Page 1

w

® ET2000 (500 SERIES) PROGRAMMING GUIDE

ET2000 (500 SERIES)

IRRIGATION CONTROLLER

PROGRAMMING GUIDE

making

ater work

since 1986

Page 2

w

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION 1: CONTROLLER DESCRIPTION

I. ET2000 KEY PAD DESCRIPTION

II. WHAT CAN BE PROGRAMMED AT EACH

SCREEN

III. USING THIS GUIDE WITH THE ET2000

CONTROLLER

SECTION 2: SETUP

A. COMMUNICATIONS

1. CONTROLLER(S) WITH CENTRAL

COMMUNICATION

B. PART & SERIAL NUMBER

C. DATE & TIME

D. STATIONS IN USE

E. 12-MONTH MODE

F. ACCESS CONTROL

SECTION 3: PROGRAMS & STATIONS

A. START TIMES AND WATER DAYS

B. STATIONS (STATION PROGRAMMING)

1. CYCLE AND SOAK EXAMPLES

2. TEST A STATION AT THE STATION

PROGRAMMING SCREEN

3. SET NO WATER DAYS AT THE

STATION PROGRAMMING SCREEN

C. STATION TO STATION COPY

1. COPY A STATION TO ANOTHER

STATION

2. COPY A STATION TO ALL STATIONS

ON A PROGRAM, OR ALL STATIONS

ON THE CONTROLLER

D. STATIONS BY PROGRAM

SECTION 4: FLOW

A. FLOW METER SETUP

1. ESTIMATED WATER USAGE

2. FMBX FLOW METER SETUP

3. REGULAR FLOW METER SETUP

4. LEARN EXPECTEDS (FLOW RATE)

B. LINE FILL & VALVE CLOSE TIMES

C. MASTER VALVE

D. PUMP

E. MAIN LINE CAPACITY

F. ON-AT-A-TIME

G. FLOW CHECKING

H. ALERT ACTIONS

SECTION 5: WEATHER

A. ET GAGE (-G OPTION)

1. ET GAGE SETUP

B. RAIN BUCKET (-RB OPTION)

1. RAIN SETUP (WITH RAIN BUCKET

INSTALLED)

2. RAIN SETUP (WITHOUT

BUCKET INSTALLED) AND YOU ARE

SHARING RAIN TO CONTROLLER

C. WIND GAGE (-WG OPTION)

1. WIND GAGE SETUP

2. RESPOND TO WIND BY PROGRAM

D. RAIN SWITCH

1. RAIN SWITCH SETUP

E. ET

1. IRRIGATE USING ET TABLE

2. USE ET AVERAGING

3. ALLOWABLE % OF HISTORICAL ET

4. CROP COEFFICIENTS

5. STATION FLOW RATES WITHOUT A

FLOW METER PRESENT

6. STATION FLOW RATES & AREA WITH

FLOW METER INSTALLED

F. BUDGET

1. DIRECTLY ENTER THE MONTHLY

BUDGETS

2. CONTROLLER WILL

AUTOMATICALLY CALCULATE THE

BUDGET AMOUNT USING THE

TOTAL SQUARE FOOTAGE AND

YOUR CITY ET

3. ENTER A YEARLY BUDGET AND

HAVE THE CONTROLLER DIVIDE IT

AMONG THE MONTHS USING YOUR

CITY ET

®

RAIN

making

ater work

since 1986

Page 3

w

® TABLE OF CONTENTS

G. MOISTURE

1. MOISTURE SENSOR SETUP

2. MOISTURE SENSOR ASSIGNMENT

3. TEST MOISTURE SENSOR

H. ET COUNTY / CITY

1. ET COUNTY / CITY SETUP

SECTION 6: REPORTS

A. THIS MONTH / LAST MONTH

B. 24 MONTH

C. HOLD-OVER

D. ET AND RAI N TABLES

1. REPORTS / ET & RAIN TABLE (ET)

2. REPORTS / ET & RAIN TABLE (RAIN)

E. ALERTS

F. STATION HISTORY

G. USE VS. BUDGET

H. LIVE SCREENS

1. IRRIGATION ACTIVITY

2. IRRIGATION DETAILS

3. REAL-TIME FLOW

SECTION 7: LIGHTS (-L OPTION)

A. PROGRAMMING A LIGHTS SCHEDULE

B. TESTING A LIGHTS CIRCUIT

SECTION 8: RADIO REMOTE (-RR OPTION)

A. ENABLE RADIO REMOTE

SECTION 9: NO WATER KEY

A. NO WATER KEY DESCRIPTION

1. TURN CONTROLLER OFF

2. APPLY NO WATER DAYS TO

PROGRAM

3. NO WATER DAYS BY STATION

SECTION 10: MANUAL KEY

A. MANUAL WATERING

1. MANUAL WATER A STATION

2. MANUAL WATER A PROGRAM

3. CYCLE AND SOAK DURING

MANUAL

B. TEST

1. LEARN THE EXPECTED (FLOW

RATE) AT A STATION

2. TEST A STATION

3. TEST A STATION MOISTURE

SENSOR (see SECTION 5

MOISTURE)

C. MV (MASTER VALVE) OVERRIDE

1. OPEN MASTER VALVE FOR

SPECIFIED TIME

2. WEEKLY SCHEDULE FOR

OPENING MASTER VALVE

D. LEARN EXPECTEDS (FLOW RATE)

E. MANUAL PROGRAM 1

F. MANUAL PROGRAM 2 (see MANUAL

PROGRAM 1)

G. WALK THRU

H. USE HOLD OVER

SECTION 11: FLOWSENSE® (-FL OPTION)

A. MULTIPLE CONTROLLER COMMUNICATION

SETUP

B. MULTIPLE CONTROLLER FLOW SETUP

1. MAINLINE CAPACITY

2. FLOW CHECKING

3. ON-AT-A-TIME

SECTION 12: (-F OPTION)

A. MULTIPLE FLOW METER SETUP

1. FMBX FLOW METER SETUP

2. REGULAR FLOW METER SETUP

3. LEARN EXPECTEDS (FLOW

RATES)

ENCLOSURES

1. ET2000 IRRIGATION CONTROLLER SCREEN

MAP

2. FLAG LETTER DEFINITION SHEET

making

ater work

since 1986

Page 4

w

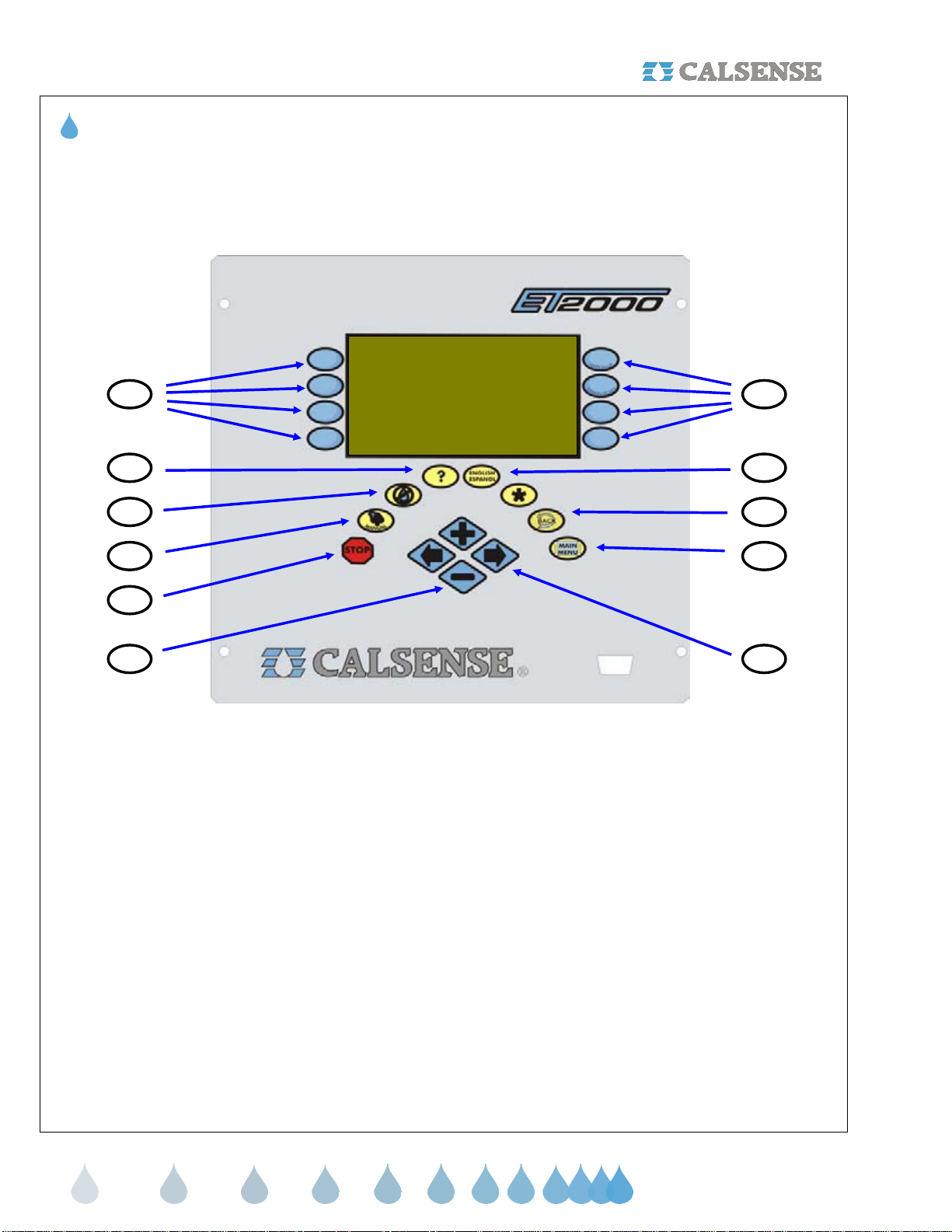

SECTION 1 / I. ET2000 KEY PAD DESCRIPTION ®

SECTION 1 CONTROLLER DESCRIPTION

I. ET2000 KEY PAD DESCRIPTION

8

4

3

2

1

10 9

1 STOP – The STOP key will stop any currently

running Scheduled watering Cycle, Manual

Cycle, Test Cycle, Manual Programs.

2 MANUAL – The MANUAL key will perform

Manual Water, Test, Master Valve Override,

Manual Program 1 & 2, Walk-thru, and

Use Hold-over.

3 NO WATER – The NO WATER key is used for

turning the controller Off and to set No Water

Days.

4 ? – The ? key is used to access the controller

Help screens.

5 ENGLISH / ESPANOL – The ENGLISH /

ESPANOL key allows you to toggle

the displayed

text between English and Spanish.

6 BACK – The BACK key will go back to the

previous screen.

8

5

6

7

7 MAIN MENU – The MAIN MENU key is used to

access the different program features of the

controller.

8 MENU KEYS – MENU keys are used to select

the different features of commands in the

various screens. The text in the screen will point

towards the MENU key that needs to be

pressed.

9 LEFT / RIGHT ARROW KEYS – The LEFT /

RIGHT ARROW keys move the highlighted

cursor around the different screens when

setting up or editing the controller’s

features and options.

10 PLUS / MINUS KEYS – The PLUS / MINUS

keys are used to increase or decrease values

or answer Yes or No questions in the different

screens.

making

ater work

since 1986

Page 5

w

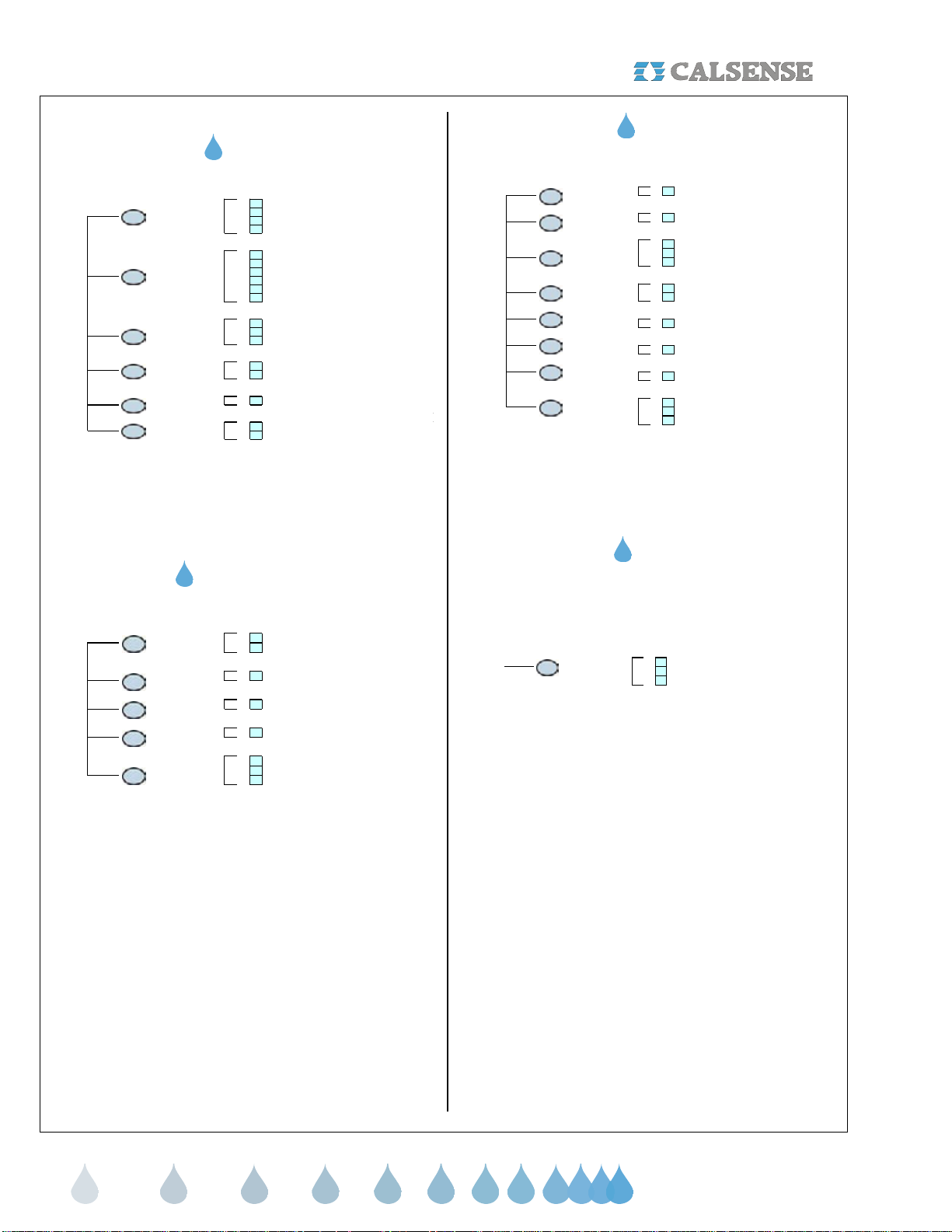

® SECTION 1 / II. WHAT CAN BE PROGRAMMED AT EACH SCREEN

Programs & Stations

Select Program

Set Program Start Time

Programs & Stations

Start Times & Water

Days

Station

Programming

Station-To-Station

Copy

Station-By-Program

Weather

ET Gage

Rain Bucket

Select Program Description (optional)

Set Number Of Water Day s in Schedule

Set Water Days

Set Program Stop Time (optional)

If 12 Month Schedule Is Enabled:

Set All The Above For Each Month Of The Year

Select Stop Time

If Not In Daily ET Mode:

Set Station Program Assignment

Set Total Minutes

Set M i n utes Per Cycle

Set Soak-In-Time

Set No Water Days

Test Station

If In Daily ET Mode:

Set Station Program Assignment

Set % ET

Set M i n utes Per Cycle

Set Area (Sq . F t. )

Set No Water Days

Test Station

Copy Statio n-To-Station

Copy Station-To-Program

View Station By Program

Move Station From Program To Program

Select Irrigation Day Window

Select To Use ET Gage

Select To Log Et Pulses

Reset Full ET Gage

Manually Set Gage Amount In Inches

Set Skip Tonight

Set Minimum Rai n

Set Maximum Hourly Rain

Set Maximum 24 Hour Rain

Set Maximum Total Rain

Set Use Of Rain By Program

Flow

Line Fill & Valve

Close Times

Alert Actions

Master Valve

Pump

Flow Meter

Mainline Capacity

On-At-A-Time

Manual Programs

Manual Water

Test

Master Valve

Override

Flow

Line Fill By Program

Valve Close By Program

Set High Flow Alert Actions By Program

Set Low Flow Alert Actions By Program

Select Type Of Master Valve

Select Use Of Pump (By Program)

Select To Use A Flow Meter

Select To Use List Or Enter Own Parameters

Set Flow Meter Size / Set Own parameters

Learn Expecteds By Program

Set Mainline Break Numbers

Set System Maximum Flow Rates

Set Valves On At A Time Within Program

Set Valves On At A Time Within

Controller / System (IF More Than One Controller)

Manual Water A Station

Manual Water A Program

Cycle And Soak During Manual

Learn The Expected At A Station

Test Station

Test Station Moisture Sensor

Open Master Valve For Hours

Weekly Schedule For Opening Master Valve

Weather

Select The Use Of Wind Gage

Wind Gage

Rain Switch

ET

Budget Select Budget By City ET

Moisture

ET County / City

Set Wind Speed For Pausing Irrigation

Set Wind Speed to Resume Irrigation

Respond To Wind By Program

Select To Use A Rain Switch Device

Select To Use Daily ET (By Program)

Select To Use ET Averaging (By Program)

Crop Coefficients In Use Setting

Select To Use A Budget

Select Budget By Square Footage

Select Budget By Monthly Direct Enter

Calculate Budget

Select To Use Moisture Sensors

Assign Sensor Slaving To Valves

Select County And City For ET

Enter Your Own ET Numbers

View Historical ET Totals

Manual Programs

Learn Expected

Manual Program 1

Manual Program 2

Walk-Thru

Use Hold-Over

Learn The Expected By Program

Schedule Water Days For Manual Program 1

Set Up To 6 Start Times For Manual Program 1

Set Run Duration From / To

Set Station Times

Schedule Water Days For Manual Program 2

Set Up To 6 Start Times For Manual Program 2

Set Run Duration From / To

Set Station Times

Set Walk Thru Count Down

Set Station Run Times

Set Walk-Thru Station Order

Begin Countdown

Select Use Hold-Over

Set Start Times For Hold-Over Use

Set Stop Time For Hold-Over Use

Select Water Days For Hold-Over

making

ater work

since 1986

Page 6

w

SECTION 1 / II. WHAT CAN BE PROGRAMMED AT EACH SCREEN

®

Setup

Select If Part Of FLOWSENSE® Chain

Communications

Part & Serial

Number

Setup

Date & Time Change Date & Time

Stations In Use

12 Month Mode Turn On Twelve Month Mode

Access Control

Select Number Of Controllers In Chain

Set Communication s Address

View Controller Information

View R.O.M. Version

View Controller Baud Rate

View Part Number

View Serial Number

View CC4 Version Required

View Expected Communication Signal Levels

View Current Date & Time

Use Day Light Savings Time

Select To Activate A Station

Select To Deactivate A Station

View Current Access Level

Enter Your Access C ode

Miscellaneous

This Month / Last

ET & Rain Tables

Reports

Station History

Use Vs. Budget

Live Screens

Month

24 Month

Hold-Over

Alerts

Reports

View Water Usage And Irrigation Time

View Yearly Water Usage & Budget Totals

View Station Hold-Over

Clear All Hold-Over

Clear Station Hold-Over

View Or Edit ET Tables

View Rain Table

View Controller Alerts

View Station History

View Actual & Expected Water Usage

Compared To Budget

View Irrigation Activity

View Irrigation Details

View Real-Time Flow

No Water

Miscellaneous

Lights

Radio Remote

Station Alerts

Controller Alerts

Status

Set Up Four Separate Lights Schedules

Manually Start Lights For 4 hours

Enable Radio Remote

View And Clear Station Alerts

View And Clear Controller Alerts

View Current Status Of Controller

View Next Scheduled Irrigation

Turn Controller ON (If It Has Been Turned OFF)

No Water

Turn Controller OFF

Apply No Water Days To Program

No Water Days By Station

No Water

making

ater work

since 1986

Page 7

w

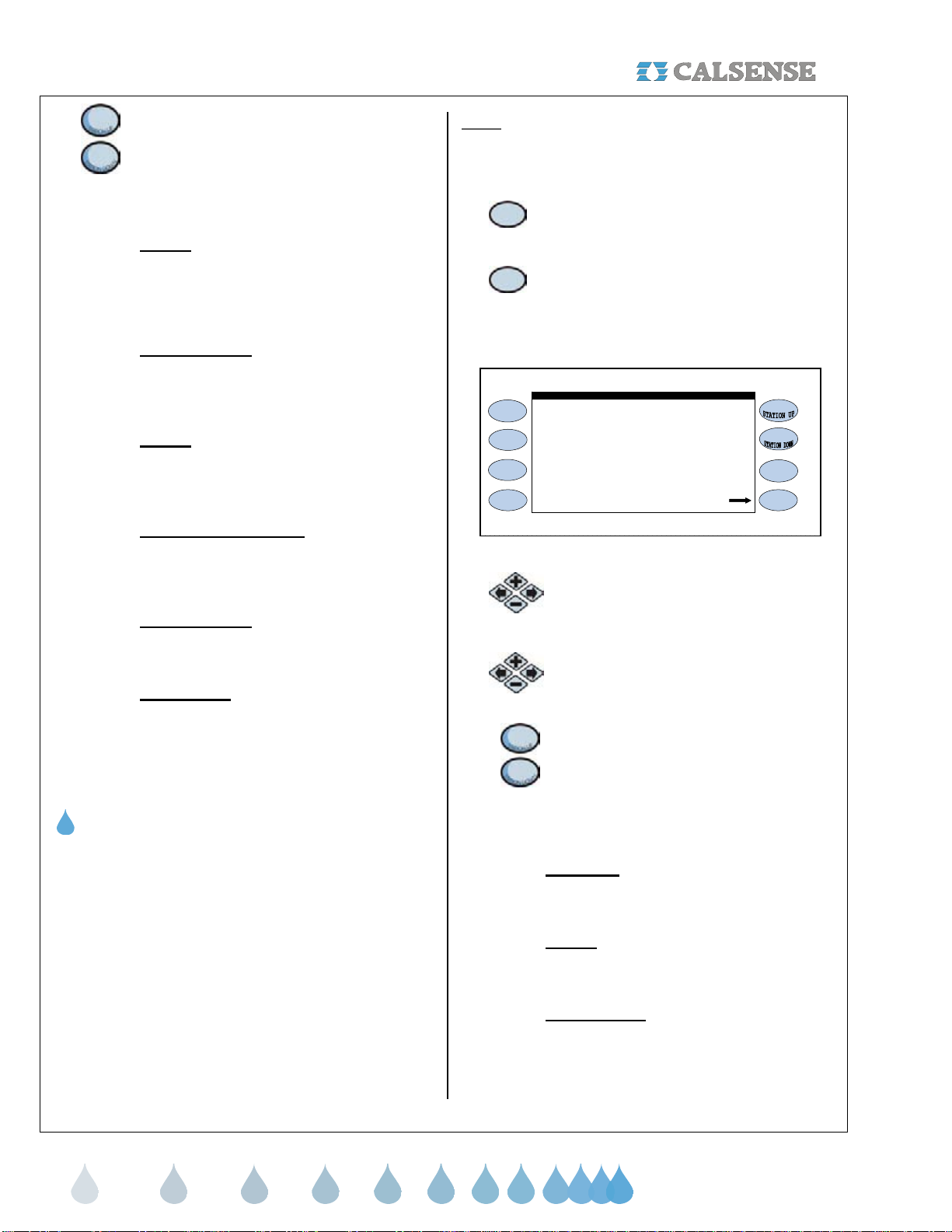

® SECTION 1 / III. USING THIS GUIDE WITH THE ET2000 CONTROLLER

III. USING THIS GUIDE WITH THE ET2000 CONTROLLER

This guide will explain the operation and programming of the ET2000 Controller. The following describes the

conventions used throughout this guide. When instructed to press a key, the name of the key will be

CAPITALIZED AND BOLD. The illustration below shows the name and location of keys used for operating and

programming the ET2000 Controller.

MENU KEYS:

indicates the choice available and will change with each screen. The arrow will point to the Menu key that is to be

pressed, and the name of the key will be CAPITALIZED AND BOLD.

HOT KEYS:

MANUAL, NO WATER, HELP, ENGLISH / SPANISH, BACK, and MAIN MENU key.

PLUS / MINUS & ARROW KEYS:

keys. When a screen is accessed, certain information on the screen can be changed. There will be a highlighted

cursor on the screen, which you can move with either ARROW key. A change can only be made to a setting while

it is highlighted by the cursor. Once a setting is highlighted, use the PLUS or MINUS key to make the change. If

the setting is a number, you can quickly scroll to the desired setting by holding down the PLUS or MINUS key.

The Controller’s screen in the illustration below shows the Main Menu, which can be accessed at any time by

pressing the MAIN MENU key. The description on the screen with the arrows, point to the Menu keys which can

be pressed to access the various parts of the controller’s programming (See Enclosure 1 ET2000 IRRIGATION

CONTROLLER SCREEN MAP). You can always return to a previous screen by pressing the BACK key.

The eight (8) blue keys located on either side of the controller screen. The text next to the key

The eight (8) keys in a horseshoe shape directly below the display screen. They are the STOP,

The last four (4) keys are the PLUS key, MINUS key and the two (2) ARROW

Month UP key

Month DOW N key

Menu keys

Help key

No Wate r k ey

Manual key

Stop key

Menu Key Name Controller Screen Showing M ain Menu

CALSENSE WATER MAN A G EMENT SYSTEM

Programs & Stations Lights

W eather Reports

Flow Radio Remote

Setup Status

Arrow key

ET2000 Irrigatio n C o ntroll er K ey Pl acement and D escription

Plus or Mi nus k ey

Station UP key

Station DOWN key

Menu Keys

English /

Spanish key

Star key

Back key

Main Menu key

making

ater work

since 1986

Page 8

w

)

(

)

A

SECTION 2 SETUP

®

SECTION 2: SETUP

The Setup section of the controller is used for

programming the following:

• Communication addresses

• Accessing the controller’s Part & Serial

number information

• Setting Time & Date

• Activating stations in use

• Utilizing a 12 month schedule

• Inputting access codes

A. COMMUNICATIONS

Skip communication setup section if controlle r(s) has

no communications option installed.

The Communications screen can be used to set the

communications address in the controller. This

address is used for communicating back to a central

computer, and is also used to differentiate one

controller from another in a communications chain.

From the MAIN MENU screen.

1.

Press the SETUP Menu key.

The GENERAL SETUP screen is displayed

(Figure 2.1).

ET2000-40 -MSR-RR (576.i

Communication 12 Month Mode

Part & Serial Numbers

ET-40-MSR-RR

This is not a -FL controller.

FLOWSENSE irrigation between multiple

controllers is not availible.

Communications Addr ess: ! ! A

Controller Info

576.i

Figure 2.2

1.

Press the blue ARROW keys to

highlight the Communications address.

2.

Press the PLUS or MINUS keys to

set the first character.

3.

Press the blue ARROW keys to move

the cursor to the next character.

Repeat the process described above until all three

characters are set (The character furthest to the right

must be a letter).

Note: With multiple controllers one of the controllers

must be the Master with an address ending in a

Capitol “A”. All other controllers will have addresses

ending in B, C, D, etc. No two controllers can have

the same exact address when communicating to the

same central computer. The Master controller must

be the controller communicating back to the central.

To view the controller’s communications

information:

Date & Time

Stations In Use Access Control

Figure 2.1

2. Press the COMMUNICATION Menu

key, the COMMUNICATION screen

will appear.

1. Controller(s) with central communication:

Note:

If FLOWSENSE® option is installed (This can

be verified by looking for a (-FL) in the part number

of the controller section 1B) See Section 11 for

detailed instructions.

The communication screen should look like the one

in Figure 2.2 if your controller does not

FLOWSENSE

® option.

have the

4.

Press the CONTROLLER INFO

Menu key.

The PART & SERIAL NUMBERS screen is

displayed (Figure 2.3).

576.i s=6 c=6 A=14400 B=14 400

ET2000-40-MSR-RR

Serial Num: 0 0000 CC4 Ver: 4.0.11.26

(the normally expected signal levels)

RTS CTS DTR DSR CD RI

: L L L L L L

B: L L L L L L

Copyright Calsense Inc. 1987-20 05

All Rights Reserved

(use * Key for special menu)

PART & SERIAL NUMBERS

Figure 2.3

THIS CONCLUDES THE COMMUNICATIONS

SECTION

making

ater work

since 1986

Page 9

w

® SECTION 2 SETUP

B. PART & SERIAL NUMBER

This screen contains part & serial number

information along with communication information for

the controller.

From the MAIN MENU screen.

1.

Press the SETUP Menu key.

2.

Press the PART & SERIAL NUMBERS

Menu key.

The PART & SERIAL NUMBERS screen is

displayed (Figure 2.4).

576.i s=6 c= 6 A=14400 B=14400

ET2000-40-MSR-RR

Serial Num: 12345 CC4 V er: 4.0. 11.26

(the normally expected signal levels)

RTS CTS DT R DSR CD RI

A: L L L L L L

B: L L L L L L

Copyright Calsense I n c. 1987- 2005

All Rights Reserved

(use * Key for spe cial menu)

PART & SERIAL NUMBERS

Figure 2.4

THIS CONCLUDES THE PART A& SERIAL

NUMBER SECTION

C. DATE & TIME

The Date & Time setting on a new controller will be

set to Pacific Standard Time and will need to be

changed to the local time by the customer upon

receipt.

From the MAIN MENU screen.

1. Press the SETUP Menu key.

2. Press the DATE & TIME Menu key.

The DATE AND TIME screen is displayed

(Figure 2.5).

DATE & TIME

Current Da te & Time :

Oct 28 2005, Fri 10:49:49AM

Date & Time to S et:

Oct 28 2005, Fri 10:49:49AM

PUSH here to SET IT

Use Day Light Savings? YES

3.

Press the PLUS or MINUS keys to

change the Month setting.

4.

Press the blue ARROW keys to move

the cursor to the next entry.

5. Press the PLUS or MINUS keys to

change the next entry. Continue on

until the correct date and time are

displayed.

Use this same method to highlight the “Use Day

Light Savings?” entry and change it to the desired

setting. If you select YES the controller will

automatically change time for Day Light Savings.

6. Once you have completed this press

the PUSH HERE TO SET IT Menu

key.

IMPORTANT:

The changes do not take effect until this button is

pressed.

THIS CONCLUDES THE DATE AND TIME

SECTION

D. STATIONS IN USE

At this screen you can turn-off non-required station

outputs. These stations will no longer be visible for

programming in any other screen.

From the MAIN MENU screen.

1. Press the SETUP Menu key.

2. Press the STATIONS IN USE Menu

key.

The STATIONS IN USE screen is displayed

(Figure 2.6)

1 2 3 4 5 6 7 8 9 10

11 12 13 - - - - 16 17 18 - - 20

21 22 23 24 25 26 27 28 29 30

31 32 33 34 35 36 37 38 39 40

STAT IONS IN USE

Figure 2.5

Figure 2.6

making

ater work

since 1986

Page 10

w

A

SECTION 2 SETUP

®

3. To turn a station off press the blue

ARROW keys to move the cursor to

the desired station.

4.

Press the PLUS or MINUS keys to

turn off the station, two dashed lines

will appear instead of the station

number. In figure 2.6 station 14, 15,

and 19 are turned off. To turn them

back on,

5.

Press the blue ARROW key

to highlight the station.

6.

Then press the PLUS or MINUS key,

the station number will reappear.

THIS CONCLUDES THE STATIONS IN USE

SECTION

E. 12 MONTH MODE

The 12 Month Mode feature allows you to preprogram an irrigation schedule for each month of the

year. Each month can be programmed with different

Start Times, Water Days, Number of Days in

Schedule, Total Minutes, Minutes Per Cycle and

Soak in Time.

Note:

A 12 month schedule is not required to water

all year around.

Note:

As soon as 12-Month Schedule is enabled,

the controller will copy the current irrigation schedule

to all twelve months of the year. All of the months

will keep this schedule until you re-program each

month’s schedule. If you enable 12-Month schedule

before the controller has been programmed with an

irrigation schedule, there will be no Start Times,

water Days or Run Times on all twelve months of the

year. Be sure an irrigation schedule has been

programmed for all twelve months of the year.

From the MAIN MENU screen.

1.

Press the SETUP Menu key.

2.

Press the 12-MONTH MODE Menu

key.

The USE OF 12 MONTH MODE screen is displayed

(Figure 2.7)

Using 12-Month mode in addition to

"Daily ET" may not be necessary.

To Use 12-Month mode requires support

from you as a user. Y ou m ust understand

the mode and be prepar ed to enter water

days, start ti m es, and irrigation amount

f or each month of the year.

Use 12 Month Schedling ? NO

USE OF 12 MONTH MODE

Figure 2.7

3.

Press the PLUS or MINUS key to

change the setting.

If you select YES you will have to return to the

START TIMES & WATER DAYS and STATIONS

screens and enter the information for each month

accordingly. This can be accomplished by using the

two upper most blue Menu keys to the left of the

display screen.

THIS CONCLUDES THE 12 MONTH MODE

SECTION

F. ACCESS CONTROL

Using the Calsense Command Center software, a

three character password can be sent to the

controller, once a password has been sent, the user

will only be able to make changes to screens the

operator has given him access to via the password

entered by the user at the ACCESS CONTROL

screen.

From the MAIN MENU screen.

1. Press the SETUP Menu key,

the GENERAL SETUP screen will

appear.

2.

Press the ACCESS Menu key.

The ACCESS CONTROL screen is displayed

(Figure 2.8).

You may be blocked from making changes

in areas of the con troller. If you

have an access code you may be able

to make those changes.

Current Access is Level 0

Enter Your Access Code: 0 0 0

and Push To Log In

CCESS CONTROL

Figure 2.8

making

ater work

since 1986

Page 11

w

® SECTION 2 SETUP / SECTION 3 PROGRAMS & STATIONS

3. Enter the first character of the

password by pressing the PLUS or

MINUS key until the character

appears.

4.

the cursor to the next character, repeat

the process described above until all

three password characters appear.

5.

Menu key, a message will appear

confirming that the log in was

successful and the LOG OUT prompt

will appear.

THIS CONCLUDES THE ACCESS CONTROL

Press the blue ARROW Keys to move

Press the PUSH TO LOG IN

SECTION

SECTION 3: PROGRAMS & STATIONS

The Programs & Stations section of the controller is

used for programming or viewing the following:

• Start Times & Water days

• Individual station programming

• Station to station copying

• Viewing stations by program

A. START TIMES & WATER DAYS

The Start Times & Water Days section of the

controller is used to setup individual program start

times, program name (optional),number of days in a

schedule, schedule days, and stop times.

From the Main MENU screen.

1.

Menu key.

2.

WATER DAYS Menu key.

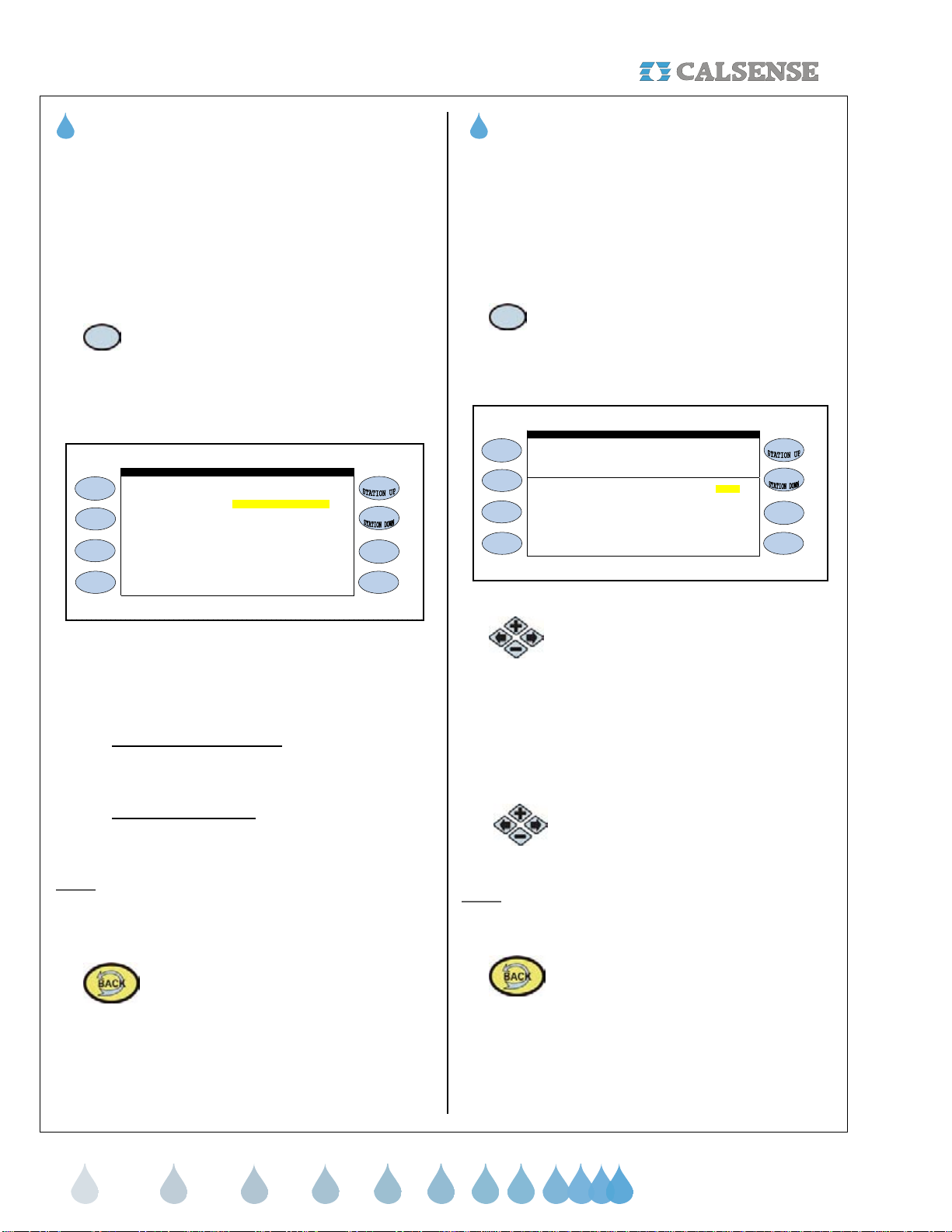

The START TIMES & WATER DAYS screen is

displayed (Figure 3.1).

3.

the cursor to the setting you wish to

change.

4.

change the highlighted setting.

Press the PROGRAMS & STATIONS

Press the START TIMES &

Program : PROG A Sart Time : 11:30PM

Number of Days in Schedule : 07

WEEK 1 on -- on -- on on on

STOP T IME : OFF

START TIMES & WATER DA Y S

Name : . . . . . . . . . . . . . . . . . .

Sun Mon Tue Wed Thu Fri SAT

Figure 3.1

Press the blue ARROW keys to move

Press the PLUS or MINUS keys to

making

ater work

since 1986

Page 12

w

A

SECTION 3 PROGRAMS & STATIONS

®

5. When at the START TIMES & WATER

DAYS screen the two (2) top right

Menu keys can be used to scroll to the

different programs. The following

explains each setting on the START

TIMES & WATER DAYS screen.

• PROG: Indicates the current program.

Program A is being programmed in the

example figure 3.1. The ET2000 Controller

has seven (7) programs A, B, C, D, E,

Drip1, and Drip 2.

• START TIME: The Start Time for

scheduled irrigation on the current

program. Program A has a 11:30 PM Start

Time.

• NAME:

A program description can be

selected which describes the type of plant

material and irrigation heads assigned to

that program (this setting is optional).

• DAYS IN SCHEDULE:

The ET2000 can

be set with a 7-Day schedule (shown in

figure 3.1), 14-Day Schedule, 21-Day

Schedule or 28-Day Schedule.

• WATER DAYS:

The days of the week in

the schedule to irrigate. “on” represents a

water day, “- -“ represents an off day.

• STOP TIME:

A time at which irrigation is

forced to end, even if the scheduled

irrigation cycle is not finished.

THIS CONCLUDES THE START TIMES & WATER

DAYS SECTION

B. STATIONS (STATION PROGRAMMING)

The stations section of the controller is used to setup

the following:

• Individual station program assignments

• Total minutes

• Minutes per cycle

• Soak-In Times

• No water days

• % of ET (If in Daily ET mode)

• Expected Flow Rates (If in Daily ET mode, or

in Budgets mode)

• Area square footages (If in Daily ET mode)

• Precipitation rates (If in Daily ET mode)

Station description’s can be entered via the

Note:

Command Center software.

From the MAIN MENU screen.

1.

Press the PROGRAMS & STATIONS

Menu key.

2.

Press the STATIONS Menu key.

The STATION PROGRAMMING screen is displayed

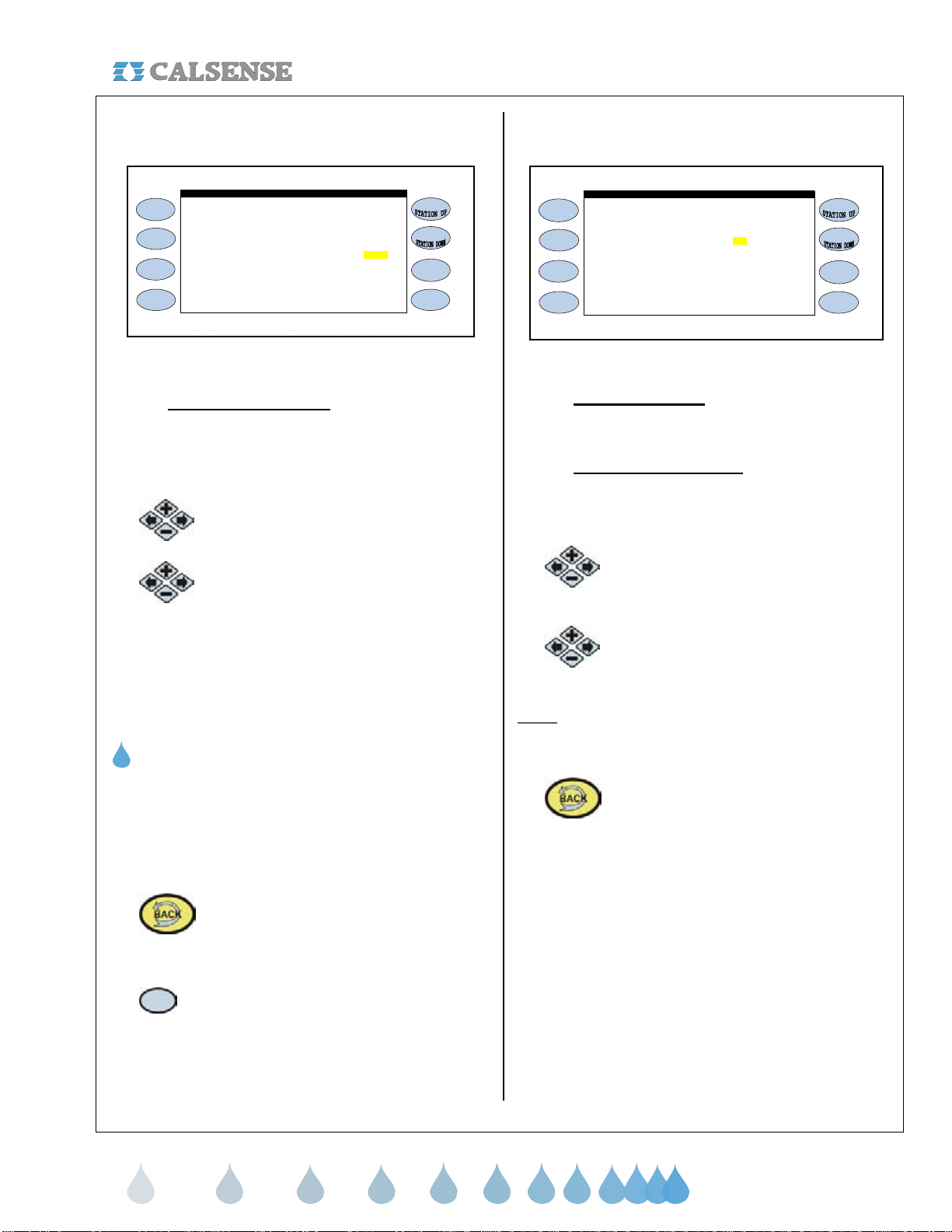

(Figure 3.2).

Station 1 . . . . . . . . . . . . . . PR OG

Total Mins : 15.0

Mins per Cycle : 5

Soak-in Time : 60 No Water Day 0

Test

STATION PROGRAM MING

Figure 3.2

3.

Press the blue ARROW keys to

move the cursor to the setting you

want to change.

4.

Press the PLUS or MINUS keys to

change the highlighted setting.

5. When at the Station Programming

screen, the two (2) top right Menu keys

are used for STATION UP and

STATION DOWN . The following

explains each setting on the STATION

PROGRAMMING screen.

• STATION:

Indicates the current station

number (Station 1 is the example in figure

3.2).

• PROG:

Indicates the program that the

current station is assigned to (Program A

is the example in figure 3.2).

• TOTAL MINS:

The total amount of

irrigation time that will be applied in each

24 our watering period.

making

ater work

since 1986

Page 13

w

® SECTION 3 PROGRAMS & STATIONS

• MINS PER CYCLE: The amount of

irrigation time applied in each cycle of a 24

hour watering period.

• SOAK-IN TIME:

The amount of time (In

Minutes) between multiple cycle starts.

1. Cycle and soak examples:

In the example shown in figure 3.2, station 1 will

irrigate for 5.0 minutes (the Mins per Cycle setting)

then wait 60 minutes (the Soak-in Time setting), it will

repeat the process two (2) more times until the total

irrigation applied is 15 minutes ( the Total Mins

setting), this feature is called Cycle and Soak. Each

station’s Cycle and Soak setting can be set

independent of any other station’s settings. The

following shows some examples of Cycle and Soak

settings:

Example 1

Total Mins: 10.0

Mins per Cycle: 2.0

Soak-in Time: 15

In this example the controller will irrigate 5 cycles of 2 minutes, for a

total of 10 minutes with a soak in time of 15 minutes between cycles.

Example 2

Total Mins: 10.0

Mins per Cycle: 10.0

Soak-in Time: 5.0

In this example the total minutes and the minutes per cycle are the

same, therefore the controller will irrigate one cycle of ten minutes.

The soak in time will be ignored

.

Example 3

Total Mins: 10.0

Mins per Cycle: 20.0

Soak-in Time: 10

In this example the controller will irrigate 1 cycle of 10 minutes. The

Mins per Cycle Time and Soak-In Time will be ignored.

2. Test a Station at the Station Programming

Screen

1. Press the TEST Menu key to turn the

current station on. The run time will be

the time set at the Valve Testing

screen.

3. Set NO Water Days at the Station

Programming Screen

No Water Days gives you the ability to turn a specific

station off for a certain amount of days consecutively

starting from today’s date. This setting will only affect

the station involved.

1. To turn the current station off for 1 to

31 days, press the blue ARROW keys

to highlight the NO Water day setting.

2.

Press the PLUS or MINUS keys to set

the number of NO Water Days

desired.

THIS CONCLUDES THE STATION PROGRAMMING

SECTION

C. STATION-TO-STATION COPY

The Station to Station Copy feature allows you to copy

programming from one station to another, copy the

programming from one station to all stations, or any

program.

The settings that are copied are:

• Total Minutes (except in Daily ET mode)

• Minutes Per Cycle

• Soak-In Time

From the MAIN MENU screen.

1.

Press the PROGRAMS & STATIONS

Menu key.

2.

Press the STATION – TO –

STATION COPY Menu key.

The STATION TO STATION COPY screen is

displayed (Figure 3.3).

Items copied from Station to Station:

Total M ins*

Mins per Cycle

Soak-in T ime

* except to Daily ET stations

Copy from Station 6 to Station 7

Copy Station 6 to PROG A Station s

STAT ION T O ST ATION COP Y

2.

Pressing the STOP key at anytime will

end the test.

Figure 3.3

making

ater work

since 1986

Page 14

w

SECTION 3 PROGRAMS & STATIONS

®

1. Copy a Station to another Station

1.

At the Station To Station Copy screen

press the PLUS or MINUS key until

the station you want to copy is

highlighted. (station 6 was

selected in figure 3.3).

2.

Press the blue ARROW keys to

highlight the station you want to copy

to.

3.

Press the PLUS or MINUS keys to

change the station to copy to.( station

7 was selected in the example above).

4.

Press the COPY FROM STATION

TO STATION Menu key, the station

will be copied and you will be

asked to press any key to continue.

2. Copy a Station to All Stations on a Program,

or All Stations on the Controller:

1. At the STATION TO STATION COPY

screen press the Blue ARROW keys

to move the cursor.

2.

Press the PLUS or MINUS key to

select all stations or a specific

program.

The PROGRAM ASSIGNMENT SUMMARY screen is

displayed (Figure 3.4).

PROGRAM ASSIGNMENT SUMMARY

PROG A: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

PROG B: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2, 3, 4, 5, 6, 7, 8

PROG C: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROG D: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Move Station

(move cursor to see more)

Figure 3.4

2.

Press the PLUS or MINUS keys to

scroll through the programs.

3.

Press the blue ARROW keys to

highlight the station that you want to

move.

4.

Press the MOVE STATION Menu

key.

The CHANGE STATION PROGRAM ASSIGNMENT

screen is displayed (Figure 3.5)

CHANGE S TAT ION PROGRAM ASSIGNMENT

Change Station 1:

FROM: PROG A: . . . . . . . . . . . . . . . . . . . . . . . . . . .

TO: PROG B: . . . . . . . . . . . . . . . . . . . . . . . . . . .

Make the Change

Press ANY key except the one above

to leave screen WITHOUT maki ng

the change.

3.

Press the COPY STATION TO

PROG Menu key, the station will

copy and you will be asked to press

any key to continue.

THIS CONCLUDES THE STATION TO STATION

COPY SECTION

D. STATIONS-BY-PROGRAM

This section of the controller allows you to view each

station, by program, that it is currently assigned to.

You can also move individual stations from one

program to another.

1. At the PROGRAMS & STATION

screen press the STATIONS-BY-

PROGRAM Menu key.

Figure 3.5

5.

Press the PLUS or MINUS keys to

change the program.

6.

Press the MAKE THE CHANGE

Menu key to change the station to

It’s new program.

THIS CONCLUDES THE STATION BY PROGRAM

SECTION

making

ater work

since 1986

Page 15

w

R

® SECTION 4 FLOW

SECTION 4: FLOW

The Flow section of the controller is used for setting up

the following:

• Line Fill & Valve close times

• Alert Action settings

• Master Valve type

• Use of Pump by program

• Flow Meter size and K & Offset values

• Flow Checking parameters

• Mainline Capacity parameters

• Valve On-at-a Time settings

From the MAIN MENU screen.

1.

Press the FLOW Menu key.

The FLOW METER, MASTER VALVE & PUMP screen

is displayed (Figure 4.1).

FLOW METER, MASTER VALVE & PUMP

Flow Meter

1. Estimated Water Usage

The Estimated Water Use setting is set to YES only if

there is NO flow meter installed, and the following

items are turned off:

• System Capacity

• Daily ET

• Budgets

If none of these items are in use, and you want to track

estimated water usage, change the DO YOU WANT

TO TRACK ESTIMATED WATER USE FOR

REPORTS? setting to YES, return to the Station

Programming screen and set the flow rate for each

station (the flow rate setting appears on the station

programming screen only when the estimated water

use setting is set to YES).

The FLOW METER screen is displayed (Figure 4.2).

Is a Flow Meter in use ? NO

Do you want to track estimated

water use for Reports? NO

FLOW METER

Master Valve Mainline Capacity

Pump On-at-a-Time

Figure 4.1

A. FLOW METER SETUP

The flow meter setup is used to enter the type and size

of a single, or multiple flow meters assigned to this

controller. You can also enter the K & Offset values for

FMBX style flow meters.

Note:

The multiple flow meter option will only be

available if the (-F) option is installed in the controller.

See section 12 for more information.

From the FLOW METER, MASTER VALVE & PUMP

screen (Figure 4.1).

1. Press the FLOW METER Menu key.

Figure 4.2

If Using a Flow Meter use the following directions:

1.

Press the PLUS or MINUS keys to

change the IS A FLOW METER IN

USE ? to YES.

The Flow Meter screen will appear (It will appear as

shown in Figure 4.3 only after the Flow Meter In Use

setting is set to YES).

Is a Flow Meter in use ? YES

Use your own K & Offset ? NO

METER 1

SIZE: FM-1

(Expected Flow Rates can be

automatically learned.)

Learn Expecteds

FLOW METE

Figure 4.3

making

ater work

since 1986

Page 16

w

SECTION 4 FLOW

®

2. Press the blue ARROW keys to

move the cursor to the USE YOUR

OWN K & OFFSET setting, which is

set to NO as the default.

If using a FMBX flow meter see:

2. FMBX flow meter setup

If using a regular flow meter see:

3. Regular flow meter setup

2. FMBX flow meter setup

If the flow meter installed on the system is a Calsense

FMBX, change the “Use your own K & Offset” to YES,

(The screen will appear as shown in Figure 4.4).

Is a Flow Meter in use ? YES

Use your own K & Offset ? YES

METER 1

K: 10.000

OFFSET: 0.200

(Expected Fl ow Rates can be

automatically learned.)

Learn Expecteds

FLOW METER

Figure 4.4

3. Regular flow meter setup

If the answer to Use your own K & Offset is NO.

1.

Press the blue ARROW keys to move

the cursor to the SIZE setting.

2.

Press the PLUS or MINUS keys to

change the flow meter type.

Refer to the chart (Figure 4.5), to choose the correct

flow meter type.

MODEL NUMBER SIZE

FM-1

FM-1B

FM-1.25B

FM-1.5

FM-2

FM-3

1” PLASTIC FLOW METER

1” BRASS FLOW METER

1 ¼” BRASS FLOW METER

1 ½” PLASTIC FLOW METER

2” PLASTIC FLOW METER

3” PLASTIC FLOW METER

Figure 4.5

4. Learn Expecteds (Flow rate)

The Learn Expecteds option on the controller will learn

the expected flow rate for each station on each

program selected.

1.

Press the blue ARROW keys to

move the cursor to the K: setting.

2.

Press the PLUS or MINUS keys to

change the number.

3.

Press the blue ARROW keys to

move the cursor to the OFFSET:

setting.

4.

Press the PLUS or MINUS keys to

change the number.

Note:

The two settings that must be set are the K

value and the Offset. If you know these values enter

them now. If not, Call Calsense at 1-(800)-572-8608

for assistance.

1.

After you have entered the appropriate

Flow Meter(s) select the LEARN

EXPECTEDS Menu key (Figure 4.6).

Is a Flow Meter in use ? YES

Use your own K & Offset ? NO

METER 1

SIZE: FM-1

(Expected Flow Rates can be

automatically learned.)

Learn Expecteds

FLOW METER

Figure 4.6

making

ater work

since 1986

Page 17

w

® SECTION 4 FLOW

The LEARN THE EXPECTED FLOW RATES screen

is displayed (Figure 4.7).

LEARN THE EXPECTED FLOW RATES

At the next program start , turn on

each station and use the measured flow

to set the expected flo w rate.

Learn The Expected Flow Rates for:

PROG A . . . . . . . . . . . . . . . . . . . . . . . NO

PROG B . . . . . . . . . . . . . . . . . . . . . . . NO

PROG C . . . . . . . . . . . . . . . . . . . . . . . NO

PROG D . . . . . . . . . . . . . . . . . . . . . . . NO

PROG E . . . . . . . . . . . . . . . . . . . . . . . NO

DRIP 1 . . . . . . . . . . . . . . . . . . . . . . . NO

DRIP 2 . . . . . . . . . . . . . . . . . . . . . . . NO

Figure 4.7

• LEARN EXPECTEDS:

This allows you to

learn the expected flow rate for each station at

the next program start. Once the flow rate has

been recorded the entry on the screen will

default back to NO.

2.

Press the PLUS or MINUS keys to

select the program.

The LINE FILL & VALVE CLOSE TIMES screen is

displayed (Figure 4.8).

LINE FILL & VALVE CLOSE TIMES

Line Valve

Fill Close

PROG A . . . . . . . . . . . . . . 60 60

PROG B . . . . . . . . . . . . . . 60 60

PROG C . . . . . . . . . . . . . . 60 60

PROG D . . . . . . . . . . . . . . 60 60

PROG E . . . . . . . . . . . . . . 60 60

DRIP 1 . . . . . . . . . . . . . 60 60

DRIP 2 . . . . . . . . . . . . . 60 60

( times are in seconds )

Figure 4.8

• LINE FILL TIMES: The delay time in seconds

that the controller will wait to check flow rates

on a station allowing the flow to stabilize.

• VALVE CLOSE TIMES: The delay time in

seconds that the controller will wait to check

flow on the very next valve allowing time for

the previous valve to close.

3.

Press the blue ARROW keys to

change the setting.

THIS CONCLUDES THE FLOW METER

SECTION

B. LINE FILL & VALVE CLOSE TIMES

The Line Fill & Valve Close times are used to allow

each valve time to stabilize before checking flow.

After you have enabled the flow meter on the FLOW

METER screen as described on the previous page:

1.

Press the BACK key twice to return

to the FLOW METER, MASTER

VALVE, & PUMP screen (Figure 4.1).

2. Press the LINE FILL & VALVE

CLOSE TIMES Menu key.

3.

Press the blue ARROW keys to move

the cursor to the PROG A LINE

FILL TIME.

4.

Press the PLUS or MINUS keys to

set the desired seconds.

Note:

Use this same method to change the VALVE

CLOSE TIME for program A and then repeat these

steps for each program on the list.

5.

Press the BACK key to return to

the FLOW METER, MASTER

VALVE, & PUMP SETUP screen

(Figure 4.9).

THIS CONCLUDES THE LINE FILL & VALVE

CLOSE TIMES SECTION

making

ater work

since 1986

Page 18

w

SECTION 4 FLOW

®

C. MASTER VALVE

This section of the controller allows you to select from

two types of master valves available:

• Normally Open

• Normally Closed

From the FLOW METER, MASTER VALVE & PUMP

SETUP screen (Figure 4.1).

1.

Press the MASTER VALVE Menu

key.

The TYPE OF MASTER VALVE screen is displayed

(Figure 4.9).

TYPE OF MASTER VALVE

The MASTER VALVE is NORMALLY CLOSED

Figure 4.9

The Master Valve default setting is for a normally

closed Master Valve. There are two (2) settings,

• NORMALLY CLOSED:

A normally closed

master Valve is in the closed position until

voltage is applied to open it.

• NORMALLY OPEN:

A normally open Master

Valve is in the open position until voltage is

applied to close it.

Note:

Be sure to select the correct type of Master

Valve installed, if it is incorrect the Master Valve will

close whenever a station is irrigated and no water will

flow when a valve is turned on

.

D. PUMP

If you are using a pump for any one of your valves you

will have to set the controller to recognize that there is

a pump in use and on which program it will be used

on.

From the FLOW METER, MASTER VALVE & PUMP

screen (Figure 4.1).

1.

Press the PUMP Menu key.

The WHICH PROGRAMS USE THE PUMP screen is

displayed (Figure 4.10).

WHIC H PROGRAMS USE THE PUMP

For each program, select YES

if you would like to use the pump

PROG A . . . . . . . . . . . . . . . . . . . . . . . YES

PROG B . . . . . . . . . . . . . . . . . . . . . . . YES

PROG C . . . . . . . . . . . . . . . . . . . . . . . YES

PROG D . . . . . . . . . . . . . . . . . . . . . . . YES

PROG E . . . . . . . . . . . . . . . . . . . . . . . YES

DRIP 1 . . . . . . . . . . . . . . . . . . . . . . . YES

DRIP 2 . . . . . . . . . . . . . . . . . . . . . . . YES

Figure 4.10

2.

Press the blue ARROW keys to

move the cursor to the Program

desired.

The default setting is set to YES on all programs. This

means that the controller’s pump output will be

activated whenever a station on any program is

activated.

3.

Press the PLUS or MINUS keys to

change any Program.

Note:

If the Pump Output Enabled setting is set to NO

on a program, the pump output will not activate when a

station on that program is activated.

2.

Press the BACK key to return to the

FLOW METER, MASTER VALVE, &

PUMP SETUP screen (shown Figure

4.1).

THIS CONCLUDES THE MASTER VALVE

SECTION

4.

Press the BACK key to return to the

Flow Meter, Master Valve & Pump

screen (See figure 4.1).

THIS CONCLUDES THE PUMP

SECTION

making

ater work

since 1986

Page 19

w

® SECTION 4 FLOW

E. MAINLINE CAPACITY

System capacity is defined by the max flow rate of

water that your system can operate at during irrigation.

From the FLOW METER, MASTER VALVE & PUMP

screen (Figure 4.1).

4.

Press the MAINLINE CAPACITY

Menu key.

The MAINLINE BREAK SETTINGS screen is

displayed (Figure 4.11).

Dur ing Irr igation 400 gpm

ALL Other T imes 150 gpm

----------------------SYSTEM CAPACITY SETTINGS---------------------- Use capacity to limit the

number of stations on? NO

MAINLIN E BR EAK SETT INGS

Figure 4.11

5.

move the cursor to the DURING

IRRIGATION gpm.

6.

change the number.

Use the same method to change the ALL OTHER

TIMES number.

• DURING IRRIGATION:

• ALL OTHER TIMES:

• USE CAPACITY TO LIMIT THE NUMBER OF

This will open up the portion of the screen dealing with

Capacity with or without Pump (Figure 4.12).

Press the blue ARROW keys to

Press the PLUS or MINUS keys to

The during irrigation

number is the mainline break number used

while the controller is irrigating.

The all other times

number is the mainline break number used

when the controller is not irrigating.

STATIONS ON ?: If you want to use capacity

to limit the number of stations on change to

YES.

7.

Press the PLUS or MINUS key to

change the capacity numbers.

During Irrigation 400 gpm

ALL Other Times 150 gpm

----------------------SYSTEM CAPACITY SETT INGS---------------------- Use capacity to limit the

number of stations on? YES

Capacity with Pump 200 gpm

Capacity without Pump 100 gpm

(set which programs use the p ump )

MAINLINE BREA K SETTINGS

Figure 4.12

Capacity with pump: When a program irrigates by

use of pump the GPM limit set will not be exceeded.

Capacity without pump: When a program irrigates

without the use of a pump the GPM limit will not be

exceeded.

Note:

Pump and non-pump programs will not run

simultaneously on the same controller / system.

8.

If you did not select SET WHICH

PROGRAMS TO USE PUMP in the

pump section of this manual then

press the SET WHICH PROGRAMS

TO USE THE PUMP Menu key

(Figure 4.12).

See Part D of this section for instructions.

THIS CONCLUDES THE MAINLINE CAPACITY

SECTION

F. ON – AT – A – TIME

The On-at-a-Time section of the controller is used to

set up the number of valves that you want to come on

simultaneously within a program, and also within a

controller.

From the FLOW METER, MASTER VALVE & PUMP

screen (Figure 4.1).

1.

Press the ON-AT-A-TIME Menu key.

making

ater work

since 1986

Page 20

w

SECTION 4 FLOW

®

The STATIONS ON-AT-A-TIME screen is displayed

(Figure 4.13).

STATION S ON-AT-A-TIME

W ithin W ithin

Program Controller

PROG A . . . . . . . . . . . . . . 1 1

PROG B . . . . . . . . . . . . . . 1 1

PROG C . . . . . . . . . . . . . . 1 1

PROG D . . . . . . . . . . . . . . 1 1

PROG E . . . . . . . . . . . . . . 1 1

DRIP 1 . . . . . . . . . . . . . 1 1

DRIP 2 . . . . . . . . . . . . . 1 1

An "X" means don't use this

On-At-A-Time as a limit

Figure 4.13

2.

Press the blue ARROW keys to move

the cursor to the Program and Within

Program setting desired.

Note: The default setting is set to 1 on all programs.

3. To change the settings press the

PLUS or MINUS keys for any number

to change the setting.

• WITHIN PROGRAM:

This section allows you

to choose the amount of valves that you want

to set as a limit to come on at a time within a

program.

• WITHIN CONTROLLER:

This section allows

you to choose the amount of valves that you

want to set as a limit to come on at a time

within the controller.

Example:

Within Program

Program A 1 2

Program B 1 2

Within Controller

This example allows the user to set up one (1) valve

on at a time for Programs A and B. The controller will

allow both Programs to have one (1) valve each run

simultaneously for a total of two (2) on within

controller.

Example:

Within Program

Program A 1 1

Program B 3 3

Within Controller

This example allows the user to set up one (1) valve

on at a time for Programs A. The controller will only

allow one valve to operate while program A is running.

Program B is set up to operate 3 valves on at a time,

and will only operate up to three valves when Program

B is running.

4. Press the BACK key to return to the

FLOW METER, MASTER VALVE, &

PUMP screen (See figure 4.9).

THIS CONCLUDES THE ON AT A TIME SECTION

G. FLOW CHECKING

Flow checking allows you to have the controller

compare the flow of each station during irrigation to

the learned expected flow and alert you of any

problems.

From the FLOW METER, MASTER VALVE & PUMP

SETUP screen (Figure 4.1).

1.

Press the FLOW CHECKING Menu

key

The FLOW CHECKING screen is displayed

(Figure 4.14).

FLOW CHECKING

When Irrigating COMPARE the

flow rate to the expected? NO

Figure 4.14

This will open up the ALLOWABLE portion of the

screen when you select YES to the WHEN

IRRIGATING COMPARE THE FLOW TO THE

EXPECTED ? question (Figure 4.15).

making

ater work

since 1986

Page 21

w

® SECTION 4 FLOW

FLOW CH EC KI NG

When Irrigating COMPARE the

flow rate to the expected? YES

A LLOWA BLE

Below 30 gpm -5 / +5

From 30 gpm to 100 gpm -10 / +10

Above 100 gpm -15 / +15

(-gpm / +gpm)

Figure 4.15

2.

Press the blue ARROW keys to

change the Allowable settings.

The default settings are:

BELOW: -5 / +5

FROM / TO: -10 / +10

ABOVE: -15 / +15

Note:

The above settings are defaulted in the

controller and can be changed by the user.

3.

To change the settings press the

PLUS or MINUS keys for any number

to change the setting.

Below:

This section allows you to enter the fluctuation

range for the low end of your normal operating flow.

Use the (-) and (+) entries to set the range.

Example:

If you set the below limit at 30 gallons per minute.

Then set your (-) limit at 5, and your (+) limit at 5.

You will be alerted if the flow at the low end of the

scale fluctuates by more than five gallons per minute

in either direction.

That is less than 25 gpm or more than 35 gpm

From / to:

This section allows you to set the

fluctuation limits for the full range of flow. In this box

you want to enter the normal operating range of water

flow. Then in the (-) and (+) blocks enter the range of

fluctuation that you deem normal.

Example:

If you set the limit at 30 gpm to 100 gpm.

Then set your (-) limit at 10, and your (+) limit at 10.

You will be alerted if the flow at the middle of the scale

fluctuates by more than ten gallons per minute in

either direction.

That is less than 20 gpm or more than 110 gpm

Above: This section allows you to enter the fluctuation

range for the high end of your normal operating flow.

Use the (-) and (+) entries to set the range.

Note:

You will want to set this allowable range up a

little wider due to the amount of water flow.

Example:

If you set the above limit at 100 gallons per minute.

Then set your (-) limit at 15, and your (+) limit at 15.

You will be alerted if the flow at the high end of the

scale fluctuates by more than fifteen gallons per

minute in either direction.

That is less than 85 gpm or more than 115 gpm

4. Press the BACK key to return to the

FLOW METER, MASTER VALVE, &

PUMP screen (Figure 4.1).

Note:

Notice that the Alert Actions option has now

been added to this screen (See figure 4.16).

FLOW METER, MASTER VALVE & PUMP

Line Fill Flow Meter

& Valve Close Times

Alert Acti ons Flow Checking

Master Valve Mainline Capacity

Pump On-at-a-Time

Figure 4.16

THIS CONCLUDES THE FLOW CHECKING

SECTION

making

ater work

since 1986

Page 22

w

W

SECTION 4 FLOW / SECTION 5 WEATHER

®

H. ALERT ACTIONS

The Alert Actions section of the controller allows you

to setup the way in which you want the controller to

inform you of any problems. The Alert Actions

setting defaults with Alert / No Action set for all

programs. There are three possible settings:

• Alert / No Action:

An alert is displayed on

the screen but the valve continues to

irrigate.

• Alert / Shut-Off:

An alert is displayed on the

screen and the value is shut off.

• No Alerts:

No alert is displayed and the

valve continues to irrigate.

From the FLOW METER, MASTER VALVE & PUMP

screen (Figure 4.1).

1.

Press the ALERT ACTIONS Menu

key.

The ALERT ACTIONS screen is displayed

(Figure 4.17).

SECTION 5: WEATHER

The weather section of the controller is used to set

up the ET Gage, Rain bucket, Wind Gage, Rain

switch, budgets, and Moisture sensors.

A. ET GAGE

The ET Gage setting in the controller is used for:

• Setting ET irrigation day

• *Selecting ET gage Usage

• *Logging ET Gage Pulses

• *Setting Gage fill percentage

• **Manually entering pulses

• **Skipping tonight’s entries

* Only if (-G) option installed in controller and an ET

Gage is connected.

** Used for troubleshooting, or servicing ET Gage.

1. ET Gage setup

From the MAIN MENU screen (Figure 5.1).

1.

Press the WEATHER Menu key.

ALERT ACTION S

HIGH FLOW LOW FLO

PROG A . . . . . . . . . . . . . . Alert / No Action Alert / No Action

PROG B . . . . . . . . . . . . . . Alert / No Action Alert / No Action

PROG C . . . . . . . . . . . . . . Alert / No Action Alert / No Action

PROG D . . . . . . . . . . . . . . Alert / No Action Alert / No Action

PROG E . . . . . . . . . . . . . . Alert / No Action Alert / No Action

DRIP 1 . . . . . . . . . . . . . . Alert / No Action Alert / No Action

DRIP 2 . . . . . . . . . . . . . . Alert / No Action Alert / No Action

Figure 4.17

2.

Press the blue ARROW keys to move

the cursor to the Program HIGH

FLOW and LOW FLOW settings.

3.

Press the PLUS or MINUS keys to

change the settings.

4.

Press the MAIN MENU key to return

to the MAIN MENU screen.

THIS CONCLUDES THE ALERTS / ACTIONS

SECTION

CALSENSE WAT ER M ANAGEM ENT SYSTEM

Programs & Stations Lights

Weather Reports

Flow Radio Remote

Setup Status

Figure 5.1

The WEATHER SETUP screen is displayed

(Figure 5.2).

ET Gage ET

Rain Bucket Budget

Wind Gage Moisture

Rain Switch

WEATHER SETUP

Figure 5.2

2.

Press the ET GAGE Menu key.

making

ater work

since 1986

Page 23

w

® SECTION 5 WEATHER

The ET GAGE screen is displayed (Figure 5.3).

ET GAGE

Irrigation Day is from 8:00PM to 8:00PM

Is there an ET Gage? NO

If YES is selected the screen will change to read:

(Figure 5.5).

ET GAGE

Irrigation Day is from 8:00PM to 8:00PM

Is there an ET Gage? YES

Log Pulses? NO Gage is 99% full

GAGE=.00 inches Skip tonight? YES

Figure 5.3

• Irrigation Day is from 8:00PM to 8:00PM:

This setting is for the time period that you

want your ET information to be collected for

each day. Keep in mind that you want this

time to be before your first irrigation Start

Time for that day so that you are using the

most current ET information.

3.

Press the PLUS or MINUS keys to

change the setting.

Note:

Following steps are for (-G) option only.

4.

Press the blue ARROW keys to

move the cursor to the IS THERE AN

ET GAGE? (Figure 5.4).

Irrigation Day is from 8:00PM to 8:00PM

Is there an ET Gage? NO

ET GAGE

Figure 5.5

6.

Press the blue ARROW keys to

move the cursor to the LOG

PULSES? entry (Figure 5.6).

Irrigation Day is from 8:00PM to 8:00PM

Is there an ET Gage? YES

Log Pulses? NO Gage is 99% full

GAGE=.00 inches Skip tonight? YES

ET GAGE

Figure 5.6

• Log Each Pulse?:

The default is set to NO.

Changing to the YES setting gives you the

option of keeping a record of each ET Gage

pulse sent to the controller. This information

is located in the diagnostic log. This is

helpful when first setting up the ET Gage to

make sure that it is working properly, but

can be set to NO after you are sure the ET

Gage is working properly.

Figure 5.4

5.

Press the PLUS or MINUS keys to

change the setting.

7.

Press the PLUS or MINUS keys to

change the setting.

8. Press the blue ARROW keys to

move the cursor to the GAGE IS 99%

FULL setting (Figure 5.7).

making

ater work

since 1986

Page 24

w

SECTION 5 WEATHER

®

Irrigation Day is from 8:00PM to 8:00PM

Is there an ET Gage? YES

Log Pulses? NO Gage is 99% full

GAGE=.00 inches Skip tonight? YES

ET GAGE

Figure 5.7

• Gage is 99% full:

The percent full counter is

used to reset the counter after the ET Gage

has been refilled during periodic

maintenance.

9. Press the PLUS or MINUS keys to

change the setting.

10.

Press the blue ARROW keys to

move the cursor to the GAGE=.00

INCHES setting (Figure 5.8).

Irrigation Day is from 8:00PM to 8:00PM

Is there an ET Gage? YES

Log Pulses? NO Gage is 99% ful l

GAGE=.00 inches Skip tonight? YES

ET GAGE

Figure 5.8

• The “GAGE=.00 inches ”

: This option

allows you to edit the amount of inches.

Some of the reasons for editing this number:

o Servicing the ET gage and removing

erroneous logged pulses.

o Gage temporarily not working and a

need to log pulses for that day.

o Editing number up or down due to

specific circumstances.

Note:

Daily pulses show at this location.

11.

Press the PLUS or MINUS keys to

change the setting.

12.

Press the blue ARROW keys to

move the cursor to the SKIP

TONIGHT? (Figure 5.9).

Irrigation Day is from 8:00PM to 8:00PM

Is there an ET Gage? YES

Log Pulses? NO Gage is 99% full

GAGE=.00 inches Skip tonight? YES

ET GAGE

Figure 5.9

• SKIP TONIGHT?:

Selecting YES

causes the GAGE=inc hes nu mbe r to be

left out of the ET table for this twenty

four hour period, a historical value will

be entered instead.

Note:

The Skip Tonight option is used for

troubleshooting the ET gage. Pulses created during

troubleshooting will not be entered into the ET Table

if YES is selected.

13.

Press the BACK key to return to the

WEATHER SETUP screen

(Figure 5.2).

THIS CONCLUDES THE ET GAGE

SECTION

B. RAIN BUCKET

The Rain Bucket setting in the controller is used for

recording the amount and rate of rainfall, and

calculating station run times accordingly by use of

the following:

• Setting irrigation rain stop value

• Set Maximum rain in one hour value

• Set Maximum rain in 24 hour value

• Set rain build up value

• Set use of rain by program

Skip Rain Bucket setup section if controller has no

(-RB) option and you are not

sharing rain to

controller.

making

ater work

since 1986

Page 25

w

® SECTION 5 WEATHER

If the controller in use has a (-RB) option installed

and a Rain Bucket connected see:

1. Rain setup with Rain Bucket installed

.

If the controller in use does not

have the (-RB)

option installed see:

2. Rain setup (Without Rain Bucket installed) and

you are sharing rain to controller.

1. Rain setup with Rain Bucket installed

From the WEATHER SETUP screen (Figure 5.2).

1.

Press the RAIN BUCKET Menu key.

The RAIN BUCKET SETUP screen is displayed

(Figure 5.10).

STOP Irrigation After 0.10 inches

MAXIMUM Rain in ONE Hour is 0.20 inches

MAXIMUM Rain in 24 Hours is 0.60 inches

Let Rain Only Build up to 1.50 inches

Set U se of Rain by Program

RAI N BUCKET SETUP

Figure 5.10

The four (4) settings on the screen determine how

much actual rainfall will be placed into the rain table,

which is used to offset irrigation run times. The

following is a description of each:

Note:

Each value in the following definitions denoted

in red is a default setting and can be adjusted by the

user.

• Stop irrigation after:

This setting determines

how much rain must fall, before the controller

will start accumulating rainfall values in the rain

table. It also determines when to halt any on

going irrigation. In figure 5.10, (0.10) inches of

rain will have to fall before any rain data starts to

accumulate in the rain table, or irrigation is

stopped.

• Maximum Hourly Rain:

This setting determines

the maximum amount of rain that will be put in

the rain table after a period of one (1) hour of

rain. In figure 5.10, a maximum of (0.20) inches

of rain will be put into the rain table, no matter

how much rain falls in a one (1) hour period. The

amount of rain from this setting put into the rain

table, will increase only until it reaches the 24

HOUR TOTAL setting.

• Maximum 24 Hour Total: This setting

determines the maximum amount of rain that will

be put into the rain table in a 24 hour period. In

figure 5.10, a maximum of (0.60) inches of rain

will be put into the table, no matter how much

rain falls in a 24 hour period. The amount of rain

from this setting put into the rain table, will

increase only until it reaches the LET RAIN

ONLY BUILD UP TO :setting.

• Let Rain Only Build Up to: This setting

determines the maximum amount of rain that will

be stored in the rain table. In figure 5.10, the

controller will stop storing rain data in the rain

table if the Maximum 24 Hour Total reaches

1.50 inches of rain.

2. Press the PLUS or MINUS keys to

change the settings.

3.

Press the blue ARROW key to

move the cursor to the next entry.

• Set Use of Rain by Program: This

section describes how to enable the use

of rain in the ET2000 controller. Each

Program can be set individually to either

use or not use rain to offset irrigation run

times.

From the RAIN BUCKET SETUP screen

(Figure 5.10).

4.

Press the SET USE OF RAIN BY

PROGRAM Menu key.

The USE OF RAIN BY PROGRAM screen is

displayed (Figure 5.11

Rain causes negative hold-over to build

which acts to cancel irrigation.

Allow RAIN on the following:

PROG A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES

PROG B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES

PROG C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES

PROG D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES

PROG E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES

DRIP 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . YES

DRIP 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . YES

).

USE OF RAIN BY PROGRAM

Figure 5.11

making

ater work

since 1986

Page 26

w

SECTION 5 WEATHER

®

You have the option of enabling or disabling the use

of rain (negative hold over) for any of the controller’s

seven programs. If you select YES, rain (negative

hold over) will be used for that program to reduce

irrigation run times. If you select NO, rain will have

no effect on irrigation run times for that program.

If there is no rain bucket installed and you are not

sharing rain data through the Calsense Command

Center program, these settings will have no effect on

irrigation.

5.

Press the PLUS or MINUS keys to

change the setting.

6.

Press the blue ARROW keys to

move the cursor to the next entry.

7.

Press the MAIN MENU key to return

to the MAIN MENU screen

(Figure 5.1).

THIS CONCLUDES RAIN SETUP WITH RAIN

BUCKET INSTALLED

2. Rain setup ( Without Rain Bucket

installed ) and you are sharing rain to

controller.

From the WEATHER SETUP screen (Figure 5.2).

1.

The RAIN BUCKET SETUP screen is displayed

(Figure 5.12).

Press the RAIN BUCKET Menu key.

Rain Bucket controllers have 3 more

setings. This controller does not

have a -RB interf ace.

Let Rain Only Build up to 1.50 inches

RAIN BUCKET SETUP

If a controller is not wired to a rain bucket, the RAIN

BUCKET SETUP screen will only have one setting

(Figure 5.12). This setting is described below:

• Let Rain Only Build Up to:

This setting

determines the maximum amount of rain

that can be stored in the rain table. In

figure 5.12 the controller will stop storing

rain data in the rain table if the

Maximum 24 Hour Total reaches 1.50

inches of rain.

If you are not sharing rain data using the Calsense

Command Center software, this setting will have no

effect on irrigation.

2.

Use the PLUS or MINUS key to

change the setting.

• Set Use of Rain by Program:

This

section describes how to enable the

use of rain in the ET2000 controller.

Each program can be set individually

to either use or not use rain to offset

irrigation run times.

From the RAIN BUCKET SETUP screen

(Figure 5.12).

3.

Press the SET USE OF RAIN BY

PROGRAM Menu key.

The USE OF RAIN BY PROGRAM screen is

displayed (Figure 5.13).

Rain causes negative hold-over to build

which acts to cancel irrigation.

Allow RAIN on the following:

PROG A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES

PROG B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES

PROG C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES

PROG D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES

PROG E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .YES

DRIP 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . YES

DRIP 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . YES

USE OF RAIN BY P ROGRAM

Set Use of Rain by Program

Figure 5.13

Figure 5.12

Here you will have the option of enabling or

disabling the use of negative hold-over (rain) for any

of the controller’s seven programs. If you select

YES, rain (negative hold over) will be used for that

program to reduce irrigation run times. If you select

NO, rain will have no effect on irrigation run times for

that program.

making

ater work

since 1986

Page 27

w

® SECTION 5 WEATHER

If there is no rain bucket installed and you are not

sharing rain data through the Calsense Command

Center program, these settings will have no effect on

irrigation.

The default setting is NO. If you are currently using a

wind gage on this controller then change the setting

to YES.

4.

Press the PLUS or MINUS keys to

change the setting.

5.

Press the blue ARROW keys to

move the cursor to the next entry.

6. Press the MAIN MENU key to return

to the MAIN MENU screen

(Figure 5.1).

THIS CONCLUDES RAIN SETUP WITHOUT

RAIN

BUCKET INSTALLED SECTION

C. WIND GAGE

The Wind Gage setting in the controller is used to

measure the current wind speed used to pause and

resume irrigation by use of the following:

:

• Selecting Wind Gage activation.

• Setting wind pause speed.

• Setting wind resume speed.

• Selecting use of wind by program.

1. Wind Gage setup

From the WEATHER SETUP screen (Figure 5.2).

2.

Press the PLUS or MINUS keys to

change the settings.

The WIND GAGE SETUP screen will change to

reveal the irrigation wind settings (Figure 5.15).

Is controller Wired to a

PAUSE IRRIGATION when wind is higher

t han 15 MPH

RESUME IRRIGATION when wind is less

t han 10 MPH

Response to wind by Program

WIND GAGE SET UP

WIND GA GE ? YES

Figure 5.15

Note:

The pause and resume irrigation default

settings are 15 MPH pause and 10 MPH resume.

3.

Press the blue ARROW keys to

move the cursor to the next entry

(Figure 5.16).

Is controller Wired to a

PAUSE IRRIGATION when wind is higher

t han 15 MPH

RESUME IRRIGATION when wind is less

t han 10 MPH

WIND GAGE SETUP

WIND GAGE ? YES

1.

Press the WIND GAGE Menu key.

The WIND GAGE SETUP screen is displayed

(Figure 5.14).

Is controller Wired to a

WIND GAGE SET UP

WIND GAGE ? NO

Figure 5.14

Response to wind by Program

Figure 5.16

To change the Miles Per Hour that you want the

irrigation to pause at,

4.

Press the PLUS or MINUS keys

(Figure 5.17).

5.

Press the blue ARROW keys to

move the cursor to the next entry.

To set the Miles Per Hour that you want the

controller to resume irrigation at, (Figure 5.17).

making

ater work

since 1986

Page 28

w

SECTION 5 WEATHER

®

Is controller Wired to a

PAUSE IRRIGATION when wind is higher

than 15 MPH

RESUME IRRIGATION when wind is less

than 10 MPH

Response to wind by Program

WIND GAGE SETUP

WIND GAGE ? YES

Figure 5.17

6.

Use the PLUS or MINUS keys to

change the speed (Figure 5.17).

2. Respond to wind by Program

1.

Press the RESPONSE TO WIND BY

PROGRAM Menu key.

The USE OF WIND BY PROGRAM screen

(Figure 5.18).

When the wind speed is higher

than 15 MPH irrigation will be PAUSED.

Allow WIND to pause the following:

USE OF WIND BY PROGRAM

PROG A . . . . . . . . . . . . . . . . . . . . . . . . .YES

PROG B . . . . . . . . . . . . . . . . . . . . . . . . .YES

PROG C . . . . . . . . . . . . . . . . . . . . . . . . .YES

PROG D . . . . . . . . . . . . . . . . . . . . . . . . .YES

PROG E . . . . . . . . . . . . . . . . . . . . . . . . .YES

DRIP 1 . . . . . . . . . . . . . . . . . . . . . . . . . .YES

DRIP 2 . . . . . . . . . . . . . . . . . . . . . . . . . .YES

Figure 5.18

You can select the programs that you want to be

affected by wind. The default setting is YES. If you

do not

change the setting to NO for the appropriate

program.

2. Press the PLUS or MINUS keys to

change the settings.

3.

move the cursor to the next entry.

4.

to the MAIN MENU screen

(Figure 5.1).

want programs to be effected by wind

Press the blue ARROW key to

Press the MAIN MENU key to return

THIS CONCLUDES THE WIND GAGE SETUP

SECTION

D. RAIN SWITCH

This section of the controller is used to activate the

use of a rain switch and have the controller turn

irrigation off due to rain detection.

1. Rain Switch setup

From the WEATHER SETUP screen (Figure 5.2).

1. Press the RAIN SWITCH Menu key if you want to activate a Rain Switch.

The RAIN SWITCH SETUP screen is displayed

(Figure 5.19).

Is the controller connected to

a Rain Switch Device? YES

Irrigation will be ST OPPED when the

rain switch detects rain.

A Rain Switch is a device like a

MINI-CLIC or RAIN GUARD.

There's a special way to wire them to

this controller to avoid NO CURRENT

and NO FLOW errors.

RAIN SWITCH SET UP

Figure 5.19

2.

Press the PLUS or MINUS keys to

change the setting.

If you select YES this will change the screen to read,

“Irrigation will be stopped when the rain switch

detects rain”. If you do not want irrigation to be

affected by the rain switch leave the setting at the

default setting of NO (Figure 5.20).

CAUTION:

If YES is selected, and the controller is not hooked

up to a rain switch irrigation will be halted

. This is

due to rain switch wiring requirements.

Is the controll er connected to

a Rain Switch Device? YES

Irrigation will be STOPPED when the

rain switch detects rain.

A Rain Switch is a device like a

MINI-CLIC or RAIN GUARD.

There is special way to wire them to

this controller to avoid NO CURRENT

and NO FLOW errors.

RAIN SWITCH SETUP

Figure 5.20

THIS CONCLUDES THE RAIN SWITCH SECTION

making

ater work

since 1986

Page 29

w

(

)

A

A

® SECTION 5 WEATHER

E. ET

The ET section of the controller can be programmed

to use evapotransperation data accessed from an

ET Gage, or controller pre-set values, to compute

irrigation run times using the following:

• Irrigate using ET table

• Irrigate using ET averaging

• Adjust allowable percentage of historical ET