Page 1

www.caleffi.com N A 1 0 0 7 3 . 0 2

Z-one™ Z1, Z2, Z3 Series

Function

The Z-one, a two-position spring return zone valve,

is used in heating and air-conditioning systems.

The Z-one series consist of a Z1 actuator which is

easily attached to a Z2 (2-way) or Z3 (3-way) valve

body. Z1 actuator is equipped with or without

auxiliary switch.

The Z-one actuator has a synchronous motor that

winds the return spring and moves the valve paddle

to the desired position. When power is removed the

actuator spring returns the valve paddle. 24V

actuators (except HCS) use sealed reed switch for

end switch, requiring no minimum current load.

US Patent 7,048,251

Technical Characteristics of Body

Material: - body: forged brass

(optional lead-free brass)

- seat: machined brass

- stem: stainless steel

- two o-ring seals EPDM

- paddle EPDM

Medium: water and glycol

Maximum percent of glycol: 50%

Temperature range: 32 to 240°F (0 – 115°C)

Max. static pressure: 15 psi (1 bar) steam

300 psi (20 bar)

Connection: - sweat ½”, ¾” 1” & 1 ¼”

- NPT ½”, ¾” & 1”

- SAE flare ½”

- inverted flare ½”, ¾” & 1” sweat fittings

separate

Technical Characteristics of Actuator

Material: - base and cover: polycarbonate

- base plate: aluminum

Motor: - voltage: 24 VAC 50/60 Hz Class 2

120 VAC 50/60 Hz

208 VAC 50/60 Hz

230 VAC 50/60 Hz

277 VAC 50/60 Hz

Wire lead length: 6” (15cm), 24V only -18” (45cm)

Power requirements: 5.0 W, 7 VA

Ambient temperature range: 32 - 104ºF (170ºF optional)

Auxiliary switch: 24 VAC: 0 A min,

0.4 A max, 24 V

120-277 VAC, HCS:

0.25A min, 5A max, 250 V

Humidity: 95% non-condensing

Approvals: UL874, cUL Listed & CE

UL 1995 sec. 18 (air plenum & ducts)

Normally Open Actuators must be powered down

during off-season.

Page 2

Flow Characteristics

Connection size Flow Coefficient

1/2" 1.0 Cv (0.9 kv) 75 PSI (517 kPa)

1/2"

3/4"

1/2"

3/4"

3/4"

1"

3/4"

1"

1"

1 1/4"

2.5 Cv (2.2 kv) 50 PSI (345 kPa)

3.5 Cv (3.0 kv) 30 PSI (207 kPa)

5.0 Cv (4.3 kv) 25 PSI (172 kPa)

7.5 Cv (6.5 kv) 20 PSI (138 kPa)

7.5 Cv (6.5 kv) 20 PSI (138 kPa)

Max. Close-off P

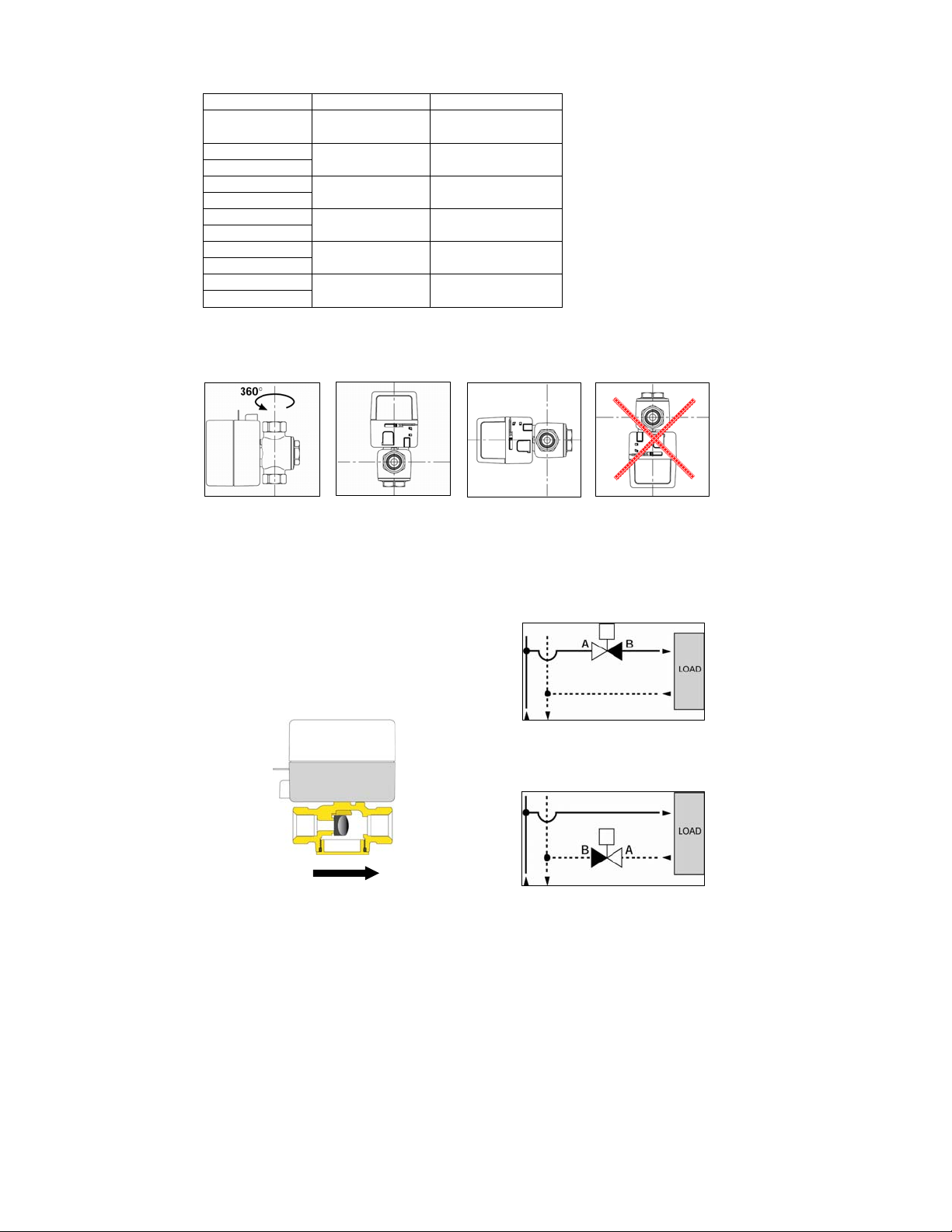

Installation

The valve can be installed vertically or horizontally, but not turned upside down.

- A 3-way valve cannot be transformed into a 2-way valve and vice versa.

- The flow is from A to B (see diagram below) and must be installed so the paddle

closes against the direction of flow as indicated in the following diagrams.

- The 2-way valves can be ins talled on the

supply or on the return; for correct

installation it is necessary to respect the

direction of flow indicated from the arrow

on the body valve.

A

B

2-way valve with normally closed actuator

2-way installed on the supply

2-way installed on the return

Page 3

3-way installed on the supply

in diverting configuration

(NC) A

3-way installed on the return

3-way valve with normally closed actuator

(Note : 3- way uses only normally closed a ctuator)

AB

B (NO)

Operation of Normally Closed Valve

2-way 3-way

Port “A” closed

N.C. without power Port “A” closed

N.C. opened with power Port “A” opened

N.C. manually opened Port “A” opened

Port “B” opened

Port “AB” opened

Port “A” opened

Port “B” closed

Port “AB” opened

Port “A” opened

Port “B” opened

Port “AB” opened

Manual Open (NC act only) Wiring Diagram

The manual opening is

achieved by moving the

manual opening lever to

the locked position. When

power is applied, the

manual lever unlocks

automatically.

Page 4

Removing the Actuator

1 2

1. Move the manual open lever to the

lock open position.

2. Press the push button in and pull the

actuator up.

Installing the Actuator

1. Move the manual open lever to the

lock open position.

3. Verify the correct position of the valve

stem into the mating actuator hole.

Rotate stem if requi red to align.

4. Press the push button in and slide the

actuator onto the valve body, release

the push button.

SAFETY INSTRUCTION

This safety alert symbol will be used in this manual to draw attention to safety

related instructions. When used, the safety alert symbol means ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED! FAILURE TO FOLLOW

THESE INSTRUCTIONS MAY RESULT IN A SAFETY HAZARD.

CAUTION: All work must be performed by qualified personnel trained in

the proper application, installation, and maintenance of systems in

accordance with all applicable codes and ordinances.

CAUTION: Over-tightening and breakage can occur with the use of

Teflon pipe joint compounds. Teflon provides lubricity so that care must

be exercised not to over-tighten joints. Failure to follow these instructions

could result in property damage and /or personal injury.

WARNING: System fluids are under pressure or temperature can be

hazardous. Be sure the pressure has been reduced to zero and the

system temperature is below 100ºF (38ºC). Failure to follow these

instructions could result in property damage and/or personal injury.

CAUTION: Avoid locations with excessive moisture, explosive vapors,

corrosive fumes or vibration. Failure to follow these instruction s could resul t

in stress corrosion resulting in property damage and/or personal injury.

Caleffi shall not be liable for damages resulting from stress corrosion, misapplication or misuse of it products.

Caleffi North America, Inc.

3883 W. Milwaukee Road / Milwaukee, WI 53208

Tel: 414.238.2360 / Fax: 414.238.2366 / www.caleffi.com

© Copyright 2011 Caleffi North America, Inc.

3

4

Loading...

Loading...