California Faucets Diverter for Roman Tub User Manual

Tel: 714-891-7797

Fax: 714-891-2478

Toll Free: 800-822 -8855

www.calfau cets.com

Calif ornia Faucets reserves the righ t t o make modification and specification changes at any time. Plea se visit www. calfaucet s.com for most cu rrent technical data .

CALIFORNIA FAUCETS RECOMMENDS THAT ALL PLUMBING PRODUCTS BE INSTALLE D BY A LICENSED ROFESS IONAL

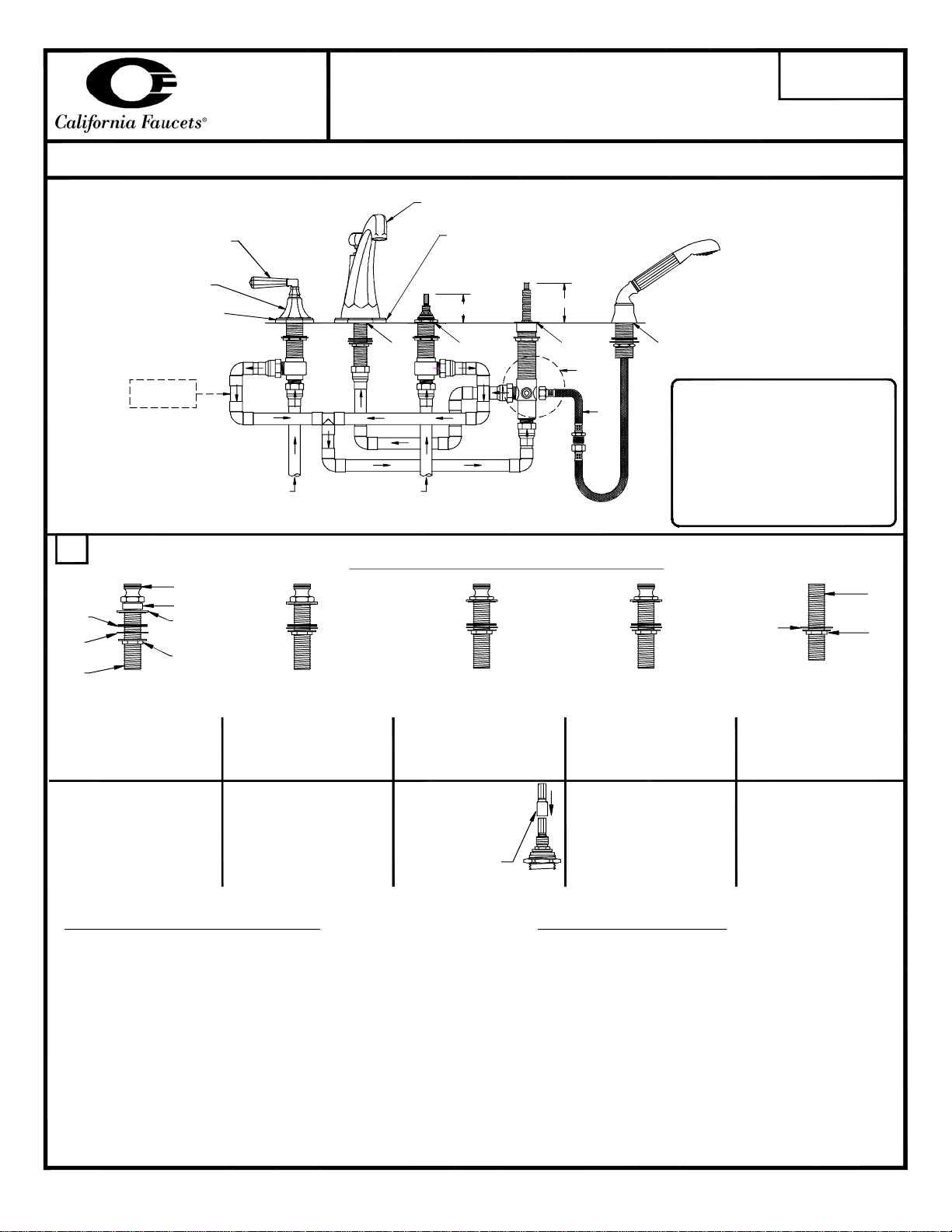

Handle

Escutcheon

Base Ring

(if applicable)

Use Rigid

Copper Pipe

ROMAN TUB SET WITH DIVERTER

& HAND HELD SHOWER

Spout

Base Ring

(if applicable)

"A"

ø1-1/2"

Hole Size

See

Step 4

Leader

Hose

ø1-1/4"

Hole Size

NOTE:

-Must use rigid copper piping

Hole Size

"A"

ø1"

ø1-1/4"

Hole Size

INSTALLATION

INSTRUCTIONS

(not flex) for all connections

between spout and valves.

1

Rubber

Washer

Plastic

Washer

Shank

Fig. 2A

Quick Connect

Model #: QC-50

Use With Rough Kit #:

08-75-50

For Series #:

5008

O-Ring

Brass Spacer

Brass Washer

w/ O-Ring

Brass Nut

Hot

Inlet

Roman Tub Spout Connectors

Fig. 2B

Quick Connect

Model #: QC-99

Use With Rough Kit #:

08-75-99

For Series #:

3208 3308 3408 3508

Cold

Inlet

Fig. 2C

Use With Rough Kit #:

3608 3808 4008 4208

4408 4508 4608 4708

5108 5508 5708 5808

Series 6308 uses

Broach Adapter

5908 6008 6108 6408

6708 6808 6908 E208

For all Quick Connect except: 08-75-75

-Remove brass nut, plastic washer and rubber washer from

Quick Connect assembly.

-Ensure that O-ring is properly seated in brass washer.

-Insert Quick Connect assembly through hole in deck.

-Place Rubber Washer, Plastic Washer and Brass Nut onto

Shank from below and firmly tighten.

-Seat Spout onto Quick Connect.

-Rotate Spout to desired position and tighten setscrew.

-Use thread sealant to seal all fittings with threads.

Fig. 1

Quick Connect

Model #: QC-63

08-75-63

For Series #:

6308

Fig. 3

-It is also recommended that an

access panel be provided for

all Roman Tub installations.

3/4"

Shank

Fig. 2D

Quick Connect

Model #: QC-63

Use With Rough Kit #:

08-75-65

For Series #:

4808

4808X

6508

6608

Washer

Fig. 2E

3/4" Nipple

Model #: QC-75

Use With Rough Kit #:

08-75-75

For Series #:

5308

7008

7208

7308

Nut

For Quick Connect: 08-75-75

-Apply thread selant to one end of the Shank and

tighten into Spout.

-Place spout base ring (if applicable) onto deck, over

the spout shank.

-Insert Shank through deck hole and from below place

Washer and Nut onto Shank.

-Rotate Spout to desired postion and firmly tighten nut.

-Use thread sealant to seal all fittings with threads.

RT.1_ii_140122

IMPORTANT: All soldering shall be performed prior to attaching fitting to Valves and Quick

Connect, otherwise severe damage may take place and void warrantee

P 1

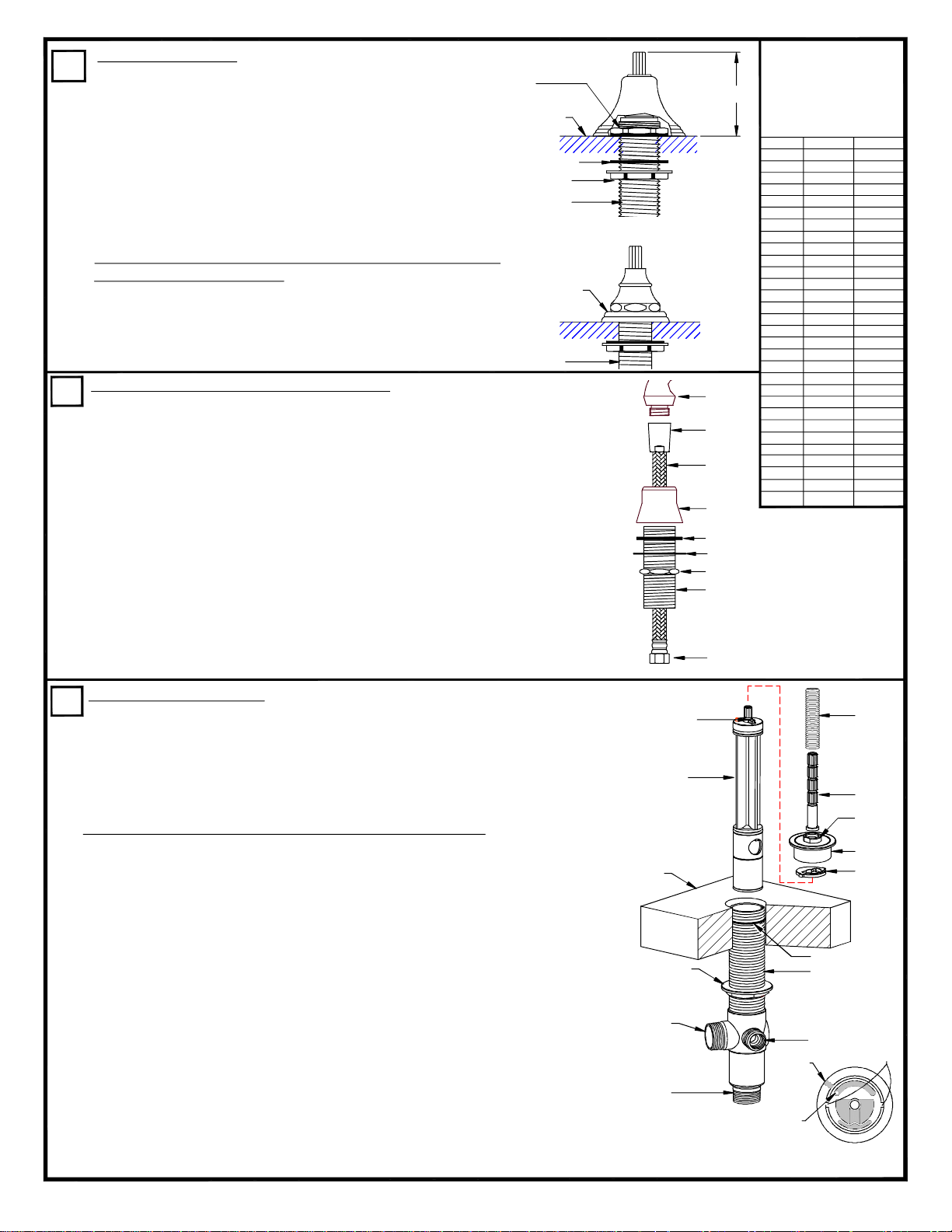

Install valve bodies:

2

NOTE: Hot & cold valves are labeled: cold=blue & hot=red.

-Remove top nut and turn bottom nut with fiber washer down

the valve until it stops.

-Insert valve through hole from below and install top nut

(if applicable), and adjust to proper height, see Fig. 4A

(also refer to "A" dimension).

-Tighten the bottom nut to secure the valve.

-Install trim parts (base ring if applicable), escutcheon and

handle and tighten handle set screws with Allen key provided.

REMINDER: Please retain allen key as handles may

require re-tightening with normal use.

Installation Note for series:

# 32, 33, 34, 35, 36, 43, 57, 60, 61, 67, 68 & 69.

The trim to those products do not require a top nut to be installed

on the valve (See Fig. 4A)

The decorative base ring and escutcheon takes the place of the

top nut. (See Fig. 4B).

Install spray holder and hand-held shower:

3

-Remove threaded nipple from spray holder. Insert threaded

nipple up through deck, keeping lock nut, steel washer and rubber

washer facing up towards deck from below. (See fig. 5)

-Reattach spray holder to threaded nipple and lock down from below.

-Insert handshower hose with hex nut end first.

-Ensure rubber washer is in the conical female receptacle

of the handshower hose and thread into the hand shower elbow.

-Place fiber washer between handshower and the handshower

elbow and thread together.

-Ensure rubber washer is in hex nut end of flexible hose and connect

to 1/2" out port of the diverter valve, (connections not provided).

-Install piping (not supplied) to connect valve, spout and diverter

(See Fig. 1 for piping diagram. See Fig. 6A for inlet/outlet configuration

of diverter).

NOTE: The manufacturer recommends these connections be made in

hard copper.

Deck Diverter Installation

4

-Remove All-thread, Broach, Trim Nut and Hub from Body.

-Hole diameter size in deck or tub needs to be 1-1/2"

-Insert Body through the hole from underside and reinstall the

Hub (hand tight only) until it stops against the O-Ring on Body.

-Align the Body into the desired postition to allow easy connection

access to ports, pull Body down and tighten the Bottom Nut securely.

Connection types: NPT Thread (or) copper sweat "solder"

-For solder connections either directly to the valve, or within 6" of the valve,

the CARTRIDGE MUST BE REMOVED from the body. When soldering do

not apply excessive heat directly to the body. WARNING: Failure to follow

these directions can cause damage to the body and/or cartridge, and

will nullify the warranty.

-Fit the Broach to the Cartridge and rotate counter-clockwise until it stops.

-Use a permanent marker to locate the Stop Pin on the Hub (See Fig. 6B).

-Remove Broach and Cartridge with stop ring from the Body.

-Connect the mixed water from valves to the bottom 3/4" inlet.

-Connect the 3/4" outlet on side to the tub spout.

-Connect 1/2" outlet on side to the hand shower hose.

-After Body has cooled, reinstall the Cartridge carefully and align Stop Pin with

the mark on the Hub (See Fig. 6B). Use Broach if neccessary to rotate the

Cartridge for alignment.

-Install the Stop Ring in top of Body (fit one way) and push down into notches.

-Install Trim Nut, Broach and All-thread (do not overtighten All-thread).

NOTE: Prior to trim installation, it may be necessary tp cut Broach and

All-thrad to dimension "A", All-thread shall be cut 1/2" less than Broach.

-Install trim (base ring if applicable), escutcheon, handle and tighten setscrews.

RT.1_ii_140122

Top

Nut

Sink/

Countertop

Fiber Washer

Bottom Nut

Valve Bo dy

Decorative

Base Ring

Valve

Fig. 5

Fig. 4A

Fig. 4B

Stop Pin

Cartridge

Deck

Bottom Nut

Outlet:

3/4" NPT Male

or 3/4" Copper

Sweat

Inlet:

3/4" NPT Male

or 3/4" Copper

Sweat

Fig. 6A

DIMENSION

"A" Dimension is

from top of counter/tub

"A"

top to tip of stem broach.

Series # Handle Diverter

3208 2 3/8" 2 3/8"

3308 2 3/8" 2 3/8"

3408 2 3/8" 2 3/8"

3508 2 3/8" 2 3/8"

3608 2 3/8" 2 3/8"

3808 2 5/8" 2 5/8"

4008 2 5/8" 2 5/8"

4208 2 5/8" 2 5/8"

4408 2 3/8" 2 3/8"

4508 2" 2"

4608 2 1/2" 2 1/2"

4708 2 1/2" 2 1/2"

4808,X 2 5/16" 2 5/16"

5008 2 1/4" 2 1/4"

5108 2 1/2" 2 1/2"

5308 2 1/4" 2 1/4"

5508 2 5/8" 2 5/8"

5708 2" 2"

5808 2 5/8" 2 5/8"

5908 2 5/8" 2 5/8"

6008 2 1/4" 2 1/4"

Elbow

Conical

Receptacle

Hand Hel d

Shower

Hose

Spray

Holder

Rubber Washer

Steel Was her

Lock Nut

Threaded Nipple

Hex Nut

6108 2 1/4" 2 1/4"

6208 1 1/8" 1 1/8"

6308 3" 3"

6408 2 5/8" 2 5/8"

6508 2" 2"

6608 2" 2"

6708 2 1/4" 2 1/4"

6808 2 3/8" 2 3/8"

6908 2 3/8" 2 3/8"

E208 2 11/16" 2 11/16"

"A"

O-Ring

Diverter

Valve

Oulet:

1/2" NPT Male

or 3/8" N PT

Fem

Mark

Stop

Pin

All

Thread

Broach

Trim

Nut

Hub

Stop

Ring

Notches

Fig. 6B

P2

Loading...

Loading...