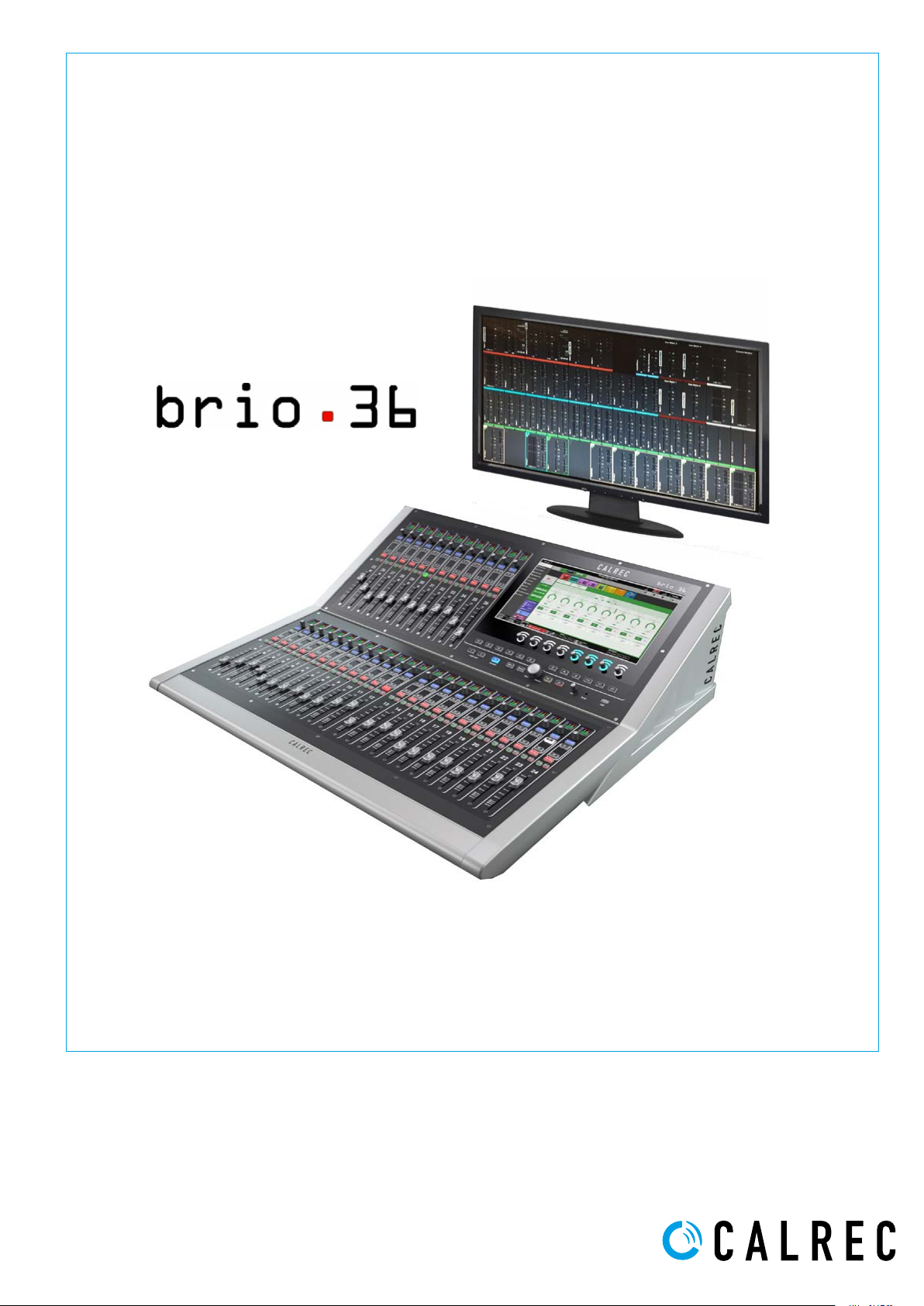

BRIO 36 USER MANUAL V1.1

Audio Production System with Optional Networking

calrec.com

Calrec Audio Ltd

Nutclough Mill

Hebden Bridge

West Yorkshire

England UK

HX7 8EZ

Tel: +44 (0)1422 842159

Fax: +44 (0)1422 845244

Email: enquiries@calrec.com

calrec.com

No part of this manual may be reproduced

or transmitted in any form or by any means,

electronic or mechanical, including photocopying

and scanning, for any purpose, without the prior

written consent of Calrec Audio Ltd.

Whilst the Company ensures that all details in this

document are correct at the time of publication,

we reserve the right to alter specifications and

equipment without notice. Any changes we make

will be reflected in subsequent issues of this

document. The latest version will be available

upon request. This publication is for International

usage.

Calrec Audio Ltd reserve the right to change

specifications without notice. E & O.E.

The established policy of Calrec Audio

Ltd. is to seek improvements to the design,

specifications and manufacture of all products.

It is not always possible to provide notice outside

the company of the alterations that take place

continually.

Despite considerable effort to produce up to

date information, no literature published by

the company nor any other material that may

be provided should be regarded as an infallible

guide to the specifications available nor does

it constitute an offer for sale of any particular

product.

Apollo, Artemis, Summa, Brio, RP1, Hydra Audio

Networking and Bluefin High Density Signal

Processing (HDSP) are trade marks of Calrec

Audio Ltd. Dolby®E is a registered trade mark

of Dolby Laboratories, Inc. All other trade marks

are acknowledged.

© 2018 Calrec Audio Ltd. All Rights Reserved.

BRIO 36

CONTENTS

CONTENTS 3

PRODUCT INFORMATION 13

INFORMATION 14

Repairs 14

Standard of Service 14

Serial Numbers 15

After Sales Modifications 15

Installation 15

Service Personnel 15

Third Party Equipment 15

ESD (Static) Handling Procedures 16

RoHS Legislation 16

ISO 9001 and ANAB Registered 16

HEALTH AND SAFETY 17

Important Safety Instructions 17

Cleaning 17

Explanation of Warning Symbols 17

Earthing 18

Lithium Battery Replacement 18

PACKAGE CONTENTS 19

SYSTEM OVERVIEW 21

SURFACE OVERVIEW 22

CONTROL SURFACE SECTIONS 23

Fader Strip 23

Fader Display 24

Control Cell Display 25

Screen Area 26

Talkback Microphone 26

Context Based Rotary Controls 26

Console Monitors 26

Studio Monitors 27

Linking Paths 27

Surface Layers 27

Global User Buttons 27

TOUCH INTERFACE 28

Touch Display Views 28

INPUTS, OUTPUTS AND BUSES 30

Identifying Paths 30

Inputs 30

Buses 31

Bus Outputs 32

Path Outputs 32

Console Outputs 32

Inserts 33

HYDRA2 PATCHBAYS 35

Console Specific or Shared 35

Remote Patching 35

Port Sharing 36

Unpatching 37

Hydra2 Patchbays at different sample rates 37

INTERFACING STYLES 38

Physical Controls 38

Touch Display 38

LAYERS 40

Layer Switching Options 40

Surface Layer Pop-up 41

96KHZ OVERVIEW FOR BRIO 36 42

SETTING UP 43

GENERAL 44

General Settings 44

Surround Leg Suffixes 44

Date and Time 44

ENERGY SAVER 45

Brightness 45

Surface Sleep 45

SYNCHRONISATION 46

Synchronisation at different sample rates: 46

Reset to First Source 48

Sources and Frame-Rates 49

HYDRA2 CONFIGURATION 50

System ID Change 50

H2O Change 51

Auto Promote 51

4 BRIO 36 Audio Production System with Optional Networking CONTENTS

REQUIRED I/O BOXES 52

Viewing Resources 52

Adding and Removing Resources 53

SHOWS 54

Entering the Shows List 56

Active Show 56

Loading a Show 56

Setting up a New Show 56

Deleting a Show 56

Shows List for Different Sample Rates 57

Editing a Show 57

Duplicating a Show 57

Moving Shows between Systems 57

Show Templates—Admin Only 58

Setting Up and Editing Templates—Admin Only 58

Updating Templates—Admin Only 58

Backing Up Shows 58

Restoring Shows 59

Settings Stored within Shows 59

MEMORIES 60

Loading a User Memory 60

Creating a new User Memory 60

Updating a User Memory 60

Creating Multiple User Memories 61

Storage Capacity 61

Memory Isolation 61

GLOBAL USER BUTTONS 64

CUSTOM STRIP CONFIGURATION 65

Custom Strip Functions / Console Wide Functions Selection 66

GETTING SIGNALS IN AND OUT 67

FADER LAYOUT 68

Attaching a Path to a Fader 69

Settings 70

Editing Labels 71

Port Labels 71

Cloning Paths 71

Moving Paths to Different Faders 72

Deleting Paths from Faders 72

Lock a Fader to the Surface 72

Consoles at 96kHz 73

I/O and Hydra2 Patchbays at 96kHz 73

5

INPUT AND OUTPUT PATCHING 74

The I/O Patching Screen 74

Selecting Sources and Destinations 74

Understanding Ports 75

Icons 76

Channel Settings 76

Layer View 76

Surface Interaction 76

Connected Destination 76

Information Display 76

Viewing and Sorting 77

Making a Patch 77

Moving a Destination 77

Protect a Patch from Memory Loads 78

Isolating a Patch 78

Removing a Patch 78

Inputs 1 and 2 78

Patching Outputs to Inputs 78

INPUT CONTROLS 79

I/O Box Input Port 79

The Channel Input 79

Mic/Gain 80

Providing Console Wide Strip User Controls 81

Group Input Controls 82

Linking Input 1 and Input 2 Trims 82

Replay 83

Stereo & 5.1 path spill leg access and independence for Input settings 84

SOURCE AND DESTINATION PROTECTION 86

Destination Protection 87

Source Protection 88

User Memory Load Protection 88

EXTERNAL INPUTS 89

Creating External Inputs 89

Removing External Inputs 90

Labelling External Inputs 90

Patching to External Inputs 90

Monitoring External Inputs 90

Metering External Inputs 91

DIRECT OUTPUTS 92

Assigning a Direct Output 92

Removing a Direct Output 92

Downmix/Spill 92

Direct Output Controls 92

6 BRIO 36 Audio Production System with Optional Networking CONTENTS

MIX MINUS OUTPUTS 94

Assigning a Mix Minus Output 94

Removing a Mix Minus Output 94

BUS OUTPUTS 95

Mains 95

Auxes 95

TONE AND OSCILLATOR 96

Routing Tone to a Channel 96

Routing Tone to Buses 96

Routing Tone to Path Outputs 97

Oscillator Controls 98

Clearing Tone 98

Tone and Talkback Active Notification 98

Tone Idents 99

PROCESSING 101

EQUALISER 102

Touch Display EQ Controls 102

Bypass and Alternate EQ 103

EQ Settings 103

EQ Independence Controls for Stereo and 5.1 Paths 104

EQ displays of Non-independent Controls for Stereo and 5.1 Paths 105

Removing Independence from Spill Legs 105

DYNAMICS 106

Compressor/Limiter 1 & 2 106

Expander/Gate/Ducker 108

Global Module Controls 108

Dynamics Links 108

Compressor/Limiter Controls 108

Expander/Gate/Ducker Controls 109

Sidechain Source 111

Sidechain EQ 112

Multiband Compressor 113

Dynamics Independence Controls for Stereo and 5.1 Paths 114

Dynamics displays of Non-independent Controls for Stereo and 5.1 Paths 115

Removing Independence from Spill Legs 115

Compressor / Limiter 1 Module and AutoMixers 115

AUTOMIXERS 116

Applying AutoMixers to Paths 116

Setting Individual Path Weightings 116

AutoMixer Controls 116

AutoMixer Global Controls 117

7

PAN CONTROLS 118

Surround Mains and Groups 118

Pan Controls 119

Pan to Auxes 119

Stereo & 5.1 path spill leg access and independence for Pan settings 120

DELAY 122

Accessing Delay Controls 122

Global Delay Controls 123

INSERTS 124

Path Inserts 124

Patching Inserts 124

In/Out 124

Insert and Width Tab Controls 125

Stereo & 5.1 path spill leg access and independence for Insert settings 126

VCA GROUPS 127

Creating and dissolving VCA Groups 127

VCA Group Status Indication 127

Secondary Master 128

Masters and Paths 129

Other VCA information 129

5.1 Surround Paths 130

VCA Group Protection 130

VCA Non-Moving Faders 130

THE FADER SCREEN 131

VCA Slave 132

VCA Master 133

VCA Slaves on Buses and Outputs Page 134

Surround Paths 134

Downmix Faders 134

CSCP control 135

AUTOFADERS 136

AutoFader Controls 136

Setting Up AutoFaders for use 137

Assigning GPI’s to AutoFaders 137

Assigning AutoFaders to faders 138

AutoFader levels 138

AutoFader parameter settings 138

Global AutoFader Bypass 138

Default Fader Interaction Mode 139

CONTROL LINKING 140

Identifying Linked Faders 140

Link Features 140

Access Follows Link 141

8 BRIO 36 Audio Production System with Optional Networking CONTENTS

PRESETS 142

Creating a Preset 142

Loading a Preset 143

Updating a Preset 143

Backing Up and Restoring Presets 144

Editing a Preset 144

Pooled Resources 144

COPY AND PASTE 145

It’s quick and easy to copy properties from one path and paste them to another 145

MONITORING 147

CONNECTING MONITORS 148

MONITOR CONTROLS 150

THE MONITORING POP-UP 151

Favourite Monitor Sources 151

Monitoring External Inputs 151

Settings 151

PFL, AFL AND OUTPUT LISTEN 153

AFL 153

PFL 153

Output Listen (OPL) 153

PFL Position in Audio Chain 153

Access from Faders 154

Access from the Touch Display 154

Global Cancel 154

Sending PFL to the Console Monitor 154

METERING 155

METER DISPLAY LAYOUT WITH CUSTOMISATION 156

Customising Meter Layouts 156

Meter Layout Presets 157

METER TYPES 158

PPM or VU? 158

Fader Meters 158

External Input Meters 159

Bus and Output Meters 159

Loudness Meters 160

Loudness Meter Controls 160

User Meters 162

Meter Position in Audio Chain 162

9

COMMUNICATIONS 163

TALKBACK 164

Touch Display Talkback Buttons 164

Surface Talkback Buttons 164

Patching to Talkback 164

On-Air / Rehearse Settings 165

Reverse Talkback 165

Talkback & Reverse Talkback Levels 166

MIX MINUS 167

Why remove a source’s own input from its foldback mix? 167

Mix Minus Output 167

Mix Minus using the Auto Minus bus 168

Mix Minus using Auxes 169

Setting up a Mix Minus output 169

Mix Minus Controls 169

Off Air Conference Bus 171

Surface Controls 171

ROUTING 173

BUSES AND OUTPUTS 174

Direct Outputs and Mix Minus 174

Unconfigured Buses 174

Configuring Buses 174

ROUTING A SIGNAL 176

Routing a signal in Brio 36 is quick and simple: 176

Partial Routing 177

CONTRIBUTION 178

DOWNMIXING 180

LoRo 180

Downmix Settings 180

Downmix Defaults 181

Offsets 181

10 BRIO 36 Audio Production System with Optional Networking CONTENTS

EXTERNAL INTERFACING 183

GENERAL PURPOSE INPUTS AND OUTPUTS 184

GPI Functions 184

Assigning GPIs 185

Moving a GPI destination 185

Removing a Destination 185

GPO Functions 186

Assigning GPOs 186

Moving a GPO Function 186

Removing a Destination 186

GPO Actions & Invert 186

Pulse Time 187

Testing GPO Functioning 187

MIC OPEN SYSTEMS AND ON AIR PROTECTION CONFIGURATION 188

Assigning Inputs to Mic Open Systems 189

Assigning to CUT/DIM Loud Speakers for On Air Protection 189

Mic Open systems and multi-leg paths 189

CONTROL PROTOCOLS 190

CSCP 190

Setting Up CSCP 190

LAN CONFIGURATION 192

CONSOLE FACILITIES 193

ON AIR PROTECTION 194

Changing Modes 194

On Air Mode via GPI 194

SYSTEM STATUS MONITORING 196

Notifications 196

COLLECTING SYSTEM LOGS 197

TERMINOLOGY 199

FEATURES BY SOFTWARE VERSION 207

FEATURES 208

V1.0 208

V1.1 209

11

12 BRIO 36 Audio Production System with Optional Networking

BRIO 36

PRODUCT INFORMATION

calrec.com

INFORMATION

Should you require any technical assistance with your Calrec product please contact your regional Calrec

distributor. Customers within the UK or Ireland should contact Calrec directly.

For a complete list of worldwide distributors by region, go to www.calrec.com or contact us for more

information.

Telephone (9:00am–5.30pm): +44 (0) 142 284 2159

Email – Technical: support@calrec.com

Email – General: enquiries@calrec.com

Postal Address: Calrec Audio Ltd

Nutclough Mill

Hebden Bridge

West Yorkshire

HX7 8EZ

UK

Our UK Customer Support team work closely with our global distributor network to provide the highest level of after sales

support. Your distributor should be your first point of contact and will often be able to provide an instant solution, be it

technical advice, spares or a site visit by an engineer.

Product Warranty

A full list of our conditions and warranties relating to goods & services is contained in the Company’s standard Terms and

Conditions. A copy of this is available on request.

Repairs

If you need to return goods to Calrec, for whatever reason, please contact your regional distributor or Calrec customer

support beforehand for guidance, as well as to log the details of the problem and receive a reference number.

For customers outside the UK and Ireland, shipping via the distributor saves customers from dealing with exportation

paperwork. If there is a need to send direct to Calrec, contact us beforehand to log the incoming repair and for assistance

with exportation documents.

Standard of Service

We strive to ensure the highest possible standards. If you have any comments on the level of service, product quality or

documentation offered to you by Calrec, please contact the Calrec Customer Support team in the UK who will endeavour

to address the issues. Calrec welcomes all customer feedback.

For feedback specific to this document, please contact enquiries@calrec.com.

Whenever you contact Calrec Customer Support please have the following information to hand:

• Name

• Company

• Email address

• Full details of enquiry (e.g. fault report)

• Serial number of faulty hardware (if applicable)

Once this information has been provided, a service ticket will be created to log your enquiry. The service ticket reference

number will be given via email.

14 BRIO 36 Audio Production System with Optional Networking PRODUCT INFORMATION

Serial Numbers

All units produced by Calrec are given a serial number and are booked into a central record system at the time of

manufacture. These records are updated whenever a piece of hardware is dispatched to or received from a customer.

When contacting Calrec Customer Support with a hardware inquiry it is important that the correct Calrec serial number is

provided to enable the customer support team to provide a high level of service. Brio 36 serial numbers can be found on

the label on the rear of the chassis as shown in Figure 1.

FIGURE 1 - LABEL ON REAR OF CHASSIS

After Sales Modifications

Please be aware that any modifications other than those made or approved by Calrec Audio Limited or their agents, may

invalidate the consoles warranty. This includes changes to cabling provided by Calrec and variations to the recommended

installation as detailed in Calrec documentation.

Modifications to this equipment by any party other than Calrec Audio Limited may invalidate EMC and safety features

designed into this equipment. Calrec Audio Limited can not be liable for any legal proceedings or problems that may

arise relating to such modifications.

If in doubt, please contact Calrec Audio Limited for guidance prior to commencing any modification work.

Installation

In many installations the AC power connectors will not be readily accessible, effectively making the equipment

permanently connected. The installation should be carried out in accordance with all applicable installation rules and

regulations.

Service Personnel

The AC power disconnect devices are the 2 x IEC (IEC60320-1 C13/C14) couplers located at the rear of each unit.

WARNING: The apparatus has a dual power system. It is essential that BOTH AC power IEC couplers are disconnected

to prevent exposure to hazardous voltage within the unit.

Third Party Equipment

Integrating third party equipment into a Calrec system may compromise the product’s ability to comply with the Class B

radiated emission limits set in the latest EMC (Electro Magnetic Compatibility) standard.

Calrec Audio Limited can not be responsible for any non-conformities due to use of third party equipment. If in doubt,

please contact Calrec Audio Limited for guidance prior to integrating any third party equipment.

15

ESD (Static) Handling Procedures

In its completed form, this equipment has been designed to have a high level of immunity to static discharges. However,

when handling individual boards and modules, many highly static-sensitive parts are exposed. In order to protect these

devices from damage and to protect your warranty, please observe static handling procedures, for example, use an

appropriately grounded anti-static wrist band.

All modules and cards should be returned to Calrec Audio Limited in anti-static wrapping. Calrec Audio Limited can

supply these items upon request, should you require assistance. This applies particularly to digital products due to the

types of devices and very small geometries used in their fabrication, analogue parts can however still be affected.

RoHS Legislation

In order to comply with European RoHS (Reduction of Hazardous Substances) legislation, Calrec PCB and cable

assemblies are produced with lead-free (tin/copper/silver) solder instead of tin/lead solder.

In the unlikely event of a customer having to carry out any re-soldering on Apollo, Artemis, Summa, Brio 36 or Hydra2

hardware, it is imperative that lead-free solder is used; contaminating lead-free solder with leaded solder is likely to have

an adverse effect on the long-term reliability of the product. Circuit boards assembled with lead-free solder can be

identified (in accordance with IPC/JEDEC standards) by a small oval logo on the top-side of the circuit board near the

PCB reference number (8xx-xxx). The same logo is used on the connector hoods of soldered cable assemblies.

If in doubt, please check with a Calrec customer support engineer before carrying out any form of re-soldering.

ISO 9001 and ANAB Registered

Calrec Audio Ltd has been issued the ISO9001: 2008 standard by the Governing Board of ISOQAR.

The award, for both UKAS and ANAB registration, is the most comprehensive of the ISO9000 international standards.

Granted in recognition of excellence across design, development, manufacture and after- sales support, the certification

follows a rigorous and thorough review of Calrec’s internal and external communication and business procedures.

FIGURE 2 - LEAD FREE

FIGURE 4 - UKAS REGISTRATION

FIGURE 3 - LEAD FREE STICKER

FIGURE 5 - ANAB REGISTRATION

16 BRIO 36 Audio Production System with Optional Networking PRODUCT INFORMATION

HEALTH AND SAFETY

Important Safety Instructions

• Read these instructions.

• Keep these instructions.

• Heed all warnings.

• Follow all instructions.

• Do not use this apparatus near water.

• Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus (including amplifiers)

that produce heat.

• Protect the power cord from being walked on or pinched particularly at the plugs, convenience receptacles, and the

point where they exit from the apparatus.

• Use only with the cart, stand, tripod, bracket, or table specified by the manufacturer, or sold with the apparatus

• When a cart is used, use caution when moving the cart/apparatus combination to avoid injury from tip-over.

• Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been damaged in any

way, such as power-supply cord or plug is damaged, liquid has been spilled or objects have fallen into the apparatus,

the apparatus has been exposed to rain or moisture, does not operate normally, or has been dropped.

• Warning: To reduce the risk of fire or electric shock, do not expose this apparatus to rain or moisture.

• Not intended for outdoor use.

• This equipment must be EARTHED.

• Before starting any servicing operation, equipment must be isolated from the AC power supply. The disconnect

devices are the 2 x IEC connectors (IEC 60320-1 C13/C14 couplers).

• Do not allow ventilation slots to be blocked. Do not leave the equipment powered up with the dust cover fitted.

Cleaning

For cleaning the front panels of the equipment we recommend using a soft anti-static cloth, lightly dampened with water

if required.

Explanation of Warning Symbols

Triangular warning symbols contain a black symbol on a yellow background, surrounded by a black border.

The lightning flash with arrow head symbol within an equilateral triangle, as shown in Figure 1, is intended to alert the

user to the presence of dangerous voltages and energy levels within the product’s enclosure that may be of sufficient

magnitude to constitute a risk of electric shock or injury.

The exclamation mark within an equilateral triangle, as shown below, is intended to prompt the user to refer to important

operating or maintenance instructions in the documentation supplied with the product.

FIGURE 1 - DANGEROUS VOLTAGES

17

FIGURE 2 - IMPORTANT INFORMATION

Earthing

This is a Class I product. An Earth connection MUST be provided in each AC power cord.

The Earth Bolt connection at the rear of the console should be connected to Earth using Earth cable at least 6mm

in cross section (10 AWG), this connection is optional and is NOT a requirement to comply with safety standards.

Lithium Battery Replacement

Caution: Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type.

Batteries must not be exposed to excessive heat such as sunshine, fire or the like.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

Other Symbols in Use

For apparatus intended to be used at altitude not exceeding 2000m, a warning label containing the following symbol

shown in Figure 3, shall fixed to the equipment at readily visible place.

FIGURE 3 - ALTITUDE WARNING SYMBOL

2

Lifting and Carrying Brio 36

Brio has two lifting handles on the rear of the unit. These should be used when lifting the unit into place. Note: this unit

weighs approximately 30kG and requires at least 2 persons to lift or carry the unit.

Levelling or Fixing Brio 36 on a surface for table mount.

Brio has four adjustable feet on its base which can be used to level the console on a surface. Alternatively these can be

removed and four M6 screws fitted to fix the console in place. Note: the screws should not screw in further than 20mm into

the body of the unit.

18 BRIO 36 Audio Production System with Optional Networking PRODUCT INFORMATION

PACKAGE CONTENTS

There are a number of options when ordering Brio 36 systems: connectivity type and I/O options.

Every system includes a control surface which contains the processing core. Small format pluggable transceivers

(SFPs) are required for Hydra2 I/O box connections with the optional Hydra 2 module and can be provided by Calrec.

I/O packages are optional. The following table shows all Brio 36 options:-

Surface and Core Packs

Brio is supplied with 36 physical faders, arranged as 3 sets of 12 fader panels and a TFT screen with

its associated controls.

Each fader has a dedicated fader meter display, 2 user definable local Switches S1 and S2 and a user

Brio 36 Surface

rotary control cell above, as well as the usual AFL/PFL and Access switches. Brio is supplied with

On/Cut button caps fitted for each fader and a software option determines if this acts as a CUT or

ON switch. The top right hand area contains the Access display area complete with touchscreen TFT,

8 context based rotary controls, 12 Global user switches G1 to G12, A/B layer selection, Link Switch,

Monitor Controls, PFL level, Reset switch and a USB port used for data transfers.

In the front of the console is provided a further USB connector and a 1/4” stereo headphone socket.

Power, Router, Control Processor, and DSP are all self contained within the unit which has 2 x IEC

connectors to provide PSU redundancy. The core operates at 44.1, 48, 88.2 & 96 kHz and supports:

64 legs as mono, stereo and 5.1 Input channels

Brio 36 Core

Cabling One Y-Split IEC cable for supplying power to the surface.

Fixed I/O

Optional I/O

36 legs as mono, stereo and 5.1 Mains & Groups, (Max of 4 Mains and 8 Groups)

24 legs as mono or stereo Auxes

64 legs as Direct or Mix-minus outputs

64 legs as Insert sends & 64 legs as Insert returns

Automatic Mix-Minus and an Off-Air Conference bus for Mix-minus.

I/O packs

Brio comes fitted with the following I/O:

24 x Analogue Mic/Line Input (XLR)

16 x Analogue Line Output (XLR)

8 x AES Digital Inputs with SRC (BNC)

8 x AES Digital Outputs (BNC)

4 x GPIO 9-Pin (D-SUB) connectors each with either 4 GPI or GPO giving a total of 8 in and 8 out.

The unit also has 3x double sized expansion slots in which any of the modules from the Modular I/O

range can be fitted.

In addition there is an optional Hydra 2 module to allow either further I/O to be connected or to

network audio with other consoles.

SFP Packs

SFPs

LX SFP Pack 4 x Single Mode SFPs

SX SFP Pack 4 x Multimode SFPs

Bi-Directional SFP Pack 2 x Bi-Directional SFPs (type A) and two Bi-Directional SFPs (type B)

Copper SFP Pack 4 x copper SFPs

19

One of the following options may be selected: LX SFP Pack; SX SFP Pack; Bi-Directional SFP Pack;

Copper SFP Pack or none if no Hydra 2 module fitted.

20 BRIO 36 Audio Production System with Optional Networking

BRIO 36

SYSTEM OVERVIEW

calrec.com

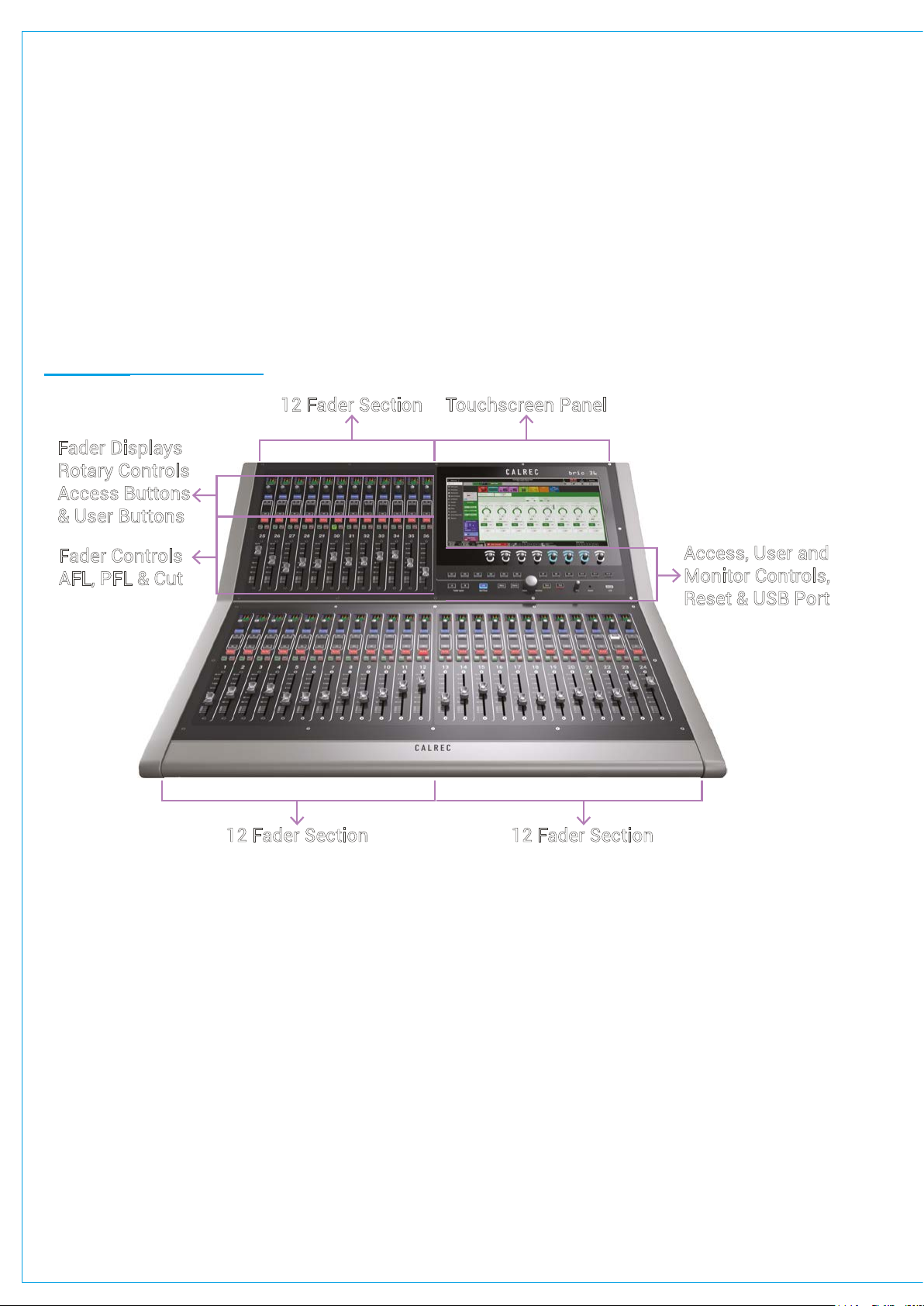

SURFACE OVERVIEW

12 Fader Section

12 Fader Section Touchscreen Panel

12 Fader Section

Access, User and

Monitor Controls,

Reset & USB Port

Fader Controls

AFL, PFL & Cut

Fader Displays

Rotary Controls

Access Buttons

& User Buttons

Brio 36 is supplied with 36 physical faders, arranged as 3 sets of 12 fader panels and a TFT screen with its

associated controls.

Each fader strip has a dedicated 5.1 capable meter display, 2 user definable local switches S1 and S2 and a user rotary

control cell, as well as the usual AFL/PFL and Path Access switches. Brio is supplied with a Path Enable button labelled

‘On/Cut’ that can be configured to act as a Cut, or and ON button. The top right hand area contains the touchscreen UI area

complete with touchscreen TFT, 8 context based rotary controls, 12 Global user switches G1 to G12, A/B layer selection,

Link Switch, Monitor Controls, PFL level, Reset switch and a USB port used for data transfers.

In the front of the console is provided a further USB connector and a 1/4” stereo headphone socket. All surface sections of

the Brio are described in detail in the following pages.

FIGURE 1 - BRIO 36 SURFACE

22 BRIO 36 Audio Production System with Optional Networking SYSTEM OVERVIEW

CONTROL SURFACE SECTIONS

Fader Strip

Each Brio 12 fader section is made up of 12 fader strips, each containing a motorised fader, several push buttons, a rotary

control knob with built-in switch and a small TFT fader display. The image below explains the operation of each button.

FIGURE 1 - FADER STRIP

23

Fader Display

Each fader strip includes a small TFT display. Figure 2 shows highlights each icon which can appear on the display.

FIGURE 2 - FADER DISPLAY

If any of the meter legs go into overload

the background of the meter display

turns RED until the level is back in range.

The AF symbol shows that there is an

AutoFader in circuit and active.

The ISO symbol is displayed if the path

has been isolated from changes made

by memory loads. The ISO icon will be

green if the path is partially isolated.

The VCA group status indicators show

whether a fader or path is a:-

Master

SubMaster

or Slave

If this area of the display is labelled

then it means that Path’s rotary control

has also been set up as a control cell.

See next page for examples.

The control label is always visible

if assigned and the control value is

displayed when the control is adjusted.

The DYN symbol shows that

there is a dynamics element

in circuit and active.

The Path label is either the native

label, or the H2O user label

generated within H2O or the

User label which can be edited

from the Brio surface.

The A1 or A2 shows that an AutoMixer is in

operation on this path. The brightness of the

coloured bar indicates the input ‘strength’ .

The link symbol is displayed in the

same space as the lock symbol if this

path is control linked with another.

The lock symbol is displayed for a

short period on faders that are locked

to the surface when changing layers.

The input meter is a small bar graph

which displays the path’s signal level

in Mono, Stereo or 5.1 Surround as

shown here Note when the signal

is off the bottom a label shows the

name of the leg. The position of the

scale markers and colour change

points, as well as PPM or VU ballistics

is selectable from System-Settings

General, under meter style.

The meter can be selected to display

input or post fader audio, per path

from the Meter and PFL button in the

Access view’s sub-header.

24 BRIO 36 Audio Production System with Optional Networking SYSTEM OVERVIEW

Control Cell Display

The Fader Display changes mode when its rotary control is altered and the bottom of the fader display shows a bargraph

with control values for the selected user function. The combination of the Fader display and the rotary control is defined

as the control cell situated at the top of each fader strip. The function of these control cells varies depending on which

control mode you have selected.

In normal mode, all control cells on the surface show the same control if valid for that path, e.g all input trim.

In custom mode, each of the control cells can be set to a different function, e.g. fader 1 Aux 1 send, fader 2 Mic Gain etc.

See Figure 3.

FIGURE 3 - CONTROL CELL

25

Screen Area

The top right hand area contains the Access display area with Touchscreen Interface TFT, Talkback Microphone,

8 context based rotary controls, 12 Global User buttons G1 to G12, A/B layer selection, Link Switch, Monitor Controls,

PFL level, Reset switch and a USB port used for data transfers. The Touch Interface is described later see “TOUCH

INTERFACE” on page 28.

FIGURE 4 -

ACCESS DISPLAY AREA

Talkback Microphone

Brio has a built-in Talkback microphone which is situated above the G1 Global User Button in the rotary controls area.

Context Based Rotary Controls

Brio has 8 rotary controls that change function in context with the display shown on the touchscreen TFT above it.

Console Monitors

The large rotary control bottom centre adjusts the console (main) monitor level, the level indication is shown at the bottom

of the touchscreen. To the left of the monitor level control are 2 buttons labelled ‘Mono’ and ‘Stereo’ pressing either of

these will replace the normal 5.1 surround output with a Mono or Stereo Downmix. To the right of the monitor level control

are 2 buttons labelled ‘Dim’ and ‘Cut’ which reduce the level of the monitor output by a set amount or mute it altogether.

Just to the right of the Dim & Cut buttons is the ‘PFL’ level control the level of which is also displayed at the bottom of

the touchscreen. There is also provision for separate loudspeakers for monitoring the console’s 5.1 PFL feed /Return

Talkback LS and 5.1 AFL LS. The level controls for these appear on the context based rotary controls together with the

Dim level and Dim, Cut and ‘PFL to Mon’ buttons when the Console Monitor Page is accessed.

26 BRIO 36 Audio Production System with Optional Networking SYSTEM OVERVIEW

Studio Monitors

Brio has two dedicated monitor feeds for relaying signals back to the studio floor or anywhere you need a monitor feed

such as the picture gallery or for headphone feeds. Studio 1 monitor is 5.1 wide, whilst Studio 2 monitor is Stereo.

The level controls for these appear on the context based rotary controls together with the Dim, Cut and Talkback buttons

when either Studio Monitor Page is accessed.

Linking Paths

When paths are linked, adjustments to the parameters of one linked path are also made for all other linked paths.

Adjustments are made relatively across all paths, preserving any offsets. The Link (Set/Clear) button, as shown in

Figure 4, bottom left (next to the Fader Layer buttons) provides a quick way to set/clear all path linking on the surface.

See “CONTROL LINKING” on page 140 for more information.

Surface Layers

The Brio surface has two layers, allowing fader-control of twice as many paths as there are faders on the surface, i.e.

72 fader paths. You can switch between layers using the Fader Layer selection buttons A & B on the surface. When

selecting a layer, all fader positions, button states and control cell states change immediately to reflect faders on the

newly selected layer. It is important to note that paths on the layer that is not visible are still active and will pass audio if

left faded up.

Surface Reset

The surface reset button is recessed to avoid it being pressed accidentally. If a reset is required a pen or similarly pointed

implement should be used to push it.

USB Ports

Brio’s USB ports can be used to connect a QWERTY keyboard or a mouse, or a keyboard/mouse combo to the system

and for data backup and restore to USB memory.

Global User Buttons

Brio’s 12 Global User Buttons can be configured to perform a whole range of functions which are described in the

”GLOBAL USER BUTTONS” on page 64 section of this manual.

27

TOUCH INTERFACE

The touch display interface is simple and intuitive. The touchscreen active show image on the following page

should help you get familiar with the names used to describe various sections of Brio 36’s touch interface.

Touch Display Views

There are three main views within the Brio 36 Touch Display interface. The Active Show view is the main page and

provides access to operation screens and settings for the currently loaded Show. The Shows List button on the top

left in the header provides access to the list of Shows stored on the Brio console, shows can be loaded, edited, saved

and backed up here. The System Settings button on the top right in the header provides access to Brio’s settings that

are stored outside the Show. These settings are still recalled in the event of a surface reset as they are stored within

Brio’s continuous memory. See ”SHOWS” on page 54 and “MEMORIES” on page 60 for more information.

28 BRIO 36 Audio Production System with Optional Networking SYSTEM OVERVIEW

FIGURE 1 -BRIO 36 USER INTERFACE DISPLAY

29

INPUTS, OUTPUTS AND BUSES

Path is a term used to represent an audio signals route through a DSP process within the Brio 36 system, which

carries audio and enables it to be processed. Paths include channels, groups, mains and auxes.

All paths can be controlled by faders and channel paths must be attached to faders to exist.

Identifying Paths

Paths can be identified easily on the surface; they are colour-coded as follows:

Channels - black background - white label, Groups - blue background - white label,

Mains - red background - white label and Auxes - green background - white label.

Inputs

Input Channels

Input channels take audio signals into the mixing console for processing, mixing and onward routing.

Input signals can be patched directly to channels from built-in or expansion slot I/O, or from external I/O boxes connected

via the optional Hydra2 module, Hydra patchbay outputs or directly from Brio’s own output buses.

Any signal present at an input port must be connected to a channel path before it can be processed and routed.

FIGURE 1 - INPUT SIGNAL FLOW – MONO CHANNEL

30 BRIO 36 Audio Production System with Optional Networking SYSTEM OVERVIEW

FIGURE 2 - INPUT SIGNAL FLOW – STEREO CHANNEL

External Inputs

• External inputs take signals into Brio 36 from it’s own Input ports, other I/O box input ports, Hydra patchbay outputs

or Brio’s own output ports, and make them available for monitoring and metering.

External Tone Input

• Patching a third party tone generator to the external tone input allows the external tone to be used as the tone source

across the console, rather than the internal oscillator.

Talkback Input

• Patching to the talkback input allows any microphone connected to any of its own Input ports or other I/O box input

ports to be used as the talkback source. The built-in talkback microphone connects to Brio’s internal I/O and may

then patched to the talkback input in order to be used.

Buses

Groups

• Multiple channel Inputs can be sub-mixed by routing them to groups.

• Groups can be processed.

• Groups can be routed to any other output or bus.

• Groups are not available for patching, but can have direct outputs and mix-minus outputs made available to them.

AFL

• When paths are AFL’d the console monitor feed is replaced by the AFL bus, providing a non-destructive solo.

• The after fader level signals from multiple paths can be sub-mixed by routing them to the AFL bus.

PFL

• When paths are PFL’d the PFL bus outputs a pre-fader version of the incoming signal and is used to check the

presence of the incoming signal prior to opening the fader.

• Pre fader level signals from multiple paths can be sub-mixed together by routing them to the PFL bus.

• Settings are available to output the PFL bus to its own dedicated loudspeaker or the console monitors.

31

Output Listen

• The output listen bus uses the same bus as AFL although signals are routed post any output delay.

• Bus outputs including Mains, Auxes & Direct Outputs can have their post output delay listened to.

See “PFL, AFL AND OUTPUT LISTEN” on page 153 for more information.

Bus Outputs

Main Outputs

• Mains are primarily used to feed transmission and/or recording devices.

• Multiple paths can be routed to mains. Mains can be routed to other mains.

• Mains are available for patching and can have Equaliser, Dynamics and Delay processing applied.

Aux Outputs

• Multiple mixes can be created by routing paths to auxes.

• Each channel has individual send level and position controls for each of the 24 Aux outputs.

• Auxes can be used in conjunction with mix minus outputs to create Interruptable Foldback feeds (IFBs).

• Auxes can be controlled by logic functions to cut the pre fader send to each individual Aux, for controlling foldback

feeds in on/off air situations.

• Auxes cannot be routed to any other bus/output.

• Auxes are available for patching and can have Equaliser, Dynamics and Delay processing applied.

Path Outputs

Mix Minus Outputs

• Each channel can have one mix minus output assigned to it, from a pool of 64 mono legs (shared with direct

outputs), providing an easy way to create a mix for a contributor using any aux, or the dedicated auto minus bus.

See “MIX MINUS” on page 167 for more information.

Direct Outputs

• Each channel can have one direct output assigned to it from a pool of 64 mono legs (shared with mix minus outputs)

to make signals available for patching. Direct outputs can be pre EQ, pre fader or post fader.

Console Outputs

Monitor Outputs

• Each monitor output is available for patching to any I/O output port which can, in turn, be connected to a loudspeaker.

• Monitor source controls are available from the touch display footer when in ‘active Show’ view allowing you to quickly

change monitor sources and the global user buttons can also be assigned as monitor source selectors.

• Brio 36 has several monitor outputs available. For more detailed information see “MONITOR CONTROLS” on page 150.

Meter Outputs

• In addition to the Console Monitor Prefade, PFL,AFL & APFL Meter outputs, there are four user meter outputs

available for patching directly to I/O box output ports to feed external, third party meters.

32 BRIO 36 Audio Production System with Optional Networking SYSTEM OVERVIEW

Talkback Output

• The talkback output feed is provided to allow you to patch the talkback feed from the console operator to a specific

location, e.g. a comms system.

Tone Output

• As well as being routed to paths, tone can be hard-patched to an I/O box or Hydra patchbay output using the tone

output.

Inserts

• Inserts provide a quick way to insert third-party signal processing equipment into a path.

• Each Insert can be placed pre EQ, pre fader or post fader. When switched in, an insert breaks the signal path,

providing a send out and a return back in, allowing devices like external effects processors to be placed within the

signal flow of a path.

• Insert sends and returns appear in the I/O patching screen from where they can be patched to I/O box ports for

connection to external devices.

• Inserts are available for faders, mains, groups and the console monitor.

• 2 fader inserts are available for each path. If the path is moved to a different fader, the insert will move along with it.

• Each insert has an individual ‘IN/OUT’ switch.

• Monitor inserts are used to insert processing into monitor feeds, such as surround processors and renderers.

See “INSERTS” on page 124 for more information.

FIGURE 3 - INSERTS—GENERAL OPERATION

33

FIGURE 4 -BRIO 36 AUDIO SCHEMATIC

34 BRIO 36 Audio Production System with Optional Networking SYSTEM OVERVIEW

HYDRA2 PATCHBAYS

Hydra2 patchbays (HPBs) allow console users to make selected DSP audio outputs available across the Hydra2

network, allowing other Hydra2 users to access them, as well as allowing console input sources and output feeds

to be changed remotely. Hydra2 patchbays are created from the H2O user interface. See the H2O user guide for

more information.

HPBs are virtual patchbays which exist within the Hydra2 domain. Like physical patchbays, HPBs have a number of input

ports which are ‘hard wired’ to their corresponding output ports. For port patching purposes, Hydra2 patchbay inputs are

destinations and Hydra2 patchbay outputs are sources.

When a source is patched to a Hydra2 patchbay input, it immediately becomes available at the corresponding Hydra2

patchbay output. For example, if a console user patches a direct output to a Hydra2 patchbay input, the direct output is

available to all Hydra2 users (who have been granted access), in the form of the corresponding Hydra2 patchbay output.

Console Specific or Shared

There are two types of HPB: ‘console specific’ and ‘shared’. Console specific HPBs are available to H2O, 3rd party

controllers (via SW-P-08) as well as the console that they have been created for. Shared HPBs are available to all Hydra2

users who have been granted access as well as H2O and 3rd party controllers (via SW-P-08). You can patch signals to

your own, or shared Hydra2 patchbay inputs, in the same way as patching to physical output ports.

Remote Patching

HPBs allow network administrators (via H2O) to patch console inputs and outputs that have been patched to HPB ports

to physical I/O ports. H2O users can choose physical input ports to connect to console HPB inputs, and physical output

ports to connect to console HPB outputs, allowing them to choose and change console feeds and output destinations.

External routers, supporting the SW-P-08 protocol, can also access HPBs, enabling 3rd party control over console

patching. Once created, HPBs can be made available for patching. They appear ‘online’ and can be added to the

console’s ‘required list’. See “REQUIRED I/O BOXES” on page 52 for more information.

35

FIGURE 1 - HYDRA PATCHBAY OPERATION

Port Sharing

Source and destination protection works as normal when dealing with HPBs for both console and H2O users.

In situations when two or more consoles are using the same feed from a HPB it is possible for one console to change the

patching of the other by changing the I/O box port which is feeding the shared Hydra2 patchbay input, either through a

memory load, or through changing the individual patch. In these circumstances it is important that you understand the

contents of the source and destination protection pop-up before accepting any changes, as these changes directly affect

other network users.

To create a fully flexible system, you can change the source feeding a HPB, which is also feeding other consoles.

However, we advise that all I/O box port to Hydra2 patchbay input patching is controlled from H2O or a third party

controller to avoid unwanted changes to other consoles’ source feeds.

FIGURE 2 - HYDRA PATCHBAY PATCH CHANGE

36 BRIO 36 Audio Production System with Optional Networking SYSTEM OVERVIEW

Unpatching

Under normal circumstances, when I/O box ports are unpatched, their input settings (Mic Gain, SRC, 48 V) are reset to

their default values. However, when using HPBs, it is possible to un-patch a port at two points in the signal chain, as

shown in Figure 3 below. If the port is first unpatched at point 2, the I/O box port’s input settings will be retained, even

when the port is also unpatched at point 1.

FIGURE 3 - HYD R A PATCHBAY UN-PATC H

Hydra2 Patchbays at different sample rates

Note: now different sample rates are available, Hydra2 patchbays can be created to operate at a different sample rate (as

shown in Figure 4) to that of the current show which is at 48kHz. HPBs and I/O Ports at a different sample rate to the

console appear with a Sample Rate kHz warning icon to indicate it cannot be used unless the sample rate of the Hydra2

patchbay is changed in H2O or a different show is loaded into the console, using the correct sample rate.

FIGURE 4 - HYDRA PATCHBAY AT A DIFFERENT SAMPLE RATE

37

INTERFACING STYLES

Interfacing with Brio 36 is simple and the touch display will be familiar from using consumer technologies such as

smartphones and tablet PCs.

Aspects of the interface will be referred to throughout this manual but this section should give you a good starting point

from where you can start exploring Brio’s intuitive interface for yourself.

Physical Controls

Faders

• Faders are used to control signal levels, either by having paths attached for direct control or as VCA master faders for

controlling the overall level of a range of paths.

Buttons

• All buttons on the Brio surface are labelled and LED back-lit to indicate their ‘on’ statuses. Buttons can either be

momentary (they trigger the function until you release them), latching (switch on or off each time they are pressed) or

auto (they latch if you tap them or act as momentary buttons if you hold them).

Rotary controls

• All physical rotary controls on the Brio surface are continuous—they have no stopping point at either extreme.

This allows the surface to be fully flexible, as all physical controls are able to control a wide range of functions within

one project.

• When a rotary control is attached to a function or parameter, the function name and options are displayed,either on

the touch display, or in the smaller fader displays.

• Once a function’s extreme—either lower or higher—is reached its value will stop updating when the rotary is turned.

When a rotary is controlling a level value or a value which has a default setting, press and hold the rotary control for a

short time to return to the default value.

Touch Display

Brio’s touch display uses the same general interfacing styles as a smartphone or tablet computer.

Below is a run down or the main gestures that you will use:

Tap

• Buttons, switches, selection fields and table column labels (for ordering purposes) can all be accessed with a short

light tap.

Two Finger Tap

• Tapping with two fingers can reset settings to their default level. For example, within the fader processing tab,

the fader can be set to zero by tapping on the fader space with two fingers.

Drag

• To turn a rotary control up or down, simply drag it vertically up/right to turn it up, or down/left to turn it down.

38 BRIO 36 Audio Production System with Optional Networking SYSTEM OVERVIEW

Touch and Drag

• To select more than one item in a table or list, touch your first selection, hold your finger in place for a short time then

drag in any direction to extend your selection. Selections are always in order, usually numeric, so if you drag to the left

or right in a vertically arranged grid, such as the external inputs screen, you will select all cells between your first and

last selection. Touch and drag can also be used to move a selection around, for example in the fader layout screen,

make a selection then hold and drag to move paths to a different set of faders.

Scrolling

• Whenever a screen is too large to be fully displayed on the touch display, drag the screen to scroll in any direction.

Scrolling and ‘flinging’ will allow the screen to scroll quickly, then decelerate to a stop.

Drag Handles

• A multiple selection can be made by dragging the selection handles once an initial selection has been made, as

shown in Figure 1.

FIGURE 1 - DRAG HANDLES TO SELECT MULTIPLE ITEMS

Buttons

Switches

Keyboard

• There are several Brio 36 functions which require the use of a Qwerty keyboard.

• Whenever the keyboard function is needed the software keyboard will appear from the bottom of the touch display.

• If there are several text fields to complete, NEXT and PREVIOUS buttons are provided to move between text fields in

order, alternatively, just tap the text fields on the touch display to move between them.

• SAVE and CANCEL buttons are provided to exit the text input mode, either saving or discarding any changes.

Alternatively tap the touch display outside the text fields to exit.

• Standard CUT, COPY and PASTE functions are available using the keyboard.

• If preferred an external keyboard or keyboard/trackpad combo can be attached to one of Brio 36’s USB ports.

• When an external keyboard is connected the software keyboard does not appear.

39

LAYERS

The Brio 36 surface has two layers allowing fader-control of twice as many paths as there are faders on the surface.

You can switch between layers using the fader layer selection buttons A or B on the surface. The A/B buttons

switch layer globally across the whole console, or can be set to switch chosen banks of faders. The Fader Layer

button in the footer also allows layer switching. Setting a bank to be “linked” in this menu sets them to follow the

A/B hardware buttons on the surface.

Layer linking options are set from the Surface Layer pop-up which is accessible from the Monitor bar along the bottom of

the Touch Display. This should be used along with Layer Switching Options which are located within Show settings.

As well as switching layer globally, or in banks, the layer can be toggled on individual faders by setting the S1 or S2

Strip User buttons to act as a B layer toggle switch.

When changing layer, all fader positions, button states and control cell states change immediately to reflect faders on the

newly selected layer. Paths are active and can pass audio on both layers, regardless of whether they are currently in view

Layer Switching Options

To access layer switching options, tap SHOW SETTINGS in the Show menu and select ‘General’. One of these two

options can be chosen:

• Change the layer of all linked fader sections

• Change only the layer of the fader section containing the Accessed fader (any linked fader sections will also

change too)

The first option can be used if you wish to prevent a section of the desk from ever switching layers. For example, on a Brio

linking sections 1 and 3 and selecting the first layer switching option means that all surface sections, other than section 2,

will switch layers when surface layer buttons or pop-up layer buttons are pressed. Fader section 2 will stay on which ever

layer you select for it within the Surface Layer pop-up.

The second layer switching option should be chosen if you always want the section containing the currently accessed

fader to switch layers (along with any linked surface sections) regardless of whether you have set some fader sections to

lock to a specific layer.

40 BRIO 36 Audio Production System with Optional Networking SYSTEM OVERVIEW

FIGURE 1 - LAYER SETTINGS

Surface Layer Pop-up

Each surface section is represented along the top of the pop-up. Link layer switches along the bottom of the pop-up can

be set to ‘on’ or ‘off’ to enable or disable layer linking. Linked layers will always be on the same surface layer.

FIGURE 2 - SURFACE LAYER POP-UP

41

96KHZ OVERVIEW FOR BRIO 36

From version v1.1, Brio 36 can now also work at 96kHz sampling frequency (sample rate), over a Hydra2 Network.

The following list is a quick overview of the impact of running Brio36 consoles at 96kHz

• The consoles can switch between 48kHz & 96kHz working as required.

• Consoles switch sampling frequency by loading a show at the required sample rate built from a template at that rate.

• The numbers of channels and buses are the same on Brio 36 at 96kHz as at 48kHz, i.e. the same as before.

• There is no reduction in the numbers of monitor inputs and outputs at 96kHz.

• I/O boxes can be set to 48kHz or 96kHz, or to follow the sample rate of a specific console, via H2O.

• The Hydra2 network supports 48kHz and 96kHz consoles and I/O boxes simultaneously.

• Hydra2 runs at 48kHz irrespective of whether the consoles and I/O boxes are running at 96kHz or not. It simply uses

2 samples per 96kHz signal.

• Because Hydra2 always runs at 48kHz, the system will still require a 48kHz sync (if using its AES3 & Wordclock

inputs) even if all consoles and I/O are at 96kHz.

• The console patching screens and required list indicate which ports, HPB, aliases, or boxes are at a different sample

rate to the desk. These ports etc. can be patched (except for System level patches) but will not work until the sample

rates are matched.

• The H2O patching screens filter the ports visible by sample rate, as it can make patches at either rate.

• Consoles cannot successfully make port to port patches (including via aliases) for I/O that is at a different sample rate

to the desk. Note: these patches can be made in H2O and by SW-P-08 and will work if patched there.

• System Status messages are produced for I/O boxes & HPB that are in the required list but are not set to the same

sample rate as the desk.

• An I/O box can run at 48kHz or 96kHz irrespective of which rack it is plugged into. If a console is running at 48kHz,

an I/O box plugged into that rack could be running at 96kHz with another console.

• Fixed format 1U MADI boxes do not support 96kHz. They are shown offline when the box is at 96kHz.

• SDI de-embedder modules do not support 96kHz on the SDI stream. They are shown offline if the box is at 96kHz.

• SDI embedder modules do not support 96kHz on the SDI stream. They are shown offline if the box is at 96kHz.

42 BRIO 36 Audio Production System with Optional Networking

SYSTEM OVERVIEW

BRIO 36

SETTING UP

calrec.com

GENERAL

To access Brio 36’s general settings, from the ‘active Show’ view, tap SYSTEM SETTINGS in the top right of the screen

and then select ‘General’’ from the menu on the left hand side. To edit these settings you must be logged in as an

administrator.

General Settings

The following general settings are available:

• The analogue level at 0 dBFS can be calibrated to 15, 18, 20, 22, 24 or 28 dBu.

• The reference level (dBFS) can be set to an integer value between -6 and -32 dBFS. The reference level sets default

level values for the dynamics and oscillator modules.

• The point at which the input impedance changes between mic and line level can be set to 18, 20, 22 or 24dBu.

• The mic input headroom for the system can be chosen. Options range from 20 dB to 36 dB.

• The default meter style can be set for all meters on the meter displays. PPM or VU scales can be chosen along with

various colour split points, controlling the level ranges of the green, yellow and red elements of the meter bar graphs.

• Cut/On button functionality can be set: With cut selected, paths are cut when cut/on buttons are active; with on

selected, paths are switched on when the cut/on buttons are active, and so paths are cut when cut/on buttons are not

active.

• When faders are under CSCP control, this can be overridden when the fader is touched; Brio 36’s faders are touch

sensitive. This feature can also be disabled.

FIGURE 1 - GENERAL SETTINGS

Surround Leg Suffixes

You can enter suffixes to be automatically displayed at the end of the individual legs of surround path port labels within the

I/O patching screen. Suggested suffixes are L, R, C, LFE, Ls, Rs. These suffixes help to keep the surround legs together

and in the correct order when sorting tables within the I/O patching screen.

Date and Time

The current date & time are displayed at the bottom of the General settings page and can be modified in Admin mode.

44 BRIO 36 Audio Production System with Optional Networking SETTING UP

ENERGY SAVER

Brightness

Brio 36’s energy saver settings allow you to control the brightness of all surface buttons and displays. There are three

rotary controls to independently set the brightness of LED’s, small displays, and Touchscreen display. Adjust these rotary

controls to see the relevant brightnesses change.

Surface Sleep

Putting Brio into surface sleep turns off all lights across the surface it has no effect on audio or operation.

Surface sleep can be set to activate after a specified duration of inactivity, ranging from one minute, to an hour.

Alternatively you can select NEVER.

FIGURE 1 - ENERGY SAVER SETTINGS

45

SYNCHRONISATION

General rules of good practise require that all equipment connected to the audio console’s digital inputs and

outputs are locked to the same referenced sync source as the console to ensure clean audio.

In systems with multiple Calrec processing cores connected together, it is of paramount importance that all connected

processing cores are locked to the same referenced sync source.

The Brio 36 processing engine has six synchronisation inputs and six levels of synchronisation source priority. The sixth

priority is always set to ‘internal reference’, so that, as a last resort, if all other sync sources fail, Brio can always run off its

own internal clock. If a clock source does fail, Brio will automatically jump down to the next sync source in the priority list.

One is the highest priority, six is the lowest.

In ‘active Show’ view, the current sync source is always displayed

within the notifications area at the top right of the touch display.

Setting Synchronisation Source Priorities:

• Tap SYSTEM SETTINGS in the top right of the touch display and select ‘synchronisation’ from the menu.

• Tap the selection cell for the sync priority level that you wish to alter. A pop-up appears with a scrolling menu of

possible sync sources. (The following figure shows the pop-up when selecting sync source priority 1).

• Tap to make your selection, scrolling down if necessary.

• The pop-up closes and Brio refreshes and syncs to the highest priority viable source.

Synchronisation at different sample rates:

Hydra2 runs at 48kHz irrespective of whether the consoles and I/O boxes are running at 96kHz or not. It simply uses 2

samples per 96kHz signal.

Hydra2 always runs at 48kHz, the system will still require a 48kHz sync if using its AES3 or Wordclock inputs even, if all

consoles and I/O are operating at 96kHz.

46 BRIO 36 Audio Production System with Optional Networking SET TING UP

FIGURE 1 - SYNCHRONISATION OPTIONS

47

Reset to First Source

It may sometimes be necessary to reset Brio’s synchronisation. To start the synchronisation reset process tap

RESET TO 1ST SOURCE. Brio will attempt to synchronise to each source in priority order, starting at priority one.

Once a viable synchronisation source is found the process will stop and the new sync source will display the ‘locked to’

tab as shown here.

It is important that the required sync source is available before the console boots up otherwise it won’t be locked to the

correct sync, if this occurs press the ‘Reset to first’ button after the sync generator is running.

FIGURE 2 - RESET TO FIRST SOURCE

48 BRIO 36 Audio Production System with Optional Networking SET TING UP

Sources and Frame-Rates

Brio has 7 sync source options:

• Video 1

• Video 2

• AES3 1 (48 kHz)

• AES3 2 (48kHz)

• TTL Wordclock 1 (48 kHz)

• TTL Wordclock 2 (48kHz)

• Internal Reference

Brio supports the following video formats:

• PAL

• NTSC

• 720p/30

• 720p/29.97

• 720p/25

• 720p/24

• 720p/23.98

• 1080i/30

• 1080i/29.97

• 1080i/25

• 1080p/30

• 1080p/29.97

• 1080p/25

• 1080p/24

• 1080p/23.98

• 1080p/50

• 1080p/59.94

• 1080p/60

49

HYDRA2 CONFIGURATION

System ID Change

From version 1.1 Brio 36’s can be used as part of a Hydra2 Network and have access to the resources of that network.

In order to facilitate this the System ID has to be altered so that it is no longer set to 192.1 which is the default for a

Standalone console as shown in Figure 1. In order to do this the user has to enter Administrator Mode. Note: a Brio

cannot be the master of the network and requires a 4U or 8U core system to connect to which acts as the network master.

This is usually a separate core, but could equally be an Apollo, Artemis or Summa Console core. Figure 2 shows the

Brio now set to a new System ID of 192.150, it has been connected to a master core and now the Brio appears as a

Networked Console. Note: it’s AutoPromote value has been increased to 70 seconds to cope with any reset of the

master core before AutoPromote takes effect otherwise the Brio might self promote when it needs to stay on the network.

FIGURE 1 - SYSTEM ID STANDALONE

FIGURE 2 - SYSTEM ID NETWORKED

50 BRIO 36 Audio Production System with Optional Networking SETTING UP

H2O Change

In addition to changing the Brio’s System ID, the Brio needs to be added as a Client on the Hydra2 network .

This needs to be setup in H2O as shown in Figure 3, before it can be seen as part of a Hydra2 Network and have access

to Hydra2 I/O resources.

FIGURE 3 - BRIO ADDED AS CLIENT IN A MASTER CORE VIA H2O

Auto Promote

A Hydra2 network needs one master router to function correctly. If anything causes the master router to go off-line,

another router on the network must be promoted to be the master to keep the system running.

Auto Promote allows this to happen automatically.

To avoid losing valuable data the Hydra database is copied from the master router to any routers in the network which

may auto promote themselves. The Hydra database stores the following information:

Details of I/O connected on network.

Patches made via H2O.

Patches made via SW-P-08.

Port labels.

A system of levels and time delays is used to control which routers can take over the master router status and in which

order. Auto Promote is setup by Calrec engineers and so should be planned with your Calrec project engineer during the

ordering process.

51

REQUIRED I/O BOXES

BRIO 36 has its own built-in I/O but this and all other I/O resources on a Hydra2 network can be used by

all consoles as long as they have been granted access from the network administration tool, H2O, and the

resources have been added to the consoles ‘required list’.

If connected to a network, and due to the scalable nature of Hydra2 the user may have access to a large amount of I/O

resources, some of which they won’t always need. The ‘required list’ provides a way to narrow the scope for individual

consoles, speeding up work-flow and making port identification easier.

Only I/O resources in the ‘required list’ will be available for patching to and from the console. If not connected to the

network only the Built-in I/O box will be shown in the required list. Brio’s internal I/O is identifiable as a console image.

The ID for internal I/O is automatically generated, based on the consoles ID in order to prevent conflict with other I/O on

the network

Viewing Resources

Tap SYSTEM SETTINGS in the top right of the touch display, then select ‘Required I/O Boxes’. The user will see a split

screen with all online resources on the left and the ‘required list’ on the right.

Both lists are held in tables with 3 columns: Hardware ID, label and type. It may help to sort these tables by tapping on

column headers. Multiple taps will switch sorting to be either ascending or descending.

Hardware IDs for physical I/O boxes are set from the dip switches on the back of the units (See “Audio I/O Connections”

in the Installation manual for more information). Hydra patchbay IDs are taken from H2O and are related to folder names.

Labels are explained in detail, here: ”INPUT AND OUTPUT PATCHING” on page 74.

FIGURE 1 - ACCESSING SYSTEM SETTINGS

52 BRIO 36 Audio Production System with Optional Networking SETTING UP

Tap to select a single online resource on the left (hold and drag or drag handles to select multiple resources) then tap

ADD TO REQUIRED LIST at the bottom left of the online resources screen. The resources will then appear in the

Required List on the right. Note: they are shaded green, with a green ‘required’ tag attached.

This is mirrored in the online list on the left so the user can quickly see which resources they have already added.

If any of the resources in the Required List go offline, they will be shaded red with an ‘offline’ tag attached.

The ‘require’ tag can be seen in the image below.

Adding and Removing Resources

To remove a resource from the list, select it, then tap REMOVE FROM REQUIRED LIST.

Note: the built-in Brio I/O is always present and is shown in Figure 2 at the top of the list.

Boxes at Different Sample Rates

The show in Figure 2 is a 96kHz show, the sample rate field shows that although the Brio is set to the correct sample rate

the AoIP box isn’t, this is because AoIP boxes do not currently operate at 96kHz

FIGURE 2 - THE ‘REQUIRED LIST’

53

SHOWS

Brio 36 uses a system of Shows, user memories and continuous memory to store settings for later recall.

Shows are used to organise user memories into sub-categories making them easier to manage, rather than having

to search through a long list of varied memories each time, you can select a Show and view the user memories

associated with that Show.

A possible use for this would be to create Shows for each type of production, e.g. ‘Morning News’, ‘Football’, ‘Chat Show’

etc.. and then create multiple user memories within each Show for different users and situations. Before saving multiple

memories into a Show, it is good practice to create one default user memory, test it, and use it as a template to create

multiple user memories. This avoids the repetitive and time consuming task of having to make the same changes to

multiple memories.

During operation, Brio constantly updates its continuous memory, which is also saved within the currently active Show

and that the user is actually saving memories within shows. When a Show is recalled, it is this continuous memory that is

recalled, not a user memory.

Note: loading a Show recalls the last-used settings, not the last-saved settings. So in order to get to a particular user

memory this will need to be loaded once the show is loaded.

FIGURE 1 - SHOWS AND MEMORIES

54 BRIO 36 Audio Production System with Optional Networking SET TING UP

FIGURE 2 - WHERE THINGS ARE SAVED

Show

User Memory

Memory

Output bus configuration X X

Path to fader assignments X X

I/O patchi ng (from Summa) X X

Inp ut settings X X

Path routing X X

Path processing X X

Active downmix se ttings X X

Layer locks X X

VC A grouping X X

User labels X X

Required list X

Continuous

GPI and GPO X

Monitor, talkb ack, meter patching X

Synchronisation settings X

Default downmix values X

Energy saver settings X

External contro l enable X

Inserts setup X

External inputs X

General System Settings X

Active control mode X X

Active fader layer X X

Monitor settings X X

Memory isolates X X

Oscil lator settings X X

Talkback levels X X

55

Entering the Shows List

Tap SHOWS LIST to the top left of the touch display. All available Shows are presented within a sortable table.

To return to ‘active Show’ view, tap ACTIVE SHOW in the top right of the touch display.

FIGURE 3 - ACCESSING THE SHOWS LIST

Active Show

The Show that is currently active is identified by the ‘active’ tab. See Figure 4 on the next page.

Loading a Show

Locate and select the Show, then tap LOAD in the control screen footer, then LOAD again to confirm the choice.

Setting up a New Show

All new Shows are based on pre-configured Show templates. To set up a new Show:

1. Tap NEW in the control screen footer.

2. Pick a template within the ‘new Show’ pop-up.

3. Enter a label and some details for the Show and tap CREATE SHOW.

The client and series text fields will already be populated as they are taken from the template.

Deleting a Show

1. Tap to select one or more Shows within the list.

2. Tap DELETE in the control screen footer.

3. Tap DELETE SELECTED, or CANCEL.

56 BRIO 36 Audio Production System with Optional Networking SETTING UP

FIGURE 4 - THE SHOWS LIST

Shows List for Different Sample Rates

The Shows List in Figure 4, is displaying a variety of shows including the 4 default shows at 44.1kHz, 48kHz, 88.2 kHz

and 96kHz. These shows were subsequently used to provide a show template for each operating frequency..

Note: there are 2 separate processes required for a show, loading a show sets up the DSP resources to run at the

required sampling rate is one. The other is to set the sampling frequency of each I/O box and Hydra Patchbay in H2O.

See “I/O Boxes & Hydra Patchbays Sample Rate Selection in H2O” on page 73.

Editing a Show

Once a Show has been created it is possible to edit its label and description:

1. Select the Show to edit and tap EDIT in the control screen footer.

2. Make changes to the label and description in the pop-up.

3. Tap SAVE or CANCEL .

Duplicating a Show

Duplicating Shows can save time when several very similar Shows are needed:

1. Select a Show and tap DUPLICATE in control screen footer.

2. Enter a new label.

3. Tap DUPLICATE or CANCEL.

Moving Shows between Systems

Shows can be transferred between Brio 36s but cannot be transferred to Apollo, Artemis or Summa consoles.

57

Show Templates—Admin Only

Whenever the user creates a new Show it must be based on a template. The generic Calrec template is always available.

Additional templates can be created by Brio 36 administrators. Show templates hold the same data as Shows but they

cannot be opened, edited or deleted without logging in as an administrator.

Setting Up and Editing Templates—Admin Only

Enter the shows list screen and tap SHOW TEMPLATES to the left of the screen header. The user is required to enter

the admin username and password for the system, then tap LOG IN and the user will have access to the available Show

templates.

From here the user can create a new template by tapping NEW and entering client, series and label information. They

can delete a template (other than the Calrec default template) by selecting it and tapping DELETE . They can edit a

template’s details by selecting it and tapping EDIT .

Updating Templates—Admin Only

The user can update Show templates to reflect the current System Settings by tapping UPDATE. The user will then be

asked to confirm or cancel the update.

Backing Up Shows

Shows & their user memories can be backed up to a USB drive connected to Brio 36’s USB ports. To back up a Show:

1. Select the Show to backup from the Shows list.

2. Tap BACKUP toward the bottom right of the display. To select multiple Shows, select them all now.

3. Tap SELECT BACKUP LOCATION and select a destination for back up, making a new folder if necessary.

4. Tap BACKUP HERE or CANCEL. If there is a previously saved version of the same Show a pop-up will appear

to ask if the user wants to OVERWRITE the show or CANCEL the backup.

FIGURE 5 - BACKING UP SHOWS

58 BRIO 36 Audio Production System with Optional Networking SETTING UP

Restoring Shows

1. Tap RESTORE in the footer of the Shows List and navigate to select the Show to restore.

2. Tap RESTORE.

Settings Stored within Shows

Tap Show Settings within the Show menu on Brio 36’s touch display and the user will see four options: General, Delay

Controls, Downmix and External Inputs.

General Settings:

• Access Follows Link defaults to on, but when turned off allows the access path to stay where it is when creating a link

using the Access buttons.

• For AutoFaders touching a fader whilst fading has two options, by default the Fader adjusts the fade-in level or

alternatively it overrides AutoFader Control.

• By default, a notch can be felt at the ‘0’ point on the fader scale. This can be switched off if required.

• The surface layer buttons can be set to operate in one of two ways. They either change all linked fader sections or

only the sections which contains the accessed fader, plus any sections which are linked to that section.

• By default, PFL can be activated momentarily by pulling the fader down below its lowest point, and deactivated once

released. This feature can be switched off for the whole surface.