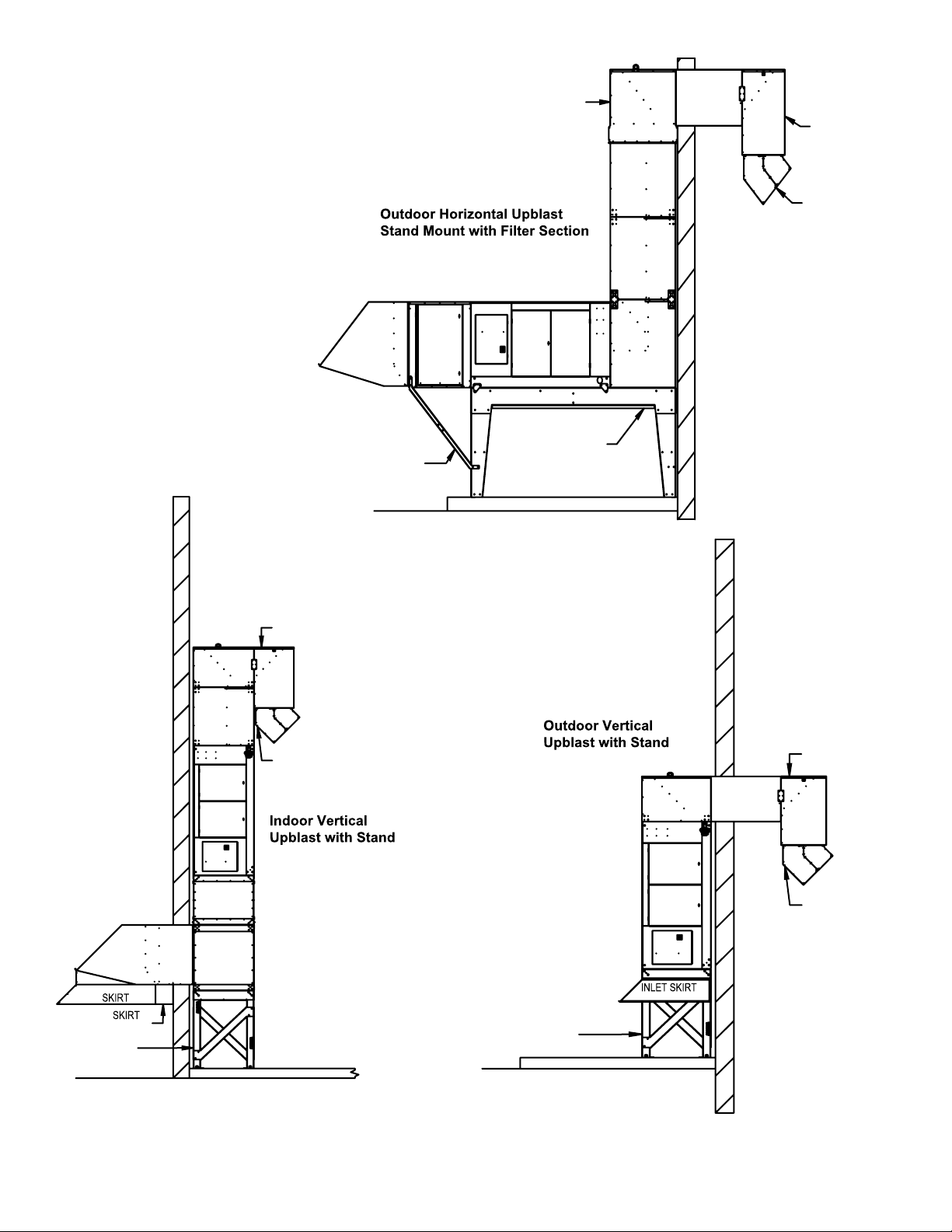

Under Roof Mounting

RH-TW

ISR

Roof Top Mounting

AMS

MR

DD

DE

Thru Wall Mounting

MC

ID

MDD

M

IE

UNIT

DT

Outdoor Vertical Mounting

MDD

UNITFS

DT

DT

MDD

UNIT

WALL SLEEVE

(BY OTHERS)

DT

DE

Roof Top / Thru Wall Mounting

RH-RT

AMS

Component Identification

AMS Adjustable Mounting Stand

DD Discharge Duct

DE Directional Elbows

DT Downturn

FS Filter Section

ID Inlet Duct

IE Inlet Elbow

IP Inlet Plenum

ISR Inlet Skirt-Rain Hood

ISU Inlet Skirt-Unit

MC Mounting Curb

MDD Motorized Discharge Damper

MR Mounting Rail

RH-RT Rain Hood-Roof Top

RH-TW Rain Hood-Thru Wall

UNIT

MDD

MR

WALL SLEEVE

(BY OTHERS)

DT

DE

Indoor Vertical Mounting

DT

DT

UNIT

RH-TW

IE

ISR

S-Series Technical Manual 3 Cambridge Air Solutions

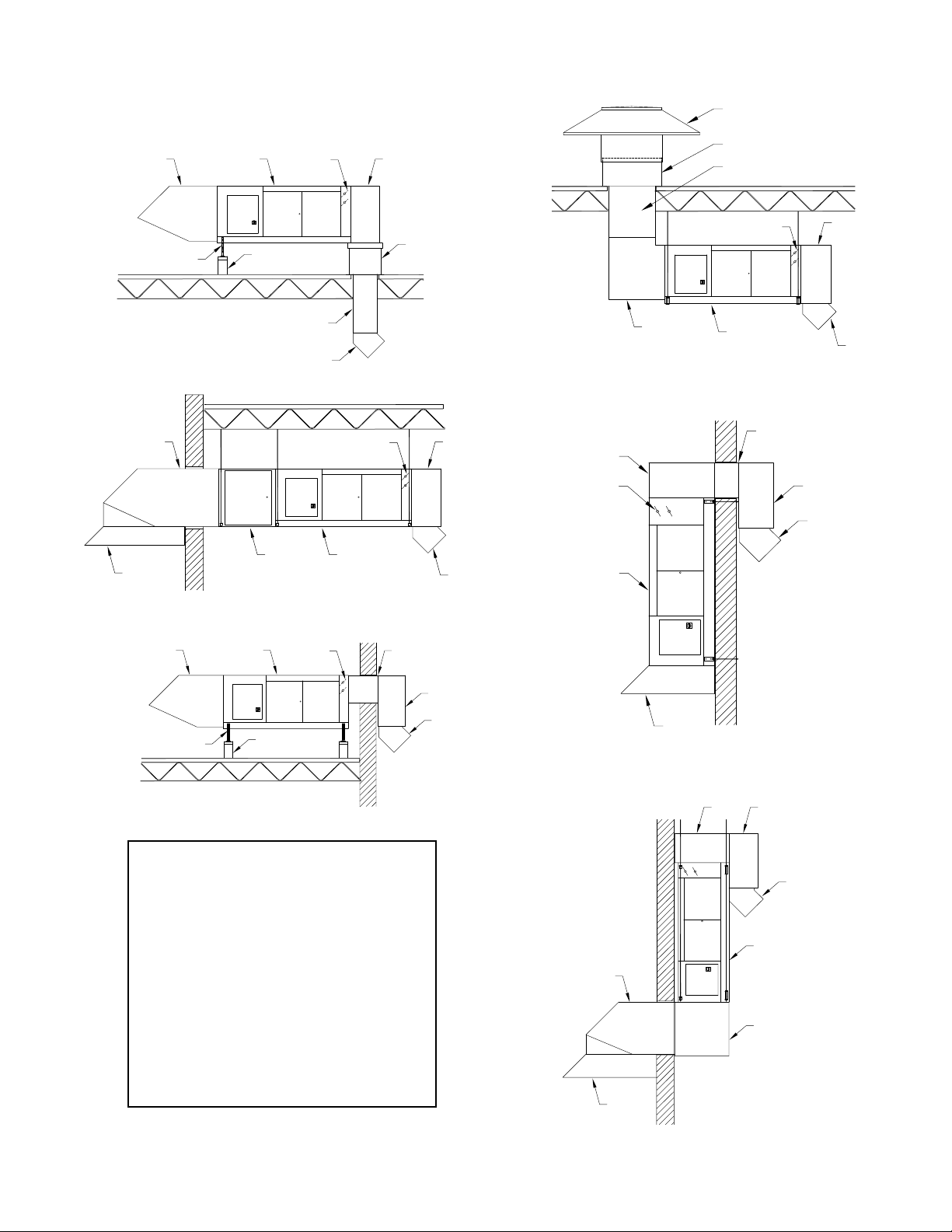

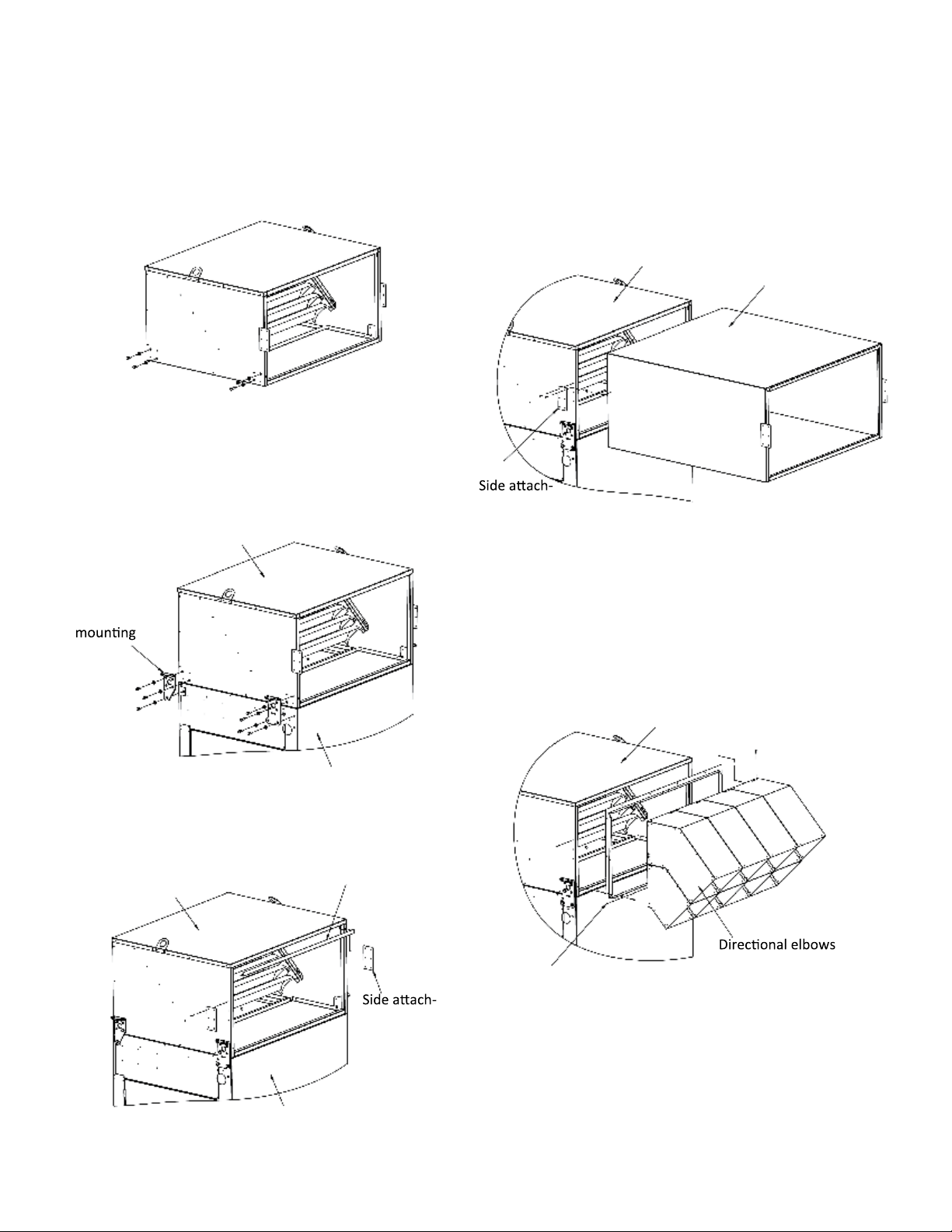

TYPICAL SYSTEM OVERVIEW

ACCESSORY IDENTIFICATION

ADJUSTABLE

ELBOW

WALL

SLEEVE

DOWNTURN

DUCT

EXTENSION

DIRECTIONAL

ELBOWS

DUCT

EXTENSION

DOWNTURN

DUCT

EXTENSION

DOWNTURN

DIRECTIONAL

ELBOWS

RAINHOOD

FILTER

SECTION

SUPPORT

FILTER

SECTION

UPTURN

HORIZONTAL

MOUNTING

STAND

DOWNTURN

WALL

SLEEVE

DIRECTIONAL

ELBOWS

RAINHOOD

EXTENSION

ADJUSTABLE

STAND

RAINHOOD

STRUCTURAL

FILTER

SECTION

STRUCTURAL

INLET

ELBOW

DOWNTURN

ADJUSTABLE

STAND

Cambridge Air Solutions 4 S-Series Technical Manual

TYPICAL SYSTEM OVERVIEW

HEATER OPERATION

Cambridge S-Series Blow-Thru® heaters are utilized

to meet the space heating requirements of commercial

or industrial buildings. The control system is typically

designed to cycle the heaters on and off in response to

the rise and fall of the space temperature. The heater

will discharge air at the temperature selected (up to

HEATER CONFIGURATION

160ºF). The operating thermostat is typically located

near the perimeter of the building in a location which

is out of the direct path of the heated discharge air,

insulated from cold surfaces, and shielded from cold

drafts created by air infiltrating the building.

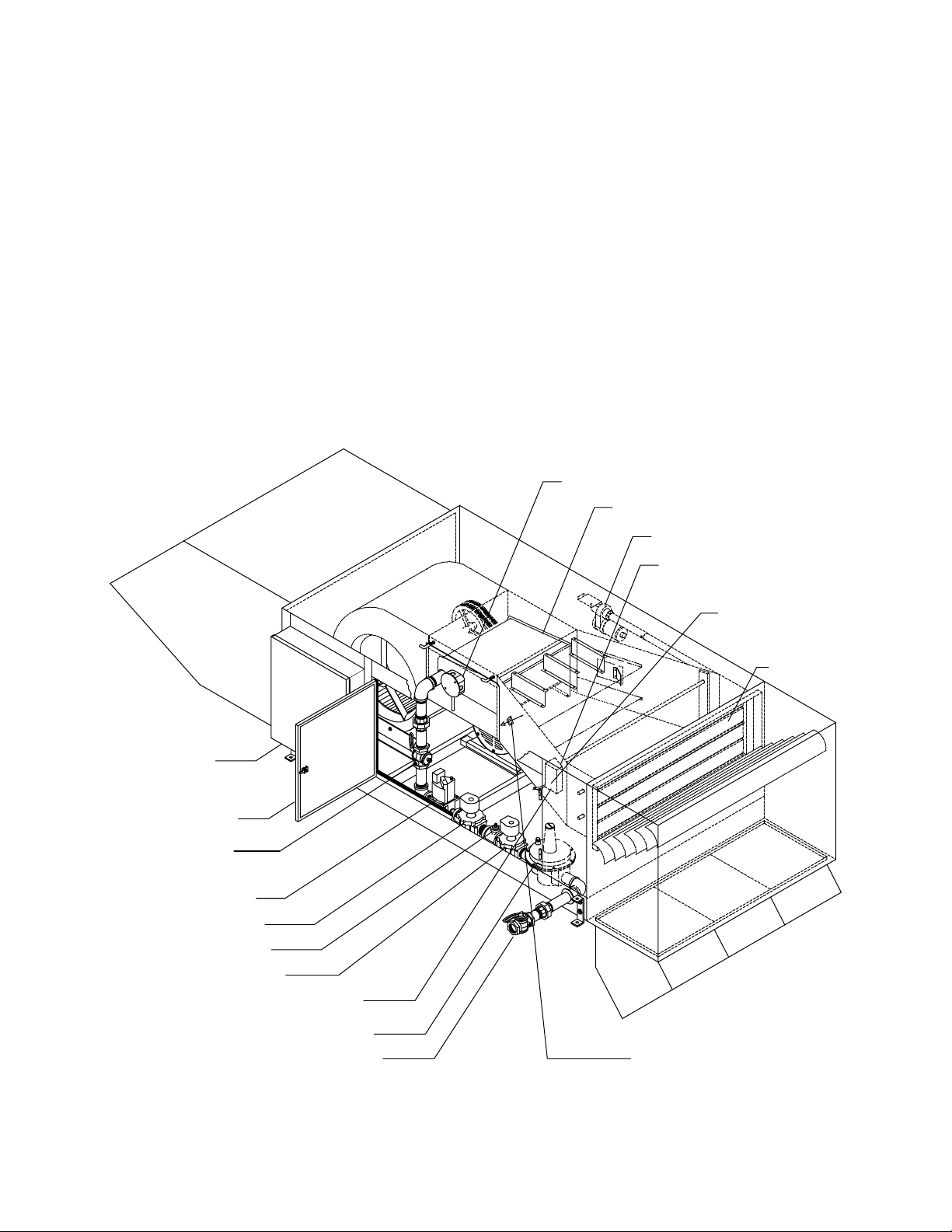

IGNITER & FLAMEROD

BURNER ASSEMBLY

DAMPER MOTOR

DISCHARGE TEMPERATURE SENSOR

ELECTRICAL

CONTROL ENCLOSURE

HINGED ACCESS DOOR

PORT FOR MEASURING

MANIFOLD PRESSURE

MODULATING GAS VALVE

SAFETY SHUT-OFF VALVE

LEAK TEST PORT

SHUT-OFF VALVE

DISCHARGE AIR TEMPERATURE

SAMPLING BOX

MANUAL SHUT-OFF VALVE BURNER VIEWPORT

HIGH LIMIT

DAMPER BLADES

REGULATOR

S-Series Technical Manual 5 Cambridge Air Solutions

INSTALLATION INSTRUCTIONS

UNCRATING INSTRUCTIONS

1. Verify that the number of items on the Bill of

Lading matches the number of items received.

2. Check for shipping damage. Take photographs of

any damage.

IMPORTANT

If damage is found, immediately file a claim with the

carrier before proceeding further.

3. Check the items received to make sure they agree

with the ordering information including verification

of data on the unit nameplate.

IMPORTANT

Do not discard any components or accessories.

MOUNTING LOCATION

Verify feasibility of the installation location selected

with respect to accessibility to the heater for service

and maintenance functions. Ensure the positioning

of the heater does not inhibit fork truck operation,

storage rack locations, or other operations within

the facility. Ensure the heater inlet and outlet are not

blocked or severely restricted in any way that would

affect the rated airflow through the heater or affect the

desired air distribution pattern of the heater.

It is the responsibility of the installer to communicate

any potential problems with the installation to

the person or persons responsible for providing

the installation instructions or drawings prior to

proceeding with the installation.

IMPORTANT

Where the mounting height of the heater is a

consideration, work platforms or service lifts should

be provided for accessibility to the equipment for

service and maintenance activities.

IMPORTANT

Field constructed intake accessories should be

designed to minimize the entry of snow and rain.

IMPORTANT

The minimum clearance from the face of the

electrical control enclosure to surrounding

grounded surfaces for service activities is 42”.

Adequate clearance of 42” for burner removal is

also required. Access for service functions is also

required on the side of the unit opposite the control

enclosure for a distance of 24”.

Cambridge Air Solutions 6 S-Series Technical Manual

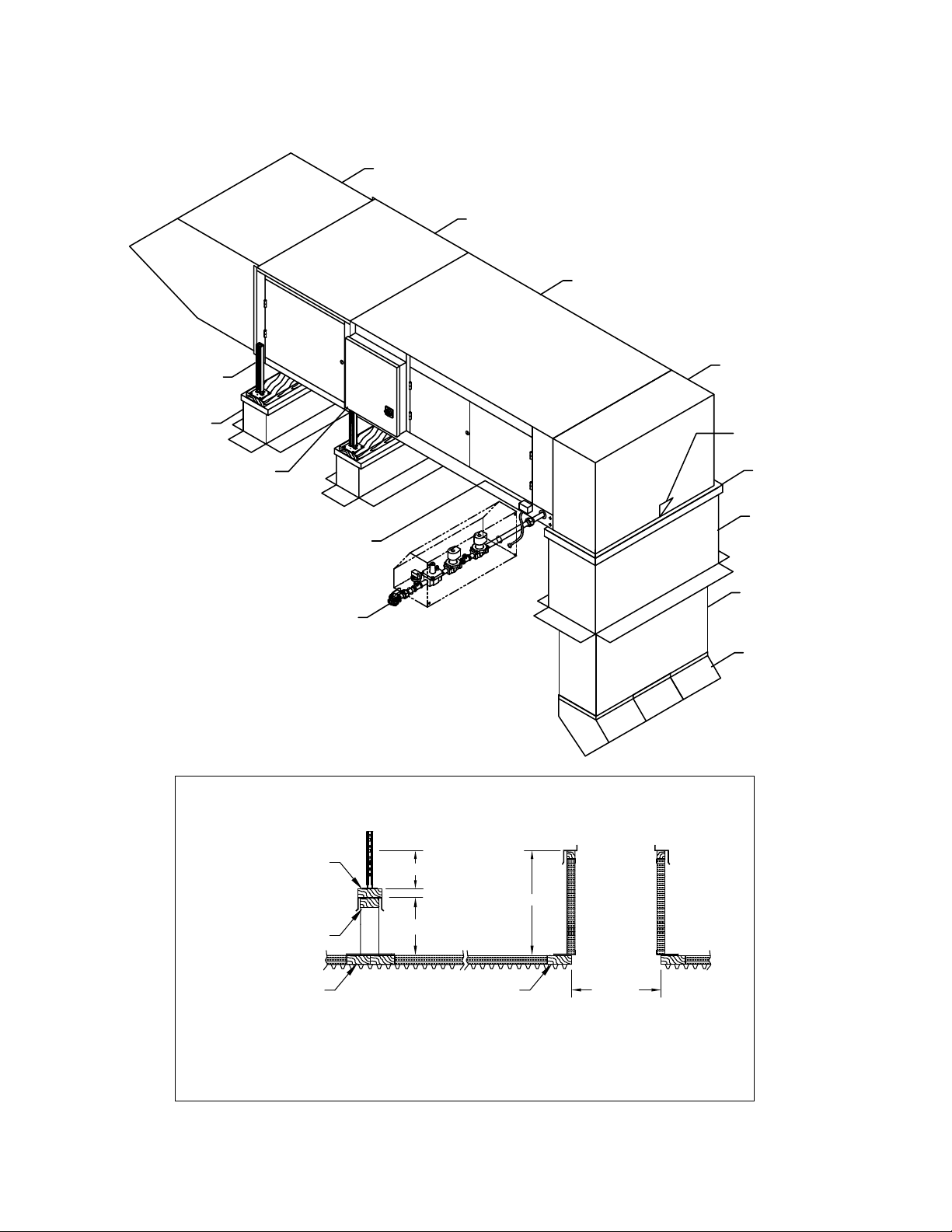

INSTALLATION INSTRUCTIONS

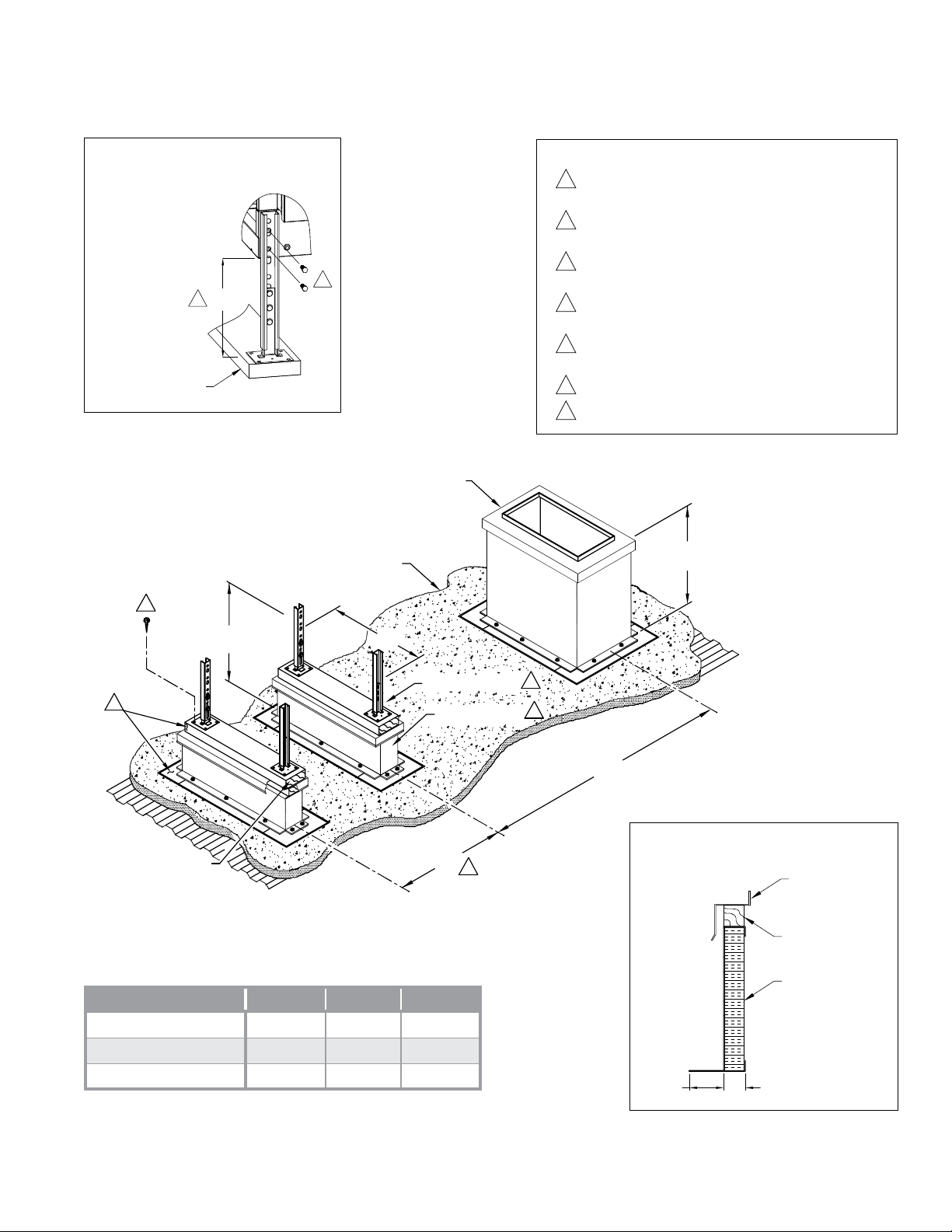

ROOF TOP MOUNTING - CURB / STAND / RAIL

STAND DETAIL

2 x 6 TREATED LUMBER

NOTES

1

TREATED TIMBER AS REQUIRED UNDER MOUNTING

CURB, RAIL AND STAND TO SECURE AND LEVEL UNIT.

2

SECURE MOUNTING STAND TO TIMBER WITH WOOD LAG

SCREWS AS SHOWN.

3

SECOND MOUNTING ASSEMBLY IS REQUIRED ONLY ON

6

10½"

7

DOWNTURN / CURB

WITH FLASHING

ROOF INSULATION

UNITS WITH FILTER SECTIONS.

4

MOUNTING STAND CONSTRUCTION:

12 GA. GALVANIZED STEEL

5

MOUNTING RAIL CONSTRUCTION:

18 GA. GALVANIZED STEEL

6

REMOVE HANGER BRACKET AND REPLACE SCREWS

7

ADJUSTABLE ± 3¾”

24"

REF.

2

TYP.

1

2 X 6 TREATED LUMBER

Model A B C

S400/S800

S950/S1200/S1600

S1850/S2200/S3200

24"

65½” 33¼” 25 3/8”

78 5/8” 33¼” 42”

90¼” 36¼” 47 1/8”

C

MOUNTING STAND

MOUNTING RAIL

B

3

4

5

A

CURB SECTION

FLASHING

2 x 2 WOOD NAILER

(PROVIDED)

INSULATION

S-Series Technical Manual 7 Cambridge Air Solutions

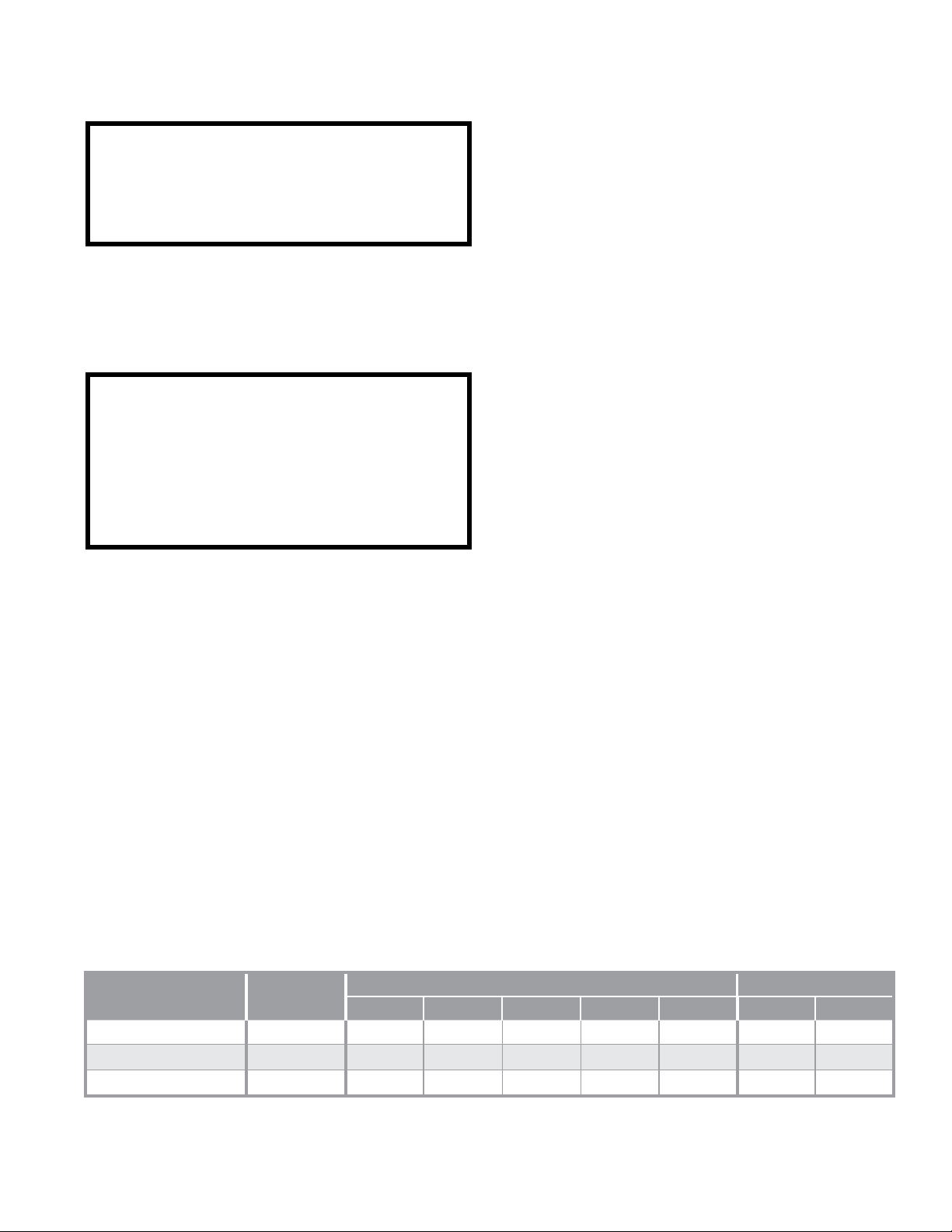

INSTALLATION INSTRUCTIONS

ROOF INSULATION

2 x 6 TREATED LUMBER

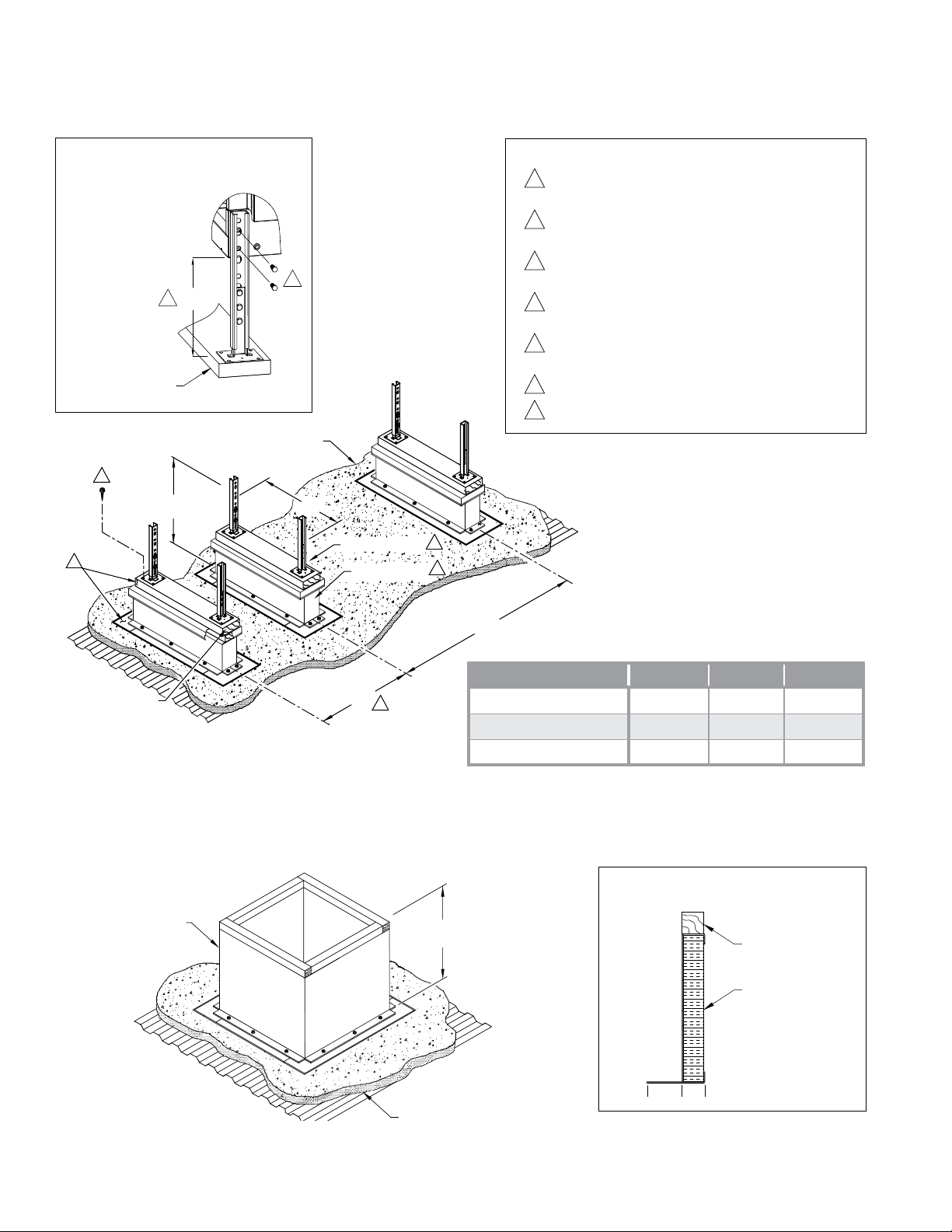

ROOF TOP / THRU WALL MOUNTING - STAND / RAIL

STAND DETAIL

2

1

7

TYP.

NOTES

1

TREATED TIMBER AS REQUIRED UNDER MOUNTING RAIL

AND STAND TO SECURE AND LEVEL UNIT.

2

SECURE MOUNTING STAND TO TIMBER WITH WOOD LAG

SCREWS AS SHOWN.

3

THIRD MOUNTING ASSEMBLY IS REQUIRED ONLY ON

6

10½"

ROOF INSULATION

24"

C

MOUNTING STAND

MOUNTING RAIL

4

5

UNITS WITH FILTER SECTIONS.

4

MOUNTING STAND CONSTRUCTION:

12 GA. GALVANIZED STEEL

5

MOUNTING RAIL CONSTRUCTION:

18 GA. GALVANIZED STEEL

6

REMOVE HANGER BRACKET AND REPLACE SCREWS

7

STAND IS ADJUSTABLE ±3¾”

2 X 6 TREATED LUMBER

B

3

UNDER ROOF MOUNTING - CURB

CURB

A

S400/S800

S950/S1200/S1600

S1850/S2200/S3200

24"

REF.

Model A B C

57 7/8” 33¼” 25 3/8”

69 7/8” 33¼” 42”

75¾” 36¾ ” 47 1/8”

CURB SECTION

2 x 2 WOOD NAILER

(PROVIDED)

INSULATION

Cambridge Air Solutions 8 S-Series Technical Manual

INSTALLATION INSTRUCTIONS

ROOF TOP MOUNTING

mWARNING:

Due to the size and weight of this equipment, it

is recommended the heater mounting structure

be reviewed and approved by a qualified

structural engineer and the roof manufacturer

before installing this equipment.

IMPORTANT

Before proceeding with the installation, verify the

feasibility of the location selected with respect to

accessibility for service and maintenance functions.

IMPORTANT

To minimize snow and rain ingestion, position the

heater inlet opposite the prevailing winds.

mCAUTION

To prevent contaminated air from being drawn

into the heater, install the heater’s inlet at least

10 feet from any building exhaust, process

exhaust, sewer stacks, or other sources that

would allow contaminants to be drawn into

the heater. Consult local codes for additional

references.

1. Prepare roof penetration to the dimensions below.

See page 6 for Roof Top Mounting - Curb/Stand/

Rail drawing.

IMPORTANT

Accurate measurements are critical and will affect

the installation process. Verify that the roof opening

aligns with the curb opening.

2. Secure the mounting curb and mounting rail(s) per

the structural engineer and roof manufacturer’s

recommendations.

IMPORTANT

The roof curb and mounting rail(s) should be

installed so that the heater will mount level.

Cambridge recommends mounting the heater a

minimum of 24” off the roof surface in areas where

snow accumulation could impact heater operations.

3. Attach the mounting stands to the heater while the

heater is on the ground. Adjust the height of the

stands so the heater inlet is slightly (1/8” below

level) lower than the discharge. This allows any

ingested moisture to drain out of the heater, through

weep holes located at the inlet of the heater, onto

the roof surface.

4. Lower the discharge duct through the mounting

curb and the roof opening and secure the

counterflashing to the mounting curb.

5. Use a crane or comparable lifting device to raise

and position the equipment. Use a spreader bar to

prevent damage and connect slings to the lifting

brackets.

mWARNING:

Do not attach lifting means to heater accessories.

Make connections to heater only.

IMPORTANT

Inlet accessories may be attached on the ground or

on the roof depending on the method chosen by the

installer.

6. Caulk all the joints between the heater and the

accessories with silicone caulk to prevent water

leaks.

IMPORTANT

Do not caulk the downturn/counterflashing for the

curb interface.

7. Seal all roof penetrations to prevent roof leaks.

8. Install the directional elbows. Consult the job

layout for the orientation of the elbows.

Roof Opening*

Model L W

S400/S800

S950/S1200/S1600

S1850/S2200/S3200

Weight

550 lbs. 13” 24¾”

800 lbs. 15” 41½”

1500 lbs. 24¼” 46½”

S-Series Technical Manual 9 Cambridge Air Solutions

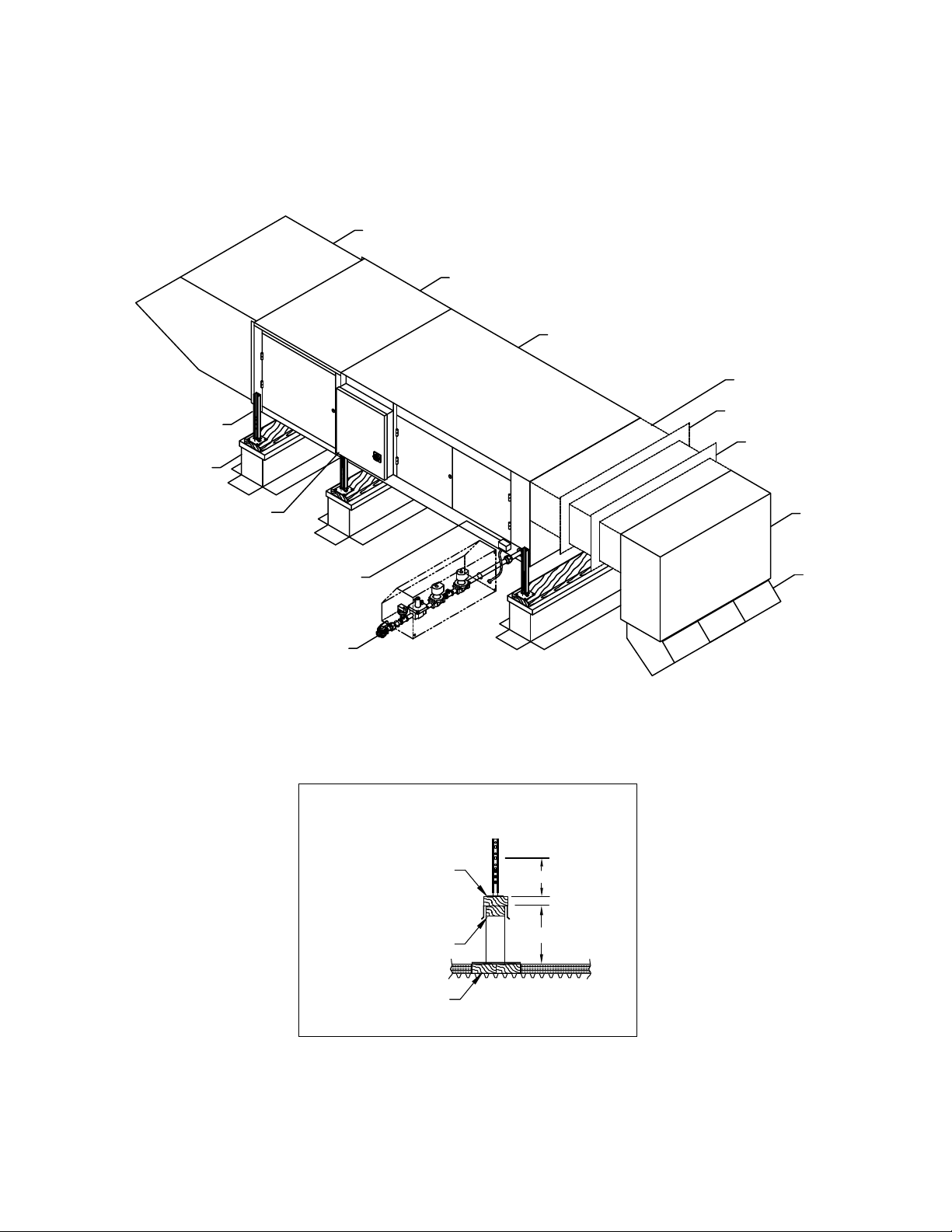

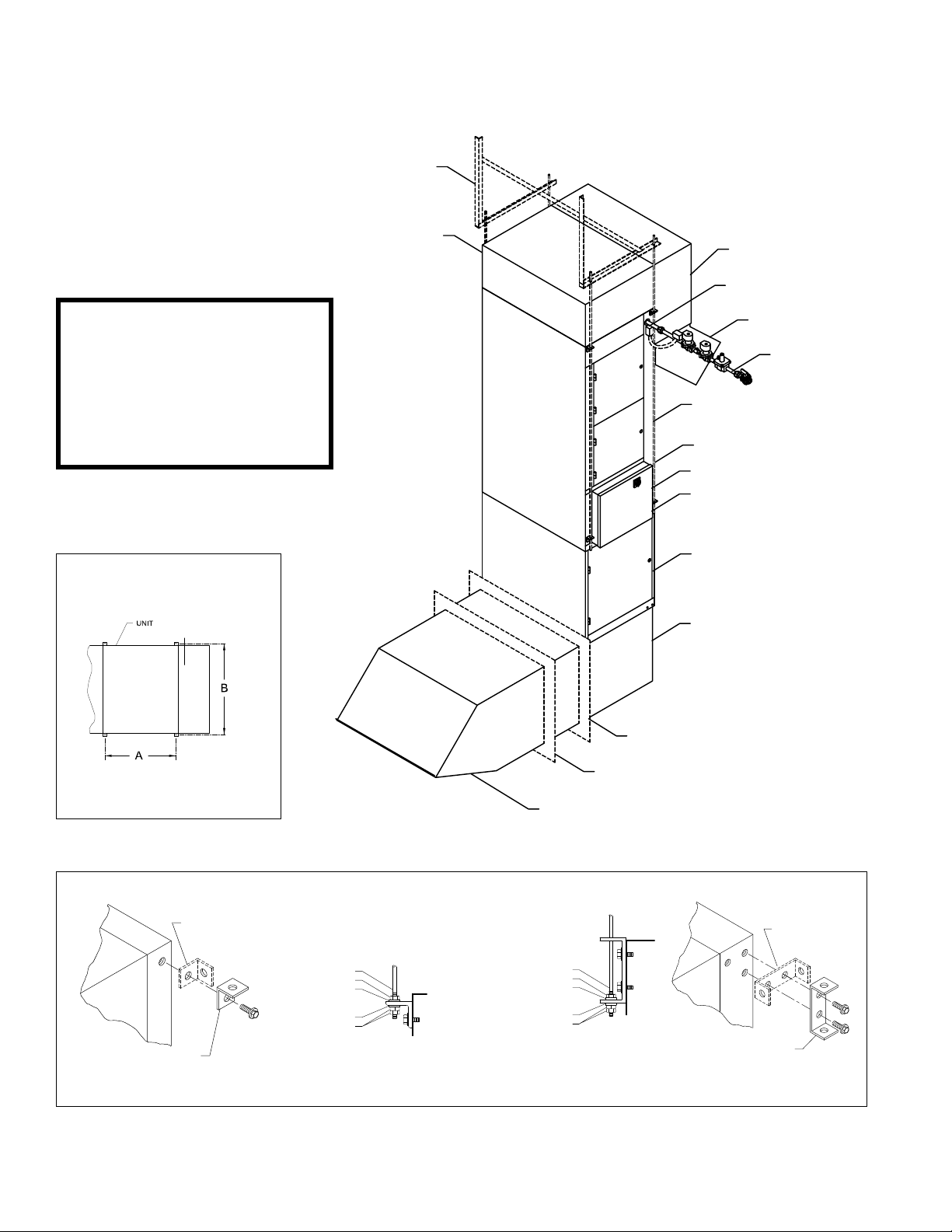

TYPICAL INSTALLATION

ROOF TOP MOUNTING

RAIN HOOD

FILTER SECTION

(OPTIONAL)

UNIT

ADJUSTABLE MOUNTING STAND

MOUNTING RAIL

ELECTRICAL CONTROL ENCLOSURE

(PROVIDED WITH EXTERNAL GAS TRAIN)

EXTERNAL GAS TRAIN WITH ENCLOSURE

(APPLICABLE TO SOME FM AND XL GAPS OPTIONS)

XL GAPS: FORMERLY IRI (INDUSTRIAL RISK INSURERS)

ELECTRICAL JUNCTION BOX

FM: FACTORY MUTUAL

CURB / RAIL / STAND DETAIL

DOWNTURN

NOTE:

DO NOT CAULK

THIS JOINT

COUNTERFLASHING

MOUNTING CURB

DISCHARGE DUCT

DIRECTIONAL

ELBOWS

2 X 6 TREATED LUMBER

2 X 4 TREATED LUMBER

(BY OTHERS)

(PROVIDED)

TREATED LUMBER

(BY OTHERS)

TREATED LUMBER (THICKNESS OF ROOF INSULATION) AS

REQUIRED UNDER MOUNTING STANDS AND CURB TO SECURE

AND LEVEL THE UNIT AND TO SPREAD THE LOAD. (BY OTHERS)

10½"

12"

TREATED LUMBER

(BY OTHERS)

24"

ROOF

OPENING

* Dimensions allow for ¾” clearance on each side

Cambridge Air Solutions 10 S-Series Technical Manual

INSTALLATION INSTRUCTIONS

THRU WALL MOUNTING

mWARNING:

Due to the size and weight of this equipment, it

is recommended the heater mounting structure be

reviewed and approved by a qualified structural

engineer before installing this equipment.

IMPORTANT

Before proceeding with the installation, verify the

feasibility of the location selected with respect to accessibility to the equipment for service and maintenance functions.

mCAUTION

To prevent contaminated air from being drawn into

the heater, install the heater’s inlet at least 10 feet

from any building exhaust, process exhaust, sewer

stacks, or other sources that would allow contaminants to be drawn into the heater. Consult local

codes for additional references.

1. Prepare wall penetration to the dimensions below.

2. Connect inlet accessories to the unit including

filter section (optional) and rain hood prior to lifting the heater in place. Note the inlet skirt for rain

hood (optional) is installed from the outside of the

building (page 20).

5. Use a forklift or comparable lifting device to

raise and position the heater. Take precautions

to prevent equipment damage (dents and/or

scratches) when the heater is being lifted into

position.

6. Use washers and double lock nuts to secure the

unit on the hanging rods.

IMPORTANT

The discharge end of the heater should be raised

slightly (1/8” above level). This allows any ingested

moisture to drain out of the heater through weep

holes located in the rain hood to the exterior of the

building.

7. Apply shims, by others, at the bottom of the rain

hood to take up slack in the opening, leaving a

small joint between the top of the rain hood and

the wall.

8. Install fiberglass insulation in the gaps around the

wall opening and the rain hood. Apply enough

material to accommodate the full thickness of the

wall.

9. Install finish trim pieces (by others) to the top,

sides and bottom of the rain hood on both the

inside and outside wall surfaces.

3. Install hanging rods to adequate ceiling supports

and align with the hanging brackets on the unit.

Refer to hanging rod size shown on table below.

Locate the hanging rods so that the weep holes

provided in the rain hood are located a minimum

of 3” beyond the outside wall surface.

4. Remove the lag bolts used to fasten the unit to the

skid. Do not remove the hanging brackets from the

side of the heater. On S400/S800 model heaters,

rotatethemountingbrackets180˚andretightenthe

securing hardware.

Model Qty. Size A B* C H W

S400/S800

S950/S1200/S1600

S1850/S2200/S3200

*Foroptionalltersection

** Dimensions allow for 1” clearance on each side

Weight

550 lbs. 4 (6*) 3/8” dia. 57 7/8” 33¼” 27 7/8” 26” 25½”

800 lbs. 4 (6*) 3/8” dia. 69 7/8” 33¼” 43 7/8” 29” 42¼”

1500 lbs. 4 (6*) 1/2” dia. 75¾” 36¾” 48 7/8” 38¾” 47¼”

10. Apply silicone caulk at the joint between the top

of the rain hood and the outside wall surface.

Make certain this is a continuous bead and that it

runs the entire width of the rain hood. Caulk all

other exposed joints.

11. Install the directional elbows. Consult the job

layout for the orientation of the elbows.

Hanging Rods Wall Opening**

S-Series Technical Manual 11 Cambridge Air Solutions

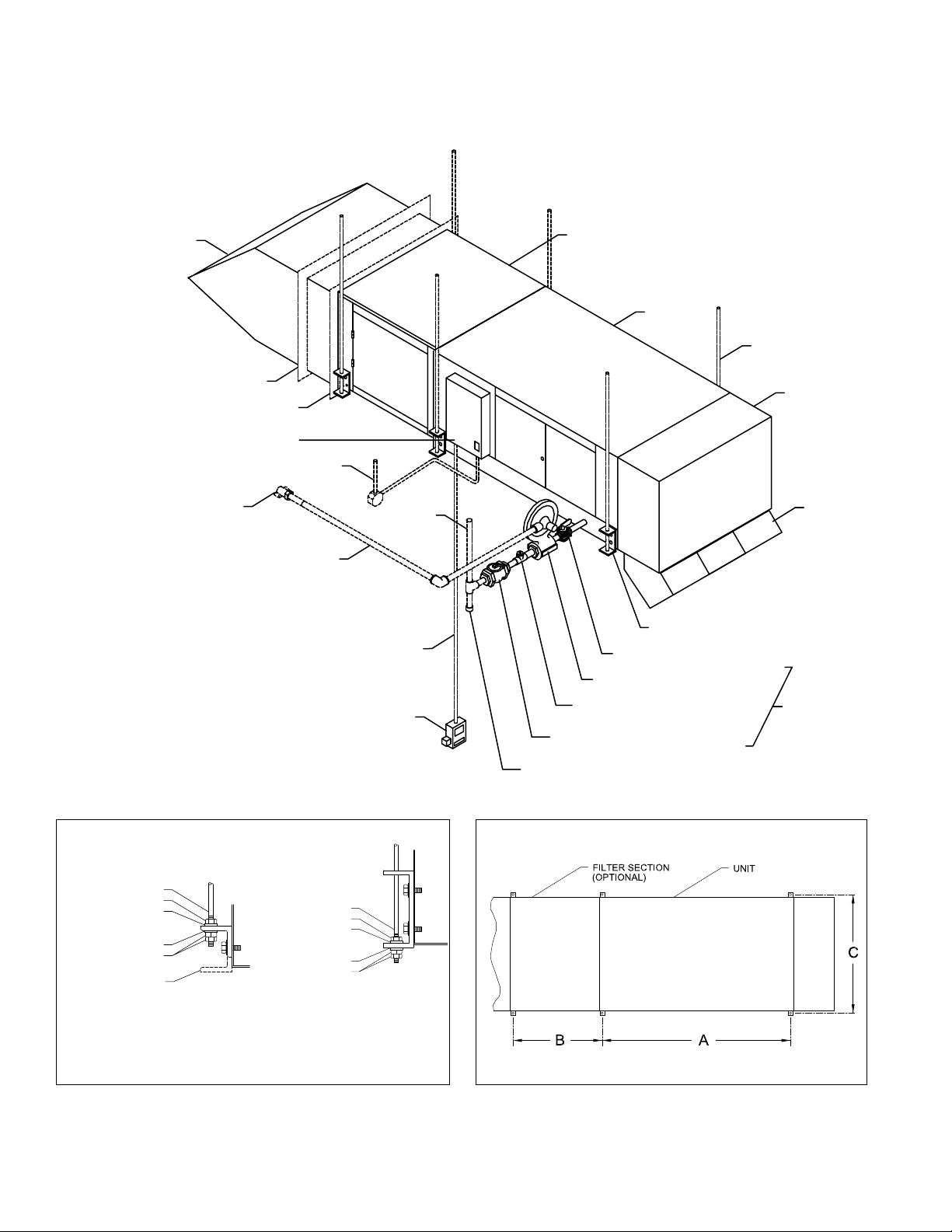

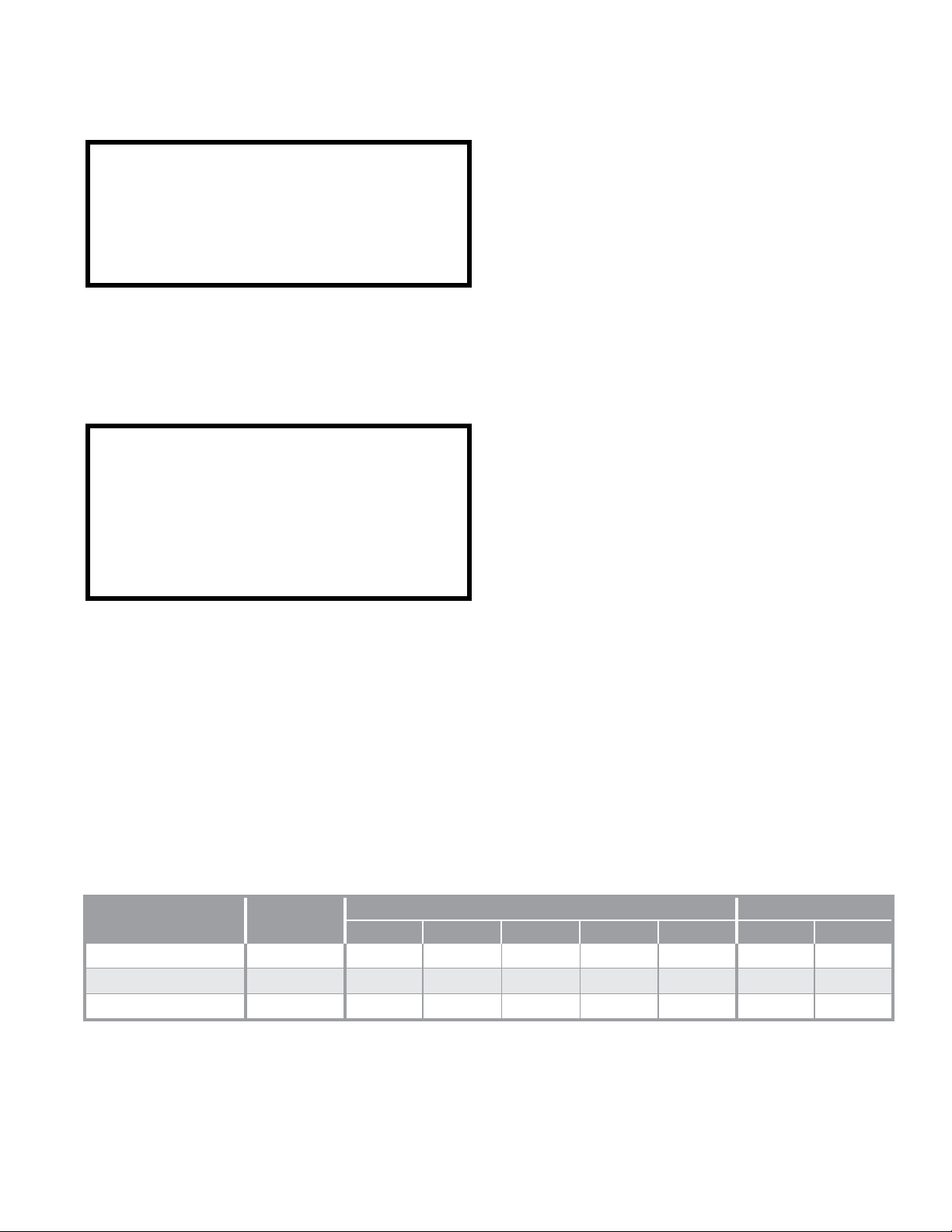

TYPICAL INSTALLATION

SHIPPING POSITION

THRU WALL MOUNTING

RAINHOOD

EXTERIOR WALL TRIM

(BY OTHERS)

INTERIOR WALL TRIM

ELECTRICAL CONTROL ENCLOSURE

(LOCATE MIN. 10 FT. FROM INTAKE)

VENT w/SCREEN

(BY OTHERS)

INCOMING POWER

VENT PIPE TO OUTDOORS

(BY OTHERS)

CONTROL WIRING CONDUIT

INLET GAS PIPE

(BY OTHERS)

FILTER SECTION

(OPTIONAL)

UNIT

HANGING BRACKET

LOW PRESSURE SHUT-OFF VALVE

HIGH PRESSURE REGULATOR (HPR)

HANGING ROD

(BY OTHERS)

DOWNTURN

DIRECTIONAL

ELBOWS

HANGING ROD

NUT

WASHER

DOUBLE LOCK NUTS

WASHER

HANGING RODS, NUTS AND WASHERS BY OTHERS

L BRACKET

FOR S400 - S800 UNITS

REMOTE CONTROL STATION

HANGING ROD

NUT

WASHER

DOUBLE LOCK NUTS

WASHER

C BRACKET

FOR S950 - S3200 UNITS

HIGH PRESSURE SUPPLY TAP

HIGH PRESSURE SHUT-OFF VALVE

SEDIMENT TRAP

HANGING ROD DETAILHANGING BRACKET DETAIL

(OPTIONAL)

Cambridge Air Solutions 12 S-Series Technical Manual

INSTALLATION INSTRUCTIONS

ROOF TOP / THRU WALL MOUNTING

mWARNING:

Due to the size and weight of this equipment, it

is recommended the heater mounting structure be

reviewed and approved by a qualified structural

engineer and the roof manufacturer before

installing this equipment.

IMPORTANT

Before proceeding with the installation, verify the feasibility of the location selected with respect to accessibility to the equipment for service and maintenance

functions.

IMPORTANT

To minimize snow and rain ingestion, position the

heater inlet opposite the prevailing winds.

mCAUTION

To prevent contaminated air from being drawn

into the heater, install the heater’s inlet at least 10

feet from any building exhaust, process exhaust,

sewer stacks, or other sources that would allow

contaminants to be drawn into the heater. Consult

local codes for additional references.

1. Prepare wall penetration to the dimensions below.

See page 7 for Roof Top/Thru Wall Mounting

Stand/Rail drawing.

IMPORTANT

3. Attach the mounting stands to the heater while

the heater is on the ground. Adjust the height

of the stands so the heater inlet is slightly (1/8”

below level) lower than the discharge. This allows

any ingested moisture to drain out of the heater,

through weep holes located at the inlet of the heater, onto the roof surface.

4. Use a crane or comparable lifting device to raise

and position equipment. Use a spreader bar to

prevent damage and connect slings to the lifting

brackets.

mWARNING:

Do not attach lifting means to heater accessories.

Make connections to heater only.

IMPORTANT

Inlet accessories may be attached on the ground or

on the roof depending on the method chosen by the

installer.

5. Install the wall sleeve to the heater discharge.

6. Install fiberglass insulation in gaps around the wall

opening and wall sleeve. Apply enough material to

accommodate the full thickness of the wall.

7. Install finish trim pieces (by others) to top, sides

and bottom of the wall sleeve on both the inside

and outside wall surfaces.

Accurate measurements are critical and will affect

installation process.

2. Secure the mounting rails per the structural

engineer and roof manufacturer’s

recommendations.

IMPORTANT

The mounting rails should be installed so that the

heater will mount level. Cambridge recommends

mounting the heater a minimum of 24” off the roof

surface in areas where snow accumulation could

impact heater operations

Model H W

S400/S800

S950/S1200/S1600

S1850/S2200/S3200

1500 lbs. 27½” 50”

Weight

550 lbs. 16” 28¼”

800 lbs. 18” 45”

8. Apply silicone caulk at the joint between the top

of the wall sleeve and the outside wall surface.

Make certain this is a continuous bead and that it

runs the entire width of the wall sleeve. Caulk all

other exposed joints.

9. Seal all roof penetrations to prevent roof leaks.

10. Install the downturn and directional elbows.

Consult the job layout for the orientation of the

elbows.

Wall Opening*

S-Series Technical Manual 13 Cambridge Air Solutions

TYPICAL INSTALLATION

(BY OTHERS)

ROOF TOP / THRU WALL MOUNTING

RAIN HOOD

ADJUSTABLE MOUNTING STAND

MOUNTING RAIL

FILTER SECTION

(OPTIONAL)

UNIT

WALL SLEEVE

EXTERIOR WALL TRIM

(BY OTHERS)

INTERIOR WALL TRIM

(BY OTHERS)

ELECTRICAL CONTROL ENCLOSURE

(PROVIDED WITH EXTERNAL GAS TRAIN)

EXTERNAL GAS TRAIN WITH ENCLOSURE

(APPLICABLE TO SOME FM AND XL GAPS OPTIONS)

ELECTRICAL JUNCTION BOX

STAND DETAIL

2 X 6 TREATED LUMBER

2 X 4 TREATED LUMBER

(BY OTHERS)

(PROVIDED)

10½"

12"

DOWNTURN

DIRECTIONAL

ELBOWS

TREATED LUMBER

* Dimensions allow for 1½” clearance on each side

Cambridge Air Solutions 14 S-Series Technical Manual

INSTALLATION INSTRUCTIONS

UNDER ROOF MOUNTING

mWARNING:

Due to the size and weight of this equipment, it

is recommended the heater mounting structure be

reviewed and approved by a qualified structural

engineer and the roof manufacturer before

installing this equipment.

IMPORTANT

Before proceeding with the installation, verify the

feasibility of the location selected with respect to accessibility to the equipment for service and maintenance functions.

m CAUTION

To prevent contaminated air from being drawn

into the heater, install the heater’s inlet at least 10

feet from any building exhaust, process exhaust,

sewer stacks, or other sources that would allow

contaminants to be drawn into the heater. Consult

local codes for additional references.

IMPORTANT

The mounting curb or mounting structure should

be installed such that the heater’s inlet plenum will

mount level.

3. Seal all roof penetrations to prevent roof leaks.

4. Lower the inlet duct through the mounting curb

and the roof opening.

5. Secure the inlet plenum to the curb.

6. Connect inlet accessories to the heater including

filter section (optional) and inlet elbow prior to

lifting the heater in place.

7. Install hanging rods to adequate ceiling supports

and align with the hanging brackets on the heater.

Refer to hanging rod size shown on table below.

8. Remove the lag bolts used to fasten the unit to the

skid. Do not remove the hanging brackets from the

side of the heater. On S400/S800 model heaters,

rotatethehangingbrackets180˚,andretightenthe

securing hardware.

1. Prepare roof penetration to the dimensions below.

See page 7 for Under Roof Mounting - Curb drawing

IMPORTANT

Accurate measurements are critical and will affect

the installation process. Verify that the roof opening

aligns with the curb opening.

2. Install the mounting curb and the mounting structure per the structural engineer and roof manufacturer’s recommendations.

Model Qty. Size A B* C L W

S400/S800

S950/S1200/S1600

S1850/S2200/S3200

*Foroptionalltersection

** Dimensions allow for ¾” clearance on each side

Weight

550 lbs. 4 (6*) 3/8” dia. 57 7/8” 33¼” 27 7/8” 25” 25”

800 lbs. 4 (6*) 3/8” dia. 69 7/8” 33¼” 43 7/8” 30” 41¼”

1500 lbs. 4 (6*) 1/2” dia. 75¾” 36¾” 48 7/8” 37¼” 46¾”

9. Use a forklift or comparable lifting device to

raise and position the heater. Take precautions

to prevent equipment damage (dents and/or

scratches) when the heater is being lifted into

position.

10. Use washers and double lock nuts to secure

equipment on the hanging rods.

11. Install the directional elbows. Consult the job

layout for the orientation of the elbows.

Hanging Rods Roof Opening**

S-Series Technical Manual 15 Cambridge Air Solutions

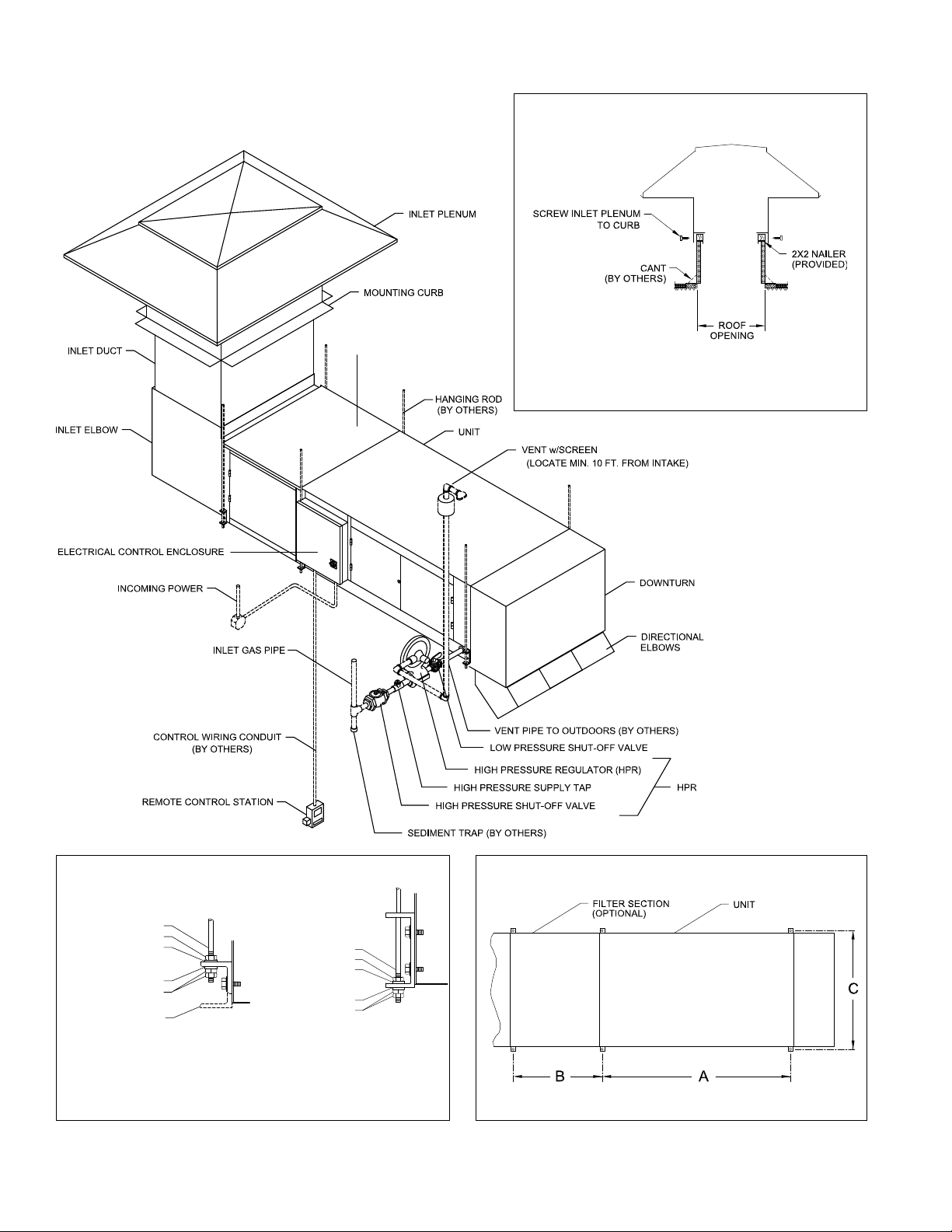

TYPICAL INSTALLATION

SHIPPING POSITION

UNDER ROOF MOUNTING

CURB DETAIL

FILTER SECTION (OPTIONAL)

TREATED LUMBER (THICKNESS OF ROOF INSULATION) AS

REQUIRED UNDER MOUNTING CURB TO SECURE AND LEVEL

THE UNIT AND TO SPREAD THE LOAD. (BY OTHERS)

DOUBLE LOCK NUTS

FOR S400 - S800 UNITS

Cambridge Air Solutions 16 S-Series Technical Manual

HANGING ROD

NUT

WASHER

WASHER

DOUBLE LOCK NUTS

HANGING RODS, NUTS AND WASHERS BY OTHERS

L BRACKET

FOR S950 - S3200 UNITS

HANGING ROD

NUT

WASHER

WASHER

C BRACKET

HANGING ROD DETAILHANGING BRACKET DETAIL

INSTALLATION INSTRUCTIONS

VERTICAL INDOOR MOUNTING

mWARNING:

Due to the size and weight of this equipment, it

is recommended the heater mounting structure be

reviewed and approved by a qualified structural

engineer before installing this equipment.

IMPORTANT

Before proceeding with the installation, verify the

feasibility of the location selected with respect to accessibility to the equipment for service and maintenance functions.

m CAUTION

To prevent contaminated air from being drawn

into the heater, install the heater’s inlet at least 10

feet from any building exhaust, process exhaust,

sewer stacks, or other sources that would allow

contaminants to be drawn into the heater. Consult

local codes for additional references.

1. Prepare wall penetration to the dimensions below.

2. Connect the inlet accessories to the heater including

the filter section (optional), the inlet elbow and the

rain hood prior to standing the heater upright. Note

the inlet skirt for the rain hood (optional) is installed

from the outside of the building (page 20).

3. Install hanging rods to adequate ceiling and/or wall

supports per the structural engineer’s recommendations and align with the hanging brackets on the

heater. Refer to the hanging rod size shown on the

table below. Locate the hanging rods so that the

weep holes provided in the rain hood are located a

minimum of 3” beyond the outside wall surface.

4. Remove the lag bolts used to fasten the unit to the

skid. Rotate the hanging brackets for the vertical

application and retighten the securing hardware.

5. Utilizing the lifting brackets on the front of the heater,

use a forklift or comparable lifting device to raise

and position the heater. Take precautions to prevent

equipment damage (dents and/or scratches) when the

heater is being lifted into position.

6. Use washers and double lock nuts to secure

equipment on hanging rods.

IMPORTANT

The rain hood should be sloped slightly (1/8” off

level). This allows any ingested moisture to drain out

of the heater through weep holes located in the rain

hood to the exterior of the building.

7. Apply shims at the bottom of the rain hood to take up

slack in the opening, leaving a minimal joint between

the top of the rain hood and the wall.

8. Install fiberglass insulation in the gaps around the

wall opening and the rain hood. Apply enough

material to accommodate the full thickness of the

wall.

9. Install finish trim pieces (by others) to the top, sides

and bottom of the rain hood on both the inside and

outside wall surfaces.

10. Apply silicone caulk at the joint between the top

of the rain hood and the outside wall surface.

Make certain this is a continuous bead and that it

runs the entire width of the rain hood. Caulk all

other exposed joints.

11. Install the second downturn and directional

elbows. Consult the job layout for the orientation

of the elbows.

Model Weight

S400/S800

S950/S1200/S1600

S1850/S2200/S3200

Qty. Size A B H W

650 lbs. 4 3/8” dia. 23 3/8” 27 7/8” 26” 25½”

950 lbs. 4 3/8” dia. 26” 43 7/8” 29” 42¼”

1750 lbs. 4 1/2” dia. 34 7/8” 48 7/8” 38¾” 47¼”

Hanging Rods Wall Opening*

S-Series Technical Manual 17 Cambridge Air Solutions

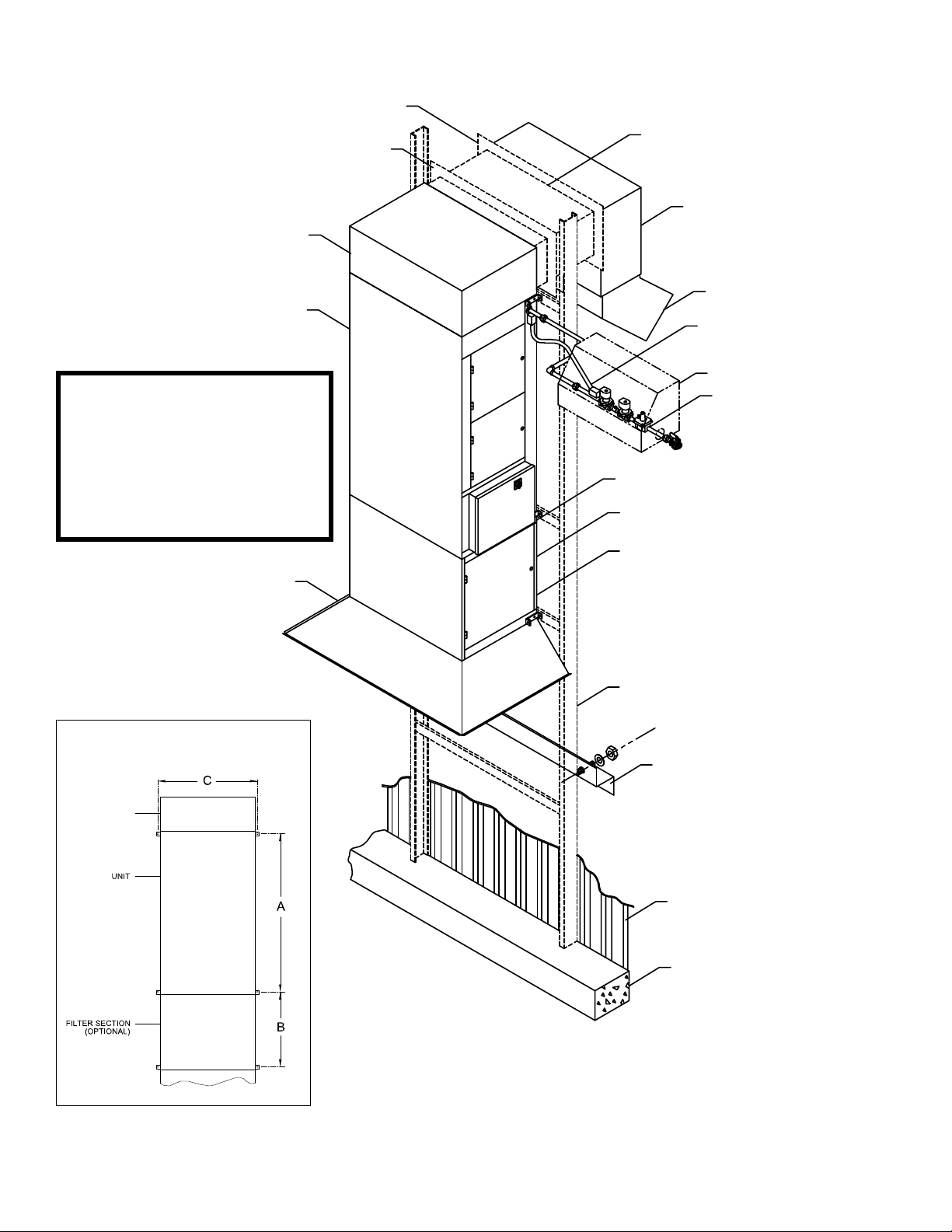

TYPICAL VERTICAL INDOOR INSTALLATION

STRUCTURAL

KNEE BRACE

(BY OTHERS)

mWARNING:

The primary structural support

element of a vertically mounted

heater is the base. Any support

to the heater cabinet should be

considered secondary, only as a

means to help stabilize the heater.

HANGING ROD DETAIL

SECOND DOWNTURN

(OPTIONAL)

DOWNTURN

DOWNTURN

SECOND DOWNTURN

(OPTIONAL)

GAS TRAIN WIRING

(FIELD CONNECTED)

DIRECTIONAL

ELBOWS

GAS TRAIN

HANGING ROD

(BY OTHERS)

UNIT

BASE OF HEATER

ELECTRICAL CONTROL

ENCLOSURE

FILTER SECTION

(OPTIONAL)

INLET ELBOW

INTERIOR WALL TRIM

(BY OTHERS)

EXTERIOR WALL TRIM

(BY OTHERS)

RAIN HOOD

HANGING BRACKET DETAIL

SHIPPING POSITION

DOUBLE LOCK NUTS

MOUNTING POSITION

L BRACKET

FOR S400 - S800 UNITS

* Dimensions allow for 1” clearance on each side

HANGING RODS, NUTS AND WASHERS BY OTHERS

HANGING ROD

NUT

WASHER

WASHER

HANGING ROD

NUT

WASHER

WASHER

DOUBLE LOCK NUTS

SHIPPING POSITION

MOUNTING POSITION

C BRACKET

FOR S950 - S3200 UNITS

Cambridge Air Solutions 18 S-Series Technical Manual

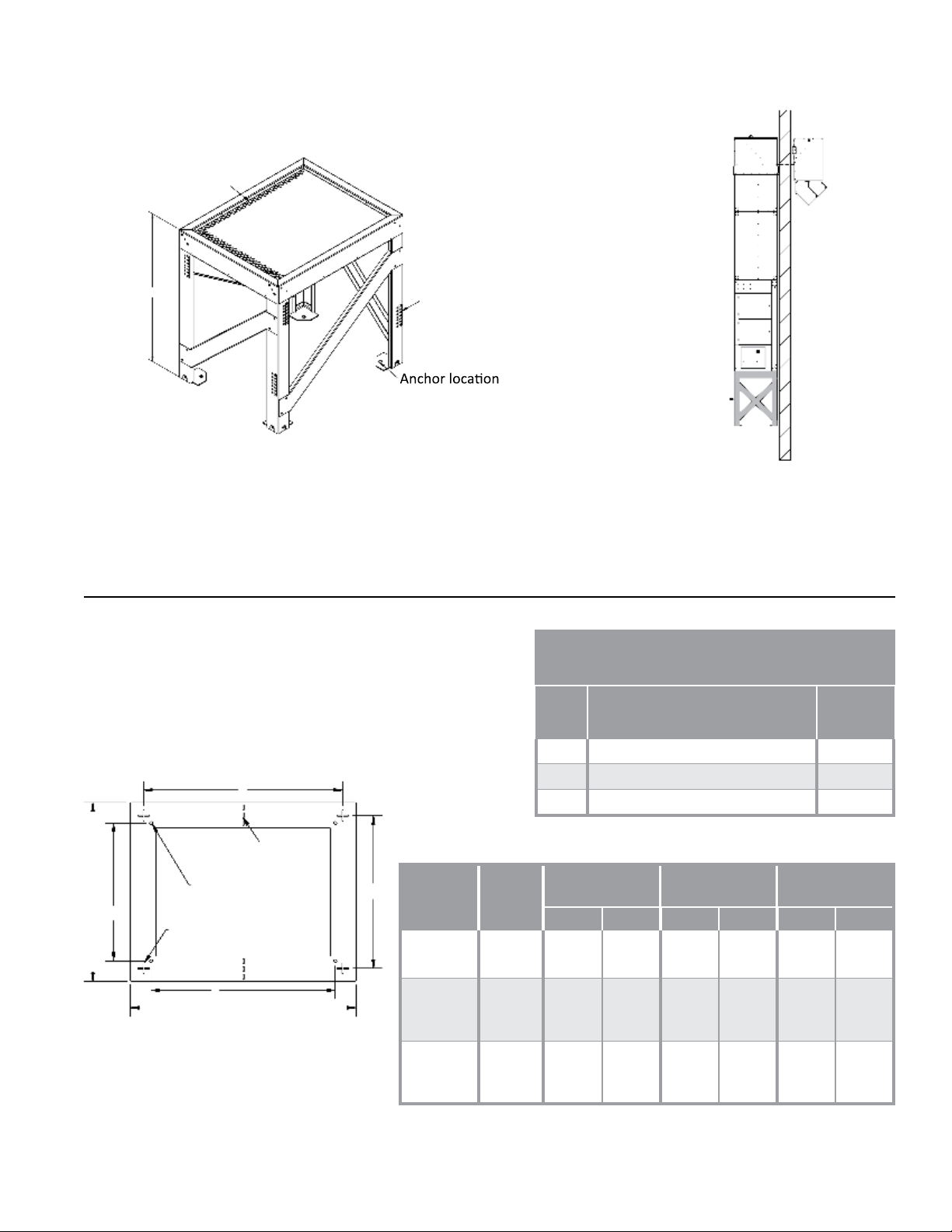

INSTALLATION INSTRUCTIONS

VERTICAL OUTDOOR MOUNTING

mWARNING:

Due to the size and weight of this equipment, it

is recommended the heater mounting structure be

reviewed and approved by a qualified structural

engineer before installing this equipment.

IMPORTANT

Before proceeding with the installation, verify the

feasibility of the location selected with respect to accessibility to the equipment for service and maintenance functions.

mCAUTION

To prevent contaminated air from being drawn

into the heater, install the heater’s inlet at least 10

feet from any building exhaust, process exhaust,

sewer stacks, or other sources that would allow

contaminants to be drawn into the heater. Consult

local codes for additional references.

1. Prepare wall penetration to the dimensions below.

2. Connect the inlet accessories to the heater including the filter section (optional).

7. Install the wall sleeve to the downturn.

8. Install fiberglass insulation in the gaps around the

wall opening and the wall sleeve. Apply enough

material to accommodate the full thickness of the

wall.

9. Install finish trim pieces (by others) to the top,

sides and bottom of the wall sleeve on both the

inside and outside wall surfaces.

10. Apply silicone caulk at the joint between the wall

sleeve and the outside wall surface. Make certain

this is a continuous bead and that it runs the entire

width of the wall sleeve. Caulk all other exposed

joints.

11. Mount the gas train enclosure to the wall structure

and connect gas piping between the heater and the

enclosure.

12. Install the inlet skirt to the heater inlet and attach

the skirt extension to the exterior wall (page 21).

13. Install wall sleeve, second downturn and

directional elbows. Consult the job layout for the

orientation of the elbows.

3. Install structural uprights and associated wall supports per structural engineers recommendations.

4. Remove the lag bolts used to fasten the unit to the

skid.

5. Utilizing the lifting brackets on the front of the

heater, use a forklift or comparable lifting device

to raise and position the heater. Take precautions to prevent equipment damage (dents and/or

scratches) when the heater is being lifted into position.

6. Secure the heater in place with contractor supplied

hardware.

* Dimensions allow for 1½” clearance on each side

S-Series Technical Manual 19 Cambridge Air Solutions

TYPICAL VERTICAL OUTDOOR INSTALLATION

INTERIOR WALL FLASHING

(BY OTHERS)

EXTERIOR WALL FLASHING

(BY OTHERS)

DOWNTURN

UNIT

mWARNING:

The primary structural support

element of a vertically mounted

heater is the base. Any support

to the heater cabinet should be

considered secondary, only as a

means to help stabilize the heater.

WALL SLEEVE

SECOND DOWNTURN

(OPTIONAL)

DIRECTIONAL

ELBOWS

GAS TRAIN WIRING

(FIELD CONNECTED)

GAS TRAIN ENCLOSURE

GAS TRAIN

ELECTRICAL CONTROL ENCLOSURE

BASE OF HEATER

INLET SKIRT

(FIELD ASSEMBLED)

MOUNTING DETAIL

DOWNTURN

FILTER SECTION

(OPTIONAL)

CHANNEL SUPPORT

(BY OTHERS)

SECURE STRUCTURAL CHANNEL

TO WALL (AS REQUIRED)

(BY OTHERS)

BUILDING WALL

BUILDING FOOTING

Cambridge Air Solutions 20 S-Series Technical Manual

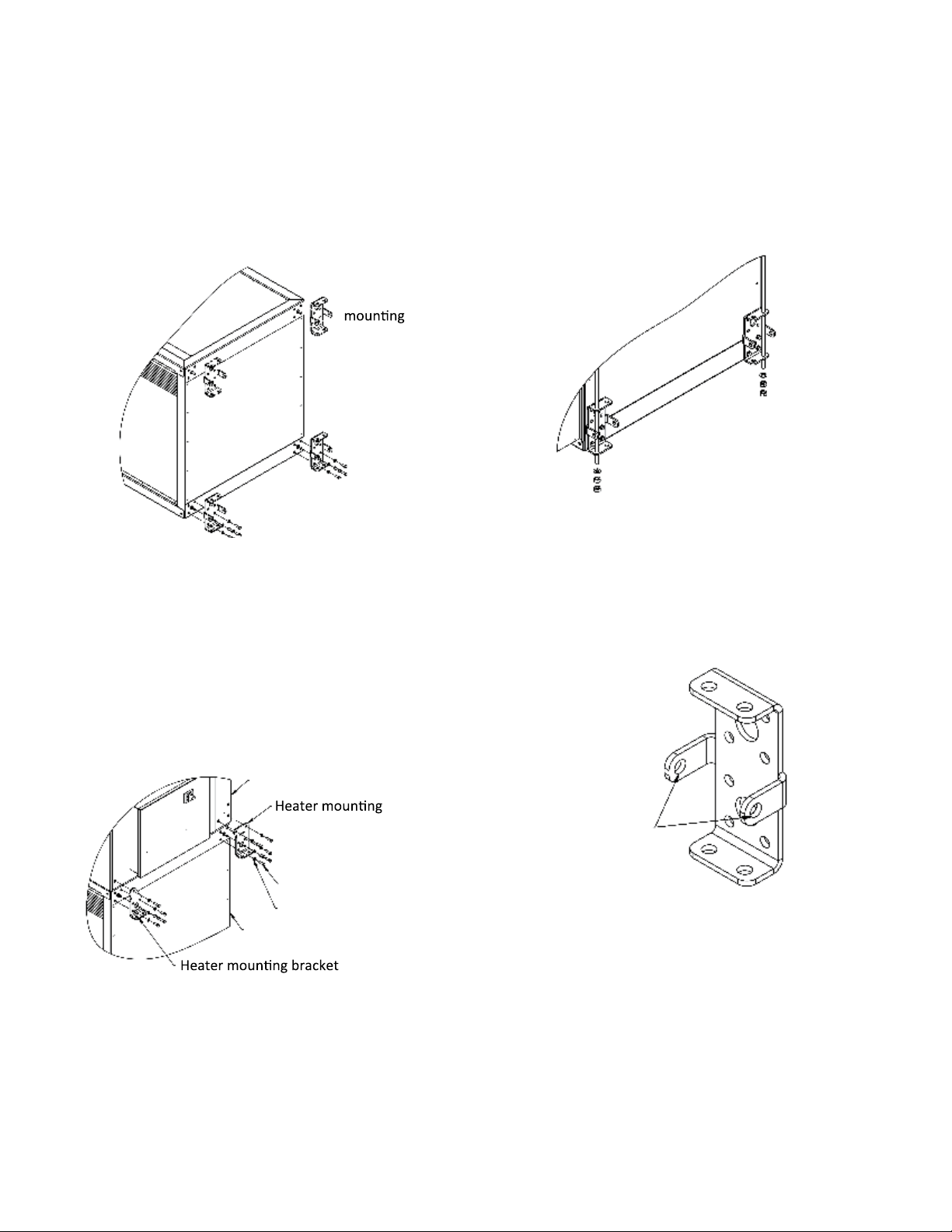

INSTALLATION INSTRUCTIONS

brackets (4 plcs)

Airflow

Stand-Mounted

Structural

inlet elbow

Floor-Mounted

Structural

inlet elbow

Ceiling-Mounted

Structural

inlet elbow

Retaining clip

Retaining clip

(downblast

VERTICAL S-SERIES STRUCTURAL INLET ELBOW

Ceiling-Mounted

brackets (4 plcs)

Stand-Mounted

Retaining clip

Structural

Retaining clip

(downblast

Airflow

The vertical S-Series structural inlet elbow is suitable for indoor or outdoor use. The elbow has been structurally

reinforced to support the weight of the unit and any additional accessories applicable to your installation. It can be

used in floor-mounted applications, with or without a stand, as well as ceiling-mounted applications when hanging

the unit with threaded rod. The elbow is insulated to prevent condensation and reduce noise levels.

Structural

inlet elbow

Model Weight A B C

inlet elbow

Floor-Mounted

Structural

inlet elbow

A

S400/S800

S950/S1200/S1600

S1850/S2200/S3200

C

B

150 lbs. 27 1/2” 25 3/8” 25 3/8”

205 lbs. 30 3/4” 28” 42”

300 lbs. 40 3/8” 37 3/8” 47 1/8”

S-Series Technical Manual 21 Cambridge Air Solutions

INSTALLATION INSTRUCTIONS

Ø 5/8” holes for

wall support

Accessory

bracket

VERTICAL S-SERIES STRUCTURAL INLET ELBOW

CEILING-MOUNTED APPLICATIONS

1. Remove the accessory mounting brackets from the top

of the inlet elbow and reattach them on the bottom of

the inlet elbow for hanging.

Accessory

bracket

2. If heater is vertical downblast, remove the retaining

clip and attach to the opposite flange. .

3. Use the included heater mounting brackets to attach

the inlet elbow to the heater (or filter section if

applicable).

6. Secure threaded rod to ceiling structure as needed.

7. Double-nut the end of the rod below the mounting

bracket at the bottom of the inlet elbow.

8. It is recommended to run support back to the wall to

prevent swaying or tipping of heater and accessories.

• Use the provided holes in the mounting brackets to

run threaded rod (by others) to support on walls (by

others).

• If filter section is included, attach heater to filter

sec-tion using provided accessory mounting brackets

after inlet elbow and filter section are connected.

Heater

bracket

Bolts

Lock washers

Structural inlet elbow

4. If not already attached, secure elbow to discharge of

heater using provided heater mounting brackets.

5. Position heater with attached accessories upright and

lift into place.

Ø 5/8” holes for

wall support

9. For indoor installations, attach thru-wall rain hood and

inlet skirt if applicable.

Cambridge Air Solutions 22 S-Series Technical Manual

INSTALLATION INSTRUCTIONS

Ø 5/8” holes for

wall support

Structural inlet

elbow

Accessory

bracket

Adjustable stand

Bolt

Lock washer

Ø 5/8” holes for

wall support

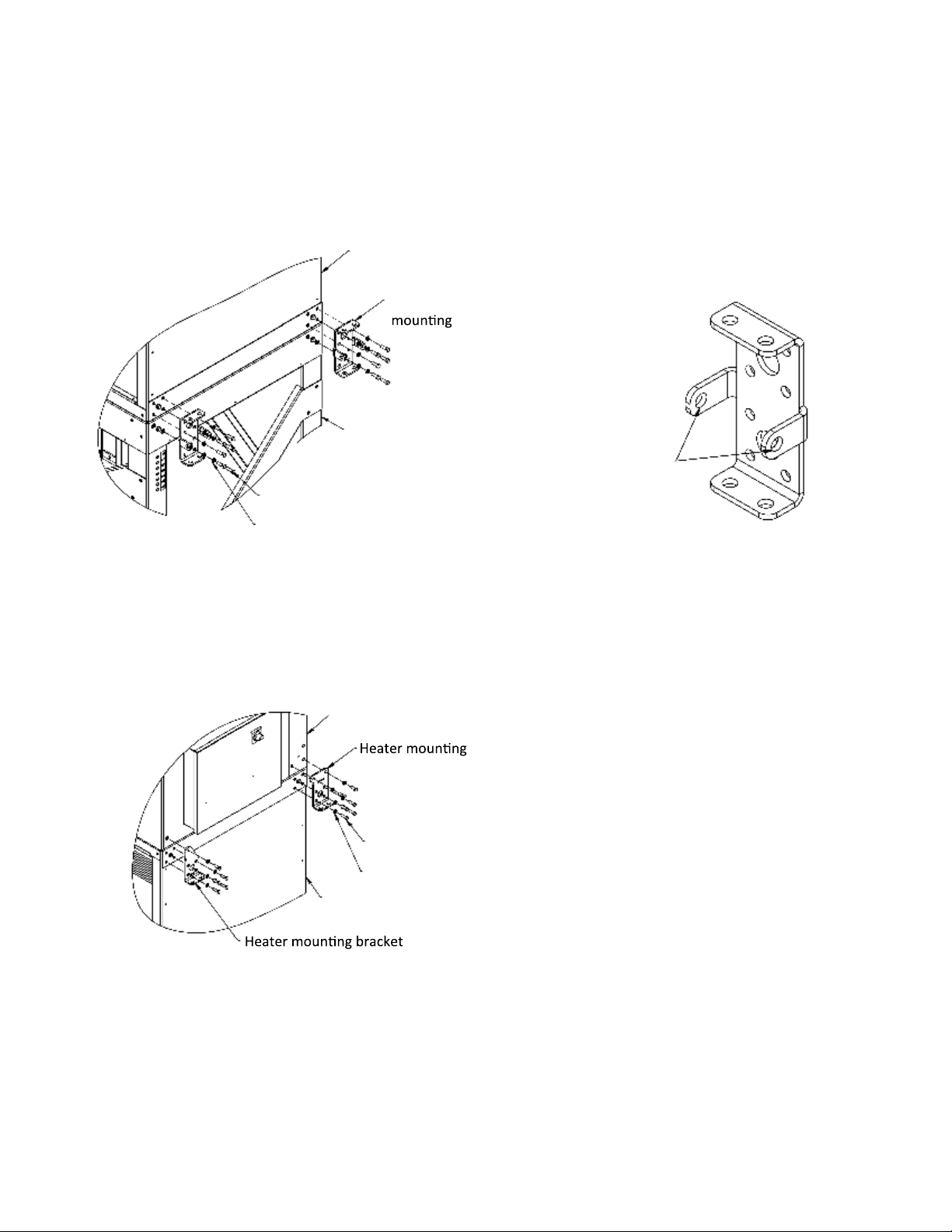

VERTICAL S-SERIES STRUCTURAL INLET ELBOW

STAND-MOUNTED APPLICATIONS

1. Once the stand is set, attach inlet elbow to stand using

the provided accessory mounting brackets.

Structural inlet

elbow

Accessory

bracket

Adjustable stand

Bolt

Lock washer

2. If filter section included, attach filter section to

inlet elbow using the provided accessory mounting

brackets. If filter section is not included, skip to

step 3.

3. Attach heater to inlet elbow (or filter section) below

using the provided heater mounting brackets.

5. It is recommended to run support back to the wall to

prevent swaying or tipping of heater and accessories.

• Use the provided holes in the mounting brackets to

run threaded rod (by others) to support on walls (by

others).

Ø 5/8” holes for

wall support

6. For indoor installations, attach thru-wall rain hood and

inlet skirt if applicable.

Heater

bracket

Bolts

Lock washers

Structural inlet elbow

4. Continue attaching discharge accessories with

provided mounting brackets as needed.

S-Series Technical Manual 23 Cambridge Air Solutions

INSTALLATION INSTRUCTIONS

Ø 5/8” holes for

wall support

Heater

bracket

Bolts

Lock washers

Structural inlet elbow

Heater

bracket

Bolts

Lock washers

Structural inlet elbow

Heater

bracket

Bolts

Lock washers

Structural inlet elbow

VERTICAL S-SERIES STRUCTURAL INLET ELBOW

FLOOR-MOUNTED APPLICATIONS

1. Remove the mounting brackets from the top of the

inlet elbow and reattach them on the bottom of the

inlet elbow for anchoring to the floor.

2. Determine the distance needed between the building

wall and the heater.

3. Place inlet elbow where desired and mark anchor locations using holes in the attached mounting brackets.

9. Continue attaching discharge accessories to heater as

needed using the provided mounting brackets.

Heater

bracket

Bolts

10. It is recommended to run support back to the wall to

prevent swaying or tipping of heater and accessories.

• Use the provided holes in the mounting brackets to

run threaded rod (by others) to support on walls (by

others).

Lock washers

Structural inlet elbow

11. For indoor installations, attach thru-wall rain hood

and inlet skirt if applicable.

4. Install wedge anchors, minimum 0.5”x6” (not

provided), as recommended by manufacturer into

concrete floor where marked.

5. Set inlet elbow over anchors.

6. Make sure inlet elbow is level using shims (by others)

if necessary.

7. Once level, secure elbow to anchors with washer and

Ø 5/8” holes for

wall support

lock nut (not provided).

8. Attach heater (or filter section if applicable) to inlet

elbow using the provided mounting brackets.

bracket

Anchor lock nut

Washer

Installed anchor

Cambridge Air Solutions 24 S-Series Technical Manual

INSTALLATION INSTRUCTIONS

Non-adjustable elbows

Non-adjustable

elbows

Airflow

ment plates

Retaining clip

VERTICAL S-SERIES NON-ADJUSTABLE ELBOW

brackets (Qty 2)

Airflow

Retaining clip

Non-adjustable elbows

ment plates

The non-adjustable elbow is suitable for discharge ductwork to turn air 90° for either indoor or outdoor S-Series

installations. It attaches to the discharge end of a vertical heater or vertical duct extensions with 4 accessory

Non-adjustable

elbows

mounting brackets (shipped with the heater or vertical duct extension) that can either be suspended via threaded

hanging rod or secured horizontal to the wall in stand mounted applications. The discharge end of the elbow attaches

easily to wall sleeves or downturns with lugs. directional elbows with a discharge collar can also be attached directly

to the non-adjustable elbow if desired. Non-adjustable elbows are insulated to help mitigate noise and thermal losses.

A

Model Weight A B C

S400/S800

S950/S1200/S1600

S1850/S2200/S3200

Airflow

C

B

45 lbs. 13” 25 3/8” 25 3/8”

75 lbs. 15” 28” 42”

130 lbs. 24 5/8” 37 1/2” 47”

S-Series Technical Manual 25 Cambridge Air Solutions

INSTALLATION INSTRUCTIONS

Non-adjustable elbow

Non-adjustable elbow

Wall sleeve

Non-adjustable

elbow

Accessory

bracket

Heater

Retaining clip

Non-adjustable elbow

Discharge collar

Non-adjustable elbow

ment plates

Wall sleeve

Non-adjustable elbow

Non-adjustable elbow

ment plates

Wall sleeve

Non-adjustable elbow

Wall sleeve

VERTICAL S-SERIES NON-ADJUSTABLE ELBOW

1. Prepare the non-adjustable elbow for assembly by

re moving the bolts and washers from the sides.

For ceiling mounted applications please refer to the

installation instructions for the structural inlet elbows.

2. Prepare the upstream accessory or heater by removing

the accessory mounting brackets.

3. Lift the non-adjustable elbow into place and secure it

using the bolts and washers removed in the previous

step.

Accessory

bracket

Non-adjustable

elbow

5a. If attaching a wall sleeve or a downturn with lugs,

secure it using both the retaining clip and side

attachment plates. Follow additional installation steps

detailed in the appropriate accessory installation

instructions.

Non-adjustable elbow

Wall sleeve

ment plates

5b. If attaching a discharge collar and directional elbows

replace the screws removed in step 4. Attach the

dis-charge collar to the discharge face of the nonadjustable elbow and secure using self-tapping

screws. Arrange the directional elbows in the desired

configu-ration before securing them to the discharge

collar.

Heater

4. If not already done, remove the side attachment plates

from the discharge end of the non-adjustable elbow. If

attaching a discharge collar with directional elbows,

also remove the retaining clip.

Non-adjustable

elbow

ment plates

Discharge collar

6. Seal all seams between heater and accessories

using appropriate contractor grade caulk to mitigate

Heater

potential water ingestion and pressure loss.

Cambridge Air Solutions 26 S-Series Technical Manual

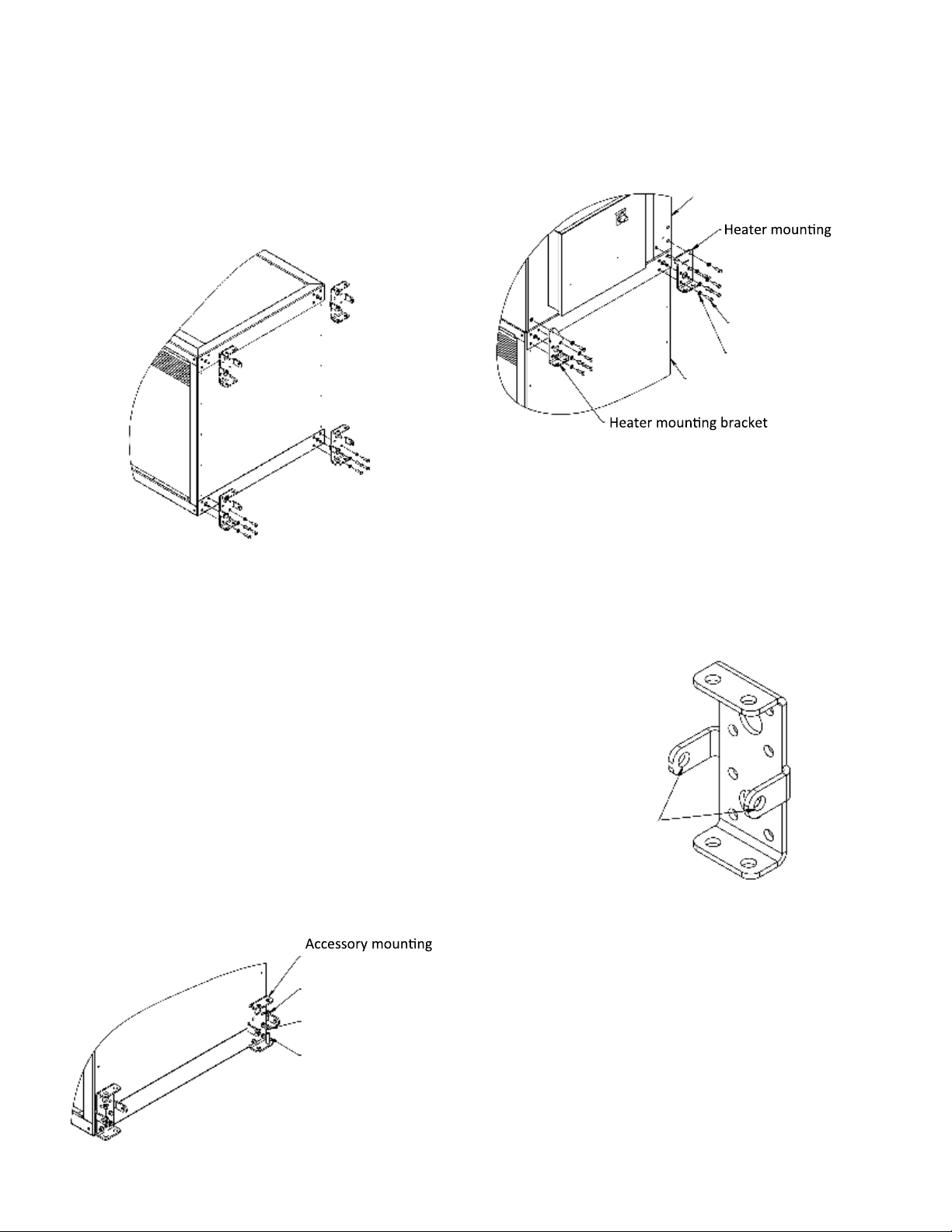

INSTALLATION INSTRUCTIONS

Adjustable

stand

Height adjustment

label (2/leg)

(4 plcs)

48”-54”

Inlet screen

VERTICAL S-SERIES ADJUSTABLE STAND

Inlet screen

48”-54”

Height adjustment

label (2/leg)

(4 plcs)

Adjustable

stand

The Vertical S-Series Adjustable Stand is suitable for use in the up blast configuration in both indoor and outdoor

locations. The 48” height is low enough so the control can may still be accessible without lifts or ladders, but high

enough to avoid snow ingestion from the ground during winter months. The stand features 6” of adjustment (up to

54”) and is suitable for applica-tions when you prefer the heater to be easily accessible for service, yet floor space or

slab size may come at a premium.

1. Determine distance needed between building wall and

heater (12” recommended).

Parts List

• Outer edge of template matches footprint of vertical

unit and stand w/ centerline of heater indicated.

Item Description Qty.

Adjustable stand (assembled) 1

Template 1

Leveling shims 20

Anchor

Footprint

A B C D E F

Locations (o)

Sonotube

Locations (+)

A

1

Template Detail

E

Centerline

Anchor center

C

Sonotube center

D

B

F

Stand

Size

S400/

S800

S950/

S1200/

S1600

S1850/

S2200/

S3200

Weight

176 lbs. 25 1/2” 25 1/2” 16 3/4” 16 3/4” 19 7/8” 19 7/8”

196 lbs. 28” 42” 19 1/2” 33 1/2” 36 1/2” 22 1/2”

222 lbs. 37 1/2” 47” 28 7/8” 38 1/2” 41 5/8” 32”

2

3

Heater/Stand

S-Series Technical Manual 27 Cambridge Air Solutions

INSTALLATION INSTRUCTIONS

Anchor lock nut

Washer

Stand shim

Stand leg

Anchor lock nut

Washer

Stand shim

Stand leg

VERTICAL S-SERIES ADJUSTABLE STAND

2. Use provided template to mark anchor locations on

existing concrete slab. Consult structural engineer as

to adequacy of existing slab for structural support.

• If no slab available, installation of sonotubes with

housekeeping pad is recommended. Use template to

mark center locations of sono-tubes (indicated with

”+” cutout).

• Install sonotubes as recommended by struc-tural

engineer and use template to mark an-chor locations

(indicated with ”o” hole) on sonotubes.

Anchor-

holes

Drilled holes for

anchors

Template

Centerline

Sonotube-

cutouts

Concrete slab

7. Make sure stand is both level and square.

• If shimming necessary, insert provided shims where

needed to level the stand.

• Once level and square, secure base to anchors with

washer and lock nut (not provided).

• Shims are NOT intended to be used for ad-justing

the overall stand height. See next step.

Anchor lock nut

Stand leg

Washer

Stand shim

8. Determine if default stand height (48”) is correct for

heater installation.

• If adjustment needed, remove height adjust-ment

bolts (2/leg), and raise stand necessary amount using

the height label as a guide.

3. Once concrete/sonotubes are marked, remove and

discard template.

4. Drill holes for anchors.

5. Set stand over anchor locations.

6. Install outdoor rated wedge anchors, minimum

0.5”x6” (not provided), as recommended by

manufacturer into concrete slab/sonotubes where

marked.

• Reattach height adjustment bolts.

Washer

Height

adjustment

bolt (2/leg)

Height label

Nut

Lock washer

Cambridge Air Solutions 28 S-Series Technical Manual

Loading...

Loading...