GSA

Gas-Fired Steam Boilers

Boiler Manual

Contents Page

1 Prepare boiler location ........................................................ 2

2 Prepare boiler ..................................................................... 6

3 Install piping ........................................................................ 9

4 Install controls .................................................................. 11

5 Install gas piping ............................................................... 12

6 Field wiring ....................................................................... 13

7 Start-up ............................................................................ 14

8 Checkout procedure ......................................................... 16

9 Sequence of operation ...................................................... 17

10 Lighting instructions .......................................................... 18

11 Service and maintenance ................................................. 20

12 Troubleshooting ................................................................ 24

13 Replacement parts ........................................................... 26

14 Dimensions ...................................................................... 30

15 Ratings ............................................................................. 31

Hazard definitions

Hazards that will cause severe personal injury,

death or substantial property damage.

Hazards that can cause severe personal injury,

death or substantial property damage.

INSTALLER — Read all instructions before

installing. Read page 2 first. Follow all instructions

in proper order to prevent personal injury or death.

• Consider piping and installation when determining

boiler location.

• Any claims for damage or shortage in shipment

must be filed immediately against the transportation

company by the consignee.

• GSA boilers cannot be adapted for heater use.

This manual must only be used by a qualified heating installer/service technician. Failure to comply could result in

severe personal injury, death or substantial property damage.

When calling or writing about the boiler— Please have: • boiler model number from the boiler rating label and • CP number

from the boiler jacket. You may list the CP number in the space provided on the “Installation and service certificate” found on

page 16.

Hazards that will or can cause minor personal injury

or property damage.

Special instructions on installation, operation or

maintenance that are important but not related to

personal injury or property damage.

USER — Please read the following. Failure to

comply could result in severe personal injury, death

or substantial property damage.

• This manual is for use only by your qualified

heating installer/service technician.

• Please see the User’s Information Manual for your

reference.

• Have the boiler serviced by a qualified service

technician, at least annually.

Part Number 550-110-738/0703

GSA

Gas-Fired Steam Boilers – Boiler Manual

1 Prepare boiler locationRead this first!

Failure to adhere to the guidelines below can

result in severe personal injury, death or

substantial property damage.

The boiler contains ceramic fiber and

fiberglass materials. Use care when handling

these materials per instructions on page 32

of this manual. Failure to comply could result

in severe personal injury.

When servicing boiler —

1. To avoid electric shock, disconnect electrical supply

before performing maintenance.

2. To avoid severe burns, allow boiler to cool before

performing maintenance.

Boiler operation —

3. Do not block flow of combustion or ventilation air to boiler.

4. Should overheating occur, turn off or disconnect electrical

supply to boiler and shut off the gas supply at a location

external to the appliance, if possible.

5. Do not use this boiler if any part has been under water.

Immediately call a qualified service technician to inspect

the boiler and to replace any part of the control system

and any gas control that has been under water.

Boiler water —

6. DO NOT use petroleum-based cleaning or sealing

compounds in boiler system. Water seal deterioration will

occur, causing leakage between boiler sections, circulator

flanges, diaphragm tanks or other system components.

This can result in substantial property damage.

7. DO NOT use "homemade cures" or "boiler patent

medicines". Serious damage to boiler, personnel and/or

property may result.

8. Continual fresh makeup water will reduce boiler life. Mineral

buildup in sections reduces heat transfer, overheats cast

iron, and causes section failure. Addition of oxygen and

other gases can cause internal corrosion. Leaks in boiler

or piping must be repaired at once to prevent makeup

water.

9. Do not add cold water to hot boiler. Thermal shock can

cause sections to crack.

Codes & checklist

Installations must follow these codes:

• Local, state, provincial, and national codes, laws, regulations

and ordinances.

• National Fuel Gas Code, ANSI Z223.1–latest edition.

• Standard for Controls and Safety Devices for Automatically

Fired Boilers, ANSI/ASME CSD-1, when required.

• National Electrical Code.

• For Canada only: B149.1 or B149.2 Installation Code, CSA

C22.1 Canadian Electrical Code Part 1 and any local codes.

Certification

The GSA boiler gas manifold and controls met safe

lighting and other performance criteria when boiler

underwent tests specified in ANSI Z21.13–latest

edition.

Before locating the boiler:

❏ Check for nearby connection to:

• Venting connections

• Gas supply piping

• Electrical power

❏ Check area around boiler. Remove any combustible materials,

gasoline and other flammable liquids.

Failure to keep boiler area clear and free of

combustible materials, gasoline and other flammable

liquids and vapors can result in severe personal

injury, death or substantial property damage.

❏ Boiler must be installed so that gas control system components

are protected from dripping or spraying water or rain during

operation or service.

❏ If new boiler will replace existing boiler, check for and correct

system problems, such as:

1. System leaks causing oxygen corrosion or section cracks

from hard water deposits.

2 Part Number 550-110-738/0703

GSA

1 Prepare boiler location continued

Clearances

Gas-Fired Steam Boilers – Boiler Manual

Service clearances

1. Provide minimum clearances for cleaning and servicing the

boiler and for access to controls and components as listed in

the table below.

2. Provide at least screwdriver clearance to jacket front panel

screws for removal of front panel for inspection and minor

service. If unable to provide at least screwdriver clearance,

install unions and shutoff valves in system so boiler can be

moved for servicing.

Service clearances: Minimum

Top

(for cleaning flueways)

Front

(for access to controls and components)

46"

18"

Back 6"

Left side

(for cleaning and servicing)

24"

Right side 6"

Minimum clearance to combustible materials

General — all installations

1. Hot water pipes must be at least ½" from combustible material.

2. Single-wall vent pipe must be at least 6 inches from combustible

material.

3. Type B double-wall metal vent pipe — See vent manufacturer’s

recommendation for clearances to combustible material.

Small space — alcove (not closet) installation

GSA boilers are not approved for closet installation

— only for alcove installation, with minimum

clearances as shown in Figure 1 and the table below,

and the front side completely open — that is, a 3walled room.

Clearances from combustible materials: Minimum

Top 46"

Front

(provide means of access)

Back 6"

Left side

(provide means of access)

Right side 4"

Large space — (see minimum room volume, below)

If installed in a four-walled room, the room volume must be no less

than the following (Ceiling height, if over 8 feet, can only be counted

as 8 feet.):

GSA-075 & GSA-100 147 cubic feet

GSA-125 & GSA-150 184 cubic feet

GSA-175 & GSA-200 221 cubic feet

GSA-250 257 cubic feet

The room must provide the following minimum clearances (in all

directions) to the boiler and components:

Jacket and flue collector sides & rear 6 inches

Jacket front 18 inches

Vent pipe (other than Type B vent) 6 inches

Vent damper 6 inches

3"

4"

Figure 1 Minimum clearances - alcove installation only

Residential garage installation

Take the following special precautions when installing the boiler in

a residential garage. If the boiler is located in a residential garage,

per ANSI Z223.1, paragraph 5.1.9:

• Mount the boiler a minimum of 18 inches above the floor of the

garage to assure the burner and ignition devices will be no less

than 18 inches above the floor.

• Locate or protect the boiler so it cannot be damaged by a moving

vehicle.

Flooring and foundation

Do not install boiler on combustible flooring or

carpeting even if a concrete or aerated foundation is

used. Fire can result, causing severe personal injury,

death or substantial property damage.

1. Provide a solid brick or minimum 2-inch thick concrete

foundation pad if any of the following is true:

• floor can become flooded.

• the boiler mounting area is not level.

2. See Table 1 for minimum foundation dimensions.

3. Use a foundation with airways when:

• Electrical wiring or telephone cables buried in the concrete

floor of the boiler room.

• Concrete floor is “green”.

• Water is channeled under the concrete.

Table 1 Minimum foundation size

Boiler

model

GSA-075 — GSA-100

GSA-125 — GSA-150

GSA-175 — GSA-200

GSA-250

Minimum

foundation

length

5

29

/

8

"

5

29

/

8

" 23

5

29

/

8

" 27

5

29

/

8

" 31

Minimum

foundation

width

19"

1

/

4

1

/

2

3

/

4

"

"

"

3Part Number 550-110-738/0703

GSA

Gas-Fired Steam Boilers – Boiler Manual

1 Prepare boiler location continued

Vent system

Failure to follow all instructions can result in flue gas

spillage and carbon monoxide emissions, causing

severe personal injury or death.

Inspect existing chimney before installing boiler.

Failure to clean or replace perforated pipe or tile lining

will cause severe personal injury or death.

Do not alter boiler draft diverter or place any

obstruction or non-certified vent damper in breeching

or vent system. CSA certification will become void.

Flue gas spillage and carbon monoxide emissions

will occur causing severe personal injury or death.

The following requirements apply when you remove

an existing boiler from a vent system shared with

other appliances. If the new boiler will not use the

common vent, you must test (as described below)

each remaining appliance — operating by itself — to

verify that the vent system operates adequately.

When removing boiler from existing common vent

system:

At the time of removal of an existing boiler, the following steps shall

be followed with each appliance remaining connected to the common

venting system placed in operation, while the other appliances

remaining connected to the common venting system are not in

operation.

a. Seal any unused openings in the common venting system.

b. Visually inspect the venting system for proper size and horizontal

pitch and determine there is no blockage or restriction, leakage,

corrosion or other deficiencies which could cause an unsafe

condition.

c. Test vent system — Insofar as is practical, close all building

doors and windows and all doors between the space in which

the appliances remaining connected to the common venting

system are located and other spaces of the building. Turn on

clothes dryers and any appliance not connected to the common

venting system. Turn on any exhaust fans, such as range hoods

and bathroom exhausts, so they will operate at maximum speed.

Do not operate a summer exhaust fan. Close fireplace dampers.

d. Place in operation the appliance being inspected. Follow the

lighting instructions. Adjust thermostat so appliance will operate

continuously.

e. Test for spillage at draft diverter relief opening after 5 minutes

of main burner operation. Use the flame of a match or candle.

f. After it has been determined that each appliance remaining

connected to the common venting system properly vents when

tested as outlined above, return doors, windows, exhaust fans,

fireplace dampers, and any other gas-burning appliance to their

previous conditions of use.

Any improper operation of common venting system should be

corrected so the installation conforms with the National Fuel Gas

Code, ANSI Z223.1–latest edition. Correct by resizing to approach

the minimum size as determined using the appropriate tables in

Part 11 of that code. Canadian installations must comply with B149.1

or B149.2 Installation Code.

Equipment”, of National Fuel Gas Code, ANSI Z223.1–latest

edition and applicable building codes. Canadian installations

must comply with B149.1 or B149.2 Installation Codes.

2. See “Ratings” on page 31 for minimum chimney or vent sizes.

Chimney or vent termination:

• A chimney, or any vent other than a Type B vent with listed

vent cap, must extend at least 3 feet above the highest point

where it passes through a roof of a building, and at least

2 feet higher than any portion of a building within a horizontal

distance of 10 feet.

• Type B vents with listed caps may terminate as in Figure 2

if no closer than 8 feet from a vertical wall or similar

obstruction.

• Otherwise, Type B vents must terminate at least 2 feet above

the roof penetration and at least 2 feet higher than any portion

of a building within 10 feet.

3. A lined chimney is preferred and must be used when required

by local, state, provincial and national codes, laws, regulations

and ordinances. Vitreous tile linings with joints that prevent

retention of moisture and linings made of noncorrosive materials

are best. Advice for flue connections and chimney linings can

be obtained from local gas utility. Type B double-wall metal vent

pipe or single-wall vent pipe may be used as a liner.

4. Cold masonry chimneys, also known as outside chimneys,

typically have one or more walls exposed to outside air.

When any atmospheric gas-fired boiler with automatic vent

damper is vented through this type of chimney, the potential

exists for condensation to occur. Condensation can damage a

masonry chimney. The following are recommended to prevent

possible damage.

a. Line chimney with corrosion-resistant metal liner such as

AL29-4C® single-wall stainless steel or B-vent. Size liner

per National Fuel Gas Code ANSI Z223.1–latest edition.

b. Provide drain trap to remove any condensate.

5. Where two or more gas appliances vent into a common

chimney or vent, equivalent area should be at least equal to

area of vent outlet on largest appliance plus 50 percent of vent

outlet area of additional appliances.

Figure 2 Terminations with Type B vent fitted with

listed cap, provided vent is at least 8 feet

from any vertical wall or similar obstruction

Chimney or vent requirements

1. Venting must be installed according to Part 7, “Venting of

4 Part Number 550-110-738/0703

GSA

Gas-Fired Steam Boilers – Boiler Manual

1 Prepare boiler location continued

Air contamination Air openings

Please review the following information on potential combustion air

contamination problems.

See Table 2 for products and areas which may cause contaminated

combustion air.

To prevent potential of severe personal injury or death,

check for products or areas listed below before

installing boiler. If any of these contaminants are found:

• Remove contaminants permanently.

— OR —

• Isolate boiler and provide outside combustion air. See

national, provincial or local codes for further

information.

Table 2 Corrosive contaminants and likely locations

Products to avoid

Spray cans containing chloro/fluorocarbons

Permanent wave solutions

Chlorinated waxes/cleaners

Chlorine-based swimming pool chemicals

Calcium chloride used for thawing

Sodium chloride used for water softening

Refrigerant leaks

Paint or varnish removers

Hydrochloric acid/muriatic acid

Cements and glues

Antistatic fabric softeners used in clothes dryers

Chlorine-type bleaches, detergents, and cleaning solvents found in

household laundry rooms

Adhesives used to fasten building products and other similar products

Combustion air and ventilation openings must comply with Section

5.3, “Air for Combustion and Ventilation”, of National Fuel Gas Code

ANSI Z223.1–latest edition, or applicable local building codes.

Canadian installations must comply with B149.1 or B149.2

Installation Codes.

See table below for minimum combustion/ventilation air opening

sizes. Where openings are required, provide two (2) openings —

one within 12 inches of the ceiling, the other within 12 inches of the

floor, as shown in the table illustrations.

Provide adequate combustion and ventilation air to

assure proper combustion and reduce the risk of

severe personal injury, death or substantial property

damage caused by flue gas spillage and carbon

monoxide emissions.

Areas likely to have contaminants

Dry cleaning/laundry areas and establishments

Swimming pools

Metal fabrication plants

Beauty shops

Refrigeration repair shops

Photo processing plants

Auto body shops

Plastic manufacturing plants

Furniture refinishing areas and establishments

New building construction

Remodeling areas

Garages with workshops

5Part Number 550-110-738/0703

GSA

Gas-Fired Steam Boilers – Boiler Manual

1 Prepare boiler location continued

Air openings continued

Exhaust fans and air movers

The appliance space must never be under a negative pressure.

Always provide air openings sized not only to the dimensions

required for the firing rate of all appliances, but also to handle the air

movement rate of the exhaust fans or air movers using air from the

building or space.

2 Prepare boiler

Placement and setup

Place boiler/crate near position

1. Leave boiler in crate and on pallet until installation site is

ready.

2. Move entire crate and pallet next to selected location.

3. Remove crate. Leave boiler on pallet.

4. Unbolt boiler from pallet.

5. Remove boiler from pallet.

Motorized air dampers

If the air openings are fitted with motorized dampers, electrically

interlock the damper to:

• Prevent the boiler from firing if the damper is not fully open.

• Shut the boiler down should the damper close during boiler

operation.

To accomplish this interlock, wire an

damper open) in series with the thermostat input to the boiler. The

boiler will not start if this damper is closed, and will shut down should

damper close during operation.

Table 3 Manifold orifice sizing

isolated contact

(proving the

Inspect orifices and burners

1. Remove front jacket door. Remove base access panel (see

Figure 16, item 14, page 26).

2. Check for correctly-sized manifold orifices. See Table 3 for sizing.

(The orifice size is stamped on the orifice spud barrel.)

Correctly-sized manifold orifices must be used. Failure

to do so will result in severe personal injury, death or

substantial property damage.

3. Level and straighten burners.

Burners must be properly seated in slots in burner

rest with their openings face up. Main burner orifices

must inject down center of burner. Failure to properly

seat burners will result in severe personal injury,

death or substantial property damage.

4. Reinstall base access panel.

Do not operate boiler without access panel secured

in place. Failure to comply could cause momentary

flame rollout on ignition of main flame, resulting in

possible fire or personal injury hazard.

Pressure test

Perform hydrostatic pressure test

Pressure test boiler before attaching water or gas piping or electrical

supply.

Prepare boiler for test

1. Plug tappings or openings.

2. Do not use gauge supplied with boiler for pressure testing. Install

gauge with appropriate range.

Fill and pressure test

1. Fill boiler with water. Vent all air. Test boilers between 45-50 psi.

Do not leave boiler unattended. A cold water fill could

expand and cause excessive pressure resulting in

severe personal injury, death or substantial property

damage.

2. Check for maintained gauge pressure for more than 10 minutes.

Visually check for leaks if gauge pressure drops.

6 Part Number 550-110-738/0703

GSA

Gas-Fired Steam Boilers – Boiler Manual

2 Prepare boiler continued

Pressure test continued Draft diverter & spill switch

Drain and remove fittings

1. Drain boiler and repair leaks if found.

Leaks must be repaired at once. Failure to do so can

damage boiler, resulting in substantial property

damage.

Do not use petroleum based cleaning or sealing

compounds in boiler system. Severe damage to boiler

will result, causing substantial property damage.

2. Retest boiler after repairing leaks.

3. Remove plugs from any tappings that will be used for controls

and accessories. Refer to Table 4 and Figure 3, below.

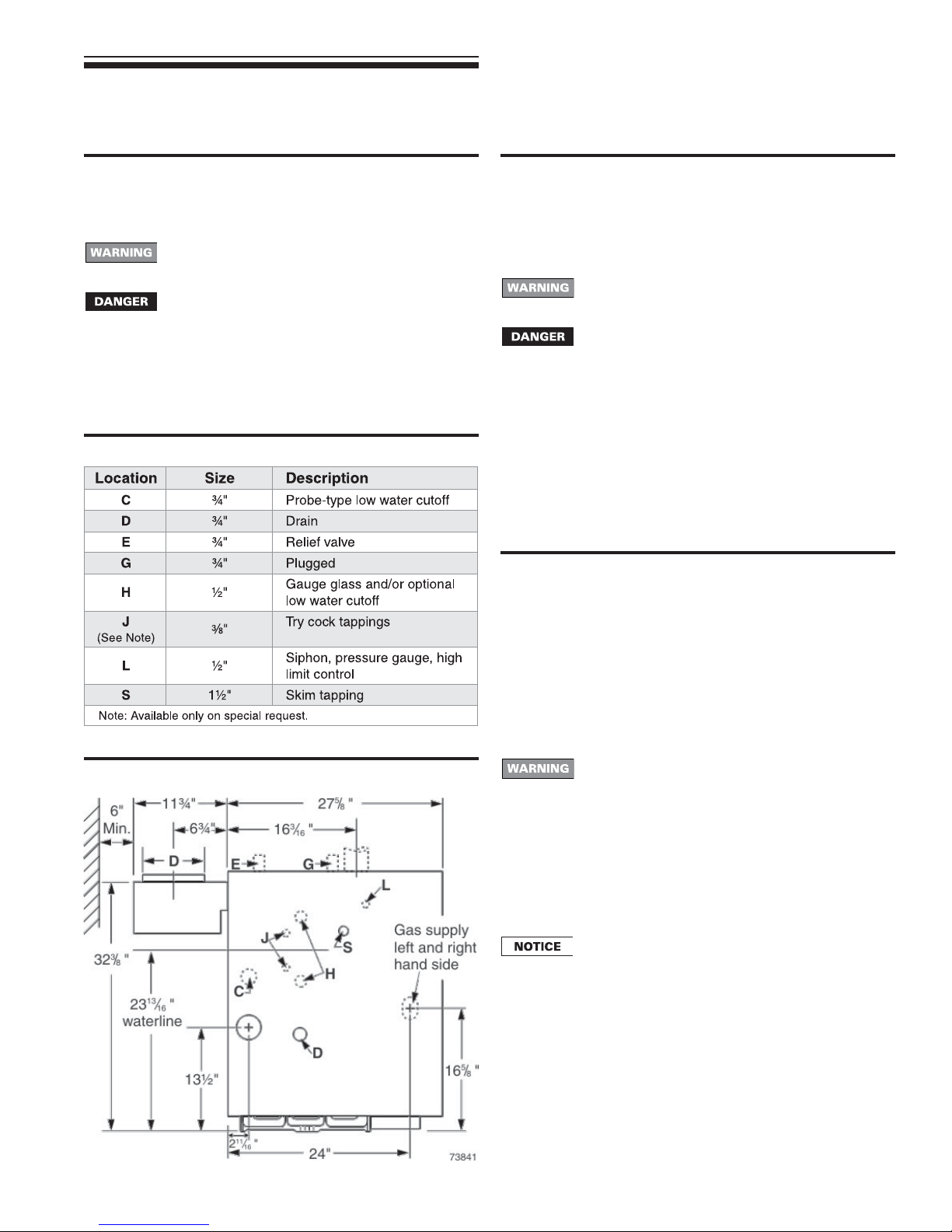

Table 4 Control tapping

Figure 3 Control tapping locations

Draft diverter installation

1. Secure draft diverter to flue collector hood with sheet metal

screws. See Figure 16, items 1 and 9, on page 26. Use boiler

cement to provide gas tight seal.

Failure to maintain gas-tight seal can cause flue gas

spillage and carbon monoxide emissions, resulting

in severe personal injury or death.

Do not alter boiler draft diverter or place any

obstruction or non-approved vent damper in

breeching or vent system. CSA certification will

become void. Flue gas spillage and carbon monoxide

emissions will occur causing severe personal injury

or death.

Spill switch installation

1. Fasten spill switch to draft diverter as shown in Figure 16, item

20, page 26.

2. See Wiring diagram on page 17 to connect wires.

Install vent piping

1. Connect from draft diverter or vent damper outlet to chimney or

vent with same size vent connector.

2. Where possible, vertical venting to the outside from the draft

diverter or vent damper outlet will offer best performance.

3. Where horizontal vent connector is used, slope upward at least

¼" per lineal foot toward chimney or vent and support with

hangers to prevent sagging.

4. Breeching must not be connected to any portion of a mechanical

draft system that can operate under positive pressure.

Long horizontal vent connector, excessive number

of elbow or tees, or other obstructions that restrict

the flow of combustion gases should be avoided.

Severe personal injury, death or substantial property

damage could result.

Float-type low water cutoff — If field installing a floattype low water cutoff, it must be piped only to the

gauge glass tappings, items H, Figure 3. The tappings

are spaced 9" on center. Use only float-type low water

cutoffs with quick-connect hookups that will provide

a low water cutoff point no higher than 2" above the

center of the bottom tapping. See page 11, Figure 9,

for a typical installation.

7Part Number 550-110-738/0703

GSA

Gas-Fired Steam Boilers – Boiler Manual

2 Prepare boiler continued

Vent damper

These systems are used on gas-fired boilers with

vent dampers as shipped from factory. Boiler will not

operate without vent damper installed.

Damper blade

See vent manufacturer’s instructions to install plug (shipped with

damper) in damper hole. Install plug with

damper hole.

Minimum clearances

Provide a minimum of 6" between the vent damper and any

combustible material. (See “Minimum clearance to combustible

materials,” page 3, for minimum clearance from jacket top to ceiling

to maintain this dimension.)

Damper installation

Do not modify draft diverter or vent damper, or make

another connection between draft diverter and vent

damper or boiler except as noted below. This will void

CSA certification and will not be covered by warranty.

Any changes will cause severe personal injury, death

or substantial property damage.

1. Install vent damper as shown in vent damper manufacturer’s

instructions. Vent damper must be installed so that it serves

only one boiler and so damper blade indicator is visible to the

user. See Figure 4.

2. Screws or rivets used to secure the vent damper to the draft

diverter must not interfere with rotation of the damper blade.

3. Install damper harness between damper actuator and knockout

in jacket top panel. Use strain relief connectors and locknuts to

secure both ends of damper harness.

Keep wiring harness clear of all hot surfaces. Wire

insulation could be damaged, causing risk of electrical

short-circuit.

3

/

8" diameter hole in vent

4. Read and apply the harness plug warning label (shown above)

so that it is visible after installation

5. Plug damper harness receptacle into damper harness plug.

Bypassing (jumpering) vent damper will cause flue

products such as carbon monoxide to escape into

the house. This will cause severe personal injury or

death.

After boiler has operated once, if either end of harness

is disconnected, the system safety shutdown will

occur. The boiler will not operate until harness is

reconnected.

Effikal damper — Damper hold open switch must be

in Automatic Operation position for system to operate

properly.

Figure 4 Vent damper assemblies

8 Part Number 550-110-738/0703

3 Install piping

GSA

Gas-Fired Steam Boilers – Boiler Manual

General

1. Pipe before installing controls. Connect return piping after jacket

is attached. Connect supply piping before or after jacket is

attached.

Failure to properly pipe the boiler may result in

improper operation and damage to the boiler or

building.

2. See Figure 5 and Table 5. Pipe exactly as shown. Satisfactory

operation of a steam heating system depends on adequate

condensate return to boiler to maintain a steady water level.

Avoid adding raw makeup water. Where condensate return is

not adequate, install low water cutoff/pump control, condensate

receiver and condensate boiler feed pump. Refer to Table 7,

page 10, for sizing. See page 7, Table 4, for tapping locations.

Figure 5 Recommended piping, piping for parallel-

flow systems only.

Connecting to counterflow piping

Apply the recommended piping in Figures 4 through 7 only when

connecting to a parallel-flow system. When connecting to a

counterflow system, the boiler steam supply must connect into the

top of the counterflow system header, as shown in Figure 6.

Figure 6 Connection to counterflow steam piping

Table 5 Recommended pipe sizing

Boiler model number Riser (A) Header (H)

GSA-075 and GSA-100 2" 2" 1½"

GSA-125 through GSA-175 2½" 2 ½" 1½"

GSA-200 and GSA-250 3" 3" 1½"

Note: 24" minimum from waterline to header.

see Note

Equalizer (J)

Relief valve

Install relief valve in tapping on top of boiler. See Table 4, page 7,

for control tapping locations. See the tag attached to the relief valve

for manufacturer’s instructions.

Follow the steps below to avoid potential severe

personal injury, death or substantial property damage.

• When installing the relief valve, ensure that all

connections, including the valve inlet, are clean and

free from any foreign matter.

• Mount the relief valve only in the vertical position,

directly connected to the tapping designated in the

manual on top of the boiler.

• Use pipe compound sparingly, or tape, on external

threads only.

• Do not use a pipe wrench! Use proper type and size

wrench on wrench pads only.

9Part Number 550-110-738/0703

GSA

Gas-Fired Steam Boilers – Boiler Manual

3 Install piping continued

Relief valve continued

During operation, this valve may discharge large

amounts of steam and/or hot water. Therefore, to

reduce the potential for bodily injury and property

damage, a discharge line MUST be installed that:

• Is connected from the outlet to a safe point of

discharge with no intervening valve.

• Allows complete drainage of both the valve and the

discharge line.

• Is independently supported and securely anchored

so as to avoid applied stress as possible.

• Terminates freely to atmosphere where any

discharge will be clearly visible and is at no risk of

freezing.

• Is, over its entire length, of a pipe size equal to or

greater than that of the valve outlet.

Use only schedule 40 metal pipe for discharge. (Do

not use schedule 80, extra strong or double strong

pipe or connections.) DO NOT CAP, PLUG OR

OTHERWISE OBSTRUCT DISCHARGE PIPE

OUTLET! If discharge is piped upward, a condensate

drain must be provided in the elbow below the vertical

pipe to prevent condensate from returning into the

valve. Failure to comply with these instructions will

cause a dangerous spray of hot water and steam

that would cause severe personal injury or death.

Table 6 Reservoir pipe sizing

Boiler

model

number

GSA-075 75

GSA-100 100

GSA-125 125

GSA-150 150

GSA-175 175 1¾

GSA-200 200 2

GSA-250 250 2½

Designed full capacity steaming time of modern boilers is 10 minutes.

Boiler

gross

output

MBH

Time from initial steaming to average condensate

return (boiler steaming capacity based on 970 Btu per

15 minutes 20 minutes 30 minutes

gallons

1

1

1¼

1½ 1½ 3 2½

pipe

length

(feet)

1

1

1¼

1¾

2

2¼

pound of steam)

gallons

pipe

length

(feet)

1½

1½

2

2½

2

2¼

Use boiler feed system

gallons

pipe

length

(feet)

Use boiler feed

system

Condensate return

Modern steam boilers are designed to steam for less time than

older, larger boilers. When replacing an older steam boiler the system

condensate return time may be longer than the steaming time. This

could cause the following problems:

1. Boilers fitted with an automatic water feed could overfill.

2. Units fitted with only a low water cutoff would shut down and

cycle while waiting for condensate to return.

Following is a simple method for determining whether or not a

reservoir pipe is required to lengthen steaming time for a residential

installation:

1. Disconnect condensate return line at existing boiler.

2. Heat boiler and allow to steam for 10 minutes. Turn off boiler.

3. Measure length of time from when boiler started to steam to

when condensate begins to return through condensate line.

4. Measure length of time from when condensate begins to return

to when it stops returning. Divide this time by 2.

5. Add time measured in step 3 to time calculated in step 4. This

sum is the average time required for condensate to return to

the boiler.

6. If this total time is 10 minutes or less, no reservoir pipe is needed.

If total time for condensate to return to boiler (from step 5) is more

than 10 minutes, a reservoir pipe (or boiler feed system) is

recommended. See Table 6, this page, for suggested reservoir pipe

size. Install as shown in Figure 7, below.

For larger systems (as noted in Table 6), use a boiler feed system

with a condensate tank and feed pump. You will have to install a low

water cutoff/pump control on the boiler to operate the pump. Use

Table 7 to size boiler feed systems. See page 7, Table 4, for tapping

locations. (The use of a combination condensate tank and floatcontrolled condensate return pump is not recommended.)

For most residential installations a reservoir pipe may be all that is

necessary to ensure proper operation.

Figure 7 Recommended piping for parallel-flow

systems with optional reservoir pipe

Table 7 Boiler feed system sizing

Boiler

model

number

GSA-075 63 8 2 4 6 8 0.2

GSA-100 81 10 3 6 9 12 0.3

GSA-125 102 12 4 7 11 14 0.4

GSA-150 122 15 5 9 14 18 0.5

GSA-175 142 17 5 10 15 20 0.6

GSA-200 163 20 6 12 18 24 0.7

GSA-250 203 24 7 14 22 29 0.8

Notes

1. Maximum time to when condensate returns to boiler.

2. If pump capacity exceeds capacity shown, pump can be throttled with globe or

ball valve.

I=B=R

gross

output

(pounds

steam

per hour)

Conden-

sate

(gallons

per hour)

Minimum condensate receiver

capacity gallons for boiler

steaming times (minutes) of:

15 min. 30 min. 45 min. 60 min.

(note 1)

10 Part Number 550-110-738/0703

Suggested

feed pump

capacity

(GPM @

15 PSI)

(note 2)

Loading...

Loading...