Page 1

01166/10 NA

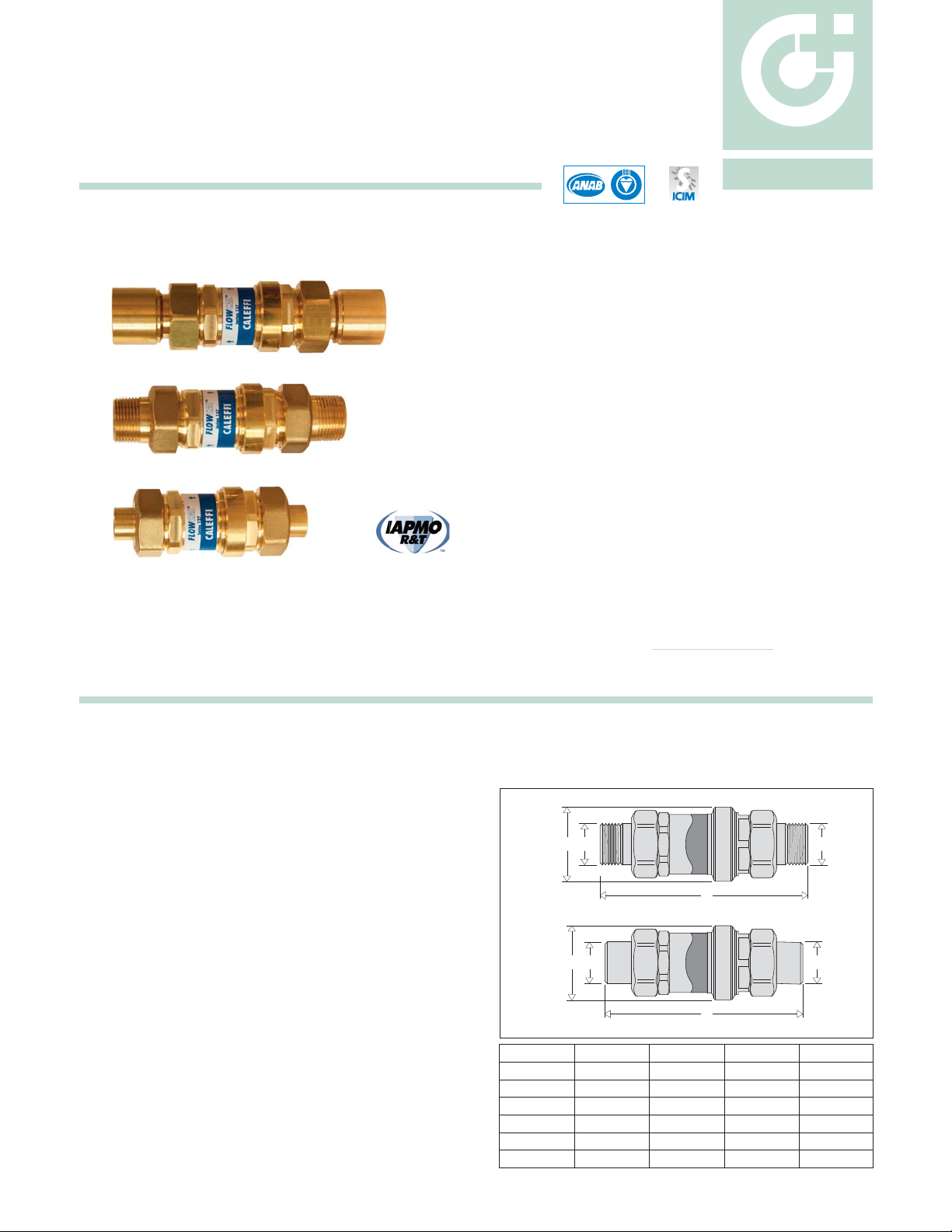

FLOWCAL™ Compact automatic flow

balancing valve

127 series

Function

The FLOWCAL™ automatic flow balancing valve maintains a fixed

flow rate within varying system differential pressure ranges.

The design incorporates an exclusive flow cartridge, made of an

anti-scale, low noise polymer and a compact low-lead brass valve

body for use in cooling, heating and domestic water systems.

Product range

127 series FLOWCAL compact automatic flow balancing valve, with polymer cartridge, NPT or Sweat Union sizes 1/2”, 3/4”, 1"

CALEFFI

Technical specifications

Materials

Body: low-lead brass (<0.25% Lead content)

Flow cartridge: anti -scale polymer

Spring: stainless steel

Seals: EPDM

Performance

Medium: water, glycol solutions

Max. percentage of glycol: 50%

Max. working pressure: 232 psi (16 bar)

Working temperature range: 32-212°F (0-100°C)

Connections: 1/2”, 3/4”and 1” NPT or Sweat Union

Flow Rate: 16 fixed flow rate settings

ranging from 0.5 - 10 GPM

Flow Accuracy: ±10%

Differential Pressure Control Ranges: 2-14, 2-32, 4-34, 5-35 psid

Agency Approval:

Lead Plumbing Law Compliance: (0.25% Max. weighted

average lead content)

Lead Plumbing Law Certified by IAPMO R&T

ACCREDITED

ISO 9001 No. 0003

ISO 9001 FM 21654

Dimensions

A

1/2" NPT

1/2" Sweat

3/4" NPT

3/4" Sweat

1" NPT

1" Sweat

B

5 13/16"

4 1/4"

5"

4 13/16"

5 5/8"

6"

C

1 9/16"

1 9/16"

1 9/16"

1 9/16"

1 9/16"

1 9/16"

Weight (lb)

1.0

0.8

1.0

0.8

1.2

1.0

Code

127341AF...

127349AF...

127351AF...

127359AF...

127361AF...

127369AF...

A

B

A

C

A

B

A

C

Page 2

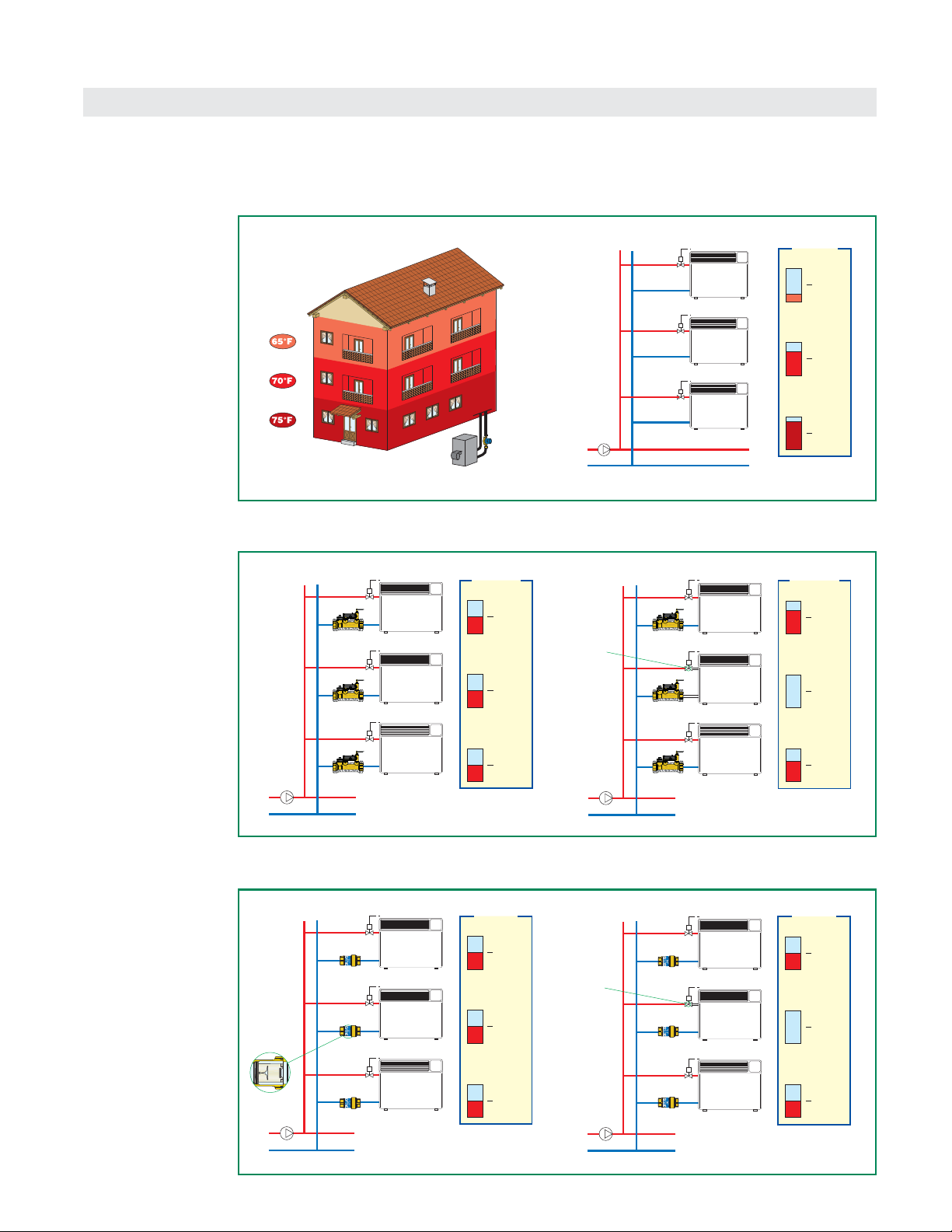

Modern heating and air-conditioning systems have to guarantee a high level of thermal comfort with a low energy consumption. This means

supplying the system terminals with the correct design flow rates, to produce balanced hydraulic circuits.

Circuit balancing

Circuits balanced with FLOWCAL

FLOWCAL balances

the hydraulic circuit

by automatically

controlling the design

flow rate to each

emitter.

Even with some

circuits partially

closed by the

control valves, the

flow rates in the open

circuits remain

constant at the

nominal value. The

system always

provides the greatest

comfort and the

highest energy

savings.

FULL LOAD

Control

valve

(closed)

PARTIAL LOAD

FLOWCAL

FLOWCAL

100 %

100 %

100 %

Flow rate

100 %

0 %

100 %

Flow rate

Circuits balanced with manual valves

Traditionally, hydraulic

circuits are balanced

using manual

calibration valves.

With these static-type

devices, such circuits

are difficult to balance

perfectly and have

operating limitations

in case of partial

closure by means of

the control valves.

The flow rate in the

open circuits does

not remain constant

at the nominal value.

FULL LOAD PARTIAL LOAD

Manual valve

Control

valve

(closed)

Manual valve

100 %

100 %

100 %

Flow rate

140 %

0 %

120 %

Flow rate

Unbalanced circuits

In case of an

unbalanced circuit,

the hydraulic

imbalance between

emitters creates areas

with temperatures

which are not

uniform, and, as

a consequence,

problems with thermal

comfort and higher

energy consumption.

50 %

140 %

180 %

Flow rate

Page 3

Function

The FLOWCAL automatic flow balancing valve guarantees a constant flow rate when the upstream/downstream pressure differential varies.

It is therefore necessary to refer to the Δp vs. flow rate diagram and to a basic diagram illustrating the operation methods and the relevant

variable effects.

Operating principle

The FLOWCAL flow cartridge is composed of a cylinder, a spring-loaded piston, and a combination of fixed and variable geometric orifices

through which the fluid flows. These variable orifice sizes increase or decrease by the piston movement, contingent on the system’s fluid thrust. A

specially calibrated spring counteracts this movement to regulate the amount of fluid which may pass through the valve orifices, maintaining a

balanced system. FLOWCAL valves are high performance automatic flow balancing valves which control selected flow rates within a very tight

tolerance (approximately 10%) and offer a wide range of operation.

*These values are for this example. The same logic applies to the other Differential Pressure Control Ranges: 2 -14, 4 - 34, and 5 -35 psid.

In this case, the spring-loaded regulating

piston remains in equilibrium without

compressing the spring and gives the fluid

the maximum free flow area. When below

the differential pressure control range the

piston acts as a fixed orifice and thus the

flow rate through the FLOWCAL depends

only on the differential pressure.

If the differential pressure is within the control

range, the spring-loaded piston is positioned

to give the fluid a free flow area permiting

regular flow at the nominal rate for which the

FLOWCAL

is set up.

In this case, the spring-loaded piston fully

compresses a spring and leaves only the

fixed orifice for the fluid to pass through.

The flow rate through the

FLOWCAL

depends only on the differential pressure.

FLUID THRUST

FLUID THRUST

FLUID THRUST

2 psi 32 psiDIFFERENTIAL

PRESSURE

FLOW RATE

G

0

Range Δp 2–32 psi

where G0 = nominal flow rate

DIFFERENTIAL

PRESSURE

FLOW RATE

G

0

Control range

Initial Δp

Final Δp

2 psi 32 psi

Range Δp 2–32 psi

where G0 = nominal flow rate

FLOW RATE

DIFFERENTIAL

PRESSURE

G

0

2 psi 32 psi

FLOWCALTMAutomatic Flow Balancing Valves

Below the differential pressure control range (< 2 psid)*

Within the differential pressure control range (2 - 32 psid)*

Above the differential pressure control range (> 32 psid)*

Page 4

Construction details

Polymer flow cartridge

The flow rate cartridge is made of an anti-scale polymer,

specially engineered for use in cooling, heating and domestic

water systems, to prevent mineral buildup.

Its mechanical behavior is excellent in a wide range of

working temperatures, it features high resistance to the

abrasion caused by continuous fluid flow, it is insensitive to

the deposit of scale and is fully compatible with glycols and

additives used in circuits.

Exclusive design

With its exclusive design, the flow cartridge is able to

accurately control the flow rate in a wide range of operating

pressures. A special internal chamber acts as a damper for

the vibrations triggered by the fluid flow, allowing low noise

operating conditions to the device.

For these reasons it can be used in systems both on zone

branch circuits and directly at the terminals.

Size the hydronic system with FLOWCAL automatic balancing

valves as follows:

1. ΔP

MAXCIRCUIT

Determine the pressure head loss for the zone circuit with

the greatest pressure drop (flow resistance). This is true for

any hydronic system with supply and return headers.

As an example, this would be circuit #8 for the 2-pipe direct

return system with circuits having identical resistance,

illustrated to the right, as it is farthest from the pump. If,

however, all circuits are not identical, choose the circuit with

the greatest pressure drop.

2. ΔP

MINFLOWCAL

Add the minimum differential operating pressure

(2, 4, or 5 psid) required for the FLOWCAL model selected

for the circuit with the greatest pressure drop.

3. PUMP HEAD = ΔP

MAXCIRCUIT + ΔPMINFLOWCAL

Pump Sizing using FLOWCAL

TM

Flow rate table

7654321 8

Control valve

FLOWCAL

TM

Code

127341AF ● ● ●

127341AF ● ● ●

127341AF ● ● ●

127341AF ● ● ●

127341AF ● ● ●

127341AF ● ● ●

0.50; 0.75; 1.00; 1.50; 2.50; 3.00; 3.50; 4.00; 4.50; 5.00; 6.00; 7.00; 8.00; 9.00; 10.00

0.50; 0.75; 1.00; 1.50; 2.50; 3.00; 3.50; 4.00; 4.50; 5.00; 6.00; 7.00; 8.00; 9.00; 10.00

0.50; 0.75; 1.00; 1.50; 2.50; 3.00; 3.50; 4.00; 4.50; 5.00; 6.00; 7.00; 8.00; 9.00; 10.00

0.50; 0.75; 1.00; 1.50; 2.50; 3.00; 3.50; 4.00; 4.50; 5.00; 6.00; 7.00; 8.00; 9.00; 10.00

0.50; 0.75; 1.00; 1.50; 2.50; 3.00; 3.50; 4.00; 4.50; 5.00; 6.00; 7.00; 8.00; 9.00; 10.00

0.50; 0.75; 1.00; 1.50; 2.50; 3.00; 3.50; 4.00; 4.50; 5.00; 6.00; 7.00; 8.00; 9.00; 10.00

Size

Δp range (psid)

Flow rates (gpm)

2–14

2–32

4–34

5–35

1/2” NPT

1/2” Sweat

3/4” NPT

3/4” Sweat

1” NPT

1” Sweat

CARTRIDGE LOCKING NUT

CARTRIDGE

BODY

This is equal to the minimum working Δp of the FLOWCAL cartridge: 2, 4 or 5 psi (13, 27 or 31 kPa).

Minimum differential pressure required

Page 5

Code Description

127341AF ... 1/2" NPT Male

127349AF ... 1/2" Sweat

127351AF ... 3/4" NPT Male

127359AF ... 3/4" Sweat

127361AF ... 1" NPT Male

127369AF ... 1" Sweat

Select desired flow rate to complete full part number.

No restrictions.

Differential Pressure Differential Pressure

Last 3 digits Control Ranges Last 3 digits Control Ranges

GPM ... (psid) GPM ... (psid)

1/2 G50

2 - 14

4 4G0

3/4 G75 4.5 4G5 2 - 32

1 1G0 5 5G0

1.5 1G5 6 6G0

2 2G0

2 - 32

7 7G0 4 - 34

2.5 2G5 8 8G0

3 3G0 9 9G0

5 - 35

3.5 3G5 10 10G

Order Code Numbering for FLOWCALTM127 series

Applications of FLOWCALTM()

For use in line with various types of heat emitters: radiators,

convectors, fan convectors, thermal strips, etc.

To guarantee the design flow rates (with open or closed valve)

to the various zones of a system.

To ensure constant flow rates (in any valve position) in

circuits with traditional temperature control.

T.A .

T.A .

T.A .

To ensure constant flow rates to each emitter.

Installation of FLOWCAL

In air-conditioning systems,

FLOWCAL

devices should preferably be installed on the circuit return pipe.

Some typical installation examples are given below.

Page 6

Applications of FLOWCALTM()

To create heat exchanger flow balancing by-passes

To control the amount of delivered water and balance the

various circuits in irrigation systems.

To limit the hot water flow rate delivered in systems with

instantaneous production or limited capacity.

To balance sanitary water distribution circuits.

SPECIFICATION SUMMARIES

127 series

Compact automatic flow balancing valve with polymer flow cartridge FLOWCAL™. Connections 1/2”, 3/4”, 1” union sweat or

NPT. Brass body. Anti-scale polymer cartridge. Stainless steel spring. EPDM seals. Water and up to 50% maximum glycol

solutions. Maximum working pressure 232 psi (16 bar). Working temperature range 32

–

212°F (0–100°C). Δp range 2–35 psi.

Range of available flow rates for all connection sizes 1/2 - 10 gpm. Accuracy ±10%.

We reserve the right to change our products and their relevant technical data, contained in this publication, at any time and without prior notice.

Caleffi North America, Inc.

3883 West Milwaukee Road / Milwaukee, WI 53208

Tel: 414.238.2360 / Fax: 414.238.2366 / www.caleffi.us

© Copyright 2010 Caleffi

CALEFFI

Loading...

Loading...