Page 1

CALEFFI

www.caleffi.com

QuickSetter™ Balancing Valve with flow meter

18106.02

© Co pyrig ht 2011 C aleff i

132 Series

Function

The balancing valve accurately controls the flow rate of heating and

cooling transfer fluid supplied to fan coils and terminal units; or where

flow balancing is required in solar thermal systems. Proper hydronic

system balancing ensures the system operates according to design

specifications, providing satisfactory thermal comfort with low energy

consumption.

The flow meter is housed in a bypass circuit on the valve body and

can be shut off during normal operation. The flow meter permits

fast and easy circuit balancing without added differential pressure

gages and charts. The balancing valve comes standard with a hot

pre-formed insulation shell to optimize thermal performance for both

hot and chilled water.

Product range

132 Series Balancing valve with flow meter sizes 1/2”, 3/4”,

Technical characteristics

Valve

Material: Body and ball: brass

Ball control stem: chrome plated brass

Ball seal seat: PTFE

Control stem guide: PSU

Seals: EPDM

Flow meter

Material: Body: brass

Headwork: brass EN 12164 CW614N

Valve stem: chrome plated brass

Springs: stainless steel

Seals: EPDM

Flow meter float and indicator cover: PSU

Performance: Medium: water, glycol solutions

Flow rate correction factor: 20%-30% glycol solutions: 0.9

Insulation

Material: closed cell expanded PE-X

Thickness: 10 mm

Density: - inner part: 30 kg/m

- outer part: 50 kg/m

Thermal conductivity (DIN 52612): - at 0°C: 0.038 W/(m·K)

Coefficient of resistance to water vapor (DIN 52615): > 1.300

Working temperature range: 32 - 212°F (0–100°C)

Reaction to fire (DIN 4102): class B2

Patent application No. MI

1”, 1 1/4”, 1 1/2” and 2"

Max. percentage of glycol: 50%

Max. working pressure: 150 psi (10 bar)

Working temperature range: 14 - 230°F (-10–110°C)

Flow rate range unit of measurement: gpm

Accuracy: ±10%

Control stem angle of rotation: 90°

Required operating wrench: 1/2”–1 1/4”: 9 mm

Threaded connections: 1/2”– 2” FNPT

40%-50% glycol solutions: 0.8

- at 40°C: 0.045 W/(m·K)

2007A000703.

1 1/2” and 2”: 12 mm

3

3

Page 2

SAFETY INSTRUCTION

7

6

5

4

3

2

7

6

5

4

3

2

765

432

765

432

This safety alert symbol will be used in this manual to draw attention to safety related

instructions. When used, the safety alert symbol means ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN A SAFETY HAZARD.

CAUTION: All work must be performed by qualified personnel trained in the

proper application, installation, and maintenance of systems in accordance

with all applicable codes and ordinances.

CAUTION: Over-tightening and breakage can occur with the use of Teflon

®

pipe joint compounds. Teflon®provides lubricity so that care must be

exercised not to over-tighten joints. Failure to follow these instructions

could result in property damage and /or personal injury.

WARNING: System fluids are under pressure or temperature can be

hazardous. Be sure the pressure has been reduced to zero and the

system temperature is below 100°F (38°C). Failure to follow these

instructions could result in property damage and/or personal injury.

Caleffi shall not be liable for damages resulting from stress corrosion, misapplication or misuse of it products.

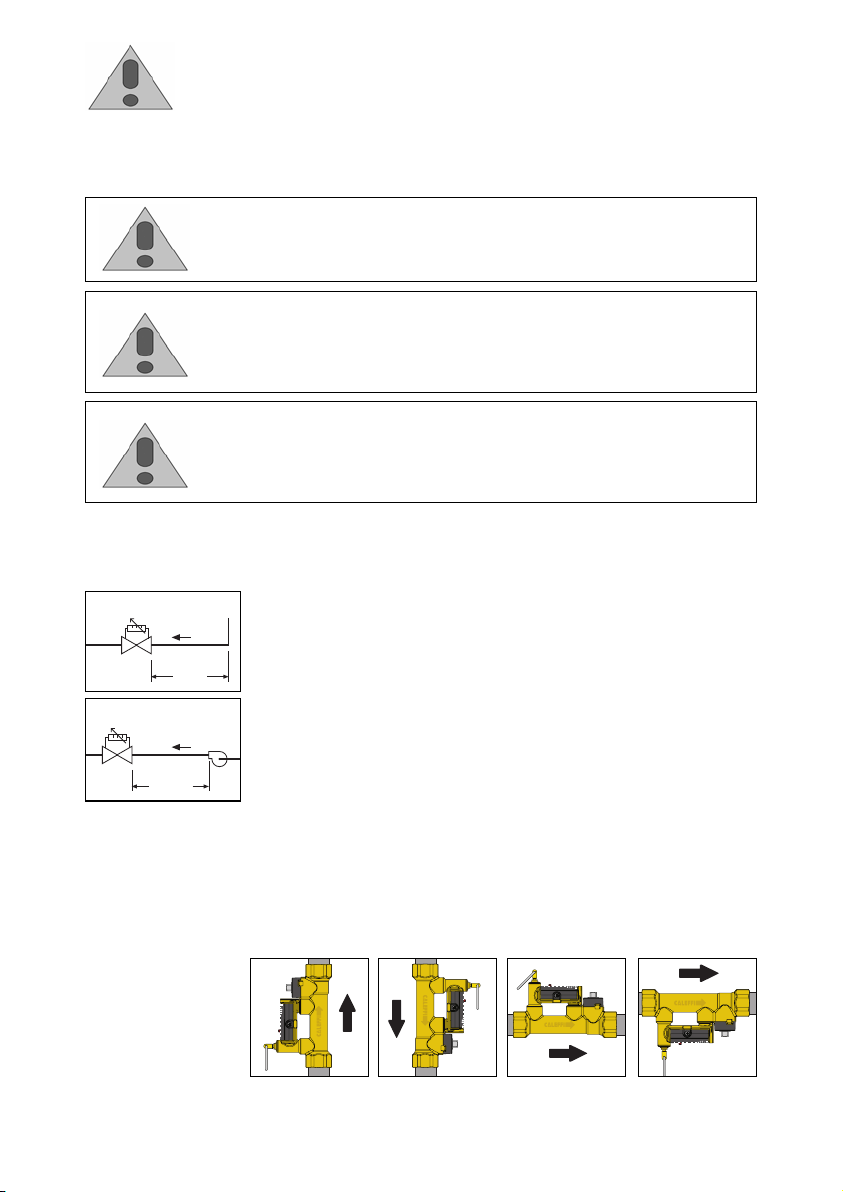

Installation

132 series

The balancing valves, with built-in flow meter, must be installed by

qualified technical personnel in accordance with the instructions given

in this manual and with current regulations.

Clean the pipes of any debris, rust, welding slag and any other

contaminants.

5D

132 series

As in all hydraulic circuits it is important to pay attention to the

cleanliness of the entire system.

Pump

For optimal operation, any air in the medium must be removed.

In order to ensure measuring accuracy, the balancing valves with flow

meter must be installed by keeping a straight section above them at

10D

least as long as five diameters, increased to at least ten diameters if

the nearest device upstream is a pump.

The valves must be installed so that:

- the direction of the flow agrees with that of the arrow on the

valve body.

- there is easy access to the flow meter valve, control stem and dial

with the calibration adjustment range.

The valves can be fitted on either vertical or horizontal pipes.

Page 3

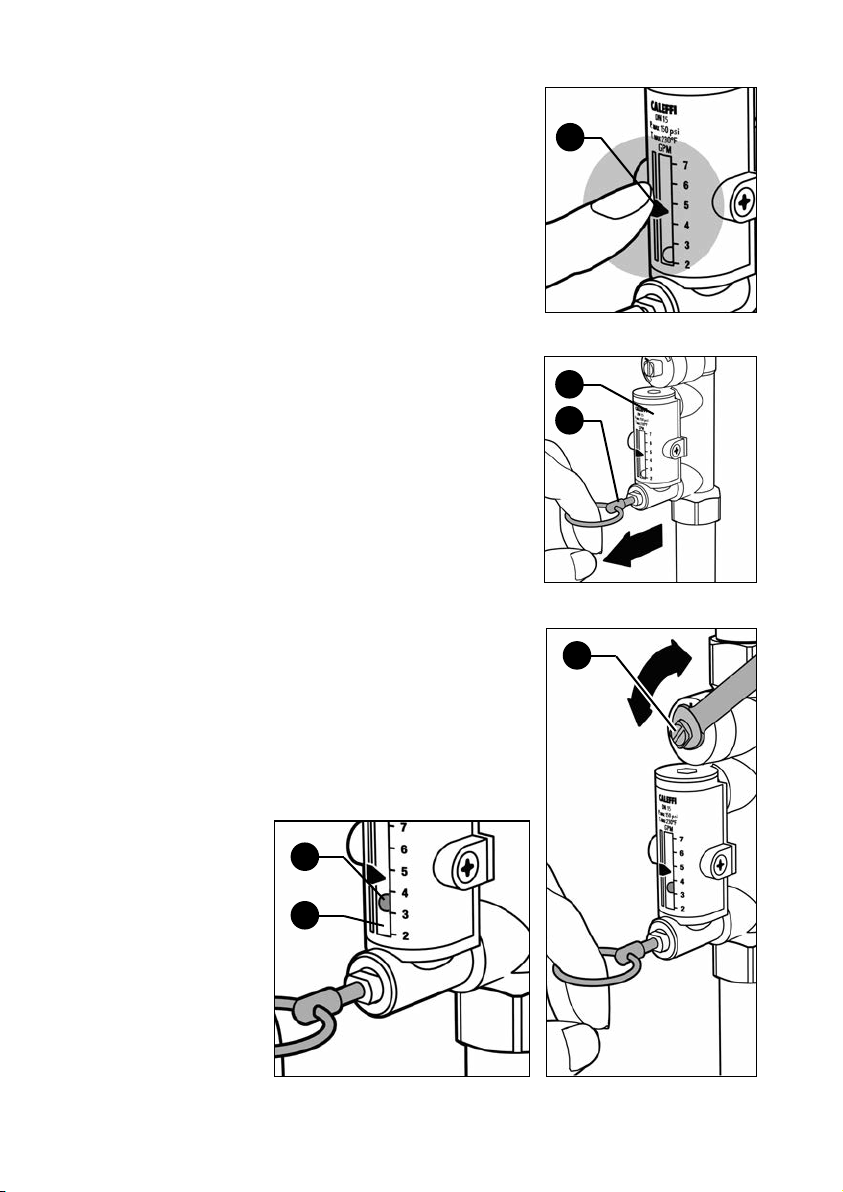

Flow rate

adjustment

The flow rate is adjusted by carrying

out the following operations:

A. With the aid of the indicator (1),

mark the reference flow rate on

which the valve is to be set.

B. Use the ring (2) to slowly open the

flow meter bypass valve that shuts

off the flow of medium in the flow

meter (3) under normal operating

conditions.

C. Keeping the flow meter bypass

valve open, apply a wrench (9 mm

for 1/2" to 1 1/4" sizes; 12 mm for

1 1/2" and 2" sizes) to the balancing

valve control stem (4) to slowly

adjust the flow rate, which is

indicated by a metal ball (5) that

runs inside a transparent cylinder

(6) alongside which there is a

graduated scale in GPM.

1

3

2

4

5

6

Page 4

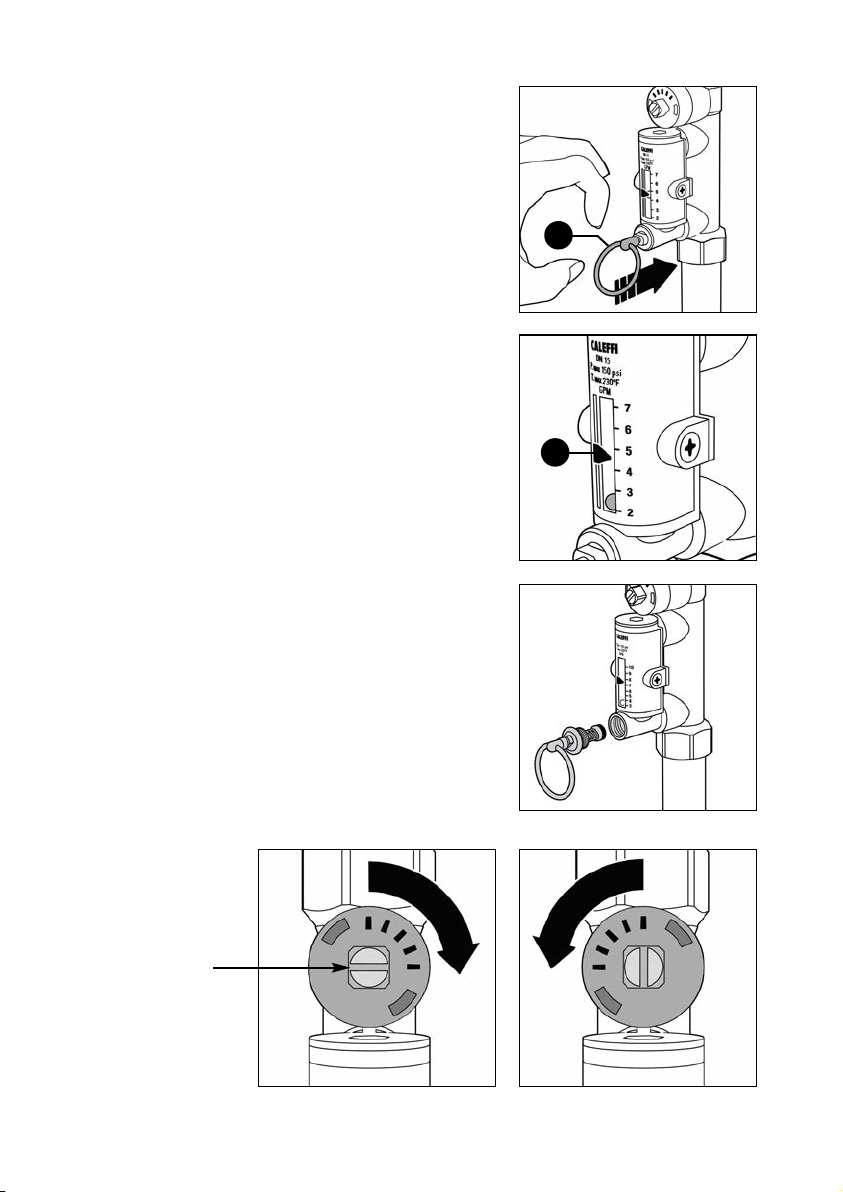

D. After completing the

balancing, release the ring (2)

of the flow meter bypass

valve, which will automatically

go back into the closed

position.

E. On completing the

adjustment, the indicator (1)

can be used to keep the

setting in memory, in case

checks need to be made

over time.

F. A replacement flow meter

bypass valve stem with

operating ring is available in

the event it is damaged and

inoperable.

Order code F19346. See

page 6 for replacement

instructions.

2

1

Complete

closing/opening

of valve

Balancing valve

control stem

Complete opening of valveComplete closing of valve

Page 5

Hydraulic

100

0.1

1

0.2

0.3

0.5

200

500

∆p (psi)

G

(l/h) (

gpm

)

10

2

3

5

20

0.1

1

0.2

0.3

0.5

(psi) (bar) (feet of head)

10

2

3

5

20

0.01

0.1

0.02

0.03

0.05

1.0

0.2

0.3

0.5

4

0.4 0.4

4

0.04

0.4

1000

2000

5000

10000

20000

1

0.2

0.5

2

5

10

2

0

50100

2

00

5

0

1/2”

3/4”

1”

1 1/4”

1 1/2”

2”

46.20

23.10

11.55

9.24

6.93

4.62

2.31

1.16

0.924

0.693

0.462

0.231

characteristics

at 100% open

Code Connection Flow rate (GPM) Cv

132432A 1/2” NPT 1/2 – 1 3/4 1.0

132552A 3/4” NPT 2.0 – 7.0 6.3

132662A 1” NPT 3.0 – 10.0 8.3

132772A 1 1/4” NPT 5.0 – 19.0 15.2

132882A 1 1/2” NPT 8.0 – 32.0 32.3

132992A 2” NPT 12.0 – 50.0 53.7

Page 6

CALEFFI

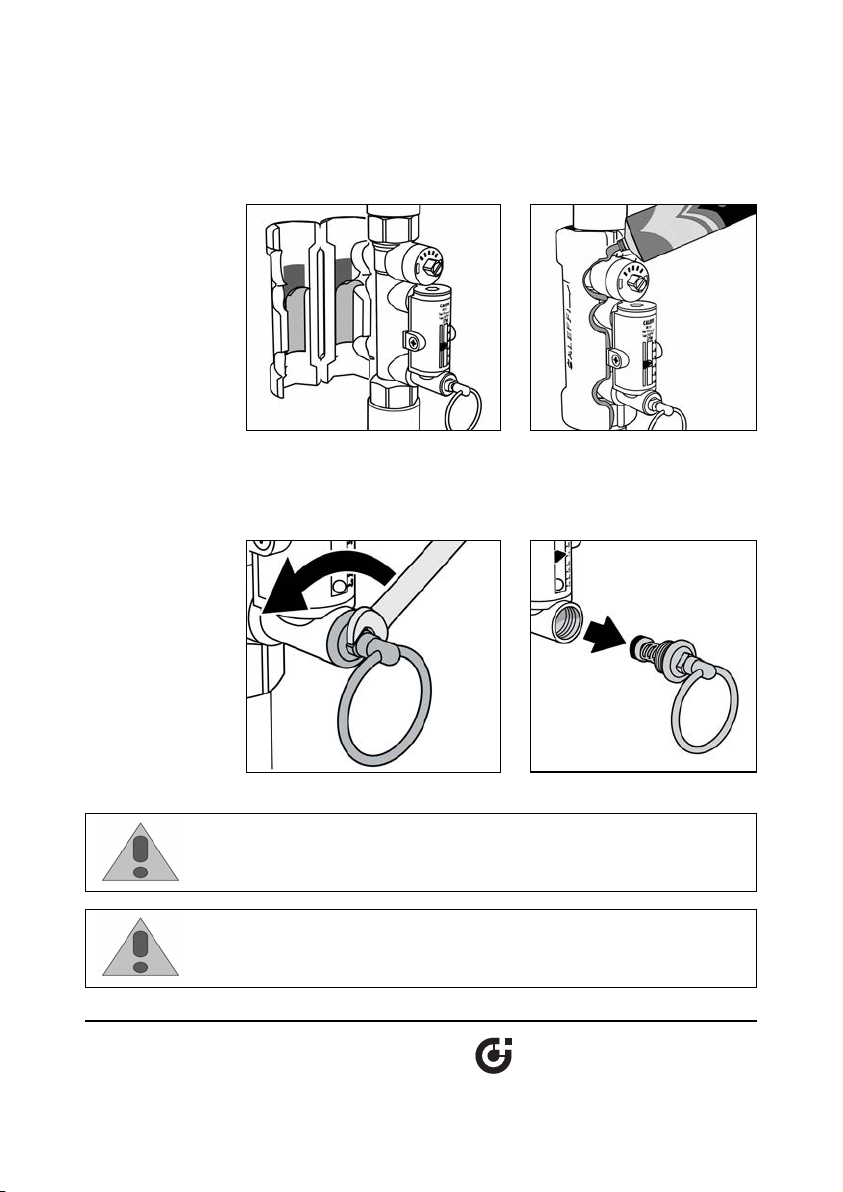

Procedure for

installation and

insulation

assembly

Procedure for

replacing bypass

valve stem with

operating ring

1.

Remove the protective strip from the adhesive

insulation shells.

2.

If the balancing valve with flow meter is used with chilled water, spread a

thin layer of sealant on the edge of the insulation and wait until the solvent

evaporates (10 minutes approx.) and then re-close it.

1.

Remove bypass valve assembly with an 8 mm wrench.

2.

Install replacement bypass valve assembly, code F19346, using locktight

to seal the threads.

surface. Re-close the

CAUTION: If the balancing valve valve is not installed, commissioned and

maintained properly, according to the instructions contained in this

manual, it may not operate correctly and may endanger the user.

CAUTION: Make sure that all the connecting pipework is water tight.

Caleffi North America, Inc.

3883 West Milwaukee Road

Milwaukee, WI 53208

T: 414.238.2360 F: 414.238.2366

Loading...

Loading...