Page 1

Hybrid electronic mixing valve

H0002123

www.caleffi.com

© Copyright 2017 Caleffi

6000 Series LEGIOMIX 2.0

INSTALLATION AND COMMISSIONING MANUAL

CONTENTS

Product range

Characteristic components

Package content

Technical specifications

Operating principle

Application diagram

Regulator-actuator

Wiring diagrams

Electronic boards description

2

3

4

5

Operating principle

The electronic hybrid mixing valve combines the typical function

of the mechanical thermostatic mixing valve and the management

efciency of an electronic mixing valve in a single device.

The thermostatic mixing valve uses the mechanical action

performed by the internal control thermostatic element, which

responds promptly to any variation in temperature, pressure and

inlet ow rate to quickly restore the mixed water temperature value

at the outlet.

This standard mixing valve is effectively handled by a motorised

actuator that, upon the signal coming from the temperature probes

and under the control of a specic regulator, changes the mixed

water temperature set position.

The electronic regulator, directly on the actuator, allows the

mixed water temperature control according to different functional

programs, both for normal control and for the thermal disinfection

for the prevention of Legionella.

An optional memory system allows recording every minute of ow

temperature, return temperature, alarm and functional statuses,

useful for monitoring the operating status of the entire system.

Appropriate relays are used to manage the alarms and external

appliances, for example for loading accumulation hot water and

switching on/off the recirculation pump.

The regulator is tted for remote control with specic transmission

protocols such as MODBUS, through optional board, for use in

Building Management Systems (BMS).

The device is provided with CE mark in accordance with

directives 2014/35/EU and 2014/30/EU.

Cables pathway

Cables wiring and positioning

Probes connection

Recommended minimum distances

Front panel

Indication on LCD display

Operating status

Plumbing installation

Commissioning

Thermal disinfection

Maintenance

Functional faults

Seals

Troubleshooting

Regulator-actuator replacement/rotation

Thermostatic function

Application diagrams

6

7

8

9

10

11

12

1

Page 2

Product range

6000 series Hybrid electronic mixing valve Sizes DN 15 (1/2”), DN 20 (3/4”), DN 25 (1”), DN 32 (1 1/4”), DN 40 (1 1/2”), DN 50 (2”)

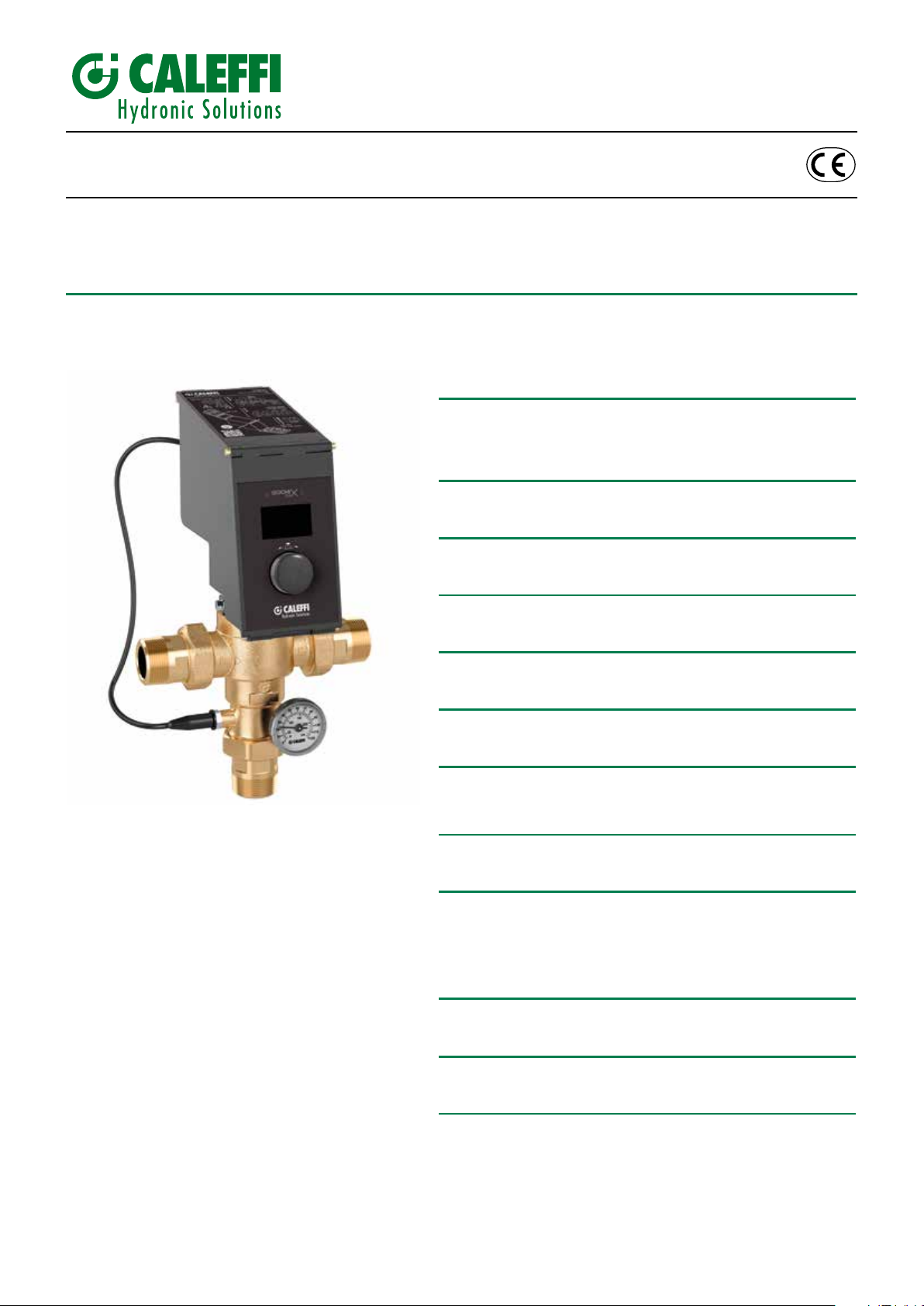

Characteristic components

1 Digital regulator with actuator in single casing

2 Control knob and LCD display

3 Fitted for cable seals and cable glands, with holes

4 Valve body

5 Mixed water temperature probe

6 Mixed water temperature gauge

7 Return temperature probe and probe holder

Package content

• Thermostatic mixing valve complete with regulator-actuator

• Temperature gauge

• Flow probe

• Return contact probe

• Cable seals/cable glands

• Installation and commissioning manual

• Programming manual

• Button battery

At the back of the actuator-regulator, there are 2 holes for mounting

the cable seals and fitted for installing 2 cable glands to ensure IP

54 protection. The cable seals and cable glands have the following

dimensions:

- Cable seals: PG7

- Cable gland: diam. 20 mm

Technical specifications

Valve body

Materials:

Body: dezincification-resistant alloy

EN 1982 CC770S

Obturator: PPSG40

Hydraulic seals: EPDM

Spring: stainless steel EN 10270-3 (AISI 302)

Maximum working pressure (static): 10 bar

Maximum inlet temperature: 90°C

Temperature gauge scale: 0 – 120°C

Connections: 1/2” - 2” M (ISO 10226-2) with union

Regulator-actuator

Material:

Housing: PA6G30 anti-UV black

Covers: PA6G30 anti-UV black

Electric supply: 230 V (ac) 50/60 Hz

Power consumption: 6,5 VA

Adjustment temperature range: 35 – 65°C

Disinfection temperature range: 50 – 85°C

Ambient temperature range:

- Operation: 0-50°C EN 60721-3-3 Cl. 3K3 max. humidity 85%

- Transportation: -30-70°C EN 60721-3-2 Cl. 2K3 max. humidity 95%

- Storage: -20-70°C EN 60721-3-1 Cl. 1K3 max. humidity 95%

Protection class: IP 54

Contact rating:

- Relay OUT1, OUT2, OUT3: 5(2) A / 250 V

- Digital inputs: without potential

Fuses: self-resettable non-replaceable (only for control unit)

Battery: CR2032 225 mAh - life approximately 1 year

(for only keeping date and time in the absence of network)

Optional battery:

ER AA Lithium - Thionyl chloride 3.6 V lasting about 10 years

(for only keeping date and time in the absence of network)

Conforms to Directives: CE

Insulation class: Class II

Temperature probes

Body material: stainless steel

Type of sensitive element: NTC

Working temperature range: -10 – 125°C

Resistance: 10000 Ohm at 25°C

Time constant: 2,5

Max. distance for flow or recirculation probe: 150 m cable 2x1

250 m cable 2x1,5

Mixing valve performance

Accuracy: ± 2°C

Max. working pressure (dynamic): 5 bar

Max. inlet pressure ratio (H/C or C/H): 2:1

Size

Kv (m3/h)

1/2"

4,3

3/4"

4,3

1”

7,6

1 1/4”

10,0

1 1/2”

13,02”18,0

RECOMMENDED flow rates to ensure stable operation and an

accuracy of ± 2°C

Size

Min (m3/h)

Max (m3/h)*

*

Δp = 1,5 bar

1/2"

0,6

5,3

3/4"

0,6

5,3

1”

1,2

9,3

1 1/4”

1,5

12,5

1 1/2”

1,5

16,0

2”

2,0

22,1

2

Page 3

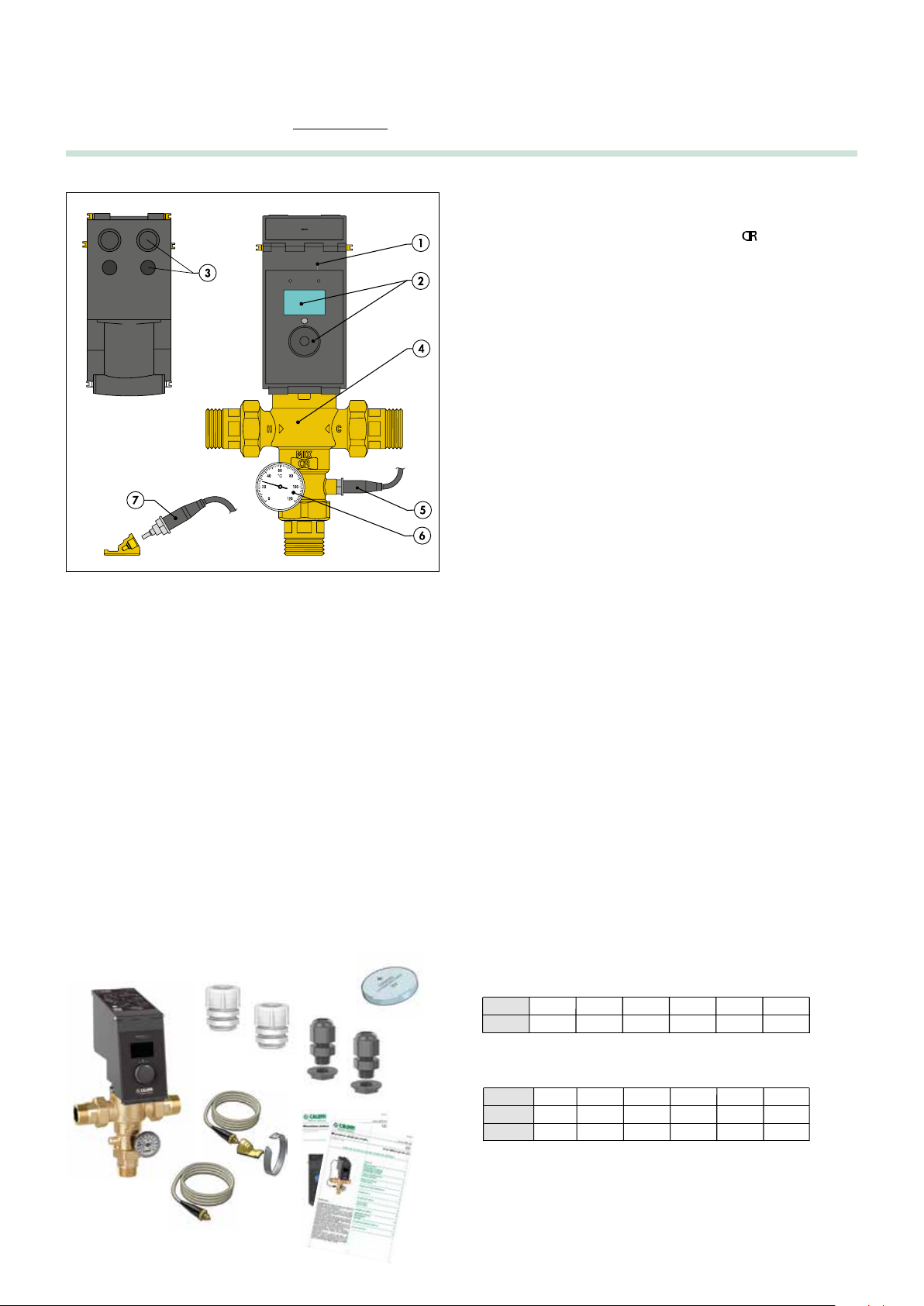

Operating principle

At the inlets the mixing valve has the hot water from the storage and

the cold water from the water mains. At the outlet there is the flow

mixed water. By means of a specific probe, the regulator measures

the temperature of the mixed water at the valve outlet and actuates

an obturator in order to maintain the setting. Temperature fluctuations

caused by flow rate or pressure variations are compensated by the

thermostat in the valve. The appliance has a built-in digital clock,

which can be used to set anti-legionella programs to disinfect

the water system and to manage a recirculation pump. The

system is disinfected by raising the water temperature to a specific

value for a set time duration. For the best thermal disinfection

control, in this type of system it may also be necessary to measure

the temperature of the water returning from the distribution network,

using the recirculation probe. When this measurement is available,

it is used to check and control the temperature reached over all

or part of the network, since the probe may be located at a significant

remote point of the system. The appliance is equipped with RS-485

interface (optional), with MODBUS protocol, for readouts and

remote setting. To use the device, it is necessary to configure the

MODBUS system with the addresses of the registers used by the

device (PC software is available).

Application diagram

COLD

HOT

MIXTURE

BMS

MODBUS

3

Page 4

LEGIOMIX

2.0

Series 6000

T

AMB.

0÷50°C

L - N: 230 V

˜

6,5 VA

IP 54

CS 176

CS 180

CS 179 (OPZ)

L N

NO C NC NO C NO C

CS 176

μ

5(2) A 250 V

˜

230 V

˜

50 Hz

ALARM

OUT1OUT3OUT

2

RETURN

PROBE

MIXED

PROBE

T2

RS485

BA

IN 2 T1IN 1

CS 180

CS 179 (OPZ)

Cale S.p.A.

S.R. 229 n° 25

28010 Fontaneto d’Agogna

Italy

Regulator-actuator

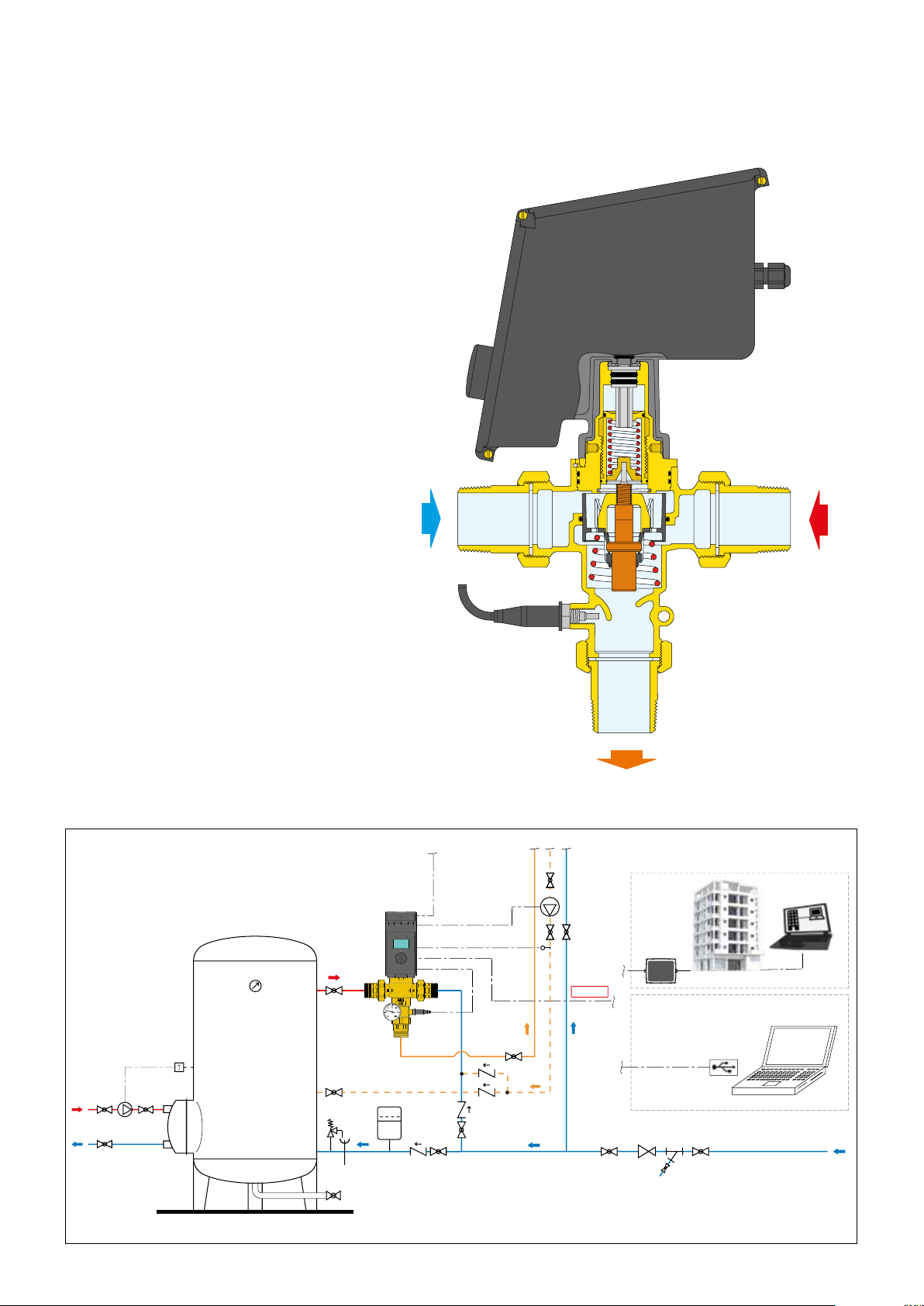

Battery installation

Before connecting the power supply, insert the battery supplied, type CR 2032. The presence of the battery

allows the clock continuous updating. In case of low or missing battery, if there is no network, the device does not

ensure that the time and date are stored and therefore that the programmed disinfections are executed correctly.

Optional battery connector

code F0000692

NOTE: It is possible to replace the button battery with

an optional battery code F0000692, type ER AA

Lithium-Chloride of thionyl 3,6 V, to be connected

to the connector on the board.

The battery life is approx. 10 years.

For connecting the optional battery, its installation

and specifications, see the instruction sheet

H0003948.

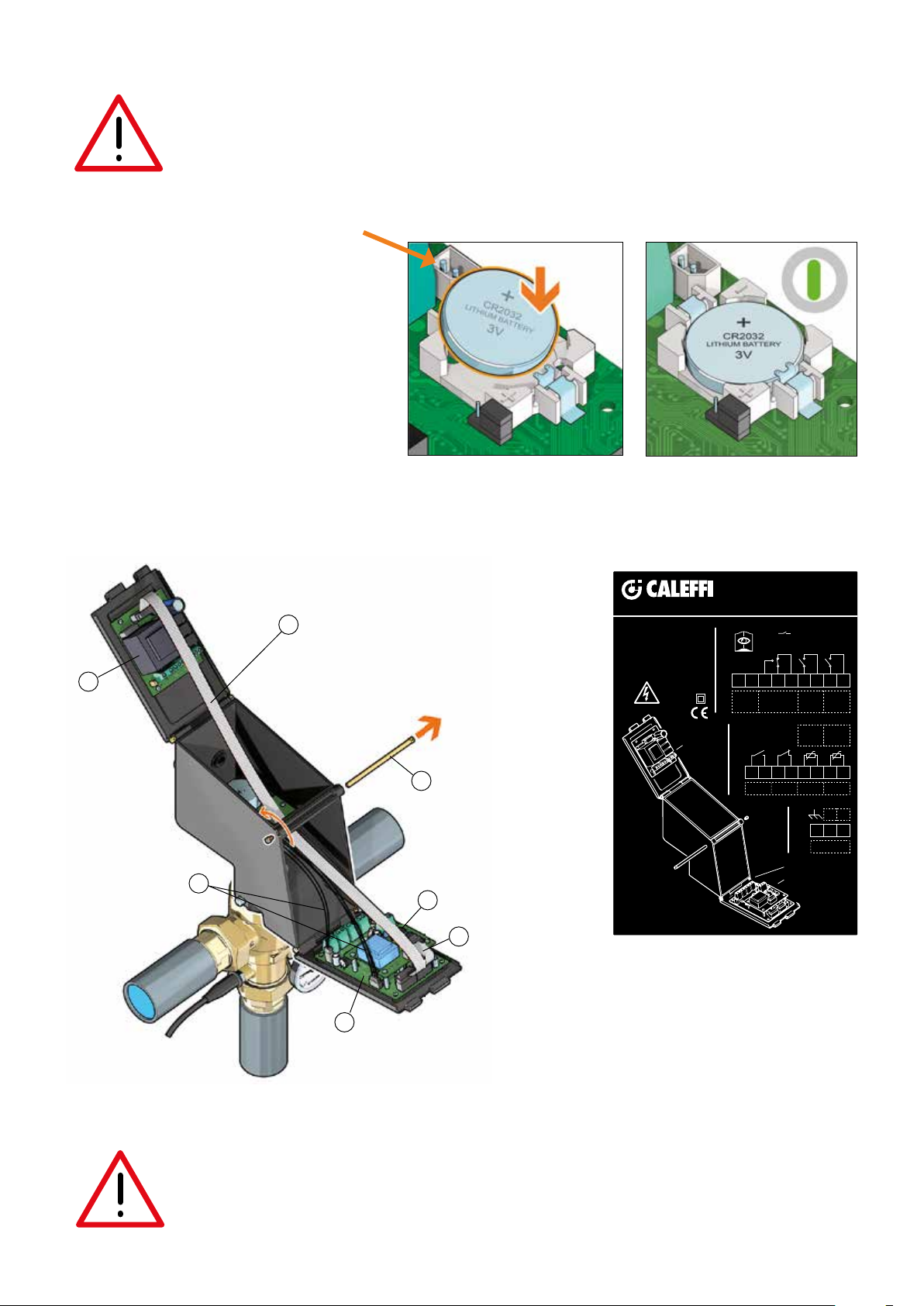

Wiring diagrams

2

4

1

5

6

3

7

1 Actuator-regulator opening/closing pin

2 Power supply board (CS176)

3 Control board (CS180)

4 Multi-pole cable for board connection*

5 Motor connection cables*

6 RS-485 Interface board (CS179) (OPTIONAL)

7 RS-485 Interface connection cable (OPTIONAL)

* already assembled in factory

IMPORTANT:

Risk of electric shock. The CS176 board is live. Cut off the electric supply before carrying out any work. Failure in following these

instructions may result in injury of persons or damage to property. In case of power failure the system can activate an alarm

through OUT1 relay. Date and time are maintained by the battery. If the battery is low, the system displays the "BATTERY LOW"

alarm.

4

Page 5

Electronic boards description

CS176 - Electric supply and relay

The following connection inputs are on the board:

- L/N = Power supply 230 V 50/60 Hz

- OUT 1 = ALARM Relay: Contact in derivation without potential

- OUT 3 = DISINFECTION IN PROGRESS relay without potential

- OUT 2 = RECIRCULATION PUMP relay without potential

(it activates the pump during thermal shock disinfection and when

recirculation programming is active)

Connector for

CS180 board

OUT 2

OUT 3

L/N

OUT 1

CS180 - Contacts and probes

The following connection inputs are on the board:

- IN1 = NO (normally open) potential-free contact for

- IN2 = potential-free contact (by default forced in closing by jumper)

- T1 = Delivery probe

- T2 = Return probe

disinfection start-end depending on the mode set

for disinfection/thermal shock stop (emergency)

IN1

IN2

T1

T2

Motor connector

Optional battery

connector

Button battery

Connector for

CS179 board

Connector for

CS176 board

CS179 - Data transmission (optional

RS-485 interface MODBUS connection.

An optional memory system allows recording the flow temperature,

return temperature, alarms and functional statuses, useful for

monitoring the operating status of the device. The connection also

allows the remote control of the mixing valve for both parameter

acquisition and modification. The communication is made with the

MODBUS RTU 9600 ON protocol.

) code 600001

RS -485 connection

Connector for

CS180 board

Board installation CS179 (optional) on CS180 board

The supply includes 4 screws for correct installation on the 4 spacers

already fitted for on the CS180 board and the multi-pole connection

cable with the CS179 board (RS-485 cable NOT supplied).

RS -485 cable

IMPORTANT:

When fitting cables for electric connections, be careful not to damage the electronic board components. Every time the regulatoractuator is removed from the valve it is necessary to perform a new zero acquisition by means of the appropriate control.

Do not disassemble the electronic boards from the appropriate supports.

Do not disassemble the motor.

5

Page 6

Storage primary pump

Cables pathway

Mimimum dimensional characteristics to respect for board electric connections: connection cable cross sections and lengths.

Observe the applicable regulations in force in the country of installation.

BOARD TERMINAL CABLE TYPE

L/N 2 X 0,75 (H05VV-F) 250 140

CS176

CS180

CS179 RS-485 2 X 1 TW+SCH 190 300

* NOTE: for installation, see page 9.

Cables wiring and positioning

The passage of the connecting cables must be prepared trying to

separate the electric supply cables from the signal cables using the

appropriate clamps. This image shows an example of a possible

cable layout and their passage through the cable seals and cable

glands included in the supply. For different cases use special

insulating sheaths.

OUT1 3 X 1 250 140

OUT2 2 X 1 250 140

OUT3 2 X 1 250 140

T2 2 X 0,75 140 250

T1 2 X 0,75 140 250

IN1 2 X 0,75 140 250

IN2 2 X 0,75 140 250

UNSHEATHING

IN mm (L) POS. A *

UNSHEATHING

IN mm (L) POS. B *

Relay contact for recirculation pump and second storage

thermostat and alarm management

Here following the wiring diagram of the OUT 2 relay for managing the

recirculation pump. The device incorporates a digital clock used to

manage a recirculating pump according to pre-set time slots.

Electric supply cords

and relays

Signal and probes

cables

Connections layout: connections must not create thrust stresses

on the circuit board.

RS-485

Recirculation pump

Here following the wiring diagram of the OUT 3 relay for connection to

the second storage thermostat.

Storage primary pump

Here following the wiring diagram of the OUT 1 relay for alarm

management.

6

Page 7

Connection of probes:

If necessary for the installation,

the cable connecting the flow and

return probes with the controller

must be installed in a raceway. If the

connection cable shares the raceway

with other power cables, an earthed

shielded cable must be used.

Probe resistance table

°C

-20

-15

-10

-5

0

5

10

15

Ω

97060

72940

55319

42324

32654

25396

19903

15714

°C

20

25

30

35

40

45

50

55

Ω

12493

10000

8056

6530

5327

4370

3603

2986

°C

60

65

70

75

80

85

90

95

Ω

2488

2083

1752

1480

1255

1070

915

787

°C

100

105

110

115

120

125

Ω

680

592

517

450

390

340

Perform the hydraulic installation of the temperature probes and provide electrical wiring.

Recommended minimum distances

In order to ensure adequate space for proper installation and

maintenance of the device, the distances shown in the figure

must be observed.

350

200

110

300

88

110

7

Page 8

Front panel

4

3

1

2

1 LCD display

2 Control knob

3 Green LED: - On (network presence)

4 Red LED: - Fixed (disinfection or thermal shock in progress, full

scale acquisition)

- Flashing (alarm condition)

Indication on LCD display

On the front of the device there is a backlit alphanumeric LCD

display for parameter setting, interventions programming, working

statuses and alarms display.

Navigating through appropriate menus, using the control knob

only, it is possible to configure the device and set the various

parameters.

For management and programming

of the device refer to the

"Programming Manual"

code H0003581

Disinfection

In this mode, the device performs thermal disinfection, which consists in

raising the mixed water temperature for a defined period of time.

The following can be set:

- Days of the week for performing the disinfection

- Minimum disinfection temperature

- Disinfection start time

- Minimum stay time above the minimum disinfection temperature in

order to evaluate the successful outcome of the disinfection

- Maximum time within which it is possible to perform the disinfection

The disinfection can be:

- Programmed: it starts in the days and hours set

- Activated through the control: it can be controlled by the device from

the "Controls submenu" or remotely through optional board

- Activated by IN1 inlet

The disinfection in progress OUT3 relay and the recirculation pump

management OUT2 relay are always activated during the disinfection.

If the disinfection temperature does not last for sufficient time and the

maximum available time is exceeded, the disinfection will be considered

as failed by signalling the relevant alarm.

CHECK ON DISINFECTION

Temperature [°C]

minimum

disinfection

temperature

Disinfection start

t

1

Σ ts> minimum disinfection time

maximum disinfection time

t

2

Time [s]

Disinfection end

Operating status

Depending on the times and the programs that have been set, the device

may be in one of the following operating modes:

• Regulation

• Disinfection

• Thermal shock*

• Zero and full scale acquisition

*(this function has priority over the disinfection/regulation).

In the event of anomalies, the device manages and signals an alarm trying

to set into a safety condition for the user. The device is equipped with a

non-rechargeable battery that keeps the clock working in the event of

electric supply failure.

Regulation

The electronics must adjust the flow temperature through the actuator in

order to reach the working set-point. The electronic actuator adjusts the

flow so as to have a temperature centered in a suitable working range,

within which the fine and dynamic adjustment is made by the thermostat.

The mixing temperature is set through the interface. The management

system always checks in real time the flow temperature detected by

the probe: if the flow temperature deviates excessively from the set

value, a correction is made through the electric motor. In the case of

installation with a return probe present, it is not used for the water mixing

temperature adjustment.

Thermal shock

In this mode, the device raises the flow temperature to the set value for

a certain period of time. The disinfection in progress OUT3 relay and the

recirculation pump management OUT2 relay are always activated during

the thermal shock.

Zero and full scale acquisition

In the zero acquisition mode, the device totally closes the adjusting screw

to check the correct phasing between the motor and the valve. In full

scale acquisition mode, the device fully opens the adjusting screw so

it can check all the stroke (potentially hazardous condition indicate with

fixed red LED). The zero and full scale acquisition controls are activated

during the installation or after the "Reset alarms” control.

Additionally, the zero acquisition mode is activated whenever an electric

supply failure occurs for at least 60 minutes and at the outlet from any

disinfection/thermal shock. It is recommended to perform the full scale

acquisition with shut-off valves closed at the mixing valves inlets.

Reset

In the menu there is a special control to reset to the initial conditions. The

history is not reset.

Test

The device performs full strokes in order to check that there are no

obstructions during the motor opening and closing strokes. The display

shows the encoder steps and the power consumption (mA). It is possible

to interrupt the test function at any time pressing the control knob.

8

Page 9

Plumbing installation

Before installing the Caleffi mixing valve, the pipes must be flushed to prevent impurities in the water from affecting performance. The following are

indicated on the body of the mixing valve:

- H hot water inlet

- C cold water inlet

- MIX mixed water outlet

In systems with mixing valves, check valves must be installed to prevent undesired backflow.

We recommend always installing strainers of sufficient capacity at the inlet of the water mains and shut-off valves forany maintenance operations.

The mixing valves must be installed according to the installation diagrams in this manual; they an be installed either vertically or horizontally, with

actuator not overturned. To facilitate the display reading and setting, it is possible to change the position of the motor related to the valve in four

positions at 90°, there is also the possibility to reverse the two panels.

In order to reverse the panels, before to electrically wire the device, it is necessary to carry out the following operations:

1 - Remove the opening/closing pin (POS. A: factory setting).

2 - Open the panels.

3 - Disconnect the board connectors, motor connector, and remove the pins.

4 - Remove and reverse the panels.

5 - Reconnect the boards connector and the motor connector, insert the pins.

6 - Close the panels and insert the opening/closing pin (POS. B).

1 2 3

POS. A

4 5 6

Max 1 N•m

POS. B

Commissioning

Due to the special purposes for which the electronic mixing valve will be used, it must be commissioned in accordance with current regulations and by

qualified personnel using suitable measuring instruments. Check that the hot and cold water supply pressures are within the operating limits of the mixing

valve. Check the temperature of the hot water from the storage, T ≥ 60°C.

In the installation log book, record all the parameter settings made and the measurements taken.

9

Page 10

Thermal disinfection

The temperatures and corresponding times for disinfection of the

system must be selected according to the type of installation and

its intended use. To meet the requirements of the most recent world

legislation on this matter, the following criteria can generally be

followed:

T = 70°C for 10 minutes

T = 65°C for 15 minutes

T = 60°C for 30 minutes

Thermal disinfection is generally carried out at times when there is

less demand on the system, for example at night; this is to minimize

the risk of users being scalded. It is recommended to perform thermal

disinfection every day and at least once a week.

Maintenance

Tests are carried out while in service, to regularly monitor the

performance of the mixing valve, since any loss of performance may

indicate the need for maintenance of the valve and/or the system.

During these tests, if the temperature of the mixed water is found

to have changed significantly compared with previous tests, we

recommend referring to the sections on installation and commissioning

and carrying out maintenance.

We recommend carrying out the following checks periodically to ensure

that the valve continues to deliver optimum levels of performance. At

least every 12 months, or more frequently if required.

1) Check and clean the filters in the system

2) Check that any check valve installed at the inlet of the Caleffi valve

is functioning correctly, and there are no leaks caused by dirt.

3) Once the maintainable components have been checked, we

recommend following the commissioning procedure again.

On the system log book, record all operations carried out.

Buffer battery replacement procedure

If necessary, it is possible to replace the buffer battery removing the

low battery from its seat and inserting the new one without forcing.

Battery type CR2032.

Functional faults

A special set of alarms has been fitted to help manage possible faults

that can occur in the device. Refer to the dedicated section of the

"Programming Manual" (code H0003581).

Seals

The screws are fitted for the installation of anti-tampering seals.

Troubleshooting

In normal operating conditions, Caleffi series 6000 hybrid electronic mixing valves provide outstanding performance. However, in special circumstances

when our maintenance schedule is not observed, the following problems may arise:

Problem Cause Solution

Hot water supplied to cold water taps a) Inlet check valves not operating

correctly or seals worn/damaged

b) Check valves not tted

Mixed water temperature uctuations a) Incorrect inlet water temperatures

b) Inlet water supply failure

c) Bad commissioning

Incorrect valve outlet ow rate a) Insufcient water supply

b) Inlet water temperature/pressure

uctuations

c) Adverse conditions due to other water

draw off points in the system

No valve outlet ow a) In-line strainers obstructed

b) Insufcient supply pressure

c) Dirt obstructing water ow through the

valve

Replace damaged check valves

Install check valves

Restore inlet conditions to within valve specication range

Stabilise supply conditions at the inlet

Clean the strainers

Restore supply conditions

Remove dirt/scale from the valve

10 11

Page 11

Regulator-actuator replacement/rotation

In case of replacement of the regulator-actuator it is necessary to remove all electric connections and perform the following operations:

Max 4 N

NOTE: Following the above operations, perform the zero and full scale acquisition.

Thermostatic function

In case of motor failure or power failure, the device is able to guarantee the temperature adjustment through the thermostatic element. To ensure

thermostatic adjustment, perform the following operations:

- Screw up to stop (clockwise)

- Make a reference

- Adjust the desired set point reading the temperature using suitable instruments (make a maximum of 1 turn)

It is possible to temporarily perform the disinfection/thermal shock turning over one turn, disabling the thermostatic control.

•

m

max 360° 35–65°C

11

Page 12

Application diagrams

Non-return valve

Ball valve

Temperature gauge

Pump

Expansion vessel

T

Thermostat

Safety relief valve

Strainer

Clock

LEAVE THIS MANUAL AS A REFERENCE GUIDE FOR THE USER

12

Loading...

Loading...