California Faucets Solimar CF-TO-V7002-9 Installation Instructions Manual

CF-TO-V7002-9_ii_160720 Pg 1

Solimar™

CF-TO-V7002-9

In-Wall Vessel Lavatory Faucet

Installation Instructions

1

IMPORTANT: Read all instructions prior to installation and provide copy of instructions to consumer.

Operating Specifications:

Recommended Supply Pressure: 20 to 70 psi

*†

Maximum Flow Rate: 1.2 gpm

* Operating pressures between hot and cold supplies should vary no more than 30 psi.

† If water pressure exceeds 70 psi, install a Pressure-Reducing Valve (RPV).

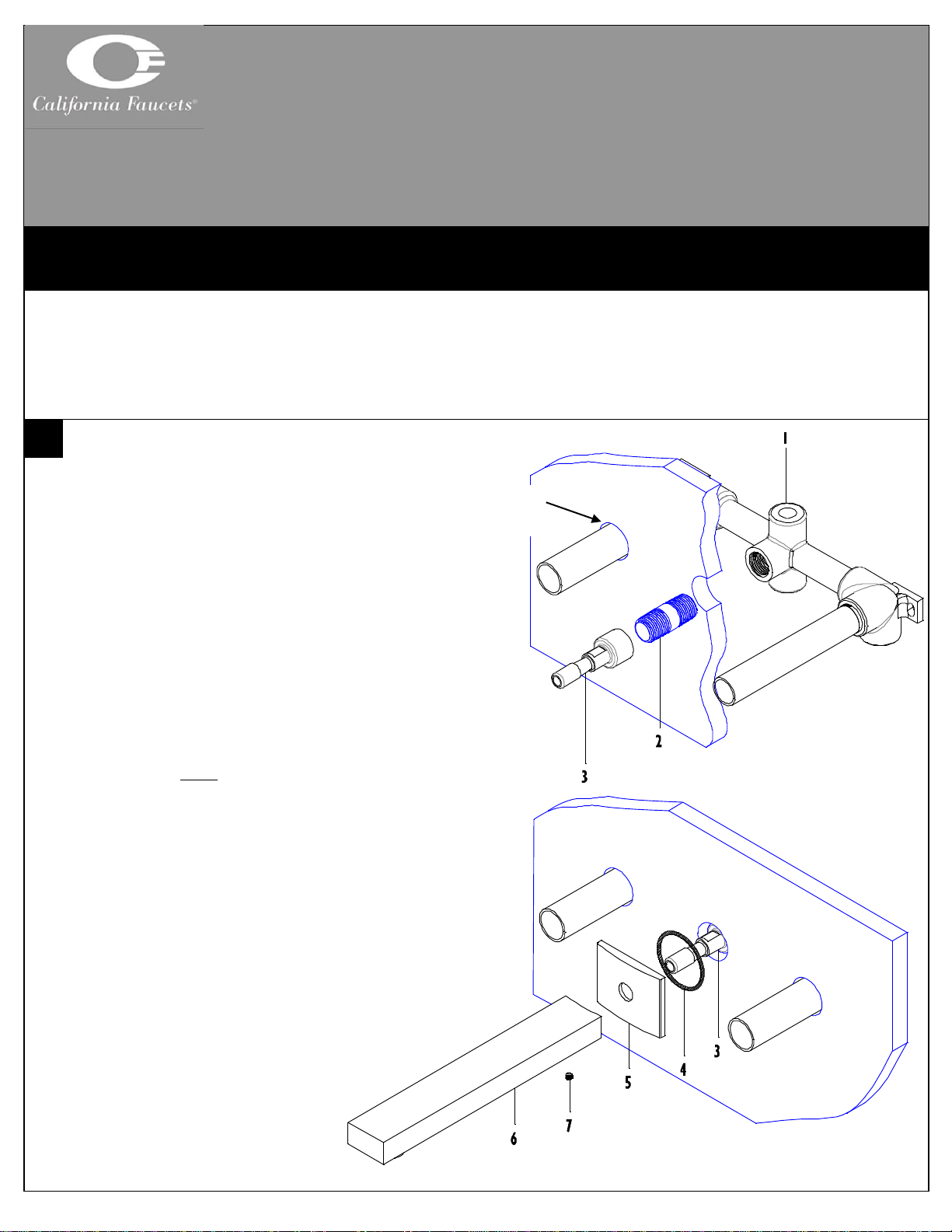

INSTALLING SPOUT TO IN-WALL VALVE

Prior to installing faucet trim in-wall vessel rough

VALVE (1), CF-VL-R, must be properly installed

and wall surface must be completely finished

Recommended through-hole size shall be Ø1-1/4”

Apply thread sealant to both threaded ends of

NIPPLE (2), not supplied, and tighten into center

outlet of VALVE (1)

Securely tighten QUICK CONNECT (3) onto end

of NIPPLE (2) using I/2” open-end wrench

Place O-RING (4) into ESCUTCHEON (5) & slide

ESCUTCHEON (5) onto QUICK CONNECT (3)

IMPORTANT: To prevent damage to internal o-ring on SPOUT

(6), QUICK CONNECT (3) MUST be free of any dirt and/or debris

Slide SPOUT (6) onto QUICK CONNECT (3),

align ESCUTCHEON (5) & SPOUT (6) and tighten

SETSCREW (7) on bottom side of SPOUT (6)

CALIFORNIA FAUCETS RECOMMENDS THAT ALL PLUMBING PRODUCTS BE INSTALLED

BY A LICENSED PROFESSIONAL

Ø1-1/4”

(3 holes)

CF-TO-V7002-9_ii_160720 Pg 2

2

3

4

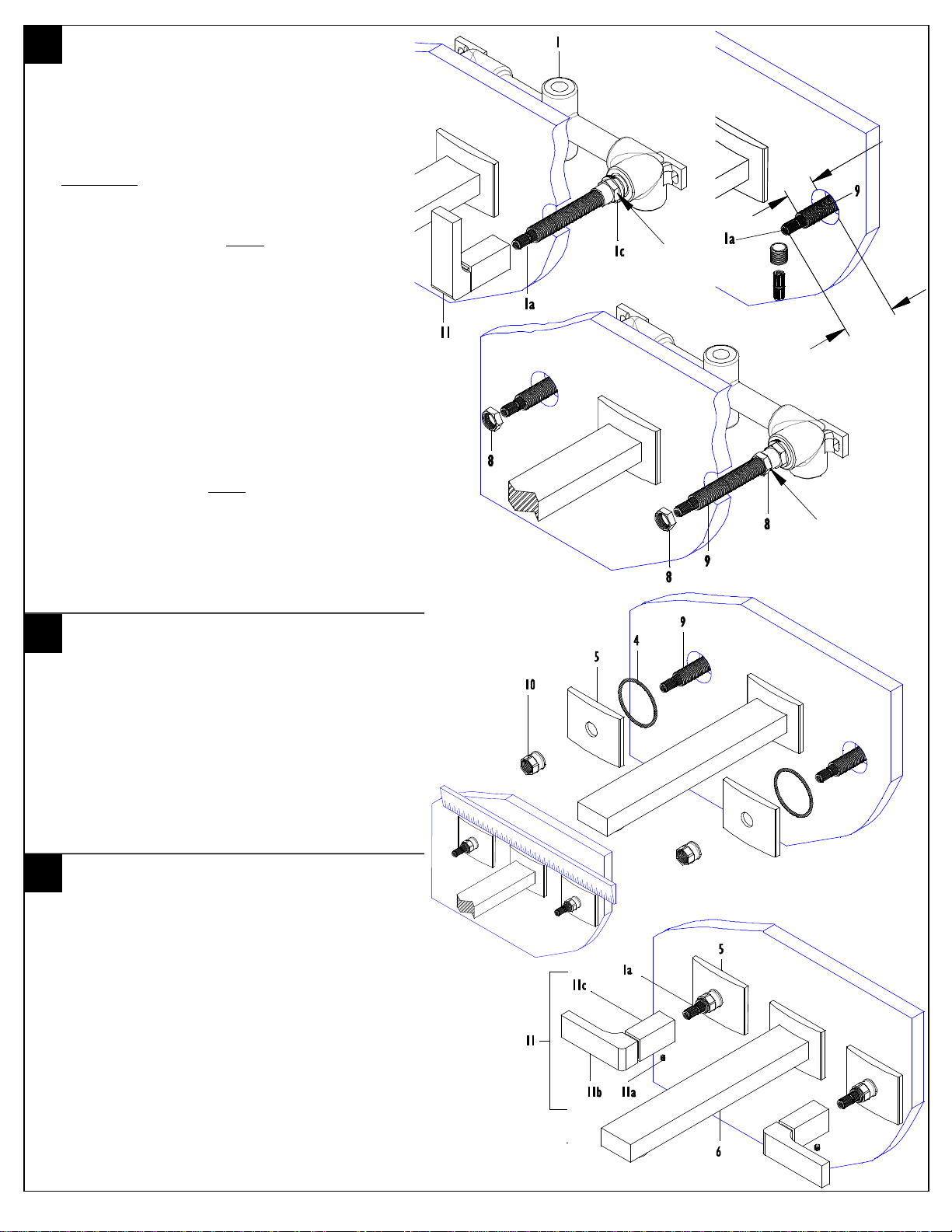

v ALIGN & TRIM VALVE STEM

Remove MUDGUARD (1b) from VALVE (1)

To obtain proper HANDLE (11) alignment it may

be necessary to re-align cartridge STEM (1a); to

align STEM (1a), slightly loosen the cartridge NUT

(1c), place HANDLE (11) on STEM (1a) and

TIGHTEN in CW direction until desired

alignment is achieved; retighten cartridge NUT (1c)

to factory torque setting of 14 ft-lbs.

WARNING: Cartridge NUT (1c) MUST be properly torqued to

prevent possible failure and/or water damage

Unscrew ALL-THREAD (9) from valve STEM (1a)

Cut STEM (1a) 1-3/8” from finished wall surface

Reattach ALL-THREAD (9) onto valve STEM (1a),

using a marking device (e.g. pencil or marker)

indicate a distance of ¾” from finished wall on ALLTHREAD (9); remove ALL-THREAD (9) and cut off

excess ALL-THREAD (9) at indicated mark &

reattach ALL-THREAD (9) onto valve STEM (1a) –

repeat on other side

IMPORTANT: To prevent HANDLE (11) rotation during operation

of faucet set LOCK-NUT (8) MUST be placed on both ALL-

THREAD (9) of VALVE (1)

Place LOCK-NUT (8) onto ALL-THREAD (9) and

tighten against cartridge NUT (1c) to prevent ALLTHREAD (9) from rotating while operating

HANDLE (11) – repeat on other side

INSTALLING ESCUTCHEON

Insert O-RING (4) into ESCUTCHEON (5) and

place onto ALL-THREAD (9)

Secure ESCUTCHEON (5) onto wall by tightening

lock NUT (10)

To align ESCUTCHEONS (5), use a ruler or

straight edge to align the spout and handle

escutcheons of the faucet as shown; after alignment

retighten lock NUTS (10)

INSTALLING HANDLE

Loosen SETSCREW (11a) from POST (11c)

IMPORTANT: Handle BLADE (11b) shall be aligned with wider

portion of handle POST (11c)

Slide HANDLE (11) down onto and engage valve

STEM (1a)

Handle POST (11c) shall completely cover lock

NUT (10) and seat against ESCUTCHEON (5)

Tighten SETSCREW (11a) and rotate handle

BLADE (11b) to check operation, open position is

when BLADE (11b) is rotated upward – repeat on

other side

1-3/8”

californiafaucets.com 5271 Argosy Ave. Huntington Beach, CA 92649 800-822-8855

13/16”

hex

3/4”

11/16”

hex

Loading...

Loading...