California Faucets CF-TO-VE302-7, CF-TO-VE302C-7 CF-TO-VE302C-7-77R, TS-E3-E3, D-E3-E3, TS-E3-77 Quick Start Manual

...

CF-TO-VE302-7_ii_190422 Pg 1

Bel Canto

®

CF-TO-VE302-7, CF-TO-VE302C-7

CF-TO-VE302C-7-77R, TS-E3-E3,

D-E3-E3, TS-E3-77, D-E3-77

In-Wall Vessel Lavatory Faucet / Tub Spout

IMPORTANT: Read all instructions prior to installation and provide copy of instructions to consumer.

Operating Specifications:

Recommended Supply Pressure: 20 to 70 psi

*†

Maximum Flow Rate: 1.2 gpm for Lavatory Vessel, 7.5 gpm for Tub Spout

* Operating pressures between hot and cold supplies should vary no more than 30 psi.

† If water pressure exceeds 70 psi, install a Pressure-Reducing Valve (PRV).

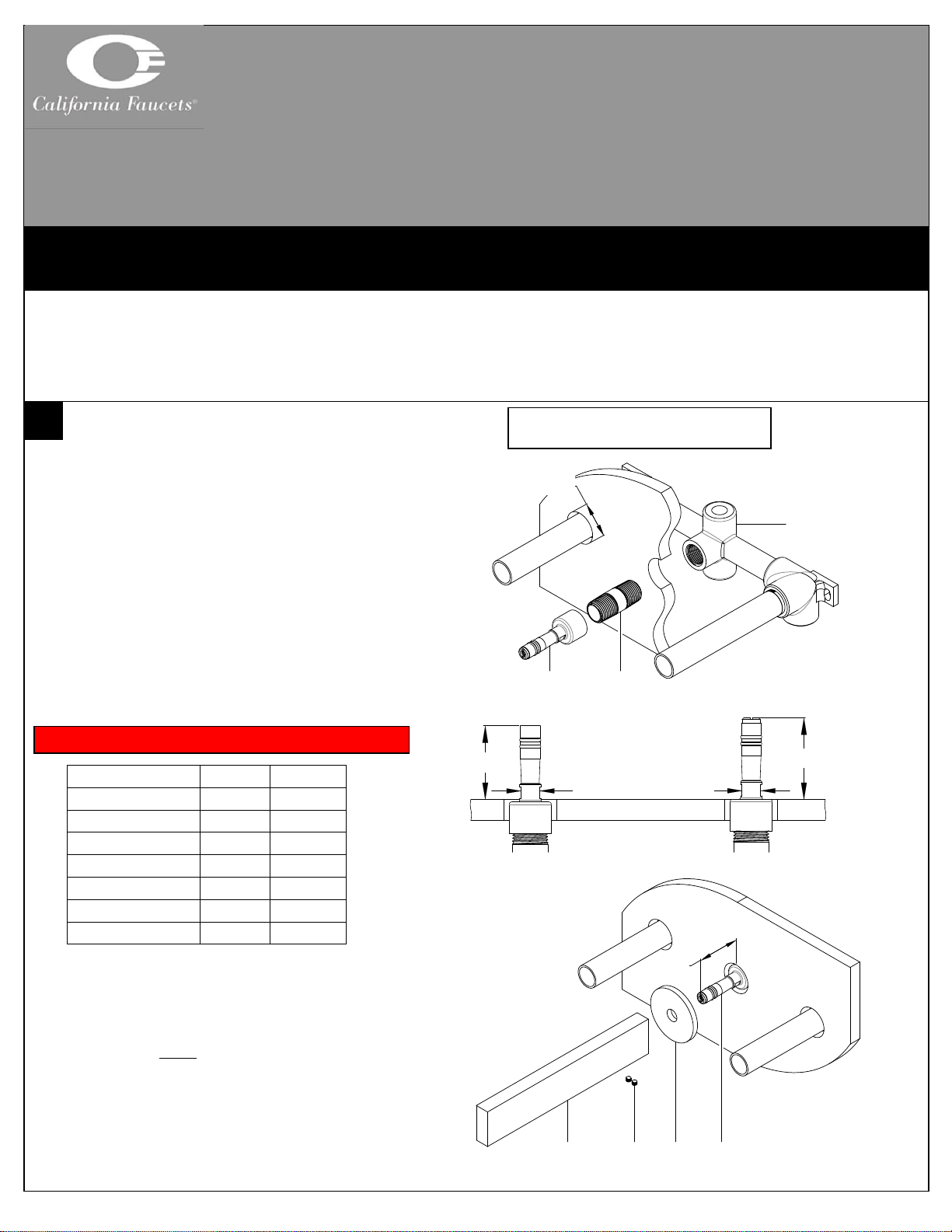

INSTALLING SPOUT

• Prior to installing faucet trim in-wall vessel rough

VALVE (1), must be properly installed and wall

surface must be completely finished

NOTE: Recommended through-hole size shall be Ø1-1/4”

• Apply thread sealant to both threaded ends of

NIPPLE (2), not supplied, and tighten into center

outlet of VALVE (1)

• Tighten QUICK CONNECT (3) onto end of

NIPPLE (2) using ½” open-end wrench

• Confirm QUICK CONNECT (3) is protruding from

finished wall the correct amount with table given

Model

MIN “A”

MAX “A”

CF-TO-VE302-7

1-11/16”

1-7/8”

CF-TO-VE302C-7

1-13/16”

1-15/16”

CF-TO-VE302C-7-77R

1-13/16”

1-15/16”

TS-E3-E3

1-9/16”

1-3/4”

D-E3-E3

1-9/16”

1-3/4”

TS-E3-77

1-11/16”

1-13/16”

D-E3-77

1-11/16”

1-13/16”

• Slide SPOUT ESCUTCHEON (4) onto QUICK

CONNECT (3)

IMPORTANT: To prevent damage to internal o-ring on SPOUT (5),

QUICK CONNECT (3) MUST be free of any dirt and/or debris

• Slide SPOUT (5) onto QUICK CONNECT (3) and

tighten both SETSCREW (5a) on bottom side of

SPOUT (5)

NOTE: If SPOUT ESCUTCHEON (4) is square, be sure to align it

with SPOUT (5)

CALIFORNIA FAUCETS RECOMMENDS THAT ALL PLUMBING PRODUCTS BE INSTALLED

BY A LICENSED PROFESSIONAL

NOTE: Spout installation shown with lavatory

vessel valve, Tub Spout installation is the same

A 3 4

5a

5

Ø1-1/4”

1 2 3

A

Tighten with

½” open-end wrench

A

For Tub Spout

For Lavatory Vessel

WARNING: Dimension “A” must be met to prevent water damage

CF-TO-VE302-7_ii_190422 Pg 2

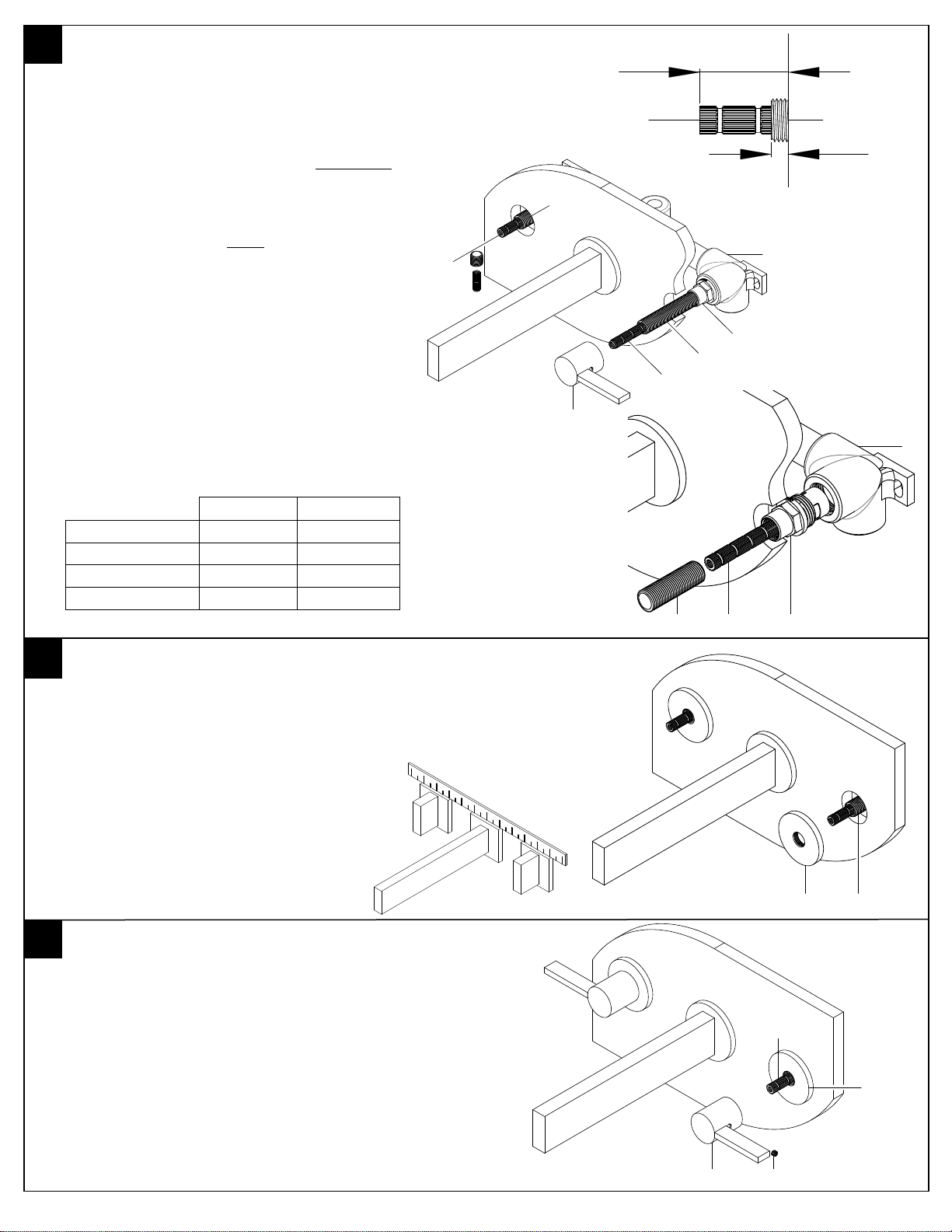

v ALIGN & TRIM VALVE STEM

• Remove mudguards from VALVE (1)

• To obtain proper HANDLE (7) alignment it may be

necessary to re-align cartridge STEM (1b); to align

STEM (1b), slightly loosen the cartridge NUT (1d),

place HANDLE (7) on STEM (1b) and TIGHTEN

in CW direction until desired alignment is achieved;

retighten cartridge NUT (1d) to factory torque

setting of 14 ft-lbs.

WARNING: Cartridge NUT (1d) MUST be properly torqued to

prevent possible failure and/or water damage

• Using a pencil/marker indicate a distance from

finished wall on ALL-THREAD (1c) (find distance in

column “MIN “C”” of table)

• Unscrew ALL-THREAD (1c) from valve STEM (1b)

• Cut STEM (1b) from finished wall surface according

to table (find distance in column “MIN “B”” of

table)

• Cut off excess ALL-THREAD (1c) at indicated mark

and reattach ALL-THREAD (1c) onto valve STEM

(1b) – repeat on other side

INSTALLING ESCUTCHEON

• Tighten handle ESCUTCHEON (6) onto ALL-

THREAD (1c)

NOTE: for VE302C-7 & VE302C-7-77R

• Tighten handle ESCUTCHEON (6) until it is secure

and aligned with spout; use ruler or straight edge to

confirm alignment

INSTALLING HANDLE

• Loosen SETSCREW (7a)

• Slide HANDLE (7) down onto and engage valve

STEM (1b) leaving a space of 1/32” between handle

and handle ESCUTCHEON (6)

• Tighten SETSCREW (7a)

• Turn on water supply and check for leaks

STEM

ALL-THREAD

Model

MIN “B”

MIN “C”

CF-TO-VE302-7

1-1/8”

3/16”

CF-TO-VE302C-7

1-1/4”

5/16”

CF-TO-VE302C-7-77R

1-1/4”

5/16”

californiafaucets.com 5271 Argosy Ave. Huntington Beach, CA 92649 800-822-8855

1b

7a 7 6

1c 6 B C 1c

1b 7 1b

1c

1d (13/16” hex)

1

1c

1b 1 1d

1b

1c

Loading...

Loading...