Page 1

Hydro Separator

series 548

CALEFFI

Function

This device consists of several different functional components,

each of which meets specific requirements, typical of the circuits

used in heating and air-conditioning systems.

· Hydronic separator

To keep connected hydronic circuits totally independent from

each other.

· Dirt remover

To permit the separation and collection of any impurities present

in the circuits. Provided with a valved connection with discharge

piping.

· Automatic air vent valve

For automatic venting of any air contained in the circuits.

Provided with a valved connection for maintenance purposes.

Product range

Series 548 NPT F hydronic separator with insulation sizes 1”, 1

1/4

”, 1

1/2

” and 2” NPT F union

sizes 2”, 2

1/2

”, 3“ and 4” ANSI Flangenoitalusni htiw rotarapes cinordyh degnalF 845 seireS

Technical specification

R

E

G

I

S

T

E

R

E

D

BSI EN ISO 9001:2000

Cert. n° FM 21654

UNI EN ISO 9001:2000

Cert. n° 0003

01076/08 NA

Replaces 01076/06 NA

sizes 1” and 1

Series NA548 Flanged hydronic separator without insulation sizes 5”, 6”, 8”, 10” and 12” ASME ANSI Flange

*NA prefix indicates ASME tagged and registered with the National Board of Boiler and Pressure Vessel Inspectors

1/4

” sweat unionSeries 548 Sweat hydronic separator with insulation

Threaded and sweat union connections

Materials: - Body: epoxy resin painted steel

- Drain and shut-off valve: brass

- Air vent body: brass

Suitable fluids: water, glycol solution

Max percentage of glycol: 50%

Max working pressure: 150 psi (10 bar)

Temperature range: - with insulation: 32÷210°F (0÷100°C)

- without insulation: 32÷250°F (0÷120°C)

Connections: - Main: 1” & 1 1/4“ sweat & NPT and 1 1/2” & 2” NPT union

- Drain: 3/4“ hose

- thermometer pocket: 1/2“

Flanged connections

Materials: - Body: epoxy resin painted steel

- Drain and shut-off valve brass

- Air vent body brass

Suitable fluids: water, glycol solution

Max percentage of glycol: 50%

Max working pressure: 150 psi (10 bar)

Temperature range: - with insulation: 32÷220°F (0÷105°C)

- without insulation: 32÷250°F (0÷120°C)

Connections: - Flanged: 2” ÷ 12” ANSI 150 CLASS

- Drain: 1 1/4” & 2” NPT F

Technical specifcation of insulation for union connection versions

- Material: double density closed cell expanded PEX

- Thickness: 3/4” (20 mm)

- Density: - internal part: 2 lb/ft (30 kg/m3)

- external part: 3 lb/ft (50 kg/m3)

- Thermal conductivity: 32ºF (0°C): 9 BTU/in (0.038 W/m·K)

-40ºF (-40°C): 11 BTU/in (0.045 W/m·K)

- Coefficient of resistance to the diffusion of vapor: > 1.300

- Temperature range: 32-210ºF (0 -100ºC)

- Reaction to fire (DIN 4102) : class B 2

Technical specifcation of insulation for fanged versions up to 4”

Internal part

- Material: rigid closed cell expanded polyurethane foam

- Thickness: 2 3/8” (60 mm)

- Density: 3 lb/ft (45 kg/m3)

- Thermal conductivity: 6 BTU/in (0.023 W/m·K)

- Temperature range: 32-220 º F (0 – 105°C)

External cover

- Material: embossed aluminium

- Thickness: 7.0-mil (0.7 mm)

- Reaction to fire: class 1

Head covers

- Heat moulded material: PS

Page 2

Dimensions

AA

HYDRO-SEPARATOR

Serie 548

max

max

T

250°F

T

220°F

max

max

P

150 psi

P

D EC

150 psi

A

A

C D E

B

C

A

2”

2 1/2”

3”

4”

5”

6”

1 1/4"

1 1/4"

1 1/4"

1 1/4"

1 1/4"

1 1/4"

B

13”

13”

15”

15”

15”

15”

Code

548006A/96A

548007A/97A

548008A

1 1/4”

1 1/2”

548009A 2"

Code

548052A

B

8 3/4”

9 3/8”

10 7/8”

C

6 1/4”

7 3/8”

7 3/4”

10 1/8”

8 5/8”

9 1/2”

10 1/4”

11 7/8”

8”

8 3/8”

8 3/4”

9 1/2”

7.5

8.3

12.5

26.012”

(gal)

0.5

11

18

0.7

26

1.3

3.5

37

A

1"

Volume

Flow (gpm)

Weight (lb)

E

D

548062A

548082A

548102A

NA548120A*

NA548

NA548150A*

* without insulation

NA prefix indicates ASME tagged and registered with the National

Board of Boiler and Pressure Vessel Inspectors.

Add NA prefix to 2” to 4” flanged connection for ASME approved.

For larger ASME sizes consult with factory.

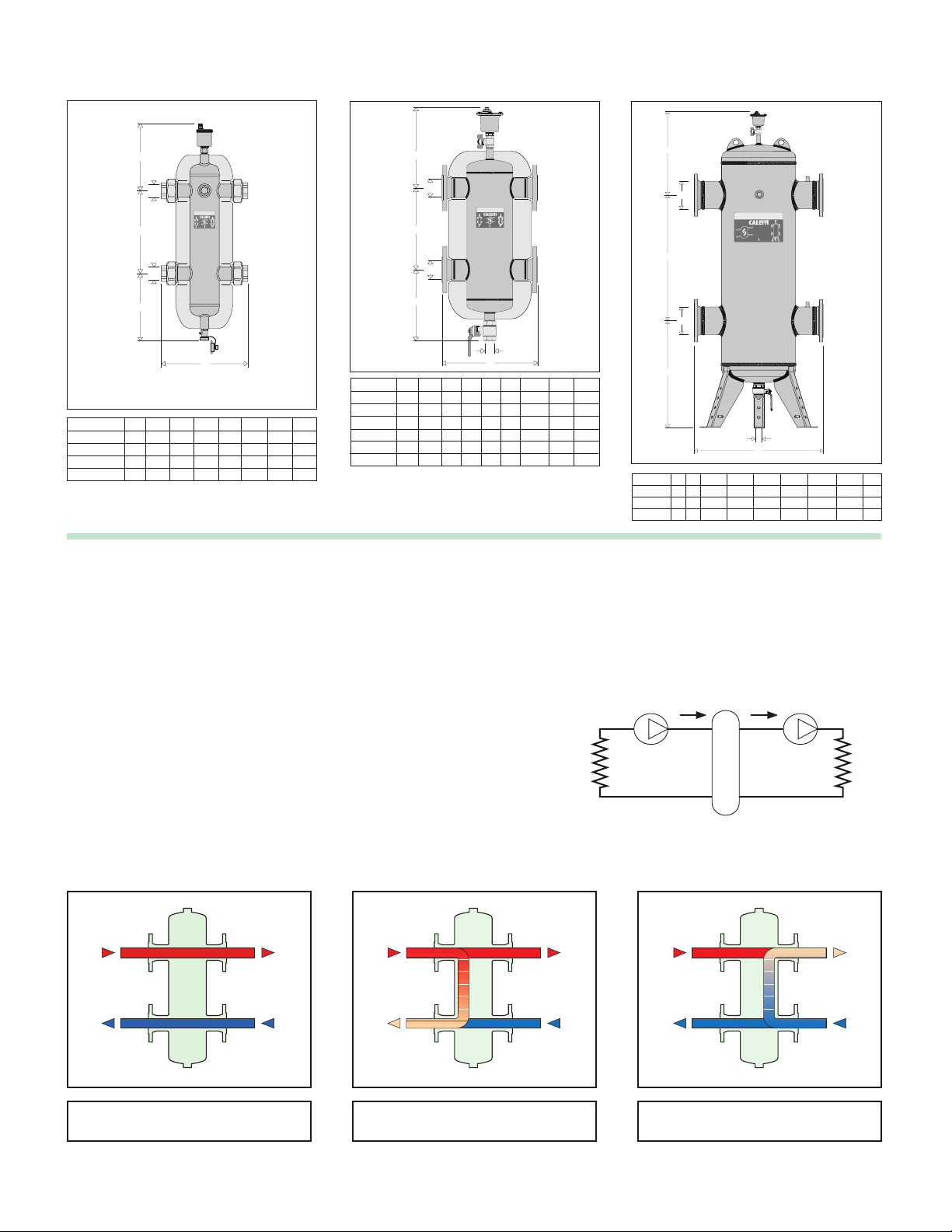

Operating principle

When a single system contains a primary production circuit, with its own

pump, and a secondary user circuit, with one or more distributions pumps,

operating conditions may arise in the system whereby the pumps interact,

creating abnormal variations in circuit flow rates and pressures.

The hydronic separator creates a zone with a low pressure loss, which

enables the primary and secondary circuits c on ne ct ed t o it t o be

hydraulically independent of each other;

the flow in one circuit does

not create a flow in the other if the pressure loss in the common

section is negligible.

HYDRO-SEPARATOR

Serie 548

T

250°F

T

220°F

max

max

P

150 psi

P

150 psi

max

max

HYDRO-SEPARATOR

Serie 548

T

250°F P

max

max

150 psi

C ED

AA

B

F

13”

13”

18”

18”

22”

22”

Weight (lb)

E

D

F

14”

14”

18”

18”

25”

25”

73

79

108

117

220

231

15”

15”

17”

17”

19”

19”

Flow (gpm)

40

80

124

247

300

484

Volume

4.0

4.0

8.0

8.0

22.5

23.2

(gal)

B

F

A

B

C

D

E

Code

NA548

NA548

NA548

200A

250A

300A

8”

2”

39

3/8

”

33

10”

2”

12”

2”

7/8

43

5/16

”

35

7/8

47

1/4

”

37

7/8

F

”

27

”

30”

”

31

Weight

1/2

”

35

1/2

”

41

3/4

”

1/2

”

47

3/4

”

1,100

When the secondary pump is off, there is no circulation in the secondary

circuit; the whole flow rate produced by the primary pump is by-passed

through the separator.

With the hydronic separator, it is thus possible to have a primary production

circuit with a constant flow rate and a secondary distribution circuit with

a variable flow rate; these operating conditions are typical of modern

heating and cooling systems.

Gp Gs

550

725

Flow

792

1,330

1,850

Volume

(gpm)(lb)

(gal)

95

175

255

In this case, the flow rate in the respective circuits depends exclusively

on the flow rate characteristics of the pumps, preventing reciprocal

influence caused by connection in series.

Therefore, using a device with these characteristics means that the flow

in the secondary circuit only circulates when the relevant pump is on,

permitting the system to meet the specific load requirements at that time.

Primary Secondary

G

primary

= G

secondary

sGpG

Primary Secondary

Gp Gs

G

primary

primary secondary

Three possible hydronic balance situations are shown below.

Primary Secondary

Gp Gs

> G

secondary

G

primary

< G

secondary

Page 3

Construction details

Isolating the air vent valve

In flanged separators, the air vent is

isolated manually, using a shut-off ball

valve. In union separators, however, the

air vent body is automatically isolated by

the check valve, which closes when the

air vent body is removed.

Dirt removing element

A vital function of the hydronic separator

is carried out by the dirt removing element

inside the device.This makes it possible

to separate and collect any impurities

which may be present in the system.

These impurities are removed by means

of the drain valve, which can be connected

to a discharge pipe, placed at the bottom

of the separator.

Insulation

Hydronic separators are available complete with a hot preformed

insulation shell. In the flanged series, u p to 4 ”, t he i ns ul at io n is

mad e of a shell in expanded polyurethane foam covered w ith a n

aluminium layer. In the threaded version the insulation is made of a

pre-formed shell in double density closed cell expanded PEX.

This insulation ensures not only perfect heat insulation but also the

tightness required to prevent atmospheric water vapors from entering

the unit. For these reasons, this type of insulation can also be used in

cooling water circuits, as it prevents the formation of condensate on the

surface of the separator body.

Hydraulic characteristics

The hydronic separator should be sized according to the maximum

flow rate value at the inlet.The selected design value must be the

greatest between the primary circuit and the secondary circuit.

Size Flow gpm (m

3

/h)

1” 11 (2.5)

1 1/4” 18 (4.0)

1 1/2”

26 (6.0)

Size Flow gpm (m3/h)

2” 40 (9)

2

1/2

” 80 (18)

3” 124 (28)

4” 247 (56)

5” 300 (75)

6” 484 (110)

Union connections

Flanged connections

Union connections Flanged connections

2” 37 (8.5)

8” 792 (180)

10” 1,330 (302)

12” 1,850 (420)

Page 4

Hydronic separator. Sweat and NPT connections with unions, 1” , 1 1/4“ , 1 1/2” , and 2” NPT . Epoxy resin painted steel body.

Temperature range 32 - 210°F (0 -100°C) with insulation or 32 - 250°F (0 -120°C) without insulation. Max. working

pressure 150 psi (10 bar). Supplied with: Automatic air vent valve 1/2” M connection with automatic check valve.

Brass body. Drain valve. Hose connection thread. Brass body. Pre-formed insulation shell is double density closed

cell expanded PEX.

SPECIFICATION SUMMARIES

Series 548

Hydronic separator. ANSI Flanged connections 2," 2 1/2", 3", 4", 5”, 6”, 8”, 10” and 12” . Epoxy resin painted steel body.

Temperature range of 32 - 220°F (0 -105°C) with insulation. Max. working pressure 150 psi (10 bar). Supplied with:

Automatic air vent with 3/8” F outlet connection and brass body. Brass body shut-off valve for air vent. Drain valve

brass body with 1 1/2” or 2” F connection. Rigid closed cell expanded polyurethane foam shell insulation with external

embossed aluminium cover. Sizes 5”, 6”, 8”, 10”, and 12” are ASME tagged and registered with the National Board of

Boiler and Pressure Vessel Inspectors, without insulation and temperature range of 32 - 250°F (0 -120°C).

Series 548

Application diagram

We reserve the right to change our products and their relevant technical data, contained in this publication, at any time and without prior notice.

CALEFFI

Caleffi North America, Inc.

3883 W. Milwaukee Rd. / Milwaukee, WI 53208

Tel: 414.238.2360 / Fax: 414.238.2366 / www.caleffi.us

© Copyright 2008 Caleffi North America, Inc.

Loading...

Loading...