Page 1

Gas Cooker

CA 5140.2 GG

❏ This appliance is for use on liquid

propane/butane gas only

❏ The aeration adjustment for this appliance has

already been set

❏ In the interest of safety this appliance must be

installed and/or serviced by a competent person

as stated in the gas safety (installation and use)

(amendment) regulations 1990.

❏ Leave these instructions

with the user

Fitters and Users Instructions

GB

Page 2

2

CONTENTS

– Introduction ........................page 2

– Installation ..............................” 3-5

– Features and

Technical Data.....................” 6

– How to use the hob burners .” 7-8

– How to use the oven

and grill................................” 9-11

– Care and maintenance..........” 12-13

– Technical information .............” 14

– After sales service

and guarantee .....................” 15

INTRODUCTION

Congratulation on your purchase of this

CALOR GAS gas cooker which has

been carefully designed and produced

to give you many years of satisfactory

use.

Before using this appliance it is

essential that the following instructions

are carefully read and fully understood.

We would emphasize that the

installation section must be fully

complied with for both your safety and

to ensure that you obtain the maximum

benefits from your appliance.

INSTALLATION and CONNECTION TO

THE GAS SUPPLY

This appliance is supplied for use on

LIQUID PROPANE/BUTANE GAS only.

In the interests of safety this appliance

must be installed and serviced by a

competent person as stated in the Gas

Safety (Intallation and Use)

(Amendment) Regulations 1990.

Reference should also be made to the

IEE wiring regulations, the Building

Regulations, the Building Standards

(Scotland) Consolidated Regulations.

Detailed recommendations are

contained in the following British

Standard Codes of Practice: - BS6172,

BS5540 Pt 2, BS6891, all editions

being current.

IMPORTANT

This appliance should be fitted by a

Corgi registered fitter, in compliance

with regulation in force.

It is illegal to provide any assistance in

the installation of gas appliances

except to Corgi registered installers.

Any Corgi registered fitter requiring

help must provide name, address and

registration number.

Information supplied will be validated

before help is provided.

When the installation has been

completed, it is essential that a

thorough gas soudness test is carried

out. If a flexible connector is used,

ensure that the hose is free from kinks

and torsional stress and is not touching

the back of the cooker.

Introduction

Page 3

3

ELECTRICAL CONNECTION

WARNING! THIS APPLIANCE

MUST BE EARTHED.

This appliance must be connected by a

competent person, using fixed wiring

via a DOUBLE POLE SWITCHED

FUSED SPUR OUTLET.

We recommend that the appliance is

connected by a qualified electrician,

who is a member of the N.l.C.E l C.

and who will comply with the l.E.E. and

local regulations.

The wires in the mains lead are

coloured in accordance with the

following code:

Green & Yellow = Earth,

Blue = Neutral,

Brown = Live.

FUSE

DOUBLE POLE SWITCHED

FUSED SPUR OUTLET

USE A 3 AMP FUSE

ON

Fig. 1

As the colours of the wires in the

mains lead for the appliance, may not

correspond with the coloured markings

identifying the terminals in your spur

box, proceed as follows:

1) The wire which is coloured green

and yellow must be connected to

the terminal marked E (Earth)

or coloured Green.

2) The wire which is coloured blue

must be connected to the terminal

marked N (Neutral), or coloured

Black.

3) The wire which is coloured brown

must be connected to the terminal

marked L (Live), or coloured Red.

Installation

Page 4

4

PROVISION FOR VENTILATION

The room containing the cooker should

have an air supply in accordance with

BS.5540: Part 2: 1989.

All rooms require an openable window

or equivalent while some rooms require

a permanent vent in addition to the

openable window.

The cooker should not be installed in a

bed-sitting room, of volume less than

21 m

3

.

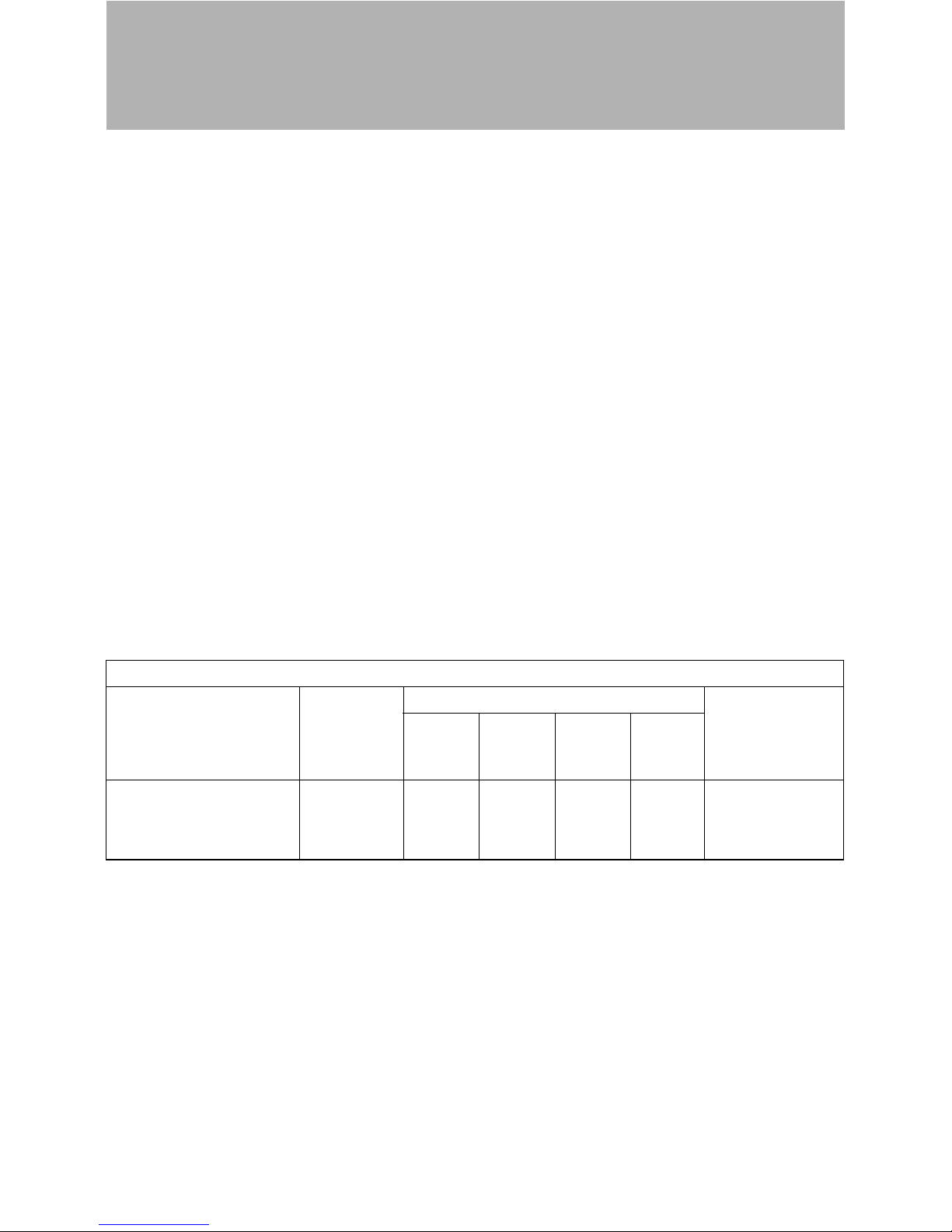

Where a DOMESTIC COOKER is

installed in a room or internal space,

that room or internal space shall be

MINIMUM PERMANENT OPENING FREE AREA FOR FLUELESS APPLIANCE

5 m3to

10 m

3

Openable

window or

equivalent also

required

Maximum

appliance

rated input

limit

Room volume

11 m3to

20 m

3

> 20 m

3

< 5 m

3

Type of appliance

Domestic oven, hot-

plate, grill or any

combination thereof.

None

50 (❊)

cm

2

Nil

cm

2

Nil

cm

2

100

cm

2

Yes

(❊) If the room or internal space containing these appliances has a door which opens

directly to outside, no permanent opening is required.

Installation

provided with a permanent opening

which communicates directly with

outside air and is sized in accordance

with table below. In domestic premises

the permanent opening shall be an air

vent.

If there are other fuel burning

appliances in the same room, BS.5540:

Part 2: 1989 should be consulted to

determine the requisite air vent

requirements.

If the cooker is installed in a cellar or

basement, it is advisable to provide an

air vent of effective area 100 cm

2

,

irrespective of the room volume.

Page 5

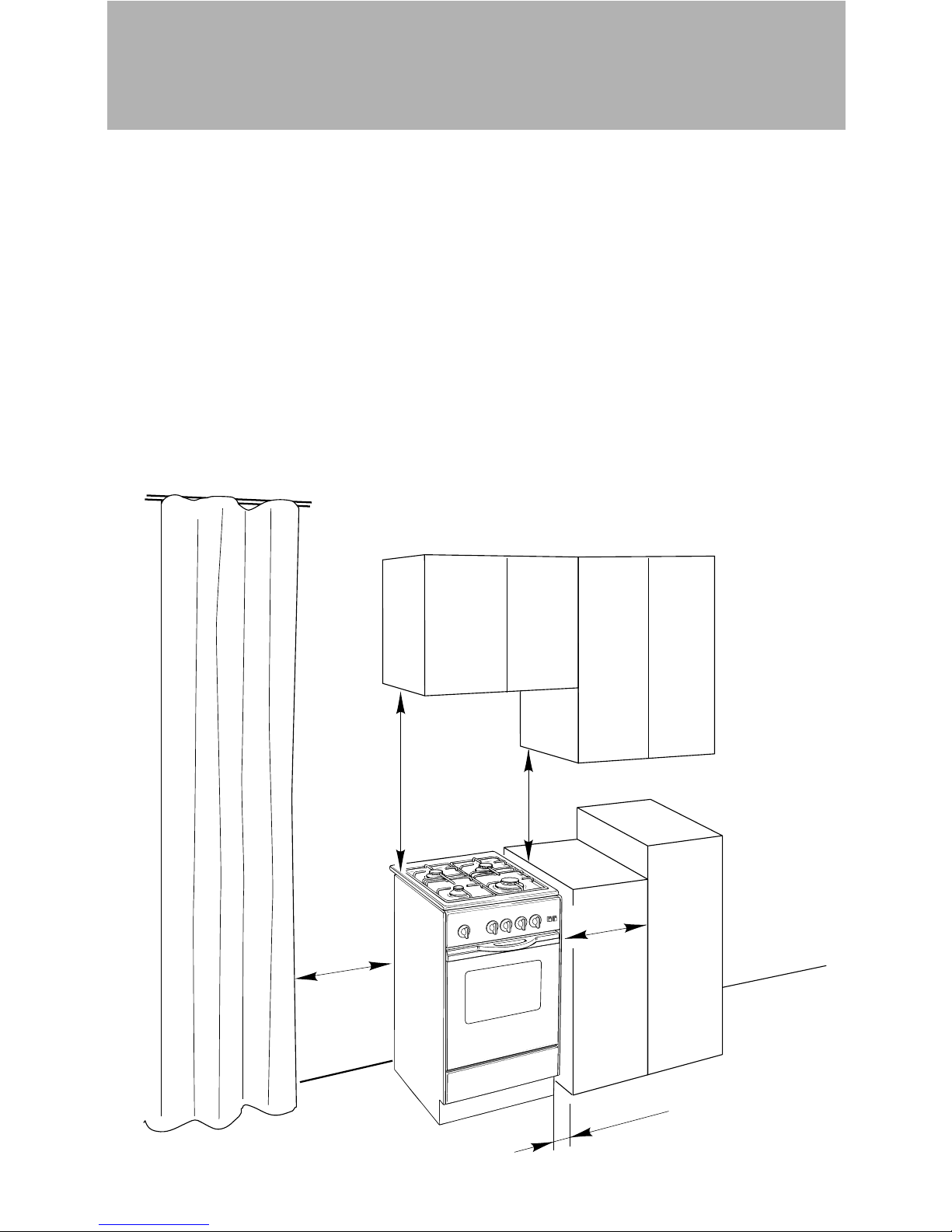

500 mm

800 mm

300 mm

19 mm

500 mm

5

LOCATION (fig. 2)

The cooker may be located in a

kitchen, a kitchen/diner or bed-sitting

room but not in a room containing a

bath or shower.

It is essential that the cooker is

positioned as stated below.

The cooker must be a minimum of 5

mm (1/5”) from the rear wall.

Shelves and wall cabinets must not be

fitted closer than 800 mm (32”) to the

hob burners.

Fig. 2

Installation

Curtains must not be fitted immediatly

behind appliance or within 500 mm

(20”) of the sides.

Base unit which are above the height

of the hotplate should be 300 mm (12”)

away.

It is advisable that the kitchen furniture

near the sides of the cooker is made

of heat resistant material, and the 19

mm (3/4”) air gap be maintained.

Page 6

6

900 mm

500 mm

500 mm

GAS BURNERS (Fig. 3)

1. Auxiliary burner (A)

1.00 kW

2. Semi-rapid burner (SR)

1.90 kW

3. Semi-rapid burner (SR)

1.90 kW

4. Rapid burner (R)

2.95 kW

GAS OVEN

– Gas burner - 3.25 kW

– Grill burner - 2.35 kW

– Usable oven volume

43 dm

3

CONTROL PANEL (Fig. 3)

5. Front right burner (4)

control knob

6. Rear right burner (3)

control knob

7. Rear left burner (2)

control knob

8. Front left burner (1)

control knob

9. Oven/Grill control knob

10. Oven light switch

11. Ignition push-button

9 8 7 6 5 10 11

2134

Fig. 3

Features and Technical Data

Page 7

7

The hob is made of steel coated with a

vitreous enamel to provide a durable

and attractive surface.

HOB BURNERS

Each hob burner is controlled by a

separate gas tap operated by a control

knob (fig. 4) which has 3 positions

marked on the bezel, these are:

– Symbol ● : tap closed (burner off)

– Symbol : High (maximum)

– Symbol : Low (minimum)

Push in and turn the knob anticlockwise to the selected position.

Low High

To turn the burner off, fully rotate the

knob clockwise to the off position: ●.

The maximum setting of the control tap

is for boiling, the minimum setting is for

slow cooking and simmering.

All working positions must be chosen

between the maximum and minimum

setting, never between the maximum

setting and the “OFF” position.

Fig. 4

LIGHTING OF HOB BURNERS

Push in and turn the appropriate

control knob in an anticlockwise

direction until the maximum position

(marked with the large flame symbol

) is reached.

Then press the ignition button

★ on

the front of the control panel.

After the burner lights, adjust the flame

to the setting you require.

How to use the Burners

Page 8

8

BURNERS POT DIAMETER

Auxiliary 16 cm

Semi-rapid 16 ÷ 22 cm

Rapid 22 ÷ 28 cm

Fig. 5

CHOICE OF BURNER

The burner must be chosen according

to the diameter of the pots and energy

required.

The hotplate has been designed with

safety in mind, however normal care in

use should be observed.

Do take care avoid burns and scalds

when reaching across the hotplate.

Pans with flat bases are more stable

than those which are warped.

Pans which are positioned centrally on

burners are more stable than those

which are offset.

It is far safer to position the pan

handles in such a way that they cannot

be accidentally knocked.

When deep fat frying fill the pan only

one third full of oil.

DO NOT cover the pan with a lid and

DO NOT leave the pan unattended.

In the unfortunate event of a fire, leave

the pan where it is and turn off all

controls.

Place a damp cloth or correct fitting lid

over the pan to smother the flames.

DO NOT use water on the fire.

Leave the pan to stand for at least 30

minutes or until cold.

How to use the Burners

Page 9

9

Fig. 6

THERMOSTAT GRADE TABLE

Knob mark Oven temperature

1 150 °C 300 °F

2 165 °C 330 °F

3 180 °C 355 °F

4 195 °C 385 °F

5 210 °C 410 °F

6 225 °C 440 °F

7 240 °C 465 °F

8 255 °C 490 °F

9 270 °C 520 °F

10 285 °C 545 °F

LIGHTING THE OVEN GAS BURNER

The thermostat allows the automatic

control of the temperature.

The gas delivery to the oven burner is

controlled by a two way thermostatic

tap (oven and grill burners) with flamefailure device.

To light the oven burner operate as

follow:

- Open the oven door and apply a

lighted mach or taper to hole “A” in

the oven base plate (fig. 6)

- Push and turn the oven knob anticlockwise to position 10.

- Once the oven burner is lit, wait for

about 15 seconds before releasing

the knob (time of priming of the

valve) and than close the oven door

slowly.

Turn the oven knob to the position

for the desired temperature (see the

thermostat grade table).

NEVER turn on the gas supply

before applying a lighted match or

taper to the hole “A”.

Ensure that the oven burner is alight

before closing the oven door.

THERMOSTAT

The thermostatic control tap knob is

marked with numbers from 1 to 10,

these correspond to the temperature

shown in the table, in addition the

“OFF” position is shown by the

symbol ●.

To choose the desired oven

temperature (check with the “Oven

cooking guide”, turn the control tap

knob until the number), required is

level with the line mark on the control

panel (facia).

How to use the Gas Oven

Fig. 7

A

Page 10

10

Fig. 8

LIGHTING THE GRILL BURNER

Do not grill with oven door closed.

Always fit the heat shield supplied

with the cooker under the front

panel before commencing operations

(Fig. 9).

WARNING. The heat shield and the

oven door reaches a very high

temperature whilst in use. Keep

children away and allow to cool

before removing.

The burner, heats a stainless steel net

which in-turn generates the infra-red

rays for grilling.

To light the grill burner operate as

follow:

- Open the oven door and apply a

lighted mach or taper to the both

sides of the grill burner (fig. 8)

- Push and turn the grill/oven knob

clockwise until you match the symbol

with the control panel reference

line.

- Once the grill burner is lit, wait for

about 15 seconds before releasing

the knob (time of priming of the

valve) and than set the oven door in

half-closed position.

NEVER turn on the gas supply

before applying a lighted match or

taper to the burner.

Partially close the oven door to the

grilling position.

Notes:

– The grill burner has only one setting,

that is full-on

– It is important that the heat shield is

fitted the correct way up, as shown

in the figure 9.

Fig. 9

How to use the Grill

Page 11

11

How to use the Oven

OVEN COOKING TEMPERATURES

MARK

APPROX. HEAT OF TYPE OF DISH TO COOK

TEMP. OVEN

1 150°C Very cool Meringue cakes,

(300°F) oven slow cooking items

1-2 150°C - 160°C Cool or Milk puddings, very rich fruit

(300°F - 320°F) slow oven cakes, i.e., Christmas

2 165°C Cool or Stews, casseroles, braising,

(300°F) slow oven rich fruit cakes, i.e., Dundee

2-3 170°C Warm oven Biscuits, rich plain cakes

(330°F) i.e., Madeira. Low temp. roasting

3 180°C Moderate Plain cakes, Victoria

(355°F) oven sandwich, raised meat pies

4 195°C Fairly hot Small cakes, savoury flans,

(380°F) oven fish

5 210°C Hot oven Plain cakes and buns, swiss rolls,

(410°F) fruit pies. High temp. roasting

6-7 225°C - 240°C Moderately Bread and bread rolls etc., scones,

(435°F - 465°F) hot oven flaky and rough puff pastry,

yorkshire pudding

8-9 255°C - 270°C Very hot Sausage rolls, mince pies, puff

(490°F - 520°F) oven pastry, pizza

10 285°C Very hot Browning ready cooked dishes

(545°F) oven

Page 12

12

CLEANING THE HOB:

Spillage on the hob can usually be

removed by a damp soapy cloth. More

obstinate stains can be removed by

rubbing gently with a soapy scouring

pad or mild household cleaner.

BURNERS

To be washed only with soapy water.

After each cleaning, make sure that the

burner-caps, as well as the burners,

have been well wiped off and

CORRECTLY POSITIONED.

It is essential to check the correct

position of the burner-caps as the least

displacement from the housing may

cause serious problems.

Fig. 10

CLEANING OVEN PARTS:

The oven interior and the chromium

plated shelves and runners can be

cleaned by damp soapy cloth.

Obstinate stains can be removed with

nylon scouring pads and gentle, nonabrasive, liquid cleaner. Provided the

oven is wiped over immediately after

roasting, only the minimum of cleaning

should be necessary.

TAPS

If a tap becomes stiff, do not force;

contact your local Service Centre.

(See enclosed Service Information)

FLEXIBLE TUBE

From time to time, check the flexible

tube connecting the gas supply to the

cooker.

It must be always in perfect condition;

in case of damage arrange for it to be

replaced by a Corgi registered fitter.

Care and Maintenance

Page 13

13

DOOR GLASS:

The glass of the oven door can be

cleaned with a soft, warm, soapy cloth,

then wiped clean with cold water and

polished with a soft clean cloth. Do not

use scouring pads or anything abrasive

on the oven door glass.

REMOVING THE OVEN DOOR:

To facilitate oven cleaning, it is possible

to remove the door.

Hinges “A” have two movable clips “B”

which can be connected to parts “C” of

the hinges when the door is completely

open in order to lock this in position.

Following this, the door can be lifted

upwards and removed.

To do this, lift on the sides of the door

near the hinges.

To remount the door, first insert the

hinges in their grooves. Now close the

door.

Do not forget to remove the two

movable clips “B” used to link to the

two hinges.

A

B

C

Fig. 11

Fig. 12

FITTING UP OF OVEN SHELVES

The oven shelves are provided with a

security block to prevent accidental

extraction.

They must be inserted operating as per

figure 12.

To pull them out operate in the reverse

order.

Care and Maintenance

Page 14

14

Description Nominal Reduced G 30/31

Power Power 28/37 mbar

By- Ø injector Ring opening Port.

[kW] [kW]

pass [1/100 mm] [mm] [g/h]

Auxiliary burner (A) 1.00 0.30 27 50 3 73

Semirapid burner (SR) 1.90 0.38 29 67 5,7 138

Rapid burner (R) 2.95 0.60 39 83 Fully open 214

Oven burner 3.25 0.85 45 - 47 86 Fully open 236

Grill burner 2.35 – – 78 Fully open 176

Cat: II 2H3+

Classe 1

Technical Information

Page 15

15

A guarantee card is supplied with this

cooker.

Your guarantee is offered as an extra

benefit and does not affect your legal

right.

In the event that you require After

Sales Service please contact your local

Service Centre as per the attached list.

For the conversion of the cooker, to

use a different gas, please contact your

local Service Centre (see enclosed

Service Information).

Components are guaranteed for a

period of 12 months from the date of

purchase, subject to the proviso that

the appliance has been:

1. Used solely for domestic purposes.

2. Used in accordance with this

instruction book.

3. Has not been subjected to misuse,

accident, or repaired or modified by

anyone not authorized to do so.

After Sales Service and Guarantee

Descriptions and illustrations in this booklet are given as simply indicative.

The manufacturer reserves the right, considering the characteristics of the models described

here, at any time and without notice, to make eventual necessary modifications for their

construction or for commercial needs.

Page 16

ß3

Ed. - Cod. 1101182

Distributed by: De' Longhi Limited

Bridle Close

Wellingborough NN8 4RJ

Manufactured by:

De' Longhi S.p.A.

31100 Treviso

Italy

Loading...

Loading...