Page 1

USC

www.caleffi.com

CALEFFI

Backflow preventer with intermediate atmospheric vent

Installation, commissioning and servicing instructions

Function

The backflow preventer with atmospheric vent is designed to

protect drinking water systems from the return, caused by

backsiphonage or backpressure, of contaminated fluids.

The Caleffi 573 series has been specifically certified to standards

CSA B64.3 and ASSE 1012.

Product range

ASSE

1012

573 series backflow preventer with atmospheric vent

size 1/2”- 3/4” NPT female threaded connection with union

size 1/2” sweat connection with union

38517.04

573 Series

Technical characteristics

Connections: 1/2”- 3/4” NPT female with union

Materials: Body: brass

Maximum working pressure: 175 psi (12 bar)

Maximum working temperature: 210°F (99°C)

Emergency back pressure temperature: 250°F (121°C)

Medium: water

Certified to: CSA B64.3 and ASSE 1012

Filter: stainless steel

Check valve: PSU

Check valve stem: brass

Diaphragm: EPDM

Seals: EPDM

1

1/2” SWT with union

Page 2

SAFETY INSTRUCTION

This safety alert symbol will be used in this manual to draw attention to safety related

instructions. When used, the safety alert symbol means ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED! FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN A SAFETY HAZARD.

CAUTION: All work must be performed by qualified personnel trained in the

proper application, installation, and maintenance of systems in accordance

with all applicable codes and ordinances.

CAUTION: If the backflow preventer is not installed, commissioned and

maintained properly, according to the instructions contained in this

manual, it may not operate correctly and may endanger the user.

CAUTION: Make sure that all the connecting pipework is water tight.

CAUTION: When making the water connections, make sure that the

backflow preventer connecting pipework is not mechanically overstressed. Over time this could cause breakages, with consequent water

losses which, in turn, could cause harm to property and/or people.

CAUTION: Water temperatures higher than 100°F can be dangerous.

During the installation, commissioning and maintenance of the backflow

preventer, take the necessary precautions to ensure that such

temperatures do not endanger people.

CAUTION: In the case of highly aggressive water, arrangements must be

made to treat the water before it enters the backflow preventer, in

accordance with current legislation. Otherwise the valve may be

damaged and will not operate correctly.

Leave this manual for the user.

2

Page 3

Flow rate graph

10

2

5

10

5

20

50

∆p (psi)

G (l/min) (

gpm

)

20

10

5

(psi) (bar)

20

1

0

.5

10

2

5

15

1

0.5

0.3

VENT

Cv = 0.7

3

Page 4

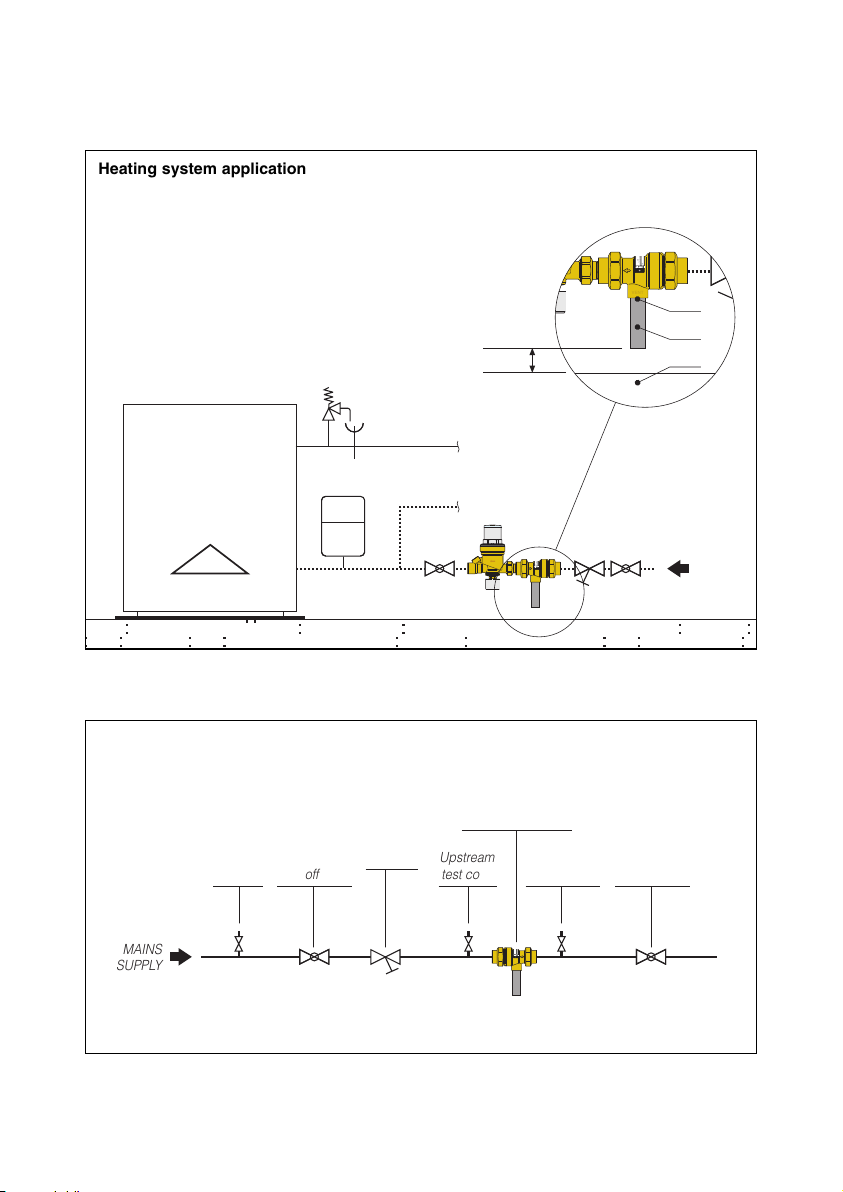

Installation

The Caleffi 573 series backflow preventer with atmospheric vent must be installed in

accordance with the diagrams contained in this instruction manual taking into account all the

applicable Codes and Regulations.

Before installing a Caleffi 573 series backflow preventer, the system must be thoroughly

flushed to remove impurities or any debris which may have accumulated during installation.

Failure to remove dirt or debris may affect performance and the manufacturer’s guarantee.

The Caleffi 573 series backflow preventer must be installed preferably horizontally and

following the flow direction indicated by the arrow on the valve body.

The Caleffi 573 series backflow preventer must be installed with one isolating valve and a

strainer upstream and one isolating valve downstream.

The Caleffi 573 series backflow preventer must be installed in an accessible location to

facilitate testing and servicing.

The Caleffi 573 series backflow preventer must be installed with the vent port connected via

an air gap to a discharge line, in accordance with the plumbing code requirements and

keeping a minumum distance of 12” from the floor.

Do not install where the discharge can could cause damage.

If field testing is required by code, it must be installed in accordance with the relevant diagram

in this instruction manual.

4

Page 5

Installation diagram

MAINS

SUPPLY

Drain

Vent

Floor

Air gap

a

a

a

a

a

a

a

BACKFL

O

W

PREVENTER

Series:

5

73

Sizes:

1/2”

- 3

/4”

S/

N

VENT

aa

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

a

a

a

a

a

a

BACKFL

O

W

PREVENTER

Series:

5

73

Sizes:

1/2”

- 3

/4”

S/

N

VENT

MAINS

SUPPLY

Upstream

test cock

Upstream

shut-off valve

Downstream

shut-off valve

Downstream

test cock

Inlet test

cock

Backflow preventer

573 series

Y-strainer

BACKFL

O

W

PREVENTER

Series:

5

73

Sizes:

1/2”

- 3

/4”

S/

N

VENT

Heating system application

Field testing installation

5

Page 6

Field testing procedure

CALEFFI

1) Check operation of the discharge. When inlet water pressure drops to atmospheric, the

valve must open the vent port and discharge the contained amount of water in the valve body.

a. -close shutoff valves upstream and downstream.

b. -open the upstream test cock

The water contained in the body must be discharged, indicating that the diaphragm has

opened the vent port.

2) Check for tightness of the internal second check valve. When backpressure is applied to

the downstream side of the valve, the internal second check valve must close back drip tight

on its seat.

a. -close shutoff valves upstream and downstream.

b. -open the upstream test cock

c. -install a removable bypass hose connecting inlet test cock to downstream test cock and

open them for admitting pressure to the downstream side of the internal second check valve

Water must not drip from the vent port indicating that the second check valve is not leaking.

Service

The internal parts of the backflow preventer are replaceable. Spare parts are available upon

request.

Caleffi North America, Inc.

3883 West Milwaukee Road

Milwaukee, WI 53208

T: 414.238.2360 F: 414.238.2366

Loading...

Loading...