CALEFFI LEGIOMIX 6000AS Series Installation Manual

www.caleffi.com

NA10679

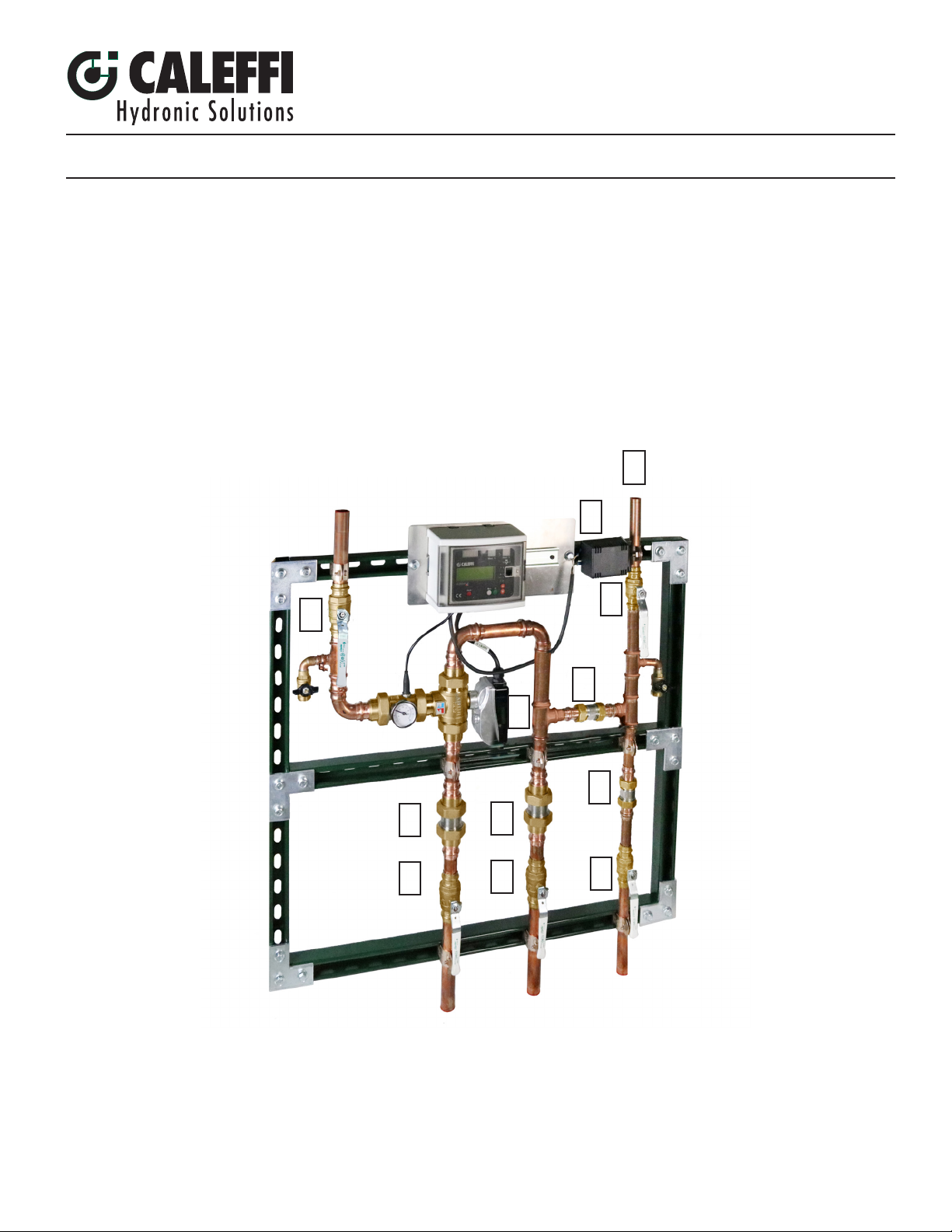

LEGIOMIX® Station electronic mixing system

© Copyright 2019 Caleffi

6000AS series

INSTALLATION GUIDE

OVERVIEW - READ BEFORE PROCEEDING!

1. Refer to the LEGIOMIX Quick Start Guide and instruction sheet, code H0002997, for complete instructions on setup

and commissioning.

2. Do not mount station in orientation with actuator upside down. If mounted other than shown, and not with actuator

upside down, remount the controller to normal horizontal position as it is shown here.

2. The LEGIOMIX Station components are shown below:

5

Recirc

3

Return

2

Mix Out

2

Extra DIN rail for

accessories

Purge to test/

commission

Strut frame

Purge to

1

4

prime the

recirculation

pump

1

1

2

1

2

2

To Tank

Cold In

Hot In

Keyed components:

1. Serviceable dual union check valves (4).

2. Isolation ball valves (5).

3. 24 V wall plug-in transformer with 20 ft cable

(not shown in this view). Strapped to strut for shipment.

4. LEGIOMIX valve/actuator.

5. Connect recirculation pump (not included, source separately) to this line.

1

1

2

3

4

SCALE

TOLERANCES UNLESS NOTED

SHEET

DIMENSIONING AND TOLERANCING PER ASME Y14.5M-1994

PROJECT:

DWN

CHKD

DATE

DATE

THIRD ANGLE

NOTICE ON REPRODUCTIONS

ANGLESDECIMALS

FINISH

MATERIAL

TITLE

PN

SIZE

Legiomix Station 1"

THIS DRAWING, THE DESIGN AND THE PATE NTS IT COVERS, ARE THE PROPERT Y OF

CALEFFI INC. THEY ARE LOANED MERELY AND ON THE BORROWER'S EXPRESS AGRE EMENT

THAT THEY WILL NOT BE REPRODUCED, COPIED, LOANED, EXHIBITED, NOR USED EXCE

PT

IN THE LIMITED WAY AND THE PRIVATE US E PERMITTED BY WRITTEN CONSENT G IVEN BY

THE LENDER TO THE BORROWER.

10/29/2018

Mike

REV

.X ±

.XX ±

.XXX ±

X° ±

B

CALEFFI NORTH AMERICA

3883 West Milwaukee Road

Milwaukee, WI 53208

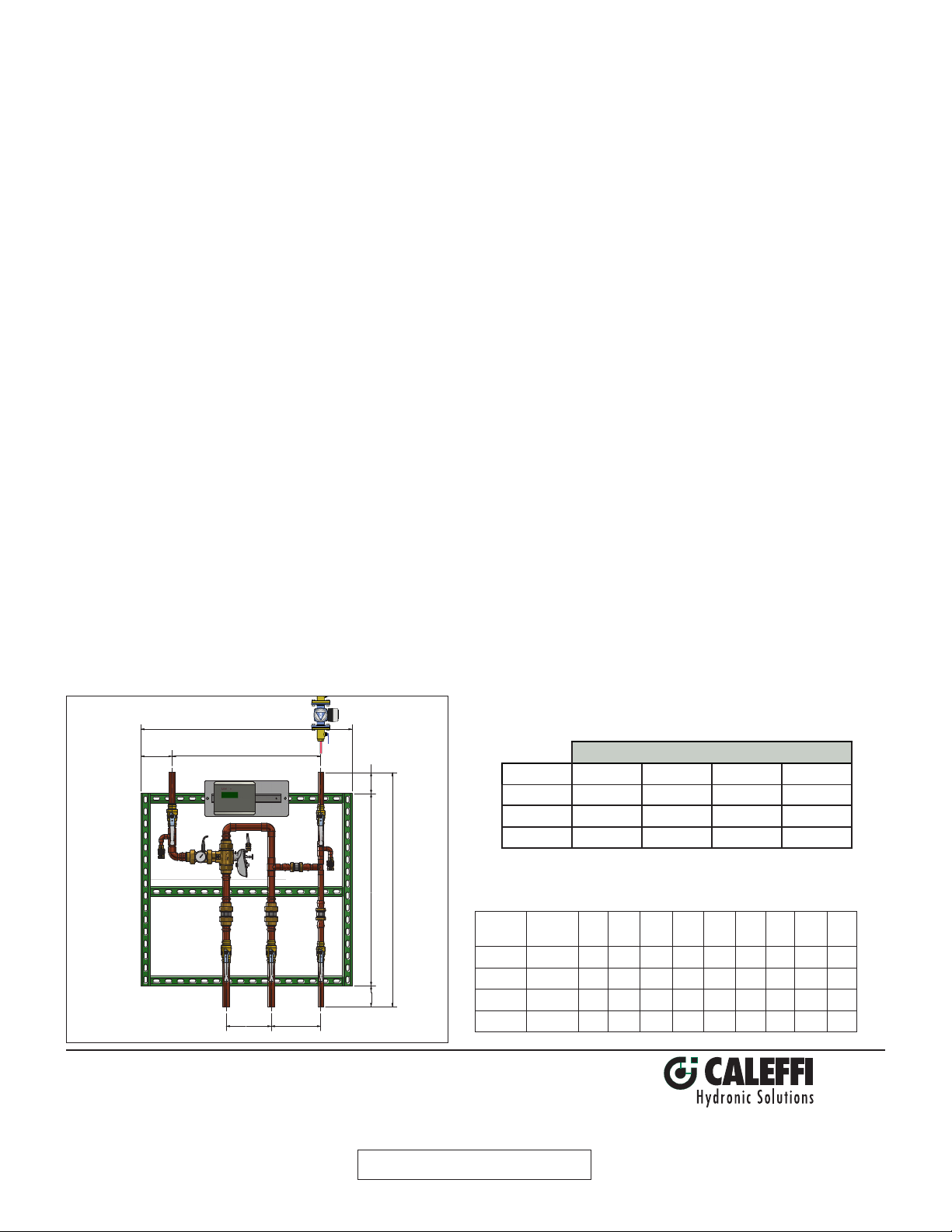

LegioMix Station Assembly Dimensions

m

DESCRIPTION A B C D E F G H I

1"

24.75

7.5

8.25 5.25 35.25 32 39 3.5 3.5

1.25" 27

7.5 9 6.25 39.25 36 43 3.5 3.5

1.5

2"

Technical specifications

Mixing valve body

Materials: - Body: DZR low-lead brass

- Ball: low-lead brass, chrome-plated

- Hydraulic seals: peroxide-cured EPDM

Max. body pressure rating (static): 230 psi (16 bar)

Max. operating pressure: 150 psi (10 bar)

Max. inlet temperature: 212°F (100°C)

Temperature gauge scale: 30 - 210°F

Suitable fluids: water

Max. water hardness: 10 grains

Main connections: -NPT male and sweat union

1", 1¼", 1½" and 2"

Actuator, 3-wire floating

Electric supply: 24 VAC - 50/60 Hz

Power consumption: 6 VA

Protection cover: self-extinguishing VO

Protection class: IP 65 (NEMA 4/4X)

Ambient temperature range: 14 - 130°F (-10 - 55°C)

Electric supply cable length: 31½” (0.8 m)

Max. distance for control signal wire:

500 ft (150 m) cable 2 conductor x AWG 18

800 ft (250 m) cable 2 conductor x AWG 16

Station components

Frame: steel uni-strut

Pipes: copper type L

Ball valves: low-lead brass

Check valves: stainless steel

Main connections: -copper

1”, 1¼”, 1½” & 2”

Controller, LCD user interface/display

Materials: - Housing: self-extinguishing ABS, color white RAL 1467

- Cover: self-extinguising SAN, smoked transparent

Electric supply: 24 VAC (min 21.6, max 26.0 VAC) - 50/60 Hz

Power consumption: 6.5 VA

Adjustment temperature range: 70 - 185°F (20 - 85°C)

Disinfection temperature range: 100 - 185°F (40 - 85°C)

Ambient temperature range: 32 - 120°F (0 - 50°C)

Protection class: IP 54 (wall mounting)

(Class II appliance)

Mounting bracket: DINrail

Dimensions

pump not included

E

D

A

Mix Out

Cold In

Hot In

B C

To Tank

LegioMix As

600066AS

Recirc

600076AS

600086AS

Return

600096AS

H

F

G

I

Contact rating (R1, R3, R4): 5 A resistance, 2 A inductance / 24 V

Mixing valve control: 5 A resistance, 2 A inductance / 24 V

Alarm relay (R2): 5 A resistance, 2 A inductance / 24 V

Fuses: 1 (main): 80 mA

Fuses: 2 (mixing valve): 1 A

Charge reserve: 15 days in the event of electric supply failure,

with a 3 cell rechargeable 3.6 V 140 mAh buffer battery

Battery recharging time: 72 hours

Approvals: CE, FCC part 15

Temperature sensors

Body material: stainless steel

Type of sensitive element: NTC

Working temperature range: 14 - 260°F (-10 - 125°C)

Resistance: 1000 Ohms at 77° F (25° C)

Time constant: 2.5

Max. distance for mixed outlet or return (recirculation) sensor:

500 ft (150 m) cable 2 conductor x AWG 18

800 ft (250 m) cable 2 conductor x AWG 16

Mixing valve performance

Accuracy: ± 3º F (± 2º C)

Max. operating differential pressure (dynamic): 75 psi (5 bar)

Max. ratio between inlet pressures (H/C or C/H): 2.1

Certifications

1. ASSE 1017/CSA B125.3, certified by ICC-ES, file PMG-1357.

2. NSF/ANSI 372-2011, Drinking Water System Components-Lead

Content Reduction of Lead in Drinking Water Act, California Health and

Safety Code 116875 S.3874, Reduction of Lead in Drinking Water Act,

certifed by ICC-ES, file PMG-1360.

Station assembly

Includes pre-piped LEGIOMIX 3-way mixing valve with union connections,

serviceable low-lead stainless steel check valves, a recirculation connection

and isolation valves for fast and simple installation. The LEGIOMIX controller is

pre-mounted and pre-wired and includes a return water temperature sensor,

in a packaged wall mount configuration with steel uni-strut frame that can bolt

to the wall through any of the perforations. The assembly also includes copper

type L pipe, low lead ball valves and a plug-in 24 VAC transformer with 10

feet of wire.

Provide with optional Modbus-to-BACnet gateway for BAS integration,

code NA10520.

Recommended Flow Rates (gpm/lpm)

Size 1" 1¼" 1½" 2"

Minimum* 3.1 / 11.7 4.4 / 16.6 6.6 / 25 8.8 / 33.3

Maximum 94 / 356 107 / 405 152 / 575 215 / 814

Cv 21 24 34 47

*to ensure stable operation and accurate temperature control.

Minimum flow rate is 0 gpm when recirculation flow rate is greater than or

equal to the valve size minimum flow rating.

connec-

Code

600066AS 1" copper 24¾" 7½" 8¼" 5¼" 35¼" 32" 39" 3½" 27.3

600076AS 1¼" copper 27" 7½" 9" 6¼" 39¼" 36" 43" 3½" 28.2

600086AS 1½" copper 33¾" 8½" 13¼" 5" 43¼" 40" 48" 4" 41

600096AS 2" copper 36¾" 87/8" 14¼" 53/8" 47¼" 50" 60" 5" 42

tions

A B C D E F G H/I

Wt

(lb)

LEAVE THIS GUIDE WITH USER

2

Caleffi North America, Inc.

3883 West Milwaukee Road

Milwaukee, WI 53208

T: 414.238.2360 F: 414.238.2366

6-17-19

Loading...

Loading...