CALEFFI SATK20 Series, SATK20403HE, SATK20103HE, SATK20203HE, SATK20305 Instructions For Installation, Commissioning And Maintenance

...Page 1

www.caleffi.com

SATK series compact wall-mounted heat interface unit

SATK20 series

INSTRUCTIONS FOR INSTALLATION, COMMISSIONING AND MAINTENANCE

Function

The SATK series heat interface unit allows independent control of heat

regulation and domestic hot water production within centralised heating

systems.

CONTENTS

78165.02 EN

Safety instructions

Dimensions

Technical specifications

Installation

Commissioning

Electronic regulator

Safety and alarms

SATK20103HE

SATK20203HE

SATK20303/SATK20403HE

SATK20305

2

3

4

4

6

7

8

10

Product range

SATK20103HE Direct wall-mounted HIU for LOW temperature

heating, instantaneous domestic hot water

production, power capacity 40 kW

SATK20203HE Direct wall-mounted HIU for MEDIUM temperature

heating, instantaneous domestic hot water

production, power capacity 40 kW

SATK20303 Direct wall-mounted HIU for HIGH temperature

heating, instantaneous domestic hot water

production, power capacity 40 kW

SATK20403HE Direct wall-mounted HIU for HIGH temperature

heating, instantaneous domestic hot water

production, power capacity 40 kW. With pump on the

primary side.

SATK20305 Direct wall-mounted HIU for HIGH temperature

heating, instantaneous domestic hot water

production, power capacity 65 kW

Maintenance

Electric connections

Troubleshooting

Commissioning checklist

1

12

13

14

16

Page 2

SAFETY INSTRUCTIONS

Primary circuit flow

Primary circuit return

Domestic hot water outlet

Domestic cold water inlet

Low temperature circuit flow

Low temperature circuit return

Medium temperature circuit flow

Medium temperature circuit return

High temperature circuit flow

High temperature circuit return

WARNINGS

1 The device must be installed, commissioned and maintained by qualified technical personnel in accordance with national regulations and/or relevant local

requirements.

2 If the device is not installed, pre-run checked and maintained correctly in accordance with the instructions provided in this manual, it may not work properly and

may endanger the user.

3 Clean the pipes of any particles, rust, incrustations, limescale, welding slag and any other contaminants. The hydraulic circuit must be clean.

4 Make sure that all connection fittings are watertight.

5 When connecting water pipes, make sure that threaded connections are not mechanically overstressed. Over time this may result in breakage, causing water

damage and/or personal injury.

6 Water temperatures higher than 50°C may cause severe burns. When installing, commissioning and maintaining the device, take the necessary precautions so

that these temperatures will not be hazardous for people.

7 In the case of particularly hard or impure water, there must be suitable provision for filtering and

current legislation. Otherwise the device may be damaged and will not work properly.

8 Any use of the device other than its intended use is prohibited.

9 Any coupling of the device with other system components must be made while taking the operational characteristics of both units into consideration.

10 An incorrect coupling could compromise the operation of the device and/or system.

IMPORTANT: Risk of electric shock. Live parts. Shut off the electric supply before opening the device box.

1 During installation and maintenance operations, always avoid direct contact with live or potentially hazardous parts.

2 The device must not be exposed to water drops or humidity, direct sunlight, the elements, heat sources or high intensity electromagnetic fields. This device cannot

be used in areas at risk of explosion or fire.

3 The device must be connected to an independent bipolar switch. If work has

automatic or time reset, or which may be reset accidentally.

4 Use suitable automatic protection devices in accordance with the electrical characteristics of the region where the device is installed and in compliance with current

legislation.

5 The device must always be earthed before it is connected to the electric supply. If the device has to be removed, always disconnect the earth connection after

disconnecting the electric supply conductors. Check that the earth connection has been made to the highest of standards under applicable legislation.

6 Electrical installation must only be carried out by a qualified technician, in accordance with legal requirements.

7 The device does not contain asbestos nor mercury.

These instructions must be read and understood before installing and maintaining the device.

IMPORTANT! FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN A SAFETY HAZARD!

treating the water before it enters the device,

to be done on the device, cut off

the electric supply first. Do not use devices with

in accordance with

Key to symbols

NOTES:

1 Install water hammer arresters to compensate for any overpressure in the domestic water circuit;

2 In the presence of hot water recirculation or if a non-return valve is fitted into the domestic cold water inlet, provision must be made to accomodate the expansion

of the water contained within the system and the heat interface unit.

3 All hydraulic connections must be checked before pressurising the system. Vibration during transport may cause the connections to become loose. DO NOT APPLY

EXCESSIVE TIGHTENING TORQUE otherwise the components may be damaged.

For the updated version of the technical documentation refer to www.caleffi.com

LEAVE THIS MANUAL AS A REFERENCE GUIDE FOR THE USER. DISPOSE OF IN ACCORDANCE WITH LOCAL REGULATIONS. THE MANUFACTURER

RESERVES THE RIGHT TO CEASE PRODUCTION AT ANY TIME AND TO MAKE ANY CHANGES DEEMED USEFUL OR NECESSARY WITHOUT THE

OBLIGATION OF PRIOR NOTICE.

2

Page 3

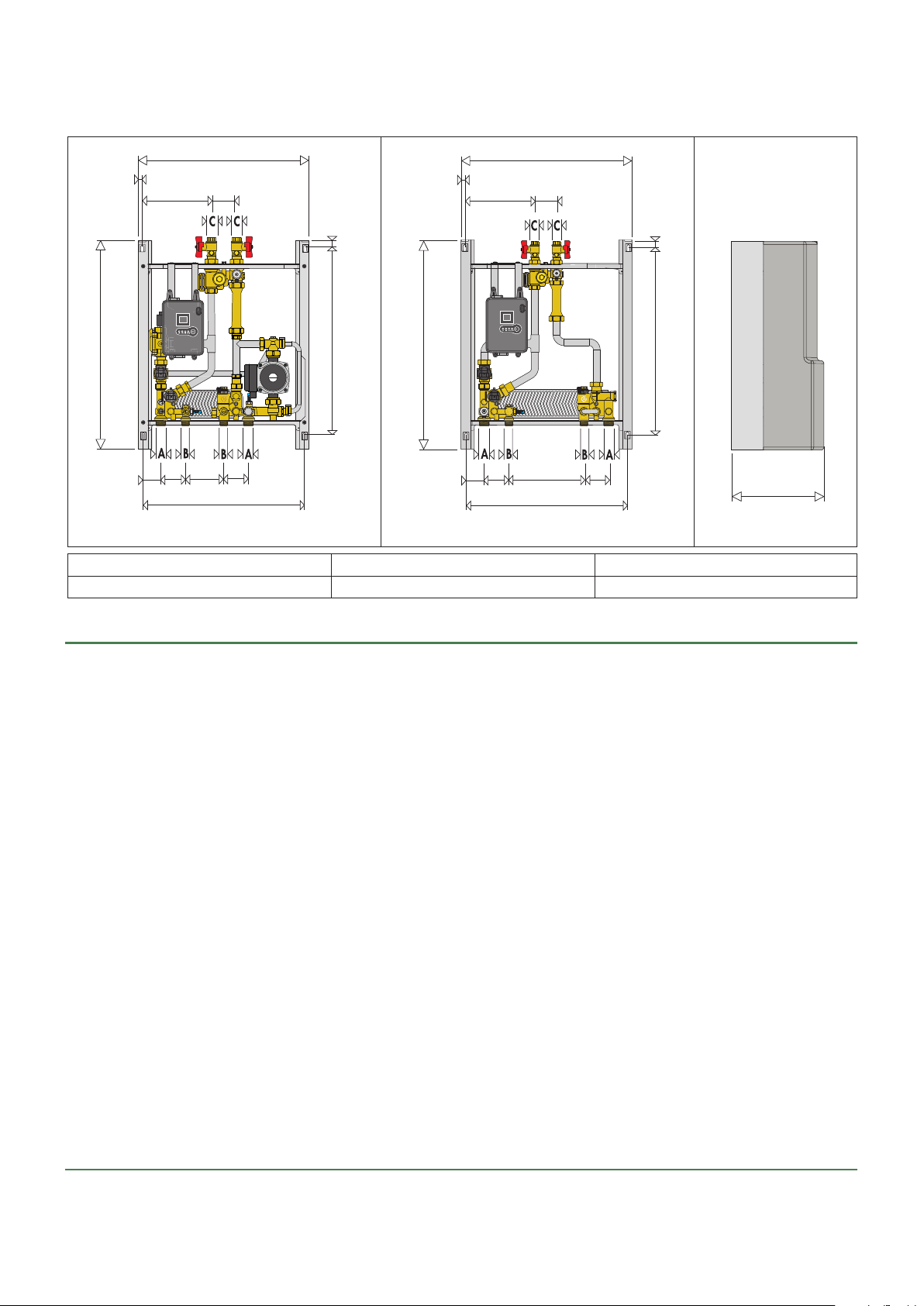

Dimensions

SATK20305

SATK20103/203/303/403

10

450

65182,5

15490

550,5

49

65 101

65

265

430

10

450

65182,5

15490

550,5

49

65 207

65

430

A B C

3/4” M 1/2” M 3/4” F

SATK20103HE - SATK20203HE SATK20303

SATK20403HE technical specifications

Medium: water

Maximum percentage of glycol: 30%

Maximum medium temperature: 85°C

Maximum working pressure: - primary circuit: 1 MPa (10 bar)

Nominal DHW exchanger capacity: 40 kW

Maximum recommended primary circuit flow rate: 1,2 m

Maximum DHW circuit flow rate: 18 l/min (0,3 l/s)

Minimum flow to activate domestic water flow meter: 2,7 l/min ±0,3

Maximum Dp on domestic water modulating valve: 90 kPa (0,9 bar)

Maximum Dp on mixing valve: 90 kPa (0,9 bar)

Electric supply: 230 V (ac) ±10% 50 Hz

Maximum power consumption: 80 W

Protection class: IP 40

Pump (not present on SATK20303): UPM3 15-70

Pump by-pass pressure setting: 45 kPa (0.45 bar)

Actuators: stepper 24 V

Probes: NTC 10 kΩ

Safety thermostat (only on SATK20103HE): 55°C ±3

Materials

Components: brass EN 12165 CW617N

Fitting pipes: steel

Frame: RAL 9010 painted steel

Protective shell cover: EPP

Heat exchanger: brazed stainless steel

- domestic circuit: 1 MPa (10 bar)

3

20 W on SATK20303

SATK20305 technical specifications

Medium: water

Maximum percentage of glycol: 30%

Maximum medium temperature: 85°C

Maximum working pressure: - primary circuit: 1 MPa (10 bar)

- domestic circuit: 1 MPa (10 bar)

Nominal DHW exchanger capacity: 65 kW

/h

Maximum recommended primary circuit flow rate: 1,2 m

3

/h

Maximum DHW circuit flow rate: 27 l/min (0,45 l/s)

Minimum flow to activate domestic water flow meter: 2,7 l/min ±0,3

Maximum Dp on domestic water modulating valve: 90 kPa (0,9 bar)

Maximum Dp on mixing valve: 90 kPa (0,9 bar)

Electric supply: 230 V (ac) ±10% 50 Hz

Maximum power consumption: 20 W

Protection class: IP 40

Actuators: stepper 24 V

Probes: NTC 10 kΩ

Materials

Components: brass EN 12165 CW617N

Fitting pipes: steel

Frame: RAL 9010 painted steel

Protective shell cover: EPP

Heat exchanger: brazed stainless steel

3

Page 4

Installation

Raumthermostat

(Potenzialfreier Kontakt)

Sonde d’ambiance

(Contact sec)

Termostato de ambiente

(Contacto sin potencial)

Ruimtesensor

(Schoon contact)

WARN IN G!

DO NOT CONNECT EXTERNAL

VOLTAGE SUPPLY TO THESE

TERMINALS

ATT EN ZI ON E!

NON ALIMENTARE IN TENSIONE

Termostato ambiente

(Contatto pulito)

Room thermostat

(Volt free connection)

Connection to the chrono-thermostat

The SATK series HIU is designed for installation in a sheltered

domestic environment (or similar), therefore cannot be installed or

used outdoors, i.e. in areas directly exposed to atmospheric

agents. Outdoor installation may cause malfunctioning and

hazards.

If the device is enclosed inside or between cabinets, sufficient

space must be provided for routine maintenance procedures. It is

advisable to avoid positioning electrical devices under the HIU to

avoid the risk of damage in the event of leaks from hydraulic

fittings. If this advice is not heeded, the manufacturer cannot be

held responsible for any resulting damage.

In the event of a malfunction, fault or incorrect operation, the device

should be deactivated; contact a qualified technician for

assistance.

Preparation

After having established the point where the device has to be

installed, perform the following operations:

· Mark the holes required for securing the HIU to the wall

· Mark the position of the hydraulic connections

Check the measurements again and begin laying the following

lines:

Hydraulic (see page 5):

1. connection to the central system line

2. heating circuit connection

3. domestic water circuit connection

Electric (see page 13):

1. 230 V (ac) – 50 Hz electric supply line

2. chrono-thermostat/thermostat line (potential-free)

3. centralised bus line for heat meter data transmission (if required)

4. centralised electric supply line for heat meter (if required)

Before installation, it is recommended to carry out accurate flushing

of all the pipes of the system in order to remove any residue or

impurities that could endanger correct operation of the HIU.

Fix the HIU to the wall.

N.B.: the wall anchors (not supplied) can only guarantee effective

support if inserted correctly (in accordance with good technical

practice) into walls built using solid or semi-solid bricks. If working

with walls built using perforated bricks or blocks, mobile dividing

panels or any masonry walls other than those indicated, a

preliminary static test must be carried out on the support system.

Electric connections

Make sure that the electrical system can withstand the maximum

power consumption of the appliance, with particular emphasis on

the cross-section of the cables.

If you have any doubts, contact a qualified technician to request a

thorough check of the electrical system.

Electrical safety of the appliance is only achieved when it is

correctly connected to an effective earthing system, made as

specified in current safety regulations. This is a compulsory safety

requirement.

The SATK series HIU is fitted for connection to a thermostat or

chrono-thermostat, both standard and OpenTherm, for ambient

temperature adjustment.

The connection to this device (potential-free contact) must be

made with the two-wire cable marked with the label shown below.

Should it be necessary to extend this cable, use one with the same

cross-section (max 1 mm

2

) and maximum length 30 m.

Commissioning

Filling the central heating system

Open the shut-off valves on the connections to the centralised line

and, in the central heating system, proceed with charging the

system to the design pressure.

Once these procedures are complete, vent the system and check

its pressure again (repeat the filling process if necessary)

System start-up

Before starting the HIU, visually check the hydraulic connection

water-tightness and the electric wiring. After finishing the check,

activate the electric supply to the HIU and check for the presence

of any error signals.

If there are any, eliminate the fault indicated and proceed as

described below, setting the set point of the domestic water and

heating cycles, programming the thermostat/chrono-thermostat

according to the desired temperatures and times, and checking the

operating cycles.

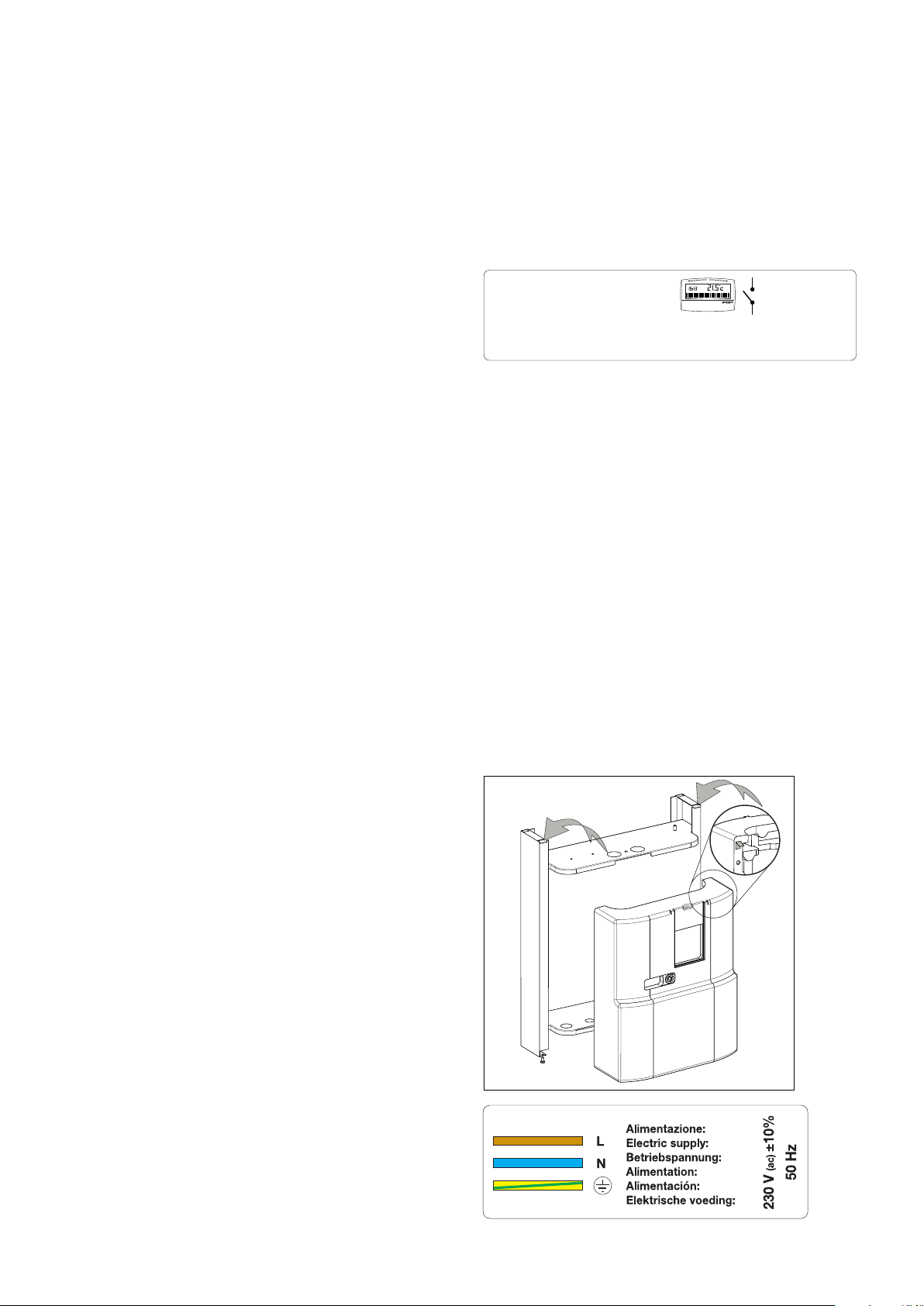

Fitting the cover

Place the casing over the frame, inserting the upper tabs (1) into

the corresponding slots (2).

Place the lower part of the casing over the frame.

Tighten the screws (3).

2

1

Connection to the main supply

The device is supplied with an electric supply cable which is not

fitted with a plug.

The device should be electrically connected to a 230 V (ac) singlephase + earth mains supply using the three-wire cable marked with

the label shown alongside, observing the LIVE (L) - NEUTRAL (N)

polarities and the earth connection. This line must be connected to

a circuit breaker device.

3

4

Page 5

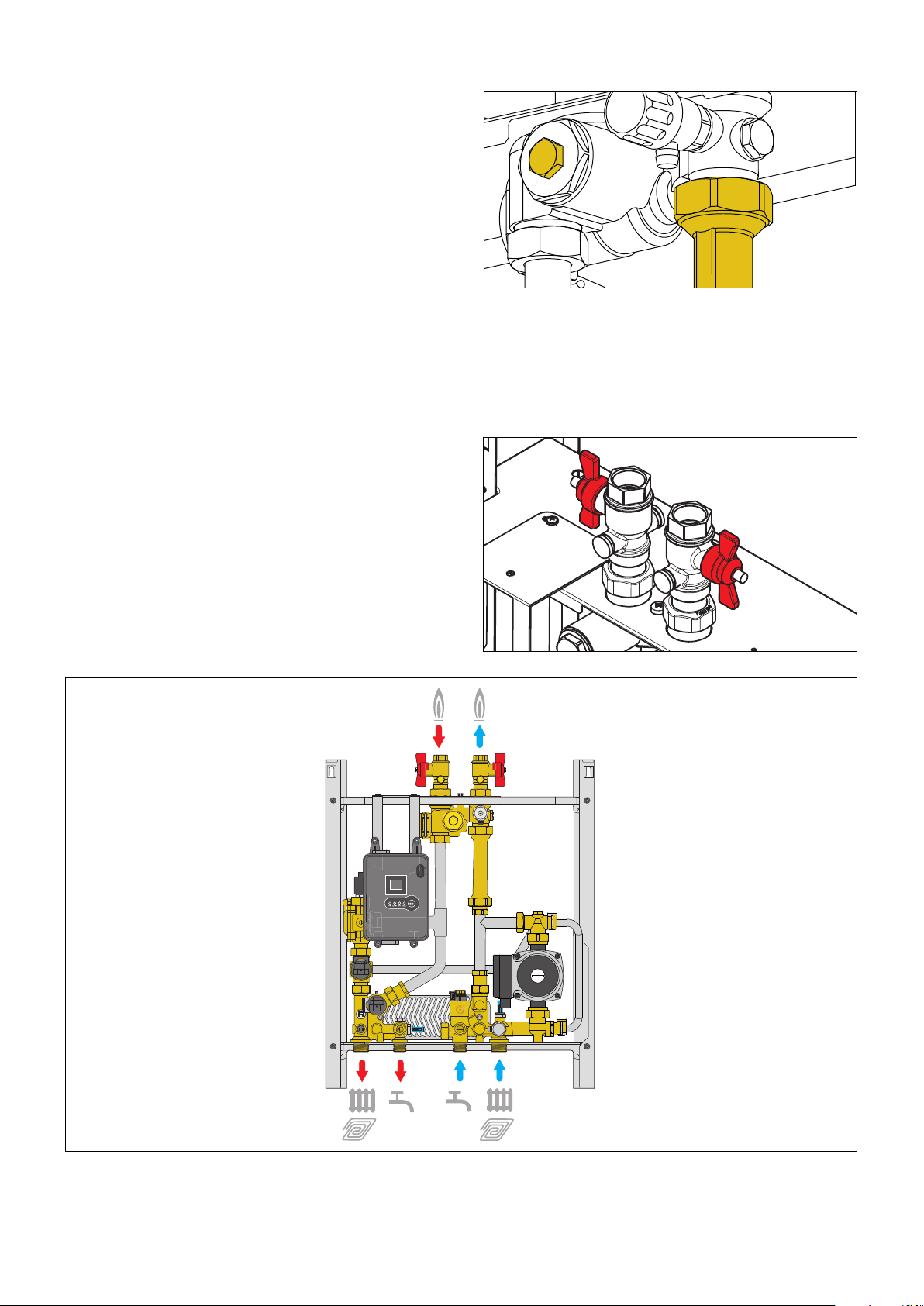

Heat meter installation

The HIU is designed to fit a compact heat meter (with incorporated

return probe) with 1” threaded connections and 130 mm gauge.

Before carrying out any maintenance, repair or part replacement

work, proceed as follows:

- cut off the electric supply

- remove the cover

- close the shut-off valves

- empty the HIU using the drain cocks provided

Proceed as described below to install the heat meter:

- remove the template (A)

- remove the cap (B)

- install the flow meter on the return pipe

- install the flow probe in the M10 pocket (B)

Please refer to the heat meter technical data sheets for further

information.

Hydraulic connections

Hydraulic connections to the centralised line must be implemented

using the manual shut-off valves supplied with the HIU, which allow

any necessary maintenance work to take place without having to

empty the centralised system.

It is advisable to install manual shut-off valves (not supplied) also

on the bottom connections to the apartment circuits.

Before installation, it is recommended to carry out accurate flushing

of all the pipes of the system in order to remove any residue or

impurities that could endanger correct operation of the HIU.

In order to facilitate these operations a manual bypass flushing

valve is available (code 789100).

B

A

N.B. Install the valves as shown in the figure

N.B.:

1 Install water hammer arresters to compensate for any overpressure in the domestic water circuit;

2 In the presence of hot water recirculation or if a non-return valve is fitted into the domestic cold water inlet, provision must be made to accomodate the expansion

of the water contained within the system and the heat interface unit;

3 All hydraulic connections must be checked before pressurising the system. Vibration during transport may cause the connections to become loose. DO NOT APPLY

EXCESSIVE TIGHTENING TORQUE otherwise the components may be damaged.

5

Page 6

60

60

48

48

Electronic regulator

123456

Operating principle

All heating and domestic hot water functions offered by

SATK20 series HIUs are controlled by a digital controller.

The controller is factory set with different parameters and settings

depending on the model (Table 1).

There are a number of specific DIP SWITCHES on the controller

circuit board; the way these are configured will determine the

settings of the various models and the optional functions enabled.

• Trimmers for set point settings

These allow setting of the temperature set point for the heating and

domestic water cycle (on low and medium temperature models)

and view the associated set value on the display.

Heating cycle

Domestic cycle

• LCD display

Allows viewing of heating and domestic hot water set point

temperatures and the error codes.

Stand-by:

The following alternate every 5 seconds on the display:

Heating temperature set point

(the return temperature is displayed if

temperature regulation with compensated set

point regulation is active, see page 9)

Domestic hot water temperature set point

User interface

The user interface, built into the PCB, consists of the following

devices:

• LED indicator

The various functions and faults are signalled by either flashing or

steady illumination of the LEDs.

ON - Electric supply 230 V (ac)

DHW - Domestic cycle

CH - Heating cycle

FAULT - Fault detected

• RESET key

This allows restoration of normal function after the

safety thermostat has been triggered and

activation/deactivation of the floor slab heating

function.

Table 1 – factory default settings

CODE

SATK20103HE

LOW temperature

6 5 4 3 2 1

see page

13

SWITCH SETTING SET POINT

Heating cycle ON:

The set point temperature is shown while the

symbol flashes:

(the return temperature is displayed if

temperature regulation with compensated set

point regulation is active, see page 9)

Domestic cycle ON:

The set point temperature is shown while the

symbol flashes:

HEATING DHW

25 – 45°C 42 – 60°C

SATK20203HE

MEDIUM temperature

SATK20303 / 20403HE / 20305

HIGH temperature

OFF

ON

OFF

ON

Factory set (do not change)

May be changed to activate optional functions

Switch 1: modulating temperature regulation with compensated set point

Switch 5: domestic hot water pre-heating function

45 – 75°C 42 – 60°C

- 42 – 60°C

6

Page 7

Safety and alarms

69

76

5

6

79

80

Error codes associated with faults signalled by illumination of the

FAULT LED are also shown on the display.

Probe fault

If a temperature probe fails, the associated cycle will be stopped

immediately and disabled.

Any requests to run cycles not associated to the previous one will

continue to run normally.

Heating probe fault

Error code: 5

Domestic hot water probe fault

Error code: 6

Thermal safety valve fault

SATK20103HE - LOW temperature

Error code 76

Removing a fault

Normal operating conditions are restored automatically once the

faulty safety valve is working properly again.

Incorrect switch setting

Error code 79

Removing a fault

Restore correct switch setting according to table 1

(page 6).

Compensation probe fault

SATK20103HE - SATK20203HE

Error code: 15

Removing a fault

Normal operating conditions are restored automatically once the

faulty probe is working properly again (see page 12).

Safety thermostat cut-out

SATK20103HE - LOW temperature

Error code 69

The HIUs configured to support low temperature heating

continuously monitor the safety thermostat controlling the flow

temperature.

If the safety thermostat is activated during a general cycle, the

heating circulation pump immediately comes to a stop and the

modulating/mixing valve is completely closed. The thermal safety

lock valve (SATK20103HE) is closed.

In the event of a power failure, the thermal safety valve prevents hot

water from entering the heating system.

After the user has reset the block imposed by the safety thermostat,

the shut-off valve can only be re-enabled when the

mixing/modulating valves are completely closed again.

This means that if a domestic water cycle is in progress, the

activation of the shut-off valve will be postponed until the end of that

domestic water cycle.

Removing a fault

To restore the operating mode press the manual

RESET button.

Incorrect dip-switch configuration (heat interface unit disabled)

Error code 80

Removing a fault

The heat interface unit is disabled due to incorrect setting of the

dip-switches. Restore correct setting according to table 1

(page 6).

Automatic controller functions

Reset mixing/modulating valve to zero

Immediately after the power supply has been switched on, the

position of the installed mixing/modulating valves is reset to zero.

Pump anti-clog

When the pump is not in use, it is powered on for a period of

5 seconds every 24 hours.

Mixing valve/modulating valve anti-clog

The anti-clogging cycle for the mixing/modulating valve is run every

24 hours.

7

Page 8

2

1

3

4

7

5

6

9

14

10

12

11

13

15

17

8

10

16

18

1

23

4564

ON

SATK20103HE LOW temperature heat interface unit with high efficiency pump

2

1

3

4

5

7

12

8

9

11

13

15

6

14

16

10

1

23

4564

ON

Characteristic components

1. Frame

2. Electronic regulator

3. Thermal safety relief valve

4. Heating mixing valve

5. DHW production modulating valve

6. Heating flow temperature probe

7. Thermal safety thermostat

8. DHW temperature probe

9. DHW heat exchanger

10. Drain cock

11. Flow temp. compensation return probe

12. Pump UPM3 15-70

13. DHW priority flow meter

14. Protective pump by-pass

15. Heat meter spacer template

16. Air vent cock

17. System strainer/heat meter flow probe pocket

18. Primary circuit shut-off valves

Functional characteristics

Heating range 25–45°C

Set point regulation

DHW production range 42–60°C

Optional functions

Domestic cycle: - DHW pre-heating function

Heating cycle: - modulating temperature regulation

with compensated set point

- floor slab heating function

Factory settings

*

* see page 13

SATK20203HE MEDIUM temperature heat interface unit with high efficiency pump

Characteristic components

1. Frame

2. Electronic regulator

3. Heating mixing valve

4. DHW production modulating valve

5. Heating flow temperature probe

6. DHW temperature probe

7. DHW heat exchanger

8. Drain cock

9. Flow temp. compensation return probe

10. Pump UPM3 15-70

11. Protective pump by-pass

12. DHW priority flow meter

13. Heat meter spacer template

14. Air vent cock

15. System strainer/heat meter flow probe pocket

16. Primary circuit shut-off valves

Functional characteristics

Heating range 45–75°C

Set point regulation

DHW production range 42–60°C

Optional functions

Domestic cycle: - DHW pre-heating function

Heating cycle: - modulating temperature regulation

with compensated set point

Factory settings

8

Page 9

5

ON

1

OFF

Operating cycles

48

60

25

48

60

Domestic water cycle

This cycle always takes priority over the heating cycle

When DHW cycle activation is requested due to DHW tapping by

the user detected by the domestic water flow meter, the regulator

controls the opening of the modulating valve in order to adjust the

temperature detected by the domestic water probe to the selected

set point value.

When tapping ends, the modulating valve is fully closed.

The active domestic hot water cycle is signalled by yellow DHW

LED steady on.

The domestic hot water cycle temperature set point can be set

using trimmer P1 and shown on the display.

Heating cycle

Set point regulation

When heating cycle activation is requested by the room thermostat,

the circulation pump is powered while the mixing valve is activated

gradually until the set point temperature is reached.

At the end of the heating cycle, the circulation pump comes to a

stop and the valve is closed.

The active heating cycle is signalled by yellow CH LED steady on.

The heating cycle temperature set point can be set using trimmer P2

and shown on the display.

Floor slab heating function - SATK20103HE

Facilitates the installation of underfloor heating systems at low

temperatures. This function can only be activated and executed if

there are no faults.

It can be activated by pressing and holding the RESET button for 8

seconds.

The yellow CH LED blinks while the floor slab heating function is in

operation.

The function lasts 240 hours and is carried out by simulating a

request to run in heating mode starting from a set point of 25°C and

rising in regular intervals to a temperature of 45°C. Once the

maximum set point has been reached, the function is executed,

following the same procedures, in reverse (from the maximum set

point to the minimum set point).

This function has priority over heating and hot water cycles, and

can be suspended at any time by pressing and holding the RESET

button for 8 seconds.

8 seconds

Optional functions (to activate/deactivate the optional functions

the electric power supply must always be turned off!)

Domestic cycle

DHW pre-heating function

The function is enabled by setting dip switch 5 to the ON position.

During periods when the domestic water cycle is not used, if the

DHW probe detects a temperature 10°C below the SET value, the

controller partially opens the domestic hot water modulating valve for

the time required (max. 5 min.) to bring the exchanger to the

condition wherein it can assure rapid DHW production.

The domestic hot water pre-heating function is signalled by the

flashing yellow DHW LED.

This function is less of a priority than any domestic water or heating

cycles.

Heating cycle

Modulating temperature regulation with compensated set point

SATK20103HE - SATK20203HE

The function is enabled by setting dip switch 1 to the OFF position.

When the function is enabled, the flow temperature is modified

according to the temperature detected by the compensation probe

(located on the user return pipe). This allows constant monitoring of

the effective thermal output of the floor slab with the consequent

minimisation of system response times.

If the function is enabled the display shows the return temperature,

and the flow temperature is adjusted in accordance with the

following formula:

D

Flow temperature = Return temperature +

In MEDIUM/HIGH temperature configuration: DT 8–22°C

In LOW temperature configuration: DT 2–8°C

T

9

Page 10

1

2

3

4

5

13

12

11

10

9

7

6

8

1

23

4564

ON

1

2

3

4

5

12

11

10

9

8

7

6

1

23

4564

ON

SATK20303 HIGH temperature heat interface unit

SATK20403HE HIGH temperature heat interface unit with high efficiency pump on the primary side

Characteristic components

1. Frame

2. Electronic regulator

3. Heating ON/OFF valve

4. DHW production modulating valve

5. Drain cock

6. DHW temperature probe

7. DHW heat exchanger

8. DHW priority flow meter

9. Pump (SATK20403HE only) UPM3 15-70 with protective

by-pass

10. Heat meter spacer template

11. System strainer/heat meter flow probe pocket

12. Air vent cock

13. Primary circuit shut-off valves

Functional characteristics

Maximum heating temp. 85°C

ON/OFF regulation

DHW production range 42–60°C

Optional functions

Domestic cycle: - DHW pre-heating function

Factory settings

SATK20305 High capacity HIGH temperature heat interface unit

Characteristic components

1. Frame

2. Electronic regulator

3. Heating ON/OFF valve

4. DHW production modulating valve

5. Drain cock

6. DHW temperature probe

7. DHW heat exchanger

8. DHW priority flow meter

9. Heat meter spacer template

10. Air vent cock

11. System strainer/heat meter flow probe pocket

12. Primary circuit shut-off valves

Functional characteristics

Maximum heating temp. 85°C

ON/OFF regulation

DHW production range 42–60°C

Optional functions

Domestic cycle: - DHW pre-heating function

Factory settings

10

Page 11

Operating cycles

48

––

48

5

ON

Domestic water cycle

This cycle always takes priority over the heating cycle.

When DHW cycle activation is requested due to DHW tapping by

the user detected by the domestic water flow meter, the regulator

controls the opening of the modulating valve in order to adjust the

temperature detected by the domestic water probe to the selected

set point value.

When tapping ends, the modulating valve is fully closed.

The active domestic hot water cycle is signalled by yellow DHW

LED steady on.

The general domestic water cycle temperature set point can be set

using trimmer P1 and shown on the display.

Heating cycle

ON-OFF regulation

When the room thermostat requests the start of a heating cycle, the

valve is opened completely, allowing water to circulate at the

temperature supplied by the central heating system (ON/OFF

regulation).

The valve is closed on completion of the heating cycle.

The active heating cycle is signalled by lighting of the yellow CH LED.

No value is shown on the display.

Optional functions (to activate/deactivate the optional functions

the electric power supply must always be turned off!)

Domestic cycle

DHW pre-heating function

The function is enabled by setting dip switch 5 to the ON position.

During periods when the domestic water cycle is not used, if the

DHW probe detects a temperature 10°C below the SET value, the

controller partially opens the domestic hot water modulating valve for

the time required (max. 5 minutes) to bring the exchanger to the

condition wherein it can assure rapid DHW production.

The domestic hot water pre-heating function is signalled by the

flashing yellow DHW LED.

This function is less of a priority than any domestic water or heating

cycles.

11

Page 12

Maintenance

All maintenance procedures should be carried out by an authorised

technician.

Regular maintenance guarantees better efficiency and helps to

save energy.

Before carrying out any maintenance, repair or part replacement

work, proceed as follows:

- Cut off the electric supply

- Remove the cover

- Close the shut-off valves

- Empty the heat interface unit using the drain cocks provided.

Replacing the valve actuator

- Disconnect the actuator cable, lightly pressing the tab on the

connector and extracting it (see page 13, ref. 4-8)

- Extract the fixing clip (D) and then the actuator

- Position the new actuator (E)

- Insert the fixing clip, respecting the correct direction

- Reconnect the connector.

D

Heat exchanger replacement

- Remove the heat exchanger, loosening the 2 hex socket head

screws fixing it in place (A)

- Replace the heat exchanger and the O-Rings.

- Tighten the two fixing screws (A).

N.B. The pins fixing the heat exchanger are positioned in such a way

as to allow it to be placed only in the correct direction.

A

Strainer cleaning

All heat interface units have a strainer on the inlet for water from the

centralised system.

To clean these strainers, carry out the following maintenance

procedure:

- Unscrew the cap (B)

- Remove the strainer mesh and discard any impurities

- Put the strainer mesh back in

- Screw the cap back on.

A

E

Replacing the valve obturator

- Disconnect the valve actuator (see previous paragraph)

- Extract the obturator, unscrewing the locking nut (F)

- Replace the obturator, screw on the locking nut (F) and then

insert the actuator

- Insert the fixing clip, respecting the correct direction

- Reconnect the connector.

F

Replacing the DHW priority flow meter

- Disconnect the flow meter cable acting on the connector (see

page 13, ref. 2)

- Extract the flow sensor (G)

- Position the new sensor

- Reconnect the connector respecting the only possible way it can

be inserted.

B

Temperature probe replacement

- Disconnect the probe cable, lightly folding the tab (C) and

extracting the connector (see page 13, ref. 1-3-7)

- Unscrew the probe

- Fit the new probe

- Reconnect the connector respecting the only possible way it can

be inserted.

C

G

Replacing or cleaning the priority flow meter turbine and strainer

- Extract the flow sensor (G)

- Unscrew and remove the cartridge (H)

- Eliminate any impurities on the strainer mesh and, if necessary,

change the cartridge

- Screw the cartridge back into place

- Refit the flow sensor.

H

When carrying out maintenance on the electrical part, for the

connections follow the diagram on page 13.

After concluding maintenance, proceed with the filling and

checking operations described in the chapter “Commissioning”

and fit the cover. If you require any information regarding spare

parts, please contact Caleffi spa.

12

Page 13

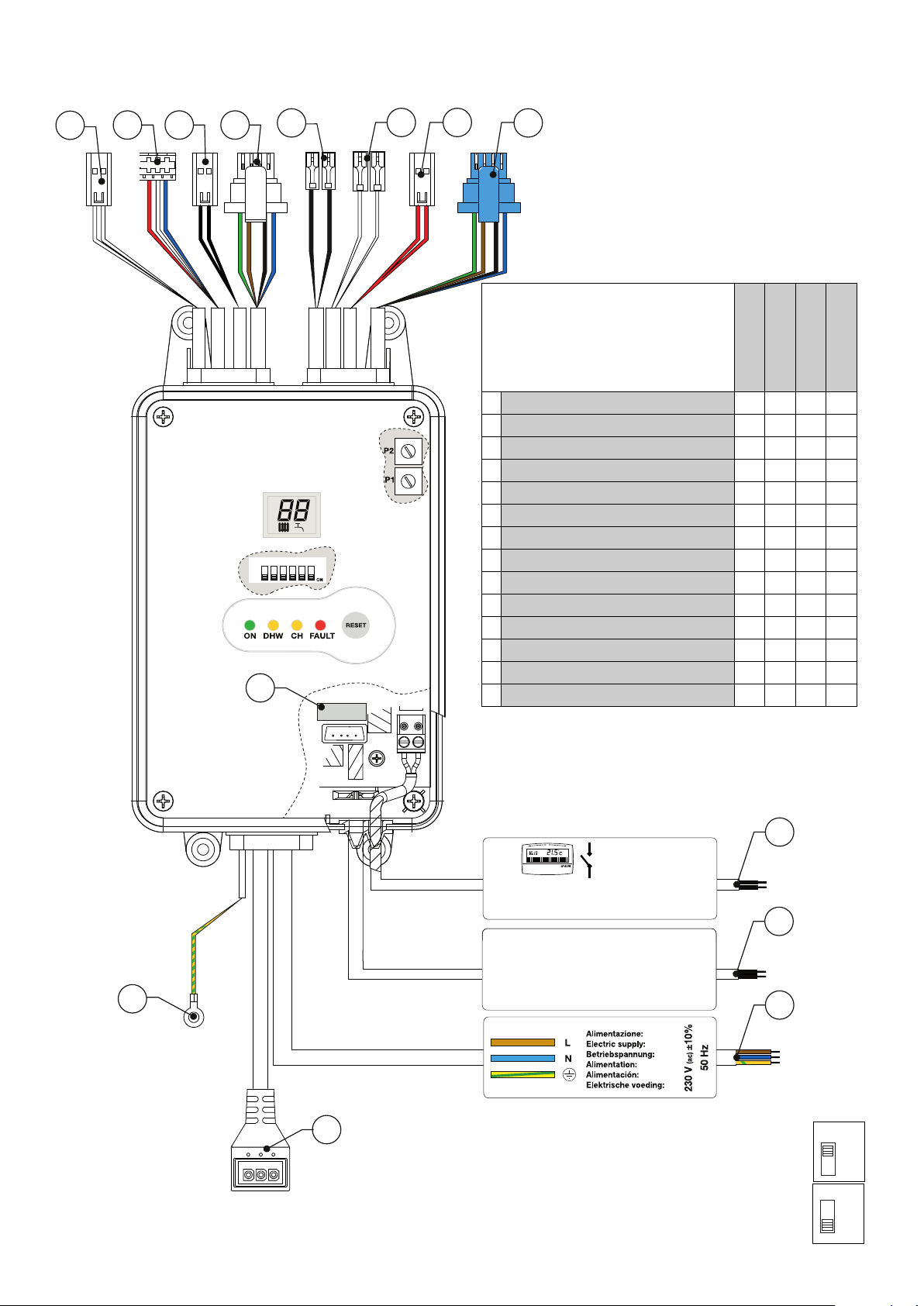

Electric connections

FUSE 5x20

1

2 3

4

6

5

9

10

13

11

12

6 35

4 21

14

s5SARESOLOPERCOLLEGAMENTOACOD

s5SETHISWIREFORCONNECTIONTOCODEONLY

s°NgUTILISERQUEPOURLALIAISONAVECCODE

s6ERWENDEN3IEDIESES'ERËTNURZUM!NSCHLUSS

ANDIE!RT.R

s'EBRUIKDEZEENKELVOORAANSLUITINGOPCODE

s5TILICESOLAMENTEPARALACONEXIØNCONCØD

s5SARESOLOPERCOLLEGAMENTOACOD

s5SETHISWIREFORCONNECTIONTOCODEONLY

s°NgUTILISERQUEPOURLALIAISONAVECCODE

s6ERWENDEN3IEDIESES'ERËTNURZUM!NSCHLUSS

ANDIE!RT.R

s'EBRUIKDEZEENKELVOORAANSLUITINGOPCODE

s5TILICESOLAMENTEPARALACONEXIØNCONCØD

7

8

Raumthermostat

(Potenzialfreier Kontakt)

Sonde d’ambiance

(Contact sec)

Termostato de ambiente

(Contacto sin potencial)

Ruimtesensor

(Schoon contact)

Termostato ambiente

(Contatto pulito)

Room thermostat

(Volt free connection)

6

ON

6

ON

1

2

3

4

5

6

7

8

9

10

11

12

13

14

DHW temperature probe

DHW priority flow meter

Flow temp. compensation return probe

DHW production valve actuator

Thermal safety thermostat

Thermal safety valve

Heating flow temperature probe

Heating valve actuator

Earth

Pump

Electric supply 230V (ac)**

Room thermostat**

Fuse

HIU enabling

SATK20303

SATK20305

SATK20203HE

SATK20103HE

SATK20403HE

xxxx

xxxx

xx

xxxx

x

x

xx

xxxx

xxxx

xx x

xxxx

xxxx

xxxx

*xxx

N.B.:

The pump cable connector is polarised. Insert the connector correctly and

do not attempt to force it in the wrong position.

* This connection may not be available

** To be wired during installation

(Room thermostat not supplied)

Dip-switch 6 configuration

If the regulator is equipped with the “HIU enabling” cable

(refer to line 14 in the above table), dip-switch 6 must be

set to OFF

Vice versa, if this connection is absent, the dip-switch

must be set to ON.

MAX 30 m

(potential-free

line)

13

Page 14

Troubleshooting

FAULT DESCRIPTION INDICATIONS POSSIBLE CAUSE OF FAULT OPERATIONS TO BE PERFORMED

primary circuit shut-off valves closed open the valves

modulating valve actuator connector disconnected reconnect actuator connector

modulating valve actuator disconnected from valve body reconnect actuator

call qualified personnel to have it

replaced

restore correct connection

call qualified personnel to have it

replaced

call qualified personnel to have it

replaced

call qualified personnel to have it

replaced

call qualified personnel to have it

replaced

call qualified personnel to have it

replaced

call qualified personnel to have it

serviced

call qualified personnel to have it

serviced

call qualified personnel to have it

replaced

call qualified personnel to have it

replaced

restore correct connection

call qualified personnel to have it

replaced

restore correct connection

call qualified personnel to have it

replaced

call qualified personnel to have it

replaced

call qualified personnel to have it

replaced

call qualified personnel to have it

serviced

open the valves

call qualified personnel to have it

serviced

call qualified personnel to have it

serviced

call qualified personnel to have it

serviced

call qualified personnel to have it

serviced

Water is not

heated

The water is hot

but does not

reach the

desired

temperature

Hot water

temperature is

too high

Hot water flow

rate is

insufficient

Hot water flow

rate is zero

DHW LED on

FAULT LED on + error

code 6 active

FAULT LED on + error

code 79 active

F

AULT LED on + error

code 80 active

DHW led off

all LEDs are off

DHW LED on

DHW LED on

DHW LED on

DHW LED off

modulating valve actuator faulty

DHW temperature probe cable inverted with heating

probe

presence of air in the system vent the system

electronic controller not working

valve obturator blocked in closed position

centralised system not working/cold contact person in charge of system

DHW temperature probe disconnected reconnect probe

DHW temperature probe faulty

incorrect switch setting restore correct switch setting

incorrect switch setting restore correct switch setting

DHW priority flow meter disconnected reconnect flow meter

DHW priority flow meter faulty

No electric power supply restore HIU electric supply

protection fuse burnt out

domestic water cycle temperature set point too low increase set point

Primary circuit strainer of the HIU clogged

heat exchanger partly clogged

modulating valve actuator faulty

valve obturator blocked in intermediate position

DHW temperature probe cable inverted with heating

probe

excessive demand for DHW decrease demand

electronic controller not working

centralised system temperature insufficient contact person in charge of system

primary circuit flow rate insufficient contact person in charge of system

domestic water cycle temperature set point too high decrease set point

DHW temperature probe cable inverted with heating

probe

modulating valve actuator faulty

valve obturator blocked in intermediate or open position

electronic controller not working

primary circuit excessive pressure contact person in charge of system

flow meter strainer clogged

possible domestic water system shut-off valves

partially closed

centralised domestic circuit cold water flow rate

insufficient

possible domestic water system shut-off valves closed open the valves

no cold water in centralised domestic circuit

flow meter strainer completely clogged

heat exchanger completely blocked

14

Page 15

FAULT DESCRIPTION INDICATIONS POSSIBLE CAUSE OF FAULT OPERATIONS TO BE PERFORMED

heating cycle temperature set point too low increase set point

check programming of chrono-

thermostat

call qualified personnel to have it

serviced

call qualified personnel to have it

replaced

call qualified personnel to have it

replaced

restore correct connection

call qualified personnel to have it

replaced

call qualified personnel to have it

replaced

check programming of chrono-

thermostat

call qualified personnel to have it

replaced

call qualified personnel to have it

replaced

The room

is not reaching

the desired

temperature

CH LED on

CH LED off

all LEDs are off

FAULT LED on + error

code 5 active

chrono-thermostat temperature setting incorrect

HIU strainer clogged

heating valve actuator faulty

heating valve obturator blocked

modulating valve actuator connector disconnected reconnect actuator connector

DHW temperature probe cable inverted with heating

probe

presence of air in the system vent the system

pump (if present) not working

pump cable (if present) not connected restore connection

possible system shut-off valves/terminals closed open the valves

centralised system temperature insufficient contact person in charge of system

electronic controller not working

primary circuit flow rate insufficient contact person in charge of system

centralised system not working contact person in charge of system

chrono-thermostat time setting incorrect

chrono-thermostat not working check chrono-thermostat

Electric supply cut off restore HIU electric supply

Protection fuse burnt out

heating temperature probe faulty

Start-up of the

heat interface

unit heating

function triggers

the safety circuit

breaker

FAULT LED on + error

code 15 active

FAULT LED on + error

code 69 active

FAULT LED on + error

code 76 active

FAULT LED on + error

code 79 active

F

AULT LED on +

error code 80 active

All LEDs are off pump connector inserted the wrong way round

compensation temperature probe faulty

safety thermostat cut-out

safety relief valve faulty

incorrect switch setting restore correct switch setting

incorrect switch setting restore correct switch setting

call qualified personnel to have it

replaced

call qualified personnel to have it

serviced

call qualified personnel to have it

serviced

check that the pump cable connector is

inserted the right way round

15

Page 16

Commissioning checklist

Model Checks to be performed

1 all Is the heat interface unit properly secured to the wall?

2 all Has the system flushing been carried out?

3 all Check strainers and clean them if necessary

4 all Is the heat meter (if present) connected?

5 all Is the heat meter (if present) connected to the building datalogger (if required)?

6 all Is the DCW line fitted with a pressure reducing valve?

7 all Is the system protected by water hammer arresters?

8 all

SATK20103HE

9

SATK20203HE

Has the domestic exchanger pre-heating function (normally off) been activated (if

required)?

Has the modulating temperature regulation with compensated set point (normally off)

been activated (if required)?

10 all Is the heat interface unit connected to the 230 V (ac) electric supply?

11 all Is the room thermostat (potential-free contact) connected?

Has the visual inspection of electrical connections inside the heat interface unit given

12 all

a positive result?

Are the connections compliant with specifications and made in accordance with best

practices?

13 all Are the shut-off valves open?

14 all Has the visual inspection of the hydraulic connections given a positive result?

15 all Has the system been filled and vented?

16 all Is the heat interface unit powered (green “ON” LED lit)?

17 all No alarm code (“fault” LED lit) on heat interface unit regulator?

18 all

SATK20103HE

19

SATK20203HE

Has the DHW temperature been set to the required value?

(42–50°C recommended)

Has the heating flow temperature been set to a correct value?

20 all Is the primary circuit at working temperature?

21 all Check that “CH” LED lights approx. 10 seconds after the thermostat trips

SATK20103HE

22

SATK20203HE

SATK20403HE

23 all

24 all

Check that the pump operates correctly on tripping of the thermostat

(check that secondary flow pipes start to heat up)

Simulate minimal DHW tapping (approx 3 l/min) and check that “DHW” LED lights

and that water is supplied at the required temperature

Simulate abundant DHW tapping and check, by means of the installed heat meter,

that the primary circuit flow rate is sufficiently high

Loading...

Loading...